验厂

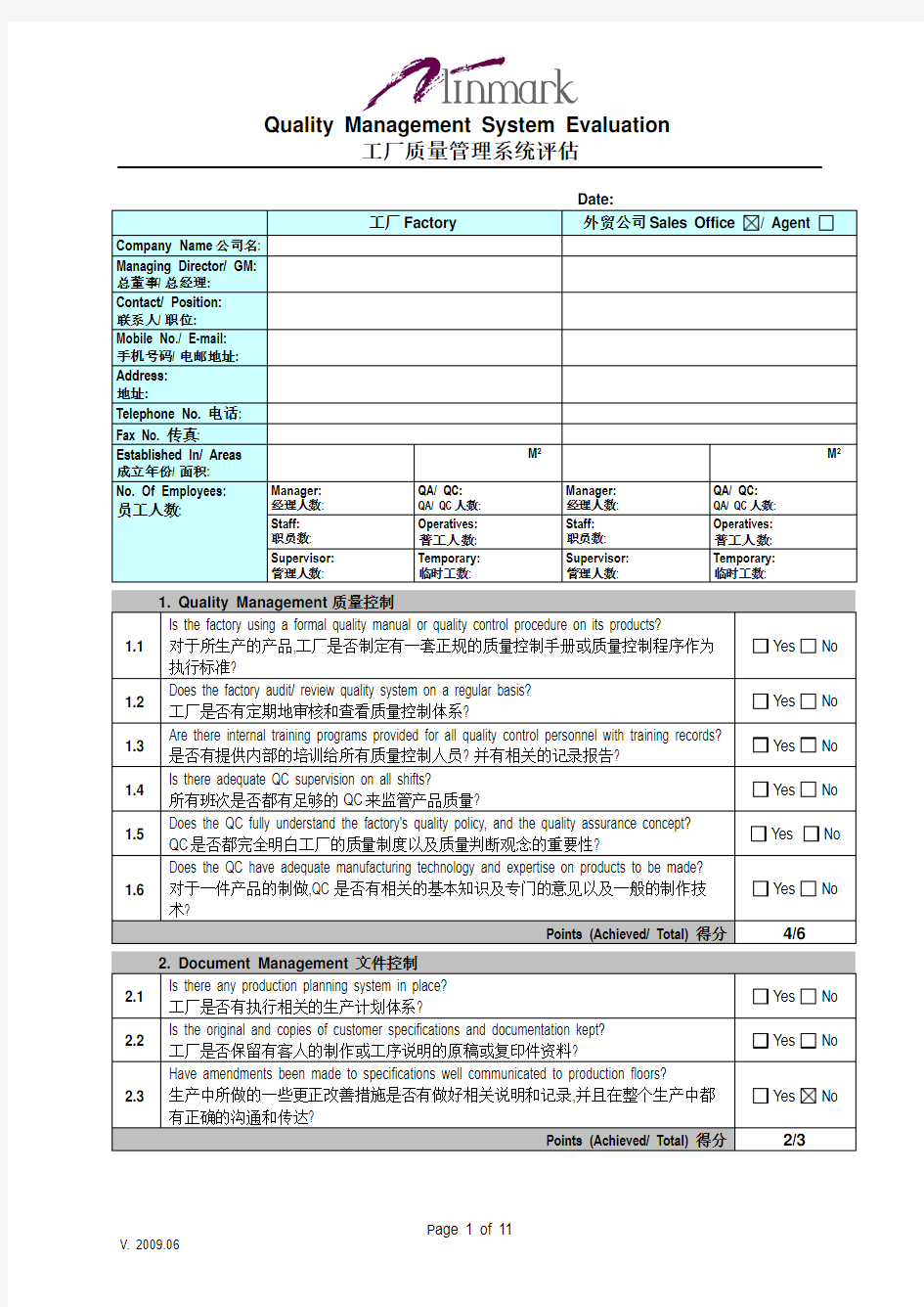

工厂质量管理系统评估

Date:

工厂Factory 外贸公司Sales Office / Agent Company Name公司名:

Managing Director/ GM:

总董事/ 总经理:

Contact/ Position:

联系人/ 职位:

Mobile No./ E-mail:

手机号码/ 电邮地址:

Address:

地址:

Telephone No. 电话:

Fax No. 传真:

Established In/ Areas

成立年份/ 面积:

M2M2

No. Of Employees: 员工人数: Manager:

经理人数:

QA/ QC:

QA/ QC人数:

Manager:

经理人数:

QA/ QC:

QA/ QC人数: Staff:

职员数:

Operatives:

普工人数:

Staff:

职员数:

Operatives:

普工人数: Supervisor:

管理人数:

Temporary:

临时工数:

Supervisor:

管理人数:

Temporary:

临时工数:

1. Quality Management质量控制

1.1 Is the factory using a formal quality manual or quality control procedure on its products?

对于所生产的产品,工厂是否制定有一套正规的质量控制手册或质量控制程序作为

执行标准?

Yes No

1.2 Does the factory audit/ review quality system on a regular basis?

工厂是否有定期地审核和查看质量控制体系?

Yes No

1.3 Are there internal training programs provided for all quality control personnel with training records?

是否有提供内部的培训给所有质量控制人员? 并有相关的记录报告?

Yes No

1.4 Is there adequate QC supervision on all shifts?

所有班次是否都有足够的QC来监管产品质量?

Yes No

1.5 Does the QC fully understand the factory's quality policy, and the quality assurance concept?

QC是否都完全明白工厂的质量制度以及质量判断观念的重要性?

Yes No

1.6

Does the QC have adequate manufacturing technology and expertise on products to be made?

对于一件产品的制做,QC 是否有相关的基本知识及专门的意见以及一般的制作技

术?

Yes No

Points (Achieved/ Total) 得分4/6

2. Document Management 文件控制

2.1 Is there any production planning system in place?

工厂是否有执行相关的生产计划体系?

Yes No

2.2 Is the original and copies of customer specifications and documentation kept?

工厂是否保留有客人的制作或工序说明的原稿或复印件资料?

Yes No

2.3 Have amendments been made to specifications well communicated to production floors?

生产中所做的一些更正改善措施是否有做好相关说明和记录,并且在整个生产中都

有正确的沟通和传达?

Yes No

Points (Achieved/ Total) 得分2/3

工厂质量管理系统评估3. General Facilities工厂整体情况

3.1 Is the general housekeeping acceptable and free from dust?

工厂是否干净整齐, 无尘污?

Yes No

3.2 Has the production area adequate ventilation?

生产工作区是否通风且空气流通?

Yes No

3.3 Has the production area adequate lighting?

生产工作区灯光是否足够光亮?

Yes No

3.4 Is there an appropriate area assigned for client's approved inspectors to conduct final inspections?

是否指派有一个独立的客人QC房用于走货前客户QC验货?

Yes No

3.5 Is all equipment properly maintained and in good condition?

所有机器设备是否有合适的保养且都完好?

Yes No

3.6 Are fax and telephone utilities with long distance call service available?

是否有可用于接通长途的传真及电话?

Yes No

3.7 Is computer with internet connection available?

电脑是否可以连接上网?

Yes No

3.8 Is a barcode reader available for use by our QC during inspections?

是否有条形码扫描仪供QC验货使用?

Yes No

3.9

Is a digital camera available for use by our QC during inspections?

是否有数码相机供QC验货使用?

Yes No

Points (Achieved/ Total) 得分8 / 9 4. Design/ Pre-Production样板设计及产前控制

4.1 Is the factory equipped with sample room/model shop?

工厂是否有独立的板房并有试身模特?

Yes No

4.2 Is the factory equipped with a computerized pattern making/ grading, fashion CAD, 2D technical

drawing (e.g. AutoCAD)/ 3D product design CAD (e.g. Pro/Engineer) system?

工厂是否有电脑纸样制作及放码系统, (如CAD 系统, 2D专业制图排麦系统)?

