Waterstable lithium ion conducting solid electrolyte of the LAGTP system with NASICONtype structure

Water-stable lithium ion conducting solid electrolyte of the Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3system (x =0–1.0)with NASICON-type structure

Peng Zhang,Masaki Matsui,Atsushi Hirano,Yasuo Takeda,Osamu Yamamoto ?,Nobuyuki Imanishi

Graduate School of Engineering,Mie University,Tsu,Mie 514-8507,Japan

a b s t r a c t

a r t i c l e i n f o Article history:

Received 14July 2013

Received in revised form 11September 2013Accepted 11September 2013Available online xxxx Keywords:

Solid electrolyte Lithium conductor Lithium –air battery

Solid ionic conductors composed of Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3(x =0–1.0)with the NASICON-type structure were synthesized with a precursor prepared using the sol –gel method.The electrical conductivity was ex-amined as a function of x in Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3at various sintering temperatures and for various sintering periods.The highest electrical conductivity was obtained for Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3sintered at 900°C for 11h in air.The total and bulk conductivities of the sintered pellet were 1.29×10?3and 2.35×10?3S cm ?1at 25°C,respectively.The grain boundary resistance of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3was signi ?cantly increased to 552Ωcm 2from 12.2Ωcm 2by immersion in distilled water at 50°C for one week,whereas the bulk resistance was not increased.However,no signi ?cant increase of the bulk and grain boundary resistance was observed after immersion in a saturated aqueous solution of LiOH and LiCl.

?2013Elsevier B.V.All rights reserved.

1.Introduction

The lithium –air battery is a promising power source for electric vehicles because of its high theoretical speci ?c energy density [1].Two types of Li –air batteries,non-aqueous [2]and aqueous [3],have been developed.The speci ?c energy density of the non-aqueous system (3460Wh kg ?1)is higher than that of the aqueous system (1910Wh kg ?1);however,the non-aqueous system has some severe problems that must still be addressed,such as lithium corrosion by water and CO 2ingression when operated in air,precip-itation of high resistance reaction products (lithium oxide)on the air electrode,and high polarization during charge process.The aqueous system could avoid these problems observed for the non-aqueous system by using a water-stable lithium electrode and an aqueous elec-trolyte.Lithium metal reacts intensely with water;therefore,the key material of a water-stable lithium electrode is the water-stable lithium ion conducting solid electrolyte,which is used to prevent direct contact of lithium with water [4].At present,only two types of high lithium ion conducing solid electrolytes are known to be stable in water;one is the Li analog of NASICON,Li 1+x A x M 2?x (PO 4)3(LAMP;A =Al,Sc,M =Ti or Ge)[5],and the garnet-type Li 7La 3Zr 2O 12(LLZ)[6].The reaction product of the aqueous lithium –air system is LiOH and the concen-tration of LiOH increases with increasing discharge https://www.360docs.net/doc/1e4542608.html,MP and LLZ are unstable in concentrated LiOH aqueous solution,but

are stable in aqueous solution saturated with LiOH and LiCl [7,8].Therefore,these compounds could be used as the protective layer of the lithium metal electrode for lithium –air batteries with a LiCl saturated aqueous solution.The electrical conductivities of the sintered LLZ and Nb-or Y-doped LLZ were reported to be 2×10?4to 8×10?4S cm ?1at room temperature [6,8–11]and LLZ is stable in contact with lithium metal [6],but it is dif ?cult to prepare a pore-free dense plate of LLZ due to the evaporation of lithium during high temperature sintering.The electrical conductivity of LAMP is dependent on the composition and the preparation method.The re-spective conductivities of the Li 1+x Al x Ti 2?x (PO 4)3glass ceramic [12]and Li 1.5Al 0.5Ge 1.5(PO 4)3[13]were as high as 1.3×10?3and 5.08×10?3S cm ?1at room https://www.360docs.net/doc/1e4542608.html,MP is unstable in contact with lithium metal;therefore,an interface layer should be used between the lithium metal and LAMP.Zhang et al.[14]reported the fabrication of a cell that consisted of a lithium metal anode,a lithium conducting polymer electrolyte composed of polyethylene oxide (PEO)with Li(CF 3SO 2)2N (LiTFSI)-BaTiO 3and a water-stable NASICON-type lithium ion conducting Li 1+x +y Al y (Ti,Ge)2?x P 3?y Si y O 12glass ceramic (Ohara plate),which had an electrode resistance of 173Ωcm 2at room temperature.The elec-trical conductivity of the Ohara plate is around 1×10?4S cm ?1at room temperature.

To reduce the resistance of the water-stable lithium metal elec-trode,a solid lithium ion conductor with a total conductivity above 10?3S cm ?1is desirable.However,the total ionic conductivity of polycrystalline lithium ion conductors with the NASICON-type struc-ture is usually in the order of 10?4S cm ?1at room temperature,ex-cept for the Li 1+x Al x Ti 2?x (PO 4)3[12]and Li 1.5Al 0.5Ge 1.5(PO 4)3

Solid State Ionics 253(2013)175–180

?Corresponding author.Tel.:+81592319420.

E-mail address:Yamamoto@chem.mie-u.ac.jp (O.

Yamamoto).0167-2738/$–see front matter ?2013Elsevier B.V.All rights reserved.

https://www.360docs.net/doc/1e4542608.html,/10.1016/j.ssi.2013.09.022

Contents lists available at ScienceDirect

Solid State Ionics

j o ur n a l h o m e p a g e :w ww.e l s e v i e r.c om /l o c a t e /s s i

glass ceramics[13].The Li1.5Al0.5Ge1.5(PO4)3glass ceramic is attrac-tive,because the conductivity of a pelletized sample of the sintered glass ceramic powder was reported to be4.62×10?3S cm?1at 27°C[13].The preparation of the glass ceramics is a little complex and germanium is an expensive element.Fu[15]also studied the Li1+x Al x Ge2?x(PO4)3glass ceramic and found the highest electri-cal conductivity of4.0×10?4S cm?1for Li1.5Al0.5Ge1.5(PO4)3.The solid solution of Li1+x Al x Ge y Ti2?x?y(PO4)3(0.2≤x≤0.8,0.8≤y≤1.0)was synthesized and studied by Maddonado-Manso et al.

[16].The highest bulk and total conductivities at room temperature were7×10?4and1.1×10?4S cm?1for Li1.5Al0.5Ti0.7Ge0.8(PO4)3,re-spectively.Xu et al.[17]have investigated the Li1.4Al0.4Ti1.6?x Ge x(PO4)3 glass ceramics and reported a maximum room temperature conductivity of6.21×10?4S cm?1for Li1.4Al0.4Ti0.53Ge1.07(PO4)4.In this study, the effect of substitution of Ge for Ti on the electrical conductivity have been examined for the whole Li1.4Al0.4Ti1.6?x Ge x(PO4)3 (x=0–1.0)system.The highest total electrical conductivity of 1.29×10?3S cm?1at25°C was found for Li1.4Al0.4Ti1.4Ge0.2(PO4)3. The stability of this high conducting solid electrolyte in aqueous so-lutions was also studied for application as the protective layer of the water-stable lithium electrode for lithium–air batteries.

2.Experimental

The precursor of Li1.4Al0.4Ti1.6?x Ge x(PO4)3was prepared by the sol–gel method using citric acid,as reported previously[18].Stoichio-metric amounts of Ge(OC2H5)4(Aldrich)and Ti(OC4H9)4(Aldrich) were dissolved in ethylene glycol,and then added to a0.2M aqueous solution of citric acid and stirred continuously with a magnetic stirrer at120°C for12h to obtain a homogeneous solution.After preparation of the gel was completed,stoichiometric amounts of LiNO3,Al(NO3)3·9-H2O,and NH4H2PO4were added to the gel solution.The molar ratio of citric acid to Li++Al3++Ge4++Ti4+was4:1.After a homoge-neous solution was formed,the gel was kept at170°C for several hours to allow evaporation of the water and to promote esteri?cation and polymerization.The gel was then heated at500°C for4h to com-plete the chemical decomposition of nitrates and organic compounds. The black product with residual carbon was ground to a uniformly ?ne powder with an agate mortar and pestle to increase the surface area of the samples before sintering at800°C for5h to complete the chemical reaction.The precursor was then grounded by wet milling with a planetary mill(Fritsch)for15h to make?ne powders,which are necessary to achieve dense ceramic sintering.The?ne powder was isostatically pressed(150MPa)into a pellet(ca.12mm diameter,ca.

1.5mm thick)and then sintered at various temperatures on a gold sheet to protect the samples from reaction with the alumina refractory board.

The crystal structure of the synthesized samples was analyzed using X-ray diffraction analysis(XRD;Rigaku RINT2500)with Cu Kαradia-tion in the2θrange from10to90°at a scanning step rate of0.02°s?1 and using Si powder as an internal standard.The microstructure and morphology of the pellets was observed using scanning electron mi-croscopy(SEM;Hitachi SEM S-4000).

