FDA官员原料药检查指南(中)

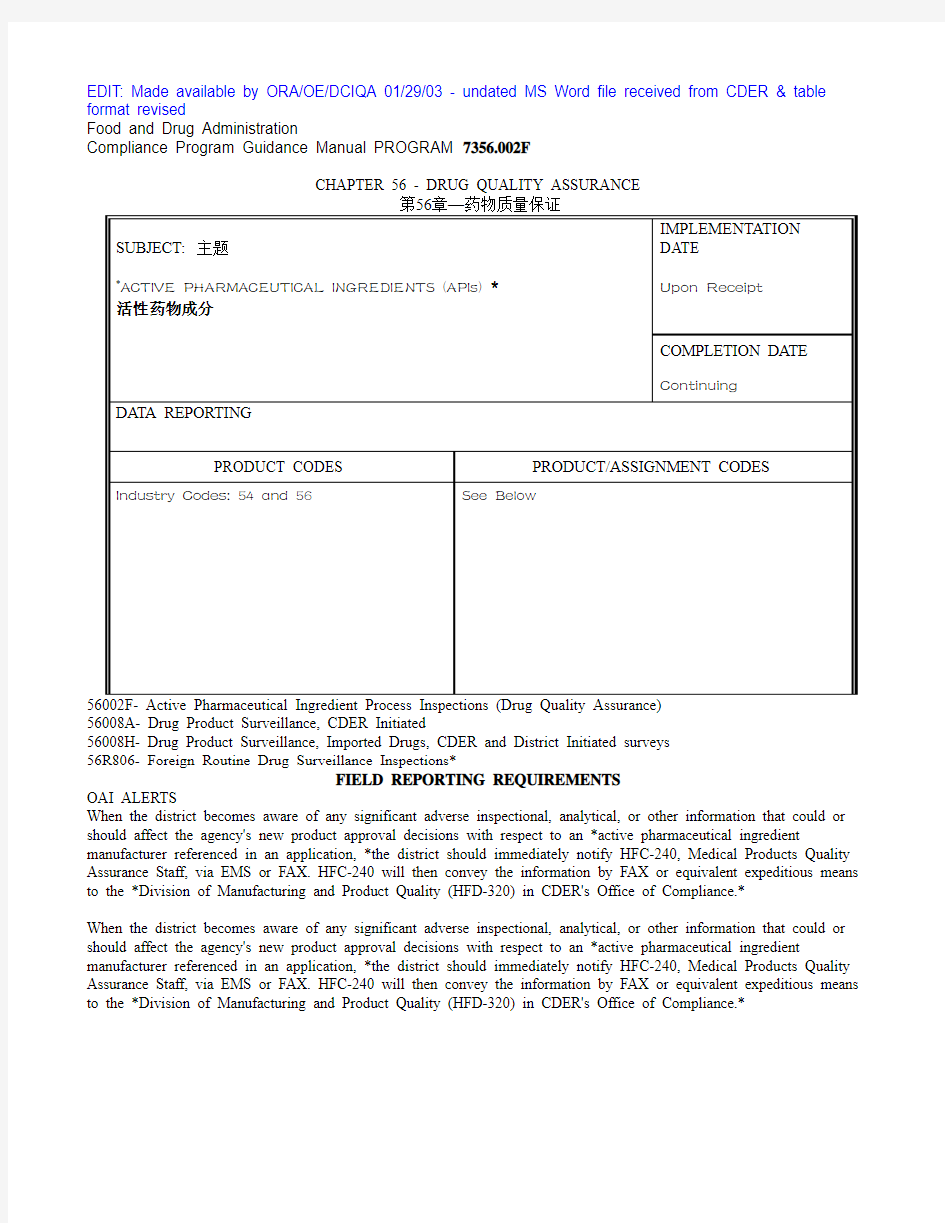

EDIT: Made available by ORA/OE/DCIQA 01/29/03 - undated MS Word file received from CDER & table format revised

Food and Drug Administration

Compliance Program Guidance Manual PROGRAM 7356.002F

CHAPTER 56 - DRUG QUALITY ASSURANCE

56008A- Drug Product Surveillance, CDER Initiated

56008H- Drug Product Surveillance, Imported Drugs, CDER and District Initiated surveys

56R806- Foreign Routine Drug Surveillance Inspections*

FIELD REPORTING REQUIREMENTS

OAI ALERTS

When the district becomes aware of any significant adverse inspectional, analytical, or other information that could or should affect the agency's new product approval decisions with respect to an *active pharmaceutical ingredient manufacturer referenced in an application, *the district should immediately notify HFC-240, Medical Products Quality Assurance Staff, via EMS or FAX. HFC-240 will then convey the information by FAX or equivalent expeditious means to the *Division of Manufacturing and Product Quality (HFD-320) in CDER's Office of Compliance.*

