Volatile organic compounds from a Tuber melanosporum fermentation system

Volatile organic compounds from a Tuber melanosporum fermentation system

Yuan-Yuan Li a ,b ,Guan Wang a ,Hong-Mei Li a ,Jian-Jiang Zhong c ,Ya-Jie Tang a ,?

a

Key Laboratory of Fermentation Engineering (Ministry of Education),Hubei University of Technology,Wuhan 430068,China

b

Research Group for Bioactive Products,Department of Biology and Chemistry,City University of Hong Kong,Kowloon,Hong Kong SAR,China c

Key Laboratory of Microbial Metabolism (Ministry of Education),School of Life Sciences and Biotechnology,Shanghai Jiao Tong University,Shanghai 200240,China

a r t i c l e i n f o Article history:

Received 18January 2012

Received in revised form 24May 2012Accepted 2July 2012

Available online 14July 2012Keywords:

Tuber melanosporum Tuberaceae Fermentation Flavor volatiles

Volatile organic compounds Qualitative analyses

a b s t r a c t

A total of 59volatile organic compounds (VOCs)were identi?ed from Tuber melanosporum fermentation:53from its fermented mycelia and 32from the fermentation broth.Alcohol-derived compounds were predominant in both the fermentation mycelia and the broth,although long chain fatty acids and isopre-noids were,for the ?rst time,also found in the mycelia.The intense wine bouquet properties of the broth arose from several speci?c ?avor substances,including sulfur compounds,pyrazines,furans and https://www.360docs.net/doc/24589840.html,paring the VOCs identi?ed in this work with those previously reported,our results are more similar to the composition of the Tuber fruiting-body than previous Tuber fermentations.The composition and accumulation of ?avor volatiles (e.g.,pyrazines,sulfur compounds,and esters)and major constitu-ents (e.g.,3-methyl-1-butanol and 2-phenylethanol)in this fermentation were signi?cantly in?uenced by the sucrose concentration in the medium.The obtained information could therefore be useful in appli-cations to convert the ?avors of truf?e mycelia similar to those of the fruiting-body by optimising the fer-mentation process.

ó2012Elsevier Ltd.All rights reserved.

1.Introduction

Because of their unique and characteristic aromas,truf?es are widely used in French and Italian cuisines,particularly the French ‘‘black diamond’’truf?e Tuber melanosporum ,the notorious white Italian truf?e Tuber magnatum and the rare summer truf?e Tuber aestivum (Mello,Murat,&Bonfante,2006).Since the 1980s,an increasing number of scientists have focused on studying the vol-atile organic compounds (VOCs)produced by truf?es to discover the secret of truf?e aromas (Claus,Hoppen,&Karg,1981;Ney &Freytag,1980).Thus far,more than 200VOCs have been identi?ed from truf?e fruiting -bodies of various species around the world (Díaz,Ibá?ez,Se?oráns,&Reglero,2003;March,Richards,&Ryan,2006;Mauriello,Marino,D’Auria,Cerone,&Rana,2004;Pelusio et al.,1995;Splivallo,Bossi,Maffei,&Bonfante,2007).Alcohols,esters,ketones,aromatics and sulfur compounds are the most common constituents in the truf?e fruiting-body,and the sulfur compounds (i.e.,dimethyl sul?de,dimethyl disul?de,dimethyl tri-sul?de,and bis(methylthio)methane)are viewed as key odorants (Bellesia,Pinetti,Bianchi,&Tirillini,1996;Bellesia,Pinetti,Bianchi,&Tirillini,1998a,1998b;Bellesia et al.,2002;Talou,Delmas,&Gaset,1989;Talou,Gaset,Delmas,Kulifaj,&Montant,1990).More-over,the composition of VOCs is altered by genetic characteristics,geographical origin,and maturity (Gioacchini et al.,2009;Splivallo et al.,2007).Some special truf?es also possess distinct VOCs,such as 5H-furan-2-one and 2-methyl-4,5-dihydrothiophene for T.borchii (Splivallo et al.,2007).

Because of the great demand for truf?es in the market as well as a natural shortage of this wild resource,a new approach is urgently needed for truf?e production on a large https://www.360docs.net/doc/24589840.html,pared to natural ?eld collection and semi-arti?cial cultivation,the submerged fermentation of truf?es is a promising method for their ef?cient production (Tang,Zhu,Li,&Li,2007).In a previous study,a novel truf?e fermentation process was developed for producing T.melanosporum truf?e mycelia and polysaccharides (Liu,Li,Li,&Tang,2008;Liu et al.,2009;Tang,Zhu,Li,Mi,&Li,2008a;Tang et al.,2008b ).The presence of androstenol,a bioactive volatile compound in the T.melanosporum fruiting-body (Claus et al.,1981)found in truf?e fermentation,was also reported (Wang,Li,Li,&Tang,2008).Additionally,we have con?rmed that the fermen-tation conditions outweigh the truf?e species in affecting the aroma of the fermented mycelia and,furthermore,that this aroma can be adjusted by controlling the fermentation process (Tang,Wang,Li,&Zhong,2009).

Splivallo et al.and Tirillini et al.have reported the composition of VOCs from T.borchii cultured mycelia,but their Tuber species and fermentation process differed from ours (Splivallo et al.,2007;Tirillini,Verdelli,Paolocci,Ciccioli,&Frattoni,2000).Fur-thermore,our previous research con?rmed that the VOC composi-tion of the mycelia was signi?cantly in?uenced by fermentation conditions (Tang et al.,2009),so it was necessary to elucidate

0308-8146/$-see front matter ó2012Elsevier Ltd.All rights reserved.https://www.360docs.net/doc/24589840.html,/10.1016/j.foodchem.2012.07.013

Corresponding author.Tel./fax:+862788015108.

E-mail address:yajietang@https://www.360docs.net/doc/24589840.html, (Y.-J.Tang).

the composition of VOCs from our T.melanosporum fermentation system.

In this work,VOCs from T.melanosporum fermentation mycelia and broth were qualitatively studied by gas chromatography and mass spectrometry(GC–MS)for the?rst time.The composition of VOCs identi?ed in our fermentation was compared to that in the literature.Interestingly,the VOC composition by fermentation varied under different sucrose concentrations in the medium.

2.Materials and methods

2.1.Chemicals and reagents

The following authentic standards were purchased from Sigma–Aldrich China Inc.(Beijing,China):3-methyl-1-butanol, 2-methyl-1-butanol,3-methylbutanal,2-methylbutanal,2-methylbutanal,3-methyl butanoic acid,2-methyl butanoic acid, oleic acid,palmitic acid,linoleic acid,butylated hydroxy toluene,toluene,ethylbenzene,o-xylene,p-xylene,benzaldehyde, 2-phenylethanol,dimethylsulfane,and geranylacetone.

2.2.Tuber mycelia,broth and culture conditions

A strain of Tuber melanosporum was provided by the Mianyang Institute of Edible Fungi(Sichuan,China).The details of the basic culture medium and procedure have been described elsewhere (Wang et al.,2008).

To study the medium’s in?uence on volatile organic compound (VOC)production in truf?e fermentation,two medium types with different initial sucrose concentrations were used(Tang et al., 2009).Medium1was composed of sucrose(35g là1),peptone (5g là1),yeast extract(5g là1),MgSO4á7H2O(1g Là1),KH2PO4 (0.5g là1),and Vitamin B1(0.05g là1).Medium2was composed of the same ingredients as medium1except that the initial sucrose concentration was80g là1.

The truf?e fermentation mycelia and broth were harvested when the maximum dry cell weight(DCW)was obtained.After being centrifuged at9391.0?g for30min,both fermentation mycelia and broth were obtained and then stored at4°C.The fer-mentation mycelia(cultured by medium1)were dried at60°C in an oven for5days to obtain dried mycelia.

2.3.Mycelial VOCs extraction

Fermentation mycelia(200g)and de-ionized H2O(2L)were placed in a round-bottom?ask(5L)connected to a Clevenger vol-atile oil trap.To concentrate the VOCs from the vapour,ethyl ace-tate(4ml)was added to the top of the water in the volatile oil trap. After3-h distillation,the VOCs collected in the ethyl acetate layer were removed and dried using anhydrous sodium sulfate,and the ?nal volume was adjusted to5ml in an EP vial by addition of ethyl acetate.Dried fermentation mycelia(200g)and fermentation broth(500ml)were individually subjected to the same method. The liquid medium(without mycelia)was processed using the same method as the blank control.

2.4.GC/MS(FID)conditions

An Agilent7890A GC system equipped with a5975C quadru-pole mass spectrometer(MS)detector(CA,USA)was used.Separa-tions were carried out on a HP-5ms capillary column (30m?0.25mm i.d.,0.25l m?lm thickness)from Agilent Tech-nologies Inc.(CA,USA).The system was operated in the constant ?ow mode(1.0ml minà1)using He as carrier gas,and the sample was injected in split mode with the split ratio of10.The GC oven temperature was maintained at35°C for the?rst6min and then ramped to200°C at a rate of3°C minà1,held for2min,and?nally ramped to300°C at30°C minà1for1min.The injection port, transfer line and ion source temperatures were maintained at 200,250and200°C,respectively.The MS was run in an electron impact(EI)mode with electron energy of70eV and the total ion chromatogram(TIC)mode.The peaks,of which the area contrib-uted more than0.05%of the total peak area,were taken into fur-ther analysis(Tang et al.,2009).The relative percentage of each identi?ed peak was calculated with the area normalization method.

Some volatiles with very low boiling points,like3-methylbut-anal,2-methylbutanal,and dimethyl sul?de,were directly indenti-?ed using Shimadzu2010plus GC-FID system(Tokyo,Japan)by comparison of the retention times with those of standard com-pounds and by the spiked-in experiments respectively.The GC–FID temperature program was beginning at30°C for15min,then ramped by3°C minà1to50°C,held for an additional2min,then ramped by30°C minà1to300°C,and?nally held for5min.

2.5.Statistical analysis

The total ion chromatogram was processed by the Agilent MSD workstation.VOC identi?cation was performed in three ways: comparison of spectra with mass spectra databases(NIST05ò), comparison of Kovàts retention indices with data in NIST05,and comparison of retention times with authentic standards using GC–MS/FID directly.Three biological replicates(n=3)were per-formed for each experiment with deviations evaluated using the R.S.D(%)of retention times and the peak areas in the TIC(Tang et al.,2009).The relative amounts of volatiles in different media were statistically compared using the paired t-test(SPSS software).

2.6.Precision and repeatability

The injection precision was assessed by repetitive injections of the same sample solution six times in one day.The R.S.D.(%)of retention times and peak areas were lower than0.26and2.73 for mycelia and0.27and2.75for broth,respectively.

The reproducibility of the analysis method was determined by analyzing six independently prepared fermentation mycelia sam-ples using the same method.It was found that the R.S.D.(%)of retention time and peak areas were no more than0.29and3.12 for mycelia and0.32and3.12for broth,respectively.

The reproducibility of the fermentation method was deter-mined by analyzing six mycelial samples fermented by the same medium in parallel,where it was established that the R.S.D.(%) of retention times and peak areas were no more than0.29and 5.85for mycelia and0.40and7.83for broth,respectively.

