Phase composition of alumina–mullite–zirconia refractory materials

Available online at https://www.360docs.net/doc/0014819809.html, Journal of the European Ceramic Society30(2010)

29–35

Phase composition of alumina–mullite–zirconia refractory materials

C.Zanelli?,M.Dondi,M.Raimondo,G.Guarini

CNR-ISTEC,Institute of Science and Technology for Ceramics,48018Faenza,Italy

Received1April2009;received in revised form15July2009;accepted16July2009

Available online28August2009

Abstract

Refractories in the Al2O3–SiO2–ZrO2system are widely used in many applications,for ceramic rollers in particular,and are characterized by high mechanical strength,excellent thermal shock resistance,resistance to corrosion by alkaline compounds and low creep at high temperature.Their performances greatly depend on the amount and chemical composition of crystalline and glassy phases,which were investigated by quantitative XRPD(RIR–Rietveld)and XRF in order to assess the effect of various Al2O3/SiO2ratios of starting batches and different alumina particle size distributions.Refractories consist of mullite,corundum,zirconia polymorphs and a vitreous phase in largely variable amounts.The mullite percentage,unit cell parameters and composition vary with sintering temperature,being mostly in?uenced by the Al2O3/SiO2ratio of the batch.Its orthorhombic unit cell increased its volume from1400to1500?C,while its stoichiometry became more aluminous.The corundum stability during ?ring is strongly affected by the Al2O3/SiO2ratio,but not by the particle size distribution of alumina raw materials.Zirconia raw materials are involved in the high temperature reactions and about one-third of the available ZrO2is dissolved in the glassy phase,ensuring excellent resistance to alkali corrosion,mainly depending on the fraction of coarse alumina.The phase composition of the vitreous phase increased with sintering temperature,being over20%when the fractions of coarse alumina in the starting batch are between0.2and0.5.

?2009Elsevier Ltd.All rights reserved.

Keywords:Mullite;Al2O3–SiO2–ZrO2;Corundum;Glassy phase;Refractory;XRD;Zirconia

1.Introduction

An important category of refractories in the Al2O3–SiO2–ZrO2system is based on corundum,mullite and baddeleyite structures.It is widely utilized in forehearth,feeders,glass-melting furnaces,as plungers,tubes,channels,mantle blocks, and ori?ce rings.1These materials are extensively used as refrac-tory rollers in fast?ring kilns for the manufacture of ceramic tiles,tableware and sanitaryware.2,3In this sector,?ring tech-nology has undergone a rapid innovation over the last decades, and has under great pressure to reduce both energy consump-tion and?ring times.Changes in tile size and composition of fast-?red bodies and glazes brought about the progressive rear-rangement of composition and properties of ceramic rollers in order to meet ever-increasing requirements.Current expecta-tions involve improved performance in terms of refractoriness (higher operating temperatures,up to1300?C),thermal shock ?Corresponding author.Tel.:+390546699718;fax:+39054646381.

E-mail address:chiara.zanelli@https://www.360docs.net/doc/0014819809.html,r.it(C.Zanelli).resistance( T about1200?C),extreme resistance to corrosion by alkaline and alkaline-earth elements(coming from contact with bodies and glazes),and creep due to increasing length of rollers(over450cm)and rising load of ceramic tiles(from10 to over20kg/m2).4

The bodies for alumina–mullite–zirconia refractories are composed of raw and calcined kaolins,alumina with different particle size distribution and zirconium compounds,includ-ing zirconia–mullite composites.Their sintering is commonly carried out in the1400–1600?C range with prolonged soak-ing times.The resulting phase composition consists of mullite, corundum,zirconia polymorphs and a vitreous phase in largely variable amounts.Several phase transformations occur during ?ring:

(a)decomposition of clay minerals,involving dehydroxilation

of kaolinite around500?C and further transformation over 1000?C into mullite and silica;

(b)quartz usually disappears over1300?C,being incorporated

in mullite or the liquid phase;

(c)zircon tends over1400?C to dissociate into zirconia,which

on cooling undergoes the polymorphic transformation from

0955-2219/$–see front matter?2009Elsevier Ltd.All rights reserved. doi:10.1016/j.jeurceramsoc.2009.07.016

30 C.Zanelli et al./Journal of the European Ceramic Society 30(2010)29–35

the tetragonal to the monoclinic form,so that both phases may occur in the ?nal product.5–8

Such considerable compositional variability,depending to some extent on the phase evolution with ?ring temper-ature,can signi?cantly affect the technological properties of refractories.9–14For this reason,several studies have focused on the possibility of improving the performances of alumina–mullite–zirconia refractories,in particular mechanical properties,thermal shock behavior and corrosion resistance,by varying amount and particle size distribution of raw materials.15–22For example,by increasing the zircon amount or adding ?ne-grained alumina densi?cation was improved through a signi?cant reduction of porosity.Faster sintering was observed together with the formation of a liquid phase ?lling interparticle voids.8–13

Therefore,many technological properties of alumina–mullite–zirconia refractories greatly depend on phase composition.For example,it is expected that an increase of the mullite-to-corundum ratio will improve the thermal shock resis-tance,since mullite has a thermal expansion coef?cient much lower than corundum.On the other hand,creep at high tempera-ture and resistance to corrosion by alkaline compounds depend to a large extent on the amount of glassy phase and its chemical composition.21

At any rate,existing literature mainly deals with alumina–mullite–zirconia refractories from the technological viewpoint and the extent of phase transformations occurring dur-ing sintering is still not suf?ciently known.The aim of the present paper is to bridge this gap by investigating how phase compo-sition,as well as chemical composition of mullite and vitreous phase,may change by varying the batch formulation and ?r-ing temperature.In particular,the effect of various Al 2O 3/SiO 2ratios and different alumina particle size distributions has been appraised by quantitative X-ray diffraction analysis.2.Experimental procedure

Twenty-three batches suitable for industrial refractory bod-ies were designed in order to get a wide range of chemical compositions (especially of Al 2O 3/SiO 2ratios)and particle size distributions (of corundum).Every body consists of kaolin (20–30%),different kinds of alumina,each with its own particle size distribution (50–60%),zirconium compounds (10–15%),and amorphous silica (<5%).

