astm a588

美国桥用美标astm a709-50W级桥梁板技术要求(2011.11.16P)

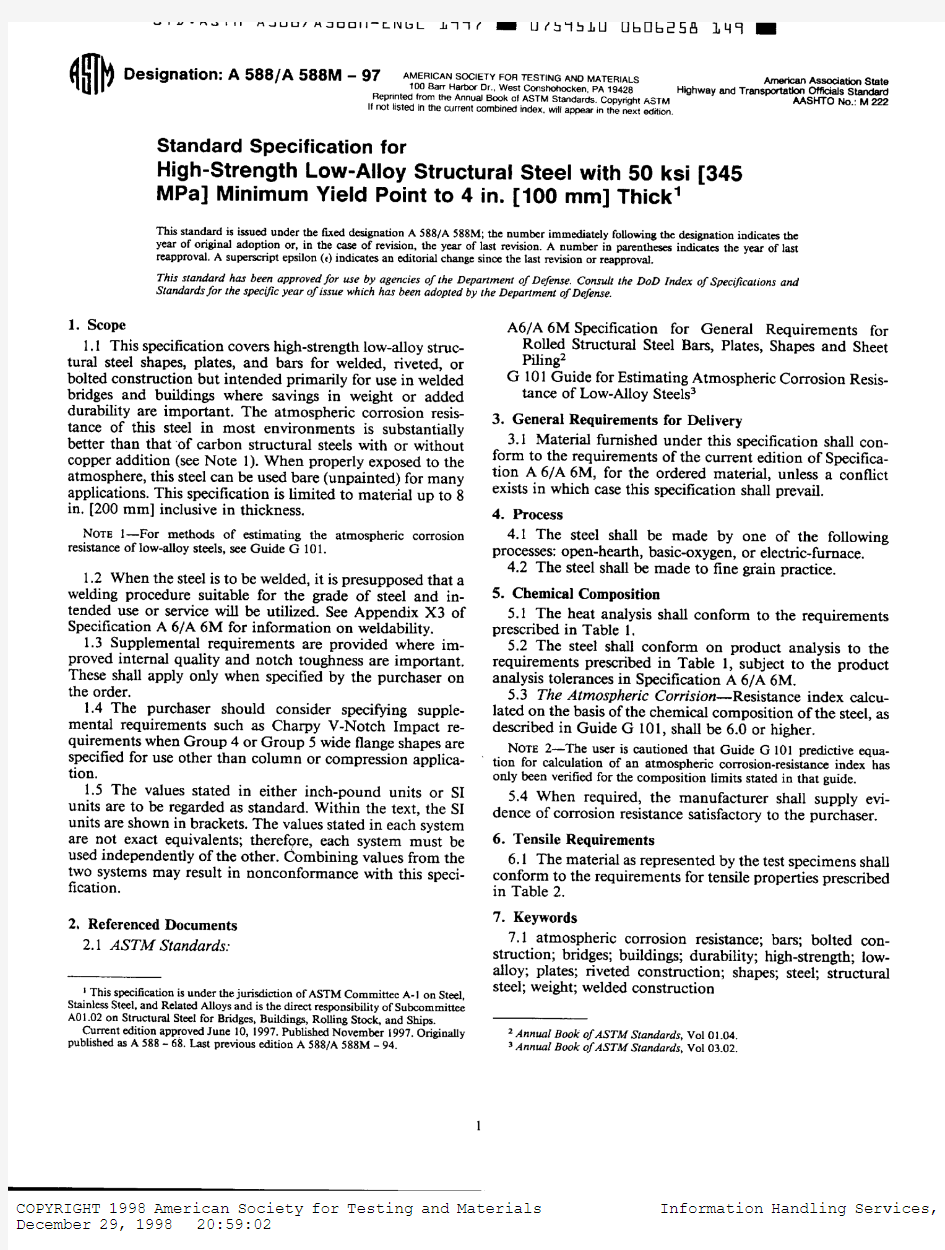

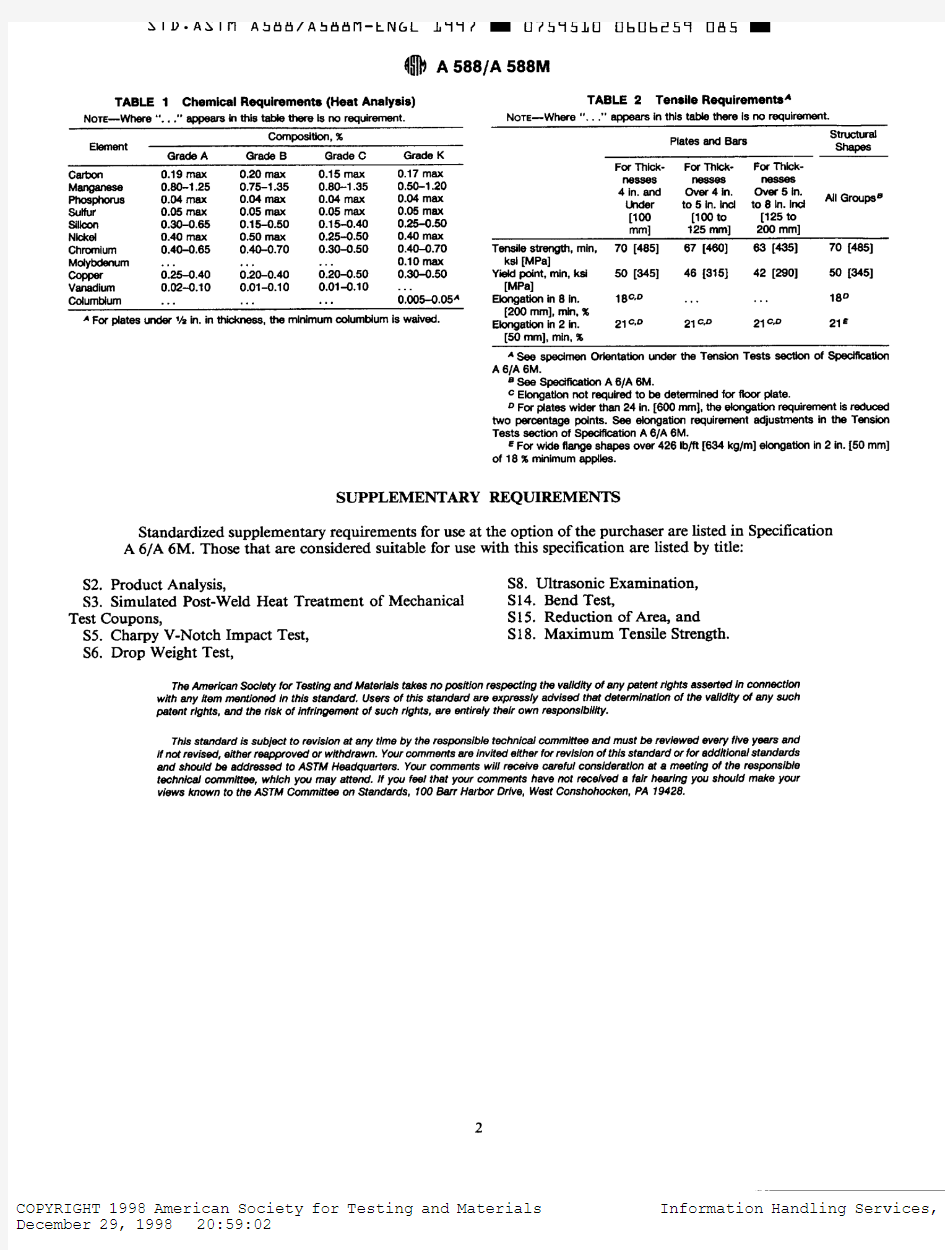

美国耐候钢桥 GR.50W钢板技术条件 1.钢板牌号: GR.50W 2. 规格:板厚≤4in.(≤100mm)。 3.钢板尺寸、外形、重量要求及允许偏差 钢板尺寸、外形、重量要求及允许偏差等应符合ASTM A6/6M 相关条款的规定。 4.技术要求 4.1化学成分(熔炼成分)应符合ASTM A709/A709M-11和表1的规定。 4.2 力学性能检验 4.2.1拉伸试样取横向样。钢板公称厚度≤3/4in.(≤20mm),拉伸试样应取钢板的全厚度,试样尺寸参照A370标准图3;钢板公称厚度>3/4in.(>20mm),拉伸试样直径1/2 in.(12.5mm),试样轴线位于钢板厚度的1/4处,试样尺寸参照A370标准图4;具体细节见A6/A6M 标准拉伸试验一节中试样取样方向与制备条款。试验的频率为每批一个。 4.2.2夏比V型缺口冲击试样取纵向样,轴线位于钢板厚度的1/4处。试验的频率为每批一组三个冲击试样。试样取样与制备具体细节见A673/A673M 标准。 4.2.3 力学性能应符合表2规定。

4.3 交货状态 钢板以热轧或控轧状态交货,允许采用正火或回火处理。 为了提高韧性,允许采用比在空气中冷却速率快的冷却方式进行冷却,但钢板要进行回火处理,回火温度范围为1100~1300℉(595~705℃),且在材质单中注明。 5. 表面质量 5.1 钢板表面不得有气泡、结疤、拉裂、折叠、夹杂和压入的氧化铁皮,不得有 分层; 5.2 表面允许有不妨碍表面检查的薄层氧化铁皮、铁锈,由于压入氧化铁皮脱落 所引起的不显著的粗糙、划痕、轧辊造成的网纹及其他局部缺陷允许存在,但不得超过厚度公差之半,并应保证钢板的最小厚度; 5.3 允许采用修磨方法消除表面缺陷,但不得焊补; 6. 探伤 根据需要,厚度6/5in.(30mm)以上钢板可以按照ASTM A435进行超声波探伤,Ⅱ级为合格。 需要探伤的钢板应在采购明细中标明。 7. 试验和检验 7.1 组批 每批由同一炉罐号、同一厚度、同一交货状态的钢板组成,每批重量<49.2ton(<50吨)。 7.2 试验次数和试样的制备及复验均符合ASTM A6/A6M标准的要求。

