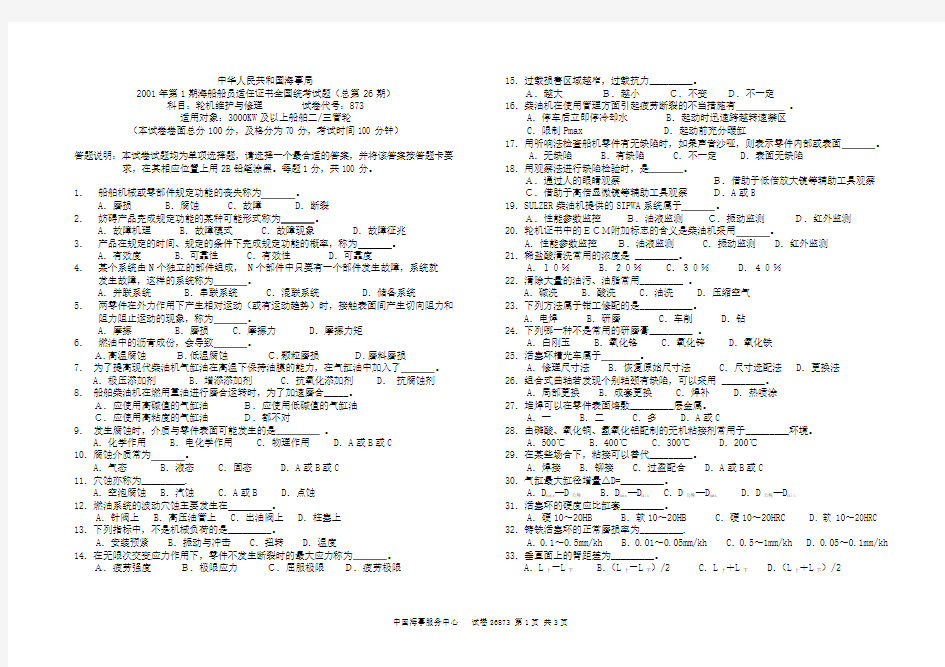

2001年第1期海船船员适任证书全国统考试题(总第26期)科目:轮机维护与修理 试卷代号:873

中华人民共和国海事局

2001年第1期海船船员适任证书全国统考试题(总第26期)

科目:轮机维护与修理试卷代号:873

适用对象:3000KW及以上船舶二/三管轮

(本试卷卷面总分100分,及格分为70分,考试时间100分钟)

答题说明:本试卷试题均为单项选择题,请选择一个最合适的答案,并将该答案按答题卡要求,在其相应位置上用2B铅笔涂黑。每题1分,共100分。

1.船舶机械或零部件规定功能的丧失称为。

A.磨损 B.腐蚀 C.故障 D.断裂

2.妨碍产品完成规定功能的某种可能形式称为。

A.故障机理 B.故障模式 C.故障现象 D.故障征兆

3.产品在规定的时间、规定的条件下完成规定功能的概率,称为。

A.有效度 B.可靠性C.有效性 D.可靠度

4.某个系统由N个独立的部件组成, N个部件中只要有一个部件发生故障,系统就发生故障,这样的系统称为。

A.并联系统 B.串联系统 C.混联系统 D.储备系统

5.两零件在外力作用下产生相对运动(或有运动趋势)时,接触表面间产生切向阻力和阻力阻止运动的现象,称为。

A.摩擦 B.磨损C.摩擦力 D.摩擦力矩

6.燃油中的沥青成份,会导致。

A.高温腐蚀B.低温腐蚀C.颗粒磨损D.磨料磨损

7.为了提高现代柴油机气缸油在高温下保持油膜的能力,在气缸油中加入了。

A.极压添加剂 B.增添添加剂 C.抗氧化添加剂 D.抗腐蚀剂8.船舶柴油机在燃用重油进行磨合运转时,为了加速磨合_____。

A.应使用高碱值的气缸油B.应使用低碱值的气缸油

C.应使用高粘度的气缸油D.都不对

9.发生腐蚀时,介质与零件表面可能发生的是。

A.化学作用 B.电化学作用 C.物理作用 D.A或B或C

10.腐蚀介质常为。

A.气态 B.液态 C.固态 D.A或B或C

11.穴蚀亦称为_________.