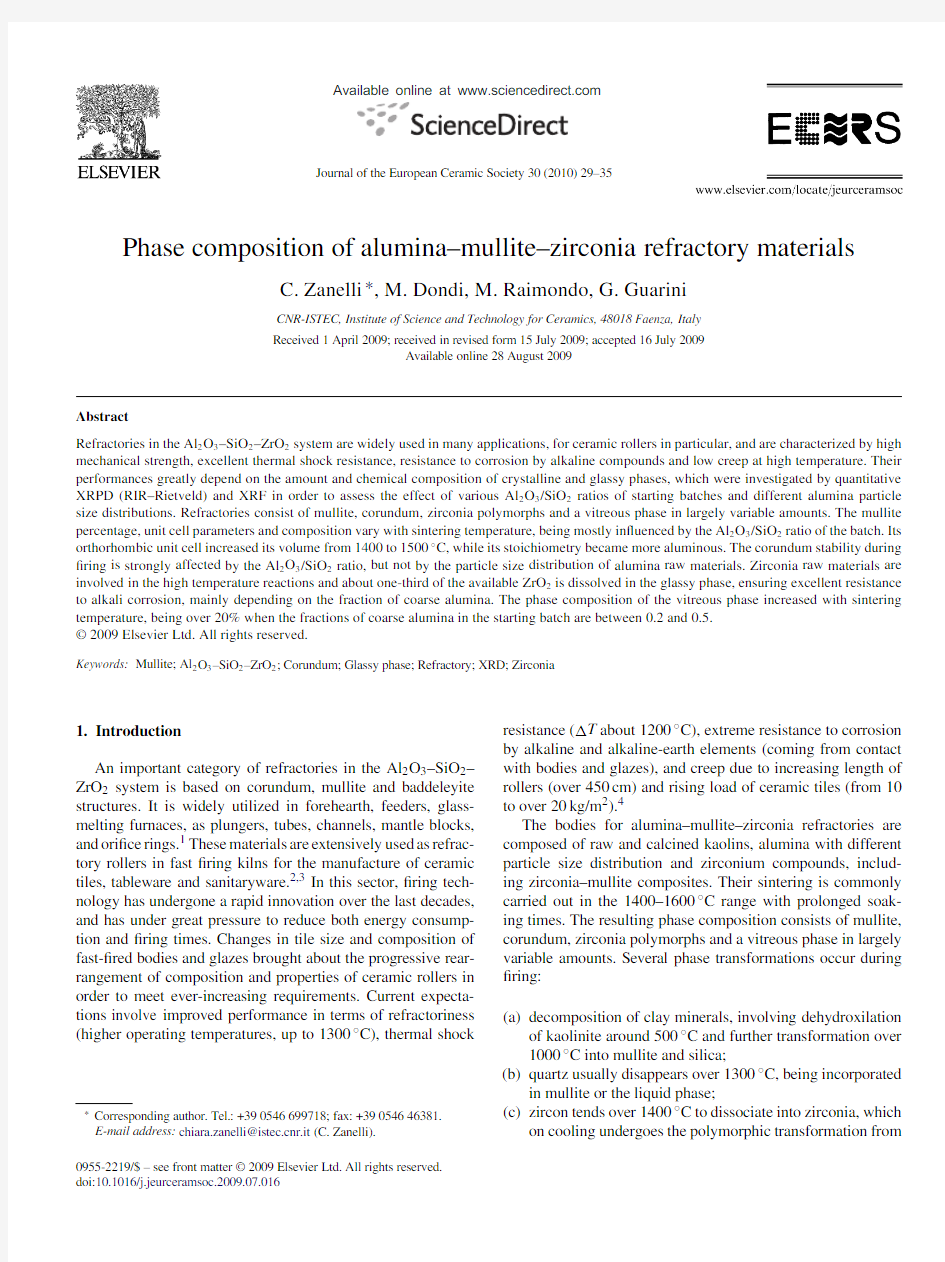

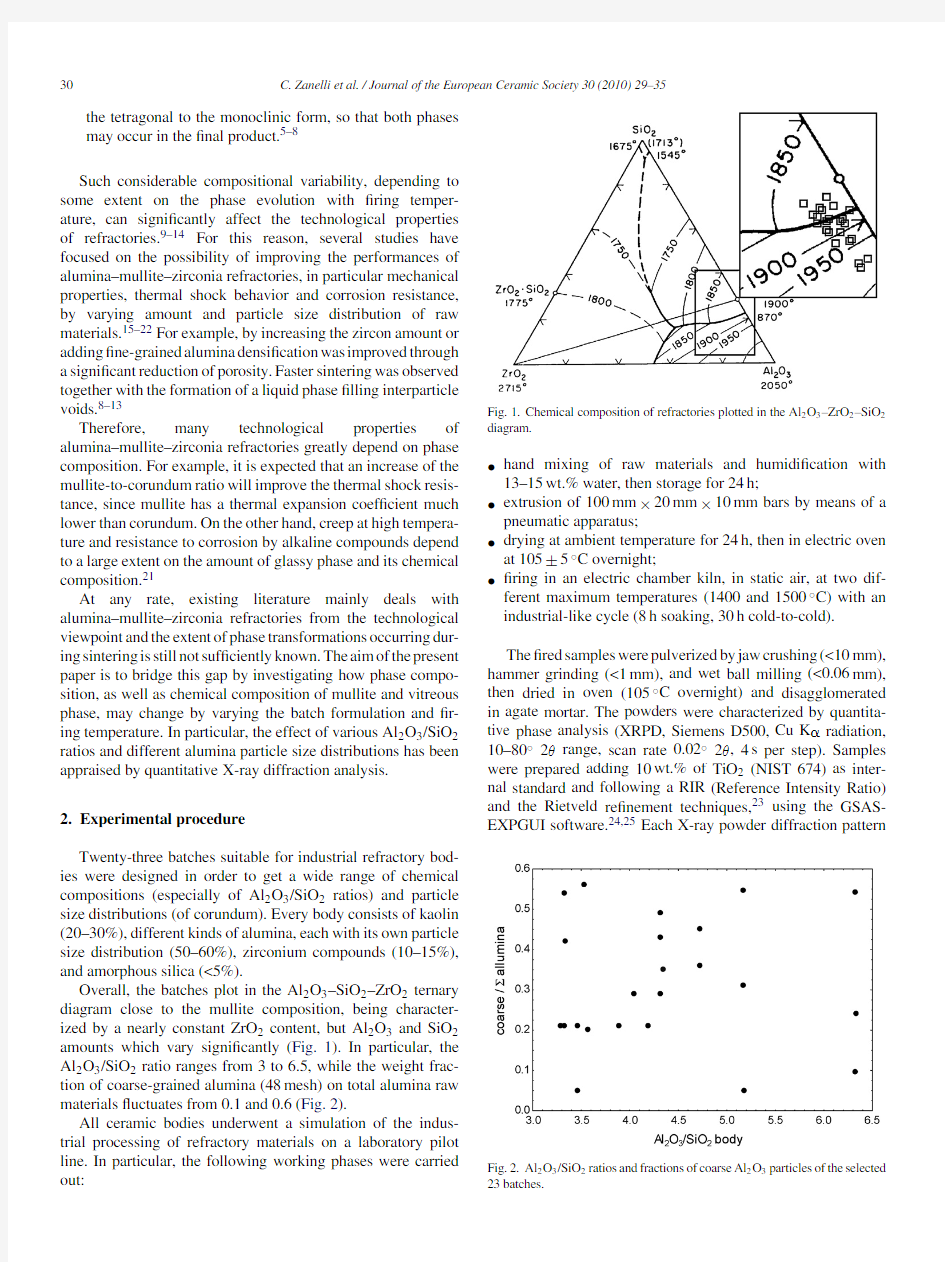

Overall,the batches plot in the Al 2O 3–SiO 2–ZrO 2ternary diagram close to the mullite composition,being character-ized by a nearly constant ZrO 2content,but Al 2O 3and SiO 2amounts which vary signi?cantly (Fig.1).In particular,the Al 2O 3/SiO 2ratio ranges from 3to 6.5,while the weight frac-tion of coarse-grained alumina (48mesh)on total alumina raw materials ?uctuates from 0.1and 0.6(Fig.2).

All ceramic bodies underwent a simulation of the indus-trial processing of refractory materials on a laboratory pilot line.In particular,the following working phases were carried

out:

Fig.1.Chemical composition of refractories plotted in the Al 2O 3–ZrO 2–SiO 2diagram.

?hand mixing of raw materials and humidi?cation with 13–15wt.%water,then storage for 24h;

?extrusion of 100mm ×20mm ×10mm bars by means of a pneumatic apparatus;

?drying at ambient temperature for 24h,then in electric oven at 105±5?C overnight;

??ring in an electric chamber kiln,in static air,at two dif-ferent maximum temperatures (1400and 1500?C)with an industrial-like cycle (8h soaking,30h cold-to-cold).The ?red samples were pulverized by jaw crushing (<10mm),hammer grinding (<1mm),and wet ball milling (<0.06mm),then dried in oven (105?C overnight)and disagglomerated in agate mortar.The powders were characterized by quantita-tive phase analysis (XRPD,Siemens D500,Cu K ?radiation,10–80?2θrange,scan rate 0.02?2θ,4s per step).Samples were prepared adding 10wt.%of TiO 2(NIST 674)as inter-nal standard and following a RIR (Reference Intensity Ratio)and the Rietveld re?nement techniques,23using the GSAS-EXPGUI software.24,25Each X-ray powder diffraction

pattern

Fig.2.Al 2O 3/SiO 2ratios and fractions of coarse Al 2O 3particles of the selected 23batches.