Yes No

4.3 Does the factory hold pre-production meetings with involvement of QC personnel?

工厂是否有召集相关的质量控制人员开产前会议?

Yes No

4.4

Is the factory running a pilot run in the line, before bulk production?

工厂是否有做产前试产板?

Yes No

Points (Achieved/ Total) 得分 3 / 4 5. Incoming Inspections来料检查

5.1 Are raw materials properly labelled, stored and traceable?

物料是否都合适摆放好,并有清晰地标识?

Yes No

5.2 Are raw materials kept in controlled storerooms to avoid theft, loss and any deterioration of quality?

物料是否都放置在合适的仓库里以免被偷或遗失和变质?

Yes No

5.3 Are If raw materials properly inspected before putting into production and are records traceable?

物料在去到车间做货前是否有进行适当的查验并有查验报告?

Yes No

5.4 Is the inspection sampling schedule adequate?

来料检查的抽样数量是否合适?

Yes No

5.5 Are there adequate written inspection instructions available as guidelines to inspectors?

是否有书面的查验说明提供给验货员做为查检指引?

Yes No

5.6 Is testing equipment sufficient and in good condition with regular calibration?

是否有对测试工具进行定期的校准和调试?

Yes No

工厂质量管理系统评估

5.7

Does the factory keep approved colour swatch, colour continuity cards for incoming inspection?

对于来料工厂是否保留有批核过的色板, 是否保留有颜色的缸差对照表?

Yes No

Points (Achieved/ Total) 得分 3 / 7 6. Non-Conforming Materials 未确认或未批核OK的物料

6.1 Is non-conforming material properly segregated at all stages?

对于那些未确认OK的物料在整个生产过程中是否都有合适的避免和隔离开?

Yes No

6.2 Is non-conforming material clearly identified?

对于未确认OK的物料是否有清晰的标识清楚?

Yes No

6.3 Can the factory demonstrate how they handle the non-conforming materials?

工厂能否证明他们对于那些未确认OK 的物料是怎样控制和处理的?

Yes No

6.4 Is scrap material handled satisfactorily?

仓存料或废余料是否合理正确的处理和监管?

Yes No

6.5 If recycle materials are used, is there adequate identification and checking against specification?

工厂如果有用到可循环利用的物料,是否有合适的标签和核查对照的说明书?

Yes No

6.6

Is the factory willing to improve the situation by implementing a corrective action plan?

工厂是否有提出相关的整改措施/改善计划来避免问题的再次发生?

Yes No

Points (Achieved/ Total) 得分 2 / 6 7. Sub-Contract外发

7.1 Does the factory make the whole production in-house and no sub-contacting required?

工厂是否将整个产品/大货放在本厂做,没有外发?

Yes No

7.2

Does the factory plan to produce Linmark orders entirely in-house, even in peak season?

工厂是否所有大货的正个生产工序都在本厂完成? 即便是在旺季的时候也是如此,

不外发?

Yes No

Points (Achieved/ Total) 得分0 / 2 8. In-Process Quality Control生产过程中的质量控制

8.1 Are there line patrols by QCs or other means to monitor the compliance of the product to meet

safety/ quality requirements?工厂是否有巡查QC或其他方法用于控制产品生产以达到

产品安全及质量上的要求?

Yes No

8.2 Are there in-process inspection records?

工厂是否有中查报告?

Yes No

8.3 Are rejected lots well identified and segregated from accepted lots?

在查验中发现的不良品是否有清晰的标识清楚并与OK没问题的产品隔离分开?

Yes No

8.4 Are there adequate approved samples attached to all areas to give inspectors or workers a

guideline? 工厂是否有提供已批核OK的样板到各个生产部门用于给查检人员和工人

作为标准参考?

Yes No

8.5 Is testing equipment calibrated accurately and is it adequate?

对于测试工具是否有精确的调试校准且该测试工具是否足够精确合适?

Yes No

8.6 Are inspection defects charted, analyzed, and monitored to improve the problems encountered?

在查验过程中发现的疵点,是否有记录下来并有进行相关分析和控制, 以免问题再次

发生?