A.空泡腐蚀 B.汽蚀 C.A或B D.点蚀

12.燃油系统的波动穴蚀主要发生在。

A.针阀上 B.高压油管上 C.出油阀上 D.柱塞上

13.下列指标中,不是机械负荷的是_________。

A.安装预紧 B.振动与冲击 C.扭转 D.温度

14.在无限次交变应力作用下,零件不发生断裂时的最大应力称为。

A.疲劳强度B.极限应力C.屈服极限D.疲劳极限15.过载损害区域越窄,过载抗力_________。

A.越大B.越小C.不变D.不一定

16.柴油机在使用管理方面引起疲劳断裂的不当措施有。

A.停车后立即停冷却水 B.起动时迅速跨越转速禁区

C.限制Pmax D.起动前充分暖缸

17.用听响法检查船机零件有无缺陷时,如果声音沙哑,则表示零件内部或表面。 A.无缺陷 B.有缺陷 C.不一定 D.表面无缺陷

18.用观察法进行缺陷检验时,是。

A.通过人的眼睛观察B.借助于低倍放大镜等辅助工具观察C.借助于高倍显微镜等辅助工具观察D.A或B

19.SULZER柴油机提供的SIPWA系统属于。

A.性能参数监控B.油液监测C.振动监测D.红外监测

20.轮机证书中的ECM附加标志的含义是柴油机采用。

A.性能参数监控B.油液监测 C.振动监测D.红外监测

21.稀盐酸清洗常用的浓度是 _________。

A.10% B.20% C.30% D.40%

22.清除大量的油污、油脂常用_________ 。

A.碱洗 B.酸洗 C.油洗 D.压缩空气

23.下列方法属于钳工修配的是___________。

A.电焊B.研磨 C.车削D.钻

24.下列哪一种不是常用的研磨膏_________ 。

A.白刚玉 B.氧化铬 C.氧化锌 D.氧化铁

25.活塞环槽光车属于。

A.修理尺寸法 B.恢复原始尺寸法C.尺寸选配法 D.更换法

26.组合式曲轴若发现个别轴颈有缺陷,可以采用 _________。

A.局部更换 B.成套更换C.焊补 D.热喷涂

27.堆焊可以在零件表面熔敷_________层金属。

A.一 B.二 C.多 D.A或C

28.由磷酸、氧化铜、氢氧化铝配制的无机粘接剂常用于_________环境。

A.500℃ B.400℃ C.300℃ D.200℃

29.在某些场合下,粘接可以替代_________。

A.焊接 B.铆接 C.过盈配合 D.A或B或C

30.气缸最大缸径增量△D=_________。

A.D

max

—D

公称

B.D

max

—D

min

C.D

公称

—D

max

D.D

公称

—D

min

31.活塞环的硬度应比缸套_________。

A.硬10~20HB B.软10~20HB C.硬10~20HRC D.软10~20HRC 32.铸铁活塞环的正常磨损率为_________.

A.0.1~0.5mm/kh B.0.01~0.05mm/kh C.0.5~1mm/kh D.0.05~0.1mm/kh 33.垂直面上的臂距差为_________。

A.L

上

-L

下

B.(L

上

-L

下

)/2 C.L

上

+L

下

D.(L

上

+L

下

)/2

34.某曲柄实测臂距差如图所示(单位mm),则。

A.上凸0.01

B.下凸

C.左凸 0.04 0.04

D.全不对 0.02 0.02

35.铜管或小直径的钢管采用。

A.电渣焊

B.气焊

C.电焊

D.等离子焊

36.柱塞套筒的磨损部位在_________处。

A.圆柱配合表面B.柱塞顶面C.套筒顶面D.螺旋泄油槽

37.检查水泵泵轴发现裂纹,应_________。

A.更新B.焊补C.粘接D.扣合

38.齿轮轮齿的过载断裂的断口为___________.

A.粗糙断口B.贝壳状断口 C.杯锥状断口D.扭转断口

39.冷却器碱洗的时间和浓度一般为___________。

A.24小时;10%B.12小时;5%

C.6小时;1%D.3小时;0.5%

40.用堵管法修理冷却器的管子,要求堵管数量不得超过总数的_________。

A.40%B.30%C.20%D.10%

41.下列对故障模式的理解,不正确的是:

A.故障模式即故障的表现形式

B.故障模式或是单一的,或是综合的

C.产品的故障模式是固定不变的

D.磨损、腐蚀、疲劳破坏等是船机设备的故障模式

42.工作到某时刻尚未发生故障的产品,在该时刻后单位时间内发生故障的概率,称为: A.故障密度函数 B.故障率

C.平均寿命 D.不可靠度

43.某船舶动力系统由3个工作单元串联而成,其中可靠度最低的单元的可靠度为0.8,则由这3个工作单元组成的系统的可靠度。

A.一定大于0.8 B.一定小于0.8 C.在0.8左右D.大小不一定44.在曲轴箱中,润滑油被剧烈地搅拌,为了防止产生稳定的泡沫,应在油加入。 A.防锈添加剂 B.清净分散剂 C.抗泡剂 D.油性剂

45.船机零件的磨损遵循的一般规律是。

A.正常磨损期、磨合期和急剧磨损期

B.正常磨损期和急剧磨损期

C.磨合期、正常磨损期和急剧磨损期

D.磨合期和急剧磨损期

46.衡量金属腐蚀的几个指标中,最适用于衡量密度不同的各金属腐蚀速度的是。

A.重量指标B.深度指标C.容量指标D.电阻性能指标47.为避免柴油机缸套的穴蚀现象,在设计中要求冷却水腔水流速度不应大于_____ m/s 。

A. 1 B.2 C.1.5 D.2.5

48.柴油机起动停车引起的热应力是热应力。

A.高频B.低频C.中频D.A或B或C49.疲劳断裂的最后断口呈。

A.粗晶状 B.细晶状 C.贝纹状 D.杯锥状

50.主轴承的不均匀磨损可以导致曲轴发生。

A.弯曲疲劳 B.扭转疲劳C.接触疲劳 D.热疲劳

51.防止热疲劳的有效途径有_________。

A.选用膨胀系数小的材料 B.选用高温强度大的材料

C.选用塑性好的材料 D.A+B+C

52.煤油白粉法适用于检查_________缺陷。

A.表面裂纹 B.表面磨损 C.内部缩孔D.内部疏松

53.在船舶柴油机的曲柄箱上设置正压传感器,在曲柄箱内压力超过极限值时报警,这种监测方法属于:

A.无损检测B.振动监测 C.油液监测D.性能参数监测54.状态监测与故障诊断相比,对操作人员的要求一般:

A.比较高 B.比较低 C.一样高 D.都不对

55.常规清洗主要是去除_________ 。

A.铁锈 B.水垢 C.积碳 D.油污

56.下列方法属于钳工修配的是。

A.电镀B.刮削C.磨削D.镗

57.运动部件的保修期为。

A.1个月B.2个月C.3个月D.4个月

58.用修理尺寸法修复之后,零件 __________。

A.有互换性 B.无互换性 C.A或B D.不一定

59.修理尺寸法适于_________ 修理。

A.批件 B.单件 C.成组 D.不一定

60.焊接与堆焊的主要区别是_________。

A.加热方式 B.施焊目的 C.焊丝 D.结合方式

61.下列关于粘结的说法中,错误的是:

A.离心泵叶轮与泵轴配合松动可用“厌氧胶”进行修理

B.氧化铜胶粘剂不允许在一块铁板上进行配制

C.无机粘结剂适用于高温且冲击负荷小的场合

D.造船厂常用无机胶粘机替代铸铁垫块以提高生产效率

62.关于粘接剂,下列叙述不正确的是_________.

A.粘接不增加零件的重量 B.不破坏材料的性能

C.室温下粘接对零件无热影响 D.固化时间长,收缩率大,膨胀系数大

63.对于船舶主机缸套的裂纹,不合理的修理方法是。

A.钳工修刮B.胶粘剂修理C.焊接D.强密扣合

64.测量气缸内径采用的量具是_________。

A.外径千分尺 B.内径千分尺 C.游标卡尺 D.塞尺

65.安装活塞环时为了防止_________须将搭口错开。

A.窜气 B.粘着 C.断裂 D.窜油

66.粘着磨损使气缸套内面产生形貌。

A.上下规则的磨痕B.局部脱落 C.鳞片状金属转移D.光洁孔洞

67.轴瓦背与轴承座应贴合良好,厚壁瓦安装完毕,_________的塞尺不得塞入。

A.0.05mm B.0.1mm C.0.15mm D.0.20mm

68.检查喷油器密封性的定性方法是_________。

A.滑动试验法B.燃油漏损定量法 C.启阀压力试验 D.雾化试验

69.用手动螺杆压力校正常规的轴件时,_________.

A.凹面向上B.凸面向上C.A或B D.不一定

70.某些低速重载的齿轮啮合表面由于干摩擦而发生___________。

A.点蚀B.胶合C.断裂D.变形

71.火管锅炉的烟管腐蚀使管壁减薄超过原壁厚_________应换新。

A.20%B.30%C.40%D.50%

72.柴油机活塞-气缸间隙由于过度磨损而导致的敲缸.窜气等故障,属于:

A.管理性故障 B.突发性故障 C.磨损性故障 D.结构性故障

73.压铅法测轴承间隙应采用根铅丝。

A.1-2 B.2-3C.3-4 D.4-5

74.有200个轴承,在同样条件下使用了500小时后,有60个发生了故障,此时可靠度为: A.0.3 B.0.7 C.0.5 D.无法计算

75.为了将零件上的沉积物清洗到油中,保持船机零件表面清洁,并把沉积物分散为极小的微粒,防止堵塞系统,必须在润滑油中加入:

A.抗泡剂 B.清净分散剂C.防锈添加剂 D.A+B+C 76.船舶柴油机的拉缸,实质上是:

A.发生了严重的磨粒磨损 B.发生了严重的腐蚀磨损

C.发生了严重的粘着磨损 D.发生了表面疲劳磨损

77.气缸套内表面存在的腐蚀有_________.

A.化学腐蚀 B.电化学腐蚀 C.穴蚀 D.A或B

78.防止气缸套穴蚀的主要途径是_________.

A.减振 B.提高抗蚀能力 C.A+B D.采用干式气缸套

79.机械疲劳断裂是交变的_________ 的结果。

A.机械应力长期作用 B.热应力长期作用 C.机械负荷作用 D.热负荷作用80.高温疲劳是指零件在高于材料的的温度,受到交变应力的作用引起的疲劳破坏。(Tm为金属的熔点)

A.0.2Tm B.0.3Tm C.0.4Tm D.0.5Tm

81.疲劳裂纹扩展时第一阶段的扩展方向为。

A.最大正应力方向 B.最大切应力方向 C.A+B D.不一定

82.运动部件配合间隙过大,易产生。

A.机械负荷B.热冲击C.蠕变 D.缝隙腐蚀

83.液压试验法可以检查船机零件。

A.表面有无缺陷 B.内部有无缺陷

C.有无穿透性裂纹 D.A+B+C 84.检验船机零件表面有无缺陷时,一般可采用。

A.渗透探伤 B.射线探伤 C.超声波探伤 D.红外探伤

85.在船舶机械的油液监测技术中,如果希望得到磨粒形貌.尺寸方面的信息,则应采用的检测方法是。

A.光谱分析 B.常规理化性能分析 C.铁谱分析 D.A或B

86.清除严重的积碳常用_________。

A.机械清洗 B.合成清洗剂 C.油洗 D.A+B

87.下列不需要研磨的零件是________ 。

A .主轴承厚壁瓦 B.精密偶件 C.进排气阀 D.A+B+C

88.在零件表面用熔化的焊条(丝)熔敷一层或多层金属的技术称为_________。

A.焊接 B.堆焊 C.喷焊 D.喷涂

89.下列关于铸铁零件的焊接工艺,错误的说法是。

A.铸铁件的黄铜钎焊属于硬钎焊

B.磨损件堆焊常用“短段热焊法”,预热到600-700℃,属于热焊的范畴

C.铸铁焊补的预热一般用气焊预热,因其热影响区域大

D.为防止焊补后产生裂纹,故焊后须进行缓冷或低温退火

90.活塞环槽过度磨损后不可采用的修理工艺是_________.