C.Zanelli et al./Journal of the European Ceramic Society30(2010)29–35

31

Fig.3.Plot of Rietveld re?nement performed on X-ray powder diffraction data. The experimental data are indicated by plus signs,the calculated pattern is the continuous line and the lower curve is the weighted difference between the calculated and observed patterns.The rows of vertical tick marks shows the allowed re?ections for the crystalline phases present in the sample. consists approximately of4000data point and400re?ections;an example of Rietveld re?nement is shown in Fig.3.The starting structural models were taken from Ban and Okada26for mullite, selecting the temperatures closer to that of body?ring(1400and 1600?C);from Oetzel and Heger27for corundum,for zirconia polymorphs from Wang et al.28,and for rutile from the database NIST.29Up to40independent variables were re?ned:phase frac-tions,zero point,15–20coef?cients of the shifted Chebyschev function to?t the background,unit cell parameters,pro?le coef-?cients(one Gaussian,G w,and one Lorentzian term,L x).For some samples the preferred orientation along the plane[330]of corundum was re?ned using the March-Dollase approximation.

The agreement indices,as de?ned in GSAS,for the ?nal least-squares cycles of all re?nements are represented by R p(%),R wp(%),X2and R(F2)(%).25,26For the re?ned patterns,they were found in the following ranges:

