A novel conversion of the groundwater

Journal of Hazardous Materials 292(2015)173–179

Contents lists available at ScienceDirect

Journal of Hazardous

Materials

j o u r n a l h o m e p a g e :w w w.e l s e v i e r.c o m /l o c a t e /j h a z m a

t

A novel conversion of the groundwater treatment sludge to magnetic particles for the adsorption of methylene blue

Suiyi Zhu a ,b ,Shuai Fang a ,Mingxin Huo a ,Yang Yu a ,Yu Chen a ,c ,Xia Yang a ,Zhi Geng a ,Yi Wang a ,Dejun Bian a ,b ,Hongliang Huo a ,?

a

School of Environment,Northeast Normal University,Changchun 130117,China

b

College of Water Conservancy and Environmental Engineering,Changchun Institute of Technology,Changchun130012,China c

Jilin Institute of Forestry Survey and Design,Changchun 130022,China

h i g h l i g h t s

?The low-content iron sludge was converted to MPs via a simple solvothermal process.

?MPs have high ef?ciency of the MB removal and can be easily separated from the treated water.?Impurities,such as Al,Si in the iron sludge,have little effect on magnetic separation of MPs.

a r t i c l e i n f o Article history:

Received 3December 2014

Received in revised form 12March 2015Accepted 14March 2015

Available online 17March 2015Keywords:

Groundwater treatment Iron sludge

Solvothermal synthesize Magnetic particles Adsorption

Methylene blue

a b s t r a c t

Iron sludge,produced from ?ltration and backwash of groundwater treatment plant,has long been con-sidered as a waste for land?ll.In this study,iron sludge was reused to synthesize Fe 3O 4magnetic particles (MPs)by using a novel solvothermal process.Iron sludge contained abundant amounts of silicon,iron,and aluminum and did not exhibit magnetic properties.After treatment for 4h,the amorphous Fe in iron sludge was transformed into magnetite Fe 3O 4,which could be easily separated from aqueous solution with a magnet.The prepared particles demonstrated the intrinsic properties of soft magnetic materials and could aggregate into a size of 1?m.MPs treated for 10h exhibited excellent magnetic properties and a saturation magnetization value of 9emu/g.The obtained particles presented the optimal adsorption of methylene blue under mild conditions,and the maximum adsorption capacity was 99.4mg/g,which was higher than that of granular active carbon.The simple solvothermal method can be used to prepare Fe 3O 4MPs from iron sludge,and the products could be applied to treatment of dyeing wastewater.

?2015Published by Elsevier B.V.

1.Introduction

In groundwater treatment plants,iron sludge precipitated from backwash wastewater via single-stage bio?ltration contains low iron and numerous impurities of aluminum,sand,and broken ?lter materials.By contrast to sludge with high iron content produced in traditional two-stage aeration-?lter systems,sludge with low iron content cannot be directly used to prepare red iron oxide.Aquatic pollution caused by leaching of metal ions with rain at dumping sites of iron sludge has attracted attention [1,2];the leached ions may contaminate soil and surface water and threaten the envi-ronment [3,4].In preventing environment pollution,iron sludge is dewatered through ?occulation,coagulation,and ?lter pressing

?Corresponding author.Tel.:+8643189165610;fax:+8643189165621.E-mail address:huohl@https://www.360docs.net/doc/2a3113620.html, (H.Huo).before disposal to land?lls but this process consumes space and requires additional costs.

Iron sludge can be recycled to prepare magnetic adsorbents,but its low contents of iron and other components complicate the in situ synthesis of magnetic materials.Such materials could be prepared using high-iron-content wastes,such as red mud in alumina re?neries [5,6]and electroplating sludge in plating factories [7].Akin et al.[8]leached ferric ions from red mud through microwave digestion and used these ions to prepare nano-size Fe 3O 4through alkaline co-precipitation.Despite the effective adsorption of arsenic ions in groundwater by the prepared Fe 3O 4-NPs,their low leaching ef?ciency and secondary contamination from leached acid sludge residues limit their application.High-temperature reduction is used to recover ferric irons from iron sludge.Samouhos et al.[6]used red mud with 43%iron content from an alumina re?nery as a raw material to prepare a magnetic concentrate with 69.3wt.%metallization degree;the experiment

https://www.360docs.net/doc/2a3113620.html,/10.1016/j.jhazmat.2015.03.0280304-3894/?2015Published by Elsevier B.V.

174S.Zhu et al./Journal of Hazardous Materials292(2015)173–179

was performed by adjusting the microwave treatment time and the amount of brown coal in the reductive microwave process.Zhu et al.

[9]also used red mud with an iron content of50.6%(in TFe)as a raw material to synthesize magnetic particles(MPs);synthesis was con-ducted through reductive roasting method with anthracite as the reducing agent.The ef?ciency of the recycled magnetic material can reach94.1%of the total Fe in the presence of a magnetic?eld.The high-temperature reductive method could be used to treat sludge with high iron content.However,this process may not be ef?cient for sludge with low iron content because the amount of residues increases by adding a reducing agent and brown coal or anthracite.

