丹佛国际机场 项目案例分析

Case Study – Denver International Airport Baggage Handling System – An illustration of ineffectual decision making

Calleam Consulting Ltd – Why Technology Projects Fail

Synopsis

Dysfunctional decision making is the poison that kills technology projects and the Denver Airport Baggage System project in the 1990’s is a classic example. Although several case studies have been written about the Denver project, the following paper re-examines the case by looking at the key decisions that set the project on the path to disaster and the forces behind those decisions. Background

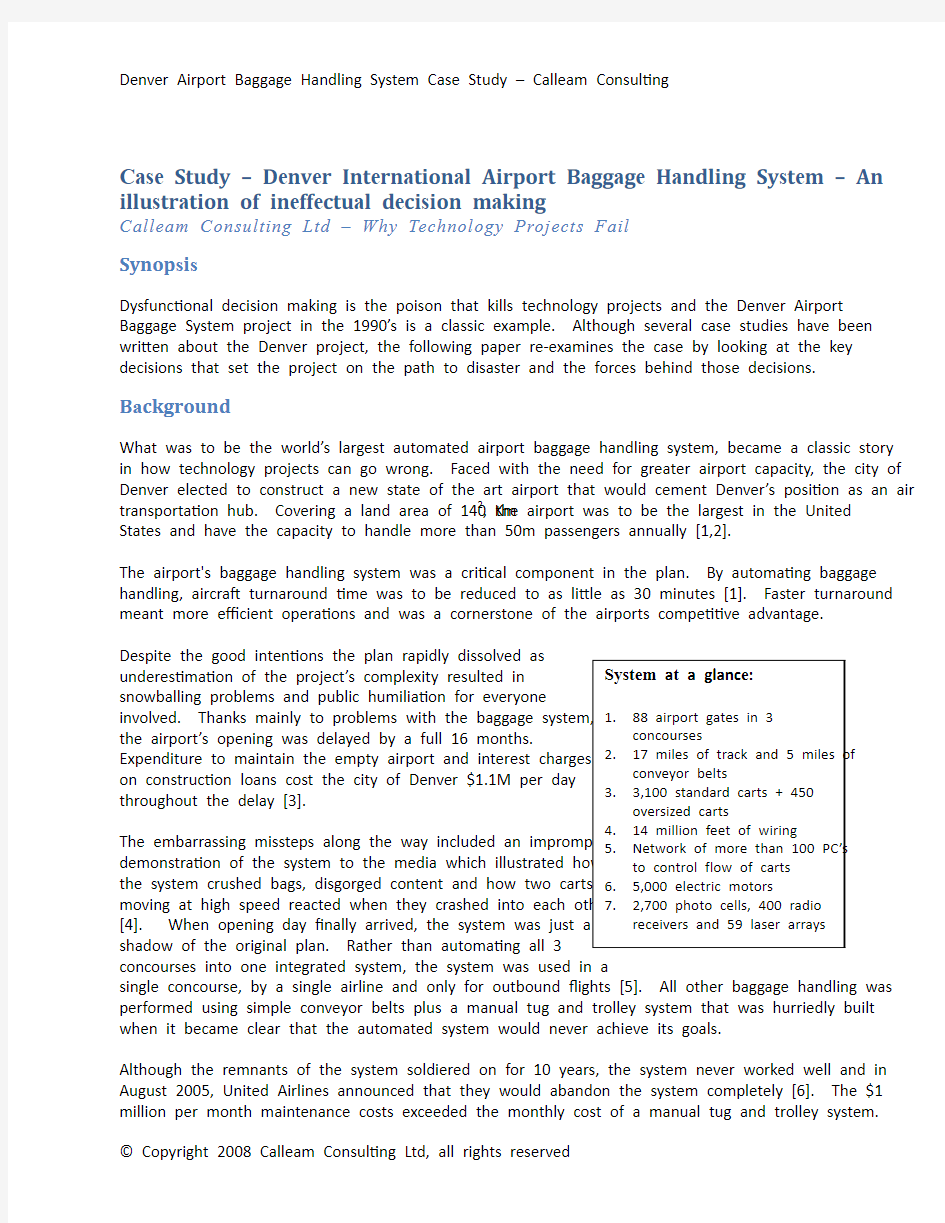

What was to be the world’s largest automated airport baggage handling system, became a classic story in how technology projects can go wrong. Faced with the need for greater airport capacity, the city of Denver elected to construct a new state of the art airport that would cement Denver’s position as an air transportation hub. Covering a land area of 140 Km2, the airport was to be the largest in the United States and have the capacity to handle more than 50m passengers annually [1,2].

The airport's baggage handling system was a critical component in the plan. By automating baggage handling, aircraft turnaround time was to be reduced to as little as 30 minutes [1]. Faster turnaround meant more efficient operations and was a cornerstone of the airports competitive advantage.

Despite the good intentions the plan rapidly dissolved as Array underestimation of the project’s complexity resulted in

snowballing problems and public humiliation for everyone

involved. Thanks mainly to problems with the baggage system,

the airport’s opening was delayed by a full 16 months.

Expenditure to maintain the empty airport and interest charges

on construction loans cost the city of Denver $1.1M per day

throughout the delay [3].

The embarrassing missteps along the way included an impromptu

demonstration of the system to the media which illustrated how

the system crushed bags, disgorged content and how two carts

moving at high speed reacted when they crashed into each other

[4]. When opening day finally arrived, the system was just a

shadow of the original plan. Rather than automating all 3

concourses into one integrated system, the system was used in a

single concourse, by a single airline and only for outbound flights [5]. All other baggage handling was performed using simple conveyor belts plus a manual tug and trolley system that was hurriedly built when it became clear that the automated system would never achieve its goals.

Although the remnants of the system soldiered on for 10 years, the system never worked well and in

August 2005, United Airlines announced that they would abandon the system completely [6]. The $1

million per month maintenance costs exceeded the monthly cost of a manual tug and trolley system.

Chronology of events:

Denver International Airport (DIA) Baggage System Development Timeline [1, 2, 3, 4, 5, 6]

Nov 1989 Work starts on the construction of the airport

Oct 1990 City of Denver engages Breier Neidle Patrone Associates to analyse feasibility of building an integrated baggage system. Reports advises that complexity makes the proposition unfeasible Feb 1991 Continental Airlines signs on and plans on using Denver as a hub

Jun 1991 United Airlines signs on and plans on using Concourse A as a hub

Jun 1991 United Airlines engages BAE Systems to build an automated baggage system for Concourse A.

BAE was a world leader in the supply, installation and operation of baggage handling equipment Summer 1991 Airport’s Project Management team recognizes that a baggage handling solution for the complete airport was required. Bids for an airport wide solution are requested

Fall 1991 Of the 16 companies included in the bidding process only 3 respond and review of proposals indicate none could be ready in time for the Oct 1993 opening. The 3 bids are all rejected

Early 1992 Denver Airport Project Management team approach BAE directly requesting a bid for the project Apr 1992 Denver Airport contracts with BAE to expand the United Airlines baggage handling system into an integrated system handling all 3 concourses, all airlines, departing as well as arriving flights. In

addition system is to handle transfer baggage automatically. Contract is hammered out in 3

intense working sessions

Aug 1992 United Airlines changes their plans and cuts out plans for the system to transfer bags between aircraft. Resulting changes save $20m, but result in a major redesign of the United Airlines

portion of the system. Change requests are raised to add automated handling of oversized

baggage and for the creation of a dedicated ski equipment handling area

Sep 1992 Continental requests ski equipment handling facilities be added to their concourse as well

Oct 1992 Chief Airport Engineer, Walter Singer dies. Mr Singer had been one of the driving forces behind the creation of the automated baggage system

Jan 1993 Change orders raised altering size of ski equipment claim area and adding maintenance tracks so carts could be serviced without having to be removed from the rails

Feb 1993 Target opening date shifted from 31 Oct 93 to 19 Dec 93 and soon thereafter to 9 Mar 94

Sep 1993 Target opening date is shifted again, new target date is 15 May 1994

31 Oct 1993 Original target for opening

19 Dec 1993 Second target for opening

Jan 1994 United Airlines requests further changes to the oversize baggage input area

9 Mar 1994 Third target for opening

Mar 1994 Problems establishing a clean electrical supply results in continual power outages that disrupt testing and development. Solution requires installation of industrial filters into the electrical

system. Ordering and installation of the filters takes several months

Apr 1994 Airport authorities arrange a demonstration for the system for the media (without first informing BAE). Demonstration is a disaster as clothes are disgorged from crushed bags

Apr 1994 Denver Mayor cancels 15 May target date and announces an indefinite delay in opening

May 1994 Logplan Consulting engaged to evaluate the project

15 May 1994 Fourth target for opening

May 1994 BAE Systems denies system is malfunctioning. Instead they say many of the issues reported to date had been caused by the airport staff using the system incorrectly

Aug 1994System testing continues to flounder. Scope of work is radically trimmed back and based on Logplan’s recommendation airport builds a manual tug and trolley system instead

Aug 1994 City of Denver starts fining BAE $12K per day for further delays

28 Feb 1995 Actual opening

Aug 2005 In order to save costs the system is scrapped in favour of a fully manual system. Maintenance costs were running at $1M per month at the time.