3.Results and discussion

3.1.VOCs from Tuber melanosporum fermentation mycelia

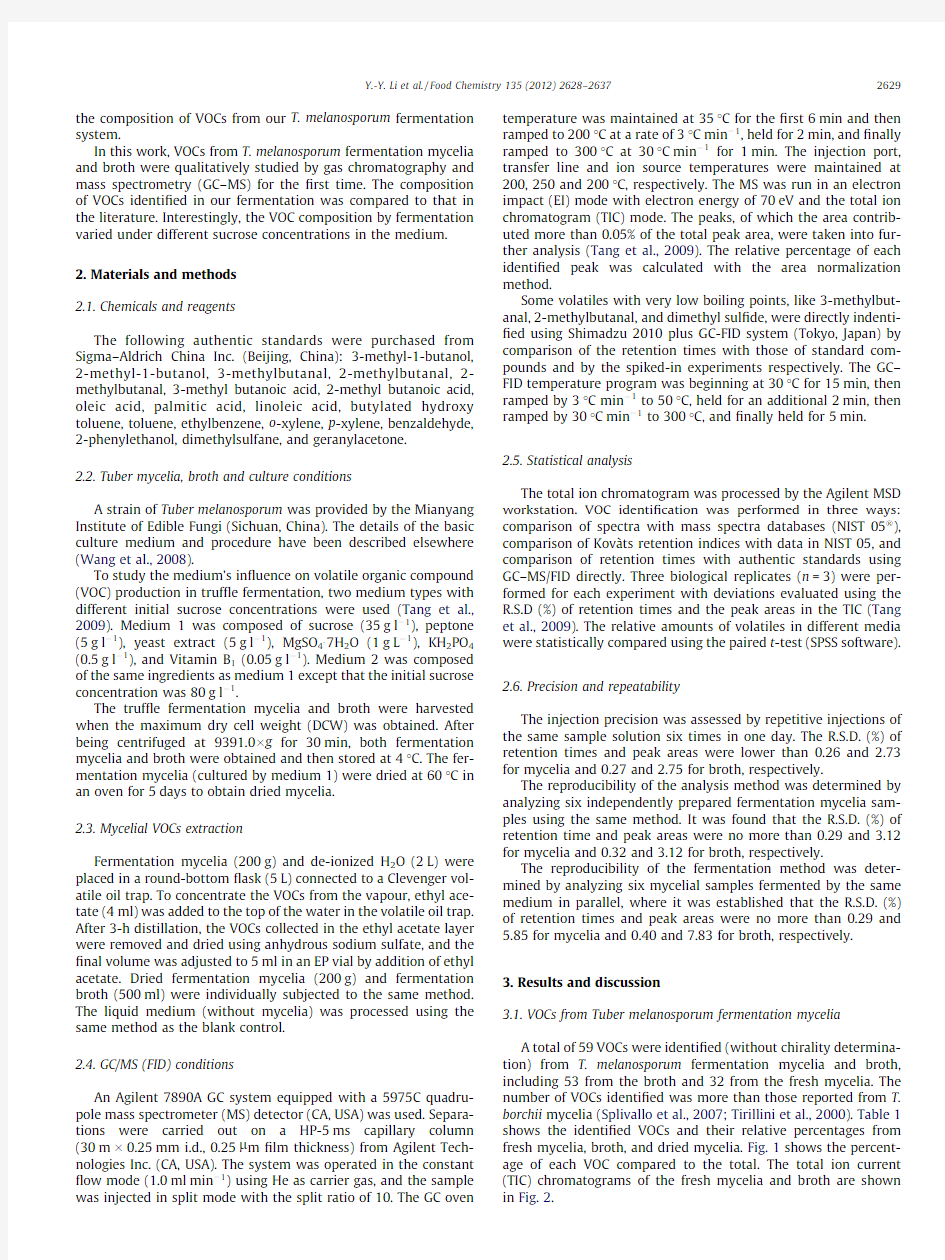

A total of59VOCs were identi?ed(without chirality determina-tion)from T.melanosporum fermentation mycelia and broth, including53from the broth and32from the fresh mycelia.The number of VOCs identi?ed was more than those reported from T. borchii mycelia(Splivallo et al.,2007;Tirillini et al.,2000).Table1 shows the identi?ed VOCs and their relative percentages from fresh mycelia,broth,and dried mycelia.Fig.1shows the percent-age of each VOC compared to the total.The total ion current (TIC)chromatograms of the fresh mycelia and broth are shown in Fig.2.

Y.-Y.Li et al./Food Chemistry135(2012)2628–26372629

Table1

Identi?ed compounds and their relative percentage by area normalization method in Tuber melanosporum fermentation broth,fresh mycelia,and dried mycelia.(n=3).

No.RI Compound Mode of

identi?cation S.I.

(%)

Fermentation broth

(%)

Fresh mycelia(%)Dried mycelia

(%)

Medium

1

Medium

2

Medium

1

Medium

2

Alcohols

86833-Methylbut-3-en-1-ol MS,RI880.15____ 106983-Methyl-1-butanol MS,RI,std9439.18a58.02a13.5017.42_ 116982-Methyl-1-butanol MS,RI,std96 4.58 3.54 2.12 2.15_ 147553-Methylbut-2-en-1-ol MS,RI89_0.18___ 269002,4-Dimethylpentan-3-ol MS,RI770.39a0.07a___ 3710782-Ethylhexan-1-ol MS,RI880.39_0.46_ 1.32 4011152,3,6-Trimethyloct-7-en-3-ol MS,RI930.080.230.120.05_ 4311961-Isopropylcyclohexane-1,2-diol MS,RI70 3.31 2.6318.8011.24_ 4512112-Methylundecan-1-ol MS,RI850.980.59 2.84 2.34_ 4812273-Isopropyl-4-methyldec-1-en-4-ol MS,RI900.150.13 4.99 2.10_ 501240a-Santoline alcohol MS,RI76 5.97 6.7925.1332.91 1.47 Aldehydes

25473-Methylbutanal RI,std970.23_0.13__ 35892-Methylbutanal RI,std880.20_0.09__ 5647Hexanal MS,RI87____0.67 3910892-Isopropyl-5-methylhex-2-enal MS,RI640.030.040.270.100.16

Ketones

461212Hexahydro-2H-naphtho[1-b]oxiren-8(8a H)-one MS,RI880.400.20 1.51 1.52_ 5112475,5-Dimethyl-3-(pro-1-penyl)cyclohex-2-enone MS700.47a0.14a__0.29 5513714-(3-Methylbut-2-enyl)cyclopent-4-ene-1,3-dione MS,RI780.29a0.09a0.300.09 1.27 5716013-Methyl-2-(pent-2-enyl)cyclopent-2-enone(jasmone)MS730.730.37___ 5916053-Methyl-2-(penta-1,3-dien-2-yl)cyclopenten-2-enone MS770.710.75___ 6116993-Methyl-2-(penta-2,4-dienyl)cyclopent-2-enone MS790.080.07___ 6217083-Methyl-2-(penta-1,3-dienyl)cyclopent-2-enone MS750.260.15___ 6317184a-Methyl-4a,5,8,8a-tetrahydronaphthale-2(1H)-one MS860.230.11___

Esters and acid

6652Ethyl propionate MS,RI,std97 1.01a0.25a 1.55 1.69_ 7673Propyl acetate MS,RI930.140.050.180.45_ 13737Isobutyl acetate MS,RI900.16_0.07_0.16 18809Butyl acetate MS,RI94 1.25_ 1.63_ 5.05 24880Ethyl but-2-enoate MS,RI83_0.07_0.14_ 30933Isopentyl acetate MS,RI82 1.28a0.32a___ 742559Methyl palmitate MS89____ 1.32 752720Ethyl palmitate MS84____0.45 762909Methyl octadeca-9,12-dienoate(methyl linoleate)MS91____ 1.68 772910Methyl octadec-10-enoate(methyl oleate)MS85____ 1.19 782988Ethyl octadeca-9,12-dienoate(ethyl linoleate)MS84____0.59 792993Ethyl octadec-10-enoate(ethyl oleate)MS84____0.71 5613984a-Methyl-3,4,4a,5,6,7-hexahydro-2H-chromen-2-one MS800.960.33 4.93 4.40_ 329553-Methyl butanoic acid MS,RI,std84 1.88a0.77a___ 349802-Methyl butanoic acid MS,RI,std84 4.18a0.54a___ 671916Hexadec-9-enoic acid(oleic acid)MS,RI,std81__0.080.04_ 681923Hexadecanoic acid(palmitic acid)MS,RI,std90__ 2.78 3.13_ 691987Octadeca-9,12-dienoic acid(linoleic acid)MS,RI,std87__ 4.00a 1.32a_

Aromatic compounds

12717Toluene MS,RI,std850.420.410.220.900.80 25896Ethylbenzene MS,RI,std950.56a0.09a0.760.32 2.80 31936o-Xylene MS,RI,std910.58a0.07a0.560.28 2.20 27910p-Xylene MS,RI,std89 1.05_0.170.150.79 33976Paredrine MS,RI84_0.08___ 361021Benzaldehyde MS,RI,std850.070.07__ 6.49 381093Benzeneacetaldehyde MS,RI880.270.20__ 5.02 4111352-Phenylethanol MS,RI,std9423.0519.32 4.06a11.38a 3.45 421186Naphthalene MS,RI80____0.12 441197Phenethyl acetate MS,RI80_0.14__ 1.68 5413755-Methyl-2-phenylhex-2-enal MS,RI70____ 3.68 6016682,6-Di-tert-butyl-4-methylphenol(Butylated Hydroxy

toluene)

MS,RI,std94____45.41 661889Diisobutyl phthalate4MS,RI970.050.050.070.40_ 7326452-Methoxyphenazin-1-amine MS65____0.32 712542Butylhexyl phthalate4MS70____0.18 702120Bis(6-methylheptyl)phthalate4MS940.450.050.600.05 1.99 Sulfur

1471Dimethylsul?de RI,std80_ 1.26___ 17796Dimethyl trisul?de MS,RI72____0.77 6518842-(Methylthio)benzo thiazole MS,RI70____0.16 Nitrogen

2630Y.-Y.Li et al./Food Chemistry135(2012)2628–2637

Table1shows that VOCs from fresh fermentation mycelia are composed of a series of compounds including alcohols,aldehydes, ketones,esters,aromatic compounds,and ethers.Alcohols were the predominant VOCs and corresponded to about60%of the total VOCs(Fig.1C and D).The most abundant VOCs were a-santoline alcohol,3-methyl-1-butanol and1-isopropylcyclohexane-1,2-diol. Among the8alcohols identi?ed,3-methylbut-2-en-1-ol,2,3,6-trimethyloct-7-en-3-ol,1-isopropylcyclohexane-1,2-diol,2-meth-ylundecan-1-ol,and a-santoline alcohol were found in the truf?e genus for the?rst time.In this regard,linear chain or branched alcohols were probably biosynthesized by either a lipid oxidation process or Strecker degradation of amino acids(Bellesia,Pinetti, Tirillini,&Bianchi,2001).For the aromatic compounds,2-phenyl-ethanol,which was also detected in T.borchii mycelia(Splivallo et al.,2007)and the fruiting-body of most Tuber species(Díaz et al.,2003;Piloni,Tat,Tonizzo,&Battistutta,2005;Splivallo et al.,2007),was identi?ed to be the major constituent of this work.This rose perfume compound is generally considered to be the biotransformation product of L-phenylalanine by fungi(Lomas-colo,Stentelaire,Asther,&Lesage-Meessen,1999).A series of homologous esters were also identi?ed from fresh mycelia,includ-ing ethyl propionate,propyl acetate,and butyl acetate.It was rea-sonable to assume that these esters are created from a series of homologous alcohols that are oxidized to the corresponding acids that,in turn,react with the initial alcohols and to produce a series of homologous esters(March et al.,2006).Some long chain fatty acids with high boiling temperature,such as palmitic,oleic and lin-oleic acids,were detected in our samples,which is to be expected from the typical volatile oil extraction method used.These fatty acids were reported as precursors for producing VOC constituents, such as alkanes,ketones,alcohols and so on,and they play an important role in truf?e maturation(Zeppa et al.,2004).Addition-ally,several isoprenoid compounds,mainly farnesol and geranylac-etone derivatives,were present in the fermentation mycelia.It was proposed that a-farnesene,which was considered to be a sex pher-omone,was speci?c to the mature fruiting-body and that gerany-lacetone was related to the increased expression of isoprenoid biosynthetic genes in the mature fruiting-body(Splivallo et al., 2007;Zeppa et al.,2004).However,the appearance of the a-farne-sene and geranylacetone analogues in the vegetative mycelia may oppose this theory,and further investigation of the biological func-tion of these compounds in truf?e is required.

