Influence of the quality and uniformity of ceramic coatings on corrosion resistance

CERAMICS

INTERNATIONAL

Available online at https://www.360docs.net/doc/064760144.html,

Ceramics International 41(2015)5138–

5146

In ?uence of the quality and uniformity of ceramic coatings

on corrosion resistance

V.Encinas-Sánchez a ,A.Macías-García a ,n ,M.A.Díaz-Díez a ,Paulo Brito b ,David Cardoso b

a

Departamento de Ingeniería Mecánica,Energética y de los Materiales,Universidad de Extremadura,Avda de Elvas s/n,E-06071Badajoz,Spain

b

C3i –Coordena??o Interdisciplinar para a Investiga??o e Inova??o,Instituto Politécnico de Portalegre,Lugar da Abadessa,Apartado 148,7301-901Portalegre,

Portugal

Received 10November 2014;received in revised form 6December 2014;accepted 15December 2014

Available online 23December 2014

Abstract

Pre-treated stainless steel substrates were dip-coated with yttria-doped zirconia,and the quality of the coatings was studied by a newly proposed non-destructive method,comparing the results with those obtained with other techniques.The objective was to analyze the effect of the coating's quality on the corrosion rate.To this end,the corrosion rate was determined by means of the linear polarization resistance method.The results showed coatings deposited on the polished substrate at a withdrawal rate of 25mm min à1to be the most uniform and homogeneous,and to present the best resistance to corrosion.

&2015Elsevier Ltd and Techna Group S.r.l.All rights reserved.

Keywords:C.Corrosion;Stainless steel;Coating;Yttria-doped zirconia;Characterization

1.Introduction

Austenitic stainless steels have numerous industrial applica-tions because of their mechanical properties and corrosion resistance [1].However,in long-time applications they are prone to localized corrosion from severe biological effects [2].In these cases,in addition to electron transport,Cl à,O 2,and H 2O species play important roles in the corrosion process [3].To prevent this phenomenon occurrence,one or more of the following methods can be used:(i)alloying the metal with elements that enrich the surface with a corrosion-resistant component during the corrosion process [4];(ii)adding aqueous inhibitors which adsorb strongly on the metal surface and prevent it from reacting with the oxidizing agent [5];and (iii)depositing protective coatings [6].The last one is the most commonly used method,especially with the application of ceramic ?lm coatings to the surface [7].The techniques involved have been extensively studied [8–12].

There are numerous methods for the preparation of coatings to deposit on metals.They include chemical vapor deposition (CVD)[13],physical vapor deposition (PVD)[14],electro-chemical deposition [15],plasma spraying [16],and the sol –gel process [17].Sol –gel coatings have many advantages,[18]including their generally low processing temperature (fre-quently close to room temperature)and the fact that thin ?lms can be produced without the need for machining or melting and by means of “green ”coating technologies (i.e.,the compounds used do not introduce impurities into the end product)[19].There have been many studies which have used the sol –gel route [20–23].

Thin ?lms can be formed by several oxides,such as Al 2O 3[24],CeO 2[25],ZrO 2[26],and Cr 2O 3[27].Zirconia (ZrO 2),for example,has good chemical stability and high hardness.It also has a high coef ?cient of thermal expansion that is very close to that of stainless steels,which can reduce the formation of cracks during high-temperature curing processes.Its proper-ties make it a good protective material [28].It has three polymorphic phases according to the temperature.The stable form is monoclinic at room temperature,but undergoes transi-tions to a tetragonal lattice between 9401C and 12501C and to

https://www.360docs.net/doc/064760144.html,/locate/ceramint

https://www.360docs.net/doc/064760144.html,/10.1016/j.ceramint.2014.12.087

0272-8842/&2015Elsevier Ltd and Techna Group S.r.l.All rights reserved.

n

Corresponding author.Tel.:t342428960086747;fax:t3424289601.E-mail address:amacgar@unex.es (A.Macías-García).

a cubic?uorite structure at23701C[29].Since the tetragonal

phase exhibits optimal mechanical properties,in order to avoid

undesirable phase transitions,zirconia needs to be stabilized

[30].A common system used for this purpose is yttria-stabilized

zirconia because its high ionic conductivity and thermal stability

improve the material's adhesion and corrosion resistance proper-

ties[31].

In sol–gel processes,the deposition of the solutions can be

performed by various techniques,including spin-coating[32],

electrodeposition[33],and dip-coating[34].Two of the

advantages of dip-coating are that it allows large areas to be

coated simply and inexpensively[35].It consists of dipping

the substrate into the sol–gel solution and then withdrawing it

at an appropriate rate to allow deposition of the?lm on the

substrate surface[36].

The quality of the coatings can be studied by electrical

characterization,measuring the impedance response[37].The

elemental composition and the oxidation state of the elements

are analyzed quantitatively by X-ray photoelectron spectro-

scopy(XPS),a surface-sensitive technique which can detect

changes in the surface's chemical composition[38].Time-of-?ight secondary ion mass spectroscopy(ToF-SIMS)is the closest technique to the ideal of chemical microscopy,provid-

ing simultaneously chemical information from surface mass

spectra down to depths of1nm and the surface distribution of

secondary ions at a lateral resolution of200nm[39].Finally,

scanning electron microscopy(SEM)is used to examine the

microstructure and surface morphology of the thin?lms[40].

The objective of the present work was to study how the

uniformity and thickness of yttria-doped zirconia coatings

deposited on AISI304stainless steel substrates in?uence the

action of various corrosive media.

2.Experimental procedure

2.1.Material

The substrate used was AISI304stainless steel.This is one

of the most versatile and most commonly used austenitic steels

in engineering.It is characterized by a low carbon content,

with its composition in weight percent being0.08%C,2.0%

Mn,18.7%Cr,11.0%Ni,0.045%P,and0.03%S.The test

pieces were fabricated to a size of20?30?2mm3.

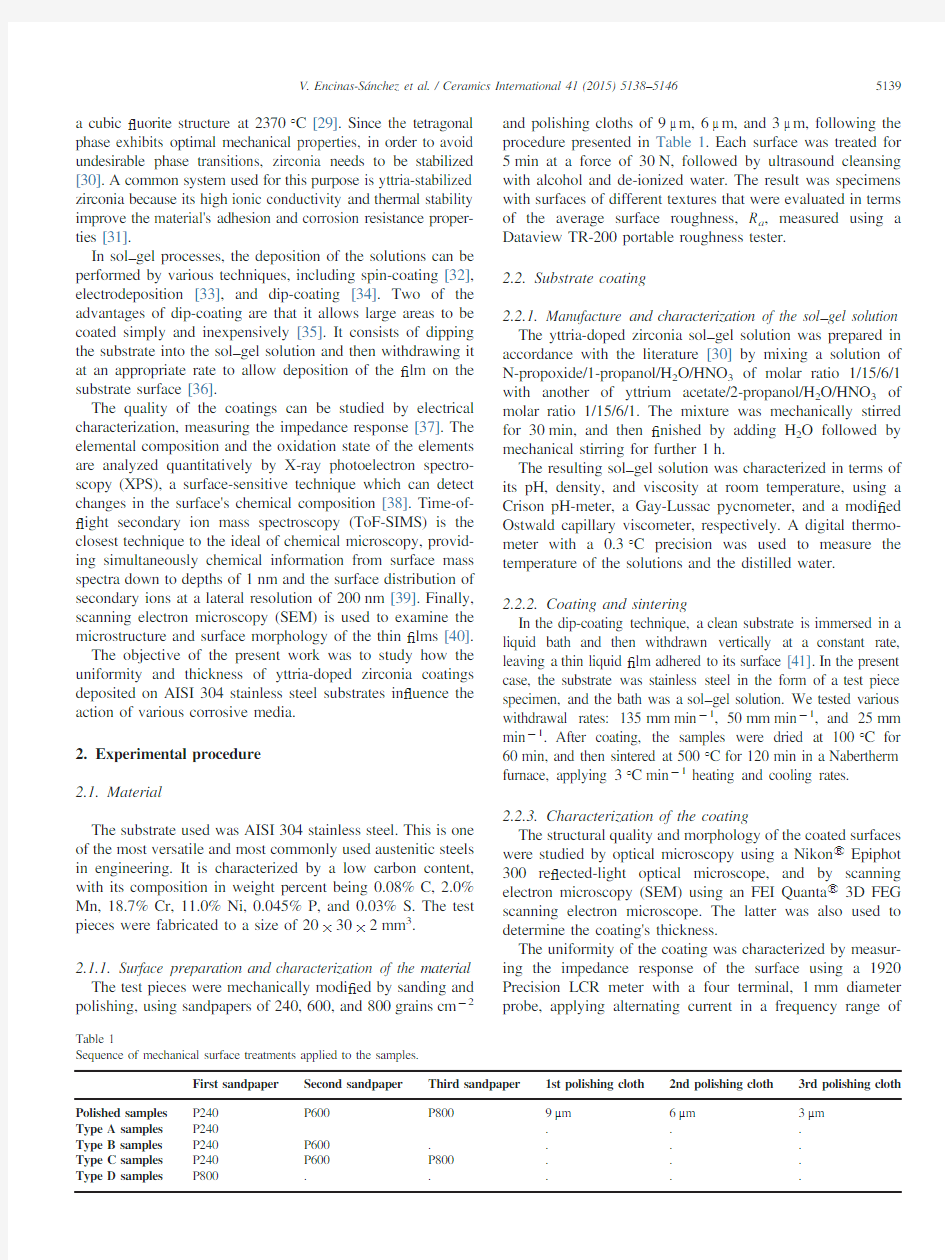

2.1.1.Surface preparation and characterization of the material The test pieces were mechanically modi?ed by sanding and polishing,using sandpapers of240,600,and800grains cmà2and polishing cloths of9m m,6m m,and3m m,following the procedure presented in Table1.Each surface was treated for 5min at a force of30N,followed by ultrasound cleansing with alcohol and de-ionized water.The result was specimens with surfaces of different textures that were evaluated in terms of the average surface roughness,R a,measured using a Dataview TR-200portable roughness tester.