8.5% 9.5% The experimental uncertainty of in the quantitative determi-nation of phases amount is within5%relative. The chemical composition of mullite was calculated by means of unit cell parameters on the basis of the empirical rela-tionship between the length of the unit cell edge a and the Al2O3 content27: Al2O3(mol.%)=1443(length of axis a)?1028.06 The chemical composition of the vitreous phase was cal-culated from the bulk chemistry of each batch,subtracting the individual contributions of every crystalline phase(mullite, corundum and zirconia according to their own stoichiometry) then normalizing to100%. In this study,the contour maps were used as a means of inter-preting the phase transformations investigated,in terms of their amounts.The contour maps were obtained by the Statistica30 software:every plot is an optimized linear interpolation from which three dimensional surfaces can be generated.The maps sort the Al2O3–SiO2–ZrO2system by its fraction of coarse par-ticles on the whole alumina of the batch on the ordinate and the Al2O3/SiO2ratio of the body on the abscissa.The amount of each phase at the two sintering temperatures(1400–1500?C)is represented by color?elds. 3.Results and discussion The industrial refractories under investigation consist of mullite,corundum,zirconia(baddeleyite predominant over the tetragonal polymorph)and a vitreous phase.The most abundant phase is mullite,usually ranging from50to60%after sinter-ing at1400?C and rising to60–80%after?ring at1500?C.As observed in the literature,5,8,31–34increasing the mullite content, a proportional decreasing of corundum occurs,whose amount goes from20–35%(1400?C)down to15–30%(1500?C),while zirconia remains in nearly constant amount(2–6%).The glassy phase,present in relatively small amount(10–13%)at the lower sintering temperature,remarkably increases after?ring at1500?C(15–25%). The unit cell parameters of mullite vary in rather restricted ranges(0.7550nm ). Fig.4.Variation of mullite a and c unit cell parameters at different sintering temperatures. 32 C.Zanelli et al./Journal of the European Ceramic Society 30(2010) 29–35 Fig.5.Al 2O 3/SiO 2ratio of the body vs.the alumina content of mullite. The corundum stability during ?ring depends to a large extent on the Al 2O 3/SiO 2ratio,as it can be appreciated in the contour maps (Fig.8).The limited effect of the particle size of alu-mina raw materials on the ?nal corundum content is somehow unexpected. Fig.6.Amount of mullite in the bodies vs.the alumina content of mullite. During sintering,mullite–corundum–zirconia refractories undergo a complex chemical balance,involving not only the phase amounts,but also the composition of mullite and vitre-ous phase.In fact,the glass formed in the 1400–1500?C range Fig.7.Contour maps of mullite amount (wt.%)at two sintering temperatures (1400–1500?C)as function of the Al 2O 3/SiO 2ratio of the body and the fraction of coarse particles (48mesh)on the total raw alumina of the batch (coarse/ alumina). () Fig.8.Contour maps of corundum amount (wt.%)at two sintering temperatures (1400–1500?C)in function of the Al 2O 3/SiO 2ratio of the body and the fraction of coarse particles (48mesh)on the total raw alumina of the batch (coarse/ alumina).(For interpretation of the references to color in this ?gure legend,the reader is referred to the web version of the article.) C.Zanelli et al./Journal of the European Ceramic Society 30(2010)29–35 33 Fig.9.Relation between the Al 2O 3/SiO 2content in the vitreous phase and the Al 2O 3/SiO 2ratio of the mixture. exhibits a wide compositional spectrum,varying in terms of Al 2O 3/SiO 2ratio from below 0.5to about 6at both sinter-ing temperatures,following to some extent the ?uctuations of the Al 2O 3/SiO 2ratio of the batch (Fig.9).Such compositional range is different and much wider than previously observed in the literature 36and might account for different behavior (e.g.resistance to alkali attack,creep). The amount of residual zirconia is not signi?cantly affected by sintering temperature,being always in the 2–6%range.How-ever,it is mainly in?uenced by the particle size distribution of raw alumina,as shown in the contour maps (Fig.10);zir-conia appears to be more stable when the fraction of coarse alumina is either very abundant (>0.5)or scarce (<0.2).Inter-estingly,the vitreous phase contains a relatively large amount of zirconia,corresponding approximately to one-third of total ZrO 2of the batch.This fact is able to explain the excellent resistance to alkali corrosion of mullite–corundum–zirconia refractories,besides their relatively high content of glassy phase.10,21 These chemical compositions of the glassy phase plot in the ternary diagram Al 2O 3–SiO 2–ZrO 2at liquidus temperatures Fig.10.Contour maps of zirconia amount (wt.%)at two sintering temperatures (1400–1500?C)in function of the Al 2O 3/SiO 2ratio of the body and the fraction of coarse particles (48mesh)on the total raw alumina of the batch (coarse/ alumina).(For interpretation of the references to color in this ?gure legend,the reader is referred to the web version of the article.) Fig.11.Contour maps of vitreous phase amount (wt.%)at two sintering temperatures (1400–1500?C)in function of the Al 2O 3/SiO 2ratio of the body and the fraction of coarse particles (48mesh)on the total raw alumina of the batch (coarse/ alumina).(For interpretation of the references to color in this ?gure legend,the reader is referred to the web version of the article.) 34 C.Zanelli et al./Journal of the European Ceramic Society30(2010)29–35 between1750and1850?C,i.e.well above the actual sintering temperatures.Therefore,the role played by impurities,mainly supplied by kaolin,which tend to concentrate in the liquid phase, lowering signi?cantly the melting temperature is important.The amount of these impurities in the glassy phase is estimated to be in the following ranges:0.3–0.5%for Fe2O3,0.2–0.5%for TiO2,0.1–0.3%for alkaline-earth elements and0.1–0.4%for alkalis. A key factor affecting phase equilibria in the mullite–corundum–zirconia refractories segment of the Al2O3–SiO2–ZrO2system seems to be the amount of silica available.The amount of mullite tends to grow up to the maximum permitted by the SiO2content of the batch.Such increasing is stressed at expenses of the glassy phase,since the mullite composition moves towards a term richer in alumina. The amount of vitreous phase at1400?C is in a narrow range(10–15%)while at1500?C it reaches in practically up to 30%for the values of all samples(Fig.11).The contour maps show that the formation of vitreous phase does not depend on the Al2O3/SiO2ratio,but mainly on the particle size distribu-tion of raw alumina:fractions of coarse alumina between0.2 and0.5ensure the formation of over20%liquid phase during sintering. 