Basic Mode of Failure

As with all failures the problems can be viewed from a number of levels. In its simplest form, the Denver International Airport (DIA) project failed because those making key decision underestimated the complexity involved. As planned, the system was the most complex baggage system ever attempted. Ten times larger than any other automated system, the increased size resulted in an exponential growth in complexity. At the heart of the complexity lay an issue know as “line balancing” [1]. To optimize system performance, empty carts had to be distributed around the airport ready to pick up new bags. With more than 100 pickup points (check in rows and arrival gates) each pickup needed to be fed with enough empty carts to meet its needs. The algorithms necessary to anticipate where empty carts should wait for new bags represented a nightmare in the mathematic modeling of queue behaviours. Failure to anticipate the number of carts correctly would result in delays in picking up bags that would undermine the system’s performance goals.

Failure to recognise the complexity and the risk involved contributed to the project being initiated too late. The process of requesting bids for the design and construction of the system was not initiated until summer of 1991 [7]. Based on the original project schedule, this left a little over two years for the contracts to be signed and for the system to be designed, built, tested and commissioned. The closest analogous projects were the San Francisco system and one installed in Munich. Although much smaller and simpler, those systems took two years to implement [7]. Given the quantum leap in terms of size and complexity, completing the Denver system in two years was an impossible task.

The underestimation of complexity led to a corresponding underestimation of the effort involved. That underestimation meant that without realising it, the Project Management team had allowed the baggage system to become the airport’s critical path. In order to meet the airport’s planned opening date, the project needed to be completed in just two years. This clearly was insufficient time and that misjudgement resulted in the project being exposed to massive levels of schedule pressure. Many of the project’s subsequent problems were likely a result of (or exacerbated by) shortcuts the team took and the mistakes they made as they tried to meet an impossible schedule.

Key Decisions that Led to Disaster

Although the basic mode of failure is fairly clear, to understand the root cause and what should have been done differently we need to examine how the critical decisions that triggered the failure were made. Project failures usually involve numerous flawed decisions, but within those many missteps, certain key decisions are the triggers that set in motion the sequence of events that lead to disaster. Key Decision 1 – A change in strategy

At the start of a project strategic decisions are made that set the project’s direction. In the DIA case, a strategic error was made that resulted in “flip-flop” being made part way through the project.

Prior to requesting bids for an integrated system in the summer of 1991, the airport’s Project Management team had assumed that individual airlines would make their own baggage handling arrangements [5]. United Airlines had indeed proceeded with their own plan by engaging BAE (Boeing Airport Equipment Automated Systems Incorporated) directly. Continental Airlines had however not

made any arrangements and given that the airport was not yet fully leased out, other sections of the airport were not being addressed.

In the summer of 1991, the airport’s Project Management team changed their strategy and realised that if an integrated system was to be built, they needed to take responsibility back from the individual airlines and run the project themselves. This change in strategy came a little more than two years prior to the airport’s planned opening date and the timing of the decision was in large part the trigger behind the excessive schedule pressure the project was exposed to.

In one way the change in strategy made sense because an integrated system required centralized control and the airport’s Project Management team was the only central group that could run the project. Clearly the timing of the decision was however extremely poor. Had the correct strategy been set at the outset, there would have been two additional years in which to develop the system. Those two years may well have been enough to allow designers to understand the complexity issue more deeply and to find ways to either overcome it or agree with the stakeholders on a simpler design.

The delay in setting the correct strategy is likely rooted in the history of how prior airport construction projects had been run. Because earlier generation baggage facilities were dedicated to individual airlines, airlines had historically built their own systems when a new airport was built [5]. The advent of the integrated airport wide system required a change in mindset. The integrated nature of the new systems meant that instead of airlines looking after their own facilities, airport’s needed to take control.

The key point the airport’s Project Management team failed to see was that the shift in technology required a corresponding shift in organizational responsibilities. The failure to recognise that shift represents a planning failure that dated back to the very start of the construction project. The public record does not detail how the original strategy was set or even if the topic had been directly considered. However, people typically see the world through the eyes of their prior experiences and given that almost all prior airport projects had left this responsibility to the airline, it is very likely that the question was simply never discussed.

In broader terms, the mistake made was a failure to link the airport’s overall strategy (the goal of having one of the world’s most efficient airports) with the sub-strategy of how to build the baggage system. The mode in which that failure occurred may well simply have been a failure to ask the critical question of where responsibility for development of the baggage system needed to be.

Key Decision 2 – The decision to proceed

Although the change in strategy is somewhat understandable, what is less understandable is why both the airport Project Management team and BAE decided to proceed with the full scale project despite clear indications that there was insufficient time left for the project to be completed successfully. Prior to entering into the BAE contract, there were at least three indications that the project required more than two years or was simply not feasible;

1.The 1990 Breier Neidle Patrone Associates report indicated the complexity was too high for the

system to be built successfully [1],

2.Analysis of the three bids received indicated that none of the vendors could build the system in time

for the Oct 1993 opening [4],

3.Experts from Munich airport advised that the much simpler Munich system had taken 2 full years to

build and that it had run 24 / 7 for 6 months prior to opening to allow bugs to be ironed out [5].

Reports indicate that the decision to proceed was based on the communications between the airport’s Chief Engineer (Walter Slinger) and BAE’s Senior Management team. While BAE had initially chosen not to bid for the airport wide contract, the rejection of the three official bids resulted in the airport team speaking directly to BAE about the possibility of expanding the United Airlines system that was already under development. Those discussions resulted in the preparation of a specification and the creation of a large scale prototype (reported to have filled up a 50,000 sq ft warehouse) [7]. Demonstration of the prototype to is said to have been the factor that convinced Slinger that the system was feasible.

Despite the fact that BAE was talking directly to Slinger about the possibility of building the system, some reports indicate that within BAE several managers were voicing concern. Again the issues related to whether or not it was feasible to build such a large system in such a short period of time. Reports indicate that several managers advised the BAE Senior Management team that the project was at minimum a four year project, not a two year project [5].

The failure by both Slinger and BAE’s Senior Management team to heed the advice they were receiving and the failure of the airport’s Project Management team to have the BAE proposal and prototype independently reviewed is the epicentre of the disaster.

Although published reports do not indicate why the expert advice was ignored, it is clear that both Slinger and BAE’s Senior Management team underestimated the complexity of the project and ignored information that may have corrected their positions. Many factors may have led them into that trap and likely issues that may have influenced the decision making include;

1.From Slinger’s perspective

a.Denver was to be a state of the art airport and as such the desire to have the most advanced

baggage system would likely have been a factor behind Slinger’s willingness to proceed,

b.Slinger’s prior experiences with baggage handling will have been based on simple conveyor

belts combined with manual tug and trolley systems. Those prior experiences may have led

Slinger to underestimate the complexity of moving to a fully automated system,

c.As a Civil Engineer, Slinger was used to the development of physical buildings and structures

rather than complex technology systems, this may have predisposed him to underestimate

the mathematical complexity associated with an issue such as “line balancing”,

d.Slinger is reported to have been a hands-on leader who liked to solve problems himself. As

such Slinger may have been inclined to make decisions on his own rather than seeking

independent advise,

e.Slinger dealt with the discussions with BAE personally, given that he was responsible for the

complete airport, he will have had considerable other duties that would have limited the

amount of time he had to focus on the baggage system,

f.On the surface the prototype may well have made it look as if BAE had overcome the

technical challenges involved in building the system and as such Slinger may have been

lured into a false sense of security.

2.From BAE’s perspective

a.The project was a big revenue opportunity and represented a chance to grow the business,

b.The prestige of securing the DIA contract would position BAE to secure other large contracts

around the world. New airports or terminals were planned for Bangkok, Hong Kong,

Singapore, London and Kuala Lumpur and BAE would be a strong contender if they could

win the DIA project.

3.Other factors

a.Both BAE and Slinger will have recognized that they were working within a tight timeframe

and the pressure to move quickly may have caused them to put due diligence to one side.

b.The belief that due to the airport’s size, a manual system would not be fast enough to meet

aircraft turnaround requirements. Note however that this belief was unfounded as the

airport functions happily today using a manual system.

Key Decision 3 – Schedule, scope and budget commitments

The schedule, budget and scope commitments a team enter into are amongst the most critical decisions they will make. The seeds of project success or failure often lie in the analysis that goes into making those decisions and the way such commitments are structured.

In the DIA case, BAE committed to deliver the complete system under a fixed scope, schedule and budget arrangement. The decision to give a firm commitment to scope, schedule and budget transferred considerable risk onto BAE’s shoulders. This move indicates strongly that those in the highest level of BAE’s management structure had completely failed to recognize the level of risk they were entering into. Had they been more aware, they almost certainly would have taken steps to limit the risk and to find ways to limit the scope to something that was more achievable in the time available.

Again the finger prints of excessive schedule pressure can be seen in the commitments BAE entered into. The contractual conditions for the agreement and the scope of work were hammered out in just three “intense” working sessions [7]. Although BAE had some level of understanding because of their contract with United Airlines, clearly the three working sessions will not have provided sufficient time for the different parties to develop an in-depth understanding of what was involved or for them to fully understand the risks they were taking.

BAE and the airport Project Management team made another major mistake during the negotiations. Although the airlines were key stakeholders in the system they were excluded from the discussions. Excluding stakeholders from discussions in which key project decisions are made is always a losing strategy. When previously excluded stakeholders are finally engaged, they usually ask for significant changes that can negate much of the previous work done on the project.

Key Decision 4 – Acceptance of change requests

Not surprisingly, as the project progressed the airlines did indeed ask for a number of significant changes. Although in the original negotiations, BAE had made it a condition that no changes would be made, the pressure to meet stakeholder needs proved to be too strong and BAE and the airport’s Project Management team were forced into accepting them. Among the major changes were; the adding of ski equipment racks, the addition of maintenance tracks to allow carts to be serviced without being removed from the rails and changes to the handling of oversized baggage. Some of the changes

made required significant redesign of portions of work already completed.

