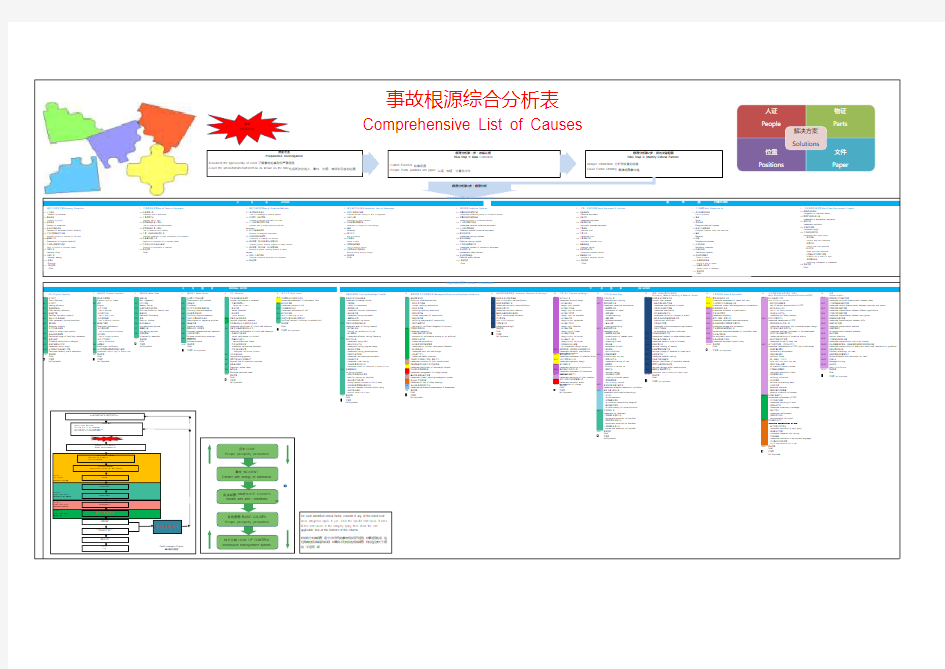

事故根源综合分析表 Comprehensive List of Causes

··

1体力 Physical Capbility2身体状况 Physical Condition3精神状态 Metal State4精神压力 Metal Stress5行为 Behavior6技术水平 Skills Level7训练知识转换 Training/Knowledge Transfer8管理监督员工的领导关系 Management/Supervision/Employee Leadership9承包商的选择和审查 Contractor Selection & Oversight10工程设计 Engineering/Design11工作计划 Work Plan12采购、材料处理及材料控制

Puchasing, Material Handling & Material Control 13工具和设备 Tools & Equipment14工作规程政策标准程序(PSP)

Work Rules/Policies/Standards/Procedures(PSP)