When the district becomes aware of any significant adverse inspectional, analytical, or other information that could or should affect the agency's new product approval decisions with respect to an *active pharmaceutical ingredient manufacturer referenced in an application, *the district should immediately notify HFC-240, Medical Products Quality Assurance Staff, via EMS or FAX. HFC-240 will then convey the information by FAX or equivalent expeditious means to the *Division of Manufacturing and Product Quality (HFD-320) in CDER's Office of Compliance.*

PROCESS PROFILE REPORTING

*In December 1995, at the request of CDER, the Medical Products Quality Assurance Staff (HFC-240) added profile classes CSN (Non Sterile API by Chemical Synthesis) and CSS (Sterile API by Chemical Synthesis) to the drug profile classification system. This change was requested because separate profile classes existed for nonsterile and sterile active pharmaceutical ingredients produced by fermentation processes, but the same did not hold true for active pharmaceutical ingredients produced by chemical synthesis processes. In implementing the change, however, MPQAS did not eliminate the profile class "CCS" because deleting the latter would have caused a loss of history in the GWQAP profiling system. 历程状态报告

1995年十二月, 在药物疗效与审评中心(以下简称CDER)的要求下,药品质量保证属(HFC-240)将CSN(由化学合成的非无菌原料药)以及CSS(由化学合成的无菌原料药)加入到了药品分类系统中。如此分类的必要性是因为通过发酵过程得到的活性药物成分就有无菌和非无菌之分,而化学合成的活性药物成分并没有这样的分类。然而在这一改变生效的过程中,MPQAS并没有去除“CCS”这一分类,因为如果去除了这一分类将会导致GWQAP 分类系统部分历史的丢失。

Therefore, effective with this program circular, discontinue using Profile class CCS (Chemical Synthesis Crude Drug) and use only the following seven bulk profile classes to report the processes covered during API inspections:*

FULL DESCRIPTION PROFILE CLASS

Non Sterile API by Chemical Synthesis CSN

Sterile API by Chemical Synthesis CSS

Non Sterile API by Fermentation CFN

Sterile API by Fermentation CFS

Plant/Animal Extraction API CEX

Biotechnology API CBI

Crude Bulk Not Elsewhere Classified (i.e., producers CRU* of bulk intermediates, and contract micronizers of APIs)

因此,为了让这一系统能有效运转,不再采用原来的CCS(化学合成原料药Chemical Synthesis Crude Drug)分类而只采用以下的七大分类来说明API检查所包含的生产过程:

完整的分类描述:

由化学合成的非无菌原料药(CSN)

由化学合成的无菌原料药(CSS)

由发酵得来的非无菌原料药(CFN)

由发酵得来的无菌原料药(CFS)

由动/植物中提取得来的原料药(CEX)

生物制品的原料药(CBI)

别处未有分类的粗制过程(ie., producers of bulk intermediates,

and contract micronizers of APIs)(CRU)*

REPORTING TO FORENSIC CHEMISTRY CENTER (FCC):

*In order to assure that foreign firms supply the requested profile samples and documentation (See Page12, Items 1 & 2), the Forensic Chemistry Center (FCC) should receive a copy of the coversheet for all inspections of foreign active pharmaceutical ingredient manufacturers. The coversheet endorsement should include a phone and fax number of the contact person at the firm. If a sample is not collected by the investigator during the inspection, the coversheet should also state that the manufacturer was instructed to collect and ship a sample and applicable records directly to FCC as per Appendix B. This will permit proper follow-up by FCC and also serve to identify the investigator who will receive a copy of the annotated collection report prepared by FCC. On a quarterly basis, FCC will send a summary of sample testing results to the Foreign Inspection Team (FIT), HFD-322.

The container/closure and product information obtained from Appendix B will be included in the Active Pharmaceutical Ingredient Databases and made available to District Import Offices to help prevent counterfeit APIs from entering the

United States market.*

*当前更改*

法医化学中心(FCC)的报告

* 为了确保国外的厂家提供的是所要求的样品及文件(见12页,1—2项),法医化学中心(FCC)应该收到海外活性药物成分制造商检查coversheet复印件。该coversheet背书里应该包括厂家的联系人的电话及传真。如果样品不是由检查官在检查时收集得到的,则coversheet里应该声明厂家被通知收集并运输一份样品以及相关记录连带附件B直接寄到FCC。这就使得FCC得以允许继续并且能够确认将收到由FCC出具的带注解的整理报告检查官。FCC将会在每一季度寄出一份样品检测结果小结给海外检查组(FIT),HFD-322。

从附件B获得的容器/包装及生产信息应该也包括在活性药物成分数据库中并且可被地区进口部可用,以帮助制止假冒伪劣的API产品进入美国市场*

REPORTING TO CDER_S DIVISION OF MANUFACTURING A

REPORTING TO CDER_S DIVISION OF MANUFACTURING AND PRODUCT QUALITY:

For domestic inspections of active pharmaceutical ingredient manufacturers, submit a copy of the EIR coversheet,

FD-483, and District issued copy of Warning Letters (after CDER review and concurrence) to CDER's Division of Manufacturing and Product Quality, HFD-320, for review and trend analysis.