4.Conclusions Detailed knowledge of phase transformations occur-ring during?ring is fundamental in the design of alumina–mullite–zirconia refractories with optimized techno-logical properties.Their phase composition consists of mullite, corundum,zirconia and a vitreous phase.The amount and chemical composition of these phases vary depending on the ?ring temperature,the Al2O3/SiO2ratio of the batches and the particle size distribution of alumina raw materials. Mullite changes its amount,unit cell parameters and compo-sition with?ring temperature,being mostly in?uenced by the Al2O3/SiO2ratio of the batch.Its structure is of the orthorhom-bic type,and undergoes an increase in its unit cell volume from 1400to1500?C,while its stoichiometry turns to terms richer in alumina. The extent of corundum reaction during?ring depends on the Al2O3/SiO2ratio of the batches,but it is unexpectedly not sig-ni?cantly in?uenced by the particle size distribution of alumina raw materials. Zirconia raw materials are involved in the high temperature reactions and about one-third of the available ZrO2is dissolved, probably giving the glassy phase its excellent resistance to alkali corrosion.Baddeleyite predominantes over tetragonal zirconia and their amount is mainly in?uenced by the particle size distri-bution of raw alumina. The vitreous phase tends to increase with sintering tem-perature,but the formation of over20%liquid phase occurs with intermediate fractions of coarse alumina in the starting batch(0.2–0.5).For the?rst time,an extensive chemical char-acterization of the vitreous phase has been accomplished for mullite–corundum–zirconia refractories.References 1.Aksel, C.,Mechanical properties and thermal shock behaviour of alumina–mullite–zirconia and alumina–mullite refractory materials by slip casting.Ceram.Int.,2003,29,311–316. 2.Sonntag,U.,Variety of ceramic roller materials:answer to increased requirements of new applications and developments.Interceram,2001,50, 380–387. 3.Bettges,H.,High-alumina rollers for rollers kilns.Interceram,1990,39, 28–30. 4.Sonntag,U.,Isenmann,B.,Knape,G.,Sussmuth,M.and Habermann, A.,New roller concepts for extreme applications.Proc.Eng.,2002,79, 22–26. 5.Mazzei,A.C.and Rodrigues,J.A.,Alumina–mullite–zirconia compos- ites obtained by reaction sintering.Part I.Microstructure and mechanical behaviour.J.Mater.Sci.,2000,35,2807–2814. 6.Mazzei,A.C.and Rodrigues,J.A.,Alumina–mullite–zirconia composites obtained by reaction sintering.Part II.R-Curve behavior.J.Mater.Sci., 2000,35,2815–2824. 7.Lee,W.E.,Argent,B.and Zhang,S.,Complex phase equilibria in refracto- ries design and use.J.Am.Ceram.Soc.,2002,85,2911–2918. 8.Ebadzadeh,T.,Reaction sintering of multicomponent mixtures for produc- ing ceramics containing zirconia.J.Eur.Ceram.Soc.,2000,20,725–729. 9.Koyama,T.,Hayashi,S.,Yasumori,A.,Okada,K.,Schmucker,M.and Schneider,H.,Microstructure and mechanical properties of mullite/zirconia composites prepared from alumina and zircon under various?ring condi-tions.J.Eur.Ceram.Soc.,1996,16,231–237. 10.Valle,M.,Gandol?,S.,Dondi,M.and Fabbri,B.,Effectiveness of various zirconium compounds in the body to improve the alkaline attack resistance of ceramic rollers.In Fourth Euro-Ceramics,vol.13,1995,pp.131–136. 11.Aksel,C.,The in?uence of zircon on the mechanical properties and thermal shock behaviour of slip-cast alumina–mullite refractories.Mater.Lett.,2002, 57,992–997. 12.Aksel,C.,The role of?ne alumina and mullute particles on the thermo- mechanical behaviour of alumina–mullite refractory materials.Mater.Lett., 2002,57,708–714. 13.Aksel,C.,Dexet,M.,Logen,N.,Porte,F.,Riley,F.L.and Konieczny,F., The in?uence of zircon in a model aluminosilicate glass tank forehearth refractory.J.Eur.Ceram.Soc.,2003,23,2083–2088. 14.Aksel,C.,The effect of mullite on the mechanical properties and thermal shock behaviour of alumina–mullite refractory materials.Ceram.Int.,2003, 29,183–188. 15.Valle,M.,Gandol?,S.,Dondi,M.and Fabbri,B.,Determination of thermal shock resistance in ceramic rollers.In Fourth Euro-Ceramics,vol.3,1995, pp.465–470. 16.Bas?pinar,M.S.,Schulle,W.and Kara,F.,Fundamental for optimization of binding for high refractory mullite products.Key Eng.Mater.,2004, 264–268,1787–1790. 17.Collini,M.and Rowcliffe,D.,Analysis and prediction of thermal shock in brittle materials.Acta Mater.,2000,48,1655–1665. 18.Wang,G.and Krstic,V.,Roles of porosity,residual stresses and grain size in the fracture of brittle solids.Philos.Mag.A,1998,78(5),1125–1135. 19.Aksel,C.,Mechanical properties of alumina–mullite–zircon refractories. Key Eng.Mater.,2004,264–268,1791–1794. 20.Aksel,C.,The in?uence of?ne alumina particles on the mechanical proper- ties and thermal shock behaviour of slip-cast alumina–mullite refractories. Key Eng.Mater.,2004,264–268,1811–1814. 21.Aksel,C.,Riley,F.L.and Konieczny,F.,The corrosion resistance of alumina–mullite–zircon refractories in molten glass.Key Eng.Mater.,2004, 264–268,1803–1806. 22.Takatak,S?.,Artir,R.,Yilmaz,S?.and Bindal,C.,Fracture toughness of alumina–mullite composites produced by in?ltration process.Key Eng. Mater.,2004,264–268,981–984. 23.Gualtieri,A.F.,Accuracy of XRPD QPA using the combined Rietveld–RIR method.J.Appl.Cryst.,2000,33,267–278. https://www.360docs.net/doc/0014819809.html,rson,A.C.and V on Dreele,R.B.,General structure analysis system (GSAS).In Los Alamos National Laboratory Report LAUR,2000,pp. 86–748. C.Zanelli et al./Journal of the European Ceramic Society30(2010)29–3535 25.Toby,B.H.,EXPGUI,a graphical user interface for GSAS.J.Appl.Cryst., 2001,34,210–221. 26.Ban,T.and Okada,K.,Structure re?nement of mullite by the Rietveld method and a new method for estimation of chemical composition.J.Am. Ceram.Soc.,1992,75,227–230. 27.Oetzel,M.and Heger,G.,Laboratory X-ray powder diffraction:a compar- ison of different geometries with special attention to the usage of the CuK alpha doublet.J.Appl.Cryst.,1999,32,799–807. 28.Wang,D.,Guo,Y.,Liang,K.and Tao,K.,Crystal structure of zirconia by Rietveld re?nement.Sci.China,1999,42,80–86. 29.SRM674b,Standard Reference Materials.In X-Ray Powder Diffrac- tion Intensity Set for Quantitative Analysis by X-Ray Powder Diffraction. National Institute of Standards&Technology,Gaithersburg,USA,2005. 