Surfactant-free hydrothermal synthesis of submicron BiFeO3 powders

Appl Phys A(2011)103:511–516

DOI10.1007/s00339-010-6024-2

Surfactant-free hydrothermal synthesis

of submicron BiFeO3powders

Jianhong Peng·Mirabbos Hojamberdiev·

Baowei Cao·Juan Wang·Yunhua Xu

Received:1April2010/Accepted:16August2010/Published online:10September2010?Springer-Verlag2010

Abstract Submicron BiFeO3powders were successfully

synthesized via a simple hydrothermal process with the as-

sistance of mineralizer(NaOH)at150–190°C,using FeCl3

and Bi(NO3)3·5H2O as reactants.The effects of mineral-izer concentration,reaction temperature and time on the

phase evolution and crystal morphology of the resulting

samples were investigated.X-ray diffraction(XRD),trans-

mission electron microscopy(TEM),thermogravimetry and

differential scanning calorimetry(TG-DSC),and vibrating

sample magnetometry(VSM)were used to characterize the

as-synthesized samples.The experimental results revealed

that a pure BiFeO3phase could be formed at a tempera-

ture ranging from170to190°C for4–20h in the pres-

ence of0.03–0.12M NaOH.It was found that the miner-

alizer concentration,reaction temperature and time played

a key role in controlling the growing speed of nuclei and

formation of BiFeO3crystallites.The possible formation

mechanisms of submicron BiFeO3powders with different

morphologies were presented.The magnetization of BiFeO3

powders showed a weak ferromagnetic behavior at room

temperature.

1Introduction

Recently,multiferroic materials exhibiting simultaneous

magnetic and ferroelectric order have been receiving inten-

sive scienti?c attention[1,2].Because of the spontaneous

J.Peng( )·M.Hojamberdiev·B.Cao·J.Wang·Y.Xu

Shaanxi Key Laboratory of Nano-materials and Technology,

Xi’an University of Architecture and Technology,Xi’an710055,

PR China

e-mail:pjhhj@https://www.360docs.net/doc/5013658841.html,

Fax:+86-29-82202886electric polarization(magnetization),which can be switched

by an applied electric?eld(magnetic?eld),and intrinsic

coupling of ferroelectric and magnetic ordering,multifer-

roic materials have a wide range of applications,including

data storage,transducer,actuator,non-volatile memory[3],

and gate ferroelectrics in?eld-effect transistors[4].So far,

considerable efforts have been made in?nding new multi-

ferroic materials and investigating the multiferroic property

in known oxides,such as BiMnO3[5],BiFeO3[6],BiScO3

[7],BiCoO3[8],and rare earth manganates[9–12].

BiFeO3(BFO)is one of the most important multifer-

roic materials,which exhibits simultaneously ferroelectric

(T c~1103K)and antiferromagnetic ordering(T n~643K) [13].Owing to its magnetoelectric coupling,BFO-based

systems could be used to develop novel applications in the

?eld of radio,television,microwave and satellite commu-

nication,bubble memory devices,audio-video and digital

recording[14–16].Up to date,various kinds of fabrica-

tion methods have been applied in order to obtain a pure

phase BFO with enhanced properties,such as solid-state

[17],sonochemical and microemulsion[18],sol-gel[19],

solution-combustion[20,21],the soft chemical route[22],

co-precipitation[23]and hydrothermal[24].Among them,

the hydrothermal method has been widely used to fabri-

cate?ne powders with narrow particle size and controlled

stoichiometry.Some researchers have applied mineralizer-

[25],polymer-[26],and surfactant-assisted[27]hydrother-

mal and mechanochemical[28]methods in order to obtain

nano-scaled BFO possessing unique physical properties due

to potential quantum con?nement effect and low dimension-

ality.

It is of interest to investigate the phase evolution and

crystal morphology of the BFO powders under hydrother-

mal process as a function of mineralizer(NaOH)concen-

tration,reaction temperature and time.In the present report,

512J.Peng et al.

we describe the effects of mineralizer(NaOH)concentra-

tion,reaction temperature and time on the formation of BFO

crystallites with different morphologies.

2Experimental

All the reagents in the present work were analytical grade

and used without further puri?cation.In a typical synthesis

procedure,20mmol Bi(NO3)3·5H2O and20mmol FeCl3 were dissolved in5mL ethylene glycol.Aqueous ammo-

nia was added dropwise to the solution to adjust pH to9–10

and an orange-yellow-colored precipitate was eventually ob-

tained.The precipitate was repeatedly washed with distilled

water and then a30mL precursor containing NaOH solution

was transferred into a Te?on-lined stainless steel autoclave

with a?lling capacity of75%.The autoclave was sealed and

maintained at140–200?C for4–20h.After hydrothermal

treatment,the autoclave was cooled down to room tempera-

ture.The products were collected,washed several times with

distilled water and dried at80?C for4h in an oven.

The phase composition of the as-prepared powders was

characterized by X-ray powder diffraction(XRD;Model

D/MAX2550,Rigaku Co.,Japan)with Cu Kαradiation

(λ=1.5406?)at40kV and50mA.Transmission elec-

tron microscopy(TEM),high-resolution transmission elec-

tron microscopy(HRTEM),and selected area electron dif-

fraction pattern(SAED)observations were performed on a

JEM-2100electron microscope(JEOL,Japan)with an ac-

celerating voltage of200kV.Thermogravimetry and dif-

ferential scanning calorimetry(TG-DSC)analysis was con-

ducted on a Q600SDT(TA Co.Ltd.,USA)at a temperature

range of400–1200?C in nitrogen ambient at a scan rate of

10?C/min.Magnetic properties of BFO powders were mea-

sured using a vibrating sample magnetometer(VSM,7303,

Lake Shore,USA)at room temperature with a maximum

magnetic?eld of10KOe.