给CDER 制造和生产质量部的报告

对于国内活性药物成分制造商的检查,提交一份EIR coversheet的复印件,FD-483,并且地区管理部门要发布警告信的复印件(CDER 讨论并且同时发布后)给CDER的制造和生产质量部,HFD-320,用于讨论和进行趋势分析。

PART I - BACKGROUND

*Since the late 1980's, the U.S. Food and Drug Administration has intensified its inspectional coverage of active pharmaceutical ingredient (API) manufacturers. This is due, in part, to an increased awareness that API quality plays a potentially significant role in the quality, efficacy, and safety of finished dosage form pharmaceuticals. For example, physical properties of APIs formulated into solid oral dosage forms, suspensions, and topicals may adversely affect drug product dissolution/bioavailability. In addition, extremely small quantities of unidentified or uncharacterized impurities in drugs may cause serious patient side effects.

第一部分-背景

*从上世纪80年代末以来,美国食品药品监督管理局已经加强了它对活性药物成分生产厂家的检查覆盖范围。由于认识到原料药的质量对于药物终产品的质量,效果以及安全性起到很重要的显著影响,例如,原料药的物理性质会带进固体口服制剂的形态,悬浮性以及分布性,这些都会导致药品的溶解度以及生物利用度产生相反的效果。另外,存在于药品中的那些特别少量的未确定或未定性的杂质将会导致严重的副作用。这些认识的不断提高是导致上述结果出现的部分原因.

FDA has long recognized that CGMP concepts, embodied in the good manufacturing practice regulations for finished pharmaceuticals (21 CFR 210 and 211), are valid and can be applied to API processes. These concepts include, among others, building quality into the product, employing appropriately qualified and trained personnel, establishing adequate written procedures and controls, establishing a system of inprocess and end product tests, process validation, and ensuring stability of APIs for the intended period of

use.*

FDA很久以来就已经认可cGMP的概念,具体体现在药品中的优良质量管理规范(21CFR 210及211),已经执行并且可应用到原料药生产过程中。除了别的一些观念以外,这些观念包括,将质量嵌入到产品中,招聘适当的合格的受过培训的人员,建立足够的书面形式的生产和控制程序,建立一套生产过程及终产品检测,工艺验证这样一套程序,并且保证原料药在以后的使用过程中的稳定性。*

The *September 1991 FDA Guide to Inspections of Bulk Pharmaceutical Chemicals, reformatted in May 1994 with minor editorial changes, contains general guidance as to the extent and application of GMP/validation concepts to API production and agency expectations regarding tests for impurities and impurity profiles. This guide must be used for inspection of both foreign and domestic facilities to promote inspectional consistency and uniformity.*

1991年九月出版的的《FDA的化学原料药检查指南》,在1994年5月进行了细小的改动,这份指南基本包含了总的指南并且要API生产和代理商在关于杂质状况检测及杂质profile中要用到GMP/验证的概念。这一指南必须应用到海外及国内厂家的检查中以提高检查的一致性与均匀性。*

*At present, FDA expects API manufacturers to apply CGMPs to all steps of an API process, beginning with the use of starting materials, and to validate critical process steps that impact the quality and purity of the final API. This approach recognizes that the control needed is highly dependent on the manufacturing process and that the level of control increases throughout the synthesis as the process proceeds from early intermediate steps to final isolation and purification steps. This approach also allows _appropriate_ levels of control, depending on the process itself (i.e., fermentation process vs. chemical synthesis) and the risk or criticalness associated with the specific process step being performed.

