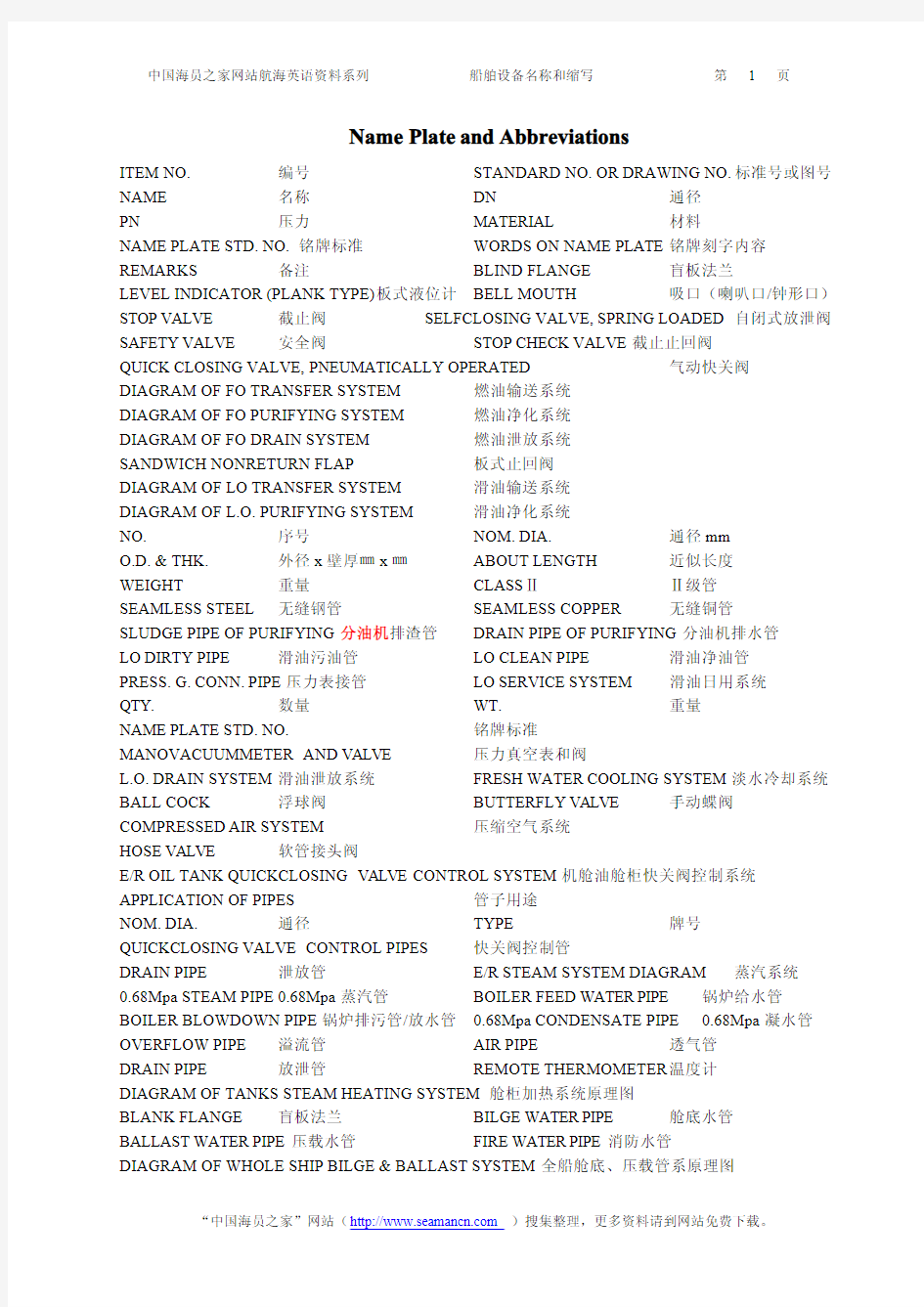

船舶设备名称和缩写

Name Plate and Abbreviations

ITEM NO. 编号 STANDARD NO. OR DRAWING NO.标准号或图号 NAME 名称 DN 通径

PN 压力 MATERIAL 材料

NAME PLATE STD. NO. 铭牌标准 WORDS ON NAME PLATE 铭牌刻字内容 REMARKS 备注 BLIND FLANGE 盲板法兰

LEVEL INDICATOR (PLANK TYPE)板式液位计 BELL MOUTH 吸口(喇叭口/钟形口) STOP VALVE 截止阀 SELF-CLOSING VALVE, SPRING LOADED自闭式放泄阀 SAFETY VALVE 安全阀 STOP CHECK VALVE 截止止回阀

QUICK CLOSING VALVE,PNEUMATICALLY OPERATED 气动快关阀 DIAGRAM OF FO TRANSFER SYSTEM 燃油输送系统

DIAGRAM OF FO PURIFYING SYSTEM 燃油净化系统

DIAGRAM OF FO DRAIN SYSTEM 燃油泄放系统

SANDWICH NON-RETURN FLAP 板式止回阀

DIAGRAM OF LO TRANSFER SYSTEM 滑油输送系统

DIAGRAM OF L.O.PURIFYING SYSTEM 滑油净化系统

NO. 序号 NOM.DIA. 通径 mm

O.D.& THK. 外径 x 壁厚㎜ x ㎜ ABOUT LENGTH 近似长度

WEIGHT 重量 CLASSⅡ Ⅱ级管

SEAMLESS STEEL 无缝钢管 SEAMLESS COPPER 无缝铜管

SLUDGE PIPE OF PURIFYING 分油机排渣管 DRAIN PIPE OF PURIFYING 分油机排水管

LO DIRTY PIPE 滑油污油管 LO CLEAN PIPE 滑油净油管

PRESS. G.CONN.PIPE 压力表接管 LO SERVICE SYSTEM 滑油日用系统

QTY. 数量 WT. 重量

NAME PLATE STD.NO. 铭牌标准

MANO-VACUUMMETER AND VALVE 压力真空表和阀

L.O.DRAIN SYSTEM 滑油泄放系统 FRESH WATER COOLING SYSTEM 淡水冷却系统 BALL COCK 浮球阀 BUTTERFLY VALVE 手动蝶阀 COMPRESSED AIR SYSTEM 压缩空气系统

HOSE VALVE 软管接头阀

E/R OIL TANK QUICK-CLOSING VALVE CONTROL SYSTEM 机舱油舱柜快关阀控制系统 APPLICATION OF PIPES 管子用途

NOM.DIA. 通径 TYPE 牌号

QUICK-CLOSING VALVE CONTROL PIPES 快关阀控制管

DRAIN PIPE 泄放管 E/R STEAM SYSTEM DIAGRAM 蒸汽系统

0.68Mpa STEAM PIPE0.68Mpa 蒸汽管 BOILER FEED WATER PIPE 锅炉给水管 BOILER BLOWDOWN PIPE 锅炉排污管/放水管 0.68Mpa CONDENSATE PIPE 0.68Mpa 凝水管 OVERFLOW PIPE 溢流管 AIR PIPE 透气管

DRAIN PIPE 放泄管 REMOTE THERMOMETER温度计

DIAGRAM OF TANKS STEAM HEATING SYSTEM 舱柜加热系统原理图

BLANK FLANGE 盲板法兰 BILGE WATER PIPE 舱底水管

BALLAST WATER PIPE 压载水管 FIRE WATER PIPE 消防水管

DIAGRAM OF WHOLE SHIP BILGE & BALLAST SYSTEM 全船舱底、压载管系原理图

BUTTERFLY VALVE HYDRAULIC ACTUATOR 液压遥控蝶阀

DISCHARGECHECK VALVE 吸入止回阀

DISCHARGE VALVE OF SELF CLOSED 自闭式放泄阀

CAST IRON 铸铁 CAST STEEL 铸钢

OILY WATER SEPARATOR SYSTEM 舱底水油水分离器系统

BILGEWATER CLARIFIER 舱底水油水分离器

S.W.PIPE 海水管 BILGE PIPE 舱底水管

DRAIN PIPE 处理水排出管 WASTE OIL PIPE 废油管

F.W.PIPE 淡水管 STEAM/CONDEN.PIPE 蒸汽/凝水管 DIAGRAM OF E/R AIR, SOUNDING& TRANSFUSE SYSTEM 机舱空气、测深、注入管系图

AIR PIPE (WEATHER DECK) 空气管(露天甲板)

SOUNDING PIPE 测深管 DRAIN PIPE 泄放管

SHIP’S AIR SOUNDING AND FILLING 全船空气、测深、注入管系图

VENT.HEAD 空气管头 INJECT HEAD 注入接头 SOUNDING HEAD 测深头

ONE SIDE WELDED BED PLATE FOR FLANGES 法兰焊接单面座板

THE HEAD LOSS IN PIPE FROM PUMP TO THE HYDRANT OF THE HIGHEST POSITION

至最高位置处消火栓,管路水力损失

SEGMENT OF PIPE 管路编号 LENGTH OF PIPE 直管段长 L(m)

I.DIA. 管子内径 di (m) FLOWRATE 管中水流量 Q (m3/h) MODULUS 局部阻力系数 NAME OF RESISTANCE 局部阻力名称

NU. 个数 n SING. 单个ξ

FLOW VEL. 管中水流速 v (m/s) RENAULT 雷诺数 Re RESISTANCE TRAIT VALUE 阻力特性值 N COEFFICENT OF FRICTION 流体摩擦系数λ(Re>N) EQUIVALENT PIPE 管子当量长度 ld (m) CALCULATING LENGTH 管子折算长度 lc (m) HEAD LOSS IN PIPE 管段压力损失 h (MPa)

THE HEAD LOSS IN PIPE FROM PUMP TO THE HYDRANT ON THE UPPER DECK FORSIDE 至上 甲板首部消火栓处,管路水力损失 H3

DIAGRAM OF FIRE FIGHTING SYSTEM 全船消防水管系图

ASSEMBLY 组合件

ISOLATING VALVE BETWEEN FIRE MAIN AND E/R

HAWSEHOLE(P) FLUSH

HAWSEHOLE(S) FLUSH

FROM EMERGENCY FIRE PUMP

TO CARGO HOLD EJECTOR

VENT BRONZE 青铜

DIAGRAM OF E/R WATER SUPPLY SYSTEM 机舱供水管系原理图

SCREW DOWN VALVE 截止阀 SCREW DOWN STOP AND CHECK VALVE 截止止回阀 ARRANGEMENT OF WHOLE SHIP WATER SUPPLY SYSTEM 全船供水管系布置图 FLUSH VALVE 冲洗阀 STRAIGHT CONNECT VALVE 直通阀

BASIN MIX VALVE 面盆混合放水阀

DIAGRAM OF SEWAGE WATER TREATMENT SYSTEM 生活污水处理装置管系原理图

GATE VALVE 闸阀 STOP& CHECK VALVE 截止止回阀

STOP VALVE 截止阀 CHECK VALVE 止回阀

STORM VALVE 可闭立式防浪阀 TO SEWAGE DISCH.MP.(P)

SOIL TO SEWAGE TR.UNIT

CLINIC SOIL TO SEWAGE TR.UNIT

SANI.TO SEWAGE TR.UNIT

F.W.FLUSHING TO SEWAGE TR. UNIT

SEWAGE TO SEWAGE STORAGE TK. 生活污水至生活污水存放舱

SEWAGE DISCH.OVERSIDE

CUTTING PUMP IN

CUTTING PUMP OUT

SEWAGE TR. UNIT OUT

DRAINAGE DISCH.TO SEWAGE STORAGE TK.