A.附加零件 B.电镀 C.堆焊 D.粘接

91.高温环境下的粘接常选用_________。

A.环氧树酯 B.氧化铜无机粘接剂 C.酚醛—缩醛 D.酚醛聚酰氨92.目前主柴油机机座垫块常用的材料是_________.

A.铸铁 B.钢 C.环氧树酯 D.A或C

93.检查活塞顶部烧蚀的方法是_________。

A.观察法 B.听响法 C.测量法 D.水压试验法

94.四冲程机与二冲程机气缸套工况的主要区别在于_________。

A.高温 B.高压 C.腐蚀 D.承受侧推力

95.酸洗壳体时,加0.5~1.0%的甲醛是为了 _________。

A.抑制腐蚀 B.中和盐酸 C.控制速度D.钝化

96.柱塞或针阀磨损后可采用_________恢复尺寸。

A.镀Cr B.镀Fe C.镀Zn D.镀Cu

97.轴瓦表面的裂纹不可采用_________方法检查。

A.着色探伤B.磁力探伤C.听响法D.观察法

98.针阀与阀体进行滑动性能试验时,一般将针阀抽出_________左右后观察其下落速度。

A.1/3 B.2/3 C.1/2 D.3/4

99.检查冷却器中的防腐Zn块(棒)时,若剩余量___________原尺寸应换新。

A.<1/5 B.<1/3 C.<1/4 D.<1/2

100.大口径的管子更换时一般先点_________焊点。

A.一个 B.二个 C.三个 D.四个

汽轮机专业中级工职业技能鉴定试题及答案

汽轮机专业中级工职业技能鉴定试题及答案 一、选择题 1.1001 当容器内工质的压力大于大气压力,工质处于() ()正压状态;()负压状态;()标准状态;()临界状态。 2.1002 在焓—熵图的湿蒸汽区,等压线与等温线() ()是相交的;()是相互垂直的;()是两条平引的直线;()重合。3.1004 朗肯循环是由()组成的。 ()两个等温过程,两个绝热过程; ()两个等压过程,两个绝热过程; ()两个等压过程,两个等温过程; ()两个等容过程,两个等温过程。 4.1005 金属材料的强度极限σ是指()。 ()金属材料在外力作用下产生弹性变形的最大应力; ()金属材料在外力作用下出现塑性变形时的应力; ()金属材料在外力作用下断裂时的应力; ()金属材料在外力作用下出现弹性变形时的应力。 5 .2007 凝汽器内蒸汽的凝结过程可以看作是() ()等容过程;()等焓过程;()绝热过程;()等压过程; 6.2008 沸腾时气体和液体同时存在,气体和液体的温度() ()相等;()不相等;()气体温度大于液体温度;()气体温度小于液体温度。 7.2009 已知介质的压力p 和温度t,在该温度下,当p 小于p 饱时,介质所处的状态是() ()未饱和水;()湿蒸汽;()干蒸汽;()过热蒸汽。 8.2010 沿程水头损失随水流的流程增长而() ()增大;()减少;()不变;()不确定; 9.3012 两台离心水泵串联运行,() ()两台水泵的扬程应该相同; ()两台水泵的扬程相同,总扬程为两泵扬程之和; ()两台水泵扬程可以不同,但总扬程为两泵扬程之和的1/2; ()两台水泵扬程可以不同,但总扬程为两泵扬程之和。 10.1016 油系统多采用()阀门。 ()暗;()明;()铜制;()铝制; 11.1017 减压门属于() ()关(截)断门; ()调节门; ()旁路阀门; ()安全门。 12.1018 凝汽器内真空升高,汽轮机排汽压力() ()升高;()降低;()不变;()不能判断。 13 1019 加热器的种类,按工作原理不同可分为() ()表面式加热器,混合式加热器;