* 目前,FDA希望API生产厂家能把cGMP应用到生产API的所有步骤中去,从原料的使用开始,一直到验证影响API终产品的质量及纯度的关键步骤。这个做法认为所需的控制是高度依赖于生产工艺的,而从早期的中间体合成步骤到到最终的分离及纯化步骤的控制水平的提高是贯穿于整个合成工艺的。这一做法还允许根据生产本身(如,发酵过程VS 化学合成过程)以及与所采用的特殊的生产过程所产生的风险与紧急情况而采取相应的控制级别。

This "control all manufacturing steps, validate critical process steps" approach is embodied in the draft FDA Guidance for Industry on the Manufacture, Processing or Holding of Active Pharmaceutical Ingredients, which was released for public discussion on September 20, 1996. The latter can be obtained from CDER_s Drug Information Branch, HFD-210, or can be downloaded from CDER_s Home Page at _https://www.360docs.net/doc/6812093142.html,/cder/api.htm._*

这一“控制所有的生产步骤,验证关键步骤”的做法具体体现在“FDA对生产,制造及持有活性药物成分的厂家指南”中,这一指南于1996年9月20日公布。可以从CDER的药品信息部,HFD-210获得该指南,或者从CDER的主页中下载。_https://www.360docs.net/doc/6812093142.html,/cder/api.htm._*

PART II - IMPLEMENTATION

OBJECTIVE

The primary objective of this compliance program is to provide comprehensive CGMP inspectional coverage of the domestic and foreign active pharmaceutical ingredient (API) industry in all profile classes (processes).

第二部分

目的

执行这一程序的主要目的是为了保证完整的cGMP检查能覆盖到所有profile类型(工艺)的国内及海外API生产厂家。

PROGRAM MANAGEMENT INSTRUCTIONS

*This program circular applies only to active pharmaceutical ingredients intended for use in drug products. An active pharmaceutical ingredient is defined as any substance that is represented for use in a drug and that, when used in the manufacturing, processing, or packaging of a drug, becomes an active ingredient or a finished dosage form of the drug. Although the agency has used the terms _bulk pharmaceutical chemicals_ and _bulk drug substances_ to describe these materials, FDA is aware that the term _active pharmaceutical ingredient_ has international recognition. In light of this and for added

clarity, the agency is adopting the term active pharmaceutical ingredient for use in this compliance program.*

程序执行说明

*这一程序只适用于用来生产药品的活性药物成分。活性药物成分(API)的定义是指在药品中所使用到的任何物质以及当在药品制造,生产或者包装中使用并且最终变成这一药物的一个活性成分或一个剂型的任何物质。尽管当局曾采用过诸如“化学原料药”及“原料药”这些术语来描述这些物质,但FDA知道“活性药物成分”是国际上认可的。根据这个并且为了增加其透明度,当局在这份执行程序中采用了这一术语。*

*Owners or operators of all domestic drug establishments, to include APIs, not exempt under section 510(g) of the

Federal Food, Drug, and Cosmetic Act, as amended, or 21 CFR 207.10 are required to register and to submit a list of every drug in commercial distribution. Foreign drug manufacturers are not required to register, although they are required to list all drugs imported or offered for import into the United States. Refer to 21 CFR 207.40 for additional information on drug listing requirements for foreign drug establishments.*

* 所有国内药品生产厂家的所有者或经营者,包括API生产厂家,都要遵守“联邦食品,药品和化妆品法”中的510(g)部分,修改过后,则每一个在商业区里的药品的注册及提交列表或者按21 CFR 207.10要求来做。海外药品生产厂家并不要求被登记,尽管他们被要求提交所有进口或提供进口到美国的药品的列表。

Although the current good manufacturing practice (CGMP) regulations, 21 CFR 210 and 211, do not apply to APIs, active pharmaceutical ingredients are subject to the broad requirement of Section 501(a)(2)(B) of the Act in that they must be prepared in conformance with current good manufacturing practice.

尽管现行优良质量管理规范(cGMP)条例,21CFR210和211都没有应用于API生产厂家,但活性药物成分受法规中501(a)(2)(B)管辖,在此,他们必须按照现行良好质量管理规范来生产。

*No distinction is made between APIs and finished pharmaceuticals in the Act, and failure of either to comply with CGMP constitutes a violation of the Act.*

Therefore, in this document, the term CGMP refers to the latter, rather than 21 CFR 210 and 211 provisions.

*法规对活性药物成分和药品成品的生产厂家并没有不同要求,不遵守cGMP则等同于违背了法规*

因此,在这份文件里,cGMP这一术语则指的是后者,而不仅仅是21 CFR 210 and 211所规定的。

EXCLUSION

*This program circular does not apply to the sterilization and aseptic processing steps of sterile active pharmaceutical ingredients, which are covered by Compliance Program 7356.002A, Sterile Drug Process Inspections. The FDA has long maintained that sterile APIs are finished drug products subject to the CGMP regulation for finished pharmaceuticals (21 CFR 210 and 211) because these are repacked as finished dosage forms under aseptic conditions without further purification or processing.*

EXCLUSION(排他)