The AC impedance of sintered pellets with sputtered gold electrodes was measured in air using a frequency response analyzer(Solartron 1260)in the temperature range from20to80°C and the frequency range of0.1Hz to1MHz.The impedance pro?les were analyzed to es-timate the bulk and grain boundary conductivities using a non-linear in-stant?t program in the ZView software package.The stability of the sintered pellets was investigated by immersion into distilled water,sat-urated LiOH,saturated LiCl,and saturated LiOH and LiCl aqueous solu-tions at50°C for one week.The pellets immersed into these solutions were then carefully washed with distilled water and dried in a vacuum at220°C for20h before measuring electrical conductivity and XRD patterns.3.Results and discussion

The sol–gel precursor of Li1.4Al0.4Ti1.4Ge0.2(PO4)3was sintered in the temperature range of880to950°C for11h.The XRD patterns of the samples sintered at880and900°C indicate the NASICON-type struc-ture without an impurity phases,although an impurity phase of AlPO4 was observed for those samples sintered at950°C,as reported by Xu et al.,[17]and Mariappan et al.[19]for the glass ceramics.The pellet sintered at880°C had a low relative density of77.9%;therefore,the sintering temperature was?xed at900°C for this study.

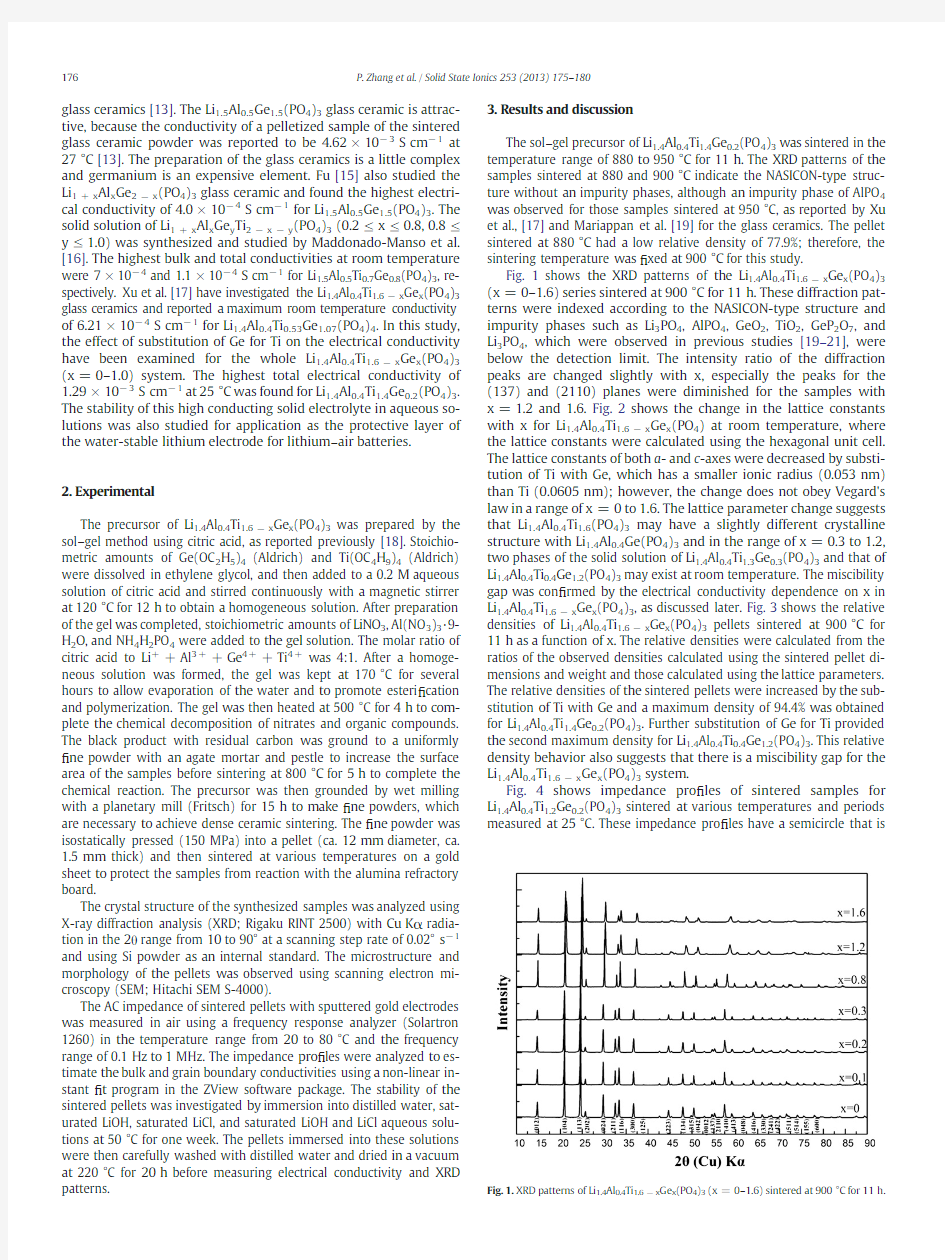

Fig.1shows the XRD patterns of the Li1.4Al0.4Ti1.6?x Ge x(PO4)3 (x=0–1.6)series sintered at900°C for11h.These diffraction pat-terns were indexed according to the NASICON-type structure and impurity phases such as Li3PO4,AlPO4,GeO2,TiO2,GeP2O7,and Li3PO4,which were observed in previous studies[19–21],were below the detection limit.The intensity ratio of the diffraction peaks are changed slightly with x,especially the peaks for the (137)and(2110)planes were diminished for the samples with x=1.2and1.6.Fig.2shows the change in the lattice constants with x for Li1.4Al0.4Ti1.6?x Ge x(PO4)at room temperature,where the lattice constants were calculated using the hexagonal unit cell. The lattice constants of both a-and c-axes were decreased by substi-tution of Ti with Ge,which has a smaller ionic radius(0.053nm) than Ti(0.0605nm);however,the change does not obey Vegard's law in a range of x=0to1.6.The lattice parameter change suggests that Li1.4Al0.4Ti1.6(PO4)3may have a slightly different crystalline structure with Li1.4Al0.4Ge(PO4)3and in the range of x=0.3to1.2, two phases of the solid solution of Li1.4Al0.4Ti1.3Ge0.3(PO4)3and that of Li1.4Al0.4Ti0.4Ge1.2(PO4)3may exist at room temperature.The miscibility gap was con?rmed by the electrical conductivity dependence on x in Li1.4Al0.4Ti1.6?x Ge x(PO4)3,as discussed later.Fig.3shows the relative densities of Li1.4Al0.4Ti1.6?x Ge x(PO4)3pellets sintered at900°C for 11h as a function of x.The relative densities were calculated from the ratios of the observed densities calculated using the sintered pellet di-mensions and weight and those calculated using the lattice parameters. The relative densities of the sintered pellets were increased by the sub-stitution of Ti with Ge and a maximum density of94.4%was obtained for Li1.4Al0.4Ti1.4Ge0.2(PO4)3.Further substitution of Ge for Ti provided the second maximum density for Li1.4Al0.4Ti0.4Ge1.2(PO4)3.This relative density behavior also suggests that there is a miscibility gap for the Li1.4Al0.4Ti1.6?x Ge x(PO4)3system.

Fig.4shows impedance pro?les of sintered samples for Li1.4Al0.4Ti1.2Ge0.2(PO4)3sintered at various temperatures and periods measured at25°C.These impedance pro?les have a semicircle that

is Fig.1.XRD patterns of Li1.4Al0.4Ti1.6?x Ge x(PO4)3(x=0–1.6)sintered at900°C for11h.

176P.Zhang et al./Solid State Ionics253(2013)175–180

attributed to the grain boundary resistance [22].The intercept of the semicircle on the real axis at high frequency represents the bulk resis-tance,and the diameter of the semicircle indicates the grain boundary resistance.The grain boundary and bulk resistances are dependent on the sintering temperature and period.The highest total conductivity was found for the sample sintered at 900°C for 11h;the total electrical conductivity for as-sintered Li 1.4Al 0.4Ti 1.2Ge 0.2(PO 4)3at 25°C was as high as 2.25×10?3S cm ?1.However,the electrical conductivity of the as-sintered samples was subject to an aging effect,and the grain boundary resistance was signi ?cantly increased with the aging peri-od.Fig.5shows the total,grain boundary,and bulk conductivities at 25°C for Li 1.4Al 0.4Ti 1.44Ge 0.16(PO 4)3,Li 1.4Al 0.4Ti 1.40Ge 0.20(PO 4)3,and Li 1.4Al 0.4Ti 1.3Ge 0.30(PO 4)3as a function of the aging period.The bulk conductivities of these samples showed no signi ?cant aging effect,but the grain boundary conductivities of all samples decreased sig-ni ?cantly with the aging period.Stable conductivity was observed after approximately one month.The Li 1.4Al 0.4Ti 1.40Ge 0.20(PO 4)3sample stored in a glove box also showed a similar increase in grain boundary resistance by aging,as shown in Fig.5(b).The grain boundary conductivity is affected by impurity phases at the grain boundary.Impurity phases such as Li 2O and AlPO 4exhibit both blocking and a space charge effect for lithium ion transport [21].The increase in grain boundary resistance with the aging period could be explained by a metastable impurity phase with high con-ductivity in the as-sintered sample,which may change to the stable low conductivity phase by aging.Similar aging behavior was ob-served for the grain boundary resistance of Li 1.4Al 0.4Ti 1.6(PO 4)-3wt.%ZrO 2(and 3wt.%Al 2O 3)[23].