3Results and discussion

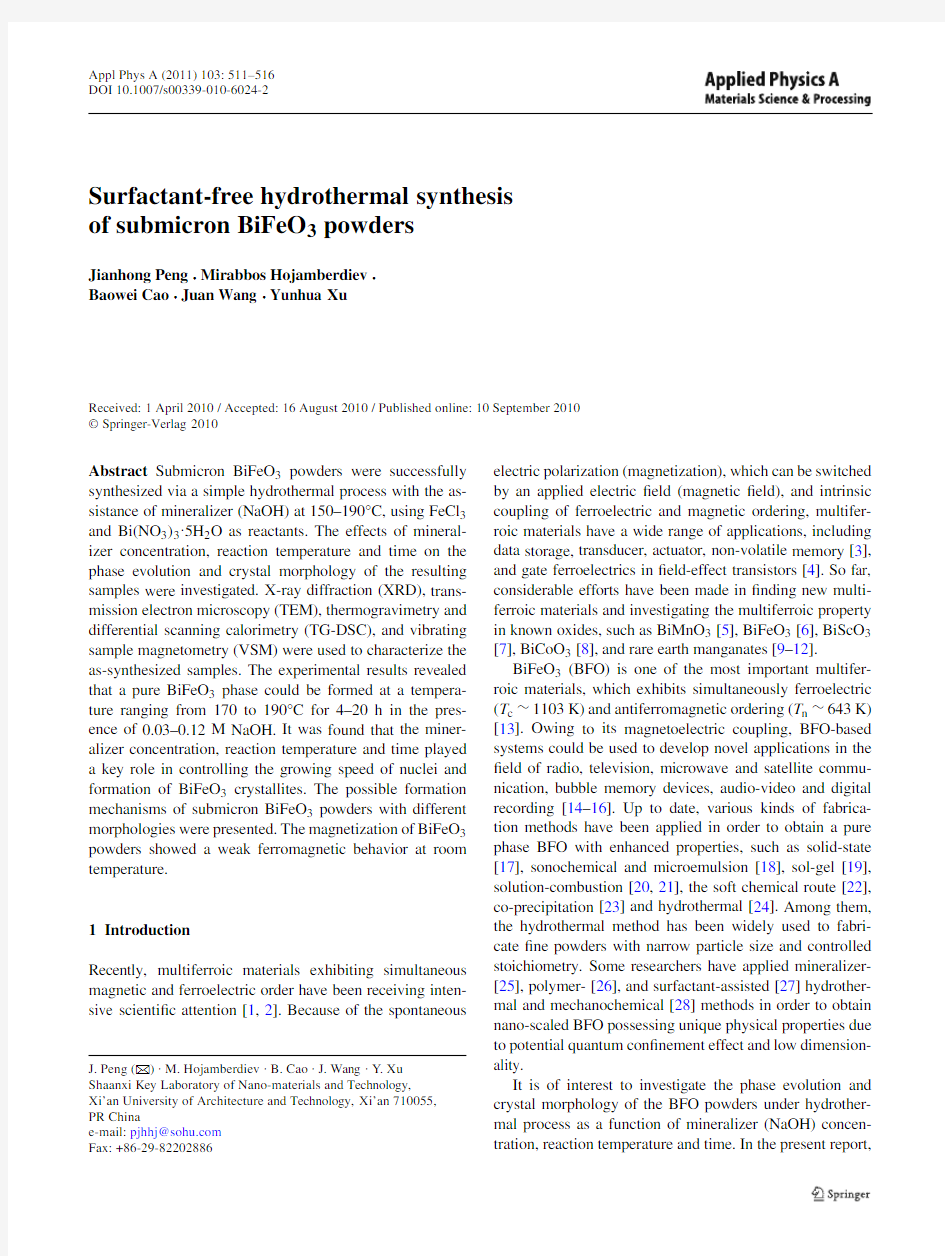

Figure1shows the XRD patterns of the BFO powders pre-

pared at170?C for16h using different NaOH concen-

trations under hydrothermal process.As can be seen,the

phase evolution of BFO crystallites was greatly affected

by NaOH concentration.That is,a NaOH concentration

of≤0.03and≥0.12M resulted the formation of impu-

rity phases,Bi2Fe4O9and Bi25FeO40.Only within0.03M

and0.12M NaOH concentrations the single-phase BFO

crystallites were obtained.All the diffraction peaks in the

XRD pattern,shown in Fig.1c,of BFO powders synthe-

sized at170?C for16h using NaOH concentration of0.07M

can be indexed to a pure hexagonal phase of BFO with

a Fig.1XRD patterns of the BFO powders synthesized at170?C for 16h using different NaOH concentrations:0.01M(a),0.03M(b), 0.07M(c),0.10M(d),0.12M(e),0.15M(f),and0.20M(g) space group of R3c.The calculated lattice parameters are a=b=0.5587nm and c=1.3880nm,which are con-sistent with the previous reported data for a bulk BiFeO3 (JCPDS card no.86-1518).The in?uences of the hydrother-mal reaction temperature ranging from140to200?C and time in the range of4–20h were also investigated in the presence of0.07M NaOH in the synthesizing system.As summarized in Table1,the pure phase BFO powders could be obtained through a hydrothermal process at the different temperatures ranging from150to190?C.However,the BFO powders synthesized beyond this range were formed along with impurity phases of Bi2Fe4O9and Bi25FeO40.It can be concluded that the formation of the secondary phases was strongly favored by140?C and200?C,0.01M and0.20M NaOH,and reaction time of6h.

