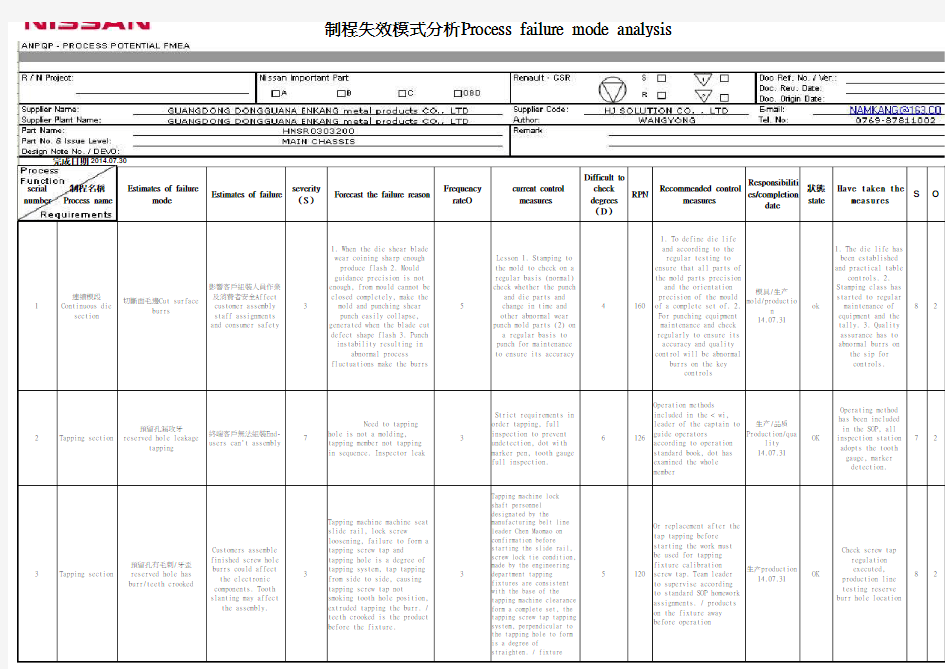

FMEA (中英文)

Or replacement after the tap tapping before starting the work must be used for tapping fixture calibration screw tap. Team leader to supervise according to standard SOP homework assignments. /products on the fixture away before operation 生产production 14.07.31生产/品质Production/qu ality 14.07.3153Tapping machine machine seat slide rail, lock screw loosening, failure to form a tapping screw tap and tapping hole is a degree of tapping system, tap tapping from side to side, causing tapping screw tap not smoking tooth hole position, extruded tapping

the burr. / teeth crooked

is the product before the

fixture.3Tapping machine lock shaft personnel designated by the manufacturing belt line leader Chen Maomao on confirmation before starting the slide rail,screw lock tie condition,made by the engineering department tapping fixtures are consistent with the clearance form a complete set, the tapping screw tap tapping system,perpendicular to the tapping hole to form is a

degree of straighten. /

fixture 2Tapping section 預留孔漏攻牙reserved hole leakage tapping 終端客戶無法組裝End-users can't assembly 3Tapping section 預留孔有毛刺/牙歪reserved hole has

burr/teeth crooked Customers assemble finished screw hole burrs could affect the electronic

components. Tooth

slanting may affect

the assembly.7 Need to tapping hole is not a molding,tapping member not tapping

in sequence. Inspector leak 3Operation methods included in the < wi,leader of the captain to guide operators according to operation standard book, dot has examined the whole

member 126severity (S) Strict requirements in order tapping, full inspection to prevent undetection, dot with marker pen, tooth gauge

full inspection.6 current control measures Difficult to check degrees

(D)Forecast the failure reason Frequency rateO 3 1. When the die shear blade wear coining sharp enough produce flash 2. Mould guidance precision is not enough, from mould cannot be closed completely, make the mold and punching shear punch easily collapse,generated when the blade

cut defect shape flash 3.

Punch instability resulting

in abnormal process

fluctuations make the burrs 期Completion date:2014.07.30

serial

number 制程名稱Process name Estimates of failure mode Estimates of failure 120RPN 狀態state Have taken the measures Recommended control measures Responsibilit ies/completio n date S O

ok 1. The die life has been established and practical table controls. 2.Stamping class has started to regular maintenance of equipment and the tally. 3. Quality assurance has to abnormal burrs on the sip for controls.82

Operating method has been included in the SOP, all inspection station adopts the tooth gauge, marker detection.72

Check screw tap regulation executed,production line testing reserve burr hole location 82

制程失效模式分析Process failure mode analysis

OK OK 1連續模段Continuous die

section 切斷面毛邊Cut surface burrs 影響客戶組裝人員作業及消費者安全Affect customer assembly staff assignments

and consumer safety 5Lesson 1. Stamping to the mold to check on a regular basis (normal)check whether the punch and die parts and change in time and other abnormal wear punch mold parts (2) on a regular basis to punch for maintenance to ensure its accuracy 4160 1. To define die life and according to the regular testing to ensure that all parts of the mold parts precision and the orientation precision of the mould of a complete set of. 2. For punching equipment maintenance and check regularly to ensure its accuracy and quality control will be

abnormal burrs on the

key controls 模具/生产mold/producti on 14.07.31

Review: Li Quan hao approval: Cai Zhenzhe TAB: wang yong

RPN 1D 322816

48