Accepting these changes into a project that was already in deep trouble raises some further troubling questions. Did the team fail to understand the impact the changes might have? Did they fail to recognise how much trouble the project was already in? Although answers to those questions are not available from the public record, the acceptance of the change requests again hints at the communications disconnects that were occurring inside the project. Clearly some of the people involved will have understood the implications, but those voices appear not to have connected with those who were making the overall decisions.

Key Decision 5 – Design of the physical building structure

Rather than being separate entities, the baggage system and the physical building represented a single integrated system. Sharing the physical space and services such as the electrical supply the designers of the physical building and the designers of the baggage system needed to work as one integrated team.

Largely because the design of the building was started before the baggage system design was known, the designers of the physical building only made general allowances for where they thought the baggage system would go. When the baggage system design was eventually started, the baggage system design team was forced to work within the constraints left to them by the designers of the physical building (estimates to change the physical structure to suit the needs of the baggage system are reported to have been up to $100M).

The resulting design meant that the baggage system had to accommodate sharp turns that were far from optimal and increased the physical loads placed on the system [1]. Those stresses were key contributors to the system’s reliability problems. In particular, navigating sharp turns is reported to have been one of the major problems that lead to bags being ejected from their carts. These problems ultimately proved so severe that the speed of the system was halved from 60 cars per minute to 30 cars in order to reduce the physical forces when negotiating tight turns. That quick fix however had the side affect that it began to undermine the performance goals the system was trying to meet.

Although the designers of the physical building likely did their best to make allowance for the baggage system, this portion of the story once again illustrates a breakdown in the overall planning of the project. The allowance of spaces in which the baggage system would operate represented a key interface between the design of the physical building and the baggage system. To make effective decisions about how to design the physical building, the designers of the physical building needed to be working alongside people who had expertise in designing baggage systems. Clearly this did not happen. What is not clear is if the designers of the physical building requested such expertise be provided or if they just went ahead in isolation. In either case, the Project Management team should have recognised the significance of the interface between the baggage system and the physical building and arranged for the appropriate people to work together.

Key Decision 6 – The decision to seek a different path

Following the embarrassing public demonstration to the press in Apr 1994, the Mayor of Denver recognized that the project was in deep trouble. The demonstration had been an unmitigated disaster

and pressure was building from various sources pushing the Mayor to intercede. When the Mayor did step in, Mattias Franz of Logplan Consulting of Germany (a specialist in the design and construction of baggage handling systems) was called in to review the situation [9]. Despite United Airlines instance that the automated system be finished, based on Logplan’s recommendation the Mayor slashed project and ordered that a manual trolley system built at an additional cost of $51M [8].

While the Mayor was correct in taking action, the timing of the intervention again reveals something about the internal dynamics of the project. By the time the Mayor took action, the airport was already 6 months behind schedule and four opening dates had already been missed. In addition the disastrous demonstration of the system had shown to the world how bad the state of the project really was.

The four missed opening dates and the disastrous demonstration indicate that those at the highest level really had little idea what the true status of the project was. Bringing in an external consultant to review the project was certainly a good decision, but again it was a decision that was made far too late. A project of this size, complexity and risk should have had a number of such reviews along the way and independent expert assessment should have been a continual part of the project.

Other failure points

While the underestimation of complexity, lack of planning, ineffective communications and poor management oversight drove the failure, the project suffered many other difficulties that compounded the problems. Some of those issues were unavoidable, but others were likely a result of the schedule pressure the project was working under. Among the other issues that affected the project;

Risk management failures

The project encountered a number of major technical problems for which no allowances had been made. One of the most significant was caused by the fact that the electrical system suffered from power fluctuations that crashed the system. The resolution to the problem required filters to be built into the electrical power system to eliminate surges. Delivery and installation of the filters took several months, during which time testing was severely constrained.

Such issues were likely predictable had the team focused on risk management activities. Again possibly as a result of the schedule pressure under which they were working, appropriate risk management strategies appear not to have been developed.

Leadership Change

In October of 1992 Walter Slinger died. Singer was the system’s de facto sponsor and his death left the project without much needed leadership. According to reports, Mr Slinger’s replacement lacked the in-depth engineering knowledge required to understand the system. In addition the replacement manager retained their prior responsibilities and hence was stretched to the limit.

Architectural and design issues

A number of reports indicate that the design the team chose to use was particularly complex and error prone. Among the issues noted;

1.The system had more than 100 individual PCs that were networked together. Failure of any one of

the PCs could result in an outage as there was no automatic backup for failed components,

2.The distributed nature of the design (with PCs dotted around the different concourses) added to the

difficulty of resolving problems when they arose,

3.The system was unable to detect jams and as a result when a jam occurred, the system simply kept

piling up more and more bags making the jam that much worse.

Again schedule pressure may well have been a factor in the design problems. When under excessive schedule pressure teams often settle for the first design they think of. In addition schedule pressure often forces teams to focus on the “happy path” design while spending little time thinking through how to deal with problems and how to make the system fault tolerant.

Conclusion

The Denver debacle is a template for failure that many other projects have followed. As with so many other failures, Denver suffered from;

1.The underestimation of complexity

2. A lack of planning resulting in subsequent changes in strategy

3.Excessive schedule pressure

https://www.360docs.net/doc/404857183.html,ck of due diligence

5.Making firm commitments in the face of massive risks and uncertainty

6.Poor stakeholder management

https://www.360docs.net/doc/404857183.html,munications breakdowns

8.People working in silos

9.Poor design

10.Failure to perform risk management

11.Failure to understand the implication change requests might have

https://www.360docs.net/doc/404857183.html,ck of management oversight

While the above points represent contributors to the failure, there is one central problem that triggered the fiasco. Successful projects are projects in which people make effective decisions and making effective decisions requires a number of ingredients. Chief among those ingredients are knowledge and expertise. Walter Slinger, the airport’s Project Management team and even the BAE’s Senior Managers did not have prior experience of a system of this scale. In addition, given that automated baggage systems were relatively new, even BAE’s Senior Management team only had a limited understanding of what was involved. That lack of knowledge, combined with the fact that expert advice was routinely ignored, is the epicentre of the failure.

The initial planning decisions, the decision to proceed with one airport wide integrated system (despite the fact that it was too late to do so) and the firm contractual commitments to scope, schedule and

budget all represented decisions that were made by people who lacked the necessary knowledge. The misjudgements resulting from those decisions were the sparks that ignited the fire.

We are often faced with situations in which we lack the prior experience to know how to proceed with certainty. The way in which we respond to those situations can spell the difference between success and failure. The first step lies in recognizing the situation and Slinger, The Project Management team and BAE’s Senior Manager seem to have fallen at that first hurdle. Had they recognized their lack of knowledge and the uncertainty they were facing, they could have taken a number of steps that would have reduced the risk. Chief among those steps would have been listening to those who did have the necessary prior knowledge.

The bright side of the story is that in Feb 1995 DIA did eventually open and despite using a largely manual trolley based system the airport proved to be an operational success [10]. Fears that a manual system would be too slow to service an airport the size of DIA proved to be unfounded.

References

1.The Baggage System at Denver: Prospects and Lessons – Dr. R. de Neufville – Journal of Air Transport

Management, Vol. 1, No. 4, Dec., pp. 229-236, 1994

2.Denver International website (https://www.360docs.net/doc/404857183.html,)

3.Software's Chronic Crisis,Trends in Computing – W. Gibbs – Scientific American – Sep 1994, P86

4.The Denver International Airport Baggage Handling System - Papers from the Information Systems

Foundations: Constructing and Criticizing Workshop at the Australian National University from 16 to

17 July 2004 S. Lukaitis, J. Cybulski, School of Information Systems, Deakin University

5.The Denver International Airport automated baggage handling system – Cal Poly – M. Schloh – Feb

16, 1996

6.Denver airport to mangle last bag – K. Johnson - International Herald Tribune - Aug 27, 2005

7.Software Forensics Centre Technical Report TR 2002-01- A Case Narrative of the Project Problems

with the Denver Airport Baggage Handling System (DABHS) - A.J.M. Donaldson - Middlesex

University, School of Computing Science

8.New Denver Airport: Impact of the Delayed Baggage System – Briefing Report (GAO/RCED-95-35BR,

Oct 14, 1994.