美标ASTM标准的中文对照大全

ASTM A6/A6M-2004 a结构用轧制钢板、型钢、板桩和棒钢通用要求 ASTM A36/A36M2004碳结构钢标准规范 ASTM A106-2002a高温用无缝碳钢公称管规范 ASTM A143-2003热侵镀锌结构钢制品防脆化的标准实施规程和催化探测方法 ASTM A179/A179M-1990a(R2001)热交换器和冷凝器用无缝冷拉低碳钢管标准规范 ASTM A192-2002高压设备用无缝碳钢锅炉管标准规范 ASTM A209/A209M-2003锅炉和过热器用无缝碳钼合金钢管标准规范 ASTM A210/A210M-2003锅炉和过热器用无缝中碳钢管技术条件 ASTM A213/A213Mb-2004锅炉过热器和换热器用无缝铁素体和奥氏体合金钢传热管技术条件 ASTM A234/A234M-2004中、高温用锻制碳钢和合金钢管道配件 ASTM A252-98(R2002)焊接钢和无缝钢管桩的标准规范 ASTM A262-2002a探测奥氏体不锈钢晶间腐蚀敏感度的标准实施规范 ASTM A269/A269-2004通用无缝和焊接奥氏体不锈钢管标准规范 ASTM A333/A333M-2004低温设备用无缝和焊接钢管的规范标准 ASTM A334/A334M-2004低温设备用无缝和焊接碳素和合金钢管的标准规范ASTM A335-2003高温设备用无缝铁素体合金钢管标准规范 ASTM A370/A370M-2003a钢制品力学性能试验方法和定义标准 ASTM A387/A387M-2003压力容器用铬钼合金钢板的标准规范 ASTM A403/A403M-2004锻制奥氏体不锈钢管配件的标准规范 ASTM A450/A450M-2004碳素钢管、铁素体合金钢管及奥氏体合金钢管一般要求的标准规范 ASTM A500-2003a圆形与异型冷成型焊接与无缝碳素钢结构管标准规范

美标材质规格

ASTM A1-00(2005) 碳素钢T型钢轨规格 ASTM A1000-05 特种弹簧质量级碳钢丝及合金钢丝规格 ASTM A100-07 硅铁规格 ASTM A1001-01(2006) 硅铁规格 ASTM A1002-99(2003) 镍-铝有序合金铸件规格 ASTM A1003/A1003M-05 冷成形框式构件用金属和非金属镀层碳素钢薄板规格 ASTM A1004/A1004M-99(2004) 准备用作冷成形框架构件的金属、涂漆金属和非金属涂敷钢薄板规格 ASTM A1005/A1005M-00(2004) 平端纵焊缝和螺旋焊缝双重埋弧焊干线用黑钢管规格ASTM A1006/A1006M-00(2004) 平端激光束焊接干线用黑钢管规格 ASTM A1007-02(被ASTM A1007-07代替) 钢丝绳用碳素钢丝规格 ASTM A1008/A1008M-07(被ASTM A1008/A1008M-07a 代替) 高强度低合金冷轧碳素结构钢薄板以及可成型性、溶液硬化和可烘烤硬化性经改进的高强度低合金冷轧碳素结构钢薄板规格 ASTM A1008/A1008M-07a 高强度低合金冷轧碳素结构钢薄板以及可成型性、溶液硬化和可烘烤硬化性经改进的高强度低合金冷轧碳素结构钢薄板规格 ASTM A1009-05 高频(10kHz-1 MHz)电力变压器和滤波感应器用软磁MnZn铁芯材料标准规范 ASTM A1010/A1010M-01e1 更高强度马氏体不锈钢厚板、薄板和带材规格 ASTM A101-04 铬铁规格 ASTM A1011/A1011M-06b(被ASTM A1011/A1011M-07代替) 高强度低合金冷轧碳素结构钢薄板和带材、可成型性经改进的高强度低合金冷轧碳素结构钢薄板和带材以及具有超高强度的低合金冷轧碳素结构钢薄板和带材的规格 ASTM A1011/A1011M-07 高强度低合金冷轧碳素结构钢薄板和带材、可成型性经改进的高强度低合金冷轧碳素结构钢薄板和带材以及具有超高强度的低合金冷轧碳素结构钢薄板和带材的规格 ASTM A1012-02(2007) 带整体式散热片的铁素体、奥氏体和二相合金钢冷凝器与热交换器无缝管及焊接管的规格 ASTM A1013-00(2005) 用伏特计、安培计和瓦特计测定可控温度下软磁芯部件的高频(10 kHz-1 MHz)磁芯损耗的标准试验方法 ASTM A1014/A1014M-06 高温工作用沉淀硬化螺栓材料(UNS N07718)规格 ASTM A1015-01(2005) 卫生设施用管状产品管内图像检测指南 ASTM A1016/A1016M-04A 铁素体合金钢、奥素体合金钢和不锈钢管通用要求规格 ASTM A1017/A1017M-07 压力容器用铬钼钨合金钢中厚板规格 ASTM A1018/A1018M-06c(被ASTM A1018/A1018M-07代替) 碳素钢、市售钢、拉制钢、结构钢、高强度低合金钢、可成型性经改进的高强度低合金钢以及超高强度钢热轧薄板、带材和特厚卷材规格 ASTM A1018/A1018M-07 碳素钢、市售钢、拉制钢、结构钢、高强度低合金钢、可成型性经改进的高强度低合金钢以及超高强度钢热轧薄板、带材和特厚卷材规格 ASTM A1019/A1019M-01(2007) 下水道和排水管用聚合物预涂的直径为36英寸或不足36英寸[900 mm]的闭合肋钢管规格 ASTM A1019/A1019M-01(被ASTM A1019/A1019M-01(2007)代替) 下水道和排水管用聚合物预涂的直径为36英寸或不足36英寸[900 mm]的闭合肋钢管规格 ASTM A1020/A1020M-02 锅炉、过热器、热交换器和冷凝器设备用溶焊碳钢和碳锰钢管道规