DRAINAGE DISCH.TO MP

DRAINAGE DISCH.OVERSIDE

DISCH.OVERSIDE

DIAGRAM OF DECK SCUPPERS 甲板疏排水管系图

DECK SCUPPER PIPE 甲板疏排水管

GALV. 镀锌

ARRANGEMENT OF SEWAGE WATER SYSTEM (GREY WATER) 卫生水疏排水管系布置图(灰水) ARRANGEMENT OF SEWAGE WATER SYSTEM (BLACK)粪便污水管系布置图(黑水)

MARINE AIR PIPE HEAD 船用空气管头 WITH FIREPROOF NET 带防火网 MECHNICAL VENTILATION LAYOUT 舱室机械通风布置图

EXHAUST NOZZLE 圆形抽风头 FIRE DAMPER 船用防火风闸 VENTILATOR COAMING

WC EXHAUST FAN 裕厕所抽风机 MUSHROOM VENTILATORS 菌形风帽 HOSPITAL EXHAUST FAN 医务室抽风机

VENT LOUVER WITH WEATHERTIGH COVER 风雨密钢质百叶

EXHAUST NOZZLE 圆形抽风头 GOOSENECK VENTILATORS 鹅颈式通风筒 MESS & MEETING EXHAUST FAN 餐厅兼会议室抽风机

LAUNDRY AND CHANGING EXHAUST FAN 西意见、更衣室抽风机

GELLY SUPPLY FAN 厨房送风风机 GELLY EXHAUST FAN 厨房抽风风机

WIRE GRILLING 通风栅 VENTILATOR COAMING 甲板接管

GALLEY PROVISION AND PROVISION STORE EXHAUST FAN 粮库,厨房,储物间抽风机

FIRE DAMPER 船用防火风闸 MUSHROOM VENTILATORS 菌形风帽

LAYOUT OF REF.MACHINE RM.VENTILATION 制冷机室通风管系布置图

REF.MACHINE EXHAUST FAN 制冷机室抽风机

VENTILATOR COAMING 甲板接管 WIRE GRILLING 通风栅 GOOSENECK VENTILATORS 鹅颈式通风筒 STAINLESS STEEL 不锈钢

TOTAL 总重 REF.PROV.PLANT SYSTEM 伙食冷库管系原理图 PRESSURE GAUGE VALVE 压力表阀 METAL-SHELL THERMOMETER金属壳水银温度计 NO.1 CONDENSER C.S.W.INLET NO.2 CONDENSER C.S.W.OUTLET

LAYOUT OF DECK COMPRESSED AIR PIPING 甲板压缩空气管系布置图

HOSE JOINT VALVE 软管接头阀 REDUCING VALVE 减压阀

SCREW DOWN VALVE 截止阀 SCREW DOWN VALVE 旋压阀/螺旋阀

MALE SCREW 外螺纹 EMER.GEN.ROOM 应急发电机室

A/C ROOM POOP DECK (P) 尾楼甲板(左) POOP DECK (S) 尾楼甲板(右) CREW DECK (P) 船员甲板(左) BOAT DECK (S) 救生艇甲板(右) CAPTAIN DECK 船长甲板 NAVIGATION DECK 驾驶甲板 UPPER DECK(P) 上甲板(左) FORECASTLE DECK(P)首楼甲板(左) STORE 储物间 EMER.FIRE PUMP ROOM 应急消防泵室 INLET OF REDUCING VALVE 减压阀入口 TO AIR HORN 至汽笛 DRAIN

BYPASS VALVE 旁通阀 OUTLET OF RECUDING VALVE 减压阀出口 FLANGE ACCORDING TO ISO 法兰按照 ISO

SETTING 0.22MPa 设定值 0.22MPa

OXYGEN&ACETYLENE PIPING DIAGRAM 氧气/乙炔管系图

OXYGEN BOTTEN 氧气瓶组 ACETYLENE CYLINDER 乙炔瓶组 OXYGEN REDUCING VALVE 氧气减压阀

ACETYLENE BACKFIRE VALVE 乙炔回火阀

ACETYLENE REDUCING VALVE 乙炔减压阀

2 – LEFT OPENED 2 – 左开 5 – RIGHT OPENED 5 – 右开

1 – DOWN OPENED 1 – 下开

NATURAL VENTILATION LAYOUT 全船自然通风布置图

STRAINER 粗滤器,滤网,过滤器

EXPANSION BELLOW 膨胀伸缩式波纹管

SLEEVE 套管 伸缩的 TELESCOPIC/RETRACTILE EXTENSION LADDER 伸缩梯

Buffer 缓冲器

Adjust valve 调节阀

OIL AND AIR SEPARATOR OF BOILER

FO PUMP OF BOILER

FO PUMP OF BOILER

FO BOOSTER MODULE

STEAM TRACE INLET DN10

PIPING SYMBOL: 管子符号

MGO PIPE: 燃料油管 轻柴油管:

STEAM TRACE PIPE: 蒸汽伴行管:

MGO SERVICE TK 轻柴油日用舱

HFO SERVICE TK 燃料油日用舱

NO.2AUX.ENGINE GEN.SETNO.2 柴油发电机组

FR.RETURN OIL OF SPRAY喷油回油

NO.1AUX.ENGINE GEN.SETNO.1 柴油发电机组

HFO https://www.360docs.net/doc/3615976428.html, OF BOILER 锅炉燃料油日用柜

MDO TK OF BOILER 锅炉点火轻柴油柜

FO BOOSTER MODULE 燃油供油单元

粗滤器 FILTER

燃油供给泵 FO SUPPLY PUMP

调压阀 REGULATING PRESS.VALVE

手动逆洗滤器 HAND BACK FLUSH FILTER

精滤器 FINE FILTER

流量计 FO FLOW METER

空气分离器 AIR SEPARATOR

燃油循环泵 FO CIRCULATING PUMP

燃油加热器 FO HEATER

自动排气浮阀 AUTO.DEGAS VALVE

控制屏 CONTROL PANEL

均质机 OMEGA-FIRE

三通切换阀 THREE WAY VALVE

粘度传感器 VSICOSITY SENSOR

蒸汽控制阀 STEAM CONTROL VALVE

HAND QUICK-CLOSING VALVE 手动快关阀

FO AND EXCUSED BOILER 燃油废气组合锅炉

DIAGRAM OF FO SERVICE SYSTEM 燃油日用系统

供油单元柴油进口 FO INLET OF FO BOOSTER MODULE

供油单元燃料油进口 HFO INLET OF FO BOOSTER MODULE

供油单元加热蒸汽进口 STEAM INLET OF FO BOOSTER MODULE

供油单元加热蒸汽冷凝水出口 COAGULATE WATER OUTLET OF FO BOOSTER MODULE

供油单元精滤器残油泄放口

LEAKAGE OIL OUTLET OF THIN STRAINER OF FO BOOSTER MODULE

供油单元燃油出口 FO OUTLET OF FO BOOSTER MODULE

供油单元燃油回油接口 RETURN OIL OUTLET OF FO BOOSTER MODULE

供油单元泄放口 1 No.1 LEAKGE OIL OUTLET OF FO BOOSTER MODULE

供油单元泄放口 2 No.2 LEAKGE OIL OUTLET OF FO BOOSTER MODULE

供油单元回油筒放气口 AIR OUTLET OF MIXING TANK OF FO BOOSTER MODULE TECHNICAL REQUIREMENTS

1.ANNOTATED SIZES OF PIPE IN THE DRAWING ARE OUT DIA.xTHICK(mm).

2. HERE PIPES PENETRATE THROUGH WATER TIGHT BULKHEADS OR DECK TO BE FITTED WITH PENETRATION PIECE ACCORDING TO CB/T3480-92.

3.ALL PIPING TO BE SECURELY SUPPORTED AND BRACED IN ACCORDING WITH CB/T3780- 1997 OR SHIPYARD STANDARD.

4.THE ITEMS WITH `` * '' OR `` ''TO BE SUPPLIED WITH EQUIPMENT.

5.HYDROSTATIC TEST:

DESIGN PRESS. MPa

BEFORE INSTALLATION MPa

AFTER INSTALLATION MPa

HFO PIPE 燃料油管

MGO PIPE 轻柴油管

6. THE MARK Item mark/Item No. REFER TO LIST OF AUTOMATIC CONTROL、MONITORING &ALARM POINTS FOR E/R(-440-01MX).

7.THE H.F.O.PIPING MUST BE PROVIDED WITH DN10(? 15X1.5)STEAM TRACING

PIPE AND TO BE COVERED WITH GLASS WOOL OR OTHER EQUIVALENT.

技术要求

1. 图中管子所注尺寸均为外径 x 壁厚(mm)。

2. 管子通过水密舱壁,甲板或舱壁时,应按 CB/T3480-92 或船厂标准设置通舱管件。

3. 管子应按 CB/T3780-1997 或船厂标准设置牢固的支架,管卡。

4. 图中带``*''或 符号为设备所带附件。

5. 液压试验: 设计压力Mpa, 装船前 Mpa 装船后 MPa

6. 图中自动化符号 项目代号/项目序号 详见"轮机自动化项目明细表"

7. 燃料油管系需设 DN10(? 15X1.5)蒸汽伴行管,在外包覆玻璃棉或其它适当的绝热材料. DIAGRAM OF FO TRANSFER SYSTEM 燃油输送系统

'STANDARD NO.OR DRAWING NO. 标准号或图号

'DN'通径 mm

NAME PLATE STD.NO. 铭牌标准 CB/T84-1998

PN 压力 Mpa

QTY.数量

WT.重量 kg

轮机说明书 SPECIFICATION OF MACHINERY PART

生 产 设 计 PRODUCTION DESIGN

NOTES: 说明:

1.ALL DUCT SHOULD BE FIXED WITH HANGER .THE DISTANCE BETWEEN TOWHANGERS IS 2 METERS MAXIMUM.