As an easy and controllable method,solvothermal synthesis has been widely used to prepare magnetic Fe3O4particles with dif-ferent sizes and morphologies in aqueous solutions[10,11].The target product can be synthesized through solvothermal method using reductive polyol and appropriate additives in an aqueous solution[12].Nevertheless,similar or better reductive effect of solvothermal method on iron sludge containing impurities remains undetermined.This study is the?rst to conduct solvothermal syn-thesis of Fe3O4MPs from iron sludge produced in a groundwater treatment plant by using ethylene glycol as solvent and reducing agent.The adsorption of methylene blue(MB)onto the obtained MPs was then investigated.

2.Materials and methods

2.1.Materials

Backwash wastewater was collected from a groundwater bio-?lter of Jilin YaTai Cement Company(China)and then precipitated for8h.After precipitation,the settled yellowish brown iron sludge was collected and dried at80?C for2h in a vacuum-drying oven.

Anhydrous sodium acetate,ethylene glycol,and MB were pur-chased from Sinopharm Chemical Reagent Co.,Ltd.(Beijing,China). Powder active carbon(PAC)and granular active carbon(GAC)were supplied by Tianjin Fuchen Chemical Reagents Factory(Tianjing, China).All chemicals and reagents were of analytical grade.

2.2.Preparation process

MPs were prepared using a one-step solvothermal method. About0.675g of dried iron sludge was mixed with20mL of eth-ylene glycol(used as solvent and reducing agent)under magnetic stirring and then added with3.6g of sodium acetate as a ligand. After stirring for30min,the suspension became yellowish brown and was transferred into a te?on-lined stainless-steel reaction ket-tle.The kettle was sealed and calcined at180?C for2h–20h with a heating rate of4?C/min in a drying oven.After the solvothermal process,the autoclave was cooled to room temperature and black Fe3O4particles at the bottom of the te?on were collected.The par-ticles were ultrasonically washed?ve times with deionized water, collected with a magnet after each washing,and vacuum dried at 40?C overnight.The effect of solvothermal treatment time on iron sludge was investigated by varying the time from2h to20h,and the obtained particles were denoted as“MP-x”(x represents the solvothermal treatment time).

2.3.Adsorption measurement

MB was used as the substrate to evaluate the adsorption capacity of the obtained MPs.About20mL of MB(10,30,60,100,150,200, and300mg/L)was mixed with14mg of MPs in an Erlenmeyer?ask. The?ask was sealed with para?lm and shaken at200rpm and25?C in an incubator.The initial pH of the mixture was6.8and was not adjusted during the experiment.After2h,the?ask was removed from the incubator and MPs were separated from the solution by using an external magnetic?eld.The supernatant was?ltered with a0.45?m?lter,and the?ltrate was collected to determine MB concentrations.PAC and GAC were used as controls.All treatments were performed in triplicates,and data were averaged.

2.4.Material characterization

Magnetization was measured at room temperature by using a magnetometer(Quantum Design,USA)with a SQUID-VSM system. X-ray diffraction patterns were determined with a diffractometer (Rigaku,Japan)using Cu K?radiation and2?range of10?–70?.The composition of iron sludge was determined using X-ray?uores-cence(Rigaku,Japan),and cations in MPs were investigated through microwave digestion according to the EPA method3051A[13]. Transmission M?ssbauer spectroscopy experiments were carried out using an MP500spectrometer(Oxford,Britain)at room tem-perature with?-Fe0as a reference.The valence states of Fe and O on the particle surface were determined through X-ray photoelectron spectroscopy(VG-ADES,Britain)with an Mg K?X-ray source at a residual gas pressure lower than10?8Pa.The surface characteris-tics of MPs were observed with a?eld-emission scanning electron microscope(FE-SEM;FEI Co.,USA)with an accelerating voltage of 200kV.The speci?c surface areas of MPs were determined through nitrogen adsorption–desorption measurements(TriStar3000).

The concentration of MB in the?ltrate was determined using a UV–vis spectrophotometer(Purkinje General,China)with OD at 655nm.The amount of adsorbed MB(q e(mg/g))was calculated using Eq.(1):

q e=(C0?C e)V/m(1) where C0and C e represent the initial and equilibrium concentra-tions of MB(mg/L),respectively,V denotes the total volume of MB solution used for analysis(L),and m is the mass of MPs(g).