CB-30成分及力学性能(根据美标ASTM A743标准)

25 Commerce Road, Orillia, Ontario, Canada L3V 6L6 Phone (705) 325-2781 Fax (705) 325-5887 ALLOY DATA SHEET CORROSION RESISTANT ALLOY CB-30REVISION: 09/95 DESCRIPTION CB-30 is a non-hardenable, ferritic Fe-Cr-Ni alloy with good resistance to nitric acid, alkaline solutions and organic chemicals and food products. The alloy also has good oxidation and sulphidation resistance at temperatures up to 1400o F and is consequently used in the mineral processing industry. COMPOSITION C Mn Si Cr Ni P S Min %18.0 Max % 0.30 1.0 1.5021.0 2.00.040.04 APPLICATIONS Valve bodies and parts, shredders, furnace brackets and hangers, rabble arms and tube supports. PRODUCT FORMS Horizontal and vertical centrifugal castings; static castings. PHYSICAL PROPERTIES Density (lbs/in3)0.272 Melting Point(o F)2725 Thermal Conductivity12.8 @ 212o F (Btu/h/ft2/ft/o F)14.5@ 1000o F Thermal Expansion 5.7@ 70-212o F (10-6in/in o F) 6.5@ 70-1000o F 6.7@ 70-1300o F Magnetic Permeability Ferromagnetic MECHANICAL PROPERTIES (Typical Values at Room Temperature) Annealed @1450o F, F.C. to1000o F, then A.C ASTM Spec.A743 U.T.S. K.S.I.9565 Min. Y.S. K.S.I.6030 Min Elong.% 15 Brinell H B 195 Key ft-lbs 2

ASTMA材质规格对照表

ASTM A 美标材质规格大全对照表 2-- ASTM A3-01(2006) 低、中、高碳素钢 (未经热处理的 )连接板规格 ASTM A302/A302M-03 压力容器用锰钼及锰钼镍合金钢厚板规格 ASTM A304-05e2 须符合端部淬火硬度要求的碳钢与合金钢棒材规格 ASTM A307-07a 抗拉强度为 60000psi 的碳素钢螺栓和螺柱的技术规范 ASTM A308/A308M-06 热浸法镀锡(铅锡合金)薄钢板规格 ASTM A309-01(2007) 用三点试验法测定长镀锌薄钢板镀层的重量成分的试验方法 ASTM A309-01( 被 ASTM A309-01(2007) 代替 ) 用三点试验法测定长镀铅锡薄钢板镀层的 重量及成份的方法 ASTM A31-04e1 钢铆钉及铆钉和压力容器用棒材 压力容器用钢铆钉和铆钉用钢棒规格 无缝焊接冷加工奥氏体不锈钢管规格 不锈钢弹簧钢丝规格 锻造用不锈及耐热钢坯及钢棒规格 高温无压部件用灰铁铸件 低温用合金钢和不锈钢螺栓材料规格 ASTM A322-06( 被 ASTM A322-07 代替 ) 标准级合金钢棒材规格 ASTM A322-07 合金钢棒材 .级别 ASTM A323-05 硼铁合金规格 ASTM A324-73(2004) 钛铁规格 ASTM A325-06( 被 ASTM A325-07 代替 ) 经热处理最小抗拉强度为 构螺栓 经热处理最小抗拉强度为 830Mpa 的热处理钢结构螺栓 铸铁冲击试验方法 铸铁冲击试验方法 (米制 ) 钢板桩规格 低温用无缝与焊接钢管规格 低温用无缝与焊接碳素合金钢管钢管规格 高温用无缝铁素体合金钢管规格 被 ASTM A336/A336M-07 代替 ) 压力与高温部件用合金钢锻件规 ASTM A338-84(2004) 用 的可锻铸铁法兰 ,管件和阀门零件 ASTM A34/A34M-06 磁性材料的抽样和采购试验的标准惯例 ASTM A340-03a 有关磁性试验用符号和定义的术语 ASTM A341/A341M-00(2005) 用直流磁导计和冲击试验法测定材料的直流磁性能的试验 方法 ASTM A342/A342M-04 磁铁材料导磁率的试验方法 ASTM A343/A343M-03 在电力频率下用瓦特计 -安培计 -伏特计法 (100-1000 赫兹 )和25 厘 米艾普斯亭 (EPSTEIN) 机架测定材料的交流电磁性能的试验方法 ASTM A345-04 磁设备用平轧电炉钢 ASTM A348/A348M-05 用瓦特计 --安培计 --伏特计法 (100-10000 赫兹)和25厘米艾普斯亭框 测定材料的交流磁性能的试验方法 ASTM A350/A350M-04A 管道部件用切口韧性试验要求的碳素钢与低合金钢锻件规格 ASTM A351/A351M-06 承压零件用奥氏体、奥氏体 -铁素体 (复合)钢铸件规格 ASTM A352/A352M-06 低温受压零件用铁素体和马氏体钢铸件规格 ASTM A353/A353M-04 压力容器用经二次正火及回火处理的含 9% 镍的合金钢厚板规格 ASTM A354-07 淬火与回火合金钢螺栓 ,双头螺栓及其他外螺纹紧固件规格 ASTM A311/A311M-04 ASTM A312/A312M-06 ASTM A313/A313M-03 ASTM A314-97(2002) ASTM A319-71(2006) ASTM A320/A320M-07 120/105ksi 的热处理钢结 ASTM A325M-05 ASTM A327-91(2006) ASTM A327M-91(2006) ASTM A328/A328M-07 ASTM A333/A333M-05 ASTM A334/A334M-04A ASTM A335/A335M-06 ASTM A336/A336M-06A( 格 压力与高温部件用合金钢锻件规格 铁路 ,船舶和其他重型装备在温度达到 650华氏度 (345 摄氏度 )时使 ASTM A336/A336M-07