第47期轮机英语

47期轮机英语考试题目 一单项选择题 A1.The___ engine is used for alternators and some times for main propulsion provide a propeller of between 90 to 120 rpm. A.four-stroke B.two-stroke. C.slow speed D.reversible B2.The abbreviation”MIP”stands for____, A.middle indicating pressure B.mean indicated pressure C.mean pitch D.middle indicated power D3.The cetane number of a diesel fuel oil indicates its____. A.viscosity B.acid content C.heating value D.ignition quality C4.In a two-stroke engine the camshaft rotates at___the enging rotational speed. A.half B.twice C.the same speed as D.four times D5.A diesel enging is similar to a gasoline engine except that the former has no ____. A.cross-head B.cylinder C.connecting rod D.spark plug C6.It is easier to replace a dry cylinder liner than a wet one because____. A.of the thin wall thickedss B.honing makes it easier to maintain the desired oil film C.water seals are not required D.it fits more loosely due to a decrease in heat transfer through the composite wall D7.A main bearing consists of two shells which are secured by means of studs and____. A.tie rods B.though bolts C.lead wires D.bearing caps C8.However fast or slow the combustion rate,it is still a____between carbon,hydrogen,sulph and oxygen that releases heat. A.physical deformation B.state exchange C.chemical reaction D.coalescence A9.During the fuel injection period,fuel pressure must exceed cylinder gas pressure to____. A.ensure penetration and distribution of the fuel in the combustion chamber B.ensure the needle valves is flushed clean duringeach injection C.prevent combustion gas blowback into the open needle valve Dprevent reflected pressure waves when the neddle valve close. B10.In a diesel engine lube oil system ,which of the following parts should be lubricated first? A.Camshaft bearings B.Main bearings C.Piston crowns D.Cylinder walls B11.In a diesel engine closed freshwater cooling system,the amount of coolant flowing through the heat exchanger is controlled by the _____, A.suction pressure regulator B.thermostatic bypass valve C.sea water temperature D.water level in the expansion tank

轮机大管轮英语真题48期

中华人民共和国海事局 2009年第5期海船船员适任证书全国统考试题(总第48期) 科目:轮机英语试卷代号:803 适用对象:无限、近洋航区3000KW及以上船舶大管轮 (本试卷卷面总分100分,及格分为70分,考试时间为100分钟) 答题说明:请选择一个最合适的答案,并将该答案按答题卡要求,在其相应位置上用2B铅笔涂黑。第1题至82题,每题1分,第83题至94题,每题1.5分。 一、单项选择题: 1. The reason why more and more of the large merchant vessels are being powered by medium-speed diesel engines is . A. they operate between 150 and 450 rpm B. they are connected to the propeller by gearing C. their smaller size and weight D. they can be connected directly to the propeller without gearing 2. The closing of the exhaust valves used on a modern, large, low-speed, main propulsion diesel engine may be directly provided by . A. large conical springs B. compressed air pressure C. hydraulic pressure D. exhaust gas pressure 3. One of the factors limiting the amount of toad which can be put on a modem marine diesel engine is the . A. governor sensitivity B. exhaust temperature C. fuel injection pressure D. speed of the cam shaft 4. The desirable properties or a marine fuel oil should inc lude . A. high flash point and high viscosity B. low flash point and high viscosity C. low heating value and high sulphur content D. high heating value and low sulphur content 5. As the plunger moves upwards in the barrel, injection will commence once the plunger bas the spill ports and the pressure builds up. A. opened up B. closed off C. lined up D. taken off 6. In an auxiliary diesel engine bypass type lubricating oil system, the main lube oil pump forces . A. all of the oil used by the engine through a filter B. some of the oil used by the engine through a filter C. some of the oil used by the engine through a centrifuge D. all of the oil used by the engine through a centrifuge 7. Because the circulating water is in a closed loop, is installed to cater for expansion and contraction of the water at different conditions of operation. A. an expansion joint B. a drain tank C. a head tank D. a contraction tank 8. The high air velocity leaving the compressor of an exhaust gas turbocharger is converted to pressure in the . A. inlet nozzle ring B. turbine wheel blade C. diffuser passages D. inlet volute 9. is usually driven by the engine camshaft and supplies pilot air to the cylinder air start valve. A. An air receiver B. An operating valve C. An automatic valve D. An air distributor 10. Diesel engines driving alternators operating in parallel must maintain a set frequency regardless of load changes. The governor characteristic used to accomplish this is known as . A. actuation B. sensitivity C. compensation D. promptness 11. By comparing the exhaust gas temperature of each cylinder, the operator can determine if the load is balanced throughout the engine. The device most commonly used is a . A. tachometer B. pyrometer C. dynamometer D. calorimeter 12. When the ship is going to enter into the harbor, ____. A. change from heavy fuel oil to diesel oil for main engine B. pumping out bilge water C. change sea chest from high level one to lower level one D. test emergency generator 13. If the jacket water temperature rises rapidly above normal in a diesel engine, you should first . A. place standby cooler in operation B. reduce engine toad C. check thermostatic valve D. clean sea water strainer 14. Air cocks, usually positioned at the in a circulating system, is used to get rid of the air in the system. A. bending joint B. expansion tank C. weld D. the highest point 15. Which of the following conditions could contribute to the cracking of a diesel engine cylinder head? A. Leaking seal ring B. Insufficient heat transfer from the exhaust valves C. Blocked cooling water passages to the head D. Excessive scavenging air provided to the engine 16. of an engine crankshaft can be detected by measuring deflections of' crank webs for each unit of the engine. A. Misalignment B. Length C. Strength D. Stresses 17. can be a direct cause of faulty operation of diesel engine fuel injection nozzles. A. Excessive fuel nozzle holder cooling B. Sediment in the fuel supply C. Distortion of the fuel spray pattern D. Improper atomization of the fuel 18. When fuel is injected late into a diesel engine cylinder . A. the exhaust will be clear B. fuel consumption will be low C. all the fuel will be burned at top dead center D. fuel consumption will be high 19. A large change in ambient temperature, or using an oil of a viscosity different than the one recommended by the manufacturer in a mechanical hydraulic governor, will result m the need to adjust the . A. pilot valve opening B. compensating needle valve C. compensating spring tension D. accumulator spring tension 20. Which of the following factors tends to increase scale formation on the saltwater side of a heat exchanger used in a diesel engine cooling water system? A. Baffle plates that have been bent during prior removal. B. Leaks m the cooler tube nest. C. Operating the engine while maintaining a high sea water outlet temperature. D. A punctured sea water strainer supplying cooling water to the heat exchanger. 21. If the scavenge fire is of a more major nature, if there is a risk of the fire extending or if the scavenge trunk is adjacent to the crankcase with risk of a hot spot developing it sometimes becomes necessary to the engine. A. stop B. start C. speed up D. slow down 22. In an operating diesel engine, which of the following conditions is an indication of a leaking air starting valve?