Yes No

8.7 Is the corrective action properly documented and implemented?

改善措施是否有合适的记录下来并正确的执行?

Yes No

Points (Achieved/ Total) 得分 3 / 7

工厂质量管理系统评估9. Final Inspections 尾查

9.1 Do factory's QCs perform any internal final inspections on merchandise?

工厂QC是否有对大货产品进行内部的最终检查?

Yes No

9.2 Are international standards used to assess their findings?

是否有用到国际上的相关标准,或者客人和其它的批核标准做查验参考?

Yes No

9.3 Does factory perform adequate checks on functionality, quality and safety?

对于产品的功能性, 质量及安全性,工厂是否有执行相关的合适检查?

Yes No

9.4 Are there written, formal inspection reports and are they properly filed and traceable to review

quality of products?

是否有书面的正式查验报告保留存档,以便可以追溯和回顾产品的质量情况?

Yes No

9.5

Is the sampling size of products for final inspection adequate enough to provide confidence of

product quality?

最终检查时样品的抽样数量是否足够?

Yes No

Points (Achieved/ Total) 得分 5 / 5 10. Control Of Sharp Tools利器工具的控制N/A

10.1 Are sharp tools attached to the working benches?

是否所有的利器工具都安全绑好在工作的位置上?

Yes No

10.2 Does factory use a one-piece sharp tool for trimming process? (So called "break away" blades are

not acceptable)

工厂是否用一完整型的利器工具作剪线/ 修剪用? (即断节刀片不可用)

Yes No

10.3 Is the distribution of sharp tools controlled by a single person or carefully handled by other means?

利器工具的派发和更换是否有专门的人员来负责和控制, 或者是否有其它小心处理

的方法?

Yes No

10.4 Is there a record book to register the issuances and return of the total number of sharp tools (even

if they are broken) at the end of the working day?

是否有一个记录本来登记金属利器工具的上班时发出和下班时收进的数量(即使利

器工具断了也有做相关记录)?

Yes No

10.5 Is there a written procedure and policy to investigate missing sharp tools? If not, is handling on the

suspicious lots satisfactory?

是否有书面的程序用来指引如何追查遗失了的利器工具? 如果没有的话,对于那些

可能被污染的大货是否有相关的处理措施?

Yes No

10.6 Are part(s) of the broken sewing needles attached onto the control log book for reference?

衣车的断针碎片是否有粘贴在相关的断针记录上用做查看和记录?

Yes No

10.7 Are photos or diagrams for securing sharp tools on benches and illustrations displayed at various

work stations to remind workers of proper policy procedure?

是否有相关利器安全控制的图片或例证张贴在各工作场所用以提醒工人怎样正确

实施利器控制程序?

Yes No

Points (Achieved/ Total) 得分 2 / 7

工厂质量管理系统评估

11. Metal Detection金属探测N/A

11.1 Is a conveyor metal detector available?

工厂是否有传输带式的验针机?

Yes No

11.2 Is it used 100% for finished production?

对于成品是否实施100%验针?

Yes No

11.3 Is the metal detector checked every hour to ensure its sensitivity and operation is normal and such

conditions will be in the log book? 对于验针机是否有每小时测试以确保机器的灵敏度和

机器运转正常, 且有相关的测试记录?

Yes No

11.4

Are other metal detectors available to locate the metal? e.g. Hand Held / Flat Bed

是否有其它的金属探测器用来查找金属? 如:手提验针机/ 平台式验针机?

Yes No

Points (Achieved/ Total) 得分 4 / 4 12. Packaging包装

12.1 Is the packaging area tidy, free of dust and other contamination?

包装区是否干净整齐,无尘污和其它的污染物?

Yes No

12.2 Is there adequate control to prevent any defective or rejected products from being packed into

master cartons? 是否有相关的监控措施用来以防有疵点的不合格品混入到合格的大

货中入箱包装?

Yes No

12.3 Are approved finished products packed immediately into polybags or properly stored and protected

in order to avoid dust and dirt?已经批核OK 的成品是否会马上包装入胶袋或者有正确合

适的存放以免灰尘和脏污?