15沟通

Communication

1-1视力低下

Vision Deficiency 2-1原先受伤或得病

Previous injury or illness

3-1判断力差

Poor Judgement

4-1全神贯注于别的问题

Preoccupation with problems

5-1不合格的操作受到奖赏

Inproper performance is rewarded

6-1对所需求技术没有充分评估

Inadequate assessment of requirement skills

7-1没有进行充分的知识转换

Inadequate knowledge transfer

8-1角色和职责冲突

Conflicting roles/responsibilities

9-1承包商未进行资格预备审

Lack of contractor pre-qualifications

10-1技术设计欠妥

Inadequate technical design

11-1工作计划欠妥

Inadequate work planning

12-1收货项目与订购项目不符

Incorrect item received

13-1需求和风险评估欠妥

Inadequate assessment of needs and risks

14-1执行任务缺乏PSP

Lack of PSP for the task

15-1在同伴间水平沟通不完善

Inadequate horizontal communication between peers

1-2听力低下

Hearing deficiency 2-2疲劳

Fatigue

3-2记忆力丧失

Memory Failure

4-2受到挫折

Frustration

·节省时间或努力

saves time or effort

6-2缺乏技术实践

Inadequate practice of skill

·不能领会

inablity to comprehend

·报告关系不明确

unclear reporting relationships

9-2承包商资格预审欠妥

Inadequate contractor pre-qualifications

·技术输入陈旧

design input obsolete

11-2预防性保养欠缺

Inadequate preventive maintenance

·给供应商的规范不正确

inadequate specifications to vendor

13-2人的因素及人机控制考虑欠缺

Inadequate human factors/ergonomics considerations

·缺乏PSP的详细职责

lack of defined responsibilities for PSP

15-2上下级间垂直沟通不完善

Inadequate vertical communication between supervisor and person

1-3其他感官缺陷

Other sensory deliciency ·由于工作量

due to workload

3-3协调不好或反应时间长

Poor coordination or reaction time

4-3对工作方向及要求模糊不清

Confusing directions/demands

·避免不便

avoids discomfort

6-3不经常操作的技术

Inadequate performance of skill

·导师资格欠缺

inadequate instructor qualifications

·报告关系矛盾

conflicting reporting relationship

9-3承包商选用欠妥

Inadequate contractor selection

·技术输入不正确

design input not correct

·维修需求评估

assessment of needs

·订购书上的规范不明确

Inadequate specification

13-3标准和规范不合适

Inadequate standards or specifications

·缺乏作业安全分析

lack of job safety analysis

15-3不同机构间沟通不完善

Inadequate communication between different organizations

1-4肺活量下降

Reduced respiratory capacity ·由于缺乏休息

due to lack of rest

3-4情绪干扰

Emotional Disturbance

4-4目标或要求相冲突

Conflicting directions/demands

·哗众取宠

gains attention

6-4缺乏技术指导

Lack of coatching on skill

·培训设备不够

inadequate training equipment

·职责分配不清

unclear assignment of responsibility

9-4雇佣未经审核批准的承包商

Use of non-approved contractor

·技术输入不可用

design input not available

·润滑/维修

lurication/servicing

·对订单修改控制不当

inadequate control on changes to orders

13-4不适当的可用性

Inadequate availability

·作业安全分析不当

Inadequate job safety analysis

15-4工作组之间沟通不完善

Inadequate communication between work groups

1-5其他永久性身体残疾

Other permanent physical dsiablities ·由于感官超载

due to sensory overload

3-5恐惧

Fears or phobias

4-5无意义的或品味低的活动

Meanningless or degrading activities

5-2没有适当的监督规范

Improper supervisory example

6-5没有充分温习训练以巩固技术

Insufficient review of instruction to establish skill

·误解指令说明

misunderstood instructions

·职责分配矛盾

conflicting assignmnet of responsibility

9-5无工程监管

Lack of job oversight

·设计输出不妥

design output inadequate

·调整/装配

adjustment/assembly

·供应商未经批准擅自更换替代品

unauthorized substitution

13-5调节、修理、保养欠妥

Inadequate adjustment/repair/maintenance

14-2PSP工作展开不力

Inadequate development of PSP

15-5班组倒班沟通不完善

Inadequate communications between shifts

1-6暂时残疾

