Ksedal 00031AM(N-35 M) 2014102001-8D report - chinese and english

No

1o

2o

1o

2o

No

Equipment 1

2

3

4

5

6

7

8

9

10

Unit:mm

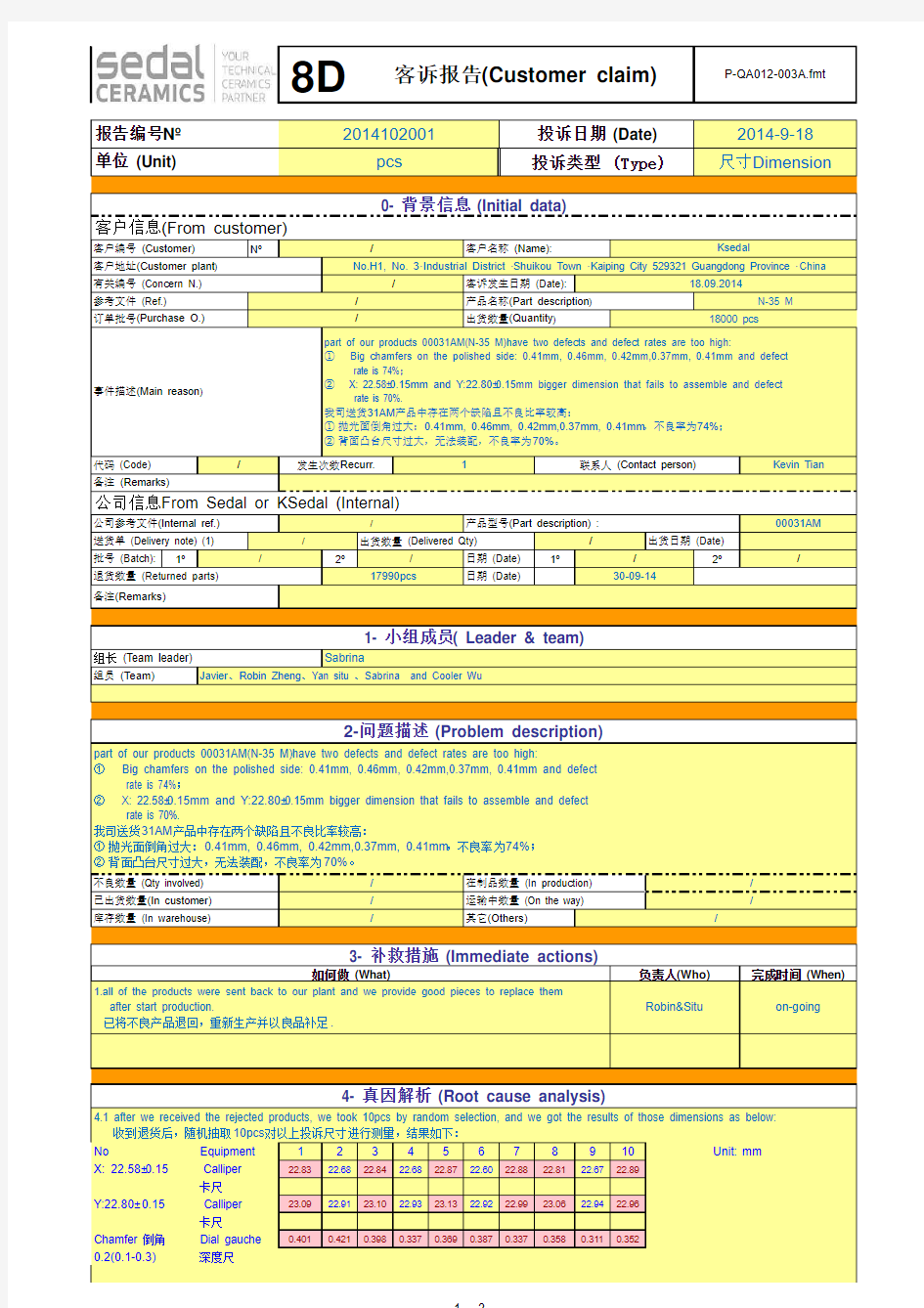

X: 22.58±0.15Calliper 22.83

22.68

22.84

22.68

22.87

22.60

22.88

22.81

22.67

22.89

卡尺Y:22.80±0.15Calliper 23.0922.9123.1022.9323.1322.9222.9923.0622.9422.96

卡尺

Chamfer 倒角Dial gauche 0.4010.4210.3980.3370.3690.3870.3370.3580.3110.352

0.2(0.1-0.3)

深度尺

No.H1, No. 3· Industrial District · Shuikou Town · Kaiping City 529321 Guangdong Province · China

Kevin Tian

1

pcs

报告编号Nopart of our products 00031AM(N-35 M)have two defects and defect rates are too high:

① Big chamfers on the polished side: 0.41mm, 0.46mm, 0.42mm,0.37mm, 0.41mm and defect rate is 74%;

② X: 22.58±0.15mm and Y:22.80±0.15mm bigger dimension that fails to assemble and defect rate is 70%.