Yes No

12.4 Are master cartons sealed immediately after filing?

大货成品入箱后是否有即刻封箱?

Yes No

12.5 Is the method of product count into master cartons accurate and to customer requirements to

prevent products short ship?

是否有正确的程序和方法按照客人的要求点数入箱, 这样以避免少数(缩数)走货?

Yes No

12.6 Does factory use scale to check carton weight?

工厂是否有用电子秤或其它测量工具来检查大货纸箱重量?

Yes No

12.7

If applicable, are heat-sealed bulk polybagged products packed into master cartons immediately

after passing through a metal detector?

如果有用到热封胶袋的话,是否有在过完验针机后马上放入大货纸箱?

Yes No

Points (Achieved/ Total) 得分 5 / 7 13. Machine/ Equipment Maintenance机器设备的维修保养

13.1 Does the factory have a service/ maintenance plan for all machine/ equipment?

对于所有的机器设备工厂是否有一个定期维修保养的计划和政策?

Yes No

13.2 Do operatives clean the machine/ equipment daily?

操作工人是否有每天都清理自己所使用的机器?

Yes No

13.3 Is the machine/ equipment in good conditions?

工厂机器设备是否都完好?

Yes No

Points (Achieved/ Total) 得分 2 / 3

工厂质量管理系统评估

14. Hardgoods – Molding Process模型制造程序N/A

14.1 Are there approval samples in polybags attached to each working machine for reference?

是否有入好胶袋的确认过的样板附在每一个作业机器上用于做货生产参考?

Yes No

14.2 Are there routine QC checks on molded parts?

对于模具的部件是否都有QC检查程序?

Yes No

14.3 Are daily QC records maintained on molded parts?

对于已成型模具部件的QC每天检查是否有查验记录?

Yes No

14.4 Are non-conforming molded parts properly segregated and labelled?

对于没有确认的模具部件是否有合适的区分开并有标识?

Yes No

14.5

Are molded parts protected from contamination with machine oil, dirt, etc.?

对于已成型的模具部件是否有防止机油和脏物污染的程序?

Yes No

Points (Achieved/ Total) 得分N / A 15. Hardgoods – Paint Spraying/ Tampo Printing喷漆/ 印刷N/A

15.1 Are approval samples/ parts attached to each workstation for worke r’s reference?

是否有确认OK 的样板或部件提供到每个工人作业处以作参考?

Yes No

15.2 Are touch-up processes satisfactory?

润色工序是否可以?

Yes No

15.3 Are painted parts properly stored and kept off of the floor?

已经着好色的部件是否正确合理地存放且不是直接放置与地?

Yes No

15.4 Are the sprayed components/ parts inspected according to a scheduled program?

已经喷好漆的部件是否有根据预定的计划检测?

Yes No

15.5 Are inspection intervals adequate?

查验的频率及抽样数是否足够?

Yes No

15.6

Are written inspection reports kept?

是否有书面的查验报告保留?

Yes No

Points (Achieved/ Total) 得分N / A 16. Softgoods – Cutting裁剪N/A

16.1 Is the fabric pre-shrunk/relaxed 24 hours prior to cutting?

开裁之前是否有提前松布24小时?

Yes No

16.2 Does the factory complete the colour continuity cards to control shade batches?

工厂是否有做相关的缸差对照表用来控制色差问题?

Yes No

16.3 Does operator cut the cutting accuracy by checking the top and bottom layers of the cut panels?

是否有抽查顶层和底层的裁片用纸样来核对裁片的精确性?

Yes No

16.4 Are the replacement panels checked for proper colour matching?

重新配片是否有合适的色差控制程序?

Yes No

16.5 Are all cut pieces properly numbered and is this numbering followed accurately in production?

是否有对所有裁片进行正确编号,且生产过程中是否严格按照裁片的编号进行?

Yes No

Points (Achieved/ Total) 得分 2 / 5

工厂质量管理系统评估

17. Softgoods – Printing/ Embroidery印花/ 绣花N/A

17.1 Is a proper approval sample kept in the workshop for production reference?

是否有正确的确认板保留在车间用作生产参考?