9.Wellington Webb: The Man, The Mayor, and the Making of Modern Denver – Fulcrum Publishing –

2007

10. Denver Airport Nestles Into Its Lair – New York Times - Mar 6, 1996

春秋航空案例分析

“春秋航空” 案例分析报告 小组成员:张美玲王晶晶余婷 张芷君张宏辉张振 目录 1.春秋航空简介 (2) 2.环境分析 (2) 3.差异化分析 (4) 4.与美国西南航空对比 (5) 5.战略风险分析 (6) 6.战略风险规避 (6) 一、春秋航空简介 春秋航空股份有限公司是首个中国民营资本独资经营的低成本航空公司专线。春秋航空是中国首批民营航空公司之硕果仅存者,是国内首家低成本航空公司,2011 年净利润逾4.7 亿元,成为当前国内最成功的低成本航空公司,总部在上海,在上海虹桥机场、上海浦东机场、石家庄正定机场、沈阳桃仙机场设有基地。春秋航空有限公司经中国民用航空总局批准成立于2004年5月26日,由春秋旅行社创办,注册资本8000万元人

民币,创立之初,只有3架租赁的飞机空客A320飞机,经营国内航空客货运输业务和旅游客运包机运输业务。2005年7月18日首航。春秋航空平均上座率达到95.4%,成为国内民航最高客座率的航空公司。 截止2013年8月,机队规模达到37架180座空客A320飞机。开通了往返于日本、韩国、泰国、马来西亚、柬埔寨、香港、澳门等的10余条国际及地区航线,及北京、上海、广州、成都、深圳、昆明、重庆、珠海、揭阳(汕头)、厦门、三亚、沈阳、哈尔滨、长春、大连、青岛、石家庄、西安、绵阳、兰州、乌鲁木齐、呼和浩特、杭州、南京、宁波、常德、张家界、桂林、南宁、淮安、洛阳等国内航线,共约70余条。 二、环境分析 1.“五力”模型分析 ●潜在新进入者的威胁: 在春秋航空之后,又陆续出现了多家民营航空公 司,如奥凯,鹰联,东星等。这些新的民营航空公司虽然目前所占市场份额较小,但是凭借低价优势和灵活市场机制,发展势头十分迅猛;同时,2014年1月起,法国航空公司、荷兰皇家航空公司等成为了在中国使用艾玛迪斯系统的首批外国航空公司,外国航空公司本身就具备良好口碑和雄厚资金,加上系统支持,如虎添翼,将会加剧中国空中市场的竞争。春秋航空同时面临国内和国外的双重挑战。 ●行业内现有竞争对手之间的竞争: 根据2014年中国航空公司排名,位于 前五的国航、东航、南航、泰航、海航占据了国内航空市场的绝大部分,同时这些行业巨头仍在不断地扩大规模,在竞争实力方面,春秋航空难

国内外枢纽机场陆侧换乘布局案例研究分析

国内外枢纽机场陆侧换乘布局案例分析

————————————————————————————————作者:————————————————————————————————日期: 2

城市道路与交通规划 读书报告 姓名: 班级:2011级城市规划 学号:20111150212 日期:2014年4月

摘要:大型机场枢纽解决了远距离快速运输,但在地面的疏散中,要注意和公共交通的对接,意在即快速舒适度又高。对于大型枢纽机场,在一个集中区域完成全部的换乘方式几乎是不可能的。所以,各国机场都不约而同采取以步行通道连接各交通换乘节点的“人车分离”手法解决该矛盾。对我们的启示是应充分认识到步行系统在陆侧交通组织中的骨架作用,它所体现的旅客满意度直接影响到陆侧交通运营的服务水平。 关键词:枢纽机场,陆测交通,公共交通,步行体系 一.北京首都国际机场案例 首都机场于1958年3月2日正式投入使用。随着民航事业的发展及客货运量的不断增长,多年来进行了大规模的扩建施工。1980年1月1日,面积为6万平方米的一号航站楼及停机坪、楼前停车场等配套工程建成并正式投入使用。一号航站楼按照每日起降飞机60架次、高峰小时旅客吞吐量1500人次进行设计。扩建完成后,首都机场飞行区域设施达到国际民航组织规定的4E标准。随着通往首都北京的国际航线数量和国际航班的密度稳步提高,1995年10月-1999年11月期间,首都机场对航站区又一次进行了扩建。1999年11月1日,建筑面积达33.6万平方米,使用现代化技术设备装备起来的二号航站楼正式投入使用,二号航站楼每年可接待超过2650万人次的旅客,高峰小时旅客吞吐量可达9210人次。北京首都国际机场二号航站楼的启用,标志着20年来首次名副其实地成为中国最繁忙的客运机场。 首都机场在屡次的扩建中都非常重视机场的换乘问题,特别是机场的停车问题(如图1)。目前机场内共有一座停车楼和5个停车场。停车楼位于T2航站楼前。

中国民航机场一览表

北京首都国际机场使用中ZBAA PEK北京市 北京南苑机场使用中ZBNY NAY北京市 北京首都第二机场拟建北京市 天津市 机场名称状态ICAO IATA服务地区 天津滨海国际机场使用中ZBTJ TSN天津市 上海市 机场名称状态ICAO IATA服务地区 上海虹桥国际机场使用中ZSSS SHA上海市 上海浦东国际机场使用中ZSPD PVG上海市 重庆市 机场名称状态ICAO IATA服务地区 重庆江北国际机场使用中ZUCK CKG重庆主城区黔江武陵山机场使用中ZUQJ JIQ黔江区 万州五桥机场使用中ZUWX WXN万州区 武隆仙女山机场拟建武隆县 巫山神女峰机场在建巫山县、奉节县 江苏省 机场名称状态ICAO IATA服务地区 南京禄口国际机场使用中ZSNJ NKG南京市 南京六合国际机场在建南京市 常州奔牛机场使用中ZSCG CZX常州市 淮安涟水机场使用中ZSSH HIA淮安市 连云港白塔埠机场使用中ZSLG LYG连云港市 南通兴东机场使用中ZSNT NTG南通市 苏南硕放国际机场使用中ZSWX WUX无锡市、苏州市徐州观音机场使用中ZSXZ XUZ徐州市 盐城南洋机场使用中ZSYN YNZ盐城市 扬州泰州机场使用中ZSYA YTY扬州市、泰州市 浙江省 机场名称状态ICAO IATA服务地区 杭州萧山国际机场使用中ZSHC HGH杭州市嘉兴机场改建嘉兴市 丽水机场拟建丽水市 宁波栎社国际机场使用中ZSNB NGB宁波市衢州机场使用中ZSJU JUZ衢州市 台州路桥机场使用中ZSLQ HYN台州市 温州龙湾国际机场使用中ZSWZ WNZ温州市义乌机场使用中ZSYW YIW金华市 舟山普陀山机场使用中ZSZS HSN舟山市

值得借鉴的样板候机楼——虹桥机场T2航站楼

一、流程清晰、交通便捷 上海虹桥国际机场(简称“虹桥机场”)第二航站楼的旅客流程非常简单易行,从出发办票、安全检查到登机,一切都安排得非常紧凑,哪怕是没有做过飞机的乘客也会明了整个流程。 虹桥机场第二航站楼路面交通十分便捷,有多种可供选择的交通方式出入机场。同时,候机楼纵深设计长度较短,旅客步行时间不长,能够很好的满足旅客对时间效率的要求。所以无论场外场内,虹桥二航站楼都可谓是有着及其优越的便利条件。 交通枢纽实现了航空、高铁、磁浮、轨道交通、城市公交等多种交通设施融为一体,56种换乘模式,设计可满足每天一百一十万人次旅客在一个建筑中实现方便换乘。今年随着沪宁、沪杭高铁的开通,这个交通枢纽的强大中转能力将进一步得以显现。

图1:枢纽专用的高架快速道路系统,将地区内交通与枢纽集散交通分离。高架道路系统采用单向大循环系统,遵循“西进西出、北进北出、南进南出”的原则,并保证了其良好的互通性,有效减少拥堵。

图2:地下一层地铁站。每班地铁到达时涌入较多的人流。 二、商业规划超前、合理 虹桥机场第二航站楼的商业规划非常超前、合理,并且执行“同城同价”原则。二航站楼的商业及餐饮的面积很大,其引入的商业店面都是世界一流的品牌。其中还有一个特别细节的地方,那就是其在香水、化妆品、手表首饰、土特产中的部分店面中,都分别在候机区及到达区两端设置多个店面,此举在于方便旅客买取,无疑

为机场获得更多的商业机会。另外,机场餐饮店种类较多,且价格范围十分广泛,低、中、高都能自由选取,一碗28元的面套餐,除了水果、小吃外,还能随意加面,这实在是算的上便宜。 从航站楼进入地铁站后,可以看到一个4层的交通商业中心,这是国内首家机场商业中心。由于交通便利,并有超前的规划,若得以有效运作,未来这个商业中心将对城区的顾客也具有很强的吸引力,也将大大为机场聚集人气、财气。

北京首都机场成功案例

科传O2O全渠道解决方案,构建首都机场智能运营管理平台 企业简介 北京首都国际机场建成于1958年,运营50多年来,北京首都国际机场年旅客吞吐量从1978年的103万人次增长到2014年的8612.83万人次,位居亚洲第1位、全球第2位。 北京首都国际机场,位于中国北京市顺义区,是中国的空中门户和对外交流的重要窗口。在国际民航权威认证机构Skytrax发布的“2015年世界前百位主要机场排名”中,位列榜单第10位。 科传系统能适应机场的特殊性质,针对性的构建信息管理平台,进行任何经营模式下的数据收集和数据接口整合,并能满足多样化的运营、管理需求。 北京首都国际机场信息化管理需求

机场旅客吞吐量的增长、机场商业管理思路的变化、新的特许经营合同所致的租金核算和财务流程的变化、移动互联网时代对系统技术更新的要求等,都需要机场能针对性的对原系统进行升级改造,用以满足原商业系统在投产运营7年后无法满足的机场业务需求。 ●需要构建一个会员管理系统,用于管理首都机场庞大的人流吞吐量,挖掘、分析短 时间滞留于机场内客流的潜在价值; ●筛选合适的商户进驻机场商铺,需要精准有效的数据分析作为支撑; ●首都机场作为中国重要的对外窗口之一,需要为应对机场内商业涉及到的多币种交 易和复杂的分类税收政策提供相关解决方案; ●针对客流来自世界各地不同地区这一特性,机场内商户需为顾客对应提供邮购或异 地取货服务; ●需要灵活对接应需求增设的各种便捷化服务App的数据接口。 科传购物中心解决方案在首都机场信息化应用中的核心价值 ●打通了会员管理系统,从多个渠道获取首都机场下辖大量商户的销售数据和会员数 据,支撑会员营销管理所需的数据分析,最终达到提高消费者转化率、复购率的作用; ●提供可视化BI报表功能,保证数据采集的及时性、有效性和数据分析准确性,同时 丰富报表的图像展示形式,帮助企业优化营销策略和提升运营能力; ●完善的商户管理平台和灵活的商务条款合同管理体系,在便捷管理操作的同时,对 商户、商铺从入驻到运营的全过程(包括铺位管理、商品进销存管理等多个方面)进行全面监控管理,帮助企业提高自身管理水平,增创企业经济效益;