我司送货31AM 产品中存在两个缺陷且不良比率较高:

① 抛光面倒角过大:0.41mm, 0.46mm, 0.42mm,0.37mm, 0.41mm ,不良率为74%;② 背面凸台尺寸过大,无法装配,不良率为70%。

/其它(Others)

/

公司信息From Sedal or KSedal (Internal)

/

N-35 M

/

//

出货数量 (Delivered Qty)P-QA012-003A.fmt

2014-9-18尺寸Dimension

part of our products 00031AM(N-35 M)have two defects and defect rates are too high:

① Big chamfers on the polished side: 0.41mm, 0.46mm, 0.42mm,0.37mm, 0.41mm and defect rate is 74%;

② X: 22.58±0.15mm and Y:22.80±0.15mm bigger dimension that fails to assemble and defect rate is 70%.

我司送货31AM 产品中存在两个缺陷且不良比率较高:

① 抛光面倒角过大:0.41mm, 0.46mm, 0.42mm,0.37mm, 0.41mm ,不良率为74%;② 背面凸台尺寸过大,无法装配,不良率为70%。

4.1 after we received the rejected products, we took 10pcs by random selection, and we got the results of those dimensions as below: 收到退货后,随机抽取10pcs 对以上投诉尺寸进行测量,结果如下:单位 (Unit)

联系人 (Contact person)

退货数量 (Returned parts)运输中数量 (On the way)不良数量 (Qty involved)批号 (Batch):

30-09-14

已出货数量(In customer)/代码 (Code)备注 (Remarks)

/

公司参考文件(Internal ref.)产品型号(Part description) :

/

发生次数Recurr.

3- 补救措施 (Immediate actions)

组长 (Team leader)

组员 (Team)

Javier 、Robin Zheng 、Yan situ 、Sabrina and Cooler Wu

18000 pcs

产品名称(Part description )00031AM

4- 真因解析 (Root cause analysis)

17990pcs

事件描述(Main reason )

备注(Remarks)

8D

客诉报告(Customer claim)

/

1.all of the products were sent back to our plant and we provide good pieces to replace them after start production.

已将不良产品退回,重新生产并以良品补足.

参考文件 (Ref.)出货日期 (Date)

/

/

客诉发生日期 (Date):/

on-going

/负责人(Who)完成时间 (When)

Robin&Situ

如何做 (What)

/在制品数量 (In production)1- 小组成员( Leader & team)

Sabrina

2014102001

客户名称 (Name):Ksedal 投诉类型 (Type)

日期 (Date)库存数量 (In warehouse)

日期 (Date)

/

送货单 (Delivery note) (1)客户地址(Customer plant )/

投诉日期 (Date)2-问题描述 (Problem description)

/

出货数量(Quantity )

18.09.2014

有关编号 (Concern N.)客户编号 (Customer)0- 背景信息 (Initial data)

客户信息(From customer)

订单批号(Purchase O.)

Conclusion 结论:we also got the problem as customer`s 客户投诉属实

控制计划l (Control plan)

作业指导书(Working instructions)