Fig.6shows the electrical conductivity (measured at 25°C)of as-sintered (900°C for 11h)Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3as a function of

x and that stored in air for one month.The conductivity measured at 25°C for the as-sintered Li 1.4Al 0.4Ti 1.6(PO 4)3(4.79×10?4S cm ?1)is comparable to that of Li 1.4Al 0.4Ti 1.6(PO 4)3prepared using sol –gel precursors (6.13×10?4S cm ?1)[24].The conductivity vs.x curves shows two conductivity peaks at x =0.2and 1.2,which suggest the formation of a miscibility gap at room temperature in the solid solution of Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3,as observed in the lattice constant change with x.The highest total conductivity of 2.25×10?3S cm ?1at 25°C was observed for as-sintered Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4).The conductivity was decreased with the aging period and a stable total conductivity of 1.29×10?3S cm ?1was observed after one month storage;the stable bulk and grain boundary conductivities were 2.35×10?3and 2.87×10?3S cm ?1at 25°C,respectively.The bulk conductivity of Li 1.4Al 0.4Ti 1.6(PO 4)3was enhanced approximately 3times and the grain boundary conductivity by one order when Ge was substituted for Ti.The high total steady state conductivity of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)could be explained by the formation of a high lithium ion mobility phase in the grains and a high grain boundary conductivity phase by the substitution of Ge for Ti.The second conductivity peak was observed at x =1.2in Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3.The steady state total,bulk,and grain boundary conductivities of Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)3were 3.43×10?4,6.67×10?4and 7.65×10?4S cm ?1at 25°C,respectively.

Fig.7shows the temperature dependence of the bulk,grain boundary and total conductivities for Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3and Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)3in the temperature range of 20to 80°C,where the samples were stored at room temperature for one month.These Arrhenius plots are linear in the examined tempera-ture range;therefore,the activation energies for the bulk,grain boundary and total conductivities were calculated from the slopes of the Arrhenius plots and are summarized with the conductivity data in Table 1.The activation energies for Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3were calculated to be 20.2kJ mol ?1for bulk conduction and 55.0kJ mol ?1for grain boundary conduction,and those for Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)

3

https://www.360docs.net/doc/1e4542608.html,ttice parameters for Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3(x =0–1.6)measured at room

temperature.

Fig.3.Relative density of Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3(x =0–1.6)pellets sintered at 900°C for 11

h.

Fig.4.Impedance pro ?les (measured at 25°C)for Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3(a)sintered at various temperatures for 11h and (b)sintered at 900°C for various periods.

177

P.Zhang et al./Solid State Ionics 253(2013)175–180

were 25.7kJ mol ?1for bulk conduction and 53.3kJ mol ?1for grain boundary conduction.The activation energy for bulk conduction in Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3is slightly lower than that for Li 1.4Al 0.4Ti 1.6(PO 4)3(21.1kJ mol ?1).These activation energies for bulk conduction are lower than those for the high lithium ion conducting glass ceramics of Li 1+x Al x Ti 2?x (PO 4)3(24.4kJ mol ?1)[25],and for Li 1.5Al 0.5Ge 1.5(PO 4)3(31.8kJ mol ?1)[20]and Li 1.6Al 0.6Ti 0.7Ge 0.8(PO 4)3(33.8kJ mol ?1)[16].Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3has the lowest activation energy for bulk conduction of the NASICON-type lithium ion conducting solids.The activation energy for bulk conduction in Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)3is slightly higher than that for Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3and lower than that for Li 1.4Al 0.4Ge 1.6(PO 4)3.The difference in the activation energy for bulk conduction between Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)3and Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3could be explained by the miscibility gap of the Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3system at room temperature,as ob-served by the change in the lattice constant with x shown in Fig.2.

The NASICON-type structure of LiM 2(PO 4)3(M =Ti or Ge)consists of a three dimensional framework of PO 4tetrahedra corner-sharing with MO 6octahedra,Li +ions partially occupying at intermediate of the framework [26].The high bulk conductivity of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3suggests that the rigid [(Ti 1.4Ge 0.2,Al 0.4)(PO 4)3]skeleton provides easier pathways for migration than that in the [(Ti 1.6Al)(PO 4)3]skeleton,because the covalency of the Ge \O bond is stronger than that of the Ti \O bond [20].The slightly higher bulk activation energy for Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)3than that of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3may be due to their slightly different crystal structures.The detailed differences in the crystal structures should be analyzed to con ?rm the change in ac-tivation energy.The activation energy for the grain boundary conduction of as-sintered Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3was as low as 30kJ mol ?1and the grain boundary conductivity was as high as 1.03×10?2S cm ?1,while the activation energy of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3stored at

room

Fig. 5.Bulk,grain boundary,and total conductivities measured at 25°C for (a)Li 1.4Al 0.4Ti 1.44Ge 0.16(PO 4)3,(b)Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3,and (c)Li 1.4Al 0.4Ti 1.3Ge 0.3(PO 4)3as a function of the aging period.Grain boundary and total conductivities of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3stored in a glove box (glove)were shown in Fig.

5-(b).

Fig.6.Total and bulk electrical conductivities measured at 25°C for as-sintered Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3(x =0–1.6)and the total electrical conductivity measured at 25°C for stored Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3(x =0–1.6)for one month in

air.

Fig.7.Temperature dependence of the bulk,grain boundary,and total conductivity of (a)Li 1.4Al 0.4Ti 0.14Ge 0.2(PO 4)3and (b)Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)3.

178P.Zhang et al./Solid State Ionics 253(2013)175–180

temperature for one month increased to 55.0kJ mol ?1,while the grain boundary conductivity was decreased to 2.87×10?4S cm ?1.The activation energies for the grain boundary conduction of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3and Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)3are slightly lower than those of Li 1.4Al 0.4Ti 1.6(PO 4)3and Li 1.4Al 0.4Ge 1.6(PO 4)3.The grain boundary conduction may be in ?uenced by impurity phases such as Li 2O and AlPO 4[21],and the similar grain boundary activation energies for Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3and Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)3suggest that the grain boundary impurity phase is similar in these phases.

The stability of the Li 1+x +y Al x (Ti,Ge)2?x Si y P 3O 12glass ceram-ic (Ohara plate)in aqueous solutions has been extensively studied by Imanishi and coworkers [7,27].The glass ceramic decomposes in strong acid solution and dissolves in strong alkaline solution.They found that the glass ceramic is stable in saturated LiCl and LiOH aqueous solution,due to the low dissociation of LiOH to ions in the presence of a high Li +ion content [7].The stability of the high lithi-um ion conducting solid electrolyte in saturated LiOH and LiCl aque-ous solution is a key issue for application as the protective layer of the lithium metal electrode in aqueous lithium –air batteries,because the reaction product for aqueous lithium –air batteries is LiOH.The sta-bility of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3stored in distilled water,saturated LiCl aqueous solution,saturated LiOH solution,and saturated LiCl and LiOH solution at 50°C for one week was examined.The XRD patterns of Li 1.4-Al 0.4Ti 1.4Ge 0.2(PO 4)3immersed in these solutions revealed no impurity phases and there was no change in the ratio of diffraction peaks before and after immersion in these solutions.However,the impedance pro-?les showed a change after immersion in these solutions,as shown in Fig.8,where the as-sintered samples were used.The grain boundary resistance of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3immersed in aqueous solution increased from 12.2to 552Ωcm 2,while the bulk resistance in-creased slightly.A similar increase in grain boundary resistance was observed for the Li 1+x +y Al x (Ti,Ge)2?x P 3?y Si y O 12glass ceramic (Ohara plate)[27].This could be explained by the ion-exchange

reaction between Li +and H +,as observed in Li 3x La 2/3T i O 3[28].The mechanical strength of the pellet also became very poor by immer-sion in distilled water at 50°C for 1week.An increase in the grain boundary resistance was observed for Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3im-mersed in saturated LiOH aqueous solution.On the other hand,the change in the electrical conductivity of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3by im-mersion in saturated LiCl aqueous solution and in saturated LiOH and LiCl aqueous solution was not signi ?cant.The conductivity of Li 1.4Al 0.4-Ti 1.4Ge 0.2(PO 4)3immersed in saturated LiOH and LiCl aqueous solution at 50°C for one week was 1.66×10?3S cm ?1at 25°C,which is comparable to that of the sample after one week aging shown in Fig.5.It could be concluded that Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3with high lithium ion electrical conductivity is stable in LiOH and LiCl saturated aqueous solution,and is thus acceptable for use as the protective layer in a water-stable lithium electrode.4.Conclusion