Yes No

17.2 Is a print durability test conducted at the work shop?

对于印花的牢固性和耐久性是否有进行相关的测试?

Yes No

17.3

Is there a broken needle policy in place at the embroidery work shop?

在绣花车间是否有实施断针控制程序?

Yes No

Points (Achieved/ Total) 得分N / A 18. Softgoods – Cleaning/ Pressing/ Finishing洗污/ 整烫/ 尾部N/A

18.1 Is there a cleaning facility available in factory?

工厂是否有洗污设备提供?

Yes No

18.2 Is the steam ducting installed properly?

蒸汽导管是否合理的安装?

Yes No

18.3 Is the boiler placed in separate room with operating license?

锅炉是否安放在一个独立的房间且有相关的锅炉操作证和登记证?

Yes No

18.4 Is the iron heated by both steam and electric heating elements?

烫斗加热是否通过蒸汽和电热原理系统?

Yes No

18.5 Is a Teflon shoe used to avoid glazing?

熨斗是否加特富龙垫来避免产生烫迹?

Yes No

18.6

Is a gold seal standard available?

是否有大货标准板提供做参考?

Yes No

Points (Achieved/ Total) 得分 6 / 6 19. Softgoods – Laundry 洗水N/A

19.1 Is the floor clean and dry?

洗水区是否干净干爽?

Yes No

19.2 Is the equipment in good condition?

洗水设备是否完好?

Yes No

19.3 Is the process controlled to avoid batch variation?

是否有相关程序用来控制洗水产生的色差问题?

Yes No

19.4 Is the waste water properly treated, in accordance with local regulations?

污水是否有按照当地的规章要求进行正确地处理?

Yes No

Points (Achieved/ Total) 得分N / A

工厂质量管理系统评估20. Code Of Practise操行守则

20.1 Does the factory have a clear child labour policy an d did it put up signs to inform all workers

regarding this? 工厂是否有一份清晰的童工制度且有将相关制度张贴出来告知所有

工人有关的信息?

Yes No

20.2 Is the factory able to confirm that all employees meet the legal age requirement?

工厂是否能确认所有员工达到法定最低工作年龄?

Yes No

20.3 Do the operatives work spontaneously?

工人们是否都自然愉快地工作?

Yes No

20.4 Are the operatives free to leave the workplace after work shift?

在下班后工人是否都可以自由离开工作场所?

Yes No

20.5 Does the factory have an occupational health and safety manual and/ or procedures written in a

language which can be understood by all the operatives? 工厂是否有一份用所有工人都能

看懂的文字/语言攥写的专业的健康安全手册或书面的程序说明?

Yes No

20.6 Does the factory have a plan to prevent operatives from being exposed to dangerous

substances/ machinery?

工厂是否有相关的措施来防止工人直接接触危险物或危险机器?

Yes No

20.7 Does the factory have an evacuation plan in the case of an emergency?

工厂是否有逃生疏散指示图用于如果有紧急情况发生?

Yes No

20.8 Does the factory have the following? 工厂是否有以下提供:

●Clean and accessible bathrooms干净可用的洗手间? Yes No ●Access to drinking water 干净可喝的饮用水? Yes No

20.9 Does the factory allow operatives to establish/ belong to trade unions or bargain collectively?

工厂是否允许工人建立/参与结社或工会组织?

Yes No

20.10 Is the factory able to confirm that it does not discriminate against the union representatives?

工厂是否能确认对于那些结社/工会代表不会有任何的歧视?

Yes No

20.11 Does the factory have procedures/ methodologies to prevent forms of discrimination?

工厂是否有反歧视的程序和相关的执行方法说明?

Yes No

20.12 Does the factory have procedures to avoid the occurrence of sexually coercive or abusive

behaviour in the factory?

工厂是否有相关的程序用于避免性别骚扰或侮辱言行的发生?