这一程序文件并不适用于无菌产品和无菌活性药物成分的无菌生产过程,而7356.002A的附属程序(无菌药物生产检查)则适用于这些生产过程。FDA 长久以来一直坚持认为无菌API产品就是等同于最终的药品,它的生产应该服从cGMP中药物成品生产的规定(21 CFR 210 and 211)因为它们没有进一步的纯化或生产过程而只是在无菌条件下重新包装成为药品成品。

PART III - INSPECTIONAL

*Inspections of active pharmaceutical ingredient manufacturers, whether foreign or domestic, should be conducted by experienced investigators with education and/or training in fermentation, chemical synthesis, recombinant DNA, and other biotechnology manufacturing methods. Use of chemists and/or microbiologists during API inspections is recommended, particularly for evaluating laboratory operations (e.g., analytical methods evaluation, analytical data, lab procedures and instrumentation), analytical review of methods used to establish impurity profiles, fermentation manufacturing processes, and complex multi-step chemical synthesis processes.*

第三部分—检查

*对于活性药物成分生产厂家的检查,不管是国外的还是国内的厂家,都应该由受过发酵,化学合成,DNA重组以及别的生物技术生产方法的教育或/和培训的有经验的检查官来进行。在API检查中推荐使用化学家或/和微生物学家,特别是要评估实验操作(如分析方法评估,分析数据,实验操作和仪器使用等),杂质状况的方法分析审查,发酵生产过程以及复杂的多步化学合成过程。

*Investigators conducting API inspections must understand the basic differences between the processes used for the production of APIs and those used for finished dosage forms. APIs are usually produced by chemical synthesis, recombinant DNA technology, fermentation, enzymatic reactions, recovery from natural materials, or combinations of these processes. The production of APIs typically involves significant changes of starting materials or intermediates by various chemical, physical, and biological processing steps. Purification is the ultimate objective.

* 检查官在对API进行检查时必须了解API生产过程与药品成品生产过程的基本差异。API通常是通过化学合成,

DNA重组技术,发酵,酶反应,天然产物提取或者结合这些方法来生产的,API的生产明显涉及到通过多种化学的,物理的以及生物的操作步骤来使得原材料或者中间体发生显著改变。纯化是最终目标。

In contrast, finished drug products are formulated from bulk raw materials that are usually subjected to some degree of quality control by the users (dosage form manufacturers). Most important, the manufacturing processes for finished pharmaceuticals typically do not involve purification steps.

相反地,药品成品的生产是从原料药形成的,它通常是由使用者(制剂生产厂家)进行不同等级的质量控制。最重要的是,药品成品的生产过程很显然地没有涉及到纯化过程。

For these reasons, the manufacturing and quality controls employed in API production and their application throughout the process (i.e., stringency of controls, written instructions, in-process controls, sampling, testing, monitoring, and documentation employed in early processing steps vs. later isolation and purification steps) differ somewhat from those found in finished dosage form plants. These differences, however, are simply reflections of different manufacturing processes, not inherent differences in the importance of GMPs for the two types of production.*

由于这些原因,API生产中的制备以及所采用的质量控制以及这些控制在整个生产中的应用(如控制的力度,书面指导,工序间控制,取样,检测,监控以及在早期步骤中所使用的文件与后面的分离纯化步骤所使用的文件的比较)都有些不同于在药品成品生产厂家中所发现的控制。然而,这些差异仅仅反映了生产过程的不同,对于这两种形式的生产过程中执行GMP的重要性并没有质的区别。

*Since manufacturers of active pharmaceutical ingredients are often referenced in many drug applications, each inspection should cover as many API processes as is feasible. This strategy will maximize the use of agency resources and avoid repeated visits to the same manufacturing site to cover different API profile classes referenced in subsequent applications. Thus, effective with this CP revision, all inspections of API manufacturers, regardless of how these are initiated, will be "GMP qualifying inspections." Inspections should cover the specific API profile classes referenced in the assignment and all other API profile classes not inspected in the last two years.

由于活性药物成分生产厂家通常在许多药品申请中被提及到,因此每次检查都应该包括尽可能多的API生产过程。这一策略将会最大化地利用当局资源并且避免了到一个相同的生产厂进行重复检查,而这些生产厂可能涉及在随后的申请中所被提及的不同类的API生产。因此,有效地进行CP修正,所有的API厂家检查,不管是如何起源的都将会是“GMP保证的检查”。检查应该包括所有在分配中提到的明确的profile分类中的API以及所有别的在这两年没有检查过的其它类的API。

For foreign API firms, investigators should only cover profile classes for APIs intended to be marketed or already marketed in the United States.

APIs selected for coverage should include those referenced in drug applications,are therapeutically significant, are intended for use in parenteral drug products, are difficult to manufacture, or those on record as having past compliance problems. However, this does not preclude the selection of less therapeutically significant active pharmaceutical ingredients to evaluate specific API processes (profile classes) not previously given in-depth coverage at the facility.