3.Results and discussion

3.1.Magnetic measurement

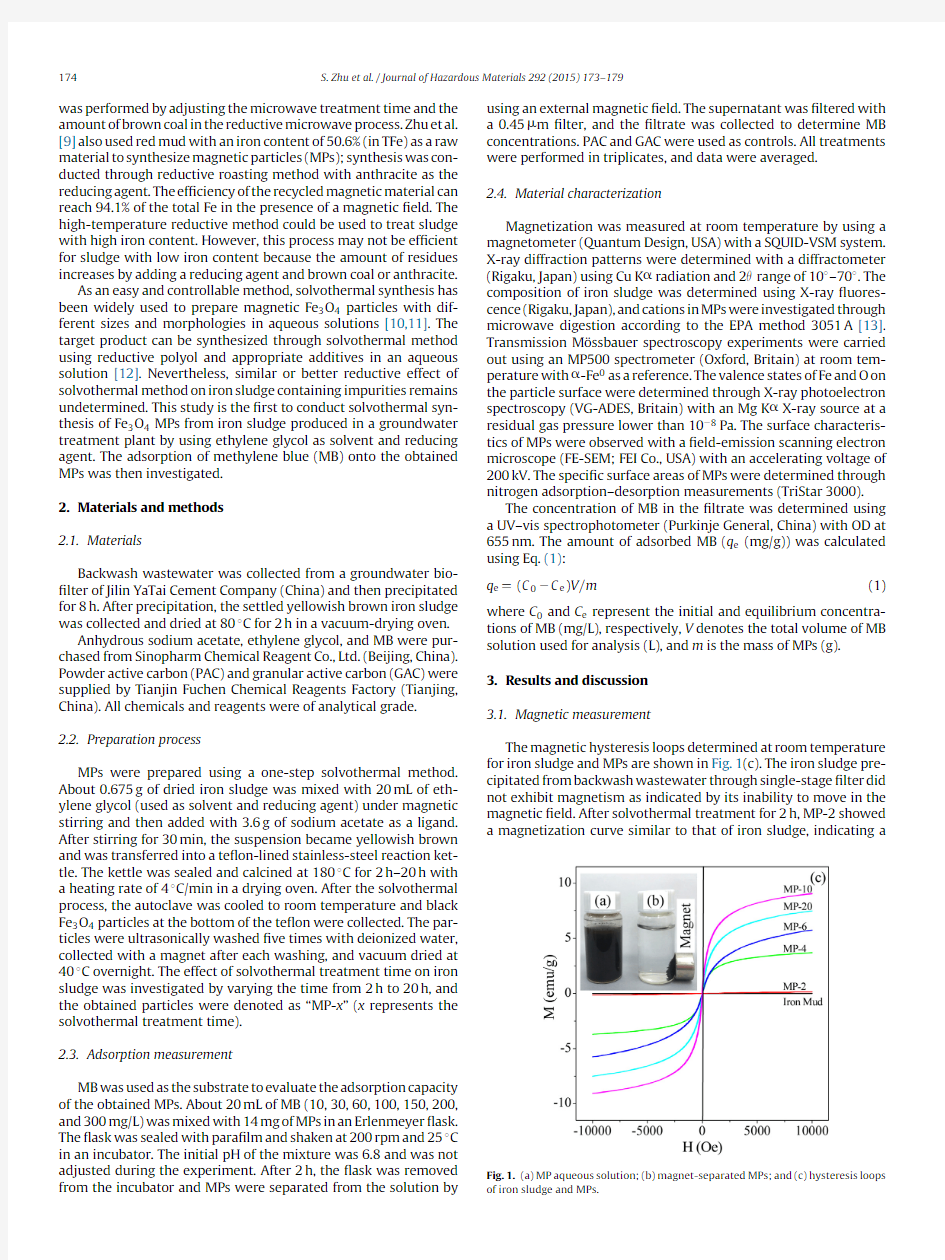

The magnetic hysteresis loops determined at room temperature for iron sludge and MPs are shown in Fig.1(c).The iron sludge pre-cipitated from backwash wastewater through single-stage?lter did not exhibit magnetism as indicated by its inability to move in the magnetic?eld.After solvothermal treatment for2h,MP-2showed a magnetization curve similar to that of iron sludge,indicating

a

Fig.1.(a)MP aqueous solution;(b)magnet-separated MPs;and(c)hysteresis loops of iron sludge and MPs.

S.Zhu et al./Journal of Hazardous Materials292(2015)173–179175

weak magnetic response.When the reaction time was extended to4h,the MP products exhibited a typical S-shape magnetization curve without apparent hysteresis loops,indicating that the sam-ples demonstrated soft magnetic properties.As the reaction time increased from4h to10h,the saturation magnetization increased and the color changed from the yellowish brown color of iron sludge to black.This?nding could be attributed to the formation of the magnetic Fe3O4phases and was consistent with the XRD and M?ssbauer data.MP-10achieved the optimal saturation magneti-zation of9emu/g,and the suspended particles in the liquid phase (Fig.1(a))could be obtained using an ordinary magnet within less than1min(Fig.1(b)).Affected by soft magnetism,MPs aggregated during the solvothermal process and their size increased beyond the critical size of superparamagnetic Fe3O4[14],resulting in the remanence of0.32emu/g.When the reaction time reached20h, MP-20exhibited a lower saturation magnetization than MP-10, which could be attributed to the non-magnetic impurities and low relative content of Fe3O4per unit mass of MP[15].