3.2.VOCs from T.melanosporum fermentation broth

By comparing the VOC pro?les of broth and mycelia cultured under the same medium(Fig.1A versus C,B versus D),it was found that both pro?les were composed of groups of alcohols,aro-matic compounds,esters,and ethers;alcohols were the predomi-nant group,comprising no less than50%of the total VOCs. Despite these similarities,there were conspicuous differences be-tween the broth and mycelia pro?les.In the VOC pro?les of the fer-mentation broth and mycelia(Fig.1A and C),the total percentage of alcohols in the broth was about12%lower than that in mycelia, and the total percentage of ethers in the broth was only one-sev-enth of that in mycelia.However,the amount of aromatic com-pounds in the broth was about four times higher than those found in mycelia.The same phenomenon was also observed in the broth and mycelia cultured under medium1(Table1).The rel-ative percentage of2-phenylethanol in the broth was six times greater than that in mycelia and was responsible for the higher percentage of aromatic compounds in the broth.Of the three major

Table1(continued)

No.RI Compound Mode of

identi?cation S.I.

(%)

Fermentation broth

(%)

Fresh mycelia(%)Dried mycelia

(%)

Medium

1

Medium

2

Medium

1

Medium

2

45932-Methylpyrazine MS82____0.06 157682,5-Dimethylprazine MS91_0.18___

167702,6-Dimethylprazine MS85_0.22___

208302-Ethyl-6-methylpyrazine MS,RI83_0.10__0.11 228402-Ethyl-5-methylpyrazine MS,RI81_0.10__0.06 218332,3,5-Trimethylpyrazine MS,RI81_0.20__0.16 299303-Ethyl-2,5-dimethylpyrazine MS80_0.17__0.18 289102-Ethyl-3,5-dimethylpyrazine MS85____ 1.03 359952-Ethyl-3,5,6-trimethypyrazine MS87____0.42 4712202-Isopentyl-3,5-dimethylpyrazine MS87____0.49

Isoprenoids

6417103,7,11-Trimethyldodeca-2,6,10-trien-1-ol(farnesol)MS,RI91__0.040.07_

4912282-Methyl-6,6-dimethylbicyclo[3.1.1]heptan-3-one

(isopinocamphone)

MS,RI74 1.33____

5313636,10-Dimethyl-5,9-undecadien-2-one(geranylacetone)MS,RI,std87____ 2.85 7225596,10,14-Trimethylpentadeca-5,9,13-trien-2-one MS88__0.030.08 1.50 Ethers

96861,1-Diethoxyethane,MS,RI840.28a0.06a0.050.09_

5815991-(3-Ethoxyprop-1-enyl)cyclohex-1-ene MS0.92a0.12a7.33 4.61_

Furanes and furanones

198102-Methyldilhydrofuran-3(2H)-one MS,RI85____0.21 23846Furan-2-carbaldehyde MS,RI920.720.26___

Indenes

5212481-Ethylidene-7a-methyloctahydro-1H-indene MS,RI790.230.09___

Three replicates were performed for VOCs identi?cation from fresh mycelia obtained in two different media,broth obtained in two different media,and dried mycelia, respectively.The initial sucrose concentration was35and80g Là1for media1and2,respectively.The relative percentage of each constituent was the average of three replicates(n=3)by area normalization method,and the standard deviation(R.S.D)of three replicates was around8%.The‘No.’of compounds from1to81was according to the Kováts indices(RI)from low to high,and each identi?ed compound was reported with their Kováts indices(RI),matching index(S.I)to the NIST‘05database(MS). Volatiles were identi?ed by one or more method mentioned under column‘Mode of identi?cation’as‘RI’(comparing their Kováts-indices with literature data),‘MS’(comparing their MS data to the NIST‘05database),and‘std’(using authentic standards under similar GC–MS conditions for comparison).Letter‘‘a’’indicated statistically signi?cant difference of relative amount in VOCs of broth or mycelia under two different medium(P60.05;paired t-test).4=the exotic contaminant..

Y.-Y.Li et al./Food Chemistry135(2012)2628–26372631

alcoholic compounds,the relative percentage of 3-methyl-1-buta-nol in the broth was higher,but the amount of 1-isopropylcyclo-hexane-1,2-diol and a -santoline was not more than one-?fth of the amount in mycelia.As described above,the total amount of alcohols in the broth was less than in the mycelia.Another differ-ence was that several groups of compounds (i.e.,sulfur,

pyrazine,

compounds (VOCs)pro?les from Tuber melanosporum fermentation.(A)broth obtained in medium 1,(B)broth obtained in medium (D)fresh mycelia obtained in medium 2,(E)the dried mycelia obtained in medium 1in oven at 60°C for 5days.Medium 1à1),yeast extract (5g l à1),MgSO 4á7H 2O (1g l à1),KH 2PO 4(0.5g),and Vitamin B 1(0.05g l à1).The composition of medium 2was concentration was at 80g l à1.The identi?ed compounds are grouped basis on their chemical structures (i.e.,ketones,esters,sulfur,each group are calculated as the total percentage of all compounds in that group (data shown in Table 1).‘‘Others’’,the value percentages of all compound groups from 100%,means the unidenti?ed compounds or compounds whose relative signal intensity calculated peak.

furan,and jasmone derivates)were only detected in the broth.The pyrazine series,whose welcome roasted ?avor is always present in fermented soybeans,cocoa,and cheese,(Maga,1992;Maga &Sizer,1973;Rizzi,1988)was identi?ed in truf?e genus for the ?rst time and was probably biosynthesized from amino acids (Belitz,Grosch,&Schieberle,2008).Of the volatile sulfur compounds,only

trace

(TIC)chromatogram of (A)fermentation broth obtained in medium 1,(B)fermentation broth obtained in medium 2,and (D)fermentation mycelia obtained in medium 2.Peak assignments are given in Table 1.

amounts of dimethyl sul?de and dimethyl trisul?de were detected in broth.These seem to be derived from methionine and are the major contributors to the?nal aroma of truf?e(Splivallo et al., 2007;Zeppa et al.,2004).Of the ketones,jasmone derivates were reported in the truf?e genus for the?rst time.These jasmone derivatives,with an enthralling jasmine fragrance,are best known as the constituents of the essential oil from plants,and the phyto-hormone plays a key role in inducible defence systems(Pickett et al.,2007).Due to low?avor threshold compounds like sulfur, pyrazine,furan and jasmone,the broth smells like an intense wine bouquet.In contrast,the fermentation mycelia smell much lighter, somewhat like the fresh mushroom.

3.3.VOCs variation during the oven drying process

To investigate the mycelia aroma variation during the drying process,the discrimination of VOCs between fresh and dried myce-lia was examined.In total,41VOCs were identi?ed in dried myce-lia,and16VOCs were produced during drying.Signi?cant differences were observed in Fig.1C and E.For example,the VOC pro?le of dried mycelia was dominated by aromatic com-pounds,whereas the predominant compounds in fresh mycelia VOCs were alcohols.As noted in Table1,only two alcoholic com-pounds(i.e.,2-ethylhexan-1-ol and a-santoline alcohol)were identi?ed in the dried mycelia,and the total relative percentage of alcohols decreased sharply from more than55%in fresh mycelia to no more than3%in dried mycelia.The disappearance of the alco-hols was mainly due to their volatilization and oxidation during oven drying.However,VOCs that have high boiling points and are stable with respect to temperature and oxygen were detected in dried mycelia,such as palmitate,oleate,linoleate,and gerany-lacetone and its derivatives.Although these compounds were spe-ci?c to dried mycelia,they are probably transformed from palmitic, oleic,and linoleic acids,as well as farnesol precursors,all of which were present in fresh mycelia.Of the predominant aromatic com-pounds,butylated hydroxyl toluene(BHT)had the highest percent-age of the total VOC amount(45%).This compound was previously reported in the fruiting-body of T.aestivum(Díaz et al.,2003),and its analogue was reported in T.borchii mycelia as well(Tirillini et al.,2000).However,contradictory results led to the assumption that BHT was a contaminant released from plastic vials or contam-inated analytical samples(Davoli,Bellesia,&Pinetti,2003).In our work,while the biosynthetic pathway is unclear,it was con?rmed that BHT was produced in the drying process because the com-pound was found in dried mycelia and undetected in the control. Additionally,its high percentage of total VOCs also suggests that it could not have been formed from degradation.The pyrazine and sul?de series,which are important?avor substances,were also identi?ed in dried mycelia.Differing from the formation in broth, pyrazine and sul?de compounds were probably the products of a Strecker and Maillard reaction between amino acids and carbohy-drates during the oven heating process,and the toasty aroma of dried mycelia is mainly attributable to these types of compounds (Belitz et al.,2008).Signi?cant differences were observed in the pro?les of VOCs from fresh and dried mycelia,and this result indi-cates that it is inadvisable to process aromatic mushrooms using oven drying because of the destruction of the original aroma.

https://www.360docs.net/doc/24589840.html,parison of VOCs identi?ed in T.melanosporum fermentation with those reported in the Tuber genus

As reported,VOC analysis of the truf?e fruiting-body was in?u-enced by species,geographical origin,intra-genetic variation, maturity,storage conditions,and analytical methods(Gioacchini et al.,2009;Splivallo et al.,2007).Due to the high inter-speci?c and intra-speci?c variation in the VOC pro?les of the natural truf?e,it was dif?cult to directly de?ne similarities or differences between the fruiting-body and fermentation by comparing the VOC spectra with inadequate sample quantities.However,through comparison of the VOCs between fermentation and the fruiting-body reported in the literature,it is possible to understand how many common VOCs exist in the fermentation and fruiting-body and their possible relationships to one another.Table2compares the VOCs identi?ed in the T.melanosporum fermentation with those found in fruiting bodies of T.melanosporum,T.borchii, T.magnatum,and T.indicum.A total of20VOCs produced by T.melanosporum fermentation were previously identi?ed in the Tuber genus.The analogues of farnesol and furan-2-carbaldehyde detected in this work were also found in the aforementioned fruiting-body.3-Methyl-1-butanol,2-methyl-1-butanol,3-methyl-butanal,2-methylbutanal,and2-phenylethanol were the most popular constituents for both the Tuber fermentation and fruiting-body VOCs.Additionally,among the aforedescribed fruit-ing-bodies,the VOC pro?le of our fermentation was more similar to that of T.melanosporum fruiting-body than the other species, because more common volatiles were found between them (Table2).However,the VOC pro?le of T.borchii mycelia was quite different:it was dominated by the aromatic compounds(Splivallo et al.,2007)or hydrocarbons(Tirillini et al.,2000),while the VOC pro?le of most truf?e fruiting bodies was dominated by alcohols. As shown in Table2,only eight common VOCs were found between T.borchii and the fruiting-bodies mentioned above.It was con-cluded that VOCs emitted from T.melanosporum fermentation were more similar to those emitted from the Tuber fruiting-body than VOCs emitted from T.borchii.