2.2.Substrate coating

2.2.1.Manufacture and characterization of the sol–gel solution The yttria-doped zirconia sol–gel solution was prepared in accordance with the literature[30]by mixing a solution of N-propoxide/1-propanol/H2O/HNO3of molar ratio1/15/6/1 with another of yttrium acetate/2-propanol/H2O/HNO3of molar ratio1/15/6/1.The mixture was mechanically stirred for30min,and then?nished by adding H2O followed by mechanical stirring for further1h.

The resulting sol–gel solution was characterized in terms of its pH,density,and viscosity at room temperature,using a Crison pH-meter,a Gay-Lussac pycnometer,and a modi?ed Ostwald capillary viscometer,respectively.A digital thermo-meter with a0.31C precision was used to measure the temperature of the solutions and the distilled water.

2.2.2.Coating and sintering

In the dip-coating technique,a clean substrate is immersed in a liquid bath and then withdrawn vertically at a constant rate, leaving a thin liquid?lm adhered to its surface[41].In the present case,the substrate was stainless steel in the form of a test piece specimen,and the bath was a sol–gel solution.We tested various withdrawal rates:135mm minà1,50mm minà1,and25mm minà1.After coating,the samples were dried at1001C for 60min,and then sintered at5001C for120min in a Nabertherm furnace,applying31C minà1heating and cooling rates.

2.2.

3.Characterization of the coating

The structural quality and morphology of the coated surfaces were studied by optical microscopy using a Nikon s Epiphot 300re?ected-light optical microscope,and by scanning electron microscopy(SEM)using an FEI Quanta s3D FEG scanning electron microscope.The latter was also used to determine the coating's thickness.

The uniformity of the coating was characterized by measur-ing the impedance response of the surface using a1920 Precision LCR meter with a four terminal,1mm diameter probe,applying alternating current in a frequency range of

Table1

Sequence of mechanical surface treatments applied to the samples.

First sandpaper Second sandpaper Third sandpaper1st polishing cloth2nd polishing cloth3rd polishing cloth Polished samples P240P600P8009μm6μm3μm

Type A samples P240...

Type B samples P240P600....

Type C samples P240P600P800...

Type D samples P800.....

V.Encinas-Sánchez et al./Ceramics International41(2015)5138–51465139

102–106Hz.In this method,a current is passed through the two outer probes,and the voltage across the two inner probes is recorded,yielding the substrate's resistance and capacitance [42].A scheme of the equipment used is shown in Fig.1.Since the capacitance is inversely proportional to the coating's thickness,a map of that thickness is obtained by taking measurements on a grid of equidistant points covering the coated area of the substrate.

The coating's chemical composition was studied by XPS using a Thermo Scienti ?c K-Alpha photoelectron spectrometer equipped with a monochromated Al K αX-ray source.The source was monochromatic radiation at 1486eV.The beam was perpendicular to the specimen's surface,the spot size was 100m m,and the take-off angle was 601relative to the normal surface.The XPS was combined with Ar tion sputtering at an energy of 2000eV,a 17m A current,and a raster area of 1mm 2in a quasi-vacuum of 4?10à8mbar pressure.For samples coated at a 50mm min à1withdrawal rate,16levels were measured,and 12levels for those coated at 25mm min à1.The sputter etching time was 90s per level.Level 0is taken to be a strictly surface assay because of the null sputtering.The etching-time dependence of the atomic percentage distribution of the various elements present was studied on the basis of the XPS data.

Further surface analyses were performed using a time-of-?ight secondary ion mass spectrometer (ToF-SIMS)equipped with a bismuth ion gun.Pulsed primary ion beams were used to desorb and ionize species from the surface of the specimens,operating with a 25kV Bi tpulsed beam for analysis and a 2kV Cs tpulsed beam for sputtering.For each scan,the total primary-ion dose was greater than 1?1012ions cm à2,and the area of each scan was 250?250m m 2with a spot size of 20.8?20.8m m 2.Negative spectra were recorded,the initial spectrum calibration being with the species H à,C à,CH à,CH 2à,CH 3à,OH à,C 2à,C 3à,C 4à,C 5à,and C 7à.Positive spectra were not recorded as this would have meant altering the oxygen signal since positive ions can only be monitored by applying sputtering with oxygen.For this reason,we applied Cs tsputtering in order to obtain a stable,real oxygen signal.To obtain the spectrum,it was necessary to use a reference sample of yttria-doped zirconia and measure the degree of reduction generated by the sputtering on the stable homo-geneous area studied.The sensitivity factor was recalculated on the basis of this degree of reduction,and then this factor was used in all the following calculations to determine the

percentage of each element in each layer.Since the main objective was to verify the homogeneity of the elemental distribution in the layer,this use of a constant reduction factor causes no problems when checking the distribution since the entire study was carried out under identical sputtering conditions.

2.2.4.Study of coating linear polarization resistance

Linear polarization resistance (LPR)measurement is a technique commonly used to determine corrosion rates.The method assumes that electrochemical corrosion is described by the Stern –Geary equation [43]i corr ?B =R p

e2:1TB ?b a b c =?2303eb a tb c T

e2:2T

where i corr is the corrosion current density,R p is the polariza-tion resistance,and b a and b c are the anodic and cathodic Tafel slopes,respectively.The LPR of the deposits was measured in three solutions:(a)3%(w/w)NaCl,(b)1M NaOH,and (c)1M HCl solutions,with an immersion time of 1h (potential stabilization time).The backs of the coated plates were painted with epoxy to keep the surface area constant and to insulate the copper wire connections.Prior to immersion in the electrolyte bath,the electrodes were rinsed with distilled water and dried.The electrochemical tests were performed in a three-electrode cell.A 316L stainless steel mesh with an apparent surface area of 100cm 2was used as the auxiliary electrode.The working electrode potential was measured against an Ag/AgCl in 1M KCl reference electrode.The LPR was determined with a Gamry 900potentiostat,applying a polarization range of 710mV and a scanning rate of 1mV/s.3.Results and discussion 3.1.Material

There have been numerous papers published on ceramic coatings with stainless steel test pieces used as substrates [44].We selected AISI 304stainless steel mainly because of its excellent properties that have led to its widespread use in industry.These properties include low thermal conductivity,and high values of ductility,tensile strength,fracture tough-ness,and work hardening rate.

3.1.1.Characterization of the material

In the characterization of the test pieces,the R a parameter varied from 0.153m m in the original specimens to 0.004m m in the polished specimens (Fig.2).Other studies have used substrates with an R a value of 0.050m m [45].3.2.Substrate coating

3.2.1.Characterization of the sol –gel solution

The ?nal pH of the yttria-doped zirconia sol –gel solution was kept at around 0.5,the density was 0.966g cm à3,the ?nal precursor/alcohol/H 2O/HNO 3mole ratio was 1/15/6/1,and

the

Fig.1.Equipment used for the electrical measurements.

V.Encinas-Sánchez et al./Ceramics International 41(2015)5138–5146

5140

yttria concentration was 3mol%.The solution's viscosity decreased from 1.3cP to 0.8cP as its temperature was increased from 101C to 301C.Various workers have used similar sol –gel solutions in the synthesis of stabilized or unstabilized ZrO 2[46–49].3.2.2.Characterization of the coating

During the immersion phase of the dip-coating method,the initial adherence of the yttria-doped zirconia thin ?lm to the substrate is due to Van der Waals type forces.Subsequently,stronger chemical bonds are formed by condensation reactions between OH groups linked to atoms of the substrate surface and OH groups or OR groups in the solid skeleton of the gel.During the sample extraction and solvent evaporation phase,and depending on the adhesion of the coating with the substrate surface,there arise tensions in the coating.These tensions are due to both contraction of the thin ?lm forming the coating during the evaporation phase and the ongoing condensation reactions.This would explain how the surface roughness of the sanded specimens (types A –D),re ?ected in their high R a values,affects negatively the homogeneity of the sintered coatings,since the sanding of the surface,the coating process,and the sintering of the ?lms leave a series of irregularities on the surface.These effects are attenuated in the polished specimens which had very low R a values.