In the solvothermal process,ethylene glycol was used as a strong reducing agent with a relatively high boiling point to reduce ferric iron.NaAc was hydrolyzed to release OH?and increased the pH of the solution.This alkaline condition was bene?cial to the nucleation and growth of Fe3O4[15].A portion of Fe3+attached on the?lter materials(impurities including quartz,albite,and kaolinite)was reduced to Fe2+.The newly formed Fe2+and the remaining Fe3+ formed Fe3O4in situ via dehydration.The formation of Fe3O4in ethylene glycol can be expressed as follows[16]:

6Fe(OH)3+2OHCH2CH2OH

→H3C CO CO CH3+2Fe3O4+12H2O

The content of Fe3O4in magnet-separated sample increased with increasing time up to10h.Under this condition,NaAc exhib-ited a weak coordination ability to decrease the yield of Fe3O4 particles[16]and causes even lower effects because of the impu-rities in the iron sludge.The anions in the impurities of sludge can form stable Fe3+complexes,which could inhibit the reduction of Fe3+in ethylene glycol[16].M?ssbauer spectra and elemental anal-ysis demonstrated that Fe3+was the major Fe in MPs,albeit the reduction of some Fe3+to Fe2+to form Fe3O4.

On the other hand,quartz can be dissolved under an alkaline environment.With extended solvothermal time,the formed sili-cate and Si hydroxy groups were polycondensated to SiO2,resulting in the aggregation of MPs with a subsequent increase in grain size. This condition also caused lattice defects,which requires more cations(such as Na,K,and Ca)to balance the charges.Silica further recrystallized into quartz,indicating that the acidity of the reac-tion system possibly increased.Thus,the relative content of Fe and the saturation magnetization of MP-20decreased.However,MP-20was easily separated from the aqueous solution with a magnet. Therefore,MPs could be used as a magnetic adsorbent to remove pollutants from wastewater.

3.2.XRD analysis

The XRD patterns of iron sludge and MPs are shown in Fig.2.Iron sludge comprised a mixture of quartz(SiO2),albite(NaAlSi3O8), kaolinite(Al4[Si4O10](OH)8),and mixed silicates.The Fe peaks were not observed in iron sludge,which was presumed to be in the amorphous form covered with the background of other compounds [17,18].After solvothermal processing for2h,the crystalline phase of MP-2remained constant.With extended solvothermal treat-ment,some new peaks appeared and gradually became signi?cant. In MP-10,new re?ections appearing in the curves at approxi-mately2?=35.4?,43.2?,57.2?,and62.7?were identi?ed as

the Fig.2.XRD patterns of ferroferric oxide(a),iron sludge(b),and MP prepared with different solvothermal times of2(c),4(d),6(e),10(f),and20h(g).

(311),(400),(511),and(440)planes of the inverse spinel struc-ture of magnetite Fe3O4(JCPDS76-1849),respectively.This?nding indicated that the amorphous form of iron sludge was converted into magnetite Fe3O4during the solvothermal process.With fur-ther extension of reaction time up to20h,the Fe peaks became less signi?cant particularly at2?=62.7?and their intensity slightly decreased(Fig.2(g));hence,other ions were possibly incorporated in the Fe3O4lattice[19,20].The diffraction peaks of quartz and albite were also detected in all products,indicating that various impurities in iron sludge were not removed by the solvothermal process but only exhibited minimal effects on magnetic separation.

https://www.360docs.net/doc/2a3113620.html,ponent analysis

The major chemical composition of iron sludge and MPs are shown in Fig.3.The relative content of SiO2in iron sludge accounted for42.3wt.%,which was higher than that of Fe and Al.After treat-ment of iron sludge for2h,the high percentage of Na(16.9%)in MP-2implied the presence of a coordination complex in the lattice of quartz and albite[20].When the reaction time was more than 4h,the percentage of Na in MPs signi?cantly decreased to1.5%and the percentage of Fe slightly increased from12.6%to approximately 17%.When the reaction time was extended to20h,the percentage of Na in MP-20increased to approximately6%.Under alkaline con-

P

e

r

c

e

n

t

a

g

e

(

%

)

Sample

Fig.3.Relative amounts of major elements in iron sludge and MPs.

176S.Zhu et al./Journal of Hazardous Materials 292(2015)173–179

R e l a t i v e T r a n s m i s s i o n (%)

Velocity (mm/s)

Fig.4.M?ssbauer spectra of MPs.

dition,the recrystallization of SiO 2induced some cations for charge balance and enhanced the aggregation of MP-20.Therefore,Na may be selected for charge balance in the lattice defects of polymerized SiO 2and may consequently exhibit an increased relative content in MP-20.In addition,few K,Ca,Mg,and Mn were present in all MP samples.