汽轮机专业试题资料

汽轮机专业试题 一、选择题: 1、电机转速为3000rpm时,振动值应小于(A)mm。A0.06B0.10C0.12D0.16 2、给水泵平衡管的作用是(D)。 A防止泵过热损坏 B防止泵超压 C防止泵过负荷 D减少轴向推力 3.发现循环水泵备用中倒转时,应判断为(B)。 A、电机启动 B、出口门不严 C、泵未排空 D、入口门不严 4.凝汽器冷却面积为(A)m2。 A、11000 B、22300 C、14096 D、9410 5.备用给水泵启动前,应先关(B)。 A、入口门 B、出口门 C、空气门 D、密封水门 6.高压除氧器的水箱有效容积是(B)m3。 A、50 B、140 C、670 D、700

7.正常巡检中,发现油净化器输油泵运行中跳闸,油位上涨,此时应首先(D)。 A、汇报 B、开放油门放油 C、关出口门 D、关闭来油门 8.水泵发生倒转时,应(B)。 A、关闭入口门 B、关闭出口门 C、开启放水门 D、立即合闸启动 9.离心泵启动正常后,开出口门时,出口压力和电流分别(B)。 A、升高,增加 B、下降,增加 C、下降,减小 D、升高,减小 10.离心泵在运行中发现供水压力低,流量下降,管道振动,泵窜轴, 则为(D)。 A、打空泵 B、打闷泵 C、出水量不足 D、水泵汽蚀 11.机组运行中,高加停止过程中,出口水温降低速度应控制在(B)℃/min以内。 A、1.5 B、2 C、2.5 D、3

12.高加注水时,用注水门控制其水侧压力上升速度不超过(D)Mpa/min。 A、0.2 B、0.3 C、0.4 D、0.5 13.10米备用油箱油位在上油位计(C)。 A、1/3以上 B、1/2以上 C、2/3以上 D、满油位 14.高压油泵投入前,调节系统充油赶空气时间为(C)min。 A、10 B、20 C、30 D、60 15.给水泵运行中润滑油压低于(B)Mpa时,给水泵跳闸。 A、0.01 B、0.05 C、0.08 D、0.10 16.发电机漏风量24h风压下降不大于(B)Mpa为合格。 A、0.01 B、0.015 C、0.02 D、0.005