The NASICON-type lithium ion conducting solid electrolyte,Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3,was prepared using a sol –gel precursor at 900°C for 11h.The electrical conductivity of the as-sintered sample exhibited an aging effect and stable conductivity was obtained after storage for approximately one month.The electrical conductivity vs.x curve for Li 1.4Al 0.4Ti 1.6?x Ge x (PO 4)3has two peaks at x =0.2and 1.2.The highest total lithium ion conductivity of 1.29×10?3S cm ?1at 25°C was found for Li 1.4Al 0.4Ti 1.4Ge 0.4(PO 4)3with a high relative den-sity of 94.4%.The bulk and grain boundary conductivities of this sample at 25°C are 2.35×10?3and 2.87×10?3S cm ?1,respectively,and the total conductivity of 1.29×10?3S cm ?1is approximately one order higher than that of Li 1.4Al 0.4Ti 1.6(PO 4)3.The high lithium ion conducting solid electrolyte exhibited stability in LiOH and LiCl saturated aqueous solution.The high lithium ion conductivity and stability in LiOH and LiCl aqueous solution of Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3suggests that this com-pound is an attractive candidate as the protective layer for the lithium metal electrode in aqueous lithium –air batteries.Acknowledgment

This study was supported by the Japan Science and Technology Agency (JST)under the “Advanced Low Carbon Technology Research and Development Program ”.References

[1]M.Armand,J.M.Tarascon,Nature 451(2008)652.

[2]T.Ogasawara,A.Debart,M.Holzapgel,P.Novak,P.G.Bruce,J.Am.Chem.Soc.128

(2006)1390.

[3]T.Zhang,N.Imanishi,S.Hasegawa,A.Hirano,J.Xie,Y.Takeda,O.Yamamoto,N.

Sammes,J.Electrochem.Soc.155(2008)A965.

[4]S.J.Visco,E.N.,B.Katz,L.C.D.Jonghe,M.Y.Chu,Abst.#53,The International Meeting

on Lithium Batteries,Nara,Japan,2004.

[5]H.Aono,E.Sugimoto,Y.Sadaoka,N.Imanaka,G.Adachi,J.Electrochem.Soc.136

(1989)590.

[6]R.Murgan,V.Thangadurai,W.Weppner,Angew.Chem.Int.Ed.46(2007)

7778.

[7]Y.Shimonishi,T.Zhang,N.Imanishi, D.Im, D.J.Lee,A.Hirano,Y.Takeda,O.

Yamamoto,N.Sammes,J.Power Sources 196(2011)5128.

Table 1

Bulk (σb ),grain boundary (σgb ),and total(σt )conductivity at 25°C and activation energy for bulk (E b ),grain boundary (E gb ),and total (E t )conduction for samples stored for one month in air.

Compound

Conductivity (S cm ?1)Activation energy (kJ mol ?1)σb

σgb σt E b E gb E t Li 1.4Al 0.4Ti 1.6(PO 4)3

8.04×10?4 2.27×10?4 1.77×10?421.160.436.4Li 1.4Al 0.4Ti 1.4Ge 0.2(PO 4)3 2.35×10?3 2.87×10?3 1.29×10?320.255.029.0Li 1.4Al 0.4Ti 0.4Ge 1.2(PO 4)3 6.67×10?47.65×10?4 3.43×10?425.753.332.2Li 1.4Al 0.4Ge 1.6(PO 4)3

4.20

×10?4

3.40

×10?4

1.77

×10?4

27.4

58.5

34.4

Fig.8.Impedance pro ?les at 25°C for (a)pristine Li 1.4Al 0.4Ti 1.44Ge 0.16(PO 4)3,and Li 1.4Al 0.4Ti 1.44Ge 0.16(PO 4)3immersed in (b)water,(c)saturated LiCl aqueous solu-tion,(d)saturated LiCl and LiOH aqueous solution,and (e)in saturated LiOH aqueous solution at 50°C for one week.

179

P.Zhang et al./Solid State Ionics 253(2013)175–180

[8]Y.Shimonishi,A.Toda,T.Zhang,A.Hirano,N.Imanishi,O.Yamamoto,Y.Takeda,

Solid State Ionics183(2011)48.

[9]S.Ohta,T.Kobayashi,T.Asaoka,J.Power Sources196(2011)3342.

[10]R.Murugan,S.Ramakumar,N.Jansmi,https://www.360docs.net/doc/1e4542608.html,mun.13(2011)1373.

[11] E.Rangasmy,J.Wolfenstin,J.Sakamoto,Solid State Ionics206(2012)29.

[12]J.Fu,Solid State Ionics96(1997)195.

[13]J.S.Thokchom,B.Kumar,J.Power Sources185(2008)480.

[14]T.Zhang,N.Imanishi,Y.Shimonishi,A.Hirano,Y.Takeda,O.Yamamoto,J.Electrochem.

Soc.157(2010)A214.

[15]J.Fu,Solid State Ionics104(1997)191.

[16]P.Maddonado-Manso,E.R.Losilla,M.Martinez-Lara,M.A.G.Aranda,S.Bruque,F.E.

Mouahid,M.Zahir,Chem.Mater.15(2003)1879.

[17]X.Xu,Z.Wen,Z.Gu,X.Xu,Z.Lin,Solid State Ionics171(2004)207.

[18]K.Takahashi,J.Ohmura,D.Im,D.L.Lee,T.Zhang,N.Imanishi,A.Hirano,M.B.

Phillipps,Y.Takeda,O.Yamamoto,J.Electrochem.Soc.159(2012)A142.[19] C.R.Mariappan,C.Yada,F.Rosciano,B.Roling,J.Power Sources195(2011)

6456.

[20]T.Salkus,A.Mindune,Z.Kamepe,J.Ronis,A.Ureinskas,A.Kezionis,A.F.Orliukas,

Solid State Ionics178(2007)1282.

[21] B.Kumar,D.Thomas,J.Kumar,J.Electrochem.Soc.159(2009)A506.

[22]P.C.Bruce,A.R.West,J.Electrochem.Soc.130(1983)662.

[23]K.Takahashi,P.Johnson,N.Imanishi,N.Sammes,Y.Takeda,O.Yamamoto,

J.Electrochem.Soc.159(2012)A1065.

[24]X.Xu,Z.Wen,J.Wu,X.Yang,Solid State Ionics178(2007)29.

[25]J.S.Thokchon,B.Kumar,J.Electrochem.Soc.154(2007)A331.

[26]J.B.Goodenough,H.Y.P.Hong,J.A.Kafalas,Mater.Res.Bull.11(1976)203.

[27]S.Hasegawa,N.Imanishi,T.Zhang,J.Xie,A.Hirano,Y.Takeda,O.Yamamoto,

J.Power Sources189(2009)371.

[28]O.Bohnke,Q.N.Pham,A.Boulant,J.Emery,T.Salkus,M.Barre,Solid State Ionics188

(2011)144.

180P.Zhang et al./Solid State Ionics253(2013)175–180

磷酸铁锂动力电池维护手册(整合版1)

沃特玛电池有限公司 磷酸铁锂动力电池使用手册 电子部 2013-3-15 [为了方面售后服务更好的对OPT管理系统进行维护,特此制定本手册,希望对售后服务有所帮助]

前言 为应对日益突出的燃油供求矛盾和环境污染问题,世界主要汽车生产国纷纷加快部署,将发展新能源汽车作为国家战略,加快推进技术研发和产业化,同时大力发展和推广应用汽车节能技术。节能与新能源汽车已成为国际汽车产业的发展方向。新能源客车,目前正在飞速发展。 当新能源客车穿行于街市,走进人们的生活时,对它的了解和认知也就成我们的必修课。然而,在这新能源之风势在必行之际,谈到动力电池,我们中大多数的人对其都知之甚少,这其中包括很多从事纯电动客车工作的相关从业人员,也正因为如此,才给你们的工作和和生活到来了诸多的困难和疑惑。 为解决这些问题,让从事纯电动客车工作的相关从业人员对动力电池有一些初步的了解和认识,本手册将通过重点介绍磷酸铁锂动力电池和管理系统的运用与维护来让大家了解动力电池的相关知识。为了更好服务客户,让相关从业人员熟悉和掌握我公司的纯电动客车动力电池,也为更好的发挥磷酸铁锂动力电池优越的性能,做好相关的维护保养工作,特制定本手册。希望此举能为大家避免在使用或维护我公司产品时造成不必要的困扰和预防产生一些不可挽回的损失。 烦请在使用或维护沃特玛公司纯电动客车动力电池之前,详细阅读本手册!