3.4.M?ssbauer analysis

The M?ssbauer spectra determined at room temperature are shown in Fig.4.The spectra of MP-4showed the presence of two different forms of iron;these forms included the highly dispersed Fe 3+superparamagnetic species [21]with 95.9%relative area (Sup-plement 1)and Fe 2+species with high spin states (4.1%relative area)[22].With extended solvothermal time,the percentage of Fe 2+increased but that of Fe 3+gradually decreased.MP-10exhibited the highest percentage of Fe 2+and presented the optimal magnetic response.The percentage of Fe 2+decreased with prolonged reac-tion time up to 20h,leading to the decline of the magnetic response of MP-20.

In iron sludge,some anions in the impurities may hinder the for-mation of Fe 3O 4[16].Other impurities,such as albite and kaolinite,react with amorphous Fe to form mineral admixtures that inhibit the reduction of ferric iron [23,24].In magnetic separation,MPs with high Fe 3O 4content were ?rst isolated from the solution and the residues without magnetic properties were not separated.After treatment for 10h,the reaction rate of Fe 3O 4gradually decreased because of OH ?exhaustion.However,the ferric irons in residual could still transform into Fe 3O 4at low reaction rates until the

12001000800600400200

(a)

F e 2p

O 1s

C 1s

S i 2s I n t e n s i t y (a .u .)

Binding energy (eV)

S i 2p

survey

(b)

Fig.5.XPS survey spectra of iron sludge (a)and MP-10(b).

residue could be separated by a magnet.Nevertheless,the later separated residue contained a high amount of Fe 3+,resulting in slightly increased Fe 3+content in MP-20.In the solvothermal pro-cess,the interaction of ferric iron and impurities,such as Al,K,Ca,and Mn,was very complex and the underlying mechanism needs to be further studied.3.5.XPS analysis

From the XPS results in Fig.5,the peaks with binding energies of 285,532,103,and 711eV were attributed to C1s ,O1s ,Si2p ,and Fe2p ,respectively.This ?nding indicated the presence of C,O,Si,and Fe in iron sludge and MP-10.Apparently,the solvothermal pro-cess for preparing MPs cannot remove impurities (i.e.,Si)from iron sludge.In Fig.6,the Fe2p spectra of iron sludge was weaker than those of MPs.After solvothermal treatment of iron sludge for 2h,the MP-2spectrum of the Fe2p 3/2peak at 711.8eV demonstrated the existence of Fe O Si connection [25].The high binding energy of Fe2p 3/2in MP-2could be related to the minimal decrease in the electron density surrounding Fe atoms;the high energy was also associated with the shrink of the shielding effect induced by the lower electronegativity of Fe than that of Si.Nevertheless,the amor-phous iron deposited on the surface defect of quartz tended to bond with silica to form Fe O Si.As a result,the magnetic response dis-appeared [26].Fig.7with extended solvothermal treatment time,the Fe2p peak shifted to the low energy side because of the increas-

I n t e n s i t y (a .u .)

(a)(b)

(c)(d)(e)

Binding energy (eV)

(f)Fe2p

Fig.6.XPS Fe2p core-level spectra of iron sludge (a)and MPs prepared at 2(b),4(c),6(d),10(e),and 20h (f).

S.Zhu et al./Journal of Hazardous Materials 292(2015)173–179177

520525

530535540545

(f)(e)(d)(c)(b)Binding energy (eV)

O1s

(a)

I n t e n s i t y (a .u .)

Fig.7.XPS O1s core-level spectra of iron sludge (a)and MPs prepared at 2(b),4(c),6(d),10(e),and 20h (f).

ing Fe 2+percentage in MPs [27].In MP-20,the peak shifted to the high energy side because of the decrease in Fe 2+percentage cor-responding to the M?ssbauer data [28].The O1s spectra of iron sludge and MPs are also recorded in Fig.8.The dominant peak for iron sludge at 532.6eV was identi?ed as the oxygen in the Si O connection.In comparison to iron sludge,the XPS O1s spectrum of MPs exhibited two remarkable features as follows:(I)after 2h of reaction,the O1s main peak shifted to the high binding energy side of 531.6eV because the amorphous Fe was present in the form of a complex oxide [29]and (II)this peak slightly shifted to the low binding energy side because of the formation of magnetite Fe 3O 4.3.6.SEM analysis

The morphologies of iron sludge used as material for MPs were investigated using FE-SEM.Fig.8(a)shows that iron sludge con-tained ?ne grains with an average size of 100nm.The nano-scale iron sludge can easily penetrate into the ?ltration fabric of the frame ?lter press and transfer into the ?ltrate,resulting in dif?cult dewatering.During the solvothermal process to form soft mag-netic Fe 3O 4,MPs aggregated to form a coarse surface of irregularly shaped particles with sizes larger than 1?m (Fig.8(b)).The effect of agglomeration was enhanced when the reaction time was extended to 10h (Fig.8(c)).3.7.Adsorption of MB

The adsorption capacities of MPs were investigated using MB as the target compound,with PAC and GAC as the references.