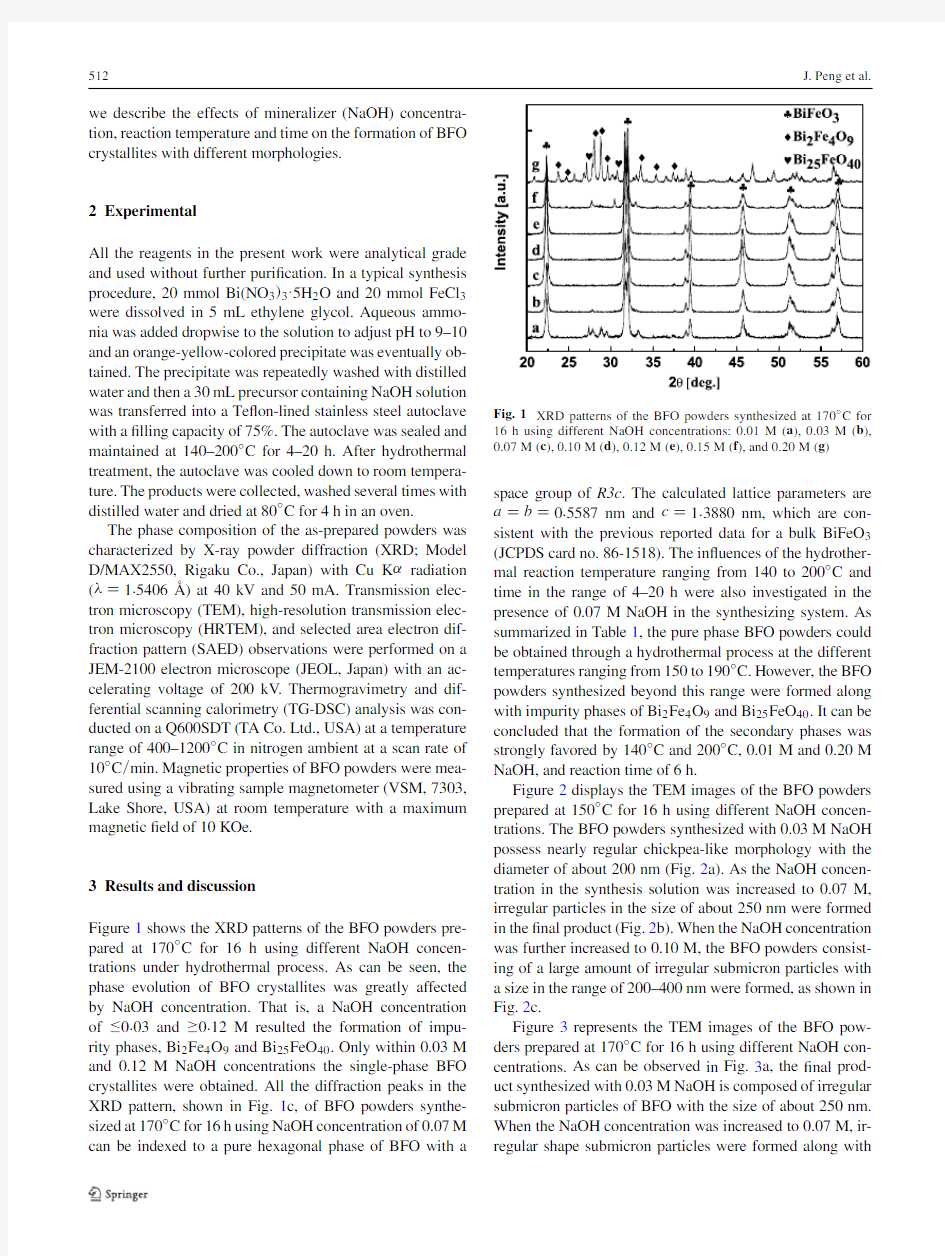

Figure2displays the TEM images of the BFO powders prepared at150?C for16h using different NaOH concen-trations.The BFO powders synthesized with0.03M NaOH possess nearly regular chickpea-like morphology with the diameter of about200nm(Fig.2a).As the NaOH concen-tration in the synthesis solution was increased to0.07M, irregular particles in the size of about250nm were formed in the?nal product(Fig.2b).When the NaOH concentration was further increased to0.10M,the BFO powders consist-ing of a large amount of irregular submicron particles with a size in the range of200–400nm were formed,as shown in Fig.2c.

Figure3represents the TEM images of the BFO pow-ders prepared at170?C for16h using different NaOH con-centrations.As can be observed in Fig.3a,the?nal prod-uct synthesized with0.03M NaOH is composed of irregular submicron particles of BFO with the size of about250nm. When the NaOH concentration was increased to0.07M,ir-regular shape submicron particles were formed along with

Surfactant-free hydrothermal synthesis of submicron BiFeO3powders513

Table1The in?uences of the processing parameters on the formation of BFO powders under hydrothermal process Concentration of Time,h Temperature,?C Formed crystal phase NaOH,M

0.0116170Bi2Fe4O9,BFO

0.0316170BFO

0.074170Bi2Fe4O9,BFO

0.076170BFO

0.0710170BFO

0.0716140Bi25FeO40,BFO

0.0716150BFO

0.0716170BFO

0.0716190BFO

0.0716200Bi2Fe4O9,BFO

0.0720170BFO

0.1016170BFO

0.1216170BFO

0.1516170Bi2Fe4O9,BFO

0.2016170Bi2Fe4O9,BFO,Bi25FeO40

Fig.2TEM images of the BFO powders synthesized at150?C for16h using different NaOH concentrations:0.03M(a),

0.07M(b),and0.10M(c

)

514J.Peng et al.

Fig.3TEM images of the BFO powders synthesized at170?C for16h using different NaOH concentrations:0.03M(a),

0.07M(b),0.10M(c);HRTEM image of the rod-like BFO particles(d)with a SAED pattern(inset

)

a few rod-like particles with the size of250nm in width and400nm in length(Fig.3b).As the NaOH concentration was further increased to0.10M,almost uniform rod-like submicron particles with the length of max.500nm were obtained,as shown in Fig.3c.Similar results were obtained by Hojamberdiev et al.[29]using0.05M LiOH.

Figure3d shows a representative HRTEM image at the end of a rod-like particle.The image reveals that the submi-cron particle is single crystalline with inter-planar spacing of about0.279nm,which corresponds to the(110)crystalline plane of the hexagonal phase BFO bulk crystal.The selected area electron diffraction(SAED)pattern taken from the rod-like particle,inserted as an inset in Fig.3d,con?rms that the observed BFO particle is single crystalline.It should be noted that with increasing hydrothermal reaction tempera-ture170?C,particles transformed to rod-like shape rather than irregular at lower temperature.