30.STATISTICA7.1.StatSoft Italia s.r.l.,2005. 31.Madsen,I.C.,Finney,R.J.,Flann,R.C.A.,Frost,M.T.and Wilson,B. W.,Quantitative analysis of high-alumina refractories using X-ray powder diffraction data and the Rietveld method.J.Am.Ceram.Soc.,1991,74, 619–624. 32.Rupo,E.D.and Anseu,M.R.,Solid state reactions in the ZrO2·SiO2– ?Al2O3system.J.Mater.Sci.,1980,15,114–118. 33.Duran,C.and Tur,Y.K.,Phase formation and texture development in mul- lite/zirconia composites fabricated by templated grain growth.J.Mater.Sci., 2006,41,3303–3313. 34.Zhao,S.,Haung,Y.,Wang,C.,Haung,X.and Guo,J.,Mullite formation from reaction sintering of ZrSiO4/?-Al2O3mixtures.Mater.Lett.,2003,57, 1716–1722. 35.Cameron,W.E.,Composition and cell dimension of mullite.Ceram.Bull., 1977,56,1003–1011. 36.Aksel,C.,The microstructural features of an alumina–mullite–zirconia refractory material corroded by molten glass.Ceram.Int.,2003,29, 305–309. Cleanert Alumina N中性氧化铝萃取柱,1000mg/6mL,30支/包 产品包装尺寸 产品参数 图文介绍 Agela Technologies 吸附型萃取柱 ·Cleanert Florisil是一种高选择性的吸附剂。这种吸附剂主要有三种成分组成,二氧化硅(84%),氧化镁(15.5%)和硫酸钠(0.5%)。是一种效果良好,成本经济的常用固相萃取填料。特定为AOAC,EPA等方法设计,用于农药残留的净化﹑分离、内分泌物及油脂的分离、PCBs,PAHs,烃类中含氮化合物和抗生素物质的分离等。常用于农残分析中去除色素,为NY761分析方法中必备的样品前处理小柱。 ·Cleanert PestiCarb采用新型碳黑材料(球形)为填料,具有高净化效果,高回收率和高重现性的优良特性,广泛应用于农残分析中,特别是蔬菜水果等色素较高的样品的前处理中。相当于Envi carb填料。常用于农残分析中去除色素等杂质。 ·Cleanert Alumina N 中性氧化铝萃取柱pH=7.5;强极性吸附剂。表面呈中性,容易保留杂环类(含氮,磷,硫基),芳香烃和有机胺等富电子化合物。经过特殊去活处理,以保证样品的前处理。应用于维生素,抗菌素,芳香油,酶,糖苷,激素等的样品前处理。广泛用于苏丹红和孔雀石绿的样品前处理。 ·Cleanert Alumina A 酸性氧化铝萃取柱pH=4.5,可作为强极性吸附和中等阳离子交换剂。经过特殊去活处理,以保证样品的回收率。可做为中等阳离子交换剂。 ·Cleanert Alumina B (碱性氧化铝萃取柱),pH=10,经过特殊去活处理,以保证样品回收率。可用于除去有机酸,酚类等。 小学生作文批改方法及 步骤 公司内部档案编码:[OPPTR-OPPT28-OPPTL98-OPPNN08] 小学生作文批改方法及步骤第一步:学生自改作文 学生在练习本上写完自己的作文后,自己阅读、修改自己的作文。但是,学生个人修改,往往“只缘身在此山中”,而且限于水平,文章中的毛病,作者常常自己看不出来。 首先要求学生对自己的作文进行复看审核,查找出标点、错别字以及不通顺的句子,并进行改正。 接着从题意、中心、内容、感情、结构、语言等方面来一个“回头望”,多问几个“是什么”或“怎么样”,对自己的作文进行从点到面,实事求是的评价。 最后,对文章再次阅读,寻找出自己本次作文的最大亮点,或指出今后作文中应该改进的地方,在这样的自我修改,自我反思的过程中,学生的写作能力也在不断提高着。 第二步:小组内互改作文 组内成员都完成作文后,在组长的带领下,针对每一个组员的作文进行一一共同阅读,共同修改。 修改时要注意: 1格式是否正确。 2找出错别字。将错字在原文处打下标记,在后面写上正确的字。 3找出病句。挑出病句划上横线,修改正确。 4标点符号。强调句号、引号、叹号、问号的使用。 5看文章的中心是否鲜明、集中。以上五点是写文章最低的要求。学生经过三四篇文章的批文实践,就能够掌握这几条要求了。修改后,组员再次阅读自己修改后的作文,最后抄写在课堂作文本上。 第三步:各小组互改互评作文 互改互评课上,各小组间交换作文。同样,在组长的带领下,对四本作文进行一一阅读、批改。 1、各小组互改的操作方法: ①格式是否正确。打开作文一看正确,拿出红笔,写上批语,格式正 确;不正确的要批语指出,并修改出正确格式。比如:书信、建议书等等格式。格式不正确扣2分。 ②页面是否整洁。希望学生批改别人作文指出书面不整洁或书写不工 整时,下次自己写作文也要注意,达到自己教育自己的目的。 ③修改错别字。将错字在原文处打下标记,写上正确的字。这样使粗心的同学也认真起来,批改的时候,手里抱着大字典,唯恐漏掉了错别字。发现错别字,每两个扣1分,最多扣5分。10个以上也不再多扣。 ④修改病句或语句不通。挑出病句划上横线,写出病因在何处,再在文中进行修改,每处病句减1分,减至5分,不再多减。 ⑤标点符号有明显错误。强调句号、引号、叹号、问号的使用。明显错误的地方,有一处扣1分,超过5分不再多扣。以上五条在组内时基本就解决完成,小组互换后只是再次检查并作扣分处理,一般经过第一次组内处理都比较好。 Properties of Alumina/Aluminum Oxide (Al2O3): Very good electrical insulation Moderate to extremely high mechanical strength Very high compressive strength High hardness Moderate thermal conductivity High corrosion and wear resistance Good gliding properties Low density Operating temperature without mechanical load 1,000 to 1,500°C. food compatible Applications of Aluminum Oxide (Al2O3): Examples of applications for aluminum oxide Al2O3 advanced ceramics are heavy-duty forming tools, substrates and resistor cores in the electronics industry, tiles for wear protection and ballistics, thread guides in textile engineering, seal and regulator discs for water taps and valves, heat-sinks for lighting systems, protection tubes in thermal processes or catalyst carriers for the chemicals industry. 3) Attention, please! I’ve something to tell you. Professor Jackson—an English disabled person will come to our school to give us a lecture from 2 to 4 o’clock on the afternoon of April 25 in Room 302, the No. 3 teaching building. His lecture is about how he smoothed away all sorts of difficulties he had met. When he was eight years old, he lost his left leg and right arm in an accident. He struggled in his life and managed to look after himself. He also achieved great success in his work. After the lecture we will have a discussion in groups on how to encourage disabled people, how to help them and how to learn from Professor Jackson. Thank you. 4) Of all the teachers, Mr Moore is the one who impresses me most. Though he is 34, he looks very young for his age. And he’s one of the most popular teachers in our school. Compared with other teachers, Mr Moore pays more attention to his way of teaching. He tries various ways to make his classes lively and interesting. In his opinion, we should not only know “what”, but also understand “why”. So, instead of giving us answers immediately, he encourages us to think by ourselves whenever he puts forward questions. With his help, we’ve learned how to analyze and settle problems. What a wonderful world of “why” he leads us to! He is such a learned person that we all admire him very much. 5) Welcome to our school. I feel it an honour to have the chance to tell you something about our school class. We have one hour activities from 4:20 to 5:20 in the afternoon. Some students read books in the reading room; some have sports on the playground; some sing songs in the theater; some learn to operate computers in the lab and others take part in their group work about different subjects. The majority are most interested in sports and computers. We hope that we can have less homework and moretime to join the activities. We are also looking forward to more visits and tour trips. Thank you. 6)Dear editor, In some places in our country the surroundings is worsening with the air filled with heavy smoke, many mountains turning deserted and rivers polluted. Waste is scattered here and there. So I strongly suggest that the government take effective measures to stop this. 小学生作文批改方法及 步骤 Company number:【WTUT-WT88Y-W8BBGB-BWYTT-19998】 小学生作文批改方法及步骤 第一步:学生自改作文 学生在练习本上写完自己的作文后,自己阅读、修改自己的作文。 但是,学生个人修改,往往“只缘身在此山中”,而且限于水平,文章中的毛病,作者常常自己看不出来。首先要求学生对自己的作文进行复看审核,查找出标点、错别字以及不通顺的句子,并进行改正。接着从题意、中心、内容、感情、结构、语言等方面来一个“回头望”,多问几个“是什么”或“怎么样”,对自己的作文进行从点到面,实事求是的评价。最后,对文章再次阅读,寻找出自己本次作文的最大亮点,或指出今后作文中应该改进的地方,在这样的自我修改,自我反思的过程中,学生的写作能力也在不断提高着。正如叶圣陶先生所说:“批改固教者之要务,然须进一步想,必使学生能自改其文,或文成达而竟不须改,乃有济也。” 第二步:小组内互改作文 组内成员都完成作文后,在组长的带领下,针对每一个组员的作文进行一一的共同阅读,共同修改。修改时要注意: 1格式是否正确。 2找出错别字。将错字在原文处打下标记,在后面写上正确的字。 3找出病句。挑出病句划上横线,修改正确。 4标点符号。强调句号、引号、叹号、问号的使用。 5看文章的中心是否鲜明、集中。 以上五点是写文章最低的要求。学生经过三四篇文章的批文实践,就能够掌握这几条要求了。修改后,组员再次阅读自己修改后的作文,最后抄写在课堂作文本上。 第三步:各小组互改互评作文 互改互评课上,各小组间交换作文。同样,在组长的带领下,对四本作文进行一一阅读、批改。