Fig.9a displays the MB adsorption isotherms for MPs,GAC,and PAC;among these isotherms,MP-6,MP-10,and MP-20exhibited signi?cantly higher MB adsorption capacity than MP-2,MP-4,and GAC but lower than PAC.This phenomenon indicated that a small fraction of SiO 2and Fe 3O 4was recrystallized in the ?rst 4h [30].In the recrystallization process,some cations,such as K,Na,and Ca,were induced in the alumino–silicate lattice of MPs and easily displaced with MB in aqueous solution [31].

The Langmuir isotherm model was used to ?t the experimen-tal data as shown in Fig.9b.The q max values obtained from the linear sections of the Langmuir model were 70.1,85.4,95.9,99.4,98.3,173.9,and 20.5mg/g for MP-2,MP-4,MP-6,MP-10,MP-20,PAC,and GAC,respectively.The results showed that MP-10demon-strated the optimal adsorption capacity among MPs,which maybe attributed to the suf?cient exchangeable cations in the adsorp-tion reaction.MB is generally used as a reagent to determine the cation exchange in soil [32]or sludge [33].The associated adsorption process was discussed as follows:(i)the rapid diffu-sion of MB molecules from the solution to the MP surface and (ii)the slow diffusion from the MP surface to the internal meso-pores.Cation exchange is the major mechanism for adsorption of MB onto the MP surface.Other non-speci?c forces,such as physiosorption (depending on the particle size),electrostatic inter-action [34],Van der Waals forces,and chemisorption [32],are also involved in adsorption.Aqueous MB is a cationic monovalent dye (C 16H 18N 3S +)[32,35,36]with strong replacing capability than other smaller monovalent cations,such as K and Na;hence,MB may be used to replace these small cations in the alumino–silicate lattice [37].

3.8.N 2adsorption

N 2adsorption–desorption isotherms and BJH pore size distri-bution curves of MPs are plotted in Fig.10.The isotherms showed the typical IV-type sorption behavior with H1-type hysteresis loop,structurally representing the mesoporous characteristic accord-ing to the IUPAC classi?cation [38].The BET surface areas of MPs (Fig.10(a))prepared at 2,4,6,10,and 20h were 73.8,59.9,58.6,69.5,and 66.2m 2/g,respectively,which were signi?cantly lower than that of GAC (442.8m 2/g)and PAC (1295.4m 2/g)with CP grade.The BET surface area of MPs presented minimal distinction,indi-cating that physical adsorption plays a minor role in MB removal.MPs further exhibited a mesoporous structure with an average pore size of 3–4nm,which was attributed to the secondary aggregation of SiO 2particles.It was also found that besides the difference at BET surface,both pore size distribution and pore volume of PAC and GAC (Fig.S1)were indeed different

from MPs samples.Both micropore and mesopore volumes of PAC and GAC were much higher than MPs samples,but some MPs samples indeed indicated

Fig.8.SEM images of iron sludge (a),MP-4(b),and MP-10(c).

178S.Zhu et al./Journal of Hazardous Materials292(2015)173–179

q

e

(

m

g

/

g

)

C

e

(mg/L)

C e

/

q

e

C

e

(mg/L)

Fig.9.(a)MB adsorption isotherms of MPs,GAC,and PAC;and(b)the linear?tting plots based on Langmuir isotherm model for MB adsorption.

V

o

l

u

m

m

e

a

d

s

o

r

b

e

d

(

c

m

3

/

g

)

Relative pressure (P/P

)

P

o

r

e

v

o

l

u

m

e

(

c

m

3

/

g

)

Pore diameter (nm)

Fig.10.N2adsorption isotherms(a)and pore size distribution(b)of MPs.

higher MB adsorption capacities,suggesting that MPs did much

higher contribution by cation exchange,electrostatic attraction and

chemisorption rather than pore-dependent physiosorption.

The as-prepared MP can be effectively used for MB removal and

presents the following bene?ts for environmental technology and

economy.(1)The utilization of iron sludge can lower the cost of

sludge treatment,save space for sludge disposal,and reduce the

potential risks of secondary pollution.(2)The fast adsorption for

MB may provide a notable advantage for MPs to reduce hydraulic

retention times,improve volumetric loading rates,and decrease

device size in water treatment.(3)MPs can also be easily sepa-

rated from water by placing an external magnetic?eld,presenting

a convenient method for operation and management of wastewater

treatments.

4.Conclusion

Iron sludge produced from groundwater treatment contains

a considerable amount of metal ions.The improper disposal of

iron sludge may generate secondary pollution that contaminates

water and lands.The solvothermal process for preparing a magnetic

adsorbent provides a simple method for iron sludge utilization.

After the solvothermal process,MP-2exhibits weak magnetism

and MP-4presents stronger magnetic response because of the

crystalline transformation from the amorphous Fe to the mag-

netite Fe3O4.MP-10demonstrate the optimal magnetic response,

with a saturation magnetization of9emu/g and remanence at a

near-zero level.The as-prepared MP-10shows a high ef?ciency

for the adsorption of MB,with a maximum adsorption capacity

of99.4mg/g,which is signi?cantly higher than that of GAC.MP-

10can also be easily separated from water by using a magnet,

whereas separating PAC from water is dif?cult.Hence,the con-

version of iron sludge to MPs and their subsequent application in

dyeing wastewater treatment may improve waste reclamation and

utilization.