Temporary disability 2-3操作能力降低

Deminished performance

3-6缺乏机械知识

Low mechniacal aptitude

4-6情绪超负荷

Emotional overload

5-3对关键的安全行为没有充分的认识

Inadequate identification of critical safe behaviors

6-6其他因素

Other

7-2不能充分回想起训练内容

inadequate recall of training material

·授权不清或不妥

improper or insufficient delegation of authority

9-6工程监管欠妥

Inadequate oversight

·设计输入不可行

design input infeasible

·清洁/涂层

cleaning/resurfacing

·产品验收不完善

Inadequate product acceptance requirements

13-6废旧物品和再次利用物资处理不妥

Inadequate salvage and reclamation

·程序和设备设计不相一致

inadequate coordination with process/euiqpment design

15-6沟通方法不完善

Inadequate communication methods

1-7无力支撑身体姿势

Inability to sustain body position ·由于温度极限

due to temporature extremes

3-7理解能力差

Low learning aptitude

4-7国际的评价决定要求

Extremed judgement/decision demands

5-4没有充分强调关键的安全行为

Inadequate reinforcement of critical safe behaviors

不适用 Not Applicable

·缺乏强化培训

Training not reinforce on thr job

8-2不适宜的领导关系

Inadequate leadership

9-7其他因素

Other

·设计输出不清

design output unclear

11-3维修性保养欠缺

Inadequate repair

·未进行产品验收

no acceptable verification performed

13-7不合适部件拆卸和更换欠妥

Inadequate removal/replacement of unsuitable items

·员工参与PSP制定安排不当

inadequate emplyee involvement in the development

15-7沟通手段缺乏

No communication methods available

1-8身体活动范围受限

Restricated range of body body movement ·由于缺氧

due to oxygen efficiency

3-8受药物影响

Influenced by medication

4-8过度的精力集中

Extreme concentration perception

demands

·正确的行为被指责

proper performance is criticized

·缺少再培训

inadequate refresher training frequency

·业绩标准缺乏或力度不够

standards of performance missing or not enforced

不适用

Not Applicable

·设计输出不正确

design output not correct

·维修需求信息沟通

communication of needed repair

12-2对材料和设备研究不足

Inadequated research on materials/equipment

13-8无设备记录档案

No equipment record history

·纠正行为的详细说明不充分

Inadequate definition of corrective actions

15-8指令不准确

Incorrect directions

1-9物质过敏症

Substence sensitivities or allergies ·由于大气压变化

due to atmosphere

3-9其他因素

Other

4-9极度的乏味

Extreme boredom

·同事的不当压力

inappropriate peer stress

7-3培训工作欠缺

inadequate trainig effort

·职责和义务不明

inadequate accoutability

·设计输出不一致

design output not correct

·工作计划安排

scheduling of work

12-3产品运输方式线路欠妥

Inadequate mode or route of shipment

13-9设备记录档案不完备

Inadequate equipment record history

·格式不妥使PSP不实用

Inadequate format for easy use

15-9工作更换没有很好沟通

Inadequate communication due to job turnover

1-1身高不够或体力不足

Inadequate size or length 2-4血糖降低

Blood sugar insufficency

不适用

Not Applicable

4-10其他因素

Other

·不适当的表现反馈

inadequate performance feedback

·培训计划设计不当

inadequate training program design

·执行情况反馈不够或错误

inadequate or incorrect performance feedback

·没有独立的设计审查

no independent design review

·部件检查

examination of parts

12-4材料处理欠妥

Improper handling of material

13-10其他因素

Other

14-3由于内容不完善,PSP执行不力

Inadequate implementation of PSP, due to deficiencies

15-10安全和健康保护资料、规章制度或指导准则没有很好沟通

Inadequate communication of safety and health data, requlations or guidelines

1-11由于药物疗法造成能力下降

Diminished capacity due to medication 2-5由于使用药物或酒精而使能力减弱

Imparement due to drug or alcohol use

不适用 Not Applicable

·不适当的纪律处置

inadequate disciplinary process

·培训目标不准确

inadequate training goals/objectives

·缺少现场走访