风管至多每隔 2米设一固定吊架。

2.ALL VENTLATORS SHOULD BE INSTALLED WITH RATPROOF WIRES.

所有通风筒应设有防鼠网。

3.AFTER FITTED ON BOARD,THE OUTSIDE SURFACE OF NON GALVANIZED FITTINGS AND DUCT SHOULD BE PAINTED 2 COATS OF RUST PREVENTIVE PAINT AND1 COAT OF FINISHING PAINT.

凡是没有镀锌的附件及管道,在装船后,其表面应涂防锈漆 2度及色漆 1 度。

4. THE FLANGES UESD FOR RECTANGULAR DUCTS IN THIS DRAWING SHOULD BE MADE IN ACC.WITH GB1561-79.

风管法兰按 GB1561-79设置。

5. PENETRATING PIECES USED FOR DUCTS TO PASS THROUGH THE A CLASS BULKHEAD OR DECK SHALL BE PROVIDED IN ACC. WITH "FIRE RESISTING DIVISION PLAN " (-103-04) and "TYPICAL NODE OF FIRE RESISTING STRUCTURE"(-362-02).

风管穿过 A 级舱壁或甲板的贯通件按《防火分隔图》(-103-04)和《典型防火节点图》(-362-02)设 置。

6. PENETRATION HAS TO BE INSULATED ACC. THE REQUIRED FIRE INTEGRITY OF THE BULKHEAD/DECK.

贯通件按照它所穿越的舱壁或甲板的防火等级进行绝缘 。

7. THE LOWEST DUCT OF SHIP STRUCTURE SHOULD BE OPENED HOLE, AS TO BE DRAIN WATER.

在通风静压箱的最低处开泄水孔。

CADET 甲板见习生

DECK STORE 甲板物料间

HOSPITAL 医务室

A/C ROOM 空调机室

UPPER DECK 上甲板

GALLEY STORE 厨房储物间

POOP DECK 尾楼甲板

STEEL PLATE 钢板

GALVANIZED STEEL 镀锌钢板

ASSEMBLY组合件

DUCT 风管

WIRE GRILLING 通风栅

VENTILATOR COAMING 甲板接管

EXHAUST FAN 轴流抽风风机

GOOSENECK VENTILATORS 鹅颈式通风筒

MUSHROOM VENT.HEAD 菌形通风筒

LAYOUT OF AIR CONDITION ROOM 空调机室通风布置图

DETAIL DESIGN 详 细 设 计

REVERSIBLE 可逆转

NOTES: 说明:

1.ALL DUCT SHOULD BE FIXED WITH HANGER .THE DISTANCE BETWEEN TOW HANGERS IS 2~3 METERS MAXIMUM.

风管至多每隔 2~3米设一固定吊架。

2.ALL VENTLATORS SHOULD BE INSTALLED WITH RATPROOF WIRES.

所有通风筒应设有防鼠网。

3.AFTER FITTED ON BOARD,THE OUTSIDE SURFACE OF NON GALVANIZED FITTINGS AND DUCT SHOULD BE PAINTED 2 COATS OF RUST PREVENTIVE PAINT AND 1 COAT OF FINISHING PAINT.

凡是没有镀锌的附件及管道,在装船后,其表面应涂防锈漆 2度及色漆 1 度。

4. THE FLANGES UESD FOR RECTANGULAR DUCTS IN THIS DRAWING SHOULD BE MADE IN ACC.WITH GB1561-79.

风管法兰 GB1561-79设置。

5. PENETRATING PIECES USED FOR DUCTS TO PASS THROUGH THE A CLASS BULKHEAD OR DECK SHALL BE PROVIDED IN ACC. WITH "FIRE RESISTING DIVISION PLAN " (-103-04) and "TYPICAL NODE OF FIRE RESISTING STRUCTURE"(-362-02).

风管穿过 A 级舱壁或甲板的贯通件按《防火分隔图》(-103-04) 和《典型防火节点图》(-362-02) 设置。

6. PENETRATION HAS TO BE INSULATED ACC. THE REQUIRED FIRE INTEGRITY OFTHE BULKHEAD/DECK.

贯通件按照它所穿越的舱壁或甲板的防火等级进行绝缘 。

7. THE LOWEST DUCT OF SHIP STRUCTURE SHOULD BE OPENED HOLE, AS TO BE DRAIN WATER.

在通风静压箱的最低处开泄水孔。

TECHNICAL REQUIREMENTS

技 术 要 求

1. EQUIPMENTS,FITTINGS/ACESSORIES, BUSHINGS, CLAMPS, WARNING NOTICES AND INSTRUCTIONS FOR THE INSTALLER IN THIS SYSTEM TO BE SUPPLIED BY MAKER.AND TO BE OF APPROVE TYPE.WARNING NOTICES TO BE PROVIDED AS PER NS 6033

本系统设备,附件,通舱套管,管夹,警告牌及安装要求等均由设备商提供,且应为认可型。警

告牌按标准提供。

2.THE CONNECTION OF PIPES TO BE BUTT WELDED AND TO BE LAID WITH FEW JOINTS AS POSSIBLE.THE PATH OF PIPE PASSAGE AND MOUNTED POSITION OF BULKHEAD PENETRATION ARE DETERMINED AT SITE.

管路连接采用对接焊形式,要求尽量减少接头,管路穿越的路径及通舱件的安装位置由现场定。

3.THE PIPES TO BE FASTENED TO THE BULKHEAD WITH PIPE CLAMPS AT INTERVALS NOT EXCEEDING 2.5m.

管子沿舱壁布置,且每隔 2.5m 左右设一个管夹。

4. PIPE & FITTINGS TO BE CLEANED IN SHOP SO TO REMOVE RUST GREASER ETC. BY DEGREASING WITH TRICHLOROE THANG OR ANOTHER EQUALLY EFFECTIVE AGENT (PETROL MUST NOT BE USED) TO BE USED, AFTER DEGEASING THE PIPES TO BE RISED WITH 10% SOLUTION OF TRISODIUMPHOSPHATE IN WATER, WITH 10% SOLUTION OF TRISODIUMPHOSPHATE IN WATER,

管子和附件应在车间用三氯乙稀或其他等效化学剂(不能用汽油)除锈,除油;除油后用 10%磷 酸三钠溶液冲洗。

5. BEFORE MOUNTING ON SHIP, PIPE & FITTINGS TO BE BLOWN WITH NITROGEN, COMPRESSED AIR OR OXYGEN MUST NOT BE USED.

船上安装前,需用氮气吹洗管子,附件,绝对不能使用压缩空气或氧气。

6.AFTER AII THE PIPES CONTRUCTED ON BOARD,TO SEAL TEST AS FOLLOWS:

全部管路在船上施工后进行气密试验如下:

a. AFTER INSTLLATION ON SHIP PIPES TO BE BLOWN CLEAN WITH NITROGEN AT A PRESSURE OF ABT 0.3MPa,WHICH TO BE INCREASED UP TO ABT 1.0MPa FOR ABOUT 10 MINUTES.

管路安装后,用压力约为 0.3MPa 的氮气将管路吹净,压力在 10 分钟内逐渐升至 1.0 MPa.

b.ON THE ACETYLINE PIPING NITROGEN TO BE USED,AND THE TEST PRESSURE TO BE OF I.O MPa. AII VALVES, JOINTS AND OTHER CONNECTIONS TO BE SWABBED WITH SOAPY WATER.AFTER 8 HOURS,THE PRESSURE DROP SHALL NOT EXCEED0.04MPa.

乙炔管路用压力 1.0 MPa 的氮气进行试验,抹肥皂水检查附件,接头的密封性,保持 8 小时,压 力降不得超过 0.04 MPa.

c. NON LEAKAGE OF OXYGENPIPES TO BE PERFORMED SAME AS ACETYLINE PIPES TEST PRESSURE TO BE1.2Mpa

氧气管路的密封试验与乙炔相同,试验压力为 1.2 MPa.

DRAWING CATALOGUE OF VENTILATION AND A/C SYSTEM

空调通风系统图纸目录

DIAGRAM OF AIR CONDITION SYSTEM 空调系统原理图

ARRANGEMENT OF AIR CONDITION ROOM 空调机室布置图

REF.PROV.PLANT SYSTEM 伙食冷库系统原理图

LAYOUT OF PIPING AND EQUIPMENT FOR PROV.CHAMMBER 伙食冷库设备、管系布置图 LAYOUT OF CARGO HOLD AND PIPE TUNNEL VENTILATION 货舱、管弄通风布置图

VENT-PIPE INSTALLTING DRAWING OF SUBSECTION601 分段通风管安装图

LAYOUT OF CARPENTRY ROOM/FWD WINDLASS CONTROL PANEL ROOM VENTILATION 木工间、锚机控制室通风布置图

LAYOUT OF BOW THRUSTER/EMERG.FIRE PUMP VENTILATION 艏侧推舱/应急消防泵舱通风 布置图

LAYOUT OF PAINT STORE VENTILATION 油漆间和储物间通风布置图

VENT-PIPE INSTALLTING DRAWING OF SUBSECTION603 分段通风管安装图 VENT-PIPE INSTALLTING DRAWING OF SUBSECTION608 分段通风管安装图 DUCT INSTALLING DRAWING OF UPEER DECK 上甲板螺旋风管安装图

DUCT INSTALLING DRAWING OF POOP DECK 艉楼甲板螺旋风管安装图

DUCT INSTALLING DRAWING OF CREW DECK 船员甲板螺旋风管安装图

DUCT INSTALLING DRAWING OF BOAT DECK 艇甲板螺旋风管安装图

DUCT INSTALLING DRAWING OF CAPTAIN DECK 船长甲板螺旋风管安装图 DUCT INSTALLING DRAWING OF NAVIGATION DECK 驾驶甲板螺旋风管安装图 DUCT INSTALLING DRAWING OF DUCT TUNNEL AREA 空调管弄螺旋风管安装图 marine engineering drawing catalog 轮机图纸目录