In general,the formation of inorganic crystallites un-der hydrothermal conditions is controlled either by situ for-mation or dissolution-recrystallization-crystal growth mech-anisms[30].It is well known that the amorphous phase with the same chemical composition as crystalline phase should normally have higher free energy.In order to in-crease the surface energy,the amorphous precursors were aggregated together.When the hydrothermal treatment was performed in a relative low alkali(i.e.,a large number of water molecules and a few[Na(H2O)n)]+cation)and low-temperature conditions,the amorphous precursors could not dissolve at all.Therefore,the main formation mechanism could be considered as an in situ transformation process,in which amorphous precursors crystallized into small parti-cles by removal of structure water.As the reaction tempera-ture and the alkali concentration(i.e.,a few water molecules and a large number of[Na(H2O)n)]+cation)increased, the dissolving rate of the amorphous precursors increased, which would accelerate the dissolution-recrystallization ki-netic processes.Once the solution is supersaturated,nucle-ation and crystallization take place in the solution,and?-nally self-organize into high-aspect ratio of submicron rods due to its high anisotropic crystal structure.Therefore,the formation of the submicron BFO rods synthesized at170?C for16h with0.10M NaOH could be considered as a result of dissolution and recrystallization mechanism.Be-cause BFO has a rhombohedrally distorted perovskite struc-

Surfactant-free hydrothermal synthesis of submicron BiFeO 3powders

515

Fig.4TG-DSC curves of the BFO powders synthesized at 170?C for 16h with 0.07M NaOH

ture with a high anisotropy,it can lead to an anisotropic growth of BFO particles under a suitable hydrothermal con-dition.

Figure 4shows the TG-DSC curves of the BFO powders synthesized at 170?C for 16h with 0.07M NaOH.The sig-ni?cant two endothermic effects were observed at 827.89?C and 964.07?C.The TG curve shows no obvious change at the temperature between 600?C to 900?C.These endother-mic effects agree very well with the phase transitions indi-cated by the phase diagram,reported by Koizumi et al.[31].The endothermic effects at about 827.89?C and 964.07?C are attributed to the ferroelectric to paraelectric phase trans-formation and the melting temperature of BFO phases,re-spectively.

It was considered that the size effect of BFO structures might be responsible for the magnetic ordering by compar-ing the magnetic property of BFO ?lms with that of BFO nanowires [32].The magnetization of the BFO powders with an applied ?eld at room temperature was also investigated.As shown in Fig.5,a weak ferromagnetism (0.3emu /g)is observed for the submicron BFO powders at room tempera-ture,which is different from the linear M–H behavior in bulk BFO [33].It may be that the cycloid structure in bulk BFO is partially destroyed in the BFO nanostructures,which leads to the weak ferromagnetism behavior at room temperature.

4Conclusions

In summary,single-phase submicron BiFeO 3powders have been successfully synthesized by hydrothermal synthesis at the temperature of 150–190?C with NaOH concentration of 0.03–0.12M.X-ray diffraction indicates that bismuth fer-rite is hexagonal phase in structure with lattice constant a =b =0.5587nm,c =1.3880nm.The NaOH concen-tration,reaction temperature and time had a great effect

on

Fig.5M–H curve measured at room temperature for the BFO pow-ders synthesized at 170?C for 16h with 0.07M NaOH

the phase composition and morphology of the resultant pow-ders.In addition,weak ferromagnetism of the BFO powders was observed at room temperature due possibly to the small particle size,which was different from the magnetic prop-erty of bulk BFO.

Acknowledgements The authors are thankful to Science Foundation of Shaanxi Provincial Education Department for the ?nancial support (No.08JZ38).

References

1.N.A.Hill,J.Phys.Chem.B 104,6694–6709(2000)

2.J.Wang,J.B.Neaton,H.Zheng,V .Nagarajan,S.B.Ogale,B.Liu,D.Viehland,V .Vaithyanathan,D.G.Schlom,U.V .Waghmare,N.A.Spaldin,K.M.Rabe,M.Wuttig,R.Rames,Science 299,1719–1722(2003)

3.N.Fujimura,T.Ishida,T.Yoshimura,T.Ito,Appl.Phys.Lett.69,1011–1013(1996)

4. D.Ito,N.Fujimura,T.Yoshimura,T.Ito,J.Appl.Phys.93,5563–5567(2003)

5. E.Montanari,G.Calestani,A.Migliori,M.Dapiaggi,F.Bolzoni,R.Cabassi,E.Gilioli,Chem.Mater.17,6457–6467(2005)

6.Y .Wang,Q.-H.Jiang,H.-C.He,C.-W.Nan,Appl.Phys.Lett.88,142503(2006)

7. A.A.Belik,S.Iikubo,K.Kodama,N.Igawa,S.-I.Shamoto,M.Maie,T.Nagai,Y .Matsui,S.Yu.Stefanovich,https://www.360docs.net/doc/5013658841.html,zo-ryak,E.Takayama-Muromachi,J.Am.Chem.Soc.128,706–707(2006)

8. A.A.Belik,S.Iikubo,K.Kodama,N.Igawa,S.-I.Shamoto,S.Niitaka,M.Azuma,Y .Shimakawa,M.Takano,F.Izumi,E.Takayama-Muromachi,Chem.Mater.18,798–803(2006)9.J.-T.Han,Y .-H.Huang,W.Huang,J.B.Goodenough,J.Am.Chem.Soc.128,14454–14455(2006)

10. B.Lorenz,Y .Q.Wang,C.-W.Chu,Phys.Rev.B 76,104405

(2007)

11.G.Zhu,P.Liu,Y .Liu,H.Miazo,J.Zhou,J.Am.Ceram.Soc.91,

3423–3427(2008)

12. F.Ye,B.Lorenz,Q.Huang,Y .Q.Wang,Y .Y .Sun,C.W.Chu,

J.A.Fernandez-Baca,P.Dai,H.A.Mook,Phys.Rev.B 76,060402(2007)

516J.Peng et al.