美标材料简介ASME ASTM AISI

This document was copied from Website. The person who uploaded this document is not responsible for the correctness. This document is only used for private study, not used for commercial. 本文件内容从网页复制,上传人不对文件内容正确性负责。本文用于学习非商业用途。 Introduction - AISI ASTM ASME and UNS Most ASTM and ASME standards list the steel grades by their UNS (Unified Numbering system) numbers but also make reference, where appropriate to the more general AISI (American Iron and Steel Institute) grade designations. These grade numbering systems are widely used in the USA, where they originated and are recognized by most stainless steel specifies and users. The American Iron and Steel Institute (AISI) developed designations such as 304, 430 etc and published compositions for these in their 'Steel Products Manual' (1974). These are NOT specifications, but steel grade composition ranges only. These grades were used by the American Society Testing and Materials (ASTM) to identify grades in a wide range of standards they published for stainless products, such as sheets and plates (ASTM A240), bars (ASTM A276) and tubes (ASTM A269). The compositions of the AISI grades were made more specific with the introduction of the 'Unified Numbering System', jointly established by ASTM and SAE (Society of Automotive Engineers). This five digit number, preceded by the letter 'S' for most stainless steels, identified the specific variant of the grade e.g. 304 being UNS S30400, 304L being UNS S30403 American Society of Mechanical Engineers (ASME) publish design codes and standards for pressure applications. ASME standards are generally based on the appropriate ASTM standards, but the standard numbers are preceded with the letters 'SA', rather than just the 'A' of the ASTM standards. Where UNS grade numbers are used, these are universal, regardless of the product type or the standard in which they appear. The AISI designations have been adopted in Japan. The AISI number is preceded with the letters SUS e.g. SUS 304. The Japanese have developed variants on some grades for certain product forms e.g. SUS 304J1 for sheet products. The composition ranges should always be checked in the appropriate standard. Composition tables The tables in this article use the UNS number as their key, but also show the related AISI and SAE numbers. Where appropriate, common names for the steels are also shown. There are some differences in the composition ranges for some grades between flat and long products. This is due to the harmonisation process which is aimed to bring US and European compositions into line. This process is more advanced for flat products than for long.

ASTM A材质规格对照表

ASTM A美标材质规格大全对照表2-- ASTM A3-01(2006) 低、中、高碳素钢(未经热处理的)连接板规格 ASTM A302/A302M-03 压力容器用锰钼及锰钼镍合金钢厚板规格 ASTM A304-05e2 须符合端部淬火硬度要求的碳钢与合金钢棒材规格 ASTM A307-07a 抗拉强度为60000psi的碳素钢螺栓和螺柱的技术规范 ASTM A308/A308M-06 热浸法镀锡(铅锡合金)薄钢板规格 ASTM A309-01(2007) 用三点试验法测定长镀锌薄钢板镀层的重量成分的试验方法ASTM A309-01(被ASTM A309-01(2007)代替) 用三点试验法测定长镀铅锡薄钢板镀层的重量及成份的方法 ASTM A31-04e1 钢铆钉及铆钉和压力容器用棒材 ASTM A311/A311M-04 压力容器用钢铆钉和铆钉用钢棒规格 ASTM A312/A312M-06 无缝焊接冷加工奥氏体不锈钢管规格 ASTM A313/A313M-03 不锈钢弹簧钢丝规格 ASTM A314-97(2002) 锻造用不锈及耐热钢坯及钢棒规格 ASTM A319-71(2006) 高温无压部件用灰铁铸件 ASTM A320/A320M-07 低温用合金钢和不锈钢螺栓材料规格 ASTM A322-06(被ASTM A322-07代替) 标准级合金钢棒材规格 ASTM A322-07 合金钢棒材.级别 ASTM A323-05 硼铁合金规格 ASTM A324-73(2004) 钛铁规格 ASTM A325-06(被ASTM A325-07代替) 经热处理最小抗拉强度为120/105ksi的热处理钢结构螺栓 ASTM A325M-05 经热处理最小抗拉强度为830Mpa的热处理钢结构螺栓 ASTM A327-91(2006) 铸铁冲击试验方法 ASTM A327M-91(2006) 铸铁冲击试验方法(米制) ASTM A328/A328M-07 钢板桩规格 ASTM A333/A333M-05 低温用无缝与焊接钢管规格 ASTM A334/A334M-04A 低温用无缝与焊接碳素合金钢管钢管规格 ASTM A335/A335M-06 高温用无缝铁素体合金钢管规格 ASTM A336/A336M-06A(被ASTM A336/A336M-07代替) 压力与高温部件用合金钢锻件规格 ASTM A336/A336M-07 压力与高温部件用合金钢锻件规格 ASTM A338-84(2004) 铁路,船舶和其他重型装备在温度达到650华氏度(345摄氏度)时使用的可锻铸铁法兰,管件和阀门零件 ASTM A34/A34M-06 磁性材料的抽样和采购试验的标准惯例 ASTM A340-03a 有关磁性试验用符号和定义的术语 ASTM A341/A341M-00(2005) 用直流磁导计和冲击试验法测定材料的直流磁性能的试验方法 ASTM A342/A342M-04 磁铁材料导磁率的试验方法 ASTM A343/A343M-03 在电力频率下用瓦特计-安培计-伏特计法(100-1000赫兹)和25 厘米艾普斯亭(EPSTEIN) 机架测定材料的交流电磁性能的试验方法 ASTM A345-04 磁设备用平轧电炉钢 ASTM A348/A348M-05 用瓦特计--安培计--伏特计法(100-10000赫兹)和25厘米艾普斯亭框