Main mechanical equipments ordering list 轮机部分主要机械设备订货明细表

Engine room arrangement plan 机舱布置图

Ventilation arrangement plan 机舱通风布置图

High sea water box fitting plan 机舱高位海水箱装置图

Low sea water box fitting plan 机舱低位海水箱装置图

Diesel generator unit base frame with ID 柴油发电机组座架及安装图

The arrangement of bow thruster & emerg fire pump tank 艏侧推舱/应急消防泵舱布置图 Steering gear room arrangement plan 舵机舱布置图

Emergency generator room arrangement plan 应急发电机室布置图

Emergency generator base frame with ID 应急发电机座架及安装图

Side rudderstocks 边舵柄/杆

Tank high, low water level alarm arrangement plan 舱柜高、低液位报警布置图 ARRANGEMENT OF CO 2 ROOM CO 2 站室布置图

Emergency fire pump tank SW box fitting drawing 应急消防泵舱海水箱装置图

marine engineering drawing catalog 轮机图纸目录

Engine room arrangement plan 机舱布置图

Smoke piping arrangement plan 机舱排烟管系布置图

Ventilation arrangement plan 机舱通风布置图

High sea water box fitting plan 机舱高位海水箱装置图

Low sea water box fitting plan 机舱低位海水箱装置图

Diesel generator unit base frame with ID 柴油发电机组座架及安装图

The arrangement of bow thruster & emerg fire pump tank

艏侧推舱/应急消防泵舱布置图

Steering gear room arrangement plan 舵机舱布置图

Emergency generator room arrangement plan 应急发电机室布置图

Emergency generator base frame with ID 应急发电机座架及安装图

Side rudderstocks 边舵柄

Tank high, low water level alarm arrangement plan 舱柜高、低液位报警布置图 ARRANGEMENT OF CO 2 ROOM CO 2 站室布置图

Emergency fire pump tank SW box fitting drawing 应急消防泵舱海水箱装置图 EMERGENCY GENERATION PLANT 应急柴油发电机组

SHAFT LINE 机组轴线

FRAME600 肋距 600

BORED TOGETHER8-? 19 配钻

CENTER LINE OF EMERG.GEN. 应急发电机组中心线

UPPER DECK 上甲板 8600

BASE FOUNDATION 船体基座

BASE OF E/G 机组底座

OTHERS: (其余)

THCHINICAL REQUIREMENTS 技 术 要 求

1. THE WELDING CHOCKS TO BE WELDED ON THE BASE PLATE ALL AROUND, AND THE WELDED SEAMS TO BE 5mm HEIGHT.

1. 焊接垫块沿四周焊于基座面板上,焊缝高度为 5mm。

2. THE SURFACES OF THE ADJUSTMENT CHOCK SHOULD BE GRINDED, AND THE INTERVAL BETWEEN THE ADJUST CHOCK AND WELDING CHOCK SHOULD NOT TO BE INSERTED IN BY PLUG GAUGE OF 0.05mm.

2. 调整垫块于现场锪平安装,垫块间用 0.05mm 塞尺检查应插不进.

BEVEL WASHER 方斜垫圈

WELDING CHOCK 焊接垫块

THIN NUT 薄螺母

CLASS: 8 强度等级:8

ACTUATOR

SOLENOIDVALVE BOX 电磁阀箱

ACCUMULATOR 蓄能器

POWER PUMP STATION

LAL

PAH

PAL

OIL TANK

PT

DETAIL DESIGN 详细设计

HYDRAULIC REMOTE CONTROL VALVE SYSTEM 阀门液压遥控系统

TECHNICAL REQUIREMENTS 技术要求

1.ANNOTATED SIZES OF PIPE IN THE DRAWING ARE OUT DIA. X THICKNESS(mm x mm). 1. 图中管子所注尺寸均为外径×壁厚。

2. WHERE PIPES PENETRATE THROUGH WATER TIGHT BULKHEADS OR DECK TO BE FITTED WITH PENETRATION PIECE ACCORDING TO CB/T3480-92 OR SHIPYARD STANDARDS.2. 管子通过水密舱壁,甲板或舱壁时,应按 CB/T3480-92 或船厂标准设置通舱管件。

3.ALL PIPING TO BE SECURELY SUPPORTED AND BRACED IN ACCORDING WITH CB/T3780- 1997 OR SHIPYARD STANDARDS.

3. 管子应按 CB/T3780-1997 或船厂标准设置牢固的支架,管卡。

4.THE ITEMS WITH"*" OR" "TO BE SUPPLIED WITH EQUIPMENT.

4. 图中带``*''或 符号为设备所带附件。

5.HYDRAULIC TEST:

5. 液压试验:

6. ALL BUTTERFLY VALVES IN THE SYSTEM ARE SUPPLIED BY NANTONG NAVIGATION MACHINERY CO., LTD. THE USAGE AND THE POSITION OF THESE VALVES CAN REFER TO "DIAGRAM OF WHOLE SHIP BILGE & BALLAST SYSTEM"(-510-02).

6. 本系统中所有液压蝶阀由南通航海机械有限公司配套提供,具体作用及布置见"全船舱底、压 载管系布置图 "(-510-02)。

1.ANNOTATED SIZES OF PIPE IN THE DRAWING ARE OUT DIA.x THICK (mm). 1. 图中管子所注尺寸均为外径 x 壁厚(mm)。

2. WHERE PIPES PENETRATE THROUGH WATER TIGHT BULKHEADS OR DECK TO BE FITTED WITH PENETRATION PIECE ACCORDING TO CB/T3480-92 OR SHIPYARD STANDARD. 2. 管子通过水密舱壁,甲板或舱壁时,应按 CB/T3480-92 或船厂标准设置通舱管件。

3.ALL PIPING TO BE SECURELY SUPPORTED AND BRACED IN ACCORDING WITH CB/T3780- 1997 OR SHIPYARD STANDARD.

3. 管子应按 CB/T3780-1997 或船厂标准设置牢固的支架,管卡。

4.THE ITEMS WITH `` * '' OR `` ''TO BE SUPPLIED WITH EQUIPMENT.

4. 图中带``*''或 符号为设备所带附件。

5.HYDROSTATIC TEST: 液压试验:

6.THE MARK

Item mark

Item No. REFER TO LIST OF AUTOMATIC CONTROL 、MONITORING

&ALARM POINTS FOR E/R(-440-01MX). 图中自动化符号

项目代号

项目序号 详见"轮机自动化项目明细表"(-440-01MX)

7. THE H.F.O. PIPING MUST BE PROVIDED WITH DN10 (? 15X1.5) STEAM TRACING PIPE AND TO BE COVERED WITH GLASS WOOL OR OTHER EQUIVALENT.

7. 燃料油管系需设 DN10(? 15X1.5)蒸汽伴行管,在外包覆玻璃棉或其它适当的绝热材料. DIAGRAM OF FO TRANSFER SYSTEM 燃油输送系统 HFO TK(PS) 燃料油舱(左) FTF37

NAME 名称 DESIGN PRESS.设计 压力 MPa BEFORE INSTALLATION 装船前 MPa AFTER INSTALLATION 装船后 MPa HFO PIPE 燃料油输送管 0.57

0.855

0.855

MDO PIPE 轻柴油输送管

0.57

0.855

0.855

NAME 名 称 DESIGN PRESSURE 设计压力 MPa

BEFORE INSTALLATION ON BOARD 装船前 (MPa) AFTER ASSEMBLY ON BOARD 装船后 (MPa) HYDRAULIC OIL PIPES

6.0

9.0

9.0

LAH

LS

FTV50

MDO TK(SB) 柴油舱(右)

AREA: 0.1875m

H.F.O.SLUDGE TK 燃油油渣舱

FTF45

FO OVERFLOW TK 燃油溢油舱

PIPING SYMBOL: 管子符号:

MDO PIPE: 轻柴油管:

HFO PIPE: 燃料油管:

TRACE HEATING PIPE 伴行管:

DIRTY FO TK 污燃油舱

TO HFO SEPARATOR SEE:-461-02

至燃油分油机见:-461-02

FROM LO SLUDGE TK.SEE:-462-02

来自滑油油渣舱见:-462-02

HFO TK(SB) 燃料油舱(右)

通舱管件 pipe penetration piece/ pipe penetrating piece

pipe pieces 管件

1.This drawing is PS block, the SB block is symmetric except as noted,

2.IN this drawing the end style of stiffener draw according to CB 3183-83

3.IN this drawing the cutout& doubling plates draw according to CB 3182-83

4.The form and dimension of welding reference to "scheme of welding"SC4386-190-01JB

5.All notch to be10X10 can weld full unless otherwise specified?

https://www.360docs.net/doc/3615976428.html,yout of pipe tunnel ventilation seeSC4386-541-10.

1.本分段除注明外,左右对称。

2.本图中型材端部形状按 《船体结构型材端部形状》标准设绘。 2.本图中型材端部形状按 《船体结构型材端部形状》标准设绘。

4.本分段构件焊接见《船体结构焊接规格表》图号 施焊。

5.本图中未注明切口均为 可焊没。

6.管弄通风,详见管弄通风布置图, SC4386-541-10.

7.货舱通风,详见货舱通风布置图, SC4386-541-01.