With respect to the different withdrawal rates,the higher the value of R a ,the smaller the amount of coating that was deposited.This is because more ROH and H 2O are released during the sintering for higher values of R a .It was also observed that the amount of coating deposited on the substrates decreased with decreasing withdrawal rate.

The coatings were characterized texturally by optical microscopy.Fig.3shows the optical micrographs for some selected samples,illustrating the progressive improvement of the coating as the values of R a decrease with increasing severity of the mechanical treatment of the substrates.Simi-larly,the surface termination also becomes progressively more uniform and homogeneous.

The SEM characterization of the morphology of the coatings showed that the cracking of the ?lms (Fig.4)increases with

increasing withdrawal rate.This may be attributed to the amount of deposited material,which is directly related to the withdrawal rate,and to the increased ROH and H 2O removal during sintering as the deposition grows.

One clearly concludes from the results that the best coatings are attained with polished substrates (lowest values of R a )and lower withdrawal rates.Henceforth therefore,we shall report ?ndings only with the polished samples coated at the 25and 50mm min à1withdrawal rates.The results reported in this section indicate that the coating's homogeneity is probably closely related to the low R a value of the polished samples,and to the fact that,in draining,the receding drying line speed is very close to the withdrawal rate [50].

As described in Section 2.2.3,the uniformity of the coating's thickness was characterized electrically,with appropriate soft-ware converting the experimental data into the corresponding coating maps.These show the measured capacitances (Z axis)as a function of the position on the coated surface (X and

Y

Fig.2.R a parameter values obtained for the samples before

coating.

Fig.3.Optical micrographs of the coated samples:(a)original (R a ?0.153μm);(b)type A (R a ?0.083μm);and (c)polished (R a ?0.004μm).

V.Encinas-Sánchez et al./Ceramics International 41(2015)5138–51465141

axes),with the capacitance being inversely proportional to the coating's thickness.The maps are presented using a color scale for the different capacitance intervals.We measured the capacitance at 16points distributed over the coated area of the substrate.Fig.5shows the two maps for sanded and polished samples coated at the same withdrawal rate (25mm min à1).One clearly observes the improvement in the coating with the greater severity of the mechanical treatment of the substrates,as was to be expected,with the coating's thickness

being uniform across the polished sample.Fig.6shows the two maps for polished samples coated at different withdrawal rates.Again,one clearly observes the improvement in the coating at the lower withdrawal rate.This is attributable to the formation of thinner ?lms at the lower rates,hence release of less ROH and H 2O during the sintering process,and conse-quently greater uniformity in the coating's thickness.The observed area of irregularities in coating thickness is due to edge effects during the coating process which result from inhomogeneities created during the substrate preparation.Fig.7shows SEM observations of the coating thickness of the polished specimens at the withdrawal rates of 25mm min à1and 50mm min à1.One observes that the thicknesses are roughly the same (around 500nm),implying that a critical value has been attained.

Fig.8shows the results of the XPS analysis for these same two samples.One observes that there is a clear similarity of the patterns for the different etching times,con ?rming the homo-geneity of the coating thicknesses observed in the capacitance maps.Quanti ?cation of the Zr(3d),O(1s),Y(3d),and Fe(2p)peaks in the two spectra yielded the elemental atomic percentages as functions of the etching time for the two specimens (Fig.9).The depth pro ?les indicate a uniform and homogeneous central area consisting of the oxides of zirconia and

yttria.

Fig.4.Scanning electron micrographs of the evolution of the ?lms'cracking on the polished substrate for different withdrawal rates:(a)25mm min à1;(b)50mm min à1;and (c)135mm min à1

.

Fig. 5.The coating's uniformity for the 25mm min à1withdrawal rate according to the mechanical treatment applied to the substrate:(a)type C and (b)polished.

V.Encinas-Sánchez et al./Ceramics International 41(2015)5138–5146

5142

The ToF-SIMS technique used allowed a maximum depth of analysis of about 2nm.The sequence followed was a scan analysis followed by a 1-s sputtering time,and then allowing a period of stabilization (0.5s),with this sequence being repeated several times.Fig.10shows the results of monitoring the ions of interest in the two samples.There is clear con ?rmation of the XPS results.The central area (Zone II),basically zirconia and yttria,is very homogeneous,with essentially ?at plateaux being found for these compounds.The plateaux are ?atter in the 25mm min à1coated sample,implying that this withdrawal rate leads to a more uniform and homogeneous coating.One also sees from the two pro ?les that the resistance to the application of Cs ions is greater in the specimen coated at 50mm min à1,coherent with the thicker coating indicated by the SEM study.

3.2.3.Study of the coating's linear polarization resistance Table 2presents the results of the normalized linear polarization resistance study for each sample in the three types of solution used:HCl (1M),NaCl (1M),and NaOH (1M).The resistances are greatest in the basic medium,intermediate in the saline medium,and very low in the acidic medium.

High

Fig. 6.The coating's uniformity on polished substrates according to the withdrawal rate:(a)25mm min à1and (b)50mm min à1

.

Fig.7.Coating thickness of polished specimens coated at withdrawal rates of (a)25mm min à1(448.5nm)and (b)50mm min à1(544.0

nm).

Fig.8.XPS depth pro ?les for samples coated at withdrawal rates of (a)25mm min à1and (b)50mm min à1.

V.Encinas-Sánchez et al./Ceramics International 41(2015)5138–51465143

values of the resistance indicate a low corrosion rate,i.e.,good anti-corrosion behavior of the coated sample (Eq.(2.1)).

With respect to the specimen's surface treatment and the withdrawal rate,the best results were obtained with the polished samples and the higher withdrawal rate,i.e.,50mm min à1.Thus,considering ?rst the treatment of the surface,the polished samples presented greater coating uniformity than the type C samples (Fig.5),and the ToF-SIMS analysis showed their coatings to be very homogeneous (Fig.9a).These two aspects,uniformity and homogeneity,are closely related to linear polarization resistance,and consequently to corrosion resistance.Considering second the withdrawal rate,the sam-ples coated at 25mm min à1had greater uniformity and homogeneity than those coated at 50mm min à1(Figs.6and 9).Although the 50mm min à1withdrawal rate coatings were thicker,and one might have expected greater thickness to correspond to greater corrosion resistance,their R p values were lower (Table 2),so that these samples would have faster corrosion rates.To understand this behavior,it is important to bear in mind that the critical phase of the sol –gel coating process is the formation of the thin ?lm when the wet gel is drying.In this phase,fractures can appear as a result of both the high capillarity forces that arise when the solvent

evaporates and of the contraction tensions.This is seen in Fig.4b which corresponds to the polished sample coated at a withdrawal rate of 50mm min à1.This clearly shows that the coating's thickness has a major in ?uence on the linear polarization resistance,and hence lower the corrosion resistance,greater will be the thickness.4.Conclusions

Using optical and scanning electron micrographs,an elec-trical method previously developed by our research group,and XPS and ToF-SIMS characterization techniques,we found the coatings on polished specimens to be very regular in uni-formity and thickness,in concordance with the values mea-sured for the R a roughness parameter.The discontinuities in the coating were greater as R a increased.Also,low withdrawal rates were found to yield coatings that were more homoge-neous and uniform.

From the results,one may conclude that the thickness,homogeneity,and uniformity of the coatings,and consequently the R a value of the substrates and the withdrawal rate used in the coating process,have a major effect on linear polarization resistance,and therefore on the corrosion rate.In

particular,

Fig.9.Atomic percentage of elements depending on the etching

time.

Fig.10.ToF-SIMS analysis of the samples coated at withdrawal rates of (a)25mm min à1and (b)50mm min à1.

V.Encinas-Sánchez et al./Ceramics International 41(2015)5138–5146

5144

greater uniformity and homogeneity of the coatings,and hence lower values of R a and the withdrawal rate,imply greater corrosion resistance.

The linear polarization resistances were lower in the thicker samples,obtained at a withdrawal rate of50mm minà1.This greater thickness seems to in?uence the appearance of cracks, since these samples presented the beginnings of cracking, which is closely related to the tensions created during the sintering process and to the greater coating mass deposited on the sample.Although the cracks actually observed were slight, they seemed to reach the substrate,and would thus lead to poor anti-corrosion behavior.Since the coating's thickness is closely related to corrosion resistance,the straightforward electrical method used here to measure the surface's electrical capaci-tance in order to evaluate the uniformity of that thickness would seem to be of particular interest in these applications. References

[1]J.Z.Lu,H.Qi,K.Y.Luo,M.Luo,X.N.Cheng,Corrosion behavior of

AISI304stainless steel subjected to massive laser shock peening impacts with different pulse energies,Corros.Sci.80(2014)53–59.

[2]A.Parsapour,S.Nouri Khorasani,M.Hossein Fathi,Effect of surface

treatment and metallic coating on corrosion behavior and biocompatibility of surgical316L stainless steel implant,J.Mater.Sci.Technol.28(2012) 125–131.