目录 前言2 第一章为何选择磷酸铁锂电池作为动力电池5 1.1电池的概念 (5) 1.2磷酸铁锂电池优势: (5) 1.3动力电池种类性能对比: (5) 1.4.关键设计说明 (6) 1.5.产品用途 (7) 第二章动力电池系统构成8 2.1.电池组的主要参数(以五洲龙为例)8 2.2电池组结构说明及其示意图 (9) 第三章技术特性13 3.1 单体放电特性 (13) 3.2不同放电倍率下的放电曲线 (13) 3.3 单体充电特性 (14) 3.4 五洲龙电池系统充放电特性曲线图 (15) 3.5 保存特性 (15) 3.6寿命特性 (16) 第四章. 电池系统的使用与安装17 4.1 电池系统使用环境 (17) 4.2 电池系统的使用 (18) 4.4电池系统的安装 (18) 第五章动力电池信息仪表认识23 5.1混合动力电池信息仪表认识 (23) 5.2纯电动电池信息仪表认识 (24) 第六章动力电池存储、维护与保养25 6.1 储存、维护和保养基本要求 (25) 6.2维护与保养: (25) 6.3日常保养: (27) 6.4周保养: (28) 6.5.月保养: (29) 第七章OPT管理系统运用与维护31 7.1电池管理系统BMS基本结构 (31) 7.2 BMS管理系统安装 (33) 7.3 BMS故障处理方法 (34) 第八章紧急处理方案43

基于单片机的太阳能充电器

本科生毕业设计便携式太阳能充电器 2013 年04 月

独创性声明 本人郑重声明:所呈交的毕业设计是本人在指导老师指导下取得的研究成果。除了文中特别加以注释和致谢的地方外,设计中不包含其他人已经发表的研究成果。与本研究成果相关的所有人所做出的任何贡献均已在设计中作了明确的说明并表示了谢意。 签名: 年月日 授权声明 本人完全了解许昌学院有关保留、使用本科生毕业设计的规定,即:有权保留并向国家有关部门或机构送交毕业设计的复印件和磁盘,允许毕业设计被查阅和借阅。本人授权许昌学院可以将毕业设计的全部或部分内容编入有关数据库进行检索,可以采用影印、缩印或扫描等复制手段保存、汇编设计。 本人设计中有原创性数据需要保密的部分为(如没有,请填写“无”): 学生签名: 年月日 指导教师签名: 年月日

便携式太阳能充电器 摘要 16到20世纪,随着工业革命的兴起,科学技术的不断发展,人们对自然界中化石能源的索取速度越来越快、数量越来越多。与此同时,化石能源的燃烧对于自然界的生态环境造成了难以弥补的破坏。作为可再生能源,太阳能有着广阔的应用前景,可以成为移动设备供电的有吸引力的能源。当我们外出或旅游时,常常因为手机没电所带来的麻烦而苦恼,但又不能及时找到可以充电的场所,影响了手机的正常使用。为了解决这一问题,本毕业设计介绍一种便携式的太阳能手机充电器,利用单片机控制,实现对移动设备充放电的自由与智能控制。与常规的充电器相比,太阳能充电器必将因为便携式而得到长远的发展。 关键词:能源;太阳能;电池;单片机;便携式

Portable Solar Charger based on Microcontroller Abstract From 16 to 20 century, with the rise of industrial revolution and continuous development of science and technology, people demand a large quantity of fossil energy with increasing speed. At the same time, the burning of fossil energy has caused irreparable damage to the environment. As a renewable energy, solar energy enjoys broad application prospect. Solar power is attractive, because it supplies power for portable devices. When we go out or travel, we are often bothered by the failing power of cellphone. And we can’t find places to charge in time, which affects the normal use of mobile phone. In order to solve this problem, this thesis will introduce a type of portable solar mobile charger, using single-chip microcomputer so that the charge and discharge of mobile devices can be freely and intelligently controlled. Compared with the conventional charger, solar energy charger will definitly have a long-term development for its portable type. Key words: energy;solar energy;battery;intelligent;portable

石墨烯聚乳酸复合材料

Preparation of Polylactide/Graphene Composites From Liquid-Phase Exfoliated Graphite Sheets Xianye Li,1Yinghong Xiao,2Anne Bergeret,3Marc Longerey,3Jianfei Che1 1Key Laboratory of Soft Chemistry and Functional Materials,Nanjing University of Science and Technology, Nanjing210094,China 2Jiangsu Collaborative Innovation Center of Biomedical Functional Materials,Jiangsu Key Laboratory of Biomedical Materials,College of Chemistry and Materials Science,Nanjing Normal University, Nanjing210046,China 3Materials Center,Ales School of Mines,30319Ales Cedex,France Polylactide(PLA)/graphene nanocomposites were pre-pared by a facile and low-cost method of solution-blending of PLA with liquid-phase exfoliated graphene using chloroform as a mutual solvent.Transmission electron microscopy(TEM)was used to observe the structure and morphology of the exfoliated graphene. The dispersion of graphene in PLA matrix was exam-ined by scanning electron microscope,X-ray diffrac-tion,and TEM.FTIR spectrum and the relatively low I D/I G ratio in Raman spectroscopy indicate that the structure of graphene sheets(GSs)is intact and can act as good reinforcement fillers in PLA matrix.Ther-mogravimetric analysis and dynamic mechanical analy-sis reveal that the addition of GSs greatly improves the thermal stability of PLA/GSs nanocomposites.More-over,tensile strength of PLA/GSs nanocomposites is much higher than that of PLA homopolymer,increasing from36.64(pure PLA)up to51.14MPa(PLA/GSs-1.0). https://www.360docs.net/doc/1e4542608.html,POS.,35:396–403,2014.V C2013Society of Plastics Engineers INTRODUCTION Polylactide(PLA),a renewable,sustainable,biode-gradable,and eco-friendly thermoplastic polyester,has balanced properties of mechanical strength[1],thermal plasticity[2],and compostibility for short-term commod-ity applications[3,4].It is currently considered as a promising polymer for various end-use applications for disposable and degradable plastic products[5–8].Never-theless,improvement in thermal and mechanical proper-ties of PLA is still needed to pursue commercial success. To achieve high performance of PLA,many studies on PLA-based nanocomposites have been performed by incorporating nanoparticles,such as clays[9,10],carbon nanotubes[11–13],and hydroxyapatite[14].However, research on PLA-based nanocomposites containing gra-phene sheets(GSs)or graphite nanoplatelets has just started[15–17].GSs exhibit unique structural features and physical properties.It has been known that GSs have excellent mechanical strength(Young’s modulus of1,060 GPa)[18],electrical conductivity of104S/cm[19],high specific surface area of2,630m2/g[20],and thermal sta-bility[21].Polymer nanocomposites based on graphene show substantial property enhancement at much lower fil-ler loadings than polymer composites with conventional micron-scale fillers,such as glass[22]or carbon fibers [23],which ultimately results in lower filler ratio and simple processing.Moreover,the multifunctional property enhancement of nanocomposites may create new applica-tions of polymers. However,the incorporation of graphene into PLA matrix is restricted by cost and yield.Although the weak interactions that hold GSs together in graphite allow them to slide readily over each other,the numerous weak bonds make it difficult to separate GSs homogeneously in sol-vents and polymer matrices[24].Many methods have been reported for exfoliation of graphite,such as interca-lation with alkali metals[25]or oxidation in strong acidic conditions[26–29].Recently,exfoliation of graphite in liquid-phase was found to be able to give oxide-free GSs with high quality and yield at relatively low cost[30–35]. Correspondence to:Y.H.Xiao;e-mail:yhxiao@https://www.360docs.net/doc/1e4542608.html, or J.F.Che; e-mail:xiaoche@https://www.360docs.net/doc/1e4542608.html, Contract grant sponsor:Specialized Research Fund for the Doctoral Program of Higher Education of China;contract grant number: 20123219110010;contract grant sponsor:Natural Science Foundation of Jiangsu Province of China;contract grant number:BK2012845;contract grant sponsors:Priority Academic Program Development of Jiangsu Higher Education Institutions(PAPD),contract grant sponsor:Financial support for short visit from Ales School of Mines,France. DOI10.1002/pc.22673 Published online in Wiley Online Library(https://www.360docs.net/doc/1e4542608.html,). V C2013Society of Plastics Engineers POLYMER COMPOSITES—2014