货舱通风修改

man hole modify

货舱梯修改

BL4423 STRINGER 舷侧纵桁

INNER BOTTOM 内底板

SHELL EXPANSION 外 板 展 开

ICE STRENGTHEN(7000WL~3150WL) 冰带加强区域(7000水线~3150 水线) BOTTOM LONGITUDINAL STIF.,FRAME BP180x40x9

船底纵骨 BP200x44x10肋骨 BP180x40x9

UPPER DECK 上 甲 板 BOTTOM 船 底

INNER BOTTOM 内底 A/C ROOM 空调室

REF.MACHINE 冷冻机,制冷机 ENGINE STORE

EMERGENCY GEN.应急发电机 STEERING GEAR ROOM 舵机室

CHANGE RM 更衣室 PROVISION STORE 食品库,储备库存/粮食库 CREW MESS 船员餐厅 LAUNDRY洗衣间

LINEN 亚麻(布)/制品 GALLEY 船上厨房

OFFICER MESS 高级船员餐厅 OFFICER PANTRY高级船员配膳间/室/餐具室 PNEUMATIC LOADING PIPE SYSTEM 气动装料管系统

DUST COLLECTOR 吸尘器/集尘器/除尘器 AERATION PANELS 通风板

UPPER DECK 上甲板 CARPENTER’S ROOM 木工室

WINDLASS CONTROL ROOM 锚机控制室/起锚控制室

CL=CENTER LINE 中心线 DESIGN DRAFT 设计吃水

BOND 封关库 CABLE HOLD 缆索舱

STORE 仓库 ENGINE CASING 机舱围壁

PAINT LOCKER 喷漆室/油漆间 COMPRESSOR ROOM 压缩机室/舱 PNEUMATIC UNLOADING 气动卸载 OUTLET TO HOLD 至货舱出口

LOADING POINT 装载点

HORIZONTAL SCREW CONVEYOR 卧式螺旋输送机/器

VERTICAL SCREW CONVEYOR 立式螺旋输送器/螺旋升运器

TRUCK LOADING SYSTEM(FUTURE OPTION) 装车系统(期货选项)

BLOW PUMP SYTEM 鼓风泵系统

TRANSFER BOX 中间电缆/无配电板的分线箱

LEVEL INDICATOR 液面指示器/液位计/水平仪/水平指示器

ALL MEASUREMENTS ARE PRELIMINARY 所有的测量都是初步的

PRINCIPAL PARTICULARS 主要参数/规范/详细数据/要素

LENGTH O.A. 117.00M

LENGTH B.P. 110.00M

BREADTH 19.7.M

DEPTH 8.50M

DRAFT DESIGN/SCANTLING 6.40/6.45M

DEADWEIGHT DESIGN/SCANTLING APPROX.7660/7756t

7700DWT Container Vessel Converted to Self-Unloading Cement Carrier

7700DWT 集装箱改装为自卸水泥船

Scale 比例尺 Dwg.No. 图号

Drawn by pw Total weight[Kg]

ISO methode E Design checked by

Rev.修改 Spec. nr.

Indicates Ra in μm

Sweden

This document, its design, text and content are protected under applicable copyrights, trademarks, trade secrets and other proprietary rights and are the property of BMH Marine AB.Neither this document in its entirety, nor any of the elements thereof may be used, reproduced or distributed, in any form or by any means without BMH Marine’s express prior written permission.All rights reserved.

本文件、设计、文本及内容受适用版权、商标、商业机密和其 他所有权的保护, 知识产权属于 BMH Machine AB 公司。 未经 BMH Marine 事先明确的书面允许,不得以任何形式或方法使用、复 制或者公开本文件的全部或者任何部分。版权所有,不得翻印。 This drawing and the information contained is the exclusive property of SDARI and must not be copied or handed over to third parties without our written permission.

本图(文件)及所含内容的知识产权属于上海船舶研究设计院 (SDARI)。未经本院书面许可,任何人不得复制或转交第三方。

目录

HOLD1????????????????????????????????????????????????????No.1 货舱 ???????????????????????????????????????????????????????5 HOLD2????????????????????????????????????????????????????No.2 货舱 ???????????????????????????????????????????????????????6 HOLD3????????????????????????????????????????????????????No.3 货舱 ???????????????????????????????????????????????????????7 HFOP???????????????????????????????????????????????????????燃料油舱 左????????????????????????????????????????????????????8 HFOS???????????????????????????????????????????????????????燃料油舱 右????????????????????????????????????????????????????9 HFO.SERV??????????????????????????????????????????????燃料油日用舱????????????????????????????????????????????????10 HFO.SETT??????????????????????????????????????????????燃料油澄清舱????????????????????????????????????????????????11 MDOP?????????????????????????????????????????????????????轻柴油舱 左??????????????????????????????????????????????????12 MDOS?????????????????????????????????????????????????????轻柴油舱 右??????????????????????????????????????????????????13 MDO.SERV1??????????????????????????????????????????No.1 轻柴油日用舱???????????????????????????????????????14 MDO.SERV2??????????????????????????????????????????No.2 轻柴油日用舱???????????????????????????????????????15 MDO.SETT?????????????????????????????????????????????轻柴油澄清舱????????????????????????????????????????????????16 LO.CIR.MEP?????????????????????????????????????????? 主机滑油循环舱 左?????????????????????????????????????17 LO.CIR.MES?????????????????????????????????????????? 主机滑油循环舱 右?????????????????????????????????????18 LO.STOR.ME?????????????????????????????????????????主机滑油贮藏舱????????????????????????????????????????????19 LO.PURI.ME??????????????????????????????????????????主机滑油净油舱????????????????????????????????????????????20 LO.GE.BOX.STO.AE?????????????????????????????辅机齿轮箱滑油贮藏舱???????????????????????????????21 FWAP??????????????????????????????????????????????????????尾淡水舱 左??????????????????????????????????????????????????22 FWAS??????????????????????????????????????????????????????尾淡水舱 右??????????????????????????????????????????????????23 FWFP??????????????????????????????????????????????????????首淡水舱 左??????????????????????????????????????????????????24 FWFS??????????????????????????????????????????????????????首淡水舱 右??????????????????????????????????????????????????25 WB1????????????????????????????????????????????????????????No.1 压载水舱???????????????????????????????????????????????26 WB2P??????????????????????????????????????????????????????No.2 压载水舱 左?????????????????????????????????????????27 WB2S??????????????????????????????????????????????????????No.2 压载水舱 右?????????????????????????????????????????28 WB3P??????????????????????????????????????????????????????No.3 压载水舱 左?????????????????????????????????????????29 WB3S??????????????????????????????????????????????????????No.3 压载水舱 右?????????????????????????????????????????30 WB4P??????????????????????????????????????????????????????No.4 压载水舱 左?????????????????????????????????????????31 WB4S??????????????????????????????????????????????????????No.4 压载水舱 右?????????????????????????????????????????32 WB5P??????????????????????????????????????????????????????No.5 压载水舱 左?????????????????????????????????????????33 WB5S??????????????????????????????????????????????????????No.5 压载水舱 右?????????????????????????????????????????37 WBL1P????????????????????????????????????????????????????No.1 下边压载水舱 左?????????????????????????????????35 WBL1S????????????????????????????????????????????????????No.1 下边压载水舱 右?????????????????????????????????36 WBL2P????????????????????????????????????????????????????No.2 下边压载水舱 左?????????????????????????????????37 WBL2S????????????????????????????????????????????????????No.2 下边压载水舱 右?????????????????????????????????38 WBL3P????????????????????????????????????????????????????No.3 下边压载水舱 左?????????????????????????????????39 WBL3S????????????????????????????????????????????????????No.3 下边压载水舱 右?????????????????????????????????40 WBL4P????????????????????????????????????????????????????No.4 下边压载水舱 左?????????????????????????????????41 WBL4S????????????????????????????????????????????????????No.4 下边压载水舱 右?????????????????????????????????42 WBL5P????????????????????????????????????????????????????No.5 下边压载水舱 左?????????????????????????????????43 WBL5S????????????????????????????????????????????????????No.5 下边压载水舱 右?????????????????????????????????44 WBU1P???????????????????????????????????????????????????No.1 上边压载水舱 左?????????????????????????????????45 WBU1S???????????????????????????????????????????????????No.1 上边压载水舱 右?????????????????????????????????46 WBU2P???????????????????????????????????????????????????No.2 上边压载水舱 左?????????????????????????????????47 WBU2S???????????????????????????????????????????????????No.2 上边压载水舱 右?????????????????????????????????48

WBU3P???????????????????????????????????????????????????No.3 上边压载水舱 左?????????????????????????????????49 WBU3S???????????????????????????????????????????????????No.3 上边压载水舱 右?????????????????????????????????50 WBU4P???????????????????????????????????????????????????No.4 上边压载水舱 左?????????????????????????????????51 WBU4S???????????????????????????????????????????????????No.4 上边压载水舱 右?????????????????????????????????52 WBAP?????????????????????????????????????????????????????尾压载水舱 左??????????????????????????????????????????????53 WBAS?????????????????????????????????????????????????????尾压载水舱 右??????????????????????????????????????????????54 WBASHP????????????????????????????????????????????????尾轴压载水舱 左??????????????????????????????????????????55 WBASHS????????????????????????????????????????????????尾轴压载水舱 右??????????????????????????????????????????56 WBFPC???????????????????????????????????????????????????首尖舱????????????????????????????????????????????????????????????57 SLU.HFO.OVE???????????????????????????????????????燃油溢油舱????????????????????????????????????????????????????58 SLU.HFO.DIR????????????????????????????????????????污燃油舱????????????????????????????????????????????????????????59 SLU.LO.DIR.ME????????????????????????????????????主机污滑油舱????????????????????????????????????????????????60 https://www.360docs.net/doc/3615976428.html,??????????????????????????????????????????燃油油渣舱????????????????????????????????????????????????????61 https://www.360docs.net/doc/3615976428.html,?????????????????????????????????????????????滑油油渣舱????????????????????????????????????????????????????62 SLU.WT.DIR??????????????????????????????????????????生活污水存放舱????????????????????????????????????????????63 SLU.BILGE????????????????????????????????????????????舱底水存放舱????????????????????????????????????????????????64

★PRINCIPAL PARTICULARS

主要参数

PRINCIPAL DIMENSIONS

主要尺度

MAIN CHARACTERISTICS OF THE VESSEL 主尺度

--------------------------------------------

Length between perpendiculars 垂线间长 110.00 m Breadth, moulded 型 宽 19.70 m Design draught 设计吃水 6.40 m Scantling draught 结构吃水 6.45 m

X-coord. of after perpendicular 尾垂线坐标 0.00 m

X-coord. of midship section 船中坐标 55.00 m

X-coord. of building frame 0 0 号肋位坐标 0.00 m

EXPLANATION OF SYMBOLS 符号说明

----------------------------------------------

HEIGHT height 距舱底高度 m FILL filling degree 装载率 % VNET net volume 净容积 m3 MASS weight of load 重量 t LCG x-coordinate of center of gravity 重心纵坐标 m TCG y-coordinate of center of gravity 重心横坐标 m VCG z-coordinate of center of gravity 重心竖坐标 m AWP area of waterplane 表面积 m2 FRS.MOM free surf. mom/real 自由液面矩 tm Compartment : HOLD1

Description : NO.1 CARGO HOLD

Contents : A).Cargo

Rho : 1.000 t/m3

Max.Capacity : 100 %

2282.3 m3

2282.3 t

Free surfaces : 4198.3 tm (Maximum)