ASTMASME美标碳锰硅钢板SA537CL1,SA537CL2

一、概述: ASTM/ASME美标碳锰硅钢板SA537CL1,SA537CL2,SA537CL3二、详细说明:ASTM/ASME 美标碳锰硅钢板SA537CL1,SA537CL2,SA537CL3执行标准:ASTM/ASME 用途:美标压力容器板,广泛应用于石油、化工、电站、锅炉等行业,用于制作反应换热器、分离器、球罐、油气罐、液化气罐、核能反应堆压力壳、锅炉汽包、液化石汽瓶、水电站高压水管、水轮机蜗壳等设备及构件。 二、 1.SA537的化学成分 2.SA537钢板的机械性能 3.SA537钢板的低温冲击性能

三、舞阳钢厂钢板直销,钢厂一级代理商,面向企业终端供应。有钢板需求请直接来电。 185*955*03577专业销售舞阳钢厂生产的各规格特宽厚钢板,主要产品有:容器板,合金板,建筑板,高强度板,模具板,耐磨板,耐腐蚀板,密度板,桥梁板,核电用钢,军工钢等。公司一贯坚持“质量第一,用户至上,优质服务,信守合同”的宗旨,凭借着高质量的产品,良好的信誉,优质的服务,产品畅销全国近三十多个省、市、自治区以及远销美英日等国家。竭诚与国内外商家双赢合作,共同发展,共创辉煌! 我公司供应如下钢板牌号:调质高强度钢板:WH70Q,(C、D、E、),WH80Q,(D、E),WH100QD,WQ690D, WQ690E,WQ700D,WQ700E,Q690D,Q690E,A/SA533B,A/SA533C,SA514系列,SA514Q,SA514QF,SA514GrF,A516GrQ,A517GrQ,S690Q,S690QL,S890Q,S960Q,S960QL,WQ890 D,WQ960C,WQ960D,WQ960E。 TMCP热机械控制工艺、高强度钢板:其钢板牌号: Q500E,E500,S500 压力钢管及蜗壳用调质型高强钢板:WDB620,WDB620C,WDB620D,WDB620E。 调质:造船钢板及海上采油平台用钢板:EQ56,EQ70, E420,E550。 桥梁钢板 :A709M-HPS-485W临氢Cr-Mo: 临氢SA387Gr11, 临氢SA387Gr12, 临氢SA387Gr22, 临氢15CrMoR, 临氢14Cr1MoR,临氢12Cr2Mo1R, 临氢12Cr2Mo1VR 临氢2.25Cr1Mo0.25V。非临氢Cr-Mo:15CrMoR,SA387Gr11, SA387Gr12, SA387Gr22,12Cr2Mo1R,13CrMo4-5,15CrMo,10CrMo9-10。压力容器板:12Cr1MoV,13MnNiMoR, 13MnNiMoNbR,14Cr1MoR, 20MnMoR, 20MnMo,20MnMoNi55,25CrMoVA,A48CPR,SA612,A/SA533,SA533GrB CL2,A302,SA302M,SA302GrA, SA302GrB, SA302GrC, A302GrD ,SA387Gr5。 锅炉汽包板:SA299A/B,BHW35,DlWA353, 13MnNiMo5-4。 HlC,R-HIC系列钢板:SA516Gr65 (HlC),SA516Gr70 (HlC),16MnR (A- HlC),16MnR (R- HlC). 核电用压力容器钢板: 16MnHR,(Q345R),20HR,(Q275R),20MnHR。 低温钢板: SA203 管线用钢及管件用钢:X70 级、X80 级、抗大变形管线钢及所有级别管线钢板(WPHY70 、WPHY485、WFHY510、X80 (ST)、X60(ST)。 军工用钢板: 603、(30CrMnMoRE),675、(30CrNi3MoV),GY4、(28Cr2Mo),GY5、(26SiMnMo),GS80,厚度≥150mm的Z35 钢、厚度≥200mm的Z15、Z25、Z35、钢。

美标ASTM标准的中文对照大全

A S T M A6/A6M-2004a结构用轧制钢板、型钢、板桩和棒钢通用要求A S T M A36/A36M2004碳结构钢标准规范A S T M A106-2002a高温用无缝碳钢公称管规范A S T M A143-2003热侵镀锌结构钢制品防脆化的标准实施规程和催化探测方法A S T M A179/A179M-1990a(R2001)热交换器和冷凝器用无缝冷拉低碳钢管标准规范A S T M A192-2002高压设备用无缝碳钢锅炉管标准规范A S T M A209/A209M-2003锅炉和过热器用无缝碳钼合金钢管标准规范A S T M A210/A210M-2003锅炉和过热器用无缝中碳钢管技术条件