Acknowledgements

The authors are grateful for the?nancial support obtained from

the National Natural Science Foundation of China(NSFC,Contract

No:51378098,51238001,51408110and51108069)and the Jilin

Provincial Research Foundation(20130101038JC,20140520151JH

and2014340).We are also grateful for the assistance provided

by Prof.Liu Milan,Prof.Xu Wei Prof Li Fengyan,and his doctoral

student Kong Minghui.

Appendix A.Supplementary data

Supplementary data associated with this article can be found,

in the online version,at https://www.360docs.net/doc/2a3113620.html,/10.1016/j.jhazmat.

2015.03.028.

References

[1]K.M.Hassan,K.Fukushi,K.Turikuzzaman,S.M.Moniruzzaman,Effects of

using arsenic-iron sludge wastes in brick making,Waste Manage.34(2014)

1072–1078.

S.Zhu et al./Journal of Hazardous Materials292(2015)173–179179

[2]A.Sales,F.R.de Souza,Concretes and mortars recycled with water treatment

sludge and construction and demolition rubble,Constr.Build.Mater.23

(2009)2362–2370.

[3]R.B.Sotero-Santos,O.Rocha,J.Povinelli,Evaluation of water treatment

sludges toxicity using the Daphnia bioassay,Water Res.39(2005)3909–3917.

[4]C.Sullivan,M.Tyrer,C.R.Cheeseman,N.J.Graham,Disposal of water

treatment wastes containing arsenic–a review,Sci.Total Environ.408(2010) 1770–1778.

[5]S.Wang,H.M.Ang,M.O.Tade,Novel applications of red mud as coagulant,

adsorbent and catalyst for environmentally benign processes,Chemosphere 72(2008)1621–1635.

[6]M.Samouhos,M.Taxiarchou,P.E.Tsakiridis,K.Potiriadis,Greek red mud

residue:a study of microwave reductive roasting followed by magnetic

separation for a metallic iron recovery process,J.Hazard.Mater.254–255

(2013)193–205.

[7]C.D.Hills,L.Koe,C.J.Sollars,R.Perry,Early heat of hydration during the

solidi?cation of a metal plating sludge,Cem.Concr.Res.22(1992)822–832.

[8]I.Akin,G.Arslan,A.Tor,M.Ersoz,Y.Cengeloglu,Arsenic(V)removal from

underground water by magnetic nanoparticles synthesized from waste red mud,J.Hazard.Mater.235–236(2012)62–68.

[9]D.-q Zhu,T.-j Chun,J.Pan,Z.He,Recovery of iron from high-iron red mud by

reduction roasting with adding sodium salt,J.Iron Steel Res.Int.19(2012)

1–5.

[10]L.H.Yan,Aiguo Liu,Pingting Hao,Xihai Liu,Yuejun,solvothermal synthesis

and electromagnetic properties of Fe3O4and its Zn2+substituted Zn1?x Fe2+x O4 nanocrystallines,Chemical Journal of Chinese University,31,(2010),

447–451.

[11]J.Shi,L.Tong,X.Ren,Q.Li,H.Yang,Multifuctional Fe3O4@C/YVO4:Dy3+

nanopowers:preparation,luminescence and magnetic properties,Ceram.Int.

39(2013)6391–6397.

[12]M.Zhu,G.Diao,Synthesis of porous Fe3O4nanospheres and its application for

the catalytic degradation of xylenol orange,J.Phys.Chem.C115(2011)

18923–18934.

[13]C.M.M.S.Valérie Sandroni,Microwave digestion of sludge,soil and sediment

samples for metal analysis by inductively coupled plasma-atomic emission spectometry,Anal.Chim.Acta468(2002)335–344.

[14]M.J.Chen,H.Shen,X.Li,H.F.Liu,Facile synthesis of oil-soluble Fe3O4

nanoparticles based on a phase transfer mechanism,Appl.Surf.Sci.307

(2014)306–310.

[15]L.Yuan,X.Weng,J.Xie,W.Du,L.Deng,Solvothermal synthesis and

visible/infrared optical properties of Al/Fe3O4core–shell magnetic composite pigments,J.Alloys Compd.580(2013)108–113.

[16]F.Chen,R.Liu,S.Xiao,C.Zhang,Solvothermal synthesis in ethylene glycol and

adsorption property of magnetic Fe3O4microspheres,Mater.Res.Bull.55

(2014)38–42.

[17]S.Sushil,A.M.Alabdulrahman,M.Balakrishnan,V.S.Batra,R.A.Blackley,J.

Clapp,J.S.Hargreaves,A.Monaghan,I.D.Pulford,J.L.Rico,W.Zhou,Carbon

deposition and phase transformations in red mud on exposure to methane,J.

Hazard.Mater.180(2010)409–418.