inadequate work site walk-through

10-2所采用标准、规范和设计指导思想欠妥

Inadequate standards, specifications,

and/or design criteria

·部件更换

parts substitution

12-5材料或零部件保管不妥

Improper storage of materials or spare parts

不适用 Not Applicable

·自相矛盾的需求

contradictory requirements

15-11没有选用标准术语

Standard terminology not used

1-12其他因素

Other 2-6其他因素

Other

5-5过分的急功好进

Inappropriate aggression

·对新员工缺乏教育

inadequate new employee orientation

·安全推广不力

inadequate safety promotion

10-3潜在问题估计不足

Inadequate assessment of potential failure

11-4过度磨损和撕裂

Excessive wear and tear

12-6材料包装不妥

Inadequate material packing

·混款含糊的模式

confusion format

15-12没有使用查证和重复技术

Verification/repeat back techniques not used

不适用

Not Applicable

不适用

Not Applicable

5-6使用不适当的方法刺激生产

Improper use of production incentives

·初始培训不妥

inadequate initial training

8-3工地或工作中隐患(危险)整改不力

Inadequate correction of prior hazard/incident

10-4人机工程学设计欠妥

Inadequate ergonomic design

·使用计划不当

inadequate planning of use

12-7危险品不能正确鉴别

Improper identification of hazardous maerials

·每一步超过一个行为

more than one action per step

15-13口信过长

Messages too long 5-7监督暗中催促

Sueprvisor implied haste

·无法判定是否合适上岗

inadequate means to determine if qulified for job

8-4不能明确鉴别工地和工作中危险隐患

Inadequate identification of worksite/job hazards

10-5施工监察欠妥

Inadequate monitoring of construction

·超期服役

extension of service life

12-8使用不当或废弃材料处置

Improper salvage and/or waste disposal

·程序中无确认步骤

no check-off spaces provided

15-14讲话干扰

Speech interference 5-8雇员性急

Employee perceived haste

7-4没有提供培训

No traning provided

8-5不合适的变更管理系统

Inadequate management of change system

10-6操作准备工作评估欠妥

Inadequate assessment of operational

readiness

·装载不当

Improper loading

12-9健康安全资料使用不当

Inadequate use of safety and health data

·不准确的步骤顺序

inaccurate sequence of steps

15-15其他因素

Other 5-9其他因素

Other

·没有认识到培训的必要性

need for training not identified

8-6事故报告调查机制不完善

Inadequate incident reporting/investigation system

10-7对最初操作监察不力

Inadequate monitoring of initial operation

·未经训练的人使用

used by untrained people

12-10其他因素

Other

·混乱模糊的指令

confusing instructions

不适用 Not Applicable 不适用

Not Applicable

·培训记录不对或过期

training records incorrect or out of date

8-7安全会议不足或没有

Inadequate or lack of safety meetings

10-8评估欠妥和文档变更管理欠妥

Inadequate evaluation and/or

documentation of change

·使用意图错误

use of wrong purpose

不适用 Not Applicable

·技术性错误

technical error/missing steps

·未经培训就使用新的操作方法

new work methods introdued without traiing

8-8安全业绩考核和评估不当

Inadequate performance measurement & assessment

10-9其他因素

Other

11-5有关参考资料或文献不足

Inadequate reference materials or publication

·过多的说明

excessive reference

·故意不参加培训

decision made not to train

8-9其他因素

Other

不适用

Not Applicable

11-6审核检查监视欠缺

Inadequate audit/inspection/monitoring

·潜在的情形没有覆盖

potential situations not covered

7-5其他因素

Other

不适用

Not Applicable

·无文件

no documentation

14-4PSP强化措施不力

Inadequated enforcement of PSP

不适用

Not Applicable

·未明确整改责任

no correction responsibility assigned

·对工作缺乏监察

inadequate monitoring of work

·整改措施不落实

no accountability for corrective action

·监督知识不足

inadequate supervisory knowledge

11-7工作安排欠妥

Inadequate job placement

·强化不充分

Inadequate reinforcement

·没有确定合适的人选

appropriate personnel not identified

·没有纠正不符合