13.I.Sosnowska,A.K.Zvezdin,J.Magn.Magn.Mater.140–144,

167–168(1995)

14. F.Kubel,H.Schmid,Acta Cryst.B46,698–702(1990)

15.V.R.Palkar,R.Pinto,Pramana J.Phys.58,1003–1008(2002)

16.Y.P.Wang,L.Zhou,M.F.Zhang,X.Y.Chen,J.-M.Liu,Z.G.Liu,

Appl.Phys.Lett.84,1731–1733(2004)

17.G.D.Achenbach,W.J.James,R.Gerson,J.Am.Ceram.Soc.50,

437(1967)

18.N.Das,R.Majumdar,A.Sen,H.S.Maiti,Mater.Lett.61,2100–

2104(2007)

19. F.Gao,X.Y.Chen,K.B.Yin,S.Dong,Z.F.Ren,F.Yuan,T.Yu,

Z.G.Zou,J.-M.Liu,Adv.Mater.19,2889–2892(2007)

20.S.Ghosh,S.Dasgupta,A.Sen,H.S.Maiti,Mater.Res.Bull.40,

2073–2079(2005)

21.V.Fruth,L.Mitoseriu, D.Berger, A.Ianculescu, C.Matei,

S.Preda,M.Zaharescu,Prog.Sol.State Chem.35,193–202 (2007)

22.S.Ghosh,S.Dasgupta,A.Sen,H.S.Maiti,J.Am.Ceram.Soc.88,

1349–1352(2005)

23.S.Shetty,V.R.Palkar,R.Pinto,Pramana J.Phys.58,1027–1030

(2002)24. C.Chen,J.Cheng,S.Yu,L.Che,Z.Meng,J.Cryst.Growth291,

135–139(2006)

25.Y.Wang,G.Xu,Z.Ren,X.Wei,W.Weng,P.Du,G.Shen,G.Han,

J.Am.Ceram.Soc.90,2615–2617(2007)

26.Y.Wang,G.Xu,Z.Ren,X.Wei,W.Weng,P.Du,G.Shen,G.Han,

Ceram.Int.34,1569–1571(2008)

27.L.Xiaomeng,X.Jimin,S.Yuanzhi,L.Jiamin,J.Mater.Sci.42,

6824–6827(2007)

28.I.Szafraniak,M.Po?omska, B.Hilczer, A.Pietraszko,

L.K?e pi′n ski,J.Eur.Ceram.Soc.27,4399–4402(2007)

29.M.Hojamberdiev,Y.Xu,F.Wang,J.Wang,W.Liu,M.Wang,

Ceram-Silikaty53,113–117(2009)

30.M.Hirano,E.Kato,J.Am.Ceram.Soc.82,786–788(1999)

31.H.Koizumi,N.Niizeki,T.Ikeda,Jpn.J.Appl.Phys.3,495–496

(1964)

32. F.Gao,Y.Yuan,K.F.Wang,X.Y.Chen,F.Chen,J.-M.Liu,

Z.F.Ren,Appl.Phys.Lett.89,102506(2006)

33.S.T.Zhang,M.H.Lu,D.Wu,Y.F.Chen,N.B.Ming,Appl.Phys.

Lett.87,262907(2005)

fluid inclusions

The application of fluid inclusions in the mineralization lijin The department of geochemistry,Yangtze university Abstract. Fluid inclusion analysis is an important tool in modern studies of mineral deposits, as reflected by the statistics indicating that about a quarter of the papers published in Economic Geology contain fluid inclusion studies. Fluid inclusions play an important role in the classification of mineral deposits and in the study of the composition, temperature and pressure of mineralizing fluids. Among the principal mechanisms of ore precipitation, flu-id phase separation and fluid mixing derive their key evidence mainly from studies of fluid inclusions. Data on mineralizing fluid composition obtained from fluid inclusion analysis are key to understanding how metals were transported in hydrothermal fluids. Recent progresses in metal transport in vapor have been mainly contributed by fluid inclusion studies. Data on fluid temperature and pressure from fluid inclusion studies provide important constraints on hydrodynamic models of mineralization. Most metal ore deposits are formed in the geological fluid.The formation and characteristics of hydrothermal ore deposits are closely related including temperature, pressure and composition. Although these information can be gained through the study of macro geological characteristics of ore deposit and the geochemical characteristics of the mineral , but the composition of ore-forming fluid, temperature, and pressure from fluid inclusion is the most direct evidence.Fluid inclusion is the only remain in ancient ore-forming fluid. So, the study of fluid inclusion becomes one of the important ways of genesis research naturally. For Economic Geology sampling survey, the proportion of fluid inclusion research papers, from 5% in 1975 to 15% in 1985, 27% in 1995, then remained at about 25%, about 1 in 4 papers of deposits essay involves the study of fluid inclusions. Although the fluid inclusion research has expanded to petroleum geology, magma, and the earth's interior processes, etc.its mian application in the field of ore deposit research . The application of fluid inclusions in ore deposit has a lot of monographs. but these works focus on basic principles , methods of the study and the characteristics of different deposit types.This paper mainly discusses the application of fluid inclusions in the study of ore deposits. Keywords: geochemistry, fluid inclusions, hydrothermal deposits, mineralizing fluids, ore precipitation, metal transportation. 1.Fluid inclusion is one of the basis of the classification of the ore deposit According to the geological characteristics and genesis, ore deposit can be divided into different types, But at present very few scholars classify the ore deposits completely according to the geological characteristics, such as shear zone gold deposits, stratabound lead-zinc deposit or causes such as high temperature