厦门高崎机场案例分析报告(终稿)

厦门高崎国际机场 T3地下停车场免取卡管理系统 案 例 分 析 厦门市路桥信息工程有限公司 2013年7月

目录 一、项目背景 (3) 1.1 厦门高崎国际机场 (3) 1.2一路?免取卡管理系统 (3) 二、案例分析 (5) 2.1方案设计 (5) 2.2案例特点 (6) 2.3效益分析 (7) 2.3.1社会效益分析 (7) 2.3.2经济效益分析 (8) 三、武汉天河机场停车场升级改造建议 (8) 3.1采用免取卡停车场管理系统 (9) 3.2停车诱导与智能寻车系统 (9) 3.3智能照明与引导系统 (10) 四、公司简介 (10) 4.1厦门信息集团 (10) 4.2厦门路桥信息工程有限公司 (12) 五、部分工程实例 (13)

一、项目背景 1.1 厦门高崎国际机场 目前,厦门高崎国际机场拥有位于地面的东停车场、南停车场和3号候机楼的地下停车场,共3个停车场。东停车场主要供大中巴车、部分小型社会车辆停放;南停车场仅面向内部驻场员工开放,属于免费的停车场;3号候机楼地下停车场除的士禁入外,接送旅客的车辆可以在此停放,此停车场是离机场主楼最近最方便的停车场,人们可通过自动步道、电梯、扶梯到达候机楼的到达层和出发层,3号候机楼地下停车场是厦门高崎国际机场一扇重要的对外形象窗口。 3号候机楼(以下简称“T3”)地下停车场,位于厦门高崎国际机场3号候机楼南侧园林广场喷水池地块,占地面积60094 m2,总建筑面积:48460m2,其中地下室建筑面积:47860m2,楼梯上地面部分面积为600m2。 2013年1月25日,T3地下停车场正式对外开放,整个建设工期约一年零九个月,该工程比计划工期提前三个月,于2013年春运前夕投入使用,自投入运行以来,系统稳定高效、应用效果良好,出入口车辆通行效率大幅提高,大大缓解了机场停车拥挤问题,获得了社会大众的一致好评,进一步提升了厦门空港的保障能力。 T3地下停车场共有1075个停车位,设计4进11出,共15个车道。由于出入口数量较多,车位数量也比较多,为确保停车楼能够持续高效运转,同时提高停车楼的信息化、智能化管理水平,给车主提供方便快捷、轻松开放的停车环境,机场相关部门在该停车楼的设施配备上,引入了厦门市路桥信息工程有限公司的一路?免取卡停车场管理系统,对停车楼进行全方位的“智能武装”。 1.2一路?免取卡管理系统 一路?免取卡停车场管理系统源自“免取卡,自由行”的停车场管理新理念,基于射频识别技术(Radio Frequency Indentification,简称RFID),以车载电子标签(厦门路桥卡)识别为主、车牌识别为辅,在保证收费信息精确的基础上实现车辆进出停车场“入口免取卡,出口不停车”。 入场时,车主无需停车取卡即可入场,系统会自动记录车辆信息及入场时间;出场时,车辆行驶至收费岗亭处,系统即根据停留时间快速自动计算出需缴费金额,提示缴费,免费、月租以及通过中央收费处缴纳停车费的车辆可不停车快速

国际贸易实务经典案例分析集锦

[案例1] 有一份CIF合同在美国订立,由美国商人A出售一批IBM电脑给香港商人B,按CIF香港条件成交。双方在执行合同的过程中,对合同的形式及合同有关条款的解释发生争议。请分析解决此项纠纷应适用香港法律还是美国法律? [案例分析]结论:应适用于美国法律。 理由:合同与美国关系最密切,因为订约地和履约地都在美国。 分析:在按CIF香港条件成交的合同中,出口方在出口国装运港履行交货义务,所以履约地在美国装运港,而非目的港香港。(有关CIF条件的内容参见“贸易术语”) 第二章货物的质量 [案例1] 商品质量不符引起的纠纷案 我生产企业向马来西亚客户出口汽车配件,品名为YZ-8303R/L,但生产企业提供了YZ-8301R/L,两种型号的产品在外型上非常相似,但却用在不同的车型上,因此客户不能接受,要求我方要调换产品或降低价格。我方考虑到退货相当麻烦,费用很高,因此只好降低价格15%,了结此案子。 [案例分析]商品的质量是国际货物买卖合同中不可缺少的主要条件之一,是十分重要的条款。卖方属于重大违约,因此赔偿对方损失是不可避免的。 [案例2]我某出口公司与德国一家公司签定出口一批农产品的合同。其中品质规格为:水分最高15%,杂质不超过3%,交货品质以中国商检局品质检验为最后依据。但在成交前我方公司曾向对方寄送过样品,合同签定后又电告对方,确认成交货物与样品相似。货物装运前由中国商检局品质检验签发品质规格合格证书。货物运抵德国后,该外国公司提出:虽然有检验证书,但货物品质比样品差,卖方有责任交付与样品一致的货物,因此要求每吨减价6英磅。 我公司以合同中并未规定凭样交货为由不同意减价。于是,德国公司请该国某检验公司检验,出具了所交货物平均品质比样品差7%的检验证明,并据此提出索赔要求。我方不服,提出该产品系农产品,不可能做到与样品完全相符,但不至于低7%。由于我方留存的样品遗失,无法证明,最终只好赔付一笔品质差价。[案例分析] 此例是一宗既凭品质规格交货,又凭样品买卖的交易。 卖方成交前的寄样行为及订约后的“电告”都是合同的组成部分。 根据商品特点正确选择表示品质的方法,能用一种表示就不要用两种,避免双重标准。 既凭规格,又凭样品的交易,两个条件都要满足。 样品的管理要严格。如“复样”、“留样”或“封样”的妥善保管,是日后重要的物证。[案例3]1997年10月,香港某商行向内地一企业按FOB条件订购5000吨铸铁井盖,合同总金额为305万美元(约人民币2534.5万元)。货物由买方提供图样进行生产。 该合同品质条款规定:铸件表面应光洁;铸件不得有裂纹、气孔、砂眼、缩孔、夹渣和其他铸造缺陷。 合同规定(1):订约后10天内卖方须向买方预付约人民币25万元的“反保证金”,交第一批货物后5天内退还保证金。 合同规定(2):货物装运前,卖方应通知买方前往产地抽样检验,并签署质量合格确认书;若质量不符合同要求,买方有权拒收货物;不经双方一致同意,

设计始于人本——以虹桥国际机场T2航站楼建筑设计项目为例

设计始于人本——以虹桥国际机场T2航站楼建筑设计项目为例 【摘要】以人为本,是目前社会都倡导的一种观念,尤其在设计行业,以人为本显得尤为重要,虹桥国际机场T2航站楼设计以此为出发点,在设计中始终强调公平性、使用灵活性、简单直观、信息明确、容错性强、低能耗、尺度空间可接近等原则,设计力求与人方便,处处体现了“为人而设计”的本质,无处不在的人性化设计体现出对“人”的关怀。 【关键词】以人为本;建筑设计 【abstract 】it is with the person this, is the society advocated idea, especially in design industry, it is with the person this is particularly important, hongqiao international airport terminals design T2 from that starting point, in the design emphasis on equality, always use flexibility, simple, intuitive information clearly and fault tolerance is strong, low energy consumption, scale space can close to the principle of design and easy for people to, is reflected in the “for people and design”, the essence of the ubiquity of humanized design reflects the concern of “person”. 【key words 】people-oriented; Architectural design 虹桥综合交通枢纽T2航站楼是虹桥国际机场的扩建工程,也是上海城市西面新的空中门户。T2航站楼位于虹桥综合交通枢纽东端,隔两条跑道与原有东航站楼相望。作为虹桥综合交通枢纽的重要组成部分,T2航站楼西面与东交通广场相连,东面以飞行区停机坪为界,与枢纽建筑统一规划设计,相辅相成,功能分区明确,流程便捷顺畅。总体预留有未来发展的用地和空间,一次规划,分期实施。虹桥国际机场扩建内容包括在现有跑道的西侧兴建一条新的近距平行跑道,一座新的航站楼和新的航空货运区。根据2005年10月完成并审批通过的虹桥机场总体规划修编,机场总体规划的目标是年旅客吞吐量3000万人次,其中虹桥机场T2航站楼规划的目标是在近期满足年旅客吞吐量2100万人次,并预留未来发展到3000万人次的能力。 扩建虹桥机场不仅是满足虹桥一个机场业务量增长需求,也是完善整个上海航空枢纽功能的重要举措之一。发展浦东国际机场,凸现国际航空枢纽功能,将提升浦东机场在国际航空运输市场中的综合竞争力;由于上海地区航空客运市场是上海机场得以快速发展的重要基础,所以发展虹桥机场将强化上海航空城市对航线运作能力,满足往返上海国内旅客始发到达的需求,强化上海国内航空枢纽功能,T2航站楼的建成将使虹桥国际机场同时拥有东、西两座航站楼,这两个航站楼的分配和运作模式为:T2航站楼为国内航站楼,处理国内旅客的出发、到达、中转,东航、上航和其他航空公司在T2航站楼运作;T1航站楼仍然同时具备国际和国内功能,国际包机及廉价航空公司留在T1航站楼。另外,磁悬浮未来将连通浦东与虹桥两个机场,实现虹桥、浦东两场的无缝隙衔接,拉近两场