在以前的作文批改中,我首先对所有学生的作文通览一遍,找出其中具有代表性的文章,在作文课上和学生一起进行批改。同时,注意向学生介绍规范性的批改符号,讲解具体的批改方法,从点到面,对典型作文进行全方位的改评。这样做,不但使学生学到了别人作文的长处,起到取长补短,互相促进的作用,而且也使学生学到了作文修改的方法。 1、各小组互改的操作方法: ①格式是否正确。打开作文一看正确,拿出红笔,写上批语,格式正确;不正确的要批语指出,并修改出正确格式。比如:书信、建议书等等格式。格式不正确扣2分。 ②页面是否整洁。希望学生批改别人作文指出书面不整洁或书写不工整时,下次自己写作文也要注意,达到自己教育自己的目的。酌情扣2—3分。 Cleanert Alumina A酸性氧化铝,1000mg/6mL,30支/包 产品包装尺寸 产品参数 图文介绍 Agela Technologies 吸附型萃取柱 ·Cleanert Florisil是一种高选择性的吸附剂。这种吸附剂主要有三种成分组成,二氧化硅(84%),氧化镁(15.5%)和硫酸钠(0.5%)。是一种效果良好,成本经济的常用固相萃取填料。特定为AOAC,EPA等方法设计,用于农药残留的净化﹑分离、内分泌物及油脂的分离、PCBs,PAHs,烃类中含氮化合物和抗生素物质的分离等。常用于农残分析中去除色素,为NY761分析方法中必备的样品前处理小柱。 ·Cleanert PestiCarb采用新型碳黑材料(球形)为填料,具有高净化效果,高回收率和高重现性的优良特性,广泛应用于农残分析中,特别是蔬菜水果等色素较高的样品的前处理中。相当于Envi carb填料。常用于农残分析中去除色素等杂质。 ·Cleanert Alumina N 中性氧化铝萃取柱pH=7.5;强极性吸附剂。表面呈中性,容易保留杂环类(含氮,磷,硫基),芳香烃和有机胺等富电子化合物。经过特殊去活处理,以保证样品的前处理。应用于维生素,抗菌素,芳香油,酶,糖苷,激素等的样品前处理。广泛用于苏丹红和孔雀石绿的样品前处理。 ·Cleanert Alumina A 酸性氧化铝萃取柱pH=4.5,可作为强极性吸附和中等阳离子交换剂。经过特殊去活处理,以保证样品的回收率。可做为中等阳离子交换剂。 ·Cleanert Alumina B (碱性氧化铝萃取柱),pH=10,经过特殊去活处理,以保证样品回收率。可用于除去有机酸,酚类等。 产品Products 铝锭Aluminum Ingot 氧化铝alumina ,aluminum oxide 氢氧化铝Hydrogen alumina 电解铝electrolyse aluminum 镀铝aluminum plating 铝板Aluminum Board/plate/sheet 花纹铝板Aluminum embossed sheet 彩铝板colored Aluminum plate 纯铝板pure Aluminum plate 复合铝板clad aluminium 硬铝板duralumin sheet 铝合金Aluminum alloy 锻用铝合金aluminum alloy for temper 铝铜合金aluminum copper alloy 铝基合金aluminum base alloy 铝铁合金aluminum iron alloy 铝镁合金aluminum magnesium alloy 铝镍合金aluminum nickel alloy 铝硅合金aluminum silicon alloy 铝基硅镁合金anticorodal 耐蚀铝合金corrosion-proof/ corrosion- resistant/ corrosion resisting aluminum alloy 铝黄铜aluminum brass 铝青铜aluminum bronze 高铝砖alumina brick 铝合金型材aluminum alloy sections 铝合金线Aluminum alloy wire 铝型材Aluminum profile 铝棒Aluminum stick/rod 铝圆棒Aluminum round bar 铝箔Aluminum foil 铝卷Aluminum roll 铝带/铝条Aluminum strip 铝线Aluminum thread/wire 钢芯铝绞线aluminum cable steel reinforcing 铝管Aluminum pipe/tube 精拉铝管finishing Aluminum tube 伸缩铝管extension Aluminum tube 挤压铝管extruded aluminum pipe 铝管避雷器aluminum cell lightning arrester 挤压铝窗台extruded aluminum sill 铝斜坡Aluminum Ramps 铝曲管bended aluminum tube 铝行业的一些常用英语词汇 产品 Products 铝锭Aluminum Ingot 氧化铝 alumina ,aluminum oxide 氢氧化铝 Hydrogen alumina 电解铝electrolyse aluminum 镀铝aluminum plating 铝板Aluminum Board/plate/sheet 花纹铝板 Aluminum embossed sheet 彩铝板 colored Aluminum plate 纯铝板pure Aluminum plate 复合铝板clad aluminium 硬铝板 duralumin sheet 铝合金Aluminum alloy 锻用铝合金aluminum alloy for temper 铝铜合金aluminum copper alloy 铝基合金aluminum base alloy 铝铁合金aluminum iron alloy 铝镁合金aluminum magnesium alloy 铝镍合金aluminum nickel alloy 铝硅合金aluminum silicon alloy 铝基硅镁合金anticorodal 耐蚀铝合金corrosion-proof/ corrosion- resistant/ corrosion resisting aluminum alloy 铝黄铜aluminum brass 铝青铜aluminum bronze 高铝砖alumina brick 铝合金型材aluminium alloy sections 铝合金线Aluminum alloy wire 铝型材Aluminum profile 铝棒 Aluminum stick/rod 铝圆棒Aluminum round bar 铝箔 Aluminum foil 铝卷 Aluminum roll Phone [301] 695-9400 ? Fax [301] 695-7065 ? trans .tech @https://www.360docs.net/doc/0014819809.html, ? www. trans https://www.360docs.net/doc/0014819809.html, 202896A ? Trans -Tech Propri etary I nformation ? Products and Product Information are Subject to Change Without Notice ? June 13, 2013 1 DATA SHEET Dielectric and Alumina Supports Dielectric Supports Dielectric supports can be used with all disc or cylinder type Dielectric Resonators (DRs) to improve coupling and temperature stability. Contact Trans -Tech , Inc. (TTI) for other support configurations . Figure 1. Disk and Cylinder Types Note: For disk type support, only use the D s and L s dimensions. s s Alumina Supports High Frequency Applications For high frequency applications (above 6 GHz), TTI offer s a special grade of alumina with the properties listed in Table 3. Table 3. Material Characteristics—Alumina Supports for High Cellular and PCS Applications For cellular and PCS frequencies , TTI offer s a different grade of alumina with the properties listed in Table 3. Note: Contact TTI’s factory for available sizes. Table 4. Material Characteristics—Alumina Supports for Cellular 小学生作文的指导方法和要求 以写人物为例说明:(引) 写人,是小学作文训练的基本功之一。在记叙文中,人和事是不可分的,关键是看题目如何要求。要求写事的题目,文中的人要为事服务;要求写人的题目,文中的事必须为人服务。写人为主的记叙文,就是要通过一件或几件事,来表现人物一种或多种品质。写人的继续文,叙事不要求完整;记事的记叙文,虚实要求完整,而且要贯穿文章始终。 (一)通过一件事来写人 通过一件事来写人,通常是表现人物的一种品质或性格的一个方面。为了刻画人物,对所写人物必须进行必要的外貌、语言、动作、心理等方面的描写。但是,从以事写人这个角度来说,最好是选择一件最能反映此人某一特点的事,并把这件事写好。 在写事情的时候,要选择典型的事例。所谓典型,就是能集中反映中心思想的事,能够表现人物的好思想、好品质、美好情感的事。对小学生来说,选择典型事例,要着眼于小事,选择那些最能反映深刻意义的小事。这样的事表面上看,都是普普通通的凡人小事,但是其中却蕴涵着深刻的意义,这就是我们常说的“小中见大”。 (二)通过几件事写人 可以分成两种情况:以是用几件事表现某个人的一种品质;二是用几件事表现某个人的多种品质。 要注意:用几件事写人,这些事可以是完整的,作者必须把事情发生的时间、地点、人物、事件(起因、经过、结果),一一交代清楚,也可以是不完整的,只着重于某几点进行叙述。更多的是在一篇文章中,有的事详写;有的事略写;有的事要求写得比较完整,有的事要求写得比较简单。通过几件事写人,同样要对人物进行必要的外貌、行动、语言、心理的描写。 (三)学会刻画人物 写人的文章要会在叙事的过程中,对最能表现人物思想感情、性格特点的外貌、语言、动作、心理活动等方面进行描写,也就是学会刻画人物。 1.外貌描写 也叫肖像描写,是通过对人物的容貌、神情、衣着、姿态、语调、外貌特征的描写。来揭示人物性格的一种方法。人物的的外貌和人物内心世界密切的联系,具体说:通过外貌描写,使人物的形象更丰满,能给读者留下深刻印象;通过外貌描写,揭示人物的身份;通过外貌描写,展示人物在特定场合的内心世界;通过外貌描写,表现人物性格、精神面貌和思想品质。 总之,外貌描写要和表现人物特点、突出文章的中心思想紧密配合。外貌描写要传神, 中考Composition:一模冲刺作文话题之友情 作文评分标准 中考作文一般从内容、语言、组织结构这三方面进行评分(总分20分):(一)内容(满分8) 7-8分:内容切题,意思连贯,表达清楚、完整。 5-6分:内容基本切题,意思大致连贯,表达基本清楚、但不够完整。 2-4分:内容不够切题,意思不够连贯,表达不够清楚、有些离题。 0-1分:文不对题,表达不清。 (二)语言(满分8) 词数:每少5个单词扣0.5分,以此类推。只写出个别单词、词不成句不给分。 拼写:每处错误扣0.5分,同一错误不重复计数。 语法:每处错误扣0.5分,同一语法错误不重复扣分。 标点符号、大小写:每两处错误扣0.5分,但扣分总和不超过1分。 (三)组织结构(满分4) 内容充实,上下文连贯,用语规范,表达准确,无语法错误;词汇和句型句式运用恰当,多见好句型和习惯表达用语者,可给3-4分。 内容充实,不写废话,上下文连贯,用语规范,表达准确,无或少见语法错误;词汇和句型句式运用恰当,多见好句型和习惯表达用语者,可给2分。 一般情况下,内容和语言累计得分在15分以上者(含),方可得到1-2分组织结构分。 内容和语言在15分以下者,如文中有值得肯定的好的句型和表达,可酌情考虑给1分组织结构分。 通篇句型句式单一、词汇贫乏者,即使无语法错误,一般也不予给组织结构分。 分类作文提纲 一、话题:友情 二、写作思路及结构: 1. 在审题时,学生要注意描写友情时,内容不能太空洞,而是要通过实例来突出某一项品质,或者对自己的影响等;以及朋友是通过哪些具体的方法帮助自己。 2. 注意使用连接词以及高级词汇,使文章逻辑清晰,内容充实;用具体的实例支撑我的观点。最后进行总结; 3. 围绕友谊可以给出一些建议或者保持友谊的秘诀。 三、高频词:happiness,precious,friendship,colorful, meaningful,problems, comfort, regard, discuss, important,charming, smile, success, confident, responsibility, In my opinion,Independence,brave,encourage, experiences,succeed, difficulties, unforgettable, friendly, suggestions, helpful,understand, unbelievable, disappointed,difficult, boring, improve 四、高频短语:get ready for,learn about, by ourselves, as often as possible, face our future life,give up , make friends, get on well with,make efforts, at that time, believe in themselves, make some mistakes, makegreat progress, try my best to, communicate with, look forwards to, have someproblems with, deal with, stop them from doing it, as soon as possible, have anunforgettable experience, increase our knowledge 五、高频句型: 小学作文修改的步骤及方法 修改作文的步骤及方法 建始县实验小学姜灿俊 指导作文修该是贴近学生习作实际的一次指导。