对于海外API生产厂家,检查官应该只检查涉及到那些将要或已经在美国上市的API。所选出来作为代表的API 都应该包括在那些在药品申请中所涉及到的API,比如那些具有治疗重要性的API,将要用于制备非肠道给药药品的API,对于厂家难于生产的API或者那些过去有问题记录在案的API。然而,这些并不排除选择那些缺少治疗重要性的活性药物成分来评估特定的但之前没有给予深入覆盖的API生产过程(profile classes的)。Investigators conducting API inspections should understand the general inspection strategy set forth in Part II of this program. Recognizing that API firms vary greatly in size, diversity of operations, and quality assurance systems, investigators should carefully plan their inspectional strategy at each firm. Of particular concern are API manufacturing operations located in developing countries. *Impurities and contaminants present in components, process water, and solvents used in the production of APIs may carry over into the active pharmaceutical ingredient and may not be detected by analytical tests conducted by either the API manufacturer or the dosage form manufacturer. During inspections, investigators should review the quality of process water and solvents used in isolation and purification steps, the firm's procedures for preventing API contamination/cross-contamination, procedures for controlling impurities, and the procedures and test methods for establishing a complete impurity profile for each API process.* These are covered in detail in the September 1991 FDA Guide to Inspection of Bulk Pharmaceutical Chemicals and its "Appendix A."

检查官进行API检查应该了解在这份文件中Part II的通常检查策略。为了要充分了解API厂家的规模,操作的多样性以及质量保证系统,检查官应该仔细地规划他们对每一个厂家的检查策略。特别是对于那些位于发展中

国家的API生产厂家。*以成分出现的杂质及污染物,工艺用水以及在生产API中所使用到的溶剂都有可能带到活性药物成分产品中并且有可能不会被API生产商或制剂厂商的分析检测出。在检查期间,检查官应该对在分离和纯化步骤中所用到的工艺用水和溶剂的质量,厂家用于防止API被污染/交叉污染的操作过程以及厂家为每一个API工艺建立一套完整的杂质状况而建立的操作及检测方法进行检查。* 这些均包括在1991年9月所出的“FDA 对于化学原料药的检查指南”以及它的“附录A”中。

During inspections, investigators should review the batches manufactured during the last year to determine not only those released, but any rejections. The firm_s policy on reprocessing and reworking of APIs should also be examined. Some batches start off as a pharmaceutical grade and then become technical grade. This could indicate a problem with the validated process. In addition, equipment cleaning validation should be reviewed to assure that the firm can remove residues, microbial contamination, and endotoxins to acceptable levels when the end product is intended for parenteral or liquid dosage forms.

*For API inspections initiated by a preapproval assignment, review guidance provided in CP 7346.832, Pre-Approval Inspections/Investigations, and assess the authenticity and accuracy of data contained in drug applications and drug master files. Report inspectional time under the appropriate program assignment codes (PACs) referenced in both compliance programs, based on coverage afforded to each program.*

检查期间,检查官应该对过去一年中所生产出来的各批产品,不仅是那些被放行的批次而且还包括对任何被拒绝的批次进行回顾性检查以下定论。还要对厂家API重加工及返工的计划进行检查。一些批次由药品级变为技术级,这个能显示出验证过程中的一个问题。另外,设备清洗验证应该被检查到以确保厂家能去除残留、微生物污染以及当一个终产品将会用于非肠道制剂或液体制剂时,它的内毒素能达到一个可接受的范围。

*对于一个批准前的指定的API 检查,回顾CP 7346.832中所提供的指南中的“批准前的检查/调查”,评估那些在药品申请及药物主文件中数据的真实性和准确性。参照基于每个程序所覆盖的顺应程序中对应的程序分配代码(PACs)来报告检查的时间.

*CHANGES IN THE FOREIGN DRUG INSPECTION PROGRAM

Beginning in FY 97, ORA and CDER agreed to implement several changes to the foreign drug inspection program to streamline the compliance review process. The Division of Emergency and Investigational Operations (ORO/DEIO), will continue to work with foreign governments in scheduling foreign inspections, making travel arrangements for inspection teams, and resolving logistical problems.

*海外药品生产企业检查程序的一些更改*

从FY97开始,为了顺应检查程序,ORA及CDER即同意对海外药品生产企业的检查程序进行好几处更改。Emergency and Investigational Operations (ORO/DEIO)(突发事件及调查操作部)将致力于按国外检查时间表与海外政府合作,安排检查组的行程以及解决后勤问题

However, new procedures are in effect for handling a foreign firm's response to an FD-483, submitting establishment inspection reports, and commenting on a foreign firm's response to an FD-483.