Although some common VOCs exist in both T.melanosporum fermentation and fruiting-body,they do not necessarily have the same aroma.Even though the truf?e aroma was produced by the ‘‘synergistic’’function of various VOCs,some distinctive com-pounds may have a decisive in?uence on the aroma.The discrim-ination in aroma between T.melanosporum fermentation and fruiting-body was primarily attributed to some key volatiles.Sulfur compounds were deemed responsible for the earthy aroma of truf-?e fruiting-body.However,only a trace amount of dimethyl sul?de and dimethyl trisul?de was detected in the fermentation broth, and none were found in the mycelia.Pyrazine compounds were speci?c to the fermentation broth,but were not detected in the fruiting-body.Due to its low?avor threshold,the presence of pyrazine would signi?cantly affect the fragrance of the broth, making it more like a wine bouquet than the truf?es’earthy aroma. 1-Octen-3-ol and3-octanone,C8alcohols and ketones,are responsible for the typical mushroom smell(Venkateshwarlu, Chandravadana,&Tewari,1999;Wnouk,Kinastowski,&Kaminski, 1983)and were previously identi?ed in various Tuber species but not found in our fermentation system.Therefore,through adjusting the fermentation strategy,if some?avor constituents, including sulfur compounds,1-occten-3-ol and their analogue, could be increased,meanwhile,pyrazine and its derivatives could be reduced or removed,the aroma produced by T.melanosporum fermentation would be much more similar to its fruiting bodies.

3.5.Effect of fermentation medium on the VOCs accumulation

From previous work,it was demonstrated that the VOCs from fresh mycelia were in?uenced signi?cantly by fermentation condi-tions(Tang et al.,2009).However,what types of VOCs were in?u-enced by the fermentation condition was unknown at the time.To study the in?uence of initial sucrose concentration on the VOC pro-?le,TIC chromatograms of both mycelia and broth in the fermen-tation system at an initial sucrose concentration of35(medium 1)and80g là1(medium2)were compared(Fig.2).For the broth VOCs,the discrimination of GC chromatograms was observed

2634Y.-Y.Li et al./Food Chemistry135(2012)2628–2637

between6to15min(Fig.2A and2B).Peak8(3-methylbut-3-en-1-ol),13(isobutyl acetate),and18(butyl acetate)only appeared in the broth in medium1,while peak14(3-methylbut-2-en-1-ol), 15(2,5-dimethylpyrazine),16(2,6-dimethylpyrazine),17(di-methyl trisul?de),20(2-ethyl-6-methylpyrazine),22(2-ethyl-5-methylpyrazine),and24(ethyl but-2-enoate)only appeared in the broth in the medium2.As shown in Fig.1A and B,the broth VOC pro?les in medium1and medium2were quite different. One difference is the relative percentage of alcohol compounds, which increased by nearly20%when the initial sucrose concentra-tion was increased from35to80g là1.Another difference is that the relative percentage of esters markedly decreased with increase in sucrose concentration.As shown in Table1,when the sucrose concentration increased from35to80g là1,the relative amounts of12VOCs signi?cantly changed.For example,the relative amount of3-methyl-1-butanol increased from39.18%to58.02%,while that of2-methyl butanoic acid,2,4-dimethylpentan-3-ol and2-methyl-butanal decreased from4.18%to0.54%,0.39%to0.07%,and1.01% to0.25%,respectively.These results indicate that3-methyl-1-buta-nol was the sole VOC in the fermentation broth,whose relative amount increased with the increase of sucrose concentration in the medium.For the mycelia VOCs,discrimination of the GC chro-matograms was also observed between6–19min(Fig.2C and2D). Peak13(isobutyl acetate),18(butyl acetate)and37(2-ethylhex-an-1-ol)were only observed in the mycelia cultured under med-ium1,while peak24(ethyl but-2-enoate)was speci?c to the mycelia cultured under medium2.As shown in Fig.1C and1D, no signi?cant difference was observed in the VOC pro?les of myce-lia cultured under medium1and2.The only change was observed in the aromatic compounds,whose relative percentage increased

Table2

Common VOCs in Tuber melanosporum fermentation and in the fruiting-body of T.melanosporum,T.borchii,T.magnatum,T.indicum,and T.aestivum.

Compound Truf?e fermentation system VOCs reported in fruiting-body(c)

Fresh mycelia of T .mel.(a)Broth of T

.mel.(a)

Mycelia of T.

borc.(b)

T.mel.T.

borc.

T.magn.T

.ind..

T.

aest.

Alcohols

3-Methyl-1-butanol p p p

71,3,6,77,1327,104,6,

9

2-Methyl-1-butanol p p p

71,3,4,6132,12,15–4,6,

9

2-Ethylhexan-1-ol p p

–47––4,9

1-Octen-3-ol––p

72,4,77,8,

13

2,1474,9

Aldehydes

3-Methylbutanal p p

–1,2,4,5,6,7132,15104,6,

9

Ethyl propionate p p

–1,2,3,4,5,

6,7

132,15104,6,

9

2-Isopropyl-5-methylhex-2-enal p p

–7––––

Esters and acid Ethyl propionate p p

–67––6

Ethyl but-2-enoate p p

––7–––

Isopentyl acetate–p

––7–––

Aromatic compounds Toluene p p

––––104

Ethylbenzene p p

–4–––4

o-Xylene p p

–4–––4,9

p-Xylene p p

–4–––4

Benzaldehyde–p p

74,77–7,104,9

Benzeneacetaldehyde–p

–7––74,9

2-Phenylethanol p p p

74,7712,1477

Phenylmethanol––p

777–7–

Sulfur

Dimethylsulfane–p

–1,2,3,4–2,12,14104,9

Methyl disul?de–p

–2,3,472,12,14,

15

–4

Dimethyl trisul?de––p

114,7–2,15–4,9

Furanes and furanones

Furan-2-carbaldehyde–p

–––12?,14?–4

Isoprenoids

2-Methyl-6,6-dimethylbicyclo[3.1.1]heptan-3-one (isopinocamphone)–

p

––8––

3,7,11-Trimethyldodeca-2,6,10-trien-1-ol(farnesol)p

–––8?–––

others

3-Octanone––p

7,112,4,772,1474,9

Compounds marked with‘p

’and‘

p

+numbers’in the Columns(a)and(b)were the common VOCs in the truf?e fermentation and the fruiting-body of T.melanosporum,T.

borchii,T.magnatum,T.indicum,and T.aestivum.

The marked compounds in Column(a)were the VOCs emitted from T.melanosporum culture mycelia or broth in either of two media.

The marked compounds in Column(b)were the VOCs emitted from T.borchii mycelia,and the number in Columns(b)and(c)indicated the corresponding literature which reported the compound.

Literature:(1)Talou et al.,1987;(2)Pelusio et al.,1995;(3)Bellesia et al.,1998b;(4)Díaz et al.,2003;(5)Mauriello,Marino,D’Auria,Cerone,&Rana,2004;(6)March et al., 2006;(7)Splivallo et al.,2007;(8)Zeppa et al.,2004;(9)Díaz,Ibá?ez,Reglero,&Se?oráns,2009;(10)Bellesia et al.,2002;(11)Tirillini et al.,2000;(12)Piloni et al.,2005;(13) Bellesia et al.,2001;(14)Aprea et al.,2007;(15)Bellesia et al.,1996.

Numbers marked with‘?’in Column(c)means the analogue of the corresponding compounds identi?ed in the literature.

Y.-Y.Li et al./Food Chemistry135(2012)2628–26372635

twofold when the initial sucrose concentration increased from35 to80g là1.As shown in Table1,only two compounds(2-phenyl-ethanol and linoleic acid)presented a signi?cant difference when the sucrose concentration was altered.The change in aromatic compounds(Fig.1C and D)was mainly due to an increase in 2-phenylethanol.All these variations in VOCs demonstrate that volatiles in T.melanosporum,such as pyrazine,sulfur,ester,and the predominant constituents,3-methyl-1-butanol and2-phenyl-ethanol,were signi?cantly in?uenced by the initial sucrose https://www.360docs.net/doc/24589840.html,pared to the VOCs of mycelia,the VOCs of broth were more strongly affected by the medium sucrose concentration. Furthermore,due to the different culture methods,the VOCs from T.borchii mycelia produced by two research groups were signi?-cantly different(Splivallo et al.,2007;Tirillini et al.,2000).Such a difference in T.borchii mycelia also con?rmed our theory that fermentation conditions were a key factor in affecting the VOC pro?le and accumulation.Therefore,it was possible to optimize the truf?e mycelia?avor and make its VOC chromatogram more like that of the fruiting-body through fermentation process control.

4.Conclusions

For the?rst time,a total of59VOCs were identi?ed from a Tu-ber melanosporum fermentation system.The VOCs in both mycelia and broth are composed of a series of compounds including alco-hols,aldehydes,ketones,esters,aromatic compounds,and ethers. Long chain fatty acids(i.e.,palmitic,oleic and linoleic acids)and isoprenoids(i.e.,farnesol and geranylacetone derivates)were found in T.melanosporum mycelia for the?rst time.The intense wine bouquet of the broth was mainly due to the presence of sev-eral speci?c?avor substances,such as sulfur compound,pyrazine, furan,and jasmone.Signi?cant variation in mycelia VOCs after oven drying demonstrated that drying procedure was not suitable to process aromatic mushroom by heating,and material pretreat-ment should be very careful to keep the preferable VOCs.By com-paring the VOCs identi?ed in this work to those in the literature, it was clear that our VOCs from T.melanosporum fermentation system were closer in composition to the Tuber fruiting-body than previously reported in Tuber fermentation mycelia.The su-crose concentration in the medium was found to have a signi?-cant in?uence on?avor volatiles,such as pyrazine,sulfur and esters,as well as3-methyl-1-butanol https://www.360docs.net/doc/24589840.html,-pared to the VOCs of mycelia,the VOCs from fermentation were more easily affected by the medium initial sucrose concentration. This discovery could be of special interest to optimize truf?e mycelia?avor to make it more similar to that of fruiting-body through bioprocess control and optimization.This work also pro-vides a good method for producing mushroom?avor substances through large scale fermentation.

Acknowledgements

Financial supports from the National Natural Science Foundation of China(NSFC,Project Nos.20976038and21176059),the Key Project of Chinese Ministry of Education(Project No.210132),Hubei Provincial Natural Science Foundation for Agriculture,Scienti?c Research Key Project of Hubei Provincial Department of Education (Project No.Z20101401),the Open Project Programs for the Key Laboratory of Fermentation Engineering(Ministry of Education), the National Key Laboratory of Biochemical Engineering(Project No.2010KF-06),and the State Key Laboratory of Bioreactor Engineering are gratefully acknowledged.Ya-Jie Tang also thanks the Chutian Scholar Program(Hubei Provincial Department of Education,China)(2006)and Program for New Century Excellent Talents in University(NCET-11-0961).Appendix A.Supplementary data

Supplementary data associated with this article can be found,in the online version,at https://www.360docs.net/doc/24589840.html,/10.1016/j.foodchem.2012.

07.013.

References

Aprea,E.,Biasioli,F.,Carlin,S.,Versini,G.,M?rk,T.D.,&Gasperi,F.(2007).Rapid white truf?e headspace analysis by proton transfer reaction mass spectrometry and comparison with solid-phase microextraction coupled with gas chromatography/mass spectrometry.Rapid communications in mass spectrometry,21,2564–2572.