5919.1 tm (IMO(A749))

Extreme coordinates: aft end: frame nr. 122.0 (from AP: 78.85 m)

fore end: frame nr. 156.0 (from AP: 100.95 m)

lowest point above BL: 1.300 m

highest point above BL: 10.200 m

船舶常用英文缩写

Common Abbreviation Abbr.Full Name Chinese Explanation AA ALWAYS AFLOAT 永远漂浮 A/C Air Compressor & Air Conditioner 空压机&空调 ACOL AFTER COMPLETION OF LOADING 装货结束之后 ACCU AUTOMATIC CONTROL SYSTEM CERTIFI ED FOR UNATTENDED ENG.ROOM 无人机舱自动控机系统鉴定 A/E ACCEPT/EXCEPT 接受/除外 AFMT AFTER FIXING MAIN TERMS 固定主要条款之后AD AIR DRAFT 水上高度 A/O AND/OR 和/或 AP ADDITIONAL PREMIUM 附加保险费 APS ARRIVAL PILOT STATION 到达引航站 A/R ALL RISKS 一切风险 A/S ACCOUNT SALE 销货账 A/S AFTER SIGHT 远期付款 A.T. American terms( grain trade) 美国条款(谷物交易)AAR AGAINST ALL RISKS 针对所有风险 ABS AMERICAN BUREAU OF SHIPPING 美国船级社 AMBT ambient temperature 冻柜的环境温度ADDCOM ADDRESS COMMISSION 回扣佣金 AFSP ARRIVAL FIRST SEA PILOT 首次海上引水抵达时间 AGS Aden Gulf Surcharge 亚丁湾附加费(防海盗费)也有称ERS Emergency Risk Surcharge,直译为亚丁湾紧急风险附加费,中海CSCL写成ARS。 AGM Asia gypsy moth(INSPECTION) 无亚洲型舞毒蛾检验AGW ALL GOES WELL 一切顺利 AHL AUSTRALIAN HOLD LADDER 澳梯

船舶英语及船型简称和缩写

船舶英语 船舶英语和基本词汇 改编加整合 目录 一、造船部分------------------------------------------------------------------3 1、船体部分--------------------------------------------------------------------3 2、机舱部分-------------------------------------------------------------------9 3、电气部分-------------------------------------------------------------------13 4、船装部分-------------------------------------------------------------------23 二、造机部分-----------------------------------------------------------------29 三、修造部分-----------------------------------------------------------------31

一、造船部分 1、HULL PART 船体部分 1、1结构S t r u c t u r e 12 船厂 d o c k y a r d/s h i p y a r d船坞 d o c k/b o a t y a r d 船东 s h i p-o w n e r船舷 S h i p's s i d e 船码头 q u a y/d o c k船的栏杆 S h i p's r a i l 船舱 h o l d甲板 D e c k 船籍 S h i p's r e g i s t r y住舱甲板 a c c o m m o d a t i o n d e c k 船首 b o w梁拱甲板 a r c h d e c k 船梯 l a d d e r载货甲板 c a r g o d e c k 船尾 s t e r n首楼甲板 F o r e c a s t l e d e c k 上甲板 U p p e r d e c k 下甲板 L o w e r d e c k 主甲板 M a i n d e c k 货舱甲板 H o l d d e c k 桥楼甲板 B r i d g e d e c k 水密甲板 W a t e r t i g h t d e c k 34 驾驶甲板 N a v i g a t i o n d e c k铜-钢复合板 C o p p e r s h e a t h i n g s t e e l p l a t e 艇甲板 B o a t d e c k甲板边板 D e c k s t r i n g e r p l a t e 罗经甲板 C o m p a s s d e c k斜板 S l o p i n g p l a t e 板 P l a t e加强板 R e i n f o r c e m e n t p l a t e 舭板 B i l g e p l a t e舵板 R u d d e r p l a t e 船底板 B o t t o m p l a t e舷侧外板 S i d e p l a t e 船外板 S h e l l p l a t e裙板 S k i r t p l a t e 船首外板 B o w p l a t e首柱板 S t e m p l a t e 肘板 B r a c k e t p l a t e首柱板 S t e r n p l a t e 舱壁板 B u l k h e a d p l a t e平台 p l a t f o r m 槽形舱壁板 C o r r u g a t e d b u l k h e a d p l a t e机舱平台 E n g i n e-r o o m p l a t f o r m 舷墙板 B u l w a r k p l a t e分段 B l o c k 围板 C o a m i n g p l a t e首段 B o w b l o c k 连续板 C o n n e c t i o n p l a t e中段 M i d s h i p b l o c k

船舶(制造)常用英语(缩写)

HULL(船体) ABS (American Bureau of Standard)美国船级社 ANG (Angle Bar)角钢 BFE (Builder Furnish Equipment)建造商提供设备 BG (Bulk Carrier)散货船 BHD (Bulkhead)舱壁 BHP (Break Horsepower)制动马力 BL (Base Line)基线 BM (Breadth Molded)型宽 BV (Bureau Veritas)法国船级社 CAD (Computer Aided Design)计算机辅助设计 CAM (Computer Aided Manufacturing)计算机辅助制造CB (Center of Buoyancy)浮心 CCS (China Classification Society)中国船级社 CF (Center of Floatation)漂心 CFE (Contractor Furnish Equipment)承包商提供设备CG (Center of Gravity)重心 CH (Channel)槽钢爱我船舶网 CM (Metacenter)稳心 CPP (The Controllable Pitch Propeller)可调螺距桨 CS (Carbon Steel)碳素钢

DB (Double Bottom)双层底 DK (Deck)甲板 DM (Depth Molded)型深 DNV (Det Norske Veritas)挪威船级社 DWG (Drawing)图 DWL (Design Waterline)设计水线 DWT (Deadweight)载重量 FAT (Factory Acceptance Test)工厂验收试验 FB (Flat Bar)扁钢 FEM (Finite Element Method)有限元法 FPSO (Floating Production Storage Offloading)浮(船)式生产储油卸油系统FSO (Floating Storage Offloading)浮(船)式储油卸油系统 Fwd (Forward)向船艏 GL (Germanischer Lloyd)德国船级社 GM (Metacentric Height)初稳心高 HP (Half Bulb Plate)球扁钢 LBP (Length between Perpendiculars)垂线间长 LCG (Longitudinal Center of Gravity)纵向重心 LNG (Liquefied Natural Gas Vessel)液化石油气船 LOA (Overall Length)总长 Long. (Longitudinal)纵骨

船舶常用英文缩写大全

1 A/B Above Base Line 基准线以上 2 A/C Anticorrosive Paint 防腐涂料 3 A/F Antifouling Paint 防污漆 4 ABS American Bureau of Shipping 美国船级社 5 Abt Abt (About ) 大约,关于 6 ACCOM. Accommodation 船室,居住区 7 Accommodation Ladder 舷梯 8 ACCU Automatic control system certified for unattended eng. Room 无人机舱自动控制系统鉴定 9 AFRAMAX Average Freight Rate Assessment at the max. of Deadweight 最大负载时平均运费率评估 10 Bhd After Peak Bulkhead 船尖舱舱壁 11 ANSI American National Standards Institute 美国国家标准协会 12 AP After Perpendicular 艉垂线 13 API American Petroleum Institute 美国石油组织 14 APT After Peak Tank 尾尖舱 15 ARPA Automatic Rader Plotting Aids 自动雷达测图仪 16 ASTM American Society of Testing Materials 美国材料实验协会 17 B mld Moulded Breadth 型宽 18 B/C Bulk Carrier 散货船 19 Base line 基线

船体英语缩写

ABS (American Bureau of Standard)美国船级社 ANG (Angle Bar)角钢 BFE (Builder Furnish Equipment)建造商提供设备 BG (Bulk Carrier)散货船 BHD (Bulkhead)舱壁 BHP (Break Horsepower)制动马力| BL (Base Line)基线 BM (Breadth Molded)型宽 BV (Bureau Veritas)法国船级社 CAD (Computer Aided Design)计算机辅助设计 CAM (Computer Aided Manufacturing)计算机辅助制造 CB (Center of Buoyancy)浮心 CCS (China Classification Society)中国船级社 CF (Center of Floatation)漂心 CFE (Contractor Furnish Equipment)承包商提供设备 CG (Center of Gravity)重心 CH (Channel)槽钢 CM (Metacenter)稳心 CPP (The Controllable Pitch Propeller)可调螺距桨 CS (Carbon Steel)碳素钢 DB (Double Bottom)双层底 DK (Deck)甲板 DM (Depth Molded)型深 DNV (Det Norske Veritas)挪威船级社 DWG (Drawing)图 DWL (Design Waterline)设计水线 DWT (Deadweight)载重量 FAT (Factory Acceptance Test)工厂验收试验 FB (Flat Bar)扁钢 FEM (Finite Element Method)有限元法 FPSO (Floating Production Storage Offloading) 浮(船)式生产储油卸油系统浮Fwd (Forward)向船艏 GL (Germanischer Lloyd)德国船级社 GM (Metacentric Height)初稳心高 HP (Half Bulb Plate)球扁钢 LBP (Length between Perpendiculars)垂线间长 LCG (Longitudinal Center of Gravity)纵向重心 LNG (Liquefied Natural Gas Vessel) 液化石油气船 LOA (Overall Length)总长爱 Long. (Longitudinal)纵骨 LPG (Liquefied Petroleum Gas Vessel) 液化天然气船 LR (Lloyd's Register)英国劳氏船级社 MDK (Main Deck)主甲板 MODU (Mobile Offshore Drilling Units)移动式近海钻井平台

所有船舶通用的英文缩写

第一部分 1 A/B Above Base Line 基准线以上 2 A/C Anticorrosive Paint 防腐涂料 3 A/F Antifouling Paint 防污漆 4 ABS American Bureau of Shipping 美国船级社 5 Abt Abt (About ) 大约,关于 6 ACCOM. Accommodation 船室,居住区 7 ACCM.L Accommodation Ladder 舷梯 8 ACCU Automatic control system certified for unattended eng. Room 无人机舱自动控制系统鉴定 9 AFRAMAX Average Freight Rate Assessment at the max. of Deadweight C.O.T 最大负载时平均运费率评估 10 A.P Bhd After Peak Bulkhead 船尖舱舱壁 11 ANSI American National Standards Institute 美国国家标准协会 12 AP After Perpendicular 艉垂线 13 API American Petroleum Institute 美国石油组织 14 APT After Peak Tank 尾尖舱 15 ARPA Automatic Rader Plotting Aids 自动雷达测图仪 16 ASTM American Society of Testing Materials 美国材料实验协会 17 B mld Moulded Breadth 型宽 18 B/C Bulk Carrier 散货船 19 B.L Base line 基线 20 Basic Design 基本设计 21 Ballast Control Room 压载控制室 22 BHP Brake Horse Power 制动马力 23 BOG Boil-off Gas 蒸发气体 24 BOM Bill of Material 材料清单 25 Bkt Bracket 支架,肘板 26 BHD Bulkhead 隔壁, 防水壁 27 C/H Cargo Hold 货舱 28 C.T Cable Trunk 电缆管道 29 CCI Class Comment Item 船级社说明项目