国贸案例分析题

国际贸易案例 1 、FCA贸易术语案例分析 我0方出口手表到印度,按 FCA Shanghai Airport签约。交货期8月。出口企业8月31日将该手表运到上海00 虹桥机场并由航空公司收货开具航空运单。我方即电传印度发出装运通知。9月2日手表抵达孟买,将到货通知连同发票和航空运单送交孟买XX银行。该银行即通知印商提货、付款,但印商以延迟交货为由拒绝。 分析: FCA (FREE CARRIER)“货交承运人(……指定地点)”是指卖方只要将货物在指定的时间地点交给买方指定的承运人,并办理了出口清关手续,即完成交货。此案例中没有指明承运货物的航空公司是否为买方所指定的,但即便买方没有指定,卖方也可按惯例指定航空公司运输(费用到付,即买方承担),只要卖方在约定的时间内(8月31日前,包括8月31日)将货交承运人,卖方即完成交货,买方需按约付费,所谓的延迟交货不成立,卖方应立即支付所有款项。 2 、有关FOB价格术语的一个案例 我某公司以FOB条件出口一批冻鸡,合同签订后接到买方来电,称租船较为困难,委托我方代为租船,有关费用由买方负担。为了方便合同履行,我方接受了对方的要求,但时间已到了装运期,我方在规定的装运港无法租到合适的船,且买方又不同意改变装运港,因此到装运期满面时,货仍未装船。买方因销售即将结束,便来函以我方未按期租船履行交货义务为由撤销合同。问:我方应如何处理? 分析: 1、我方应拒绝撤销合同的无理要求。 2、这个安全涉及FOB术语总是根据FOB术语,买方负责租船订舱、运输、支 付运费。为了卖方装船交货方便,卖方也可以接受买方的委托,代为租船订舱,但费用和风险应由买方承担,卖方不承担租不到船的责任。 3、结合本案例,因为卖方代买方租船没有租到,买方又不同意改变装运港,因此卖方不承担因自己未租 到船而延误装运的责任。买方也不能因此撤销合同。 3 、案例:CIF合同 CIF价国要注意的选择际贸易操作中要注意的选择 某出口公司按CIF伦敦向英商出售一批核桃仁,由于该商品季节性较强,双方在合同中规定;买方须于9月底前将信用证开到,卖方保证运货船只不迟于12月2日驶抵目的港。如货轮迟于12月2日抵达目的港.买方有权取消合同,如贷款已收,卖方必须将贷款退还买方。问这一份合同的性质是否属于CIF合同 分析: 这一合同的性质不再属于CIF合同。因为合同条款内容与CIF本身的解释相抵触。抵触有二;一是合同在C1F条件下竟规定了“到货日期”.这与CIF价格术语所赋予的风险界限划分的本意相触,按CIF是装运港交货,货物超越船舷后的一切风险均由买方负责。如果限定到货日期,岂不是耍卖方承担超越船舷后的一切风险7二是CIF是“象征性交货”,只要卖方提供齐全、正确的货运单据,买方不能拒收单据,拒付货款。而该合同竞规定‘如货运船只不能如期到达,买方将收回货款,实际上成了货到付款。由此看来,该合同的一些主要条款已与CIF价格术语的本意相抵触。尽管名义上是按CIF成交,但实质上并不是CIF合同性质。 4 、案例: 一法国商人于某日上午走访我国外贸企业洽购某商品。我方口头发盘后,对方未置可否,当日下午法

上海虹桥国际机场VIP贵宾室施工方案

一、施工技术方案 1 工程概况 1.1 工程名称 虹桥机场候机楼A楼1号集中式VIP休息室改造工程 1.2 工程性质 工程地址:上海虹桥国际机场候机楼B楼 建设单位:上海机场(集团)有限公司 设计单位:华东建筑设计研究院有限公司 总包单位:上海第七建筑有限公司 1.3 编制依据 1. 本工程设计图纸 2. 中华人民共和国的现行施工验收规范和操作规程 GB50026-93 《工程测量规范》 GB50300-2001 《建筑工程施工质量验收统一标准》 QBL838-93 《室内装饰工程质量规范》 GB50210-2001 《建筑装饰装修工程质量验收规范》 GB50194-93 《建设工程施工现场供电安全规范》 GB50209-2002 《建筑地面工程施工质量验收规范》 GB50242-2002 《建筑给水排水及采暖工程施工质量验收规范》

GB50303-2002 《建筑电气工程施工质量验收规范》 GB/T50328-2001 《建设工程文件归档整理规范》 GBJ16-87-2001 《建筑设计防火规范》 GB50325-2001 《民用建筑工程室内环境污染控制规范》 JGJ147-2004 《建筑拆除工程安全技术规范》 JGJ146-2004 《建筑施工现场环境与卫生标准》 JGJ59-99 《建筑施工安全检查标准》 JGJ33-2001 《建筑机械使用安全技术规程》 JGJ46-2005 《施工现场临时用电安全技术规范》 3. 中华人民共和国有关安全生产、文明施工规定;及沪建建管(2002)第105号《关于进一步加强文明施工管理的通知》的要求;《上海市建设工程文明施工管理暂行规定》、《建筑安全生产监督管理规定》的要求。 4. 《GB/T24001-1996 idsISO14000:1996环境管理体系》要求以及《中华人民共和国环境保护法(试行)》的有关规定。 5. 施工现场勘查情况,以及机场各部门的相关规定和要求 6.《关于精简建设工程投标文件的有关通知》<沪建建管(2005)第092号>规定 1.4 改造施工简况 本工程位上海市虹桥机场候机楼A楼B段二层(原上海楼室精品区域),涉及建筑面积约735㎡,建筑类别二级,建筑耐火等级为一级。原

空港经济区案例汇总

(一)国外空港经济发展概况及案例分析 纵观世界空港地区的发展,大体经历由航空运输区向临空产业区发展,再向航空城发展的阶段。自爱尔兰香农国际机场建立自由贸易区之后,随着经济的发展和航空业的进步,国际上许多国家和地区非常重视依托机场资源发展区域经济,纷纷在机场周边发展临空产业,并且都在使临空产业区向航空城发展,形成了一些临空经济发展比较成熟的范例,如美国孟菲斯机场、荷兰阿姆斯特丹史基浦国际机场、德国慕尼黑机场等。 1、美国孟菲斯:联邦快递—空港物流 美国孟菲斯市于1929年建立了孟菲斯市机场。1973年,独具慧眼的施伟德(原联邦快递集团董事会主席、总裁兼首席执行官)把联邦快递总部和转运中心设在了孟菲斯。经过30多的发展,联邦快递从一个不起眼的小货运企业成长为世界四大航空物流公司之一,孟菲斯和孟菲斯国际机场也实现了巨大的飞跃。联邦快递超级中心货运量从1995年的86.17万吨增长为2004年的181.41万吨,贡献了孟菲斯国际机场93.6%的吞吐量。同一期间,联邦快递对孟菲斯地区的直接/间接经济产值贡献从1995年的71亿美元上升到2004年的111亿美元,直接/间接雇佣人员从1995年的43000人上升到2004年的67000人。 图1 联邦快递公司对孟菲斯经济发展的贡献 孟菲斯国际机场的货物和旅客流量在孟菲斯产生了巨大的经济效应。根据2004年统计,该机场为孟菲斯创造了166000个工作岗位(占该地

区所有工作岗位的27%)和207亿美元的直接经济产值。2004年,孟菲斯国际机场货运吞吐量为地区带来了195亿美元的经济产值和155872个就业岗位(共56亿美元收入);旅客流量为地区带来了12亿美元的经济产值和9487个就业岗位(共3.4亿美元收入)。2004年,孟菲斯机场为孟菲斯运送了1197912名游客,这些游客在孟菲斯共花费4亿美元,创造了7.79亿美元的经济产出和11000个就业岗位。 近20年来,航空物流对美国新经济的飞速发展起到极其关键的辅助作用。从1980年到1999年的20年间,物流成本占美国GDP的比例从7.6%下降到3.6%,美国的库存和销售之间的比率下降了34%,美国总的商务库存减少了4.6万亿美元(几乎是美国GDP总量的一半)。而所有这些,都和速递业的发展密不可分。 图2 航空物流对美国经济的作用 在孟菲斯国际机场最大的使用者——联邦快递的主导作用下,孟菲斯的国际物流、健康保健和医疗设备行业以及非常发达。联邦快递为孟菲斯带来了许多全新的商业模式,特别是近年来盛行的电子商务,如美国着名的Submit https://www.360docs.net/doc/404857183.html,公司就因为联邦快递的便捷服务而选择了在孟菲斯落户。 2、阿姆斯特丹史基浦机场——着名空港城市 史基浦机场(SCHIPHOL),位于荷兰首都阿姆斯特丹城西南部,于1916年建成,现在的史基浦机场已经不单单是个机场,确切地说,它是一个汇集了人流、物流、展览、观光以及娱乐的“空港城市”。 史基浦机场地区,是一个多种交通模式并存的集合处:拥有航空交