Belitz,H.D.,Grosch,W.,&Schieberle,P.(2008).Food chemistry(4th ed.).Berlin Heidelderg:Springer-Verlag.

Bellesia,F.,Pinetti,A.,Bianchi,A.,&Tirillini,B.(1996).Volatile compounds of white truf?e(Tuber magnatum Pico)from Middle Italy.Flavour and Fragrance Journal, 11,239–243.

Bellesia, F.,Pinetti, A.,Bianchi, A.,&Tirillini, B.(1998a).The volatile organic compounds of Tuber uncinatum from Middle Italy.Journal of Essential Oil Research,10,483–488.

Bellesia, F.,Pinetti, A.,Bianchi, A.,&Tirillini, B.(1998b).The volatile organic compounds of black truf?e(Tuber melanosporum Vitt.)from Middle Italy.

Flavour and Fragrance Journal,13,56–58.

Bellesia,F.,Pinetti,A.,Tirillini,B.,&Bianchi,A.(2001).Temperature-dependent evolution of volatile organic compounds in Tuber borchii from Italy.Flavour and Fragrance Journal,16,1–6.

Bellesia,F.,Pinetti,A.,Tirillini,B.,Paolocci,F.,Rubini,A.,Arcioni,S.,et al.(2002).The headspace volatiles of the Asian truf?e Tuber indicum Cook et Mass.Journal of Essential Oil Research,14,3–5.

Claus,R.,Hoppen,H.O.,&Karg,H.(1981).The secret of truf?es:A steroidal pheromone?Experientia,37,1178–1179.

Davoli,P.,Bellesia,F.,&Pinetti,A.(2003).Comments on truf?e aroma analysis by headspace solid phase microextraction[is butylated hydroxytoluene(BHT)a ‘‘Natural’’volatile constituent of truf?e?].Journal of Agricltural and Food Chemistry,51,4483.

Díaz,P.,Ibá?ez,E.,Reglero,G.,&Se?oráns,F.J.(2009).Optimization of summer truf?e aroma analysis by SPME:Comparison of extraction with different polarity?bres.LWT–Food Science and Technology,42,1253–1259.

Díaz,P.,Ibá?ez, E.,Se?oráns, F.J.,&Reglero,G.(2003).Truf?e aroma characterization by headspace solid-phase microextraction.Journal of Chromatography A,1017,207–214.

Gioacchini,A.M.,Menotta,M.,Guescini,M.,Saltarelli,R.,Ceccaroli,P.,Amicucci,A., et al.(2009).Geographical traceability of Italian white truf?e(Tuber magnatum Pico)by the analysis of volatile organic compounds.Rapid Communication in Mass Spectrometry,22,3147–3153.

Liu,R.S.,Li,D.S.,Li,H.M.,&Tang,Y.J.(2008).Response surface modeling the signi?cance of nitrogen source on the cell growth and Tuber polysaccharides production by submerged cultivation of Chinese truf?e Tuber sinense.Process Biochemistry,43,868–876.

Liu,Q.N.,Liu,R.S.,Wang,Y.H.,Mi,Z.Y.,Li,D.S.,&Tang,Y.J.(2009).Fed-batch fermentation of Tuber melanosporum for the hyperproduction of mycelia and bioactive Tuber polysaccharides.Bioresource Technology,100,3644–3649. Lomascolo, A.,Stentelaire, C.,Asther,M.,&Lesage-Meessen,L.(1999).

Basidiomycetes as new biotechnological tools to generate natural aromatic ?avors for the food industry.Trends in Biotechnology,17,282–289.

Maga,J.A.(1992).Pyrazine update.Food Reviews International,8,479–558. Maga,J.A.,&Sizer,C.E.(1973).Pyrazines in foods.A review.Journal of Agricltural and Food Chemistry,21,22–30.

March,R.E.,Richards,D.S.,&Ryan,R.W.(2006).Volatile compounds from six species of truf?e–head-space analysis and vapor analysis at high mass resolution.International Journal of Mass Spectrometry,249,60–67.

Mauriello,G.,Marino,R.,D’Auria,M.,Cerone,G.,&Rana,G.L.(2004).Determination of volatile organic compounds from truf?es via SPME-GC–MS.Journal of Chromatographic Science,42,299–305.

Mello,A.,Murat,C.,&Bonfante,P.(2006).Truf?es:Much more than a prized and local fungal delicacy.Fems Microbiology Letters,260,1–8.

Ney,K.H.,&Freytag,W.G.(1980).Trüffel-Aroma.Gordian,9,214.in German. Pelusio,F.,Nilsson,T.,Montanarella,L.,Tilio,R.,Larse,B.,Facchetti,S.,et al.(1995).

Headspace solid-phase microextraction analysis of volatile organic sulfur compounds in black and white truf?e aroma.Journal of Agricltural and Food Chemistry,43,2138–2143.

Pickett,J.A.,Birkett,M.A.,Bruce,T.J.A.,Chamberlain,B.K.,Gordon-Weeks,R., Matthes,M. C.,et al.(2007).Developments in aspects of ecological phytochemistry:The role of cis-jasmone in inducible defense system in plants.Phytochemistry,68,2937–2945.

Piloni,M.,Tat,L.,Tonizzo,A.,&Battistutta,F.(2005).Aroma characterisation of white truf?e by GC–MS and GC-O.Italian Journal of Food Science,17,463–468. Rizzi,G.P.(1988).The biogenesis of food-related pyrazines.Food Reviews International,4,375–400.

Splivallo,R.,Bossi,S.,Maffei,M.,&Bonfante,P.(2007).Discrimination of truf?e fruiting-body versus mycelial aromas by stir bar sorptive extraction.

Phytochemistry,68,2584–2598.

2636Y.-Y.Li et al./Food Chemistry135(2012)2628–2637

Talou,T.,Delmas,M.,&Gaset,A.(1987).Principal constituents of black truf?e (Tuber melanosporum)aroma.Journal of Agricultural and Food Chemistry,35, 774–777.

Talou,T.,Delmas,M.,&Gaset,A.(1989).Direct capture of volatiles emitted from entire black Perigord truf?e.Journal of Essential Oil Research,1,281–286. Talou,T.,Gaset,A.,Delmas,M.,Kulifaj,M.,&Montant,C.(1990).Dimethyl sulphide: The secret for black truf?e hunting by animals?Mycological Research,94, 277–278.

Tang,Y.J.,Wang,G.,Li,Y.Y.,&Zhong,J.J.(2009).Fermentation condition outweighed truf?e species in affecting volatile organic compounds analyzed by chromatographic?ngerprint system.Analytical Chimica Acta,647,40–45. Tang,Y.J.,Zhu,L.W.,Li,H.M.,&Li,D.S.(2007).Submerged fermentation of mushroom in bioreactors–Challenges,current state-of-the-art,and future prospects.Food Technology and Biotechnology,45,221–229.

Tang,Y.J.,Zhu,L.L.,Li,D.S.,Mi,Z.Y.,&Li,H.M.(2008a).Signi?cance of inoculation density and carbon source on the mycelia growth and Tuber polysaccharides production by submerged fermentation of Chinese truf?e Tuber sinense.Process Biochemistry,43,576–586.

Tang,Y.J.,Zhu,L.L.,Liu,R.S.,Li,H.M.,Li,D.S.,&Mi,Z.Y.(2008b).Quantitative response of cell growth and Tuber polysaccharides biosynthesis by medicinal

mushroom Chinese truf?e Tuber sinense to metal ion in culture medium.

Bioresource Technology,99,7606–7615.

Tirillini,B.,Verdelli,G.,Paolocci,F.,Ciccioli,P.,&Frattoni,M.(2000).The volatile organic compounds from the mycelia of Tuber borchii Vitt.Phytochemistry,55, 983–985.

Venkateshwarlu,G.,Chandravadana,M.V.,&Tewari,R.P.(1999).Volatile?avour components of some edible mushrooms(Basidiomycetes).Flavour and Fragrance Journal,14,191–194.

Wang,G.,Li,Y.Y.,Li,D.S.,&Tang,Y.J.(2008).Determination of5a-androst-16-en-3a-ol in truf?e fermentation broth by solid-phase extraction coupled with gas chromatography-?ame ionization detector_electron impact mass spectrometry.

Journal of Chromatography B,870,209–215.

Wnouk,S.,Kinastowski,S.,&Kaminski,E.(1983).Synthesis and analysis of1-octen-3-ol,the main?avor component of mushrooms.Nahrung,27,479–486. Zeppa,S.,Gioacchini,A.M.,Guidi,C.,Guescini,M.,Pierleoni,R.,Zambonelli,A.,et al.

(2004).Determination of speci?c volatile organic compounds synthesized during Tuber borchii fruit body development by solid phase microextraction and gas chromatography/mass spectrometry.Rapid Communication in Mass Spectrometry,18,199–205.

Y.-Y.Li et al./Food Chemistry135(2012)2628–26372637

控制软件说明书

控制软件说明书 PC端软件FTM 安装及应用 系统运行环境: 操作系统中英文Windows 98/2000/ NT/XP/WIN7/ Vista, 最低配置 CPU:奔腾133Mhz 内存:128MB 显示卡:标准VGA,256色显示模式以上 硬盘:典型安装 10M 串行通讯口:标准RS232通讯接口或其兼容型号。 其它设备:鼠标器 开始系统 系统运行前,确保下列连线正常: 1:运行本软件的计算机的RS232线已正确连接至控制器。 2:相关控制器的信号线,电源线已连接正确; 系统运行步骤: 1:打开控制器电源,控制电源指示灯将亮起。 绿色,代表处于开机运行状态;橙色代表待机状态。 2. 运行本软件 找到控制软件文件夹,点击FWM.exe运行。出现程序操作界面:

根据安装软件版本不同,上图示例中的界面及其内容可能会存在某些差别,可咨询我们的相关的售后服务人员。 上图中用红色字体标出操作界面的各部分的功能说明: 1. 菜单区:一些相关的菜单功能选择执行区。 2. 操作区:每一个方格单元代表对应的控制屏幕,可以通过鼠标或键盘的点选,拖拉的方式选择相应控制单元。 3.功能区:包含常用的功能按钮。 4.用户标题区:用户可根据本身要求,更改界面上的标题显示 5.用户图片区:用户可根据本身要求,更改界面上的图片显示,比如公司或工程相关LOGO图片。 6.附加功能区:根据版本不同有不同的附加项目。 7.状态区:显示通讯口状态,操作权限状态,和当前的本机时间,日期等。 如何开始使用 1. 通讯设置 单击主菜单中“系统配置”――》“通讯配置” 选择正确的通讯端口号,系统才能正常工作。 可以设置打开程序时自动打开串口。 2.系统配置

用友T软件软件操作手册

用友T6管理软件操作手册总账日常业务处理 日常业务流程 1、进入用友企业应用平台。 T6 双击桌面上的 如设置有密码,输入密码。没有密码就直接确定。 2、填制凭证进入系统之后打开总账菜单下面的填制凭证。如下图 丄总账[演示版】国B设畫 -二疑证 i :卜0 直接双击填制凭证,然后在弹出凭证框里点增 制单日期可以根据业务情况直接修改,输入附单据数数(可以不输),凭证摘要(在后面的匝可以选择常用摘要),选择科目直接选择(不知道可以选按F2或点击后面的一), 输入借贷方金额,凭证完后如需继续作按增加自动保存,按保存也可,再按增加 3.修改凭证 填制凭证 证 证 证 总 £ ■ 凭 汇 汇 流