non-compliance not correct

·没有可用的合适人选

appropriate personnel not available

14-5PSP沟通传达不力

Inadequate communication of PSP

·没有提供合适人选

appropriate personnel not provided

·给工作组分发不完全

incomplete dsitribution to work group

11-8其他因素

Other

·培训整合不完善

incomplete integration with training

不适用

Not Applicable

·不妥的翻译

inadequate translation to appropriate languages

·已过是的PSP仍在使用

out of date revisions still in use

14-6其他因素

Other

不适用

Not Applicable

可能的直接原因 POSSIBLE SYSTEM CAUSES

行 为 类 ACTIONS条 件 类 CONDITIONS

人 为 因 素 PERSONAL FATORS工 作 因 素 JOB FATORS

可能的系统原因 POSSIBLE SYSTEM CAUSES

事故根源综合分析表

Comprehensive List of Causes

事故

INCIDENT

调查准备

Preparation Investigation

·Document the type/severity of event 记录事故的类型和严重程度

·Cover the who/what/when/where/how as known as the time包括所涉及的人、事件、时间、地点和目前的进展

根源分析第一步:收集证据

RCA Step 1: Data Collection

·Collect Evidence 收集证据

·People, Parts, positions and paper 认证、物证、位置和文件

根源分析第2步:找出关键起因

RAC Step 2: Identify Critical Factors

·Analyze Information 分析所收集的信息

·Cause Factor Charting 重建起因事件链

人证

People

物证

Parts

位置

Positions

文件

Paper

解决方案

Solutions

根源分析第3步:根源分析

Management Suppor and Responsibility

管理层支持和责任体系创建事故分析的企业文化

Preparing 准备

Classfication System 事故分类系统

Policy Procedures for notification事故通报程序

Policy Procedures for notification成立事故调查小组

Team supplies and training小组成员培训和组件

Management Suppor and Responsibility

事故通报、事件分类和启动调查小组

Begain Investigation 开始调查

Develop Specific Plan 制定调查计划

Secure Evidence保护证据

Collect Evidence收集证据

People, Parts,Position and Paper 人证、物证、位置和文件

Protective Evidence

保护证据

Overall Investigation Progress

事故调查总流程图

RCA Step 1

Data Collection

根源分析第一步收集证据

Analyse Information

分析所收集的信息

Identify Critical Causal Factors

识别事故关键起因

Identify Root Cause

事故起因根源分析

看不清楚原文

Formal Report

完成调查报告

Implement Recommendation 实施整改计划建议

Follow-up / Audit

后续检查审核看不清楚原文

RCA Step 2

Identify Critical Factors

根源分析第二步找出关键原因

RCA Step 3

Identify Critical Factors

根源分析第三步根源分析

RCA Step 4

Identify Critical Factors

根源分析第四步????

Complete

结束

损失LOSE

People,preoperty, production

事故INCIDENT

Contatc with energy or substance

直接起因IMMEDIATE CAUSES

Unsafe acts and / consitions

系统原因BASIC CAUSES

People,preoperty, production

缺乏控制LACK OF CONTROL

Inadeqaute management system

引

发

C

A

U

S

A

T

I

O

N调查

INVESTIGATION

For each identified critical factor, consider if any of the listed root

cause categories applu. If 'yes', circle the specific root cause. if none

of the root causes in the category apply, then check the 'not

applicable' box at the bottom of the column.

针对每个关键起因,逐个分析所列的事故根源是否适用。如果适用的话,选

定具体的根源编号和说明,如果找不到相应的根源起因,则可选定美栏下面

的“不适用”项

1 遵守工作程序方面Following Procedure

1-1 个人违规

Violation by individual

1-2 集体违规

Violation by group

1-3 监督违规

Violation by supervisor

1-4 未经许可操作设备

Operation of equipment without authority

1-5 工作位置或姿态不正确

Improper position or posture for the task"

1-6 超体能工作

Overexertion of physical capability"

1-7 工作或运载速度不适宜

Work or motion at improper speed"

1-8 吊装欠妥

Improper lifting"

1-9 加载欠妥

Improper loading

1-10 走捷径

Shortcuts

1-11 其他因素

Other 2 工具或设备使用Use of Tools or Equipment

2-1 设备使用欠妥

Impreoper use of equipment

2-2 工具使用不当

Improper use of tools

2-3 使用有缺陷设备(明知)

Use of detective equipment(aware)

2-4 使用有缺陷工具(明知)