三管轮轮机英语大证考试真题41期

中华人民共和国海事局 2006年第3期海船船员适任证书全国统考试题(总第41期) 科目:轮机英语试卷代号:805 适用对象:无限、近洋航区3000KW及以上船舶二/三管轮 (本试卷卷面总分100分,及格分为70分,考试时间为100分钟) 答题说明:请选择一个最合适的答案,并将该答案按答题卡要求,在其相应位置上用2B铅笔涂黑。第1题至74题,每题1分,第75题至78题,每题1.5分,第79题至80题, 每题10分。 一、单项选择题 1. A diesel engine is similar to a gasoline engine except that the former has no ______. A. cross-head B. spark plug C. connecting rod D. cylinder 2. A diesel engine which is rated for normal operation at a crankshaft speed of 800 RPM, is commonly classed as a ______. A. slow-speed diesel B. medium-speed diesel C. high-speed diesel D. constant-speed diesel 3.Which of the diesel engine components listed increases air density and helps to improve engine operating efficiency? A. Impeller B. Compressor C. After-cooler D. Exhaust diffuser 4.For a given size engine, the two-stroke/cycle diesel engine will deliver more power than a four- stroke/cycle diesel engine because ______. A. it has a longer power stroke B. more air gets into the cylinder each stroke C. it develops twice as many power strokes at the same speed D. higher combustion pressure is developed 5.The intake valves in a diesel engine are reseated by ______. A. cam followers B. push rods C. combustion gases D. valve springs 6.According to the way the energy of the exhaust gases is utilized, pressure-charging can be divided into two main systems, namely, the constant-pressure system and ______. A. the pulse-phase system B. the pulse Doppler system C. the pulse system D. the pulse interval system 7.An over-speed safety device is usually fitted to a generator engine for______in the event of over- speed. A. cutting power off the engine B. increasing the fuel pump setting C. braking the crankshaft D. stabilizing the ship speed 8.What preventative maintenance should be done frequently to diesel engine starting air receivers? A. Drain the accumulated moisture. B. Test the relief valves. C. Watch the temperature to prevent fluctuations in pressure. D. Clean the interior to remove oil and foreign matter. 9.Immediately after any diesel engine is started, the engineer should check the ______. A. crankcase pressure B. lube oil pressure C. seawater pressure D. exhaust temperature 10. A controllable pitch propeller on a diesel driven vessel eliminates the need for ______. A. friction clutches B. disconnect clutches C. reversing gears D. reduction gears 11.In motor ship, ______is often used to recover some of the heat carried in the exhaust gases from the main engine. A. an diesel oil heater B. a waste heat boiler C. a fresh water generator D. a donkey boiler 12.An exhaust gas bypass is installed on a waste heat boiler in order to ______. A. bypass exhaust gas at high loads to prevent excessive back pressure B. bypass a portion of the exhaust gas at peak loads for better efficiency C. recycle exhaust gas to the turbocharger D. minimize moisture condensation in the boiler gas passages at low loads 13.Prior to lighting off a cold automatically fired auxiliary boiler, you should ______. A. check and regulate the water level B. close the air cock once fires are lit C. blow down the gage glass D. assure protective steam flow 14.Flame failure in an automatically fired auxiliary boiler can mostly result from a/an ______. A. incorrect electrode setting B. incorrect nozzle position C. clogged fuel nozzle D. broken high tension lead 15.Waterside scale in a fire-tube boiler may cause ______. A. increased heat transfer B. fireside erosion C. high steam demand D. overheated tubes 16.Which of the following will be the advantage of a centrifugal pump as compared with a reciprocating pump? I. Its discharge is continuous; II. It has no internal valves; III. Upon accidental closing of discharge valve, excessive pressure will not build up A. I, II B. II, III C. I, II, III D. II only 17.Why are removable sleeves installed on centrifugal pump shafts? A. They make it easier to replace the pump shaft packing. B. They can be economically replaced as they wear out. C. They can be removed when it is necessary to lighten the weight of the pump. D. They increase the strength of the shaft. 18.If one of the bilge system manifold valves does not properly seat, the ______. A. bilge well connected to that valve, plus the second bilge well being pumped will be completely emptied B. bilge system will lose vacuum and prevent the other bilges from being pumped out C. bilge well aft connected to that valve will siphon(虹吸) its contents to the forward bilge wells D. discharge pressure will be too high. 19.Which of the listed statements is correct concerning the starting of centrifugal pumps? A. They should always be started with the discharge valve closed. B. They should always be started with the discharge valve opened. C. A priming pump is always required to flood the impeller suction. D. They should always be started with the sealing line valves closed. 20.The simplest method to use for determining if a centrifugal pump is operating as designed, is to ______. A. closely observe the pump discharge temperature B. close off the discharge valve, and watch for a rise in pressure C. momentarily close off the suction valve, and watch for a rise in pressure D. use a clamp on ammeter and compare the readings to past records

轮机英语历年真题43期

中华人民共和国海事局 2007年第2期海船船员适任证书全国统考试题(总第43期) 科目:轮机英语试卷代号:805 适用对象:无限、近洋航区3000KW及以上船舶二/三管轮 (本试卷卷面总分100分,及格分为70分,考试时间为100分钟) 答题说明:请选择一个最合适的答案,并将该答案按答题卡要求,在其相应位置上用2B铅笔涂黑。第1题至74题,每题1分,第75题至78题,每题1.5分,第79题至80题, 每题10分。 一、单项选择题 1.______ the engines, the diesel engine is ______ used engine on board. A. Between/more commonly B. Among/the most commonly C. Between/not more commonly D. Among/ not the most commonly 2.The average pressure exerted on a piston during each power stroke is termed ______. A. indicated horsepower B. mean effective pressure C. exhaust back pressure D. compression pressure 3.The cetane number rates fuels for diesel engines according to its ______. A. antiknock characteristics B. ignition qualities C. rates of vaporization D. viscosity 4.The time between injection and ignition of the fuel is known as ______. A. turbulence lag B. after burning ratio C. pre-ignition lag D. ignition delay 5.______ controls the fuel oil temperature in order to provide oil at the correct viscosity for combustion. A. The viscosity regulator B. The temperature controller C. The flow meter D. The pressure switch 6.Constant cooling the various components of diesel engine has a number of functions except for ______. A. good lubrication B. low thermal stress C. good mechanical properties D. acid corrosion 7. A device which functions to bring a diesel engine to a full stop to protect it from damage is known as a/an ______. A. torque limiter B. over-speed trip C. over-speed governor D. load limit governor 8.Engine speeds at which resonance can occur are termed ______. A. maximum speeds B. full speeds C. sea speeds D. critical speeds 9.Prolonged operation of a diesel engine with a closed cooling water system at lower than normal designed operating temperatures can ______. A. increase power output B. decrease lube oil viscosity C. eliminate fuel knock D. cause sulfuric acid formation 10.______ on a ship transmits power from the engine to the propeller. A. The automatic control system B. The speed regularly system C. The transmission system D. The compression air system 11.In a _____ boiler the hot gases from the furnace pass through the tubes while the water is on the outside. A. water-tube B. fire-tube C. exhaust gas D. composite 12.The fuel supply system to an automatic auxiliary boiler, will be automatically shutdown if the boiler ______. A.salinity is abnormally B.high steam demand is too high C.feed-water flow is low D.water level is abnormally low 13.The water in a steaming auxiliary boiler should be tested daily for ______. A. dissolved oxygen B. chlorides C. sludge D. dissolved nitrogen 14.Ignition failure in an automatically controlled auxiliary boiler could be caused by ______. A. carbon deposits on the flame scanner B. high fuel oil temperature C. low fuel oil viscosity D. high steam pressure 15.The concentration of total dissolved solids in the water of an auxiliary boiler can increase as a result of ______. A. seawater contamination B. frequent surface blows C. dissolved oxygen de-aeration D. frequent bottom blows