没有审核的凭证直接在填制凭证上面直接修改,改完之后按保存。(审核、记帐了凭 证不可以修改,如需修改必须先取消记帐、取消审核)。 4.作废删除凭证只有没有审核、记帐的凭证才可以删除。在“填制凭证”第二个菜单“制单” 下面有 一个“作废恢复”,先作废,然后再到“制单”下面“整理凭证”,这样这张凭证才被彻底删除。 5.审核凭证 双击凭证里的审核凭证菜单,需用具有审核权限而且不是制单人进入审核凭证才能审核(制单单人不能审核自己做的凭证) 选择月份,确定。 再确定。 直接点击“审核”或在第二个“审核”菜单下的“成批审核” 6.取消审核 如上所述,在“成批审核”下面有一个“成批取消审核”,只有没有记帐的凭证才可 以取消审核

7.凭证记账 所有审核过的凭证才可以记帐,未审核的凭证不能记账,在“总帐——凭证——记账” 然后按照提示一步一步往下按,最后提示记帐完成。 8.取消记帐 在“总帐”—“期末”—“对帐”菜单按“ Ctrl+H ” 系统会提示“恢复记帐前状态已被激活”。然后按“总帐”——“凭证”——“恢复 记帐前状态”。最后选“月初状态”,按确定,有密码则输入密码,再确定。 10、月末结转收支 当本月所有的业务凭证全部做完,并且记账后,我们就要进行当月的期间损益结转。 点击:月末转账并选择期间损益结转。 选择要结转的月份,然后单击“全选”。点击确定后

智能窗户控制系统软件说明

智能窗户控制系统软件V1.0设计说明 目录 前言 (1) 第一章软件总体设计 (1) 1.1. 软件需求概括 (1) 1.2. 定义 (1) 1.3. 功能概述 (1) 1.4. 总体结构和模块接口设计 (2) 第二章控制系统的总体设计 (3) 2.1. 功能设计 (3) 第三章软件控制系统的设计与实现 (5) 3.1. RF解码过程程序设计介绍 (5) 3.2. RF对码过程设计 (6) 3.3. 通信程序设计 (8) 3.4. IIC程序设计介绍 (9) 3.5. 接近开关程序设计 (12) 3.6. 震动开关检测程序设计 (13) 3.7. 墙面按键程序设计 (15) 第四章智能窗户控制系统的设计 (17) 第五章实测与结果说明 (18) 第六章结论 (18)

前言 目的 编写详细设计说明书是软件开发过程必不可少的部分,其目的是为了使开发人员在完成概要设计说明书的基础上完成概要设计规定的各项模块的具体实现的设计工作。 第一章软件总体设计 1.1.软件需求概括 本软件采用传统的软件开发生命周期的方法,采用自顶向下,逐步细化,模块化编程的软件设计方法。 本软件主要有以下几方面的功能 (1)RF遥控解码 (2)键盘扫描 (3)通信 (4)安全检测 (5)电机驱动 1.2.定义 本项目定义为智能遥控窗户系统软件。它将实现人机互动的无缝对接,实现智能关窗,遥控开关窗户,防雨报警等功能。 1.3.功能概述 1.墙体面板按键控制窗户的开/关 2.RF遥控器控制窗户的开/关 3.具有限位,童锁等检测功能 4.实时检测大气中的温湿度,下雨关窗 5.具有防盗,防夹手等安全性能的检测

用友NC财务信息系统操作手册全

NC系统培训手册 编制单位:用友软件股份有限公司 中央大客户事业部 目录 一、NC系统登陆 .................................... 二、消息中心管理................................... 三、NC系统会计科目设置 ............................ 四、权限管理....................................... 五、打印模板设置................................... 六、打印模板分配................................... 七、财务制单....................................... 八、NC系统账簿查询 ................................ 九、辅助余额表查询................................. 十、辅助明细账查询................................. 十一、固定资产基础信息设置......................... 十二、卡片管理..................................... 十三、固定资产增加................................. 十四、固定资产变动................................. 十五、折旧计提..................................... 十六、折旧计算明细表...............................

软件操作说明书

门禁考勤管理软件 使 用 说 明 书

软件使用基本步骤

一.系统介绍―――――――――――――――――――――――――――――2二.软件的安装――――――――――――――――――――――――――――2 三.基本信息设置―――――――――――――――――――――――――――2 1)部门班组设置―――――――――――――――――――――――――3 2)人员资料管理―――――――――――――――――――――――――3 3)数据库维护――――――――――――――――――――――――――3 4)用户管理―――――――――――――――――――――――――――3 四.门禁管理―――――――――――――――――――――――――――――4 1)通迅端口设置―――――――――――――――――――――――――42)控制器管理――――――――――――――――――――――――――43)控制器设置――――――――――――――――――――――――――64)卡片资料管理―――――――――――――――――――――――――11 5)卡片领用注册―――――――――――――――――――――――――126)实时监控―――――――――――――――――――――――――――13 五.数据采集与事件查询――――――――――――――――――――――――13 六.考勤管理―――――――――――――――――――――――――――――14 1)班次信息设置――――――――――――――――――――――――――14 2)考勤参数设置――――――――――――――――――――――――――15 3)考勤排班――――――――――――――――――――――――――――15 4)节假日登记―――――――――――――――――――――――――――16 5)调休日期登记――――――――――――――――――――――――――16 6)请假/待料登记―――――――――――――――――――――――――17 7)原始数据修改――――――――――――――――――――――――――17 8)考勤数据处理分析――――――――――――――――――――――――17 9)考勤数据汇总―――――――—――――――――――――――――――18 10)考勤明细表—―――――――――――――――――――――――――18 11)考勤汇总表――――――――――――――――――――――――――18 12)日打卡查询――――――――――――――――――――――――――18 13)补卡记录查询—――――――――――――――――――――――――19

博思软件操作步骤

开票端操作说明 双击桌面“博思开票”图标,单击“确定”,进入开票界面: 一、开票: 日常业务——开票——选择票据类型——增加——核对票号无误后——单击“请核对票据号”——输入“缴款人或缴款单位”——选择”收费项目”、“收入标准”——单击“收费金额”。 (如需增加收费项目,可单击“增一行”) (如需加入备注栏(仅限于收款收据)),则在右侧“备注”栏内输入即可) 确认无误后,单击“打印”——“打印” 二、代收缴款书: 日常业务——代收缴款书——生成——生成缴款书——关闭——缴款——输入“专用票据号”——保存——缴款书左上角出现“已缴款”三个红字即可。 三、上报核销: 日常业务——上报核销——选择或输入核销日期的截止日期——刷新——核销。 (注意:“欠缴金额”处无论为正或为负均不可核销,解决方法见后“常见问题”)

常见问题 一、如何作废“代收缴款书” 日常业务——代收缴款书——缴款——删除“专用票据号”和“缴款日期”——保存——作废。 二、上报核销时出现欠缴金额,无法完成核销,或提示多缴。 1、首先检查有没有选择好截止日期,选择好后有没有点击“刷新”。 2、其次检查有没有做代收缴款书。注意:最后一张缴款书的日期不得晚于选择上报核 销日期。 3、若上述方法仍无效,则可能是由于以前作废过票据而未作废缴款书。解决方法: 首先作废若干张缴款书(直到不能作废为止),然后重新做一张新的缴款书。再核销。 三、打开“博思开票”时,出现“windows socket error:由于目标机器积极拒绝,无法连接。 (10061),on API’connect’” 单击“确定”,将最下面一行的连接类型“SOCKET”更换为“DCOM”,再点“连接” 即可。 四、如何设置密码 双击桌面“博思开票”,单击登录界面的右下方“改口令”输入用户编号、新密码和确认密码,单击“确认”即可。 五、更换开票人名称或增加开票人 进入开票系统——系统维护——权限管理 1、更换开票人名称:单击“用户编码”——删除“用户名”——输入新的开票人名称 ——单击“保存用户”即可。 2、增加开票人:单击“新增用户”——输入“用户编码”和“用户名”——单击“保 存用户”——单击新增的用户编码——将右边的“权限列表如下”下面的“所有”前的小方框勾上——单击右侧“保存用户权限”。 六、重装电脑系统 1、由于博思开票软件安装在D盘,所以重装电脑系统前无需做任何备份。 2、重装系统后,打开我的电脑—D盘,将“博思软件”文件夹复制到桌面上(或U盘)。 3、将安装时预留的安装光盘放入主机,打开后找到“票据核销及管理_开票端(江西欠 缴不能上报版)”(或者进入D盘----开票软件备份目录勿删文件夹里也可找到)。双 击,按提示点击“下一步”,直到“完成”。 4、双击桌面任务栏右下角“博思开票服务器”,将其关闭(或右键点击“博思开票服 务器”——“关闭服务器”)。 (这一步若找不到“博思开票服务器”,也可以用重启电脑来代替) 5、将刚才复制到桌面(或U盘)的“博思软件”再复制粘贴回D盘,若提示“此文 件夹已包含名为博思软件的文件夹”,点击下面的“全部”。 6、双击桌面“博思开票”——输入用户编码(001)——确定。 7、确认原来的票据数据没有丢失后,将桌面(或U盘)的“博思软件”文件夹删除。

控制系统使用说明

控制系统使用说明 系统针对轴流风机而设计的控制系统, 系统分为上位监视及下位控制两部分 本操作为上位监控软件的使用说明: 1: 启动计算机: 按下计算机电源开关约2秒, 计算机启动指示灯点亮, 稍过大约20秒钟屏幕出现操作系统选择菜单, 通过键盘的“↑↓”键选择“windows NT 4.0”菜单,这时系统进入WINDOWS NT 4.0操作系统,进入系统的操作画面。 2:系统操作 系统共分:开机画面、停机画面、趋势画面、报警画面、主机流程画面、轴系监测画面、润滑油站画面、动力油站画面、运行工况画面、运行记录画面等十幅画面,下面就十幅画面的作用及操作进行说明 A、开机画面: 开机: 当风机开始运转前,需对各项条件进行检查,在本画面中主要对如下指标进行检查,红色为有效: 1、静叶关闭:静叶角度在14度

2、放空阀全开:放空阀指示为0% 3、润滑油压正常 4、润滑油温正常 5、动力油压正常 6、逆止阀全关 7、存储器复位:按下存储器复位按钮,即可复位,若复位不成 需查看停机画面。 8、试验开关复位:按下试验开关按钮即可,试验开关按钮在风 机启动后,将自动消失,同时试验开关也自动复位。 当以上条件达到时,按下“允许机组启动”按钮,这时机组允许启动指示变为红色,PLC机柜里的“1KA”继电器将导通。机组允许启动信号传到高压柜,等待电机启动。开始进行高压合闸操作,主电机运转,主电机运转稳定后,屏幕上主电机运行指示变红。这时静叶释放按钮变红,按下静叶释放按钮后,静叶从14度开到22度,静叶释放成功指示变红。 应继续观察风机已平稳运行后,按下自动操作按钮,启机过程结束。 B、停机画面: 停机是指极有可能对风机产生巨大危害的下列条件成立时,PLC 会让电机停止运转: 1、风机轴位移过大