Use of detective tools (Aware)

2-5 工具、设备和材料放置欠妥

Improper placement of tools, equipments and materials

2-6 设备操作速度欠妥

Operation of equipment at a improper speed

2-7 对正在运行的设备进行维修

Servicing of equipment in operation

2-8 其他因素

Other

3 保护方法的使用Use of Protective Methods

3-1 缺乏隐患存在意识

Lack of knowledge of hazards present

3-2 未使用个人保护用品

Personal protective equipment not used

3-3 个人保护用品使用不正确

Improper use of proper personal protective

equipment

3-4 动力设备维修保养

Servicing of energized equipment

3-5 设备和材料未能固定

Equipment or material not secured

3-6 保护装置、警示系统或安全装置失效

Disabled guards, warning systems or safety devices

3-7 保护装置、警示系统、安全装置拆卸

Removal of guards, warning systems or safety

devices

3-8 没有个人保护用品

Personal protective equipment not available

3-9 其他因素

4 疏忽缺乏安全意识Inattention/ Lack of Awareness

4-1 决定欠妥或缺乏判断

Improper decision making or lack of judgement

4-2 注意力分散

Distracted by other concerns

4-3 忽视地面和周围环境

Inattention to footing and surroundings

4-4 嬉闹

Horseplay

4-5 暴力行为

Acts of violence

4-6 未做警告

Failure to warn

4-7 使用药物或酒精

Use of drugs or alcohol

4-8 无思索地进行常规活动

Routine activity without thought

4-9 其他因素

Other

5 保护系统Protective Systems

5-1 护罩和保护性装置不够

Inadequate protective guards or protective devices

5-2 护罩和保护性装置缺陷

Defective guards or protective devices

5-3 个人保护用品不适宜

Inadequate personal protective equipment

5-4 个人保护用品缺陷

Defective personal protective equipment

5-5 警示系统不适

Inadequate warning systems

5-6 警示系统缺陷

Defective warning system

5-7 工艺或设备隔离不妥

Inadequate isolation of process or equipment

5-8 安全装置欠妥

Inandequate safety devices

5-9 安全装置有缺陷

Defective safety devices

5-10 其他因素

Other

6 工具、设备及车辆Tools-Equipment & Vehicles

6-1 设备有缺陷

Defective equipment

6-2 设备不足

Inadequate equipment

6-3 设备准备不够

Improperly prepared equipment

6-4 工具缺陷

Defective tools

6-5 工具欠妥

Inadequate tools

6-6 工具准备不妥

Improperly prepared tools

6-7 车辆有缺陷

Defective vehicle

6-8 车型和用途不符

Inadequate prepared vehicle

6-9 车辆准备欠妥

Improperly prepared vehicle

6-10 其他因素

Other

7 工作暴露Work Exposures to

7-1 明火和爆炸性物品

Fire or explosion

7-2 噪音

Nosie

7-3 带点系统

Energized electrical systems

7-4 除电力外能源系统

Energized systems, other than electrical

7-5 辐射

Radiation

7-6 极温

Temperature extremes

7-7 化学危险品

Hazardous chemicals

7-8 机械危险物

Mechanical hazards

7-9 凌乱或石屑碎片

Clutter or debris

7-10 风暴或自然现象

Storms or acts of nature

7-11 地面或过道打滑

Slippery floors or walkways

7-12 其他因素

Other

8 作业场所环境布置Work Place Environment / Layout

8-1 拥挤或活动受制

Congestion or restricted motion

8-2 照明不适或光线太强

Inadequate or exxcessive illumination

8-3 通风不宜

Inadequate ventilation

8-4 无保护的高度

Uprotected height

8-5 工作场所布局不妥

Inadequate work place layout

·缺乏控制

controls less than adequate

·安置不妥

display less than adequate

·标示不妥

labels less than adequate

·位置超出可及或势力范围

locations out of reach or sight

·相矛盾的信息

confliciting information is presented

8-6 其他因素

Other