Yes No

20.13 Is the factory able to confirm that it does not use any form of corporal punishment?

工厂是否能确认没有任何的体罚形式用于对待员工?

Yes No

20.14 Is the factory able to confirm that overtime is not exceeding the legal limit?

工厂是否能确认加班时间没有超过法定要求?

Yes No

20.15 Is there one day off a week?

是否每周都有一天休息?

Yes No

20.16 Is overtime paid?

加班是否有付加班费?

Yes No

20.17 Is the salary paid regularly?

工资是否有定期地发放给工人?

Yes No

20.18 Is the itemisation of the salaries and benefits understandable to the operatives?

工人是否都清楚知道自己的工资是怎么计算和相关的福利政策?

Yes No

Points (Achieved/ Total) 得分12 / 18

工厂质量管理系统评估

Remark:

This Quality Management System checklist will be used for the factory self assessment or annual factory evaluation as completed by Linmark QA. The section 20: code of practise reflects the opinion of the factory and cannot be independently verified by Linmark at this point.

质量控制体系的检查对照清单用于工厂自己评估或者是由Linmark QA去工厂年检时使用. 第20条部分, 职业操行守则是用于反映工厂在这方面的意识/概念,在此次审查中不能独立地被验证.

工厂质量管理系统评估Evaluation Summary总评

Sections: Total Points

Achieved 工厂得分

Max. Points

Possible最高标准得分

1. Quality Management质量监管 4 6

2. Document Management 文件管理 2 3

3. General Facilities 整体设备8 9

4. Design/ Pre-Production设计/ 产前控制 3 4

5. Incoming Inspections 来料检查 4 7

6. Non-Conforming Materials 未确认材料的控制 2 6

7. Sub-Contract 外发0 2

8. In-Process Quality Control 生产过程中的质量控制 3 7

9. Final Inspections尾查 5 5

10. Control Of Sharp Tools 利器工具的控制 2 7

11. Metal Detection 金属检测(验针程序) 4 4

12. Packaging 包装 5 7

13. Machine/ Equipment Maintenance

机器设备的维修保养 2 3

14. Hardgoods – Molding Process 模具制造程序N/A N/A

15. Hardgoods – Paint Spraying/ Tampo Printing

喷漆/ 印刷N/A N/A

16. Softgoods – Cutting 裁剪 2 5

17. Softgoods – Printing/ Embroidery 印花/ 绣花N/A N/A

18. Softgoods – Cleaning/ Pressing/ Finishing

洗污/ 整烫/ 尾部 6 6

19. Softgoods – Laundry 洗水控制N/A N/A

20. Code Of Practise 职业操行12 18

Total总分: 64 99

Rating:0 to 49% – Not recommended 工厂不可用

50 to 59% – Need improvement for further evaluation

有待改善及需要再次评估,

60 to 79% – Recommended with some improvement needed

工厂可用,但有些方面需要改善,

80 to 100% – Recommended 推荐可用.Overall Rating %

评级

64.6%

(Total Points Achieved / Maximum Points Possible x 100%) 工厂得分/最高标准得分X100% = 评级

Comments & Recommendations 评语和建议:

Factory capacity (工厂月产量): 30000 pcs/month

Max. capacity for Linmark (给linmark公司的最大月产能): 1,0000 pcs/month Product type(产品类型):针织

Main customer(主要客户):以纯

relative customer with Linmark (为linmark的那个客户供货):STARBOARD Scanner 工厂是否提供扫描仪: 否

工厂质量管理系统评估

工厂适合做产品类型及品质是否合格:针织

Factory工厂Sales Office / Agent 代理商Linmark Group Limited

Company 工厂名忠信制衣有限公司Company

公司名

SHARPCO LTD

优康有限公司

Waltr.Kam

Represented 工厂代表张永青Represented

公司代表

黄涛

Company Chop And Signature 工厂盖章及厂方代表签名Company

Chop And

Signature

公司盖章

及公司代

表签名

Evaluation Conducted By 评估人:

(Name Of Linmark’s Representative)

Date 日期2015-05-20Date日期2015-05-20Date日期2015-05-20