[3]V.H.V.Sarmento,M.G.Schiavetto,P.Hammer, A.V.Benedetti,

C.S.Fugivara,P.H.Suegama,S.H.Pulcinelli,C.V.Santilli,Corrosion

protection of stainless steel by polysiloxane hybrid coatings prepared using the sol–gel process,Surf.Coat.Technol.204(2010)2689–2701.

[4]A.Pardo,M.C.Merino,A.E.Coy,R.Arrabal,F.Viejo,A.M'hich,

Corrosion behavior of AISI304stainless steel with Cu coatings in H2SO4,Appl.Surf.Sci.253(2007)9164–9176.

[5]A.S.Fouda,M.Abdallah,S.M.Al-Ashrey,A.A.Abdel-Fattah,Some

crown ethers as inhibitors for corrosion of stainless steel type430in aqueous solutions,Desalination250(2010)538–543.

[6]J.Zhang,C.Deng,J.Song,C.Deng,M.Liu,K.Zhou,MoB–CoCr as

alternatives to WC–12Co for stainless steel protective coating and its corrosion behavior in molten zinc,Surf.Coat.Technol.235(2013) 811–818.

[7]https://www.360docs.net/doc/064760144.html,zar,W.Prieto Yespica,S.Marcelin,N.Pébère,D.Samélor,

C.Tendero,C.Vahlas,Corrosion protection of304L stainless steel by

chemical vapor deposited alumina coatings,Corros.Sci.81(2014) 125–131.

[8]Z.Liu,Y.Dong,Z.Chu,Y.Yang,Y.Li,D.Yan,Corrosion behavior of

plasma sprayed ceramic and metallic coatings on carbon steel in simulated seawater,Mater.Des.52(2013)630–637.

[9]Y.Zhang,Y.Shao,T.Zhang,G.Meng, F.Wang,High corrosion

protection of a polyaniline/organophilic montmorillonite coating for magnesium alloys,https://www.360docs.net/doc/064760144.html,.Coat.76(2013)804–811.

[10]N.V.Murillo-Gutiérrez, F.Ansart,J.-P.Bonino,M.-J.Menu,

M.Gressier,Protection against corrosion of magnesium alloys with both conversion layer and sol–gel coating,Surf.Coat.Technol.232(2013) 606–615.

[11]M.Behzadnasab,S.M.Mirabedini,M.Esfandeh,Corrosion protection of

steel by epoxy nanocomposite coatings containing various combinations of clay and nanoparticulate zirconia,Corros.Sci.75(2013)134–141.

[12]A.Pardo,P.Casajús,M.Mohedano,A.E.Coy,F.Viejo,B.Torres,

E.Matykina,Corrosion protection of Mg/Al alloys by thermal sprayed

aluminium,Appl.Surf.Sci.255(2009)6968–6977.

[13]Z.Zhang,B.A.Pint,K.M.Cooley,J.A.Haynes,Formation of aluminide

coatings on Fe-based alloys by chemical vapor deposition,Surf.Coat.

Technol.202(2008)3839–3849.

[14]H.Altun,S.Sen,The effect of PVD coatings on the wear behavior of

magnesium alloys,Mater.Charact.58(2007)917–921.

[15]Y.Yan,Q.Ding,Y.Huang,S.Han,X.Pang,Magnesium substituted

hydroxyapatite coating on titanium with nanotublar TiO2intermediate layer via electrochemical deposition,Appl.Surf.Sci.305(2014)77–85.

[16]J.J.Kang, B.S.Xu,H.D.Wang, C.B.Wang,In?uence of spraying

parameters on the microstructure and properties of plasma-sprayed Al2O3/ 40%TiO2coating,Phys.Procedia50(2013)169–176.

[17]Y.Harada,S.Kumai,Effect of ceramics coating using sol–gel processing

on corrosion resistance and age hardening of AZ80magnesium alloy substrate,Surf.Coat.Technol.228(2013)59–67.

[18]P.Choudhury,D.C.Agrawal,Sol–gel derived hydroxyapatite coatings on

titanium substrates,Surf.Coat.Technol.206(2011)360–365.

[19]D.Wang,G.P.Bierwagen,Sol–gel coatings on metals for corrosion

protection,https://www.360docs.net/doc/064760144.html,.Coat.64(2009)327–338.

[20]M.Touzin,F.Béclin,Fabrication and characterization of composite sol–

gel coatings on porous ceramic substrate,J.Eur.Ceram.Soc.31(2011) 1661–1667.

[21]K.A.Yasakau,J.Carneiro,M.L.Zheludkevich,M.G.S.Ferreira,In?u-

ence of sol–gel process parameters on the protection properties of sol–gel coatings applied on AA2024,Surf.Coat.Technol.246(2014)6–16. [22]M.A.Díaz-Díez,A.Macías-García,G.Silvero,R.Gordillo,R.Caruso,

Theoretical study of the molecular structure for zirconium complexes, Ceram.Int.29(2003)471–475.

[23]Fuchun Liu Hongwei Shi,Enhou Han,Corrosion behavior of sol–gel

coatings doped with cerium salts on2024-T3aluminum alloy,Mater.

Chem.Phys.124(2010)291–297.

[24]I.N.Reddy,V.R.Reddy,N.Sridhara,V.S.Rao,M.Bhattacharya,

P.Bandyopadhyay,S.Basavaraja,A.K.Mukhopadhyay,A.K.Sharma,

A.Dey,Pulsed rf magnetron sputtered alumina thin?lms,Ceram.Int.40

(2014)9571–9582.

[25]Y.Yang,Y.Yang,T.Fu,J.Zhu,J.Fan,Z.Zhang,J.Zhang,In?uence of

ethanol content in the precursor solution on anodic electrodeposited CeO2 thin?lms,Thin Solid Films556(2014)128–136.

[26]I.Espitia-Cabrera,H.Orozco-Hernández,R.Torres-Sánchez,M.E.Contreras-

García,P.Bartolo-Pérez,L.Martínez,Synthesis of nanostructured zirconia electrodeposited?lms on AISI316L stainless steel and its behavior in corrosion resistance assessment,Mater.Lett.58(2003)191–195.

[27]A.Tarre,J.Aarik,H.M?ndar, A.Niilisk,R.P?ma,R.Rammula,

T.Uustare,A.Rosental,V.Sammelselg,Atomic layer deposition of Cr2O3thin?lms:effect of crystallization on growth and properties,Appl.

Surf.Sci.254(2008)5149–5156.

[28]M.Norouzi,A.A.Garekani,Corrosion protection by zirconia-based thin?lms

deposited by a sol–gel spin-coating method,Ceram.Int.40(2014)2857–2861.

[29]S.K.Tiwari,M.Tripathi,R.Singh,Electrochemical behavior of zirconia

based coatings on mild steel prepared by sol–gel method,Corros.Sci.63 (2012)334–341.

[30]A.Díaz-Parralejo,A.Macías-García,J.Sánchez-González,M.A.Díaz-Díez,

E.M.Cuerda-Correa,A novel strategy for the preparation of yttria-stabilized

Table2

Normalized linear polarization resistance of the coated samples.

Solution

HCl (1M)NaCl

(1M)

NaOH

(1M)

R p(kΩ/cm2)

Original sample0.20.4 2.2 Type C sample coated at

50mm minà1

0.4 4.432.7

Polished sample coated at

50mm minà1

0.410.058.7 Type C sample coated at

25mm minà1

0.726.2112.4

Polished sample coated at 25mm minà18.9108.2169.3

V.Encinas-Sánchez et al./Ceramics International41(2015)5138–51465145

zirconia powders.Deposition and scratching of thin?lms obtained by the sol–gel method,J.Non-Cryst.Solids357(2011)1090–1095.

[31]M.A.Domínguez-Crespo, A.García-Murillo, A.M.Torres-Huerta,

F.J.Carrillo-Romo,E.Onofre-Bustamante,C.Yá?ez-Zamora,Characteriza-

tion of ceramic sol–gel coatings as an alternative chemical conversion treatment on commercial carbon steel,Electrochim.Acta54(2009) 2932–2940.

[32]E.Salahinejad,M.J.Hadianfard, D.Vashaee,L.Tayebi,In?uence of

annealing temperature on the structural and anti-corrosion characteristics of sol–gel derived,spin-coated thin?lms,Ceram.Int.40(2014)2885–2890.

[33]M.Sheffer,A.Groysman,D.Mandler,Electrodeposition of sol–gel?lms

on Al for corrosion protection,Corros.Sci.45(2003)2893–2904. [34]R.Ashiri,A.Nemati,M.Sasani Ghamsari,Crack-free nanostructured

BaTiO3thin?lms prepared by sol–gel dip-coating technique,Ceram.Int.

40(2014)8613–8619.

[35]K.Mimura,K.Kato,Characteristics of barium titanate nanocube ordered

assembly thin?lms fabricated by dip-coating method,Jpn.J.Appl.Phys.

52(2013)1–5.