所有船舶常用的英文缩写

所有船舶常用的英文缩 写 Company Document number:WTUT-WT88Y-W8BBGB-BWYTT-19998

第一部分 1 A/B Above Base Line 基准线以上 2 A/C Anticorrosive Paint 防腐涂料 3 A/F Antifouling Paint 防污漆 4 ABS American Bureau of Shipping 美国船级社 5 Abt Abt (About ) 大约,关于 6 ACCOM. Accommodation 船室,居住区 7 Accommodation Ladder 舷梯 8 ACCU Automatic control system certified for unattended eng. Room 无人机舱自动控制系统鉴定 9 AFRAMAX Average Freight Rate Assessment at the max. of Deadweight 最大负载时平均运费率评估 10 Bhd After Peak Bulkhead 船尖舱舱壁 11 ANSI American National Standards Institute 美国国家标准协会 12 AP After Perpendicular 艉垂线 13 API American Petroleum Institute 美国石油组织 14 APT After Peak Tank 尾尖舱 15 ARPA Automatic Rader Plotting Aids 自动雷达测图仪 16 ASTM American Society of Testing Materials 美国材料实验协会 17 B mld Moulded Breadth 型宽 18 B/C Bulk Carrier 散货船 19 Base line 基线 20 Basic Design 基本设计 21 Ballast Control Room 压载控制室 22 BHP Brake Horse Power 制动马力 23 BOG Boil-off Gas 蒸发气体 24 BOM Bill of Material 材料清单 25 Bkt Bracket 支架,肘板 26 BHD Bulkhead 隔壁, 防水壁 27 C/H Cargo Hold 货舱 28 Cable Trunk 电缆管道 29 CCI Class Comment Item 船级社说明项目 30 CCR Cargo Control ? 31C, C/L Center Line 中心线 32 Center of Gravity 重心 33Cert. Certificate 证书 34CFR Code of Federal Regulations 联合代码 35CGT Compensated Gross Tonnage 补偿总吨 36 Chain Locker 锚链舱 37C/Eng. Chief Engineer 轮机长 38C/D Cofferdam 隔离舱,围堰

常用航海英语缩写

ABTabout大约 ABVabove以上 ACCTaccount由…承担,租船人,租家ADVadvise通知 ADDaddress地址 AFMTafterfixmainterms主要条款定下之后AGTagent代理 ARBIarbitration仲裁BBBbeforebreakingbulk开舱卸货前 B.DAYSbankingdays银行工作日 BENDS.BEbothends指装卸两头(港) BGDbagged袋装的 BLKbulk散装(货) BS/Lbillsoflading提单 BSS1/1bases以-个装港一个卸港为基准BWADbrackishwaterarrivaldraft船到卸港的吃水CHOPTcharterers'option租家选择CHRTScharterers租船人,租家COcharterersoption租家选择COMMcommission佣金 COUNTER还盘 CPcharterparty租约

C.Q.Dcustomaryquickdispatch按港口习惯速度尽快装卸CVSconsecutivevoyage DFDdemurrage/ dispatch 滞期/速遣DHDdemurragefreedespatch DOPdroppingoutwardpilot DRRKderrick吊杆 DwATdeadweightalltold DwCCdeadweightcargocapacity EIUevenifused即使使用 ETAexpectedtimeofarrival预抵时间ETDexpectedtimeofdeparture预离时间FHINCFridaysandholidaysincluded FIOfreein&freeout船东不负责装/卸费 FIOSTfreein,out, stowed(理舱) trimmed(平舱) FILOfreein,linerout船东不负责装,但负责卸FLTfulllinerterm全班轮条款,即船东负责装/卸费FLwSfollows下列 FRTfreight运费 FWADfreshwaterarrivaldraft GENCON,GCN金康合同

船舶英文缩写

HULL(船体): ABS (American Bureau of Standard)美国船级社 ANG (Angle Bar)角钢 BFE (Builder Furnish Equipment)建造商提供设备 BG (Bulk Carrier)散货船 BHD (Bulkhead)舱壁 BHP (Break Horsepower)制动马力 BL (Base Line)基线 BM (Breadth Molded)型宽 BV (Bureau Veritas)法国船级社 CAD (Computer Aided Design)计算机辅助设计 CAM (Computer Aided Manufacturing)计算机辅助制造 CB (Center of Buoyancy)浮心 CCS (China Classification Society)中国船级社 CF (Center of Floatation)漂心 CFE (Contractor Furnish Equipment)承包商提供设备 CG (Center of Gravity)重心 CH (Channel)槽钢 CM (Metacenter)稳心 CPP (The Controllable Pitch Propeller)可调螺距桨 CS (Carbon Steel)碳素钢 DB (Double Bottom)双层底 DK (Deck)甲板 DM (Depth Molded)型深 DNV (Det Norske Veritas)挪威船级社 DWG (Drawing)图 DWL (Design Waterline)设计水线 DWT (Deadweight)载重量 FAT (Factory Acceptance Test)工厂验收试验 FB (Flat Bar)扁钢 FEM (Finite Element Method)有限元法 FPSO (Floating Production Storage Offloading) 浮(船)式生产储油卸油 系统 FSO (Floating Storage Offloading)浮(船)式储油卸油系统 Fwd (Forward)向船艏 GL (Germanischer Lloyd)德国船级社 GM (Metacentric Height)初稳心高 HP (Half Bulb Plate)球扁钢 LBP (Length between Perpendiculars)垂线间长 LCG (Longitudinal Center of Gravity)纵向重心 LNG (Liquefied Natural Gas Vessel) 液化石油气船 LOA (Overall Length)总长 Long. (Longitudinal)纵骨

船舶常用的英文缩写

第一部分 1A/B Above Base Line基准线以上2A/C Anticorrosive Paint防腐涂料3A/F Antifouling Paint防污漆4ABS American Bureau of Shipping美国船级社 5Abt Abt(About)大约,关于6ACCOM.Accommodation船室,居住区7ACCM.L Accommodation Ladder舷梯8ACCU Automatic control system certified for unattended eng.Room无人机舱自动控制系统鉴定9AFRAMAX Average Freight Rate Assessment at the max.of Deadweight C.O.T最大负载时平均运费率评估10 A.P Bhd After Peak Bulkhead船尖舱舱壁11ANSI American National Standards Institute美国国家标准协会12AP After Perpendicular艉垂线 13API American Petroleum Institute美国石油组织14APT After Peak Tank尾尖舱15ARPA Automatic Rader Plotting Aids自动雷达测图仪16ASTM American Society of Testing Materials美国材料实验协会17B mld Moulded Breadth型宽18B/C Bulk Carrier散货船19 B.L Base line基线20Basic Design基本设计21Ballast Control Room压载控制室22BHP Brake Horse Power制动马力23BOG Boil-off Gas蒸发气体24BOM Bill of Material材料清单25Bkt Bracket支架,肘板26BHD Bulkhead隔壁,防水壁27C/H Cargo Hold货舱28 C.T Cable Trunk电缆管道29CCI Class Comment Item船级社说明项目30CCR Cargo Control 31C,C/L Center Line中心线32 C.G Center of Gravity重心33Cert.Certificate证书

各种船型英文缩写(一)

各种船型英文缩写(一) Bulk Carrier (散货船) - Handysize (灵便型) :2~5万吨左右,大灵便型:大于4万吨 - Panamax(巴拿马型): 6~7.5万吨,船的总长小于或等于274.32M,型宽小于或等于32.30M;目前平均载重吨达到8.2万吨 - Kmsarmax(卡尔萨姆型):8~8.9999万吨 - Capesize(好望角型):15万吨左右 Container(集装箱) (货舱区分:中央部位货舱——集装箱船;其他舱位——普通杂货船 可变换区分:货舱内结构可拆装——集装箱船;不可拆装——普通杂货船) Oil Tanker(油轮) - ULCC(巨型原油轮):大于30万吨 - VLCC(超大原油轮):20~30万吨 - Suezmax(苏伊士型):12~16万吨 - Aframax(阿芙拉型):8~12万吨 - Panamax(巴拿马型):6~8万吨 BC:Bulk Carrier 散货船 COT:Cargo Oil Tanker 货油轮 DFF:高速渡轮 ERRV:救援船 FLNG:浮式液化天然气船(科代替岸上传统的液化天然气工厂) FPSO:浮式生产储油船 FPV:浮式生产设备 G-Cargo Ship:杂货船 LNG:液化天然气船 LEG:液化乙烯汽船 LPG:全压式液化石油汽船

LSV:驳运支援船 LR成品油轮:stands for large range,远程成品油轮MR成品油轮:stands for medium range,中程成品油轮OSV:Offshore Support Vessel,海洋工程船 PSV:平台供应船 PC:重型石油化学制品运输船 PCC:Pure Car Carrier 汽车运输船 PCTC:Pure Car & Truck Carrier 大型轿车卡车专用船RO-RO SHIP:客滚船 Roll-on/Roll-off ship:滚装船 UCLL: Ultra Large Crude Carrier: 超大型原油轮VLOC:大型矿砂船 VLCC:巨型原油轮