N/A

N/A

/

其它方面 (Other plant) Please provide us the latest drawing as soon as possible

On-going On-going

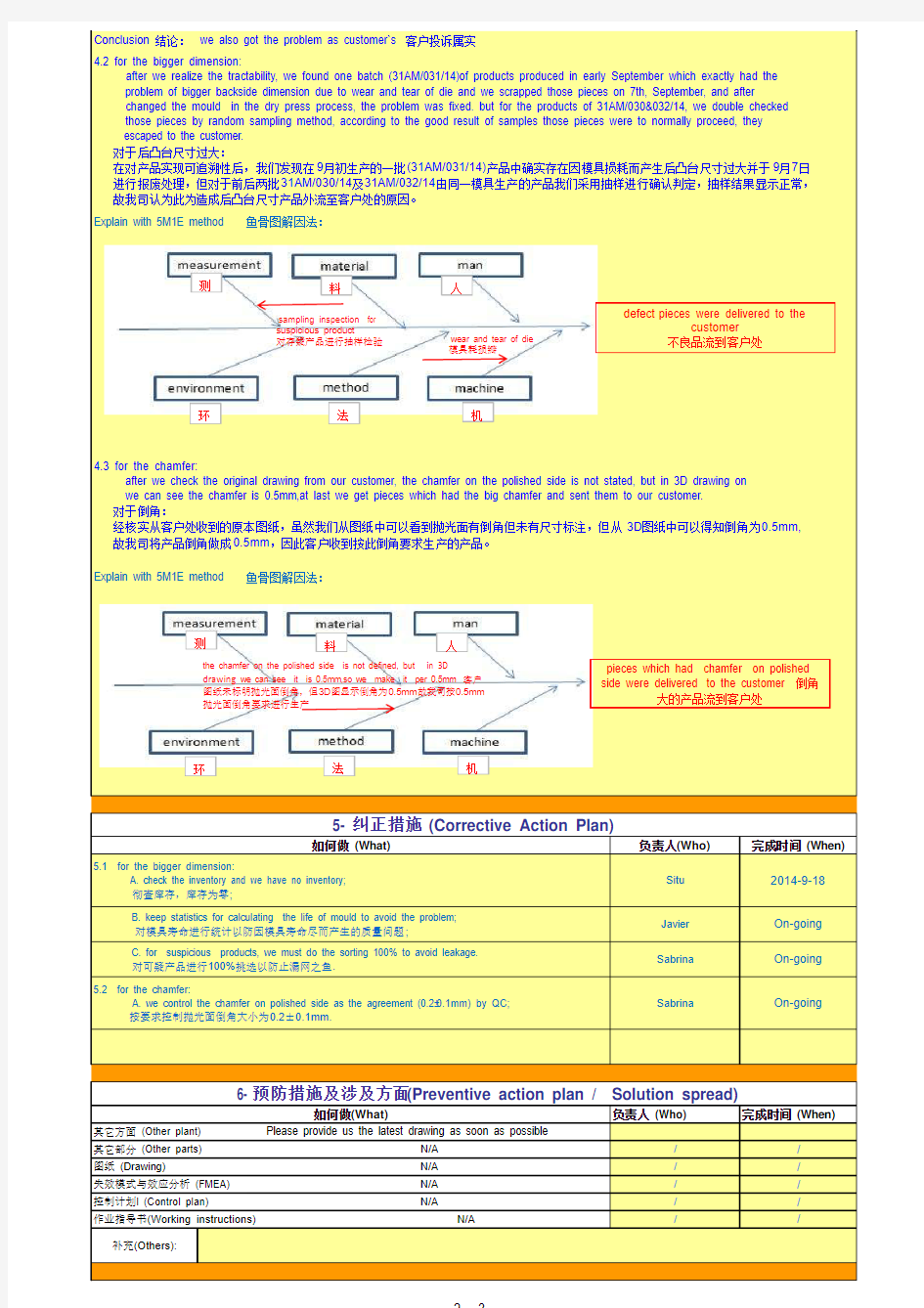

4.3 for the chamfer:

after we check the original drawing from our customer, the chamfer on the polished side is not stated, but in 3D drawing on we can see the chamfer is 0.5mm,at last we get pieces which had the big chamfer and sent them to our customer. 对于倒角:

经核实从客户处收到的原本图纸,虽然我们从图纸中可以看到抛光面有倒角但未有尺寸标注,但从3D 图纸中可以得知倒角为0.5mm, 故我司将产品倒角做成0.5mm ,因此客户收到按此倒角要求生产的产品。完成时间 (When)

如何做(What)

4.2 for the bigger dimension:

after we realize the tractability, we found one batch (31AM/031/14)of products produced in early September which exactly had the problem of bigger backside dimension due to wear and tear of die and we scrapped those pieces on 7th, September, and after

changed the mould in the dry press process, the problem was fixed. but for the products of 31AM/030&032/14, we double checked those pieces by random sampling method, according to the good result of samples those pieces were to normally proceed, they escaped to the customer. 对于后凸台尺寸过大:

在对产品实现可追溯性后,我们发现在9月初生产的一批(31AM/031/14)产品中确实存在因模具损耗而产生后凸台尺寸过大并于9月7日 进行报废处理,但对于前后两批31AM/030/14及31AM/032/14由同一模具生产的产品我们采用抽样进行确认判定,抽样结果显示正常, 故我司认为此为造成后凸台尺寸产品外流至客户处的原因。Explain with 5M1E method 鱼骨图解因法:

/

图纸 (Drawing)

失效模式与效应分析 (FMEA)N/A ///其它部分 (Other parts)N/A N/A Explain with 5M1E method 鱼骨图解因法:

5.1 for the bigger dimension:

A. check the inventory and we have no inventory; 彻查库存,库存为零;

/////补充(Others):

完成时间 (When)

Situ

5- 纠正措施 (Corrective Action Plan)

5.2 for the chamfer:

A. we control the chamfer on polished side as the agreement (0.2±0.1mm) by QC; 按要求控制抛光面倒角大小为0.2±0.1mm. 6- 预防措施及涉及方面(Preventive action plan / Solution spread)

负责人 (Who)

On-going

B. keep statistics for calculating the life of mould to avoid the problem; 对模具寿命进行统计以防因模具寿命尽而产生的质量问题;

Sabrina

Sabrina C. for suspicious products, we must do the sorting 100% to avoid leakage. 对可疑产品进行100%挑选以防止漏网之鱼.

Javier 2014-9-18

负责人(Who)

如何做 (What)

pieces which had chamfer on polished side were delivered to the customer 倒角

大的产品流到客户处

测

料人

机

法环defect pieces were delivered to the

customer 不良品流到客户处

测

料

人

机

法环wear and tear of die 模具耗损瓣

sampling inspection for suspicious product

对存疑产品进行抽样检验

the chamfer on the polished side is not defined, but in 3D

drawing we can see it is 0.5mm,so we make it per 0.5mm 客户图纸未标明抛光面倒角,但3D 图显示倒角为0.5mm 故我司按0.5mm 抛光面倒角要求进行生产