用友T+软件系统操作手册范本

用 友 T+ 软 件 系 统 操 作 手 册版本号:v1.0

目录 一、系统登录 (3) 1.1、下载T+浏览器 (3) 1.2、软件登陆 (3) 二、基础档案设置 (5) 2.1、部门、人员档案设置 (5) 2.2、往来单位设置 (6) 2.3、会计科目及结算方式设置 (6) 三、软件操作 (9) 3.1、凭证处理 (9) 3.1.1、凭证填制 (9) 3.1.2、凭证修改 (10) 3.1.3、凭证审核 (11) 3.1.4、凭证记账 (12) 3.2、月末结转 (13) 四、日常帐表查询与统计 (14) 4.1、余额表 (14) 4.2、明细账 (15) 4.3、辅助账 (16) 五、月末结账、出报表处理 (17) 5.1、总账结账 (17) 5.2、财务报表 (20)

一、系统登录 1.1、下载T+浏览器 首次登陆需要用浏览器打开软件地址,即:127.0.0.1:8000(一般服务器默认设置,具体登陆地址请参考实际配置),第一次登陆会提示下载T+浏览器,按照提示下载安装T+浏览器,然后打开T+浏览器,输入软件登陆地址。 ,T+浏览器, 1.2、软件登陆 按键盘上的“回车键(enter)”打开软件登陆页面,如下: 选择选择“普通用户”,输入软件工程师分配的用户名和密码,选择对应的账套,以下以demo 为例,如下图:

点击登陆,进入软件,

二、基础档案设置 2.1、部门、人员档案设置 新增的部门或者人员在系统中可按照如下方法进行维护,

2.2、往来单位设置 供应商客户档案的添加方法如下: 添加往来单位分类: 2.3、会计科目及结算方式设置会计科目:

威利普LEDESC控制系统操作说明书

LED-ECS编辑控制系统V5.2 用 户 手 册 目录 第一章概述 (3) 1.1LED-ECS编辑控制系统介绍 (3) 1.2运行环境 (3) 第二章安装卸载 (3) 2.1安装 (3) 2.2卸载 (5) 第三章软件介绍 (5) 3.1界面介绍 (5) 3.2操作流程介绍 (13) 3.3基本概念介绍 (21) 第四章其他功能 (25) 4.1区域对齐工具栏 (25) 4.2节目对象复制、粘贴 (26) 4.3亮度调整 (26) 第五章发送 (27) 5.1发送数据 (27) 第六章常见问题解决 (28) 6.1计算机和控制卡通讯不上 (28) 6.2显示屏区域反色或亮度不够 (29)

6.3显示屏出现拖尾现象,显示屏的后面出现闪烁不稳定 (29) 6.4注意事项 (31) 6.5显示屏花屏 (31) 6.6错列现象 (32) 6.7杂点现象 (32) 第一章概述 1.1LED-ECS编辑控制系统介绍 LED-ECS编辑控制系统,是一款专门用于LED图文控制卡的配套软件。其具有功能齐全,界面直观,操作简单、方便等优点。自发布以来,受到了广大用户的一致好评。 1.2运行环境 ?操作系统 中英文Windows/2000/NT/XP ?硬件配置 CPU:奔腾600MHz以上 内存:128M 第二章安装卸载 2.1LED-ECS编辑控制系统》软件安装很简单,操作如下:双击“LED-ECS编辑控制系统”安装程序,即可弹出安装界面,如图2-1开始安装。如图所示 图2-1 单击“下一步”进入选择安装路径界面,如图2-2,如果对此不了解使用默认安装路径即可 图2-2 图2-3 单击“完成”,完成安装过程。 2.2软件卸载如图2-2 《LED-ECS编辑控制系统V5.2》提供了自动卸载功能,使您可以方便的删除《LED-ECS编辑控制系统V5.2》的所有文件、程序组件和快捷方式。用户可以在“LED-ECS编辑控制系统V5.2”组中选择“卸载LED-ECS编辑控制系统V5.2”卸载程序。也可以在“控制面板”中选择“添加/删除程序”快速卸载。卸载程序界面如图2-4,此时选择自动选项即可卸载所有文件、程序组和快捷方式。 图2-4 第三章、软件介绍

财政票据 网络版 电子化系统开票端操作手册

财政票据(网络版)电子化系统 开票端 操 作 说 明 福建博思软件股份有限公司

目录 1.概述 业务流程 流程说明:

1.单位到财政部门申请电子票据,由财政把单位的基本信息设置好并审核完后,财政部门给用票单位发放票据,单位进行领票确认并入库。 2.在规定时间内,单位要把开据的发票带到财政核销,然后由财政进行审核。 系统登录 登入系统界面如图: 登录日期:自动读取主服务器的日期。 所属区划:选择单位所属区划编码。【00安徽省非税收入征收管理局】 所属单位:输入单位编码。 用户编码:登录单位的用户编码【002】 用户密码:默认单位密码为【123456】 验证码:当输入错误时,会自动换一张验证码图片; 记录用户编码:勾选系统自动把用户编码保存在本地,第二次登录不需要重新输入。 填写完正确信息,点【确定】即可登入系统。 进入系统 进入系统界面如图: 当单位端票据出现变动的时候,如财政或上级直管下发票据时,才会出现此界面:

出现此界面后点击最下方的确认按钮,入库完成。 当单位端票据无变动时,直接进入界面: 2.基本编码人员管理 功能说明:对单位开票人员维护,修改开票人名称。 密码管理 修改开票人员密码,重置等操作。 收发信息 查看财政部门相关通知等。

3.日常业务 电脑开票 功能说明:是用于开票据类型为电子化的票据。 在电脑开票操作界面,点击工具栏中的【增加】按钮,系统会弹出核对票号提示框,如图: 注意:必须核对放入打印机中的票据类型、号码是否和电脑中显示的一致,如果不一致打印出来的票据为无效票据,核对完后,输入缴款人或缴款单位和收费项目等信息,全部输入完后,点【增加】按钮进行保存当前票据信息或点【打印】按钮进行保存当前票据信息并把当前的票据信息打印出来;点电脑开票操作界面工具栏中的【退出】则不保存。 在票据类型下拉单框中选择所要开票的票据类型,再点【增加】进行开票。

用友T软件系统操作手册

用友T软件系统操作手 册 Pleasure Group Office【T985AB-B866SYT-B182C-BS682T-STT18】

用 友 T+ 软 件 系 统 操 作 手 册 版本号:目录

一、系统登录 、下载T+浏览器 首次登陆需要用浏览器打开软件地址,即:(一般服务器默认设置,具体登陆地址请参考实际配置),第一次登陆会提示下载T+浏览器,按照提示下载安装T+浏览器,然后打开T+浏览器,输入软件登陆地址。 ,T+浏览器, 、软件登陆 按键盘上的“回车键(enter)”打开软件登陆页面,如下: 选择选择“普通用户”,输入软件工程师分配的用户名和密码,选择对应的账套,以下以demo为例,如下图: 点击登陆,进入软件, 二、基础档案设置 、部门、人员档案设置 新增的部门或者人员在系统中可按照如下方法进行维护, 、往来单位设置 供应商客户档案的添加方法如下: 添加往来单位分类: 、会计科目及结算方式设置 会计科目: 系统预置170个《2013小企业会计准则》科目,如下:

结算方式,如下: 三、软件操作 、凭证处理 填制 进入总账填制凭证菜单,增加凭证,填制摘要和科目,注意有辅助核算的会计科目, 以下为点开总账的处理流程图: 如若现金流量系统指定错误,可按照以下步骤修改: 凭证在没有审核时,可以直接在当前凭证上修改,然后点击“保存”完成修改; 凭证审核 进入总审核凭证菜单下,如下图: 选择审核凭证的会计期间: 、凭证记账 进入凭证菜单下的记账菜单, 、月末结转 期间损益结转 四、日常帐表查询与统计 、余额表 用于查询统计各级科目的本期发生额、累计发生额和余额等。传统的总账,是以总账科目分页设账,而余额表则可输出某月或某几个月的所有总账科目或明细科目的期初余额、本期发生额、累计发生额、期末余额,在实行计算机记账后,我们建议用户用余额表代替总账。

控制软件操作说明书

创维液晶拼接控制系统 软件操作指南 【LCD-CONTROLLER12】 请在使用本产品前仔细阅读该用户指导书

温馨提示:: 温馨提示 ◆为了您和设备的安全,请您在使用设备前务必仔细阅读产品说明书。 ◆如果在使用过程中遇到疑问,请首先阅读本说明书。 正文中有设备操作的详细描述,请按书中介绍规范操作。 如仍有疑问,请联系我们,我们尽快给您满意的答复。 ◆本说明书如有版本变动,恕不另行通知,敬请见谅!

一、功能特点 二、技术参数 三、控制系统连接示意图 四、基本操作 五、故障排除 六、安全注意事项

一、功能特点创维创维--液晶液晶拼接拼接拼接控制器特点控制器特点 ★采用创维第四代V12数字阵列高速图像处理技术 视频带宽高达500MHZ,应用先进的数字高速图像处理算实时分割放大输入图像信号,在多倍分割放大处理的单屏画面上,彻底解决模/数之间转换带来的锯齿及马赛克现象,拼接画面清晰流畅,色彩鲜艳逼真。 ★具有开窗具有开窗、、漫游漫游、、叠加等功能 以屏为单元单位的前提下,真正实现图像的跨屏、开窗、画中画、缩放、叠加、漫游等个性化功能。 ★采用基于LVDS 差分传送技术差分传送技术,,增强抗干扰能力 采用并行高速总线连接技术,上位控制端发出命令后,系统能快速切换信号到命令指定的通道,实现快速响应。 采用基于LVDS 差分传送技术,提高系统抗干扰能力,外部干扰对信号的影响降到了最低,并且,抗干扰能力随频率提高而提升。★最新高速数字阵列矩阵通道切换技术 输入信号小于64路时,用户不需要再另外增加矩阵,便可以实现通道之间的任意换及显示。 ★断电前状态记忆功能 通过控制软件的提前设置,能在现场断电的情况下,重启系统后,能自动记忆设备关机前的工作模式状态。 ★全面支持全高清信号 处理器采用先进的去隔行和运动补偿算法,使得隔行信号在大屏幕拼接墙上显示更加清晰细腻,最大限度的消除了大屏幕显示的锯齿现象,图像实现了完全真正高清实时处理。纯硬件架构的视频处理模块设计,使得高清视频和高分辨率计算机信号能得到实时采样,确保了高清信号的最高视频质量,使客户看到的是高质量的完美画质。

工会经费收入专用收据(1)

工会经费收入专用收据(1) 福州博思软件开发有限公司 2010年6月 目录 第一部分初始安 装 ....................................................... (1) 1.1系统 安装 (1) 1.2系统登录 ............................................................ (4) 第二部分组成模块介 绍 ................................................... (4) 2.1模块组 成 (4) 2.1.1票据资料 .......................................................... (5) 2.1.2用户管 理 .......................................................... (5) 2.1.3 票据领用 (6) 2.1.4电脑开票 .......................................................... (6) 2.1.5手工开 票 .......................................................... (7) 2.1.6 手工批开票 (7) 2.1.7票据查询 .......................................................... (8) 第三部分软件操 作 ....................................................... (9) 3.2用户 管理 (10)

大屏幕控制系统软件详解说明V6.(完整)

大屏幕控制系统软件详解说明 一软件安装 安装注意事项: 非专业人事安装:安装前请先关闭防火墙(如360安全卫士,瑞星,诺盾等),等安装完并且成功启动本软件后可重新开启防火墙; 专业人事安装:先把防火墙拦截自动处理功能改为询问后处理,第一次打开本软件时会提示一个拦截信息; 安装前请校对系统时间,安装后不能在错误的系统时间下运行/启动软件,否则会使软件注册失效,这种情况下需要重新注册; Windows 7,注意以下设置 0.1)打开控制面板 0.2) 选择系统和安全 0.3) 选择操作中心 0.4) 选择更换用户帐户控制设置 0.5)级别设置,选择成从不通知 1.软件解压后,请选择双击,进入安装界面如图1,图2 图1