浦东国际机场和虹桥国际机场净空保护区范围的通告

关于上海浦东国际机场和虹桥国际机场净空保护区范围的通告 沪交空〔2012〕165号 为落实浦东国际机场和虹桥国际机场净空保护区管理,确保上海机场飞行安全,根据《上海市人民政府办公厅关于同意浦东国际机场和虹桥国际机场净空保护区范围的通知》(沪府办〔2012〕26号)的批复意见,现将浦东国际机场和虹桥国际机场净空保护区范围和净空保护区管理有关规定,公布如下: 一、机场净空保护区范围 (一)浦东国际机场净空保护区范围 东、北边界:伸向长江;南边界:三三公路;西边界:分为三段,北段(川杨河以北)为远东大道,中段(川杨河与沪南公路之间)为南六公路,南段(沪南公路以南)为远东大道。 (二)虹桥国际机场净空保护区范围 东边界:分为三段,北段为外环线及北延伸线,中间段(沪宁铁路与沪闵之间)为曹杨路—内环线—伊犁路—虹漕路,南段为外环线及南延伸线;南边界:剑川路;西边界:分为三段,北段(沪宁铁路以北)为沪宜公路,中段(沪宁铁路与沪杭高速公路之间)为盐铁河—新通波塘—通波塘,南段(沪杭高速公路以南)为嘉金公路;北边界:G1501公路。 二、机场净空保护区内的禁止行为 根据国务院2009年7月1日颁布实施的《民用机场管理条例》第四十九条规定,禁止在民用机场净空保护区域内从事下列活动: (一)排放大量烟雾、粉尘、火焰、废气等影响飞行安全的物质; (二)修建靶场、强烈爆炸物创库等影响飞行安全的建筑物或者其他设施; (三)设置影响民用机场目视助航设施使用或者飞行员视线的灯光、标志或者物体; (四)种植影响飞行安全或者影响民用机场助航设施使用的植物; (五)放飞影响飞行安全鸟类,升放无人驾驶的自由气球、系留气球和其他升空物体; (六)焚烧产生大量烟雾的农作物秸秆、垃圾等物质,或者燃放烟花、焰火; (七)在民用机场围界外5米范围内,搭建建筑物、种植树木,或者从事挖掘、堆积物体等影响民用机场运营安全的活动; (八)国务院民用航空主管部门规定的其他影响民用机场净空保护的行为。 三、其他规定 在机场净空保护区范围内进行各类工程建设项目,须按《上海市民用机场地区管理条例》的规定,办理相关手续。 特此公告 附件:1.浦东国际机场净空保护区图 2.虹桥国际机场净空保护区 二○一二年三月三十一日

国际贸易实务课后案例分析答案解析

国际贸易实务课后案例分析答案 案例1 案情简介: 出口合同规定的商品名称为“手工制造书写纸”。买主收到货物后,经检验发现该货物部分工序为机械操作,而我方提供的所用单据均表示为手工制造,按该国法律应属“不正当表示”和“过大宣传”,遭用户退货,以致使进口人蒙受巨大损失,要求我方赔偿。理由有二:(1)该商品的生产工序基本上是手工操作,在关键工序上完全采用手工制作;(2)该笔交易是经买方当面先看样品成交的,而实际货物质量又与样品一致,因此应认为该货物与双方约定的品质相符。后又经有关人士调解后,双方在友好协商过程中取得谅解。对此,希予评论。 要点评析: 本案例合同中约定采用“手工制造”商品制造方法表示商品品质,是属于“凭说明买卖”的一种表示方法。从各国法律和公约来看,凭说明约定商品品质,卖方所交商品的品质与合同说明不符,则买方有权撤销合同并要求损害赔偿。本案我方从根本上违反了买卖双方在合同中约定的品质说明,从而构成卖方的违约行为,应承担所交货物与合同说明不符的责任。同时贸易中如果采用样品表示商品品质需要在合同中明示或默示地做出具体规定,而本案例中合同中没有明确表示双方是采用样品成交,所以我方所说的实际所交货物与样品一致不能称为拒付理由。 本案例交易产品在实际业务中不可能采用全部手工制作,应该在合同中标明“基本手工制造书写纸”,以免双方产生争议,与实际所提交产品品质完全吻合。 案例2 案情简介: 合同规定水果罐头装入箱,每箱30听。卖方按合同规定如数交付了货物,但其中有一部分是装24听的小箱,而所交货物的总听数,并不短缺。可是,买方以包装不符合合同规定为由拒收整批货物,卖方则坚持买方应接受全部货物,理由是经买方所在地的公证人证实:不论每箱是装24听或30听,其每听市场价格完全相同。于是引起诉讼。对此,你认为法官应如何判决?依据何在? 要点评析: 根据《公约》规定,卖方需要按照合同约定的数量、品质规格交货,并按照合同规定的方式包装或者装箱,如果没有按照规定,卖方需承担违约责任。 通常合同中的包装条款针对包装方式或包装材料的规定,对于每个包装的数量,属于双方特殊的约定。如果双方约定卖方没有按照规定数量装箱,买方有权拒收货物,则本案例中买方可以拒收整批货物。但是案例中只是约定每箱的听数,一般认为卖方属于一般违约,所以买方只能提出索赔,不能以包装不符合合同规定为由拒收整批货物。 案例1 案情简介: 我某出口企业按FCA Shanghai Airport条件向印度A商出口手表一批,货价5万美元,规定交货期为8月份。自运往孟买;支付条件:买方凭由孟买某银行转交的航空公司空运到货通知即期全额电汇付款。我出口企业于8月31日将该批手表运到虹桥机场交由航空公司收

上海虹桥机场的“最人性化”之路

上海虹桥机场的“最人性化”之路 据报道,上海虹桥国际机场是我国第四大机场,也是虹桥综合交通枢纽重要组成部分,每天有近60万人次的航空、铁路、公路、轨交旅客进出,这相当于我国一座中等城市人口规模。面对人数众多、需求不同的“空地铁”旅客,保持机场一贯的高品质服务成为摆在机场管理者面前的重要课题。 2014年是虹桥机场将进入提出打造国内最人性化机场的第十个年头,而就在今年虹桥机场蝉联了国际民航组织Skytrax“中国最佳地区机场奖第一名”。Skytrax年度“世界机场大奖”评选覆盖全球390多个机场,由100多个国家1200多万名旅客通过10个月的问卷调查及投票产生,涉及出发、到达、中转流程中的39项服务产品体验,不仅注重机场服务功能的齐全性,更看重机场在服务旅客时所呈现出的品质和个性。而另一家民营机构的机场服务评测报告也显示,虹桥机场旅客综合满意度年内连续3个季度位居国内机场第一,“机场人

员服务满意”、“餐饮价格满意”、“商品丰富”、“指示牌的醒目性”、“电源插座数量充足”、“卫生间满意”等6个单项指标始终处于国内最高水准。 虹桥机场总经理袁顺周在采访时表示,虹桥机场服务赢得的口碑不是依靠管理方一家,而是依靠运营方、80多家驻场商家等一起对虹桥服务理念的认可、对服务号召的响应。虹桥机场这座有着92年历史沉淀的“老机场”,是如何在最人性化的服务之路上走得如此的精彩呢? “礼在虹桥”服务理念 “手推车服务员大多来自周边郊区,以农民工为主,平时礼貌礼仪差点,也没什么规章制度概念……”虹桥机场手推车外包单位——润泓物流的韩国人总经理郑一稿这么陈述他对手推车服务团队的第一印象,“但是短短3年间,我们就成了机场服务明星团队,今年还获得了中国质协‘全国实施用户满意工程先进服务称号’,是参评的中国服务类50强中唯一的民航项目。”郑一稿满是自豪感。 “农民工手推车服务团队”华丽转身的背后,是虹桥机场连