(H2N(C2H4)2NH2)[V4O10]ic951237c

Hydrothermal Syntheses and Structural Characterization of Layered Vanadium Oxides Incorporating Organic Cations:r-, -(H3N(CH2)2NH3)[V4O10]and r-, -(H2N(C2H4)2NH2)[V4O10] Yiping Zhang,?,?Robert C.Haushalter,*,?and Abraham Clearfield*,? NEC Research Institute,4Independence Way,Princeton,New Jersey08540,and Department of Chemistry,Texas A&M University,College Station,Texas77843 Recei V ed September26,1995X Four new layered mixed-valence vanadium oxides,which contain interlamellar organic cations,R-(H3N(CH2)2- NH3)[V4O10](1a), -(H3N(CH2)2NH3)[V4O10](1b),R-(H2N(C2H4)2NH2)[V4O10](2a),and -(H2N(C2H4)2NH2)- [V4O10](2b),have been prepared under hydrothermal conditions and their single-crystal structures determined: 1a,triclinic,space group P1h,a)6.602(2)?,b)7.638(2)?,c)5.984(2)?,R)109.55(3)°, )104.749- (2)°,γ)82.31(3)°,Z)1;1b,triclinic,P1h,a)6.387(1)?,b)7.456(2)?,c)6.244(2)?,R)99.89(2)°, )102.91(2)°,γ)78.74(2)°,Z)1;2a,triclinic,P1h,a)6.3958(5)?,b)8.182(1)?,c)6.3715(7)?,R )105.913(9)°, )104.030(8)°,γ)94.495(8)°,Z)1;2b,monoclinic,space group P21/n,a)9.360(2)?,b )6.425(3)?,c)10.391(2)?, )105.83(1)°,Z)2.All four of the compounds contain mixed-valence V5+/V4+vanadium oxide layers constructed from V5+O4tetrahedra and pairs of edge-sharing V4+O5square pyramids with protonated organic amines occupying the interlayer space. Introduction The contemporary interest in vanadium oxide bronzes reflects not only their interesting electronic and magnetic properties1 but also their complex structural chemistry,associated with the ability of vanadium to adopt a variety of coordination geometries in various oxidation states.In addition to the conventional alkali-metal bronzes A x V2O5,2a class of organic-based vanadium bronzes are also known.While most of the alkali-metal bronzes have been prepared at high temperatures,the organic-based vanadium bronzes are prepared at room temperature or slightly higher via intercalation reactions with vanadium pentoxide xerogels,V2O5?n H2O.The V2O5?n H2O host possesses a porous layered structure and is capable of intercalating a variety of neutral and charged guest species such as alkali-metal ions,3 alkylamines,4alcohols,5pyridine,6benzidine,7etc.The insertion of amines or metal complexes into V2O5hosts has also been reported.8The resulting intercalation compounds usually retain the lamellar structure with the guest species and water molecules occupying the interlayer regions.Partial reduction of V5+to V4+of the oxide layers has been observed to accompany the intercalation reactions with organic amines.In the cases of aniline9and thiophene,10the reduction of the vanadium oxide host,and the simultaneous oxidative polymerization of the guest molecules in the interlayer regions,have been observed.These intercalation compounds with reduced vanadium sites constitute an interesting class of organic-inorganic composite materials that can be viewed as molecular or polymer vanadium bronzes by analogy to alkali-metal bronzes.2However,the structural information about these intercalation compounds is very limited due to their amorphous or semicrystalline nature and lack of high-quality single crystals. Hydrothermal techniques,in combination with organic tem-plates,have been recently demonstrated to be well suited for the synthesis and crystal growth of reduced oxomolybdenum and oxovanadium phosphates and vanadium phosphonates.A series of novel organically templated molybdenum and vana-dium phosphates and vanadium phosphonates with molecular, two-dimensional layered,and three-dimensional open-frame-work structures have been prepared under hydrothermal condi-tions.11In contrast,hydrothermal synthesis of vanadium oxides using organic templates remains relatively unexplored.12While there are many examples of alkali-metal vanadium oxide bronzes with three-dimensional or two-dimensional structures in which the alkali metals occupy the channels or the interlayer regions, analogous organically templated vanadium oxides with3-D open *To whom all correspondence should be addressed. ?Texas A&M University. ?NEC Research Institute. X Abstract published in Ad V ance ACS Abstracts,August1,1996. (1)Murphy,D.W.;Christian,P.A.Science1979,205,651. (2)Hagenmuller,P.In Non-Stoichiometric Compounds,Tungsten Bronzes, Vanadium Bronzes and Related compounds;Bevan,D.J.,Hagen-muller,P.,Eds.;Pergamon Press:Oxford,U.K.,1973;Vol.1. (3)Lemordant,D.;Bouhaouss,A.;Aldebert,P.;Baffier,N.Mater.Res. Bull.1986,21,273. (4)Paul-Boucour,V.;Aldebert,P.Mater.Res.Bull.1983,18,1247. (5)Aldebert,P.;Baffier,N.;Legendre,J.-J.;Livage,J.Re V.Chim.Miner. 1982,19,485.Aldebert,P.;Baffier,N.;Gharbi,N.;Livage,J.Mater. Res.Bull.1981,16,949.Lemordant,D.;Bouhaouss,A.;Aldebert, P.;Baffier,N.J.Chim.Phys.Phys.-Chim.Biol.1986,83,105. (6)Ruiz-Hitzky,E.;Casal,B.J.Chem.Soc.,Faraday Trans.11986,82, 1597. (7)Hasbah,H.;Tinet,D.;Crespin,M.M.;Erre,R.;Setton,R.;Van Damme,H.J.Chem.Soc.,https://www.360docs.net/doc/5013658841.html,mun.1985,935. (8)Kanatzidis,M.;Marks,T.J.Inorg.Chem.1987,26,783and references therein. (9)Kanatzidis,M.;Wu,C.-G.J.Am.Chem.Soc.1989,111,4139. (10)Kanatzidis,M.;Wu,C.-G.;Marcy,H.O.;DeGroot,D.C.;Kannewurf, C.R.Chem.Mater.1990,2,222. (11)Haushalter,R.C.;Mundi,L.A.Chem.Mater.1992,4,31.Soghomo- nian,V.;Chen,Q.;Haushalter,R.C.;Zubieta,J.;O’Connor,C.J. Science1993,259,1596.Soghomonian,V.;Chen,Q.;Haushalter,R. C.;Zubieta,J.Angew.Chem.,Int.Ed.Engl.1993,32,610.Soghomo- nian,V.;Chen,Q.;Haushalter,R.C.;Zubieta,J.Chem.Mater.1993, 5,1690.Soghomonian,V.;Chen,Q.;Haushalter,R.C.;Zubieta,J., Chem.Mater.1993,5,1595.Soghomonian,V.;Haushalter,R.C.; Chen,Q.;Zubieta,J.Inorg.Chem.1994,33,1700.Zhang,Y.; Clearfield,A.;Haushalter,R.C.J.Solid State Chem.1995,117,157. Zhang,Y.;Clearfield,A.;Haushalter,R.C.Chem.Mater.1995,7, 1221. (12)Huan,G.-H.;Johnson,J.W.;Jacobson,A.J.;Merola,J.S.J.Solid State Chem.1991,91,385.Duan,C.-Y.;Tian,Y.-P.;Lu,Z.-L.;You, X.-Z.;Huang,X.-Y.Inorg.Chem.1995,34,1. 4950Inorg.Chem.1996,35,4950-4956 S0020-1669(95)01237-7CCC:$12.00?1996American Chemical Society