学生是习作讲评的主人。为了发挥学生的主体,增强训练意识, 我尝试了以下教学方法。 一.佳作展示,激发兴趣一一乐评 大教育家孔子说过,'‘知之者不如好之者,好之者不如乐之者。”激发学生的兴趣,是作文教学的良好开端。为了刺激学生的 表达欲望,调动学生参与的积极性,推岀四大版块“榜上有名”"佳作亮相” “片断欣赏” “出谋划策”。在“片断欣赏”让学生有感情 地朗读同学的好词佳句,并配上柔和的音乐,创造一种轻松愉悦 的氛围,也使学生获得成功体验,为习作的讲 评创设良好情境。 二.教师对上次作文的修改进行评价、 1、精选点评,范评引路一一会评 最有价值的知识是方法。为了解决这堂课的重点,让学生掌握如何修改作文的方法,我先选择一篇优秀习作,让学生欣赏、剖析, 并指点写作秘诀。这使得学生在接下来的讲评、修改中有个范本。接着我采用知识迁移的的方法,让学生评析“病”例。有了之 前的佳作范评,学生对“病”文的剖析就能胸有成竹。通过剖析典型作文,使学生知道什么样的作文是佳作,懂得“佳”在何处,“病”文“病”在哪里,更认识到平时要注意观察,展开联想,真情实感,遣词造句才能使作文表达更生动具体。这对学生自我评价习作有很大启发,对学生准确评价自己的习作,恰当修改自己的作文有很强的指导意义。 2、合作评改,培养能力——会改 只评不改的作文讲评课是"纸上谈兵”的空洞说教,只有让学生动手修改习作,学生才会有深切的体会,真正的领悟。叶圣陶先生 说:“教师只给些引导和指点,该怎么改让学生自己去考虑去决定。”于是我给学生创设空间,通过小组合作和集体改文实践,学生 在合作评改中互动交流,互相补充,循序渐进地培养了学生对自己作文进行修改的能力,达到举一反三、触类旁通的目的。 三指导修改教师交代本次作文修改的重点内容,回忆本次作文的要求。指导作文修改: 1、组内评改:可以让学生先说说本次作文的要求,根据习作要求确定评改要点,然后在小组内进行作文评改,并选出组内的优秀作文。 2、全班评改:即“佳作”和“病文”评改。老师选出 、二篇好文章和写得不理想的文章,师生根据本次作文的要求,针对字、词、句等进行逐一评改; METHOD 3611B ALUMINA COLUMN CLEANUP AND SEPARATION OF PETROLEUM WASTES 1.0SCOPE AND APPLICATION 1.1Alumina is a highly porous and granular form of aluminum oxide. It is available in three pH ranges (basic, neutral, and acidic) for use in chromatographic cleanup procedures. Method 3611 utilizes neutral pH alumina to separate petroleum wastes into aliphatic, aromatic, and polar fractions. 1.2Method 3611 was formerly Method 3570 in the Second Edition of this manual. 1.3This method is restricted to use by or under the supervision of trained analysts. Each analyst must demonstrate the ability to generate acceptable results with this method. 2.0SUMMARY OF METHOD 2.1The column is packed with the required amount of adsorbent, topped with a water adsorbent, and then loaded with the sample to be analyzed. Elution of the analytes is effected with a suitable solvent(s), leaving the interfering compounds on the column. The eluate is then concentrated (if necessary). 3.0INTERFERENCES 3.1 A reagent blank should be performed for the compounds of interest prior to the use of this method. The level of interferences must be below the method detection limit before this method is performed on actual samples. 3.2More extensive procedures than those outlined in this method may be necessary for reagent purification. 3.3Caution must be taken to prevent overloading of the chromatographic column. As the column loading for any of these types of wastes approaches 0.300 g of extractable organics, separation recoveries will suffer. If overloading is suspected, an aliquot of the base-neutral extract prior to cleanup may be weighed and then evaporated to dryness. A gravimetric determination on the aliquot will indicate the weight of extractable organics in the sample. 3.4Mixtures of petroleum wastes containing predominantly polar solvents, i.e., chlorinated solvents or oxygenated solvents, are not appropriate for this method. 4.0APPARATUS AND MATERIALS 4.1Chromatography column: 300 mm x 10 mm ID, with Pyrex? glass wool at bottom and a polytetrafluoroethylene (PTFE) stopcock. NOTE:Fritted glass discs are difficult to decontaminate after highly contaminated extracts have been passed through. Columns without frits may be purchased. Use a small pad of Pyrex? glass wool to retain the adsorbent. Prewash the CD-ROM3611B - 1Revision 2 December 1996 作文的具体步骤及方法 小学生的语言积累还处于初级阶段,如何写作文,如何写好作文成为他们很大的一个障碍,所以如何提高质量成了他们很关注的问题。 一、作文教学的序列目前国内正在实验的作文教学序列,主要有以下三种: (一)以统编教材为基础的作文教学序列 统编教材的作文扣除安排在教材的“基础训练”中,与阅读教学结合穿插进行。一可分三个阶段: 1、一年级.为中年级写片断做准备阶段。通过看图说话、写话、回答问题等形式训练学生说写一句完整的话、几话连贯的话,同时学写请假条、留言条、简单的日记等应用文。 2、三年级,由说话写话向命题作文过渡阶段。要求能写记人记事和状物的简短的记叙文,要求内容具体,条理比较清楚,语句比较通顺,会用标.点,同时学写板报稿、决心书、通知等应用文。 3、四、五年级,命题作文综合训练阶段。进行记叙文写作方法和作文能力的各项训练,使学生作文逐步做到思想健康、中心明确、内容具体、条理清楚、语句通顺。同时进行一般书信、读书笔记、会议记录等应用文教学。 (二)以景山学校实验教材为基础的作文教学序列 该校实行“读写结合,以作文为中心安排语文教学”,以名家名篇为典范,严格进行写作训练。 一、二年级在集中大量识字的同时,突出字词句的训练进行大量造句、抄书、听写句子和段落、看图写诗写片断、写日记等练习。同时引导学生留心观察和反映周围的人、本、秆境,养成观察习惯,积累写作素材。这样,到二年级下学期,“绝大多数学生就能在教师指导下,写出三、四百字的短文,为下一段作文启蒙打好基础。 三年级是作文启蒙阶段。主要采取“放胆文”的形式,把文章“写开”、“写顺”。从三年级下学期起,就指导学生围绕中,用逻辑思维去选择和组织生活中那些生动、形象、具体的材料,要使文章内容具体,叙述细致生动。 四年级是掌握规律,严格训练阶段,教会学生如何写人、记事、状物等。 五年级是运用规律,提高作文水平阶段,训练学生能写出夹叙夹议央抒情的儿童小品。 修改作文的步骤与方法 第一步是过判断关,就是在通读文章的基础上,对主题(中心)是否突出,观点(态度)是否鲜明,所选材料是否典型,结构是否合理,层次是否清楚,详略是否得当六个方面作出判断,对要修改的文章获得总体认识;第二步是过推敲关,就是在确认文章总体框架的基础上对字、词、句、标点符号的运用作出推敲,进行修改;第三步是过润色关,就是对通过修改后的文章,再作润色。只要教师不厌其烦地强调修改步骤,学生修改作文的良好习惯就会迅速形成,修改能力也就会很快提高。 无论选用哪种方法,均须从两个大的方面去努力。①是指导学生以多角度多层次多方位的思维观去思考修改的重点与方法。②是指导学生脚踏实地地进行逐字、逐词、逐句、逐层的分析修改。这样指导,不仅使学生在修改中懂得了修改方法的取舍,而且学会了运用作文批改术语评点修改作文的方法。 第一步:符号示意法。所谓符号示意法,就是教师在浏览学生作文时,遵循着正确的衡文标准,顺手划下符号,以符号指导学生修改。 这种批改方法,既可以把教师从繁琐的作文批改中解放出来,又可以引导学生自己动手修改文章。 第二步:自改自评法。自改中,学生感到最困难的是:将内容进一步深化。这是学生修改中的障碍,教师在眉批中要善于提出问题,解开结症,插上路标,在他们感知、感受的基础上加以感情的点化,使他们再回到经历过的事件中去,再体验、再消化,以至在认识上迅速得到突破,主题自然地得到升华。 文章自改后,再仔细阅读品味,并写下只言片语的感受,即自评。这种自评不要求全面,只要求真切,防止自评流于形式,或成为学生写作的累赘。 第三步:自评自讲法。学生自改自评后的文章交给教师,教师根据学生的自改自评情况,选出典型,当面加以辅导,让受辅导者在班上作自评自讲。这样不仅提高了该生对作文的认识,培养了口头表达能力,强化了写作兴趣,而且也交流了写作与修改的经验,同学们听来感到亲切,易于接受。与此同时,将产生一种羡慕感、追求感。 学生的自改、自评、自讲的过程,是学生作文逐渐自我完善的过程,教师要把握这一过程的规律,认真培养学生自改自评的习惯,提高学生自改的能力,使他们的文章逐渐达到“理真情切而意达”的境地。 耐火材料词汇 A acid refractory 酸性耐火材料 addition 外加剂 adhesives 粘结剂 affinage furnace 精炼炉 agglutinant 烧结剂 agitator 搅拌机 air set binder 气硬性结合剂 air stove 热风炉 albite 钠长石 alcohol 乙醇 alpha-alumina a氧化铝 alpha phase a相 alumdum powder 刚玉粉 alumdum product 电熔刚玉制品 alumina 氧化铝 sintered alumina 烧结氧化铝 alumina ball 氧化铝球 alumina brick 高铝砖 alumina carbon brick 铝碳砖 alumina carbon refractory 铝碳质耐火材料alumina cement 高铝水泥 alumina-chrome brick 铝铬砖 alumina coats 氧化铝涂层 alumina content 氧化铝含量 alumina fibres 氧化铝纤维 alumina firebrick 氧化铝耐火砖高铝砖alumina-graphite submerged nozzle 铝碳浸入式水口 alumina industry 氧化铝工业 alumina light-weight brick 氧化铝轻质砖alumina-magnesia brick 铝镁砖 alumina powder 氧化铝粉 alumina products 氧化铝制品 alumina refractory 氧化铝质耐火材料alumina refractory bubble products 氧化铝耐火空心球制品 alumina-rich brick 高铝砖 alumina scale 氧化铝结瘤 alumina silica brick 铝硅砖 alumina silica refractory raw materials 硅酸铝质耐火原料 aluminate 铝酸盐 aluminate cement 铝酸盐水泥 aluminate trihydrate 氢氧化铝 alumina ware 氧化铝制品 aluminium 铝Al aluminium carbide 碳化铝 aluminium dust 铝粉 aluminium flakes 铝粉 aluminium hydrate 氢氧化铝 aluminium hydroxide 氢氧化铝aluminium nitride 氮化铝 aluminium orthophosphate 正磷酸铝aluminium oxide 氧化铝 aluminium oxide fiber 氧化铝纤维Cleanert Alumina N中性氧化铝萃取柱,1000mg_6mL,30支_包

小学生作文批改方法及步骤

alumina ceramic

composition

小学生作文批改方法及步骤

Cleanert Alumina A酸性氧化铝,1000mg_6mL,30支_包

铝产品 Products

铝行业的一些常用英语词汇

氧化铝介质参数

小学生作文的指导方法和要求

中考 Composition:一模冲刺作文话题之友情

小学作文修改的步骤及方法

氧化铝柱净化和石油废物分离 气相色谱法US EPA 3611B-1996

作文的具体步骤及方法

修改作文的步骤与方法

耐火材料词汇