但是,新的程序对处理海外企业对每份FD-483的回复,提交检厂报告以及对海外企业的FD-483回复进行批注这些过程产生了影响.

Investigators should instruct management at foreign firms to submit the original written response to an FD-483 directly to CDER's Office of Compliance with a copy to the lead investigator. The original response with appropriate documentation should be submitted to the following address:

检查官应该提醒海外企业的管理者,在直接向CDER的Office of Compliance 提交对FD-483回复的原始的书面报告的同时还应该给如下地址也寄一份复印件:

Food and Drug Administration

Foreign Inspection Team, HFD-322

Division of Manufacturing and Product Quality

Center for Drug Evaluation and Research

7520 Standish Place

Rockville, Maryland 20855-2737

Investigators and analysts will submit written comments regarding a foreign firm's response to an FD-483 directly to

CDER's Foreign Inspection Team (FIT). After appropriate district office review and endorsement, all foreign establishment inspection reports (EIRs) will be promptly forwarded to FIT for review and final classification. FIT will continue to issue Warning Letters, Untitled Letters and other correspondence to foreign firms. FIT will also recommend automatic detention of foreign firms/products, make recommendations to review units, and request follow-up inspections, as appropriate.*

检查官以及化验员将直接给CDER的海外检查组(FIT)提交关于对海外厂家FD-483的回复的书面评论。在得到相应的地区办公室的检阅和认可之后,所有的海外生产厂家检查报告(EIRs)将会很快地送到FIT做进一步的检阅以及最终的分类。FIT 将接着做出发出警告信,无标题信(Untitled Letter)以及别的相应的回复给海外厂。FIT 还将相应地做出如自动隔离海外厂/产品,建议进行重新审评的单位以及要求进行进一步检查等相应的措施。

INSPECTION

Review the September 1991 FDA Guide to Inspections of Bulk Pharmaceutical Chemicals, (Reformatted May 1994) to become familiar with the various areas and topics that must be considered when conducting API inspections. Appendix _A_ of this CP program is a summary of areas to be covered during API inspections. Photocopy this appendix and take with you during inspections. Also obtain a copy of the drug application and/or Drug Master File (DMF), as applicable, and review these before initiating the inspection.

检查

进行API检查时,必须重新回顾1991年9月FDA的化学原料药指南(在1994年重新编排过),以熟悉必须要考虑到的多种方面及主题。这份CP程序中的附录A是关于在API检查中应包括的一些方面的小结。在检查时带上这份附录的复印件。还要带上一份药品申请或/和药物主文件(DMF),最好在开始检查前对这些文件进行审阅。Third (field) copies of applications, *supplements and annual reports* are now required (Refer to 21 CFR 314.440) and such copies are submitted by domestic firms directly to the applicant's home FDA district office. Foreign *applicants* are required to submit third copies of applications to the same headquarters units receiving the first and second copies. These are made available by DEIO to investigators before initiation of foreign inspections.

现在还要求要应用的第三份复印件是*增补及年度报告*(见21CFR 314.440),对于国内企业,他们可以直接向FDA 地区办公室的申请部门提交这份报告。而海外*申请者*则被要求提交三份申请的复印件给相同的总部单位并会收回第一份及第二份的复印件。这些文件DEIO都会在海外检厂的时候提供给检查官。

*Investigators should review all available information including prior inspectional information, FD-483s and responses, any Warning Letters, the firm's compliance history, sample analysis results, complaints, recalls, etc., to prepare for the inspection. For domestic inspections, the information is available from the Pre-Approval Monitors (PAMs) at each District Office. For foreign inspections, the information is available from DEIO or FIT.*

检查员应该回顾所有的可利用的信息,包括以前的检查信息,FD-483报告及回复,任何警告信,生产厂的一贯历史,样品分析结果,投诉,召回等信息,以对检查进行准备。对于国内检查,可以从每个当地政府的批准前监控(PAMs)得到信息。对于海外检查,可以从DEIO或FIT得到信息。*

*Additional suggested references that Investigators and Chemists should be familiar with include: the draft Guidance for Industry - Manufacture, Processing or Holding of Active Pharmaceutical Ingredients; USP <1086> Impurities in Official Articles; and the recent changes in tests for the presence of foreign substances and impurities, contained in Page 3636 of USP-NF Supplement 6, effective May 15, 1997. In addition, the Investigator should contact the Forensic Chemistry Center (FCC) to determine which APIs should be sampled, so that duplicates are not collected during different inspections.*