[18]S.Sushil,V.S.Batra,Modi?cation of red mud by acid treatment and its

application for CO removal,J.Hazard.Mater.203–204(2012)264–273. [19]D.Tripathy,A.O.Adeyeye,S.N.Piramanayagam,C.S.Mah,X.Gao,A.T.S.Wee,

Effect of cobalt doping concentration on the structural and magnetic

properties of Fe3O4,Thin Solid Films505(2006)45–49.[20]I.Ghosh,S.Guha,R.Balasubramaniam,A.V.Kumar,Leaching of metals from

fresh and sintered red mud,J.Hazard.Mater.185(2011)662–668.

[21]A.A.S.Oliveira,J.C.Trist?o,J.D.Ardisson,A.Dias,https://www.360docs.net/doc/2a3113620.html,go,Production of

nanostructured magnetic composites based on Fe0nuclei coated with carbon nano?bers and nanotubes from red mud waste and ethanol,Appl.Catal.B:

Environ.105(2011)163–170.

[22]A.Li,Y.Tong,X.Ni,J.Wang,P.Guo,G.Zhang,M?ssbauer studies on

iron-containing atmospheric suspended particles,Zhongguo Huanjing

Kexue/China Environ.Sci.21(2001)198–202.

[23]K.Mamulova Kutlakova,J.Tokarsky,P.Kovar,S.Vojteskova,A.Kovarova,B.

Smetana,J.Kukutschova,P.Capkova,V.Matejka,Preparation and

characterization of photoactive composite kaolinite/TiO(2),J.Hazard.Mater.

188(2011)212–220.

[24]H.Deng,X.Li,Q.Peng,X.Wang,J.Chen,Y.Li,Monodisperse magnetic

single-crystal ferrite microspheres,Angew.Chem.Int.Ed.Engl.44(2005)

2782–2785.

[25]F.Dang,N.Enomoto,J.Hojo,K.Enpuku,Sonochemical coating of magnetite

nanoparticles with silica,Ultrason.Sonochem.17(2010)193–199.

[26]M.Abbas,B.Parvatheeswara Rao,M.Nazrul Islam,S.M.Naga,M.Takahashi,C.

Kim,Highly stable-silica encapsulating magnetite nanoparticles(Fe3O4/SiO2) synthesized using single surfactantless-polyol process,Ceram.Int.40(2014) 1379–1385.

[27]H.Lin,H.Zhang,L.Hou,Degradation of C.I.acid orange7in aqueous solution

by a novel electro/Fe3O4/PDS process,J.Hazard.Mater.276(2014)182–191.

[28]C.Tan,N.Gao,Y.Deng,J.Deng,S.Zhou,J.Li,X.Xin,Radical induced

degradation of acetaminophen with Fe3O4magnetic nanoparticles as

heterogeneous activator of peroxymonosulfate,J.Hazard.Mater.276(2014) 452–460.

[29]W.X.Shi,J.Yang,T.J.Wang,Y.Jin,Surface organic modi?cation of magnetic

iron oxide black particles,Acta Phys.Chim.Sin.17(2001)507–510.

[30]W.Zhang,F.Shen,R.Hong,Solvothermal synthesis of magnetic Fe3O4

microparticles via self-assembly of Fe3O4nanoparticles,Particuology9(2011) 179–186.

[31]L.Y.Zhao,X.K.Wang,Y.G.Guo,N.Z.Wu,Y.C.Xie,Adsorption of methylene

blue on the muscovite,Acta Phys.Chim.Sin.19(2003)896–901.

[32]Y.Yukselen,A.Kaya,Suitability of the methylene blue test for surface area,

cation exchange capacity and swell potential determination of clayey soils, Eng.Geol.102(2008)38–45.

[33]Y.Liu,C.Lin,Y.Wu,Characterization of red mud derived from a combined

bayer process and bauxite calcination method,J.Hazard.Mater.146(2007) 255–261.

[34]M.Rafatullah,O.Sulaiman,R.Hashim,A.Ahmad,Adsorption of methylene

blue on low-cost adsorbents:a review,J.Hazard.Mater.177(2010)70–80. [35]https://www.360docs.net/doc/2a3113620.html,ribi,M.Audiguier,R.Cojean,Assessing shrink/swell properties of two

argillaceous soils from the Paris Basin:a comparison of cation exchange

determination methods,Bull.Eng.Geol.Environ.67(2008)415–424.

[36]M.K.Wang,S.L.Wang,W.M.Wang,Rapid estimation of cation-exchange

capacities of soils and clays with methylene blue exchange,Soil Sci.Soc.Am.J.

60(1996)138–141.

[37]S.J.Toth,Colloid Chemistry of Soils.In:Chemistry of the Soil,Reinhold

Publishing Corp,Michigan,1955.

[38]J.Rouquerol,F.Rouquerol,P.Llewellyn,G.Maurin,K.S.W.Sing,Adsorption by

Powders and Porous Solids:Principles,Methodology and Applications,

Second Edition,Elsevier Inc.,2015.