[36]R.Molina,Y.Segura,F.Martínez,J.A.Melero,Immobilization of active and

stable goethite coated-?lms by a dip-coating process and its application for photo-Fenton systems,Chem.Eng.J.203(2012)212–222.

[37]X.Wang,J.Mei,P.Xiao,Non-destructive evaluation of thermal barrier

coatings using impedance spectroscopy,J.Eur.Soc.21(2001)855–859.

[38]N.M.Figueiredo,N.J.M.Carvalho,A.Cavaleiro,An XPS study of Au

alloyed Al–O sputtered coatings,Appl.Surf.Sci.257(2011)5793–5798.

[39]P.Fardim, B.Holmbom,ToF-SIMS imaging:a valuable chemical

microscopy technique for paper and paper coatings,Appl.Surf.Sci.

249(2005)393–407.

[40]M.Wang,T.Toihara,M.Sakurai,W.Kurosaka,S.Miyake,Surface

morphology and tribological properties of DC sputtered nanoscale multilayered TiAlN/CN x coatings,Tribol.Int.73(2014)36–46.[41]C.J.Brinker,G.W.Sherer,Sol–Gel Science,Academic Press,New York,

1990(Chapter14).

[42]J.C.Li,Y.Wang,D.C.Ba,Characterization of semiconductor surface

conductivity by using microscopic four-point probe technique,Phys.

Procedia32(2012)347–355.

[43]M.Stern, A.L.Geary,Electrochemical polarization I.A theoretical

analysis of the shape of polarization curves,J.Electrochem.Soc.104 (1957)56–63.

[44]J.Lira-Olivares,S.González-Rodulfo,J.de Abreu de Abreu,Metallic

and ceramic coating solve economic and environment problems of developed and developing countries,https://www.360docs.net/doc/064760144.html,tin Am.Metal.Mater.31 (2011)106–121.

[45]D.A.Gómez-Hernández,P.A.Jurado-Ortiz,A.Ruben-Mu?oz,J.de la Roche-

Yepes,J.M.González,O.Sequeda,Titanium and zirconium?lm corrosión resistance produced y DC magnetron sputtering,Inf.Téc.74(2010)39–43.

[46]T.Oginaha,K.Wada,T.Yoshida,T.Yanagawa,N.Ogata,K.Yoshida,

N.Matsushita,Preparation of monodipersed zirconia–alumina and yttria–alumina particles,Ceram.Int.19(1993)159–168.

[47]R.Guinebretiere, A.Dauger,A.Leconte,H.Vesteghem,Tetragonal

zirconia powders from the zirconium n-propoxide–acetylacetone–water–isopropanol system,J.Non-Cryst.Solids147–148(1992)542–547. [48]A.J.Lecloux,E.Fran?ois,A.Mohsine,F.Noville,J.-P.Pirad,Texture

evolution of zirconium oxide xerogels prepared by sol–gel process, J.Non-Cryst.Solids147–148(1992)389–393.

[49]D.L.Bourell,Parimal,W.Kaysser,Sol–gel synthesis of nanophase yttria-

stabilized tetragonal zirconia and densi?cation behavior below1600K,J.

Am.Ceram.Soc.76(1993)705–711.

[50]C.J.Brinker,G.C.Frye,A.J.Hurd,C.S.Ashley,Fundamentals of sol–gel

dip-coating,Thin Solid Film201(1991)97–108.

V.Encinas-Sánchez et al./Ceramics International41(2015)5138–5146 5146

世界经典哲学类书籍推荐

世界经典哲学类书籍 哲学,是理论化、系统化的世界观,是自然知识、社会知识、思维知识的概括和总结,是世界观和方法论的统一。是社会意识的具体存在和表现形式,是以追求世界的本源、本质、共性或绝对、终极的形而上者为形式,以确立哲学世界观和方法论为内容的社会科学。 《性心理学》 《作为意志和表象的世界》 《理想国》 《西方哲学史》 《自然哲学的数学原理》 《权力意志》 《新工具》 《纯粹理性批判》《文明论概略》 《劝学篇》 《伦理学》 《耶稣传》 《时间简史》 《逻辑哲学论》 《精神现象学》 《物性论》 《感觉的分析》 《精神分析引论》《基督何许人也——基督抹煞论》 《科学的社会功能》《人有人的用处》《科学史》 《人类理智新论》《逻辑学》 《哲学研究》 《新系统及其说明》《道德情操论》 《实践理性批判》《美学》 《判断力批判》 《基督教的本质》《薄伽梵歌》 《伦理学中的形式主义与质料的价值伦理学》《物种起源》 《物理学》《人类的由来》 《人性论》 《人是机器》 《法哲学原理》 《狄德罗哲学选集》 《野性的思维》 《哲学史教程》 《科学与近代世界》 《人类的知识》 《精神分析引论新编》 《自然宗教对话录》 《基督教并不神秘》 《科学中华而不实的 作风》 《一年有半,续一年有 半》 《时间与自由意志》 《哲学辞典》 《历史理性批判文集》 《苏鲁支语录》 《文化科学和自然科 学》 《十六、十七世纪科 学、技术和哲学史》 《科学哲学的兴起》 《灵魂论及其他》 《斯宾诺莎书信集》 《实验心理学史》 《最后的沉思》 《纯粹现象学通论》 《近代心理学历史导 引》 《佛教逻辑》 《神圣人生论》 《逻辑与知识》 《论原因、本原与太 一》 《形而上学导论》 《诗学》 《路标》 《心的概念》 《计算机与人脑》 《十七世纪英格兰的 科学、技术与社会》 《卡布斯教诲录》 《薄伽梵歌论》 《尼各马可伦理学》 《论老年论友谊论责 任》 《实用主义》 《我的哲学的发展》 《拓扑心理学原理》 《在通向语言的途中》 《科学社会学》 《埃克哈特大师文集》 《逻辑大全》 《简论上帝、人及其心 灵健康》 《宗教的本质》 《论灵魂》 《科学的价值》 《内时间意识现象学》 《艺术即经验》 《宗教与科学》 《感觉与可感物》 《行为的结构》 《真理与方法》 《阿维斯塔》 《善的研究》 《人类知识原理》 《伦理学体系》 《科学与方法》 《第一哲学(上下卷)》 《物理学理论的目的 与结构》 《思维方式》 《发生认识论原理》 《爱因斯坦文集》 《伦理学的两个基本问题》 《数理哲学导论 《耶稣传(第一、二卷)》 《美学史》 《原始思维》 《面向思的事情》 《普通认识论》 《莱布尼茨与克拉克论战 书信集》 《对莱布尼茨哲学的批评 性解释》 《物理学和哲学》 《尼采(上下卷)》 《思想录》 《道德原则研究》 《自我的超越性》 《实验医学研究导论》 《巴曼尼得斯篇》 《人类理解论》 《笛卡尔哲学原理》 《人生的亲证》 《认识与谬误》 《哲学史讲演录》 《圣教论》 《哲学作为严格的科学》 《人类知识起源论》 《回忆苏格拉底》 《心的分析》 《任何一种能够作为科学 出现的未来形而上学导论》 《科学与假设》 《宗教经验之种种》 《声音与现象》 《苏格拉底的申辩》 《论个人在历史上的作用 问题》 《论有学识的无知》 《保卫马克思》 《艺术的起源》

第五章 老年社会工作

第五章老年社会工作 第一节老年社会工作概述 第二节老年社会工作的主要内容 第三节老年社会工作的主要方法 第一节老年社会工作概述 一、老年人与老年期 (一)年龄界定 生理年龄:生理指标与功能确定 心理年龄:心理活动程度确定 社会年龄:与他人交往的角色确定 (二)老年期的划分 低龄老年人:60-69岁 中龄老年人:70-79 高龄老年人:80岁以上 (三)划分的意义 1.三种年龄:不能仅凭日历年龄判断服务需求,而要关注不同个体在生理、心理与社会方面的差异。 2.三个时期:关注老年同期群的共性需要。 二、老年期的特点 (一)生理变化 1.生理变化的特点:九大生理系统老化 2.对开展老年社会工作的影响 (1)要特别关注老年人的身体健康状况; (2)处理好隐私的健康问题,如大小便; (3)帮助机构和家庭策划环境的调整。 (二)心理变化 1.智力、人格、记忆力的变化 智力:结晶智力强,但处理问题速度下降 人格:总结自己生命的意义 记忆力:记忆速度下降,动机决定是否学习 2.对开展老年社工的影响 (1)提供机会但尊重选择 (2)所有事放慢节奏 (3)关注身体健康对心理功能的重要性 (三)社会生活方面的变化 1.对老年社会生活变化的理论解释 (1)角色理论:丧失象征中年的社会角色 (2)活动理论:生活满足感与活动有积极联系 (3)撤离理论:接受减少与社会的交往 (4)延续理论:不能割裂看待老年阶段 (5)社会建构理论:老年是一个独特的个人过程 (6)现代化理论:现代化使老年人地位下降