Geological and isotopic evidence for magmatic-hydrothermal

ARTICLE Geological and isotopic evidence for magmatic-hydrothermal origin of the Ag –Pb –Zn deposits in the Lengshuikeng District,east-central China Changming Wang &Da Zhang &Ganguo Wu & M.Santosh &Jing Zhang &Yigan Xu &Yaoyao Zhang Received:7August 2012/Accepted:27March 2014/Published online:8April 2014#Springer-Verlag Berlin Heidelberg 2014 Abstract The Lengshuikeng ore district in east-central China has an ore reserve of ~43Mt with an average grade of 204.53g/t Ag and 4.63%Pb+Zn.Based on contrasting geological characteristics,the mineralization in the Lengshuikeng ore district can be divided into porphyry-hosted and stratabound types.The porphyry-hosted minerali-zation is distributed in and around the Lengshuikeng granite porphyry and shows a distinct alteration zoning including minor chloritization and sericitization in the proximal zone;sericitization,silicification,and carbonatization in the periph-eral zone;and sericitization and carbonatization in the distal zone.The stratabound mineralization occurs in volcano-sedimentary rocks at ~100–400m depth without obvious zoning of alterations and ore minerals.Porphyry-hosted and stratabound mineralization are both characterized by early-stage pyrite –chalcopyrite –sphalerite,middle-stage acanthite –native silver –galena –sphalerite,and late-stage pyrite –quartz –calcite.The δ34S values of pyrite,sphalerite,and galena in the ores range from ?3.8to +6.9‰with an average of +2.0‰.The C –O isotope values of siderite,calcite,and dolomite range from ?7.2to ?1.5‰with an average of ?4.4‰(V-PDB)and from +10.9to +19.5‰with an average of +14.8‰ (V-SMOW),respectively.Hydrogen,oxygen,and carbon iso-topes indicate that the hydrothermal fluids were derived main-ly from meteoric water,with addition of minor amounts of magmatic water.Geochronology employing LA –ICP –MS analyses of zircons from a quartz syenite porphyry yielded a weighted mean 206Pb/238U age of 136.3±0.8Ma considered as the emplacement age of the porphyry.Rb –Sr dating of sphalerite from the main ore stage yielded an age of 126.9±7.1Ma,marking the time of mineralization.The Lengshuikeng mineralization classifies as an epithermal Ag –Pb –Zn deposit. Keywords Stable isotope .Geochemistry .Porphyry .Stratabound .Ag –Pb –Zn .Lengshuikeng Introduction The Lengshuikeng ore district,located in the Jiangxi Province of east-central China (Fig.1a ),contains more than 50ore bodies belonging to seven deposits hosted in granite porphyry,pyroclastic,and carbonate rocks.The ore reserves in Lengshuikeng have been estimated at ~43Mt with average grades of 2.11%Pb,2.61%Zn,204.53g/t Ag,0.08g/t Au,and 0.01%Cd.The ores can be grouped into two types:(1)porphyry-hosted (Yinluling,Baojia,and Yinzhushan)and (2)stratabound (Xiabao,Yinkeng,Yinglin,and Xiaoyuan).The porphyry-hosted mineralization is distributed within and around the Lengshuikeng granite porphyry,whereas the stratabound mineralization occurs in volcano-sedimentary rocks at ~100–400m depth.The spatial distribution of the porphyry-hosted and stratabound ore bodies,their mineral constituents,and the zoning of alteration assemblages are markedly different from those of typical porphyry deposits. Editorial handling:T.Bissig and G.Beaudoin C.Wang (*): D.Zhang :G.Wu :M.Santosh :J.Zhang :Y .Xu :Y .Zhang State Key Laboratory of Geological Processes and Mineral Resources,China University of Geosciences,No.29,Xueyuan Road,Beijing 100083,People ’s Republic of China e-mail:wcm233@https://www.360docs.net/doc/5013658841.html, Y .Xu No.912Geological Surveying Team,Bureau of Geology and Mineral Exploration and Development,Yingtan 334000,China Miner Deposita (2014)49:733–749DOI 10.1007/s00126-014-0521-8

Hydrothermal synthesis of single-crystal CeCO3OH and their thermal conversion to CeO2