水热合成Fe2O3石墨烯纳米复合材料及其电化学性能研究

常熟理工学院学报(自然科学)Journal of Changshu Institute Technology (Natural Sciences )第26卷第10Vol.26No.102012年10月Oct.,2012 收稿日期:2012-09-05 作者简介:季红梅(1982—),女,江苏启东人,讲师,工学硕士,研究方向:无机功能材料.水热合成Fe 2O 3/石墨烯纳米 复合材料及其电化学性能研究 季红梅1,于湧涛2,王露1,王静1,杨刚1 (1.常熟理工学院化学与材料工程学院,江苏常熟215500;2.吉林石化公司研究院,吉林吉林132021) 摘要:利用水热法成功合成了Fe 2O 3/石墨烯(RGO )锂离子电池负极材料.导电性能良好的石墨烯网络起到连接导电性能极差的Fe 2O 3和集流体的作用.电化学性能测试表明,180℃下得到的 Fe 2O 3/RGO 具有良好的比容量和循环稳定性.在不同倍率充放电过程中,初始放电比容量为1023.6mAh/g (电流密度为40mA/g ),电流密度增加到800mA/g 时,放电比容量维持在406.6 mAh/g ,大于石墨的理论放电比容量~372mAh/g.在其他较高的电流密度下比容量均保持基本不变.该Fe 2O 3/RGO 有望成为高容量、低成本、低毒性的新一代锂离子电池负极材料.关键词:Fe 2O 3;石墨烯;负极材料中图分类号:TM911文献标识码:A 文章编号:1008-2794(2012)10-0055-05 自从P.Poizot [1]等报道过渡金属氧化物可以作为锂离子电池负极材料这一研究后,金属氧化物负极便逐渐引起人们的重视.铁的氧化物具有比容量大、倍率性能好和安全性能高等优点,且原料来源丰富、价格低廉、环境友好,因此是一类很有发展潜力的动力锂离子电池负极材料.Fe 2O 3作为一种常温下最稳定的铁氧化合物,理论容量为1005mAh/g ,远高于石墨类材料的理论比容量,已经成为锂离子电池负极材料的一个研究热点.近年来,石墨烯由于其高的电传导性,大的比表面积,良好的化学稳定性和柔韧性而被尝试用于与活性锂离子电池负极材料复合,提升材料的电化学性能.比如,Cui Y [2]课题组在溶剂热条件下两步法得到Mn 3O 4与石墨烯的复合材料,改善了Mn 3O 4的比容量和循环性能.Co 3O 4,Fe 3O 4等金属氧化物材料与石墨烯复合也有被研究,本课题组在石墨烯和金属氧化物材料复合方面也做了大量的工作[3].本文通过水热法一步合成Fe 2O 3/石墨烯纳米复合材料,并研究了其电化学性能,合成过程中采用三乙烯二胺提供反应的碱性环境,并控制Fe 2O 3的粒子生长.1 实验 1.1试剂和仪器 三乙烯二胺(C 6H 12N 2);无水三氯化铁(FeCl 3);石墨;硝酸钠(NaNO 3);浓硫酸(H 2SO 4);高锰酸钾(KMnO 4);双氧水(H 2O 2)和盐酸(HCl ),以上试剂均为分析纯.实验用水为去离子水.日本理学H-600型透射电子显微镜;日本理学D/max2200PC 型X 射线衍射仪;德国Bruker Vector 22红外光谱仪;日本JEOL-2000CX 透射电镜;美国Thermo Scientific Escalab 250Xi 光电子能谱仪;LAND 电池

LT8490锂电池充电器电路设计详解

LT8490 锂电池充电器电路设计详解 标签:LT8490(3) 低功耗(190)电源管理(505) LT8490( $12.5700)是降压升压开关稳压电池充电器,实 现恒流恒压( CCCV )充电模式,适用于大多数电池,包括密封铅酸电池( SLA )、溢流电池、胶体电池和锂电池。片上 逻辑在太阳能应用时提供自动最大功率点跟踪( MPPT),并 具有自动温度补偿功能。主要用在太阳能电池充电器、多种类型铅酸电池充电、锂电池充电器以及电池供电的工业或手持军用设备。 状态和故障引脚含有充电器的信息可以被用来驱动 LED指示灯。该器件采用扁平(高度仅0.75mm)7mm x 11mm 64 引脚QFN 封装。 图1 LT8490 框图 LT8490 主要特性

-VIN 范围:6V?80V - VBAT 范围:1.3V?80V ?单 电感器允许VIN高于,低于或等于VBAT ?自动MPPT,用于太阳能充电?自动温度补偿?无需任何软件或固件开发?从 太阳能电池板或直流电源供电?输入和输出电流监视器销弓 脚?四位一体的反馈回路?同步固定频率: 100kHz?400kHz 的-64 引脚(7mm X 11mm x 0.75mm 高度)QFN 封装LT8490 应用?太阳能电池充电器?多种铅酸蓄电池充电?锂离子电池充电器?电池供电工业产品或便携式军用设备 图2 LT8490 27.4V 锂电池充电器电路图 DC2069A( $195.9800)-LT8490 演示板高效率MPPT 电池充电器控制器17V?54V ,最高200W 太阳能电池板的输入电压。12V SLA 电池,最高16.6A 充电电流。演示电路2069A采用了LTR8490 (高性能降压-升压型转换器),实现了最大功率点跟踪功能和灵活的充电特性,适用于大多数类型的电池,如水淹电池,密封铅酸电池和锂离子电池,可在输入电压高于、低于或等于电池电压的情况下工作。 该演示板配置为17V~54V 的输入电压范围,电源可以 是太阳能电池板36?72单元(最高200W),或直流电压源。 提供两种输入接口。LTC4359($2.5500)理想的二极管控制器可以保护直流电源的输出(不受太阳能电池板回流的影响)这使得,例如在 24VDC 电源接通的同时,又可以使具有更高的电压的太阳能电池板,被用于对电路供电。

石墨烯复合材料的研究及其应用

石墨烯复合材料的研究及其应用 任成,王小军,李永祥,王建龙,曹端林 摘要:石墨烯因其独特的结构和性能,成为物理化学和材料学界的研究热点。本文综述了石墨烯复合材料的结构和分类,主要包括石墨烯-纳米粒子复合材料、石墨烯-聚合物复合材料和石墨烯-碳基材料复合材料。并简述石墨烯复合材料在催化领域、电化学领域、生物医药领域和含能材料领域的应用。 关键词:石墨烯;复合材料;纳米粒子;含能材料 Research and Application of Graphene composites ABSTRACT: Graphene has recently attracted much interest in physics,chemistry and material field due to its unique structure and properties. This paper reviews the structure and classification of graphene composites, mainly inclouding graphene-nanoparticles composites, graphene-polymer composites and graphene-carbonmaterials composites. And resume the application of graphene composites in the field of catalysis, electrochemistry, biological medicine and energetic materials. Keywords: graphene; composites; nanoparticles; energetic materials 石墨烯自2004年曼彻斯特大学Geim[1-3]等成功制备出以来,因其独特的结构和性能,颇受物理化学和材料学界的重视。石墨烯是一种由碳原子紧密堆积构成的二维晶体,是包括富勒烯、碳纳米管、石墨在内的碳的同素异形体的基本组成单元。石墨烯的制备方法主要有机械剥离法,晶体外延法,化学气相沉积法,插层剥离法以及采用氧化石墨烯的高温脱氧和化学还原法等[4-10]。与碳纳米管类似,石墨烯很难作为单一原料生产某种产品,而主要是利用其突出特性与其它材料体系进行复合.从而获得具有优异性能的新型复合材料。而氧化石墨烯由于其特殊的性质和结构,使其成为制备石墨烯和石墨烯复合材料的理想前驱体。本文综述了石墨烯复合材料的结构、分类及其在催化领域、电化学领域、生物医药领域和含能材料领域的应用。

高分子_石墨烯纳米复合材料研究进展

高分子/石墨烯纳米复合材料研究进展 高秋菊1,夏绍灵1,2* ,邹文俊1,彭 进1,曹少魁2 (1.河南工业大学材料科学与工程学院,郑州 450001;2.郑州大学材料科学与工程学院,郑州 450052 )收稿:2012-01-09;修回:2012-04- 24;基金项目:郑州科技攻关项目(0910SGYG23258- 1);作者简介:高秋菊(1984—),女,硕士研究生,主要从事高分子复合材料的研究。E-mail:gaoqiuj u2008@yahoo.com.cn;*通讯联系人,Tel:0371-67758722;E-mail:shaoling _xia@haut.edu.cn. 摘要: 石墨烯以其优异的力学、光学、电学和热学性能,得到日益广泛的关注和研究。本文介绍了石墨烯的结构、性能和特点,并对石墨烯的改性方法进行了概括。本文着重综述了高分子/石墨烯纳米复合材料的研究现状和进展,并介绍了高分子/石墨烯纳米复合材料的三种制备方法,即原位插层聚合法、溶液插层法和熔融插层法。此外,还对高分子/石墨烯纳米复合材料的应用前景进行了展望,并对石墨烯复合材料研究存在的问题和未来的研究方向进行了讨论。 关键词:石墨烯;高分子;纳米复合材料;研究进展 引言 石墨烯是以sp2 杂化连接的碳原子层构成的二维材料, 其厚度仅为一个碳原子层的厚度。这种“只有一层碳原子厚的碳薄片”,被公认为目前世界上已知的最薄、最坚硬、最有韧性的新型材料。石墨烯具 有超高的强度,碳原子间的强大作用力使其成为目前已知力学强度最高的材料。石墨烯比钻石还坚硬, 强度比世界上最好的钢铁还高100倍[1] 。石墨烯还具有特殊的电光热特性, 包括室温下高速的电子迁移率、 半整数量子霍尔效应、自旋轨道交互作用、高理论比表面积、高热导率和高模量、高强度,被认为在单分子探测器、集成电路、场效应晶体管等量子器件、功能性复合材料、储能材料、催化剂载体等方面有广泛 的应用前景[ 2] 。石墨烯是一种疏松物质,在高分子基体中易团聚,而且石墨烯本身不亲油、不亲水,在一定程度上也限制了石墨烯与高分子化合物的复合,尤其是纳米复合。因而,很多学者对石墨烯的改性进行了大量的研究,以提高石墨烯和高分子基体的亲和性,从而得到优异的复合效应。 1 石墨烯的改性方法 1.1 化学改性石墨烯 该方法基于改性Hummers法[3] 。首先,由天然石墨制得石墨氧化物, 再通过几种化学方法获得可溶性石墨烯。其化学方法包括:氧化石墨在稳定介质中的还原[4]、通过羧基酰胺化的共价改性[5] 、还原氧化石墨烯的非共价功能化[ 6]、环氧基的亲核取代[7]、重氮基盐的耦合[8] 等。此外,还出现了对石墨烯的氨基化[9]、酯化[10]、异氰酸酯[11] 改性等。用化学功能化的方法对石墨烯进行改性,不仅可以提高其溶解性 和加工性能,还可以增强有机高分子间的相互作用。1.2 电化学改性石墨烯 利用离子液体对石墨烯进行电化学改性已见报道[12] 。用电化学的方法,使石墨变成用化学改性石 墨烯的胶体悬浮体。石墨棒作为阴极,浸于水和咪唑离子液的相分离混合物中。以10~20V的恒定电 · 78· 第9期 高 分 子 通 报