图2 2.选择键,进入下一界面如图3 图3 3.选中项,再按键,进入下一界面如图4

图4 4.选择键,进入下一界面如图5 图5 5.选中项,再选择键,进入下一界面如图6

图6 6.选择键,进入下一界面如图7 图8 7.选择键,软件安装完成 二软件操作 选择WINDOWS 下开始按钮,选择程序,选择Wall Control项, 点击Wall Control软件进入大屏幕控制系统软件主界面如图9所示,整个软件分为3个区,标题区,设置区,功能区

图9 1.1标题区 大屏幕控制系统软件(只有管理员才可设置此项目) 1.2设置区 1.2.1系统 高级功能:管理员登录。 产品选型:选择拼接盒型号。 定时系统:设置定时时间。 幕墙开机:开机 幕墙关机:关机 退出:退出软件系统。 1.2.2设置 串口设置:设置使用的串口参数。 矩阵设置:设置矩阵的相关参数。 幕墙设置:幕墙设置参数。 幕墙颜色:幕墙颜色设置。 标志设置:更改幕墙名称。 系统设置:控制软件系统设置。 1.2.3工具 虚拟键盘:虚拟键盘设置。 硬件注册:可以通过时钟IC注册处理器的使用权限。 1.2.4语言 中文选择:选择软件语言类型为中文。 English:选择软件语言类型为英语。

用友财务管理系统操作手册

用友财务管理系统操作手册 北京用友政务软件有限公司 2011年05月25日

一、账务系统: 流程:1、初始化设置及期初数装入=》2、凭证录入=》 3、凭证审核=》 4、凭证记账=》 5、月结 1、初始化设置: (1)、用自己的用户名登录【账务管理系统】=》 点击界面右边【基础资料】前的【+】号=》点击【会计科 目】前的【+】号=》双击【建立会计科目】=》设置会计科 目及挂接辅助账。(2)、点击界面右边【账务】前的【+】号 =》点击【初始建账数据】前的【+】号=》双击【期初余额 装入】=》点击【确定】=》然后对期初数据进行录入 2、凭证录入:用自己的用户名登录【账务管理系统】=》点击界 面右边【账务】前的【+】号=》点击【凭证管理】前的【+】 号=》双击【编制凭证】=》然后在【编制凭证】界面录入 收入/支出的凭证。 3、凭证审核:点击界面右边【账务】前的【+】号=》点击【凭 证管理】前的【+】号=》双击【凭证处理】=》选中需要审 核凭证的日期=》在左下角选择凭证的状态【未审核】=》 点击右键全选=》点击【审核】; 4、凭证记账:点击界面右边【账务】前的【+】号=》点击【期 末处理】前的【+】号=》双击【凭证处理】=》选中需要记 账凭证的日期=》在左下角选择凭证的状态【已审核】=》 点击右键全选=》点击【记账】; 5、月结:点击界面右边【账务】前的【+】号=》点击【期末

处理】前的【+】号=》双击【期末处理向导】=》点击【结 账向导】=》全部点击【下一步】=》下到最后点击【完成】 二、电子系统: 1、输出单位资产负债表:双击【电子报表系统】=》【管理员】 登录=》在右上角【报表数】下点击【基本户】/【专账一】 /【专账二】下前的【+】号=》双击【资产负债表】=》点击 最右上面【数据】下=》=》点击【登录数据库】=》双击【账 务系统】=》用自己的用户进行登录=》如果图片闪烁就证 明已经登录=》点击【退出】=》点击最右上角找到【插入】 功能菜单=》点击【表页】=》选择出报表的最后日期(如1 月:则时间2011年1月31日)=》选择复制指定表页 =》点击放大镜=》选择【本公司】=》选中【格式】点击【确定】=》在点【确定】=》左 下角有【第201101期】=》点击编制【眼睛图标】。=》调 试报表=》点击【保存】=》打印报表。 2、输出单位支出明细表:双击【电子报表系统】=》【管理员】 登录=》在右上角【报表数】下点击【基本户】/【专账一】 /【专账二】下前的【+】号=》双击【支出明细表】=》点击 最右上面【数据】下=》=》点击【登录数据库】=》双击【账 务系统】=》用自己的用户进行登录=》如果图片闪烁就证 明已经登录=》点击【退出】=》点击最右上角找到【插入】

控制系统说明书 V1.0

目录 1,系统概述--------------------------------------------------------------------------------------------------1 1.1 系统简介---------------------------------------------------------------------------------------------2 1.2 系统主要组成---------------------------------------------------------------------------------------2 1.3 系统硬件简要连接图------------------------------------------------------------------------------3 1.4 实际连线图------------------------------------------------------------------------------------------3 2,系统软件使用软件简要说明-----------------------------------------------------------------------------5 2.1 介绍---------------------------------------------------------------------------------------------------5 2.2 操作步骤---------------------------------------------------------------------------------------------5 2.3 取景窗口---------------------------------------------------------------------------------------------7 2.4 flash/cel文件的播放--------------------------------------------------------------------------------7 注1:连接网络的相关设置修改--------------------------------------------------------------9 注2:本机IP的查询----------------------------------------------------------------------------9 注3:本机IP的修改----------------------------------------------------------------------------10 注4:控制器IP的修改-------------------------------------------------------------------------11 3,对应表制作与选择-----------------------------------------------------------------------------------------12 3.1 介绍---------------------------------------------------------------------------------------------------12 3.2 操作步骤---------------------------------------------------------------------------------------------12 4,说明-----------------------------------------------------------------------------------------------------------14 4.1 ONC1A------------------------------------------------------------------------------------------------14 4.2 ONC1B------------------------------------------------------------------------------------------------14 4.3 ONC1C------------------------------------------------------------------------------------------------15 4.4 ONC1D------------------------------------------------------------------------------------------------15 4.5 ONC1E------------------------------------------------------------------------------------------------16 4.6 ONC1F------------------------------------------------------------------------------------------------17 4.7 ONC1G------------------------------------------------------------------------------------------------17 4.8 ONC1F------------------------------------------------------------------------------------------------17 5,附件-----------------------------------------------------------------------------------------------------------19 5.1 数码按钮控制板说明--------------------------------------------------------------------------------19 5.2 象素点排列说明--------------------------------------------------------------------------------------19

福建省政府采购供应商手册

政府采购网上公开信息系统供应商操作指南 福建博思软件股份有限公司 2017年06月

目录 1. CA办理 (4) 1.1 CA办理 (4) 1.2 CA盖章 (4) 2. 系统注册 (4) 2.1系统注册 (4) 2.2 注册成功,供应商登录 (5) 3.系统基础操作 (6) 3.1 CA控件下载 (6) 3.2进行政府采购活动 (9) 3.3 供应商资料维护 (10) 3.4 供应商项目报名 (11) 3.5供应商用户管理 (11) 4.投标流程 (11) 4.1项目报名 (11)

4.2 投标文件编制 (13) 4.2.1客户端安装 (13) 4.2.2投标客户端路径修改 (15) 4.2.3应答 (16) 4.2.4标书加密 (21) 4.2.5接着点击退出系统 (21) 4.3投标文件上传: (22) 4.4合同签订: (23) 4.5验收申请: (23)

1.CA办理 供应商须办理福建省CA,进行政府采购活动 1.1CA办理 可登陆https://www.360docs.net/doc/24589840.html,/或者联系客服0591-968975。 1.2CA盖章 CA盖章操作系统为:XP(SP2)不支持(浏览器目前测试都支持)。 2. 系统注册 2.1系统注册 登入福建省政府采购网https://www.360docs.net/doc/24589840.html,/,找到登陆与注册进行供应商注册

2.2 注册成功,供应商登录 注:原省网已注册的供应商已完成迁移,请各供应商使用注册时的组织机构代码登录,密码初始为1。

3.系统基础操作 3.1 CA控件下载与安装 登录之前可先进行CA控件下载 (1)打开ISignature,点击installer.exe进行安装

用友-财务软件操作流程手册

用友财务软件操作流程手册 系统管理 一增加操作员 1、系统管理→系统→注册→输入用户名(admin)→无密码→确定 2、单击权限→操作员→点增加→输入编号、姓名、口令→点增加 二、建新账套 1、系统管理→系统→注册→输入用户名(admin)→无密码→确定 2 单击帐套→建立→输入帐套号、帐套名称、→设置会计期间→下一步→ 输入单位名称→下一步→选择企业类型(工业类型比商业类型多产成品入库单,和材料出库单)→行业性质→选择帐套主管→在“行业性质预置科目”前面打钩则系统将预置所选行业会计科目(否则不予预置)→下一步→如需分类在项目前面方框内打钩→下一步→完成 三、分配权限 1、系统管理→系统→注册→输入用户名(admin)→无密码→确定 2、赋权限的操作顺序: A 受限,明细权限设置权限”-→“权限”菜单→首先选择所需的账套→选操作员→点增加 B 帐套主管权限设置选择所需帐套→再选操作员→在帐套主管前面直接打钩 四、修改账套 1、以“账套主管(不是admin)”身份进入“系统管理”模块(进入系统服务→系统管理→注册) 2、单击帐套→修改 五.备份 打开系统管理→系统→注册admin →帐套→备份→选择存放路径 六.恢复 系统管理→系统→注册→admin →帐套→恢复(选择本分文件的路径,lst为后缀名的文件)总帐系统 初始化 一、启用及参数设置 二、设置“系统初始化”下的各项内容(其中:最后设置会计科目和录入期初余额,其余各项从上向 下依次设置) 1 会计科目设置 1、指定科目 系统初始化→会计科目→编辑(菜单栏中的)→指定科目 现金总帐科目把现金选进以选科目 银行总帐科目把银行存款选进已选科目

动环监控软件操作手册

动环监控软件操作 手册

深圳市通讯威科技有限公司 EP-MEVP SYSTEM 动力环境集中监控系统 安装使用说明书 版本 2.0

目录 第一章软件的安装卸载升级 ................................. 错误!未定义书签。 1.1软件安装对计算机的配置要求........................ 错误!未定义书签。 1.2软件的安装 ....................................................... 错误!未定义书签。 1.3软件的卸载 ....................................................... 错误!未定义书签。 1.4软件的升级 ....................................................... 错误!未定义书签。第二章软件的基本操作 .......................................... 错误!未定义书签。 2.1登录和进入软件操作界面................................ 错误!未定义书签。 2.2添加/设置/修改/删除硬件设备以及参数设置错误!未定义书签。 2.2.1添加/设置控制器、采集器参数................. 错误!未定义书签。 2.2.2修改/删除硬件设备 .................................... 错误!未定义书签。 2.3监控设置及记录查询 ....................................... 错误!未定义书签。 2.3.1报警方式定义 ............................................. 错误!未定义书签。 2.3.2语音电话报警 ............................................. 错误!未定义书签。 2.3.3短信报警 ..................................................... 错误!未定义书签。 2.3.4监控实时记录 ............................................. 错误!未定义书签。 2.3.5监控报警记录 ............................................. 错误!未定义书签。 2.3.6温湿度数据记录.......................................... 错误!未定义书签。 2.3.7 UPS监控数据记录 ...................................... 错误!未定义书签。 2.3.8 电话短信报警数据记录 .............................. 错误!未定义书签。 2.3.9 空调监控数据记录...................................... 错误!未定义书签。