ASTM A213/A213Mb-2004锅炉过热器和换热器用无缝铁素体和奥氏体合金钢传热管技术条件A S T M A234/A234M-2004中、高温用锻制碳钢和合金钢管道配件A S T M A252-98(R2002)焊接钢和无缝钢管桩的标准规范A S T M A262-2002a探测奥氏体不锈钢晶间腐蚀敏感度的标准实施规范A S T M A269/A269-2004通用无缝和焊接奥氏体不锈钢管标准规范A S T M A333/A333M-2004低温设备用无缝和焊接钢管的规范标准A S T M A334/A334M-2004低温设备用无缝和焊接碳素和合金钢管的标准规范A S T M A335-2003高温设备用无缝铁素体合金钢管标准规范

A S T M A370/A370M-2003a钢制品力学性能试验方法和定义标准A S T M A387/A387M-2003压力容器用铬钼合金钢板的标准规范A S T M A403/A403M-2004锻制奥氏体不锈钢管配件的标准规范ASTM A450/A450M-2004碳素钢管、铁素体合金钢管及奥氏体合金钢管一般要求的标准规范A S T M A500-2003a圆形与异型冷成型焊接与无缝碳素钢结构管标准规范A S T M A515-2003中温及高温压力容器用碳素钢板的标准规范A S T M A516-2004a中温及低温压力容器用碳素钢板的标准规范A S T M A530-2003特种碳素钢和合金钢管一般要求的标准规范

ASTMA美标材质规格大全对照表2

ASTM-A美标材质规格大全对照表-2 ASTM A3-01(2006)低、中、高碳素钢(未经热处理的)连接板规格 ASTM A302/A302M-03 压力容器用锰钼及锰钼镍合金钢厚板规格 ASTM A304-05e2 须符合端部淬火硬度要求的碳钢与合金钢棒材规格 ASTM A307-07a 抗拉强度为60000psi的碳素钢螺栓和螺柱的技术规范 ASTM A308/A308M-06热浸法镀锡(铅锡合金)薄钢板规格 ASTM A309-01(2007) 用三点试验法测定长镀锌薄钢板镀层的重量成分的试验方法 ASTM A309-01(被ASTM A309-01(2007)代替) 用三点试验法测定长镀铅锡薄钢板镀层的重量及成份的方法 ASTM A31-04e1 钢铆钉及铆钉和压力容器用棒材 ASTM A311/A311M-04压力容器用钢铆钉和铆钉用钢棒规格 ASTM A312/A312M-06无缝焊接冷加工奥氏体不锈钢管规格 ASTM A313/A313M-03 不锈钢弹簧钢丝规格 ASTM A314-97(2002) 锻造用不锈及耐热钢坯及钢棒规格 ASTM A319-71(2006) 高温无压部件用灰铁铸件 ASTM A320/A320M-07 低温用合金钢和不锈钢螺栓材料规格 ASTM A322-06(被ASTM A322-07代替) 标准级合金钢棒材规格 ASTM A322-07 合金钢棒材.级别 ASTM A323-05硼铁合金规格 ASTM A324-73(2004)钛铁规格 ASTM A325-06(被ASTM A325-07代替)经热处理最小抗拉强度为120/105ksi的热处理钢结构螺栓 ASTM A325M-05 经热处理最小抗拉强度为830Mpa的热处理钢结构螺栓 ASTM A327-91(2006) 铸铁冲击试验方法 ASTM A327M-91(2006) 铸铁冲击试验方法(米制) ASTM A328/A328M-07 钢板桩规格 ASTM A333/A333M-05 低温用无缝与焊接钢管规格 ASTM A334/A334M-04A低温用无缝与焊接碳素合金钢管钢管规格 ASTM A335/A335M-06 高温用无缝铁素体合金钢管规格 ASTM A336/A336M-06A(被ASTM A336/A336M-07代替) 压力与高温部件用合金钢锻件规格ASTM A336/A336M-07 压力与高温部件用合金钢锻件规格 ASTM A338-84(2004) 铁路,船舶和其他重型装备在温度达到650华氏度(345摄氏度)时使用的可锻铸铁法兰,管件和阀门零件 ASTM A34/A34M-06 磁性材料的抽样和采购试验的标准惯例 ASTM A340-03a 有关磁性试验用符号和定义的术语 ASTM A341/A341M-00(2005) 用直流磁导计和冲击试验法测定材料的直流磁性能的试验方法ASTM A342/A342M-04 磁铁材料导磁率的试验方法 ASTM A343/A343M-03在电力频率下用瓦特计-安培计-伏特计法(100-1000赫兹)和25 厘米艾普斯亭(EPSTEIN) 机架测定材料的交流电磁性能的试验方法 ASTM A345-04 磁设备用平轧电炉钢 ASTM A348/A348M-05用瓦特计--安培计--伏特计法(100-10000赫兹)和25厘米艾普斯亭框测