通信用磷酸铁锂电池及系统的原理与应用

通信用磷酸铁锂电池及系统的原理与应用 传统的阀控式密封铅酸电池以其成本低廉、技术成熟、维护方便得到广泛应用,然而,随着无线通信技术的不断发展和移动基站应用场景的复杂化,传统的蓄电池逐步显现出体积大、对环境温度要求苛刻等劣势。磷酸铁锂电池系统由于具有体积小、重量轻,高温性能突出,循环性能优异,可高倍率充、放电,绿色环保等众多优点,更适用于环境温度高、机房面积及承重小等恶劣的基站环境。同时,在末端供电磷酸铁锂电池也可作为铅酸蓄电池的有效补充。 一、目前通信后备电源面临的问题 1、传统铅酸蓄电池对环境温度要求比较高 目前市内宏基站的站址选择越来越难,室外一体化基站开始大规模建设。传统的铅酸蓄电池对环境温度要求比较高的特点造成传统的铅酸蓄电池很难适应室外高温等恶劣天气。另外,除了铅酸蓄电池外,室内宏基站的其他设备对环境温度的适应范围都比较宽。机房空调就是为了给铅酸蓄电池提供适当的环境温度。为了节能减排,目前已开发出蓄电池保温箱等蓄电池专用的小型空调设备。如果能找到一种对环境温度要求不高的电池作为后备电源,不仅能解决室外一体化基站后备电源的问题,而且还能省掉机房专用空调,这样既节省了工程初期购买空调的投资,也节省了基站运行时的大量电费开销。 2、传统铅酸蓄电池对机房面积和承重要求高 室内宏基站设备中,电源设备占比最大,而电源设备中提及和占地面积最大的就是蓄电池。室内宏基站的机房大多采用民房,根据结构专业的统计计算,民房的承重设计一般为150~200kg/m,而铅酸蓄电池对机房的承重要求不低于 400kg/m,所以在现有的民房内摆放铅酸蓄电池都需要经过加固处理。这样一方面加大了工程量,另一方面也加大了选址难度。另外,目前通信设备逐步向小型化、分散化的方向发展,末端设备的功耗越来越小,要求后备电池的体积更小,重量更轻。 3、传统铅酸蓄电池的高倍率放电性能较差 目前电网质量越来越完善,很少出现市电大面积长时间停电的状况,而基站的停电往往是由于市政项目的频繁建设所造成的短时间频繁停电,这需要蓄电池短时间大电流高倍率放电,而传统铅酸蓄电池的高倍率放电性能较差。

CN3063 CN3065和CN3082利用太阳能对电池充电

利用太阳能板对电池充电的应用 本文主要讨论太阳能电池的工作原理和电气输出特性,以及利用CN3063、CN3065和CN3082这三款芯片利用太阳能为电池充电的解决方案。 太阳能电池的I-V 特性 太阳能电池一般由p-n 结组成,p-n 结中的光能(光子)通过导致电子和空穴的重新组合而产生电流。由于p-n 结的特性类似于二极管的特性,我们一般以如图1中所示的电路作为太阳 能电池特性的一个简化模型。 IPH 图1 太阳能电池简化电路模型 电流源IPH 产生的电流和太阳能电池上的光量度成正比。在没有负载连接的时候,几乎所有产生的电流都流过二极管D ,其正向电压决定着太阳能电池的开路电压(V OC )。该电压会因各种类型太阳能电池的特性不同而有所差异。但是,对于大多数硅电池而言,这一电压都在0.5V 到0.6V 之间,这也是p-n 结二极管的正常正向电压。 在实际太阳能电池应用中,并联电阻(RP)的泄漏电流很小,而RS 则会产生连接损耗。图2展示了太阳能电池在输出上的特性。由于串联电阻(RS)的原因,电压会稍有下降。然而,有时如果通过内部二极管的电流太小,会导致偏置不够,并且穿过它的电压会随着负载电流的增加而急剧下降。最后,如果所有电流都只流过负载而不流过二极管,输出电压就会变为零。这个电流被称为太阳能电池的短路电流(I SC )。I SC 和V OC 都是定义太阳能工作性能的主要参数之一。因此,太阳能电池被认为是“电流限制”型电源。它的输出电压会随着输出电流的增加而降低,并在负载电流达到短路电流时降为零。 由于太阳能电池的输出电流同光照强度的变化而变化,所以一般不能用太阳能电池给用电系统直接供电,一般需要将太阳能电池的能量先存储在蓄电池中,然后通过电池为系统供电。这就要求充电电路能够适应太阳能电池的电压-电流输出特性。 CN3063、CN3065和CN3082就是根据太阳能电池的电压-电流输出特性而设计的,芯片内部集成有8位模数转换器,它能够根据输入电压源的电流输出能力自动调节充电电流。所以 只要太阳能电池的开路电压V OC 在4.35V~6V 之间, 那么CN3063、CN3065和CN3082就可以对电池进行充电。而且用户不需要考虑最坏情况,只要根据最好情况设置充电电流就可以了,最大限度地利用了输入电压源的电流输出能力。

石墨烯复合材料

石墨烯复合材料 石墨烯是单层碳原子通过sp2杂化形成的蜂窝点阵结构,属于二维原子晶体,此独特的空间结构,给石墨烯带来了优异的电学、力学、热学和比表面积大等性质。但是二维石墨烯由于片层之间具有较强的π-π作用和范德华力,使得石墨烯容易聚集形成石墨,限制了石墨烯在各个领域中的应用。因此,为了防止石墨烯的聚集和拓展石墨烯的应用,科研工作者将石墨烯与高分子或者无机纳米粒子进行复合,从而得到具有优异性能的复合材料。石墨烯的复合材料具有化学稳定性高、比表面积大,易回收等特点,在环境治理方面受到了科学家的青睐。 一、石墨烯复合材料的分类和制备 1、石墨烯-高分子复合材料 石墨烯-高分子复合材料,石墨烯的独特的结构和性能,对于改善高分子的导电性、热性能和吸附能力等方面有非常大的应用价值。制备石墨烯-高分复合材料最直接的方法是将高分子溶液与石墨烯的溶液混合,其中高分子和填充物在溶剂中的溶解能力是保证最佳分散度的重要因素。因此,在溶液混合时,可以将石墨基质表面功能化来提高它在多种溶剂中的溶解度。例如,异氰酸

苯酯修饰的GO在在聚苯乙烯的DMF溶液中表现出了较好的溶解度。 2、石墨烯-无机纳米粒子复合材料 无机纳米粒子存在着易于团簇的问题,并且选择合适的载体也是其广泛应用需要解决的问题。石墨烯具有多种优异的性能,并且具有较大的比表面积,可以成为无机纳米材料的载体。无机纳米粒子可以将易于团簇的石墨烯片层分开,防止团簇,从而两者形成石墨烯-无机纳米粒子新型的复合材料,这些材料广泛的应用于检测、催化和气体存储等方面。目前已报道的有负载的金属纳米粒子Ag、Au、氧化物纳米粒子ZnO和Fe3O4等。 3、其它石墨烯复合材料 石墨烯不仅仅可以和高分子、无机纳米材料复合,还可以同时结合高分子、纳米粒子和碳基材料中的一种或者两种,形成多元的含有石墨烯的复合材料。这类材料具有多功能性,用于超级电容器或者传感器等。 二、石墨烯复合材料在水治理的应用 1、吸附作用 碳材料中活性碳和碳纳米管被广泛的应用于水净化领域,将石墨烯与其它化合物进行复合,这些复合材料在吸附污染物上有非常高的效率,可以应用于染料、多芳香环烃和汽油的吸附。比如利用磁性-壳聚糖-石墨烯的复合材料可以大大提高去除溶液中的亚甲基蓝的效率,吸附能力达到

