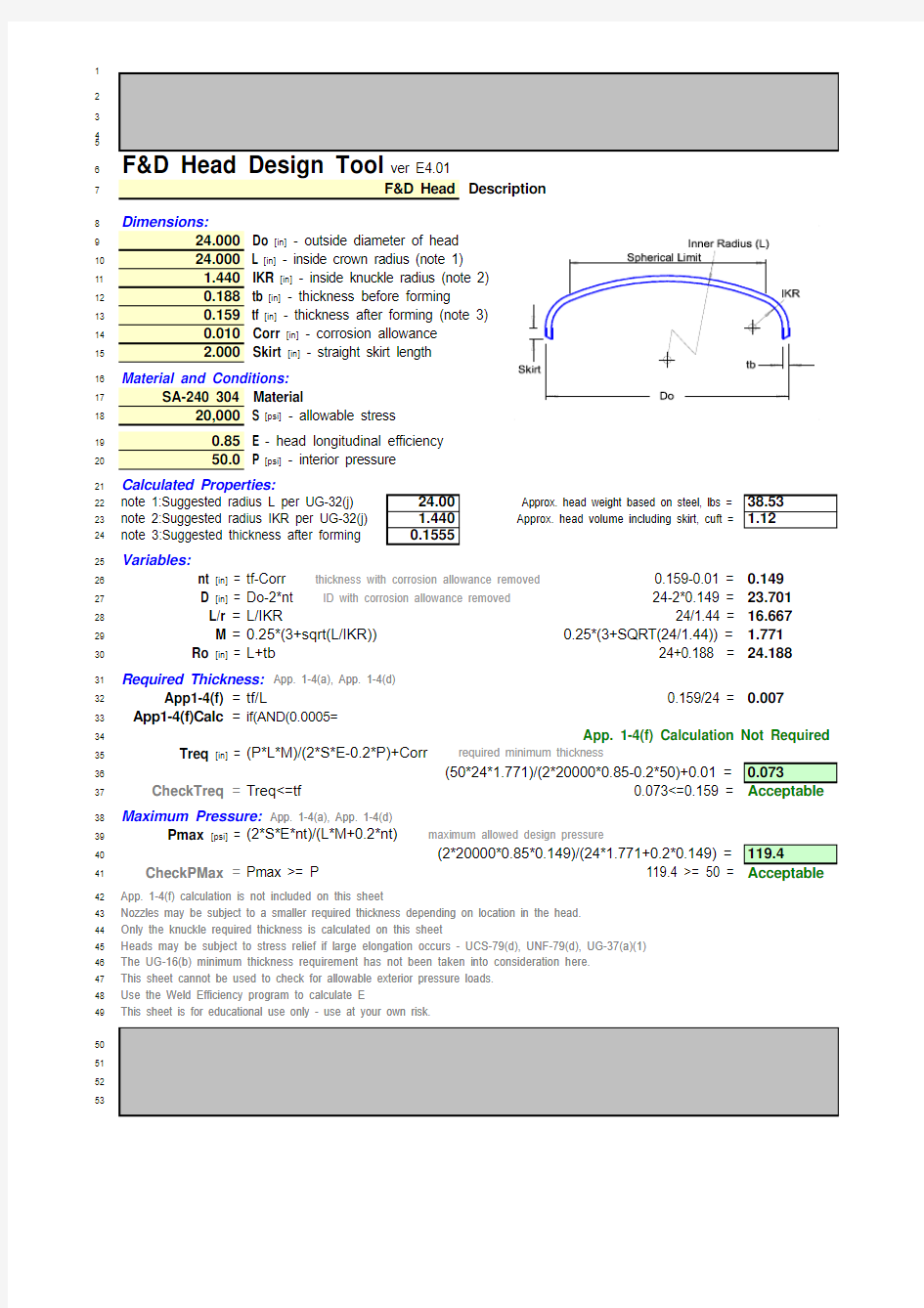

ASME计算表格(英文版)-碟形封头 F&D_Head_Design_Tool

123456

ver E4.01

7

8

9

[in] - outside diameter of head 10

[in] - inside crown radius (note 1)11

[in]

- inside knuckle radius (note 2)12[in]

- thickness before forming

13

[in] - thickness after forming (note 3)14

[in] - corrosion allowance 15[in] - straight skirt length

161718[psi] - allowable stress

19- head longitudinal efficiency 20[psi] - interior pressure

21Calculated Properties:

22note 1:Suggested radius L per UG-32(j)23note 2:Suggested radius IKR per UG-32(j)24note 3:Suggested thickness after forming

25Variables:

26nt [in] =tf-Corr thickness with corrosion allowance removed 0.159-0.01 = 0.14927 D [in] =Do-2*nt ID with corrosion allowance removed 24-2*0.149 =

23.70128L/r =L/IKR

24/1.44 =

16.66729M =0.25*(3+sqrt(L/IKR))0.25*(3+SQRT(24/1.44)) =

1.77130Ro [in] =

L+tb

24+0.188 =

24.188

31Required Thickness: App. 1-4(a), App. 1-4(d)

32App1-4(f) =tf/L 0.159/24 = 0.00733App1-4(f)Calc =34App. 1-4(f) Calculation Not Required

35Treq [in] =3637CheckTreq =Treq<=tf 38Maximum Pressure: App. 1-4(a), App. 1-4(d)

39Pmax [psi] =4041CheckPMax =Pmax >= P 42App. 1-4(f) calculation is not included on this sheet

43Nozzles may be subject to a smaller required thickness depending on location in the head.44Only the knuckle required thickness is calculated on this sheet

45Heads may be subject to stress relief if large elongation occurs - UCS-79(d), UNF-79(d), UG-37(a)(1)46The UG-16(b) minimum thickness requirement has not been taken into consideration here.47This sheet cannot be used to check for allowable exterior pressure loads.48Use the Weld Efficiency program to calculate E

49

This sheet is for educational use only - use at your own risk.

50515253

(P*L*M)/(2*S*E-0.2*P)+Corr required minimum thickness

if(AND(0.0005= (2*S*E*nt)/(L*M+0.2*nt) maximum allowed design pressure