2.理论在社会工作中的应用 (1)注意角色转变的重大生活事件 (2)注意老年个体的差异性,尊重其对生活意义的不同理解 (3)注意社会隔离可能对老年人造成的伤害 (4)改变总有可能 (5)关注社会变迁对老年人的影响,推动社会政策的调整 三、老年人的需要及问题 (一)老年人的需要 1.健康维护 2.经济保障 3.就业休闲 4.社会参与 5.婚姻家庭 6.居家安全 7.后事安排 8.一条龙照顾 (二)老年人的问题 1.慢性病问题与医疗问题 2.家庭照顾问题 3.宜居环境问题 4.代际隔阂问题 5.社会隔离问题 四、老年社会工作 (一)老年社会工作的对象 1.老年人自身:空巢、残疾、高龄老人,也包括健康老人 2.老年人周围的人:家庭成员、亲属、朋友、邻居等 3.宏观系统:单位与服务组织 (二)老年社会工作的目的 根本目标:老有所养、老有所医、老有所教、老有所学、老有所为、老有所乐 (三)老年社会工作的作用 1.个体层面:维持日常生活、获得社会支持 2.宏观层面:参与制定有关老年人的服务方案与政策 五、老年社会工作的特点 (一)老年歧视等社会价值观会影响社会工作者的态度与行为 (二)反移情是社会工作者的重要课题 (三)社会工作者要善于运用督导机制 (四)需要多学科合作 第二节老年社会工作的主要内容 一、身体健康方面的服务 二、认知与情绪问题的处理 三、精神问题的解决 四、社会支持网络的建立 五、老年人特殊问题的处理 一、身体健康方面的服务

公开课康德的理论哲学和实践哲学笔记

康德在人类文明史及哲学史取得崇高地位的原因:不是来自于其异乎寻常的思维能力,而是来自其身后拨打的人性;康德把至善看做是纯粹理性的最终目的。康德哲学的分类:世界哲学和学院哲学。人类普遍问题和专业问题。哲学的问题:我能够知道什么?我应当做什么?我可以希望什么(对自己人生的承诺和定位)?即“人是什么?”关心人的问题,而不是哲学的技术智力问题。康德一生:亚里士多德:他出生,他工作,他死了。康德《自然通史和天体理论》。本科毕业凭《自然通史与天体理论》直接进大学教书,德国哲学史上两个:康德,尼采。死于老年痴呆症。知识来源:知性和感性。感性给我们的是直观的杂多,一个不确定的经验的领域,除了具有一定的时间和空间形式外,实际上缺乏进一步的规定,本身不能构成知识,而只能成为知识的材料,人类只有通过理性的范畴把感性杂多的材料按照一定的规则综合在一起形成判断,那才叫知识。连接直观杂多的规则,就是范畴,不是来自于经验,而是来自于知性。主体或者我思把知性的先验范畴应用于感性的材料,按规则综合成为知识。旧的知识论:知识是我们主观与客观的事物符合。康德认识论:真理不是主观符合客观,而是我们的知识和判断必须符合我们的认识条件,而认识条件必须符合感性的先天形式,时间和空间以及知性的先验范畴及其运用规则。知识的两面:感性杂多与先验知性范畴。问题:不同质的先验范畴如何运用于感性直观。想象力:感性与知性之间的一种中介性的能力,沟通感性与知性,同时具有感性与知性的特性。想象力是如何使先验范畴运用于感性杂多的?用它所产生的图式。想象力是图式的承载者。图式:产生图像的规则或者程序,图像把一个范畴图示化,使其可运用于现象之上。“想象力为一个概念取得它的形象的某种普遍的处理方式的表象,我把它叫做这个概念的图式。”一方面具有普遍性,类似概念,另一方面,又是特殊的,类似图形。想象力根据图式自动产生图像,而中世纪的亚里士多德主义者认为图像是感官层面各种过程的结果,又是人理智抽象的基础。客体必须符合心灵,而不是相反,亚里士多德主义则相反。用图式的方法,根据某个概念,把各个表象综合在一个图像当中,图式使我们把现象的杂多带到了一起,散殊的杂多结合成一个图像,可以把概念用于现象。想象力,把日常生活中不可能的事物连接在一起。知性,感性,想象力——人的先天能力。黑格尔:我们对一个人的质疑和反驳,必须从接受它的前提开始,提出的质疑和反驳才是有效的。十二范畴:量(单一性,多数性,全体性),质(实在性,否定性,限制性),关系((依存性与自存性(实体与偶然),原因性与从属性(原因和结果),协同性(主动与受动之间的交互作用)),模态类(可能性-不可能性,存在-非有,必然性-偶然性)。时间是范畴运用于现象的必要条件,我们所有的外感官和内感官的现象都在时间之中,时间是一切现象的共同特征。“图式无非是按照规则的先天时间规定而已”。时间是一切表象联结的形式条件。表象只有联结在一起才能形成判断,而时间就是联结表象的形式条件。时间的先验规定是想象力的产物,在感性和执行两边都有根基,与范畴是同质的,因为是普遍的先天的;与表象同质,因为时间包含在一切经验杂多的形式中。范畴在现象上的应用,借助于现象的时间规定而成为可能,后

老年人的思维特点是怎样的

老年人的思维特点是怎样的 同时,随着记忆负荷和问题难度的增加,老年人在解决问题上的能力不如年轻人。 这不能完全归结于老年人生理上的衰退,其中有一部分原因是由于老年人处于摆脱工作负担、受人照顾的地位所决定的。 老年人的逻辑推理能力也有所下降,其原因有可能是工作记忆容量的缩小所造成的。 因为,实验表明,随着记忆负荷和课题难度的增加,年轻人同老年人在逻辑推理能力上的差异也就更加明显。 当记忆负荷较低或课题较为简单时,年轻人和老年人并没有什么差别,但当课题对记忆的要求很高或课题的难度增加时差异就会相当咀显。 另外,人到老年时,想象某个形状改变方位的能力也有所衰退。 总的来说,老年入在思维能力上有所下降,但个体问存在着明显的差异也是不可忽视的事实,即有的老年人思维和解决问题的能力明显衰退,有的人却能始终保持较高的水平。 这固然有生理机能的原因,但是与生活方式和生活态度也很有关系。 思维能力也和其他能力一样,服从子“用进废退"的原则,如果到老年时,仍然经常思考问题,关心和研究周围的事物,则这种能力多半就能保持得很好。

老年人思维变化的表现思维出现衰退较晚,特别是与自己熟悉的专业有关的思维能力在年老时仍能保持。 但是,老年人由于在感知和记忆方面的衰退,在概念、逻辑推理和解决问题的能力有所减退,尤其是思维的敏捷度、流畅性、灵活性、独创性以及创造性比中青年时期要差。 老年人思维弱化及障碍的表现形式如下:1) 思维迟钝、贫乏对有些事情联想困难,反应迟钝,语言缓慢;有些老年人不愿学习,不想思考问题,导致词汇短缺,联想易间断,说话常突然中止。 2) 思维奔逸,如对青壮年时期的事情联想迅速,说话漫无边际,滔滔不绝。 3) 强制性思维,不自主的偶发毫无意义的联想,或者反复出现而又难以排除的思维联想。 4) 逻辑障碍,主要表现为对推理及概念的紊乱,思维过程繁杂曲折,内容缺乏逻辑联系。 老年人思维变化的应对策略人在老年期思维能力的弱化在各个老年人的身上表现程度不同,有些人思维仍很清晰,甚至仍有创造思维,而有些人却有严重的思维障碍。 因此,要重视对老年人的全面身心保健,鼓励老年人以积极的态度对待生活,培养其思维品质,以恢复和保持其良好的思维能力。