国际贸易经典案例分析含答案

?案例:某出口公司向外商出售一级大米300吨,成交条件FOB上海.装船时货物经检验符合合同要求,货物出运后,卖方及时向买方发出装船通知.但是航运途中,因海浪过大,大米大半被海水浸泡,品质受到影响.货物到达目的港后,只能按三级大米价格出售,于是买方要求卖方赔偿差价损失。问应如何处理这一纠纷?卖方不应该赔偿差价损失。采用FOB条款,货物在越过船舷之后,风险和责任在买方。 ?案例:我国某内陆出口公司于2000年2月向日本出口30吨甘草膏,每吨40箱共1200箱,每吨售价1800美元,FOB新港,共54000美元,即期信用证,装运期为2月25日之前,货物必须装集装箱。该出口公司在天津设有办事处,于是在2月上旬便将货物运到天津,由天津办事处负责订箱装船,不料货物在天津存仓后的第二天,仓库午夜着火,抢救不及,1200箱甘草膏全部被焚,办事处立即通知内地公司总部并要求尽快补发30吨。否则无法按期装船。结果该出口公司因货源不济,只好要求日商将信用证的效期和装运期各延长15天。试分析其中缘由。 ?该出口公司所在地正处在铁路交通的干线上,外运公司和中远公司在该市都有集装箱中转站,既可接受拼箱托运也可接受整箱托运。假如当初采用FCA(该市名称)对外成交,出口公司在当地将1200箱交中转站或自装自集后将整箱(集装箱)交中转站,不仅风险转移给买方,而且当地承运人(即中转站)签发的货运单据即可在当地银行办理议付结汇。该公司自担风险将货物运往天津,再集装箱出口,不仅加大了自身风险,而且推迟结汇。 ?案例:我与越南某客商凭样品成交达成一笔出口镰刀的交易。合同中规定复验有效期为货物到达目的港后的60天。货物到目的港经越商复验后,未提出任何异议。但事隔半年,越商来电称:镰刀全部生锈,只能降价出售,越商因此要求我方按成交价的40%赔偿其损失。我方接电后立即查看我方留存的复样,也发现类似情况 ?问我方应否同意对方的要求,为什么? ?不同意,此案例中的买卖是凭买方样品买卖,即由提供样品由买方依样承制。在我方留存的复样中,也发现生锈,说明我方式按照买方提供的样品生产,生锈了的才是符合卖方要求的 ? ?案例:我国某公司同日本公司签订出口羊绒衫合同,供出口羊绒衫10000件,价值100万美元。合同规定羊绒含量为100%,商标上也表明“100%羊绒”。当对方对我方公司出口羊绒衫进行检验后,发现羊绒衫含量不符合合同规定而提出索赔,要求赔偿200万美元。最后我方公司赔偿数十万美元结案。 ?在合同中没有用品质机动幅度 ?案例:我某出口公司在某次交易会上与外商当面谈妥出口大米10000公吨,每公吨USD275FOB中国口岸。但我方公司在签约时,合同上只笼统地写了10000吨,我方当事人主观上认为合同上的吨就是指公吨。后来,外商来证要求按长吨供货。如果我方照证办理则要多交大米160.5公吨,折合美元为44137.5美元。于是,双方发生争议。 ?应采用国际单位制计量单位 ?案例:我某公司出口布匹以信用证结算,买方银行来证规定,数量大约为5000码,每码1美元,但金额注明为不超过总额5000美元,则我某公司如何掌握装运数量? ?大约可解释为交货数量有不超过10%的增减幅度,4500~5000 ?案例:黑龙江某贸易出口公司与俄罗斯公司成交一笔黄豆出口交易。合同的数量条款规定:每袋黄豆净重100公斤,共1000袋,合计100吨,但货物运抵俄罗斯后,经俄罗斯海关检查后,每袋黄豆净重只有96公斤,1000袋共96吨,当时正遇市场黄豆价格下跌,俄罗斯公司以单货不符为由,提出降价5%的要求,否则拒收。请问:俄罗斯的要求是否合理?我方应采取什么补救措施?另问:若该例黄豆不是用袋装而是散装,则结果又如何? ?合理,把黄豆改成散装,在5%的增减幅度内,则无须降价赔偿 ?《UCP500》第39条B款规定:除非信用证规定货物的指定数量不得有增减外,在所支付款项不超过信用证及呢的条件下,货物数量准许有5%的增减幅度,但以包装单位或个数记数时不适用 ?案例:某公司出口自行车800辆,合同规定用木箱装,来证也成为PACKED IN WOODEN CASE。但在CASE之后加

虹桥机场swot分析

上海虹桥国际机场 焦栋王哲王凯王存凯徐牧凡于嘉滨 摘要:本文主要探讨上海虹桥机场如何运用自身的优势扬长避短实现可持续快速发展,在综合分析上海虹桥机场发展现状及其枢纽功能定位的基础上,阐述其面临的问题,并给出其未来发展方向提出一些建议。 关键词: 虹桥机场 swot分析 一虹桥机场的机遇 近年来,中国的国民经济持续快速健康增长。2010年以来随着全球经济的逐步复苏,中国的外贸也逐步回归正常发展轨道。中国2009年度国内生产总值(GDP)为335353亿元,比上年同期增长8.7%;全年进出口总额2875.33亿美元,比上年增长21.1%。同时,上海及其周边地区外向型经济发展也十分迅速。2009年上海GDP14901亿元首次超过香港,人均GDP11320美元,在区域经济的发展过程中,上海已逐步成为面向全球,为长江三角洲和全国经济提供服务的重要窗口和平台。服务型经济、外向型经济的快速发展和国际交往的日益频繁,带动着上海国际航空运输产业的发展创造了得天独厚的市场资源和历史性机遇,也对上海国际航空运输业的发展提出了更高的要求。 二虹桥机场的现状 虹桥机场位于上海市西郊,距市中心仅l3公里。虹桥机场自1996年以来屡获中国民航业组织的”旅客话民航”活动、旅客吞吐量800万人次以上机场组第一名。上海虹桥国际机场扩建前占地面积26.4平方千米,拥有跑道和滑行道各一条。其中跑道长3400米、宽57.6米(4E级),停机坪达51万平方米。有停机位66个,其中有13个登机桥位,48个远机位,2个专机位,2个货机位,可满足各类飞机的起降要求。每日平均起落航班达540架左右,高峰小时起落飞机达85架次,年运送旅客量超过1488.92万人次,已开通了到达91个国内国际城市的航班。 并且虹桥机场扩建工程已完成能满足年旅客吞吐量4000万人次、货邮吞吐量100万吨和飞机起降量30万架次的要求,主要包括1座36.26万平方米的2号航站楼(T2),1条长3300米、宽60米的平行跑道和3条平行滑行道,以及站坪、货运站、业务用房、能源中心、市政道路等相关配套设施。2010年3月16日零时起,除春秋航空公司及往返日本、韩国的国际包机航班仍在1号航站楼(T1)运营外,其余航空公司的国内航班全部迁至2号航站楼(T2)运营。三虹桥机场的优势 虹桥机场的巨大优势主要来自上海这一国际大都市,主要有以下几方面: 1 优越的地理位置 上海北界长江,东濒东海,南临杭州湾,西接江苏、浙江两省,是中国东部沿海经济带与长江流域的交汇处,地处太平洋西岸,位于亚、欧、美三角航线上。因此,上海的机场具有很好的地理优势。在航程方面,上海飞往北美西海岸和欧洲的航行时间约为10小时,飞往亚洲主要城市的时间不到5小时,有利于从亚洲地区经上海前往欧美。 2 巨大的吞吐量潜力 目前,上海两大机场旅客吞吐量居全国第一位,国际旅客吞吐量约占全国的40%,旅客吞吐量年均增长速度名列全国前茅。预计到2015年,以上海为中心

国际投资学案例分析德国大众

国际直接投资案例分析-大众汽车 一、直接投资理论国际生产折衷理论通过企业对外直接投资所能够利用的是所有权优势、内部化优势和区位优势只有当企业同时具备这三种优势时才完全具备了对外直接投资的条件。 1、所有权优势1大众汽车从20世纪50年代就开始国际化经营积累了一定的在海外经营的经验具有多国经营形成的优势。在中国进行直接投资具备一定的把握市场方向和防范风险的能力。 2大众汽车的生产规模大。大众汽车公司从20世纪50年代初开始国际化经营广泛参与汽车海外销售技术转让和对外直接投资等国际化经营活动.自1998年起至2002年年底.大众汽车公司收购了布加迪兰博基尼本特利和劳斯莱斯等世界着名汽车品牌其国际化经营的程度大大加深。在美国巴西西班牙墨西哥南非中国马来西亚菲律宾中国台湾省以及泰国等国家和地区设有独立生产装配公司及销售公司.整个大众汽车公司年产销能力达300万辆成为全球十大汽车制造商之一.目前拥有十个独立汽车品牌包括奥迪兰博基尼劳斯莱斯本特利布加迪西亚特斯柯达斯堪尼亚大众商用汽车和大众汽车。 3大众汽车于1937年成立拥有较成熟的制造技术其科研开发与创新能力也极强以市场为导向能够设计出符合潮流的汽车而中国改革开放之初汽车产业发展不久其制作技术相对落后。 2、内部化特定优势与向中国出口汽车相比大众通过在中国直接投资可以绕过中国的一些贸易壁垒在一定程度上节约了成本。另外直接投资可以缩短汽车供应链减少供应链其他成员对利润的瓜分。 3、区位特定优势1978年中国政府在邓小平的领导之下开始推行经济改革和

开放政策引进国外的资金和先进的科学技术加速中国的现代化进程提高国际上的竞争能力。这一政策鼓励并方便了大众在我国的直接投资。 中国的劳动力市场巨大且价格较低廉另外中国拥有很多小型加工企业可以为大众生产各零部件。这些都可以使大众的制作成本大幅度降低。 当时中国国内汽车产业发展不久大众的汽车品牌享誉中国中国人民对进口汽车需求较大。 二、投资环境分析因素地理位置、自然资源、经济稳定性、经济发展水平、市场和产业环境、生产要素供应、涉外经济状况、基础设施、法律环境、政治环境、社会文化环境等因素进行分析。 1.地理位置 (1)距离德国和中国地理上接近这样可以帮助德国企业节省运输成本和时间也有助于投资者管理企业、了解当地市场、熟悉文化习俗、消费习惯等。 (2)重要国际运输线中国海岸线较长港口多水陆交通方便运输条件优良。 (3)市场中国的汽车需求量大市场广阔。 (4)资源中国资源丰富使得德国企业可以节省大量原材料成本和运输成本。 2.自然资源我国资源较为丰富。主要为水资源森林资源和矿产资源。全世界87的煤矿分布在俄、美、中三国80以上的稀土集中在中国。 3.经济稳定性组员何姗姗陈赛赛周上靖李锋中国是一个有着15亿人口的泱泱大国市场的巨大也同时注定了经济发展的稳定这种稳定是强大的社会基础奠定的。 4.经济发展水平中国还是一个发展中国家不同于世界上的发达国家都经历了较长的经济发展周期中国的经济发展刚刚进入到发展的高速阶段高速的发展必然