Original article Hydrothermal synthesis of single-crystal CeCO3OH and their thermal conversion to CeO2 Kun Gao a,Yi-Yang Zhu a,Da-Qing Tong a,Li Tian a,Zhao-Hui Wang a,b,Xiao-Zu Wang a,* a College of Chemistry and Chemical Engineering,Nanjing University of Technology,Nanjing210009,China b State Key Laboratory of Materials-Oriented Chemical Engineering,Nanjing University of Technology,Nanjing210009,China 1.Introduction In recent years,cerium compounds have been widely used in catalysis[1–4],fuel cells[5]and chemical materials[6–8]due to their speci?c4f energy levels of the Ce-element[9,10].Among all the cerium compounds,cerium carbonate hydroxide,as an important functional material,has been attracted much attention because of its novel electronic properties,optical properties and chemical characteristics arising from their4f electrons[9–12]. Recently,cerium carbonate hydroxide with different morphol- ogies was synthesized by different methods,such as self-assembly, sonochemical[13,14],hydrothermal[15–18],and microwave- assisted hydrothermal route[19].Among all the preparation methods,the hydrothermal process is considered to be an effective and economical route due to its merits of low synthesis temperature,high powder reactivity and versatile shape control [20–23].In a hydrothermal system,CeCO3OH with different structures corresponding to distinct morphologies have been synthesized[18,24,25].There have been suf?cient studies report- ing on the synthesis of different morphologies,for example,Guo et al.reported the synthesis of triangular micro-plate,bundle-like, shuttle-like and?ower-like structures of CeCO3OH by hydrother- mal method[15,16,18].Li and Zhao synthesized single-crystalline CeCO3OH with dendrite-like structures through a facile hydro- thermal method and obtained CeO2by heating CeCO3OH at5008C for6h[26].Zhang et al.synthesized CeCO3OH rhombic micro- plates by the precipitation method in the presence of3- aminopropyltriethoxysilane[28].However,most of these reports on the synthesis of CeCO3OH micro/nanoparticles were prepared using CO(NH2)2or HMT as the alkaline and carbon resource[13– 18]and added surfactant or template to adjust the nucleation and crystal growth of CeCO3OH particles[13,15–18,28],which makes the process complex and raw materials more costly.So it is important to explore a facile method to synthesize morphology- controlled CeCO3OH micro/nanomaterials. In this paper,we report a simple method to synthesize dendrite- like CeCO3OH crystallites using CeCl3á7H2O as the cerium source, triethylenetetramine as both an alkaline and carbon source.The polycrystalline CeO2was obtained by calcination of the precursor at 5008C for4h,partly maintaining the dendrite-like morphology.The optical absorption properties of CeO2were also investigated. 2.Experimental All chemical reagents were of analytical grade without further puri?cation.In a typical synthesis,0.001mol of CeCl3á7H2O was dissolved in60mL deionized water to form a clear solution,and then0.30mL triethylenetetramine was added to the transparent solution in order to completely react with Ce3+at258C for about 0.5h with continued stirring.The resulting homogenous solution Chinese Chemical Letters25(2014)383–386 A R T I C L E I N F O Article history: Received10August2013 Received in revised form8September2013 Accepted26September2013 Available online1December2013 Keywords: CeCO3OH Hydrothermal Cerium carbonate hydroxide Nanostructures A B S T R A C T Hexagonal single-crystalline cerium carbonate hydroxide(CeCO3OH)precursors with dendrite morphologies have been synthesized by a facile hydrothermal method at1808C using CeCl3á7H2O as the cerium source,triethylenetetramine as both an alkaline and carbon source,with triethylenete- tramine also playing an important role in the formation of the dendrite structure.Polycrystalline ceria (CeO2)have been obtained by calcining the precursor at5008C for4h.The morphology of the precursor was partly maintained during the heating process.The optical absorption spectra indicate the CeO2 nano/microstructures have a direct band gap of2.92eV,which is lower than values of the bulk powder due to the quantum size effect.The high absorption in the UV region for CeO2nano/microstructure indicated that this material was expected to be used as UV-blocking materials. ?2013Xiao-Zu Wang.Published by Elsevier B.V.on behalf of Chinese Chemical Society.All rights reserved. *Corresponding author. E-mail address:wangxiaozu@https://www.360docs.net/doc/5013658841.html,(X.-Z.Wang). Contents lists available at ScienceDirect Chinese Chemical Letters j o u rn a l h om e p a g e:w w w.e l s e v i e r.c o m/l o c a t e/c c l e t 1001-8417/$–see front matter?2013Xiao-Zu Wang.Published by Elsevier B.V.on behalf of Chinese Chemical Society.All rights reserved. https://www.360docs.net/doc/5013658841.html,/10.1016/https://www.360docs.net/doc/5013658841.html,let.2013.11.047

Hydrothermal synthesis and photocatalytic properties of layered La2Ti2O7 nanosheets

I NSTITUTE OF P HYSICS P UBLISHING N ANOTECHNOLOGY Nanotechnology17(2006)4863–4867doi:10.1088/0957-4484/17/19/014 Hydrothermal synthesis and photocatalytic properties of layered La2Ti2O7nanosheets KunWei Li,Yan Wang,Hao Wang1,Mankang Zhu and Hui Yan The College of Materials Science and Engineering,Beijing University of Technology, Beijing100022,People’s Republic of China E-mail:haowang@https://www.360docs.net/doc/5013658841.html, Received17July2006,in?nal form1August2006 Published11September2006 Online at https://www.360docs.net/doc/5013658841.html,/Nano/17/4863 Abstract Layered La2Ti2O7nanosheets were prepared through a one-step hydrothermal method at low temperature.The concentration of NaOH mineralizer plays an important role in the synthesis.The scanning electron microscopy(SEM)and transmission electron microscopy(TEM)images show that the thickness of every nanosheet is about5–10nm,while the planar dimension is more than 1μm.The photo-catalytic activities of the nanosheets were characterized by the decolourization of methyl orange solution and the evolution rate of H2.The results demonstrated that the La2Ti2O7nanosheets possess signi?cantly improved photocatalytic properties in water puri?cation and evolution rate of H2from water–ethanol solution compared with those of samples prepared by conventional solid-state reaction. 1.Introduction Lanthanide titanate(La2Ti2O7),as one of the layered compounds,has attracted widespread attention[1,2]in the photocatalytic domain due to its unique layered structure and chemical activity[3].Hwang et al have reported that La2Ti2O7 loaded with Ni–NiO has good photocatalytic activity in the water-splitting reaction[4]and the destruction of volatile organic compounds(CH3Cl)[5].However,they obtained La2Ti2O7through the conventional solid-state reaction(SSR) or the polymerizable complex method[6].Both of these methods need high temperatures and produce materials with low speci?c surface areas,nonuniform particle sizes and low phase purity,which lead to a relatively low photocatalytic activity.Zhang et al[7]obtained nanopowders of La2Ti2O7 by a metallorganic decomposition method.However,no photocatalytic properties were reported in their study.The desired catalyst should have high speci?c surface area,uniform particle sizes and pure phase.Therefore,if we control the experimental parameters to synthesize the layered compounds with a few layers,that is to say,nanosheets,the products will better answer our desire for a catalyst. The use of solution-based soft chemical methods to prepare nanocrystalline materials is expected to result in 1Author to whom any correspondence should be addressed.chemically homogeneous and phase-pure specimens,a narrow particle size distribution,and low crystallization temperatures of the materials.Among many methods,hydrothermal synthesis is particularly promising for low-cost production of advanced catalysts on a large scale.Because crystalline powders are directly produced in a hydrothermal process, the needs for high-temperature calcination and milling procedures are eliminated.Chen and Xu[8]have prepared La2Ti2O7powders through the hydrothermal treatment of La2O3·2TiO2·n H2O coprecipitation,but this method needs two steps to get the?nal product,and they did not get the La2Ti2O7 nanosheets. Here,we report the simple hydrothermal synthesis of La2Ti2O7two-dimensional(2D)nanosheets.The products were used as photocatalysts for the decolourization of methyl orange solution and the evolution of H2from water–ethanol solution. 2.Experimental details 2.1.Synthesis All reagents were of analytical grade and purchased from Beijing Chemical Reagent Ltd without further puri?cation. The exact quantity of La in the lanthanum nitrate hydrate, 0957-4484/06/194863+05$30.00?2006IOP Publishing Ltd Printed in the UK4863