哲学经典试题

乌丹一中2013届高考-----生活与哲学选择题专项训练 1.2011年12月16日,菲律宾遭受热带风暴“天鹰”袭击,损失巨大。中国驻菲律宾大使馆向菲方提供价值44万比索(约1万美元)的紧急救灾援助。有人认为,近年来,菲律宾不断在南海问题上挑起争端,中国不应援助。这种观点( ) A.只见统一,不见对立 B.只见对立,不见统一 C.没有看到联系是具体的、有条件的 D. 没有看到斗争性寓于同一性之中 2.酒与污水定律是指:如果把一匙酒倒进一桶污水中,你得到的是一桶污水;如果把一匙污水倒进一桶酒中,你得到的还是一桶污水。该定律体现的哲学原理是() ①事物的性质由矛盾的主要方面决定 ②量变达到一定程度必然发生质变 ③矛盾双方在一定条件下相互转化 ④关键部分的功能及其变化甚至对整体的功能起决定作用 A.①④ B.②③ C.①③ D.②④ 3.对于莫言的获奖,评委会给出的获奖理由称,“将魔幻现实主义与民间故事、历史与当代社会融合在一起”。从哲学角度看,莫言文学创作的成功在于: (1)注意分析和把握事物存在和发展的各种条件 (2)借助意识的作用创造了一个理想的世界 (3)通过实践实现了主体对客体的能动反映 (4)把自己头脑中的观念的存在变为了现实的存在 A.(1)(2) B.(1)(3) C.(1)(4) D.(2)(4) 4.“要想跳得更好,必须先退后一步。”(蒙田《随笔集》)下列语句中与材料体现哲理相同的是 A.人生悲剧有二:一是欲望得不到满足,二是欲望得到了满足 B.一个时代的文明成为下一个时代的肥料 C.一匹马如果没有另一匹马紧紧追赶并要超越它,就永远不会疾驰飞奔 D.人可以爬到最高峰,但他不能在那儿久住 5.下列古诗中与右边漫画《跷板游戏》的哲理启示相一致的是() A.凡物各自有根本,种禾终不生豆苗B.历尽天华成此景,人间万事出艰辛 C.蝉噪林逾静,鸟鸣山更幽D.横看成岭侧成峰,远近高低各不同 6.清能有容,仁能善断,明不伤察,直不过矫。是谓蜜饯不甜,海味不咸,才是懿德。 A矛盾的普遍性寓于特殊性 B矛盾斗争性寓于同一性 C矛盾斗争性决定矛盾同一性 D矛盾特殊性离不开普遍性 “矛盾斗争性寓于同一性"一般考查两种材料,一种材料是”关系越好的人,矛盾和摩擦往往也就比较多“,另一种材料就是”不走极端,在对立中把握统一“,也就是中国传统文化的”中庸之道“,一般考查这种意思的比较多。 7. 你幸福吗?”“我姓曾。”一位捡瓶子老人因为耳朵不好,就有了下面一席对话:您收了多少瓶子了?73岁了;您收了多少瓶子了?我吃的政府低保,630块一个月;您觉得您幸福吗?我耳朵不好。之所以出现神一样的回复说明()

马克思主义哲学教材经典名言全解析

一名言 1、物质是标志客观实在的哲学范畴,这种客观实在是人通过感觉感知的,它不依赖于我们的感觉而存在,为我们的感觉所复写、摄影、反映。 ---解析:这句话是从物质与意识的关系上来把握物质的。 2、观念的东西不外是移人人的头脑并在人的头脑中改造过的物质的东西而已。 ---解析:这句话表明,物质决定意识,意识依赖于物质并反作用于物质。 3、社会生活在本质上是实践的。 ---解析:马克思的这句话表明,要从实践出发去理解社会。社会生活的实践性主要体现在:①实践是社会关系形成的基础②实践形成了社会生活的基本领域③实践构成了社会发展 的动力。 4、世界不是既成事物的**体,而是过程的**体。 ---解析:恩格斯的这句话表明,事物发展的过程,从形式上看,是事物在时间上的持续性和空间土的广延性的交替;从内容上看,是事物在运动形式、形态、结构、功能和关系上的更新。 5、是就是,不是就不是;除此之外,都是鬼话。 ---解析:这句话是形而上学否定观,这种观点否定是外在的否定,主观任意的否定;否定是绝对的否定,是不包含肯定的否定,这就割断了事物的联系,使发展中断。 6、所谓的客观辩证法是在整个自然界中起支配作用的,而所谓的主观辩证法,即辩证的思维,不过是在自然界中到处发生作用的、对立中的运动的反映。 ---解析:恩格斯的这句话表明:①客观辩证法是指客观事物或客观存在的辩证法②主观 辩证法是指人类认识和思维运动的辩证法③主观辩证法是客观辩证法的反映④客观辩证 法与主观辩证法在本质上是统一的,但在表现形式上则是不同的。 7、一个民族想要站在科学的最高峰,就一刻也不能没有理论思维。 ---解析:恩格斯的这句话表明:辩证思维与科学研究的紧密联系、不可分割。 ①辩证思维方法是现代科学思维方法的方法论前提。 ②现代科学研究方法及其成果丰富和深化了辩证思维方法。

老年社会工作的理论基础

中国青年政治学院学报1998年第2期 老年社会工作的理论基础 江 娅 老年社会工作一直是社会工作中的一个重要内容,无论是开初的慈善服务还是当今的专业社会工作,始终对老人这一特殊群体提供特殊的帮助和服务。英国于1908——1911年通过了《养老金法》以保障老年人的基本生活需要,美国在1935年由罗斯福主持制定了美国历史上有名的《社会保障法案》,老年社会保障成为社会保险的重要内容,在公共分类救助方案中,明确把老人、贫困盲人及失依儿童作为其救助对象。至此以后,老人一直成为西方各国社会工作主要关注的对象之一;欧洲各国在渐次建立福利国家的过程中,也纷纷把提高老年人生活质量和完善老年人服务网络作为其工作的重要目标。 现实的老年社会工作急需理论的说明和指引,于是,各国学者纷纷提出了各具特色的老年理论,试图为人们的实际工作提供某种高屋建瓴的理论指导。这些理论各有自己的长处和短处,通过分析它们的利弊得失,有助于我们解决在实际的老年社会工作中所遇到的问题,提高我们的老年社会工作的质量。 一、社会撤离理论(D isengagem en t T heo ry) 社会撤离理论是从西方社会学主要流派之一的功能学派理论分离出来的,最早由美国的库明(B laine Cumm ing)和享利(W iliam E.H ery)在1961年合著的《变老》一书中提出。社会撤离理论是在老年社会工作中引起争论最多的理论。社会撤离理论认为,人的能力会不可避免地随年龄的增长而下降,老年人因活动力的下降和生活中角色的丧失,希望摆脱要求他们具有生产能力和竞争能力的社会期待,愿意扮演比较次要的社会角色,自愿地脱离社会。在社会撤离理论看来,老年人减少他们的活动水平,减少与人交往,关注内心的生命体验,这会使老年人过一种平静而令人满意的晚年生活。而且,老年人主动地撤离社会,能使社会权利井然有序地实现交接,社会也不会因老年人的突然死亡而功能受损。因此,社会撤离理论认为,老年人从社会主流生活中的撤离,无论这一过程是因老年人自愿还是由社会起动,对社会和个人都会产生积极影响。 尽管社会撤离理论最初的提出是建立在社会调查(库明和亨利曾到密苏里州的堪萨斯城对2457位50—90岁的老年人进行了调查)基础之上的,观点也不乏其合理之处,但其理论前提(假设所有老年人都原意脱离社会)显然是不能成立的。也正因为如此,它遭到了诸多学者的质疑和批判。在老年社会工作领域,这一理论也遍遭拒斥,其理由如下: (1)随着物质生活水平的提高和医疗条件的普遍改善,老年人预期寿命普遍延长,他们在离开工作岗位后还可生活20~30年,很难想象,在如此长的生命年轮里,老年人都愿意脱离社会,枯守家中,过一种仅体验内心生命的生活。而且,近年来,鉴于越来越多的老年人想重回社会主流生活而不得,各国老年社会工作者正在积极地寻求途径以帮助退休后的老年

老年社会工作主要理论

老年社会工作基本理论 在老年社会工作发展的历史中,曾经产生或引用了许多有关的理论,包括社会撤离理论、活动理论、连续性理论、符号互动理论、交换理论,等等,限于篇幅,本节只是选择其中部分理论予以介绍。 一、活动理论 活动理论针对社会撤离理论所提出的老年人因活动能力下降和生活中角色的丧失而愿意自动地脱离社会的观点,认为: 1、活动水平高的老年人比活动水平低的老年人更容易感到生活满意和更能够适应社会; 2、老年人应该尽可能长久地保持中年人的生活方式以否定老年的存在,用新的角来取代因丧偶或退休而失去角色,从而把自身与社会的距离缩小到最低限度。 活动理论对老年社会工作的意义在于,无论从医学和生物学的角度,还是从日常生活观察表明,“用进废退”基本是生物界的一个规律,因此,社会工作者不仅要在态度和价值取向上鼓励老年人积极参与他们力所能及的一切社会活动,而且更需要为老年人的社会参与提供更多的机会和条件。 不过,对于活动理论也有人提出一些质疑:第一,怎样界定活动?退休以后在家并不参加社区工作而只是在家种花养鸟或者习字绘画,这是不是活动?第二,晚年生活的满意与否除了活动因素外,是否还和经济收入、生活方式、家庭关糸、机体健康等多个因素有关?第三,一味强调活动是否忽视了老年人个性因素的存在?正因为如此,一些研究者提出了重视个性因素在衰老过程中的起重要作用的连续性理论。 二、社会损害理论和社会重建理论 社会损害理论着重讨论的是,有时老年人一些正常的情绪反应会被他人视为病兆而作出过分的反应,从而对老人的自我认知带来损害。例如,因患老年病而健康受损的老人,询问子女自己是否应该搬过去与其同住。这种询问就很可能被子女视为老人无能力再作处任何决定的表现,从此凡事处处为老人作决定。这种关心久而久之就会对老人产生一种消极暗示,让老人觉得自己的确缺乏能力而把一切决定权都交给子女。也就是说,接受消极标志的老人随后会进入消极和依赖的地位,丧失原先的独立自主能力。现实生活中有太多的案例表明,对老年人的过分关心导致老年人认为自己无用的错误认知,从而对老年人的身心带来损害。这一理论对老年社会工作者具有深刻的启示意义,它至少告诉我们,有些所谓的老人问题大多是被标定的结果,也是老年人自己受消极暗示所产生的连锁反应,因此,在帮助老年人的过程中,不仅要切实地帮助老人解决实际问题,同时也需要协助老人增强信心和提升能力。 社会重建理论就是意在改变老年人生存的客观环境以帮助老年人重建自信心。社会重建理论的基本模式是:第一阶段:让老人了解到社会上现存的对老年人之偏见及错误观念。第二阶段:改善老年人的客观环境,通过提倡政府资助的服务来解决老年人的住房、医疗、贫困等