锂电池充电电路详解

锂电池充电电路图 锂电池是继镍镉、镍氢电池之后,可充电电池家族中的佼佼者.锂离子电池以其优良的特性,被广泛应用于: 手机、摄录像机、笔记本电脑、无绳电话、电动工具、遥控或电动玩具、照相机等便携式电子设备中。 一、锂电池与镍镉、镍氢可充电池: 锂离子电池的负极为石墨晶体,正极通常为二氧化锂。充电时锂离子由正极向负极运动而嵌入石墨层中。放电时,锂离子从石墨晶体内负极表面脱离移向正极。所以,在该电池充放电过程中锂总是以锂离子形态出现,而不是以金属锂的形态出现。因而这种电池叫做锂离子电池,简称锂电池。 锂电池具有:体积小、容量大、重量轻、无污染、单节电压高、自放电率低、电池循环次数多等优点,但价格较贵。镍镉电池因容量低,自放电严重,且对环境有污染,正逐步被淘汰。镍氢电池具有较高的性能价格比,且不污染环境,但单体电压只有1.2V,因而在使用范围上受到限制。 二、锂电池的特点: 1、具有更高的重量能量比、体积能量比; 2、电压高,单节锂电池电压为3.6V,等于3只镍镉或镍氢充电电池的串联电压; 3、自放电小可长时间存放,这是该电池最突出的优越性; 4、无记忆效应。锂电池不存在镍镉电池的所谓记忆效应,所以锂电池充电前无需放电; 5、寿命长。正常工作条件下,锂电池充/放电循环次数远大于500次; 6、可以快速充电。锂电池通常可以采用0.5~1倍容量的电流充电,使充电时间缩短至1~2小时; 7、可以随意并联使用; 8、由于电池中不含镉、铅、汞等重金属元素,对环境无污染,是当代最先进的绿色电池; 9、成本高。与其它可充电池相比,锂电池价格较贵。 三、锂电池的内部结构: 锂电池通常有两种外型:圆柱型和长方型。 电池内部采用螺旋绕制结构,用一种非常精细而渗透性很强的聚乙烯薄膜隔离材料在正、负极间间隔而成。正极包括由锂和二氧化钴组成的锂离子收集极及由铝薄膜组成的电流收集极。负极由片状碳材料组成的锂离子收集极和铜薄膜组成的电流收集极组成。电池内充有有机电解质溶液。另外还装有安全阀和PTC元件,以便电池在不正常状态及输出短路时保护电池不受损坏。 单节锂电池的电压为3.6V,容量也不可能无限大,因此,常常将单节锂电池进行串、并联处理,以满足不同场合的要求。字串5 四、锂电池的充放电要求; 1、锂电池的充电:根据锂电池的结构特性,最高充电终止电压应为4.2V,不能过充,否则会因正极的锂离子拿走太多,而使电池报废。其充放电要求较高,可采用专用的恒流、恒压充电器进行充电。通常恒流充电至4.2V/节后转入恒压充电,当恒压充电电流降至100mA 以内时,应停止充电。 充电电流(mA)=0.1~1.5倍电池容量(如1350mAh的电池,其充电电流可控制在135~2025mA之间)。常规充电电流可选择在0.5倍电池容量左右,充电时间约为2~3小时。 2、锂电池的放电:因锂电池的内部结构所致,放电时锂离子不能全部移向正极,必须保留一部分锂离子在负极,以保证在下次充电时锂离子能够畅通地嵌入通道。否则,电池寿命就相应缩短。为了保证石墨层中放电后留有部分锂离子,就要严格限制放电终止最低电压,也就是说锂电池不能过放电。放电终止电压通常为3.0V/节,最低不能低于2.5V/节。电池放

石墨烯基复合材料的制备及吸波性能研究进展

石墨烯基复合材料的制备及吸波性能研究 进展 摘要随着吉赫兹(GHz)频率范围的电磁波在无线通信领域的广泛应用,诸如电磁干扰、信息泄露等问题亟待解决。此外,军事领域中的电磁隐身技术与导弹的微波制导需要,使得电磁波吸收材料受到持续而广泛的关注。因此,迫切需要发展一种厚度薄、频带宽、强吸收的吸波材料。 石墨烯作为世界上最薄硬度最强的纳米材料,优点很多,例如石墨烯制成的片状材料中,厚度最薄,比表面积较大,具有超过金刚石的强度等,这些优点满足吸波材料的需求。石墨烯基复合材料在满足吸波材料基本要求的基础上又提升了材料吸收波的能力。 本文简单地介绍了吸波材料及石墨烯,综述概况了石墨烯基复合材料的研究现状,包括石墨烯复合材料制备方法、微观形貌以及复合材料的吸波性能,提出了石墨烯基复合吸波材料未来的发展方向。 关键词石墨烯基;吸波材料;纳米材料

Progress in Preparation and absorbing properties of graphene-based composites Abstract With the gigahertz (GHz) frequency range of the electromagnetic waves are widely used in wireless communications, such as electromagnetic interference, information leaks and other problems to be solved. In addition, military stealth technology in the field of electromagnetic and microwave guided missiles require such electromagnetic wave absorbing material is subjected to a sustained and widespread concern. Therefore, an urgent need to develop a thin, wide frequency band, a strong absorption of absorbing materials. Graphene as the strongest of the world's thinnest hardness nanomaterials, has many advantages, such as a sheet material made of graphene, the thinnest, large specific surface area, with more than a diamond of strength, these benefits meet absorbers It needs. Graphene-based composites on the basis of absorbing materials to meet the basic requirements but also enhance the ability of the material to absorb waves. This article briefly describes the absorbing material and graphene, graphene reviewed before the status quo based composite materials research, including graphene composite material preparation, morphology and absorbing properties of composites made of graphene-based composite

石墨烯在复合材料中的应用

石墨烯在复合材料中的应用 龚欣 (东南大学机械工程学院南京211189) 摘要:介绍了石墨烯与有机高聚物、无机纳米粒子以及其它碳基材料的复合物,同时展望了这些材料在相关领域中的应用前景. 关键词:石墨烯纳米复合材料 2004年至今, 关于石墨烯的研究成果已在SCI检索期刊上发表了超过2000篇论文, 石墨烯开始超越碳纳米管成为了备受瞩目的国际前沿和热点.基于石墨烯的纳米复合材料在能量储存、液晶器件、电子器件、生物材料、传感材料和催化剂载体等领域展现出许多优良性能,具有广阔的应用前景.目前研究的石墨烯复合材料主要有石墨烯/聚合物复合材料和石墨烯/无机物复合材料两类,其制备方法主要有共混法、溶胶-凝胶法、插层法和原位聚合法.本文将对石墨烯的纳米复合材料及其性能等方面进行简要的综述. 一、基于石墨烯的复合物 利用石墨烯优良的特性与其它材料复合可赋予材料优异的性质.如利用石墨烯较强的机械性能,将其添加到高分子中,可以提高高分子材料的机械性能和导电性能;以石墨烯为载体负载纳米粒子,可以提高这些粒子在催化、传感器、超级电容器等领域中的应用. 1.1 石墨烯与高聚物的复合物 功能化后的石墨烯具有很好的溶液稳定性,适用于制备高性能聚合物复合材料.根据实验研究,如用异氰酸酯改性后的氧化石墨烯分散到聚苯乙烯中,还原处理后就可以得到石墨烯-聚苯乙烯高分子复合物.该复合物具有很好的导电性,添加体积分数为1%的石墨烯时,常温下该复合物的导电率可达0.1S/M,可在导电材料方面得到的应用. 添加石墨烯还可显著影响高聚物的其它性能,如玻璃化转变温度(Tg)、力学和电学性能等.例如在聚丙稀腈中添加质量分数约1%的功能化石墨烯,可使其Tg 提高40℃.在聚甲基丙烯酸甲酯(PMMA)中仅添加质量分数0.05%的石墨烯就可以将其Tg提高近30℃.添加石墨烯的PMMA比添加膨胀石墨和碳纳米管的PMMA具有更高的强度、模量以及导电率.在聚乙烯醇(PVA)和PMMA中添加质量分数0.6% 的功能化石墨烯后,其弹性模量和硬度有明显的增加.在聚苯胺中添加适量的氧化石墨烯所获得的聚苯胺-氧化石墨烯复合物的电容量(531F/g)比聚苯胺本身的电容量(约为216F/g)大1倍多,且具有较大的拉伸强度(12.6MPa).这些性能为石墨烯-聚苯胺复合物在超级电容器方面的应用创造了条件. 石墨烯在高聚物中还可形成一定的有序结构.通过还原分散在Nafition膜中