46873甲类三管轮轮机维护与修理46期试题

2008年第6期海船船员适任统考试题(总第46期) 科目:轮机维护与修理试卷代号:873 1.滑油变质,柴油机主轴承的轴承合金烧熔的故障属于——故障。 A.管理性B.突发性C.磨损性D.渐进性 2.船机磨损故障期的特点是 A.故障率低B、故障率随时间延长而增加 C.时间较长D.故障率随时间延长而降低 3.全寿命维修的核心思想是要求产品在————所耗费用最少。 A.全寿命周期内B.使用过程C。修理阶段D.研制过程 4.船舶机械有计划保养系统PMS对耐用型设备、低值设备、非生产型设备采用A.定时维修方式B.事后维修方式 C.定期维修十视情维修D。视情维修方式 5.按规定周期结合坞内检验和保持船级的“年度检验”进行的检验修理是——。 A.小修B.航修C.检修D.大修 6.为了减小摩擦与磨损.可在摩擦副间加入某种物质,使摩擦阻力降低的措施称之为。 A润滑B.摩擦C。磨损D.摩擦学 7 船舶机器在实际运转中,在、工况时摩擦副难以实现或保持液体动压润滑。 A.起动B.起动、停车C.低速运转D.高速运转 8.利用摩擦表面的相对运动产生楔形油膜或挤压油膜来承受外部载荷并隔开摩擦表面,这种润滑称为 A.流体动压润滑B.流体静压润滑C.强力润滑D.油脂润滑 9.摩擦表面间的机械作用主要表现形式是 I、变形11、剪切Ill、挤压Ⅳ、拉伸V、弯曲 AⅡ+ⅢBⅠ+Ⅱ+Ⅲ.C.Ⅰ+Ⅲ+ⅣD.Ⅰ+Ⅲ+IV+V 10.在摩擦过程中,运动副工作表面上的氧化膜不断地脱落使运动副零件金属损失的现象是一种磨损。 A腐蚀B.微动C.疲劳D.化学 11.影响船机零件磨粒磨损的主要因素有 A磨粒B.摩擦副材料C.润滑油粘度D.磨粒和摩擦副材料 12.柴油机正常运转时气缸套与活塞环的摩擦表面间可能产生的磨损类型有一。 I、粘着磨损Ⅱ、腐蚀磨损Ⅲ、磨粒磨损IV、疲劳磨损V、微动磨损 A.1+11+111.B.Ⅰ+Ⅱ+ⅤC.Ⅰ+ⅢD.Ⅰ十Ⅳ+V 13.燃油中含有较高的————是引起气缸套产生磨粒磨损的重要原因。 A钒钠含量B.铝硅含量C.硫含量D.灰分含量 14.下图为气缸套磨损后的纵截面形状和磨损示意图,其中属于异常磨损的有 A.(b)、(e)、(f)B.(b)、(e)、(f)、(g) C.(a)、(b)、(c)、(d)D.(b)、()、(d)、(e)、(f)、(g) 15.磨合时,气缸润滑油的碱值越高,发生拉缸的概率 A越大B.越小C.为零D.100% 16.为了减少船舶柴油机气缸套磨损,在日常管理中应保证气缸良好润滑条件,并Ⅰ、加强气缸油品质的选择和净化处理Ⅱ、控制气缸套的壁温Ⅲ、定时定量供油 Ⅳ、保证气缸套磨合运转符合要求V、保证气缸油的碱值与燃油匹配 A.Ⅰ+Ⅱ+ⅢB.Ⅰ+Ⅱ+ⅤC.Ⅰ+Ⅲ+ⅤD.Ⅰ十Ⅳ十Ⅴ17.柴油机正常运转时,连杆大端轴承与曲柄销颈之间形成润滑状态。 A.边界B.流体动压C.流体静压D.混合 18.柴油机正常运转期间,主轴承轴瓦烧熔通常是由于 A.材质不佳B.滑油中含水C,滑油品质稍差D.螺栓预紧力过大19.柴油机曲轴采用钢质材料,轴瓦瓦村选用轴承合金,这种材料匹配主要是为了减少 A磨粒磨损B.粘着磨损C.腐蚀磨损D.疲劳磨损 20.高温腐蚀是属于腐蚀。 A.电化学B.化学C.宏观D.微观 21.依金属腐蚀过程的特点分为腐蚀和腐蚀。 A金属/非金属B.化学/电化学C.全面/局部D.均匀/不均匀22.柴油机燃烧室零件发生高温腐蚀的条件除了燃用重油外,主要还有A零件温度高B.冷却水温度过低C.润滑不良D.零件材料差23.防止化学腐蚀的措施,正确的是 A.安装锌块B.涂覆盖层保护C.电化学保护D.进行介质处理24.金属与含氧量不同的介质接触,在氧浓度较高处金属的电极电位较为极。 A.低/阳B.低/阴C.高/阳D.高/阴 25.金属材料由于表面膜不完整,在电解质溶液中发生腐蚀。 A.化学B.宏观电化学C.微观电化学D.电偶 26.黄铜制件在酸性溶液或盐溶液中的脱锌是腐蚀。 A宏观电化学B.电偶C.应力D.微观电化学 1