赵学慧--老年社会工作理论与实务-习题库

模块一认识老年人。 项目一认知老年人的群体特征。 任务一认知老年人生理特征。 1、由于老年人机体形态的改变和功能的衰退,所以说老年人所患疾病的病症和特征容易出现不典型性特征。(√) 2、随着年龄的增长,每个老年个体的生理特征上都会出现退行性的变化,并且出现某种病症。(×) 3、糖尿病是老年人特有的疾病。(×) 4、内分泌系统不会随着老年人年龄的增长身体的变化而出现功能上的变化。(×) 任务二认知老年人的心理特征。 5、人的认知是心理活动产生发展的前提和基础。(√) 6、个体进入老年期之后,智力会发生全面的退行性变化。(√) 7、情绪和情感是人对客观事物是否符合自己的需要而产生的态度和体验。(√) 8、老年期是老人与年轻时可能会具有完全相反的性格特征。(√) 9、抑郁症是老年阶段所特有的一种持续性情绪低落的情感性心理障碍。(×) 10、老年痴呆症的晚期阶段容易出现智力完全丧失,情绪反应迟钝、运动障碍、大小便失禁、语言能力丧失、生活不能自理的症状。(√) 任务三认知老年人的社会特征。 11、社会地位主要指伴随社会角色而来的和(AB) A、社会责任。 B、社会尊严。 C、社会义务。 12、老年人社会角色的变换主要表现在两个方面:一、从职业角色转入赋闲角色; 二、从主体角色演变为依赖角色。(√) 13、空巢期是每个家庭都会经历的阶段。(√) 项目二了解老年人的需求、问题及权益保障。 任务一了解老年人的需求及面对的问题。 1、马斯洛需求理论当中属于人类个体较高层次的需求的是:ABC A、社交需求。 B、尊重需求。 C、自我实现。 D、安全需求。 2、中国老年人的收入来源主要有几个方面:(ABC) A、离退休金。 B、家庭成员的帮助。 C、个人劳动收入。 3、老年人的精神需求可以分为三个维度:(ABC) A、自尊的需求 B、期待的需求 C、亲情的需求 任务二保障老年人权益 1、老年人权益保障包括:家庭赡养与抚养、、、、、参与社会发展等六个方面对老年人的合法权益做出了具体的规定。ABCD A、社会保障 B、社会服务 C、社会优待 D、宜居环境 2、老年人保障的目标是:、、、、老有所乐。ABCD A、老有所养 B、老有所依 C、老有所为 D、老有所学 3、老年人再婚时,老人的子女可以不去赡养没有血缘关系的另一位老人。(×)

老年心理学论文

老年心理学 ——老年心理学的发展历史09级应用心理3班刘晓敏 200909150104 摘要本文以时间为顺序讲述了老年心理学的发展历史。从各个时代,分别介绍了老年心理学在中西方的发展历史、代表人物,以及老年心理学的研究现状。简略的叙述了老年心理学的定义与大致发展历程。 关键词老年心理学;发展历史 1前言 老年心理学是研究个体和群体成年以后增龄老化过程的心理活动变化、特点、规律的一门科学。是研究老年期个体的心理特征及其变化规律的发展心理学分支,又称老化心理学。它也是新兴的老年学的组成部分。老年心理学一方面是多学科的交叉学科,既有自然科学属性,又有社会科学属性,研究方法也涉及多种不同性质的学科。另一方面,老年心理学是一门年轻的交叉学科,如果在研究或临床工作中不重视方法学,可能会出现由“常识心理学”代替科学心理学的情形。 由于人的心理活动以神经系统和其他器官功能为基础,并受社会的制约,所以老年心理学涉及生物的和社会的两方面的内容。研究范围包括人的感知觉、学习、记忆、思维等心理过程以及智力、性格、社会适应等心理特点因年老而引起的变化。 老年心理学如同心理学一样,有一个漫长的过去,但却只有一个短短的历史。对于人们年龄增长的研究和探索,可以追溯到上古时代。这一点在古代埃及、中国、希腊以及古罗马时期,就为人们所认识了。在那久远的年代中,念咒僧、思想家、哲学家和医生等把高龄、死亡等问题都只看成是一种宗教仪式、一种思想,并不把它看做一门科学。 有关老年心理学的研究虽只在十九世纪以后才正式创建,但我们可以再古代、中世纪、近代的西想家、哲学家和医生所遗存的大量文献中,残缺不全地看到一些记过从心理学角度出发对高龄、死亡、衰老等进行观察所取得的研究成果。 2西方老年心理学的发展历史 2.1 古代与中世纪根据文字记载,人类对于老人、衰老问题的心理学上的兴趣,可以追溯到希腊、罗马时代。在文艺复兴时期,开始以科学的方法对生命、老年进行研究了。在最初的阶段中,还可以看到前一时期的影响十分强大,缺乏科学性。进入了十七世纪以后,才开始真正采取合理的、经验的和实验的方法进行研究。 2.2 近代在西方,第一个对人的一生进行心理学、科学分析的,可以说是数学家、统计学家、天文学家Quetelet。他以0~老年期的人为研究对象,全面系统地研究了人的出生率、死亡率、身高、体重及智力、运动等与年龄性别的关系,阐述了随着年龄的增长人的老化问题,首先采用数量化的研究手段,对发展与年龄的关系问题中的个别差异进行了研究,他把统计学的方法运用到心理学的研究,获得了相关的研究指标,积累了老年心理学研究的宝贵资料。他不仅对老年心理学,而且对整个心理学的研究都作出了许多重要的贡献。1835年他通过《人及其能力的发展》一书公布了自己关于年龄与成绩的研究,想到要预测年龄与从属变数之间的函数关系。

《老年社会工作》课后思考题

《老年社会工作》课后思考题: 第一章: 1、什么是人口老龄化?人口老龄化对社会工作有何影响? 2、老年社会工作的涵义? 3、老年社会工作的对象和内容分别是什么? 4、老年社会工作的实务原则有哪些? 5、老年社会工作的基本技巧有哪些? 6、老年社会工作者面临哪些压力与困难? 第二章: 1、老年人常见的生理疾病及其特征。 2、老年人记忆的变化有何特点? 3、老年人智力的变化有何特点? 4、老年人比较多地会表现哪些消极的情绪和情感? 5、社会损害理论及社会重建理论对老年社会工作的启示。 6、老年次文化理论的基本观点及其对老年社会工作启示。 第三章: 1、政府、非政府组织及家庭和个人在老年福利制度体系的作用有哪些? 政府组织——研究、制定和实施老年人保护的政策和法规;老年福利政策的宣传和教育;建立完善的老年社会保障制度;促进老年人的社会参与和拓展再就业的途径; 非政府组织—— 企业—— 2、你如何看待联合国关于老年人福利的五个方面18条原则? 第四章: 1、老年人个案工作的涵义? 是以生活适应不良的老年人及其家庭为对象,以专业社会工作价值理念为基础,运用有关人类关系与个人发展的各种科学知识和专业技术,针对老年人的特殊情况和需求,以个别化的方式帮助其个人或家庭减低压力,调试其外在环境的社会关系,应应用社会资源改善或恢复其社会功能,引发个人的潜能,增强社会适应能力,提高其生活质量的过程。 2、老年个案工作有哪些原则? 了解老年人的生理、心理特点;尊重老年人的基本看法和态度;与老年人建立信任关系;耐心、积极倾听老年人的谈话;运用医学知识妥当地判断老年人的行为;尊重老年人的选择;为老年人提供个别化的服务计划;提供给老年人所需要的支持;关注老年人的现在,而非过去;充分协调利用各种社会资源 3、运用怀旧和生命回顾的个案辅导技巧时需要注意哪些问题? 建立相互信任的工作关系;鼓励老年案主诉说往事,初期可集中于较为愉快的人生经历,然后才慢慢过渡到较为消沉的往事;侧重聆听老年案主在诉说经历时的感受,尤其注意他们喜怒哀乐的情绪,对那些被抑压的感受应该帮助他们抒发出来;对有子女的老年案主,他们作为父母的经历及感受需要表达出来,以协助个案的诊断和治疗;对于有丧偶的经历,加上因病或意外而导致伤残的老年案主,工作员要协助他们把痛苦的感觉渲泄出来,尤其是配偶对案主生命的意义;当怀旧情绪抒发后,工作员可以采用“时间紧迫”技巧,协助老年案主从