ASTM 美标标准号索引-中英对照表

ASTM 美标标准号索引-中英对照表 发布时间:06-11 作者:本站来源:本站点击次数:878 ASTM标准中英对照 标准号英文名称中文名称 A1-00(2005) Standard Specification for Carbon Steel Tee Rails 碳素钢丁字轨 A2-02 Standard Specification for Carbon Steel Girder Rails of Plain, Grooved, and Guard Types 普通型,带槽和防护型碳素工字钢轨 A3-01(2006) Standard Specification for Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated) 低、中、高碳素钢鱼尾(连接)板 A6/A6M-05a Standard Specification for General Requirements for Rolled Structural Steel Bars, Plates, Shapes, and Sheet Piling 轧制结构钢板材、型材和薄板桩通用技术要求 A20/A20M-05 Standard Specification for General Requirements for Steel Plates for Pressure Vessels 压力容器用钢板材通用要求 A27/A27M-05 Standard Specification for Steel Castings, Carbon, for General Application 通用碳素钢铸件 A29/A29M-05 Standard Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements for 热锻及冷加工碳素钢和合金钢棒 A31-04 Standard Specification for Steel Rivets and Bars for Rivets, Pressure Vessels 钢铆钉及铆钉和压力容器用棒材 A34/A34M-01 Standard Practice for Sampling and Procurement Testing of Magnetic Materials 磁性材料的抽样和采购试验的标准惯例A36/A36M-05 Standard Specification for Carbon Structural Steel 碳素结构钢技术规范 A47/A47M-99(2004) Standard Specification for Ferritic Malleable Iron Castings 铁素体可锻铁铸件 A48/A48M-03 Standard Specification for Gray Iron Castings 灰铁铸件 A49-01(2006) Standard Specification for Heat-Treated Carbon Steel Joint Bars, Microalloyed Joint Bars, and Forged Carbon Steel Compromise Joint Bars 热处理碳素钢连接棒材,微合金连接棒材和法兰连接棒材的标 准规范

ASTM+F+1816-1997(美标)

Designation:F1816–97(Reapproved2004) Standard Safety Speci?cation for Drawstrings on Children’s Upper Outerwear1 This standard is issued under the?xed designation F1816;the number immediately following the designation indicates the year of original adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.A superscript epsilon(e)indicates an editorial change since the last revision or reapproval. INTRODUCTION Knots,toggles,and other decorative or functional attachments on the ends of long,loose drawstrings can catch and snag on other objects.Two hazards associated with such drawstrings on children’s upper outerwear have been identi?ed:the potential strangulation hazard associated primarily with hood and neck area drawstrings of upper outerwear;the potential vehicular dragging hazard associated primarily with waist and bottom drawstrings of upper outerwear.This consumer safety speci?cation is intended to reduce the risk of drawstrings on children’s upper outwear accessing and getting snagged in various entrapment areas. 1.Scope 1.1This speci?cation covers and is intended to reduce strangulation and vehicular dragging hazards associated with drawstrings on children’s upper outerwear. 1.2The type of clothing covered by this speci?cation is girls’and boys’clothing,such as jackets and sweatshirts, generally intended to be worn on the exterior of other clothing. 1.3The sizes covered by this speci?cation are sizes2T to12 for neck/hood drawstrings and sizes2T to16for waist/bottom drawstrings. 1.4Upper outerwear with fully retractable drawstrings are exempt. The values stated in inch-pound units are to be regarded as the standard.The SI units given in parentheses are for information only. 2.Referenced Documents 2.1ASTM Standards: D5219Terminology Relating to Body Dimensions for Apparel Sizing2 3.Terminology 3.1De?nitions of Terms Speci?c to This Standard: 3.1.1bartack,n—the stitching through the drawstring and channel usually at the back center of the channel to prevent the drawstring’s being pulled through its channel. 3.1.2bottom of upper outerwear,n—the edge that circum-scribes the lowest part of the garment(most distant from the neck area). 3.1.3drawstring,n—a non-retractable cord,ribbon,or tape of any material to pull together parts of upper outerwear to provide for closure. 3.1.4hood,n—a loose,pliable covering for the head,either detachable or permanently attached to upper outerwear. 3.1.5neck area,n—the area1in.(25mm)above or below the neck opening. 3.1.6neck opening,n—the opening is de?ned by the seam between the body of the upper outerwear and the collar or hood. 3.1.7toggle,n—the wooden,plastic,metal or otherwise-composed piece attached to the loose end of the drawstring for decorative purposes or to prevent the drawstring’s being drawn through its channel. 3.1.8upper outerwear,n—clothing,such as jackets and sweatshirts,generally intended to be worn on the exterior of other garments. 3.1.9waist,n—the narrowed part of the body between the chest and hips(see Terminology D5219). 4.Performance Requirements 4.1There shall be no drawstrings in the hood and neck area of children’s upper outerwear sizes2T to12. 4.2Drawstrings at the waist and bottom of children’s upper outwear sizes2T to16shall: 4.2.1Not exceed3in.(75mm)in length outside the drawstring channel when the garment is expanded to its fullest width, 4.2.2Have no toggles,knots,or other attachments at the free ends,and 4.2.3Be bartacked,if the drawstring is one continuous string(see3.1.6). 1This speci?cation is under the jurisdiction of ASTM Committee F15on Consumer Products and is the direct responsibility of Subcommittee F15.37on Drawstrings for Children’s Clothing. Current edition approved Jan.1,2004.Published January2004.Originally approved https://www.360docs.net/doc/0f14509586.html,st previous edition approved in1997as F1816–97. 2For referenced ASTM standards,visit the ASTM website,https://www.360docs.net/doc/0f14509586.html,,or contact ASTM Customer Service at service@https://www.360docs.net/doc/0f14509586.html,.For Annual Book of ASTM Standards volume information,refer to the standard’s Document Summary page on the ASTM website. 1 Copyright?ASTM International,100Barr Harbor Drive,PO Box C700,West Conshohocken,PA19428-2959,United States.