船舶英语缩写

OHSAS18000标准-OHSAS18000全名为Occupational Health and Safety Assessment Series 18000 W.B.T 压载水舱 MDO 柴油 C.O.P 货油泵 F.W.G 制淡装置 F.O 燃油 CRIC. 循环 CYL 气缸 thruster推力器,助推器 H.F.O重油(燃料油) C.F.W pump 循环淡水泵 L.O 滑油 N.C.O 喷油器 HYD. 压力 O.D.M SAMPLING PUMP 排油监控取样泵 G/B S/B L.O PUMP 齿轮箱滑油备用泵 TRANS 输送 G/S 总用 PURI. 净化器,分油机 SERV. 日用 Sulphur 硫 ER 机舱 fire damper 防火档板 UV sterilizer紫外线消毒器 tally office 理货员办公室 Preheater预热器 Bow 艏 推力装置thruster evaporator蒸发器 booster 增压器 FW HYDROPHOR Pp 淡水输送泵 fairlead 导缆孔

order number 序号 cargo 货物 execution 实行; 履行; 执行; 完成 vibration stress 振动应力 ambient 周围的 deviation [de?vi?a?tion ] 背离 inclination angle倾角 dynamic [dy?nam?ic || da?'n?m?k] adj. 动力的; 动态的; 动力学的 static [stat?ic || 'st?t?k]adj. 静的; 静力的; 静态的; 静止的 appliance [ap?pli?ance || ?'pla??ns]n. 器具, 用具; 应用, 使用; 设备, 装置; 救火车 athwartship 横切,横向 barometric pressure 大气压 Viscosity 粘质, 粘性 cSt 是centistokes的缩写,意思是厘斯 asphaltenes 沥青质 CCAI 碳芳香度指数 class notation 船级代号 mounting hole 安装孔;固定孔 identification plate标志板 installation lable 安装标签 bracket 支架 QMD青岛齐耀瓦锡兰菱重麟山船用柴油机有限公司 wiring diagram布线图 servo 伺服电动机; 伺服机构 Pcs 数量的缩写。 Sodium 钠 separator 分离器 axle journal 轴颈 1bar=0.1Mpa stop check valve 切断式止回阀 gate valve 闸阀 check valve止回阀 butterfly valve蝶阀

船舶简称

船舶简称 各种船型英文缩写(一) 按照字母首位顺序排列: Carrier (散货船) 其类型分类有: - Handysize (灵便型) :2~5万吨左右,大灵便型:大于4万吨 - Panamax(巴拿马型): 6~万吨,船的总长小于或等于,型宽小于或等于;目前平均载重吨达到万吨 - Kmsarmax(卡尔萨姆型):8~万吨 - Capesize(好望角型):15万吨左右 (集装箱) (货舱区分:中央部位货舱——集装箱船;其他舱位——普通杂货船 可变换区分:货舱内结构可拆装——集装箱船;不可拆装——普通杂货船) Tanker(油轮) 其类型分类有: - ULCC(巨型原油轮):大于30万吨 - VLCC(超大原油轮):20~30万吨 - Suezmax(苏伊士型):12~16万吨 - Aframax(阿芙拉型):8~12万吨 - Panamax(巴拿马型):6~8万吨 各种船型英文缩写(二) 按照字母首位顺序排列: B BC:Bulk Carrier 散货船 C COT:Cargo Oil Tanker 货油轮 D DFF: 高速渡轮 E ERRV: 救援船 F FLNG: 浮式液化天然气船(科代替岸上传统的液化天然气工厂) FPSO: 浮式生产储油船 FPV: 浮式生产设备

G G-Cargo Ship: 杂货船 L LNG: 液化天然气船 LEG: 液化乙烯汽船 LPG: 全压式液化石油汽船 LSV: 驳运支援船 LR成品油轮:stands for large range, 远程成品油轮 M MR成品油轮:stands for medium range, 中程成品油轮 O OSV:Offshore Support Vessel, 海洋工程船 P PSV: 平台供应船 PC: 重型石油化学制品运输船 PCC:Pure Car Carrier 汽车运输船 PCTC:Pure Car & Truck Carrier 大型轿车卡车专用船 R RO-RO SHIP: 客滚船 Roll-on/Roll-off ship: 滚装船 U UCLL: Ultra Large Crude Carrier: 超大型原油轮 V VLOC: 大型矿砂船 VLCC: 巨型原油轮 1、DWT DWT 是DEAD WEIGHT TONNAGE 的缩写,是表示“载重吨”。 计算方式为:该船舶的“最大排水量”(MDT) 减去“船舶自重”(LDT); 有人会误以为载重吨位就是该船能装多少货物的重量,其实 DWT “载重吨”与该船舶的实际载货量是有很大区别的,因为DWT 还包括该船舶所载油(燃油,润滑油)和水(饮用和生活用水),船员及物品等的重量。 比如说,一艏 DWT 为7000吨的散货船,大概的载货吨位只有6000-6500左右;如果是冷藏船或捕捞船等,则实际载货吨位要小的多。工程船舶和特种船舶则载货吨位小的几乎可以或略。

船舶英语缩写

List of abbreviations: APBS Accident prevention on board ships at sea and in port (second edition)interntional labour geneve(ILO) ARPA Automatic radar plotting Aid BCH Code for the construstion an epuipment of ship carrying dangerous chemical in Bulk(IMO) BPG International chamber of shipping bridge procedure guide CCP Clean petroleum products CDI Chemical distribution institute CEFIC European chemical industry council CFC Chioro/Fluoro compound CFR Code of federal regulations(USCG) CLC International convention on civil liability for oil pollution damage 1969/1984(certificate of insurance) COE Certificate of entry COF Certificate of fitness COLREGS International regulational for preventing collision at sea 1972 as amended(IMO) COSWP MCA Code of safe working practices CSR Continues synopsis record

所有船舶常用英文缩写

所有船舶常用英文缩写 第一部分 1 A/B Above Base Line 基准线以上2 A/C Anticorrosive Paint 防腐涂料 3 A/F Antifouling Paint 防污漆 4 SBA? Am er ican Burea u of S hi p pi ng美国船级社 5 Abt Abt (About ) 大约,关于 6区住居,室船 noitadomcA ? 、CA? 7

AC C M、 L Acmodati o n Ladder 舷梯 8 citamotuA UCCA?cont r ol s y st e m ce rtifi ed for un a ttend e d e ng、Room 无人机舱自动控制系统鉴定 9? AFR A M A_ Average Freight Rate Assessmentat the ma_、 of Deadweight C、O、T 最大负载时平均运费率评估 01hB P、A?d After Peak B ulkhea d 船尖舱舱壁 11 ANSI American National Standards Instit ute 美国国家标准协会 12 A P After Perpe ndicular 艉垂线 31emA

IPA?r ic a n P e trole u m I ns t i tute 美国石油组织 14 APT After Peak Tank 尾尖舱1?5 ARPA Automatic Rader Plotting Aids 自动雷达测图仪 61iremA MTSA?ca nSo c i e t y of Testing M a terials 美国材料实验协会 71型 htdaerBdedluoM dlm B?宽 81散 reirraC kluB C/B?货船19 B、L Base line 基线 20 B a s icDe s i gn 基本设计2 1

船舶常用英文缩写大全教学文案

船舶常用英文缩写大 全

1 A/B Above Base Line 基准线以上 2 A/C Anticorrosive Paint 防腐涂料 3 A/F Antifouling Paint 防污漆 4 ABS American Bureau of Shipping 美国船级社 5 Abt Abt (About ) 大约,关于 6 ACCOM. Accommodation 船室,居住区 7 ACCM.L Accommodation Ladder 舷梯 8 ACCU Automatic control system certified for unattended eng. Room 无人机舱自动控制系统鉴定 9 AFRAMAX Average Freight Rate Assessment at the max. of Deadweight C.O.T 最大负载时平均运费率评估 10 A.P Bhd After Peak Bulkhead 船尖舱舱壁 11 ANSI American National Standards Institute 美国国家标准协会 12 AP After Perpendicular 艉垂线 13 API American Petroleum Institute 美国石油组织 14 APT After Peak Tank 尾尖舱 15 ARPA Automatic Rader Plotting Aids 自动雷达测图仪 16 ASTM American Society of Testing Materials 美国材料实验协会 17 B mld Moulded Breadth 型宽 18 B/C Bulk Carrier 散货船 19 B.L Base line 基线 20 Basic Design 基本设计 21 Ballast Control Room 压载控制室 22 BHP Brake Horse Power 制动马力 23 BOG Boil-off Gas 蒸发气体 24 BOM Bill of Material 材料清单 25 Bkt Bracket 支架,肘板 26 BHD Bulkhead 隔壁, 防水壁 27 C/H Cargo Hold 货舱 28 C.T Cable Trunk 电缆管道 29 CCI Class Comment Item 船级社说明项目 30 CCR Cargo Control 31 C, C/L Center Line 中心线 32 C.G Center of Gravity 重心 33 Cert. Certificate 证书 34 CFR Code of Federal Regulations 联合代码 35 CGT Compensated Gross Tonnage 补偿总吨 36 C.L Chain Locker 锚链舱 37 C/Eng. Chief Engineer 轮机长 38 C/D Cofferdam 隔离舱,围堰 39 COLREG International Regulations for Preventing Collisions at Sea 国际海上避碰规则 40 Corr. Bhd Corrugated Bulkhead 波形舱壁 41 COT Crude Oil Tanker 原油油船 42 COT Cargo Oil Tank 货油舱 43 CPU Central Processing Unit 中央处理器

船上英语常见缩写

船上英语常见缩写 Arr. Arrival 到达 a.a Always Afloat 保持(安全)漂浮 AA auto-alarm 自动报警 A.B able-bodied seaman 一级水手 A/B air bill 空运提单 ab about 大约 Ab abnormal 异常 abb. / abbr. abbreviation 缩写 AC Acdg according 根据/按照… ACDGLY accordingly 因此 acdnt accident 事故 ACG alternating current generator 交流发电机 ack acknowledge 承认/感谢 ack. Acknowledgment 接受 Acept accept 承兑 Act of God 天灾 Aw actual weight 实际重量 Ad average depth 平均深度 Adj adjacent/adjustable 邻近/可调整/可校准 Add additional 附加/额外 ADV advance 提前 Agt agent 代理人 AGW actual gross weight/all going well 实际重量/船已备妥ALRDY already 已经 ALRS Admiralty List of Radio Signal 英版无线电信号表Anwsd answered 回复 COC certificate of competency 船员适任证书 CG coast guard 海岸警备队 CG course made good 航迹向 CGH cape of Good Hope 好望角 CNF confirm 证实 C.O.D cash on delivery 货到付款 C/P Charter Party 租船合同 CSO company security officer 公司保安员 DOC document of compliance 符合证明 DS Docking Survey 坞内检验(两年一次) ECC error checking and correction 误差检验与校正 ECD estimated completion of date 预计完成日期 ECT estimated completion time 预计完成时间 E&OE errors and omissions excepted 遗误除外/错漏当差Est. estuary 河口/江海入海口