*对检查员和化学家要熟悉的参考信息的进一步的建议包括:《对生产-制造,加工或持有活性药物成分的指南草案》;USP<1086>官方条款中的杂质;于1997年5月15日起效的,USP-NF 增补6中第3636页中对于当前海外原料药及杂质检测的改变。另外,检查官应该与法医化学中心(FCC)联系以决定哪个API应该要取样,以便避免在不同的检查中重复取样。*

*The Investigator should consult the CDER Case Officer for clarification of the assignment to assure that they are aware of the previous deficiencies at the firm. During the inspection, assure that all the firms promised actions are effective at correcting the problems. If the inspection determines that the firm has resolved all the deficiencies, submit the information for input into the CARS computer system.*

检查官还应该与CDER的案例办公室咨询所要检的厂家搞清楚所分配的任务以确保他们知道厂家以前的不足之处。在检查过程,确保厂家所有承诺的行动在解决问题的时候都是有效的。如果检查认为厂家解决了所有的不足,则提供这些信息以便输入到CARS计算机系统。*

*Conduct a "GMP qualifying inspection" at each API manufacturer covering the products and processes specified in the assignment. In addition, cover in as far as possible, API processes that have not been inspected in the last two years. Also, conduct an in-depth inspection, to include examining pertinent systems and processes, whenever the District receives adverse information regarding a firm's ability to produce APIs of acceptable quality.*

*在对API生产厂家进行检查时,“GMP合格检查”要包括所有任务中指定的产品或工艺。另外,还要尽可能地覆盖到那些近两年没检查到的API加工过程。并且,每当地区办公室收到关于一个生产厂家生产合格产品能力的不良信息后,应该要进行一个深入的检查,包括检查相关的系统及工艺。

During inspections of API manufacturers:

1. *Determine if the firm has made process changes by comparing current operations against the Establishment Inspection Report (EIR) for the previous inspection. Also compare the current operations with those filed in the Drug Master File or the drug application to determine whether the firm is complying with commitments made to the agency. The following changes are typical of those that would warrant *extensive coverage* during the inspection:

a.New potential for cross-contamination arising through changes in API processes or product lines, to include

processing numerous APIs of varying therapeutic significance in common equipment and/or facilities.

b. Use of new technology requiring new expertise, significantly new equipment or new facilities.

c.*Recent changes in starting materials, intermediates, equipment, facilities, support systems, processing steps,

packaging materials, and computer software that are not referenced in the DMF or application.* 在对API生产厂家的检查中:

1.*将当前的操作与以前检查的企业检查报告(EIR)进行对比,以确定厂家是否进行了工艺更改。还要将当前的操作与“药物主文件”或“药品申请文件”相比较以确定厂家是否符合FDA的要求。以下改变是典型的在检查中要给予“广泛注意”的内容:

a.在API工艺或生产线发生改变时可能产生的新的交叉污染,其中包括在同一装置和/或设备中生产多种不

同治疗类别的API。

b.要求新的专门知识的新技术的采用,重要的新设备或装置。

c.*在DMF或申请资料中没有提到的,在起始物料,中间体,设备,装置,维持系统,生产步骤,包装材

料以及计算机软件中做的近期改变。

2. Verify that the size of the largest batch does not exceed the maximum working capacity of the firm's largest blender that is used for blending of API batches.

2.验证最大批的生产并没有超过厂家最大的混合设备的混批能力。

3. Review the firm's complaint file. Determine whether the pattern of complaints (or other information available to the District) and the firm's records of internal rejection or *reprocessing/reworking* of API batches warrant expanding the inspection. Look for weaknesses in the firm's processes, systems or controls.

3.审阅厂家的投诉档案。确定投诉案例(或者官方获得的别的信息)和厂家对于所投诉批进行的如“内部销毁”或者*再处理/返工*等决定是否超出了检查界限。找出厂家生产、系统及控制的弱点。

4. Investigate the return of APIs for any reason. Determine whether the firm conducts investigations on returned products to find out if these APIs failed to meet specifications or were contaminated. Also determine the final disposition of returned APIs, i.e., whether reprocessed or destroyed.

4.调查任何原因的API退货。确定厂家是否对返回的产品进行了调查以发现这些API是不合格品还是被污染了。另外还要确定厂家对返回的API的最终处理,如,是返工了还是销毁了。

5. If the inspection is initiated because the firm *is referenced as an API supplier in a drug application (NDA, ANDA, AADA), evaluate operations against commitments in the application and/or drug master file. Also, verify the authenticity and accuracy of data submitted in the application and/or DMF.*

5.如果检查是针对初次在新药申请中(NDA,ANDA,AADA)所提及到的API供应商,则对比申请书或药物主文件中所述来评估厂家的操作。另外,审核在申请书和/或DMF中的数据的真实性及准确性。

6. *Obtain a copy of the impurity profile for each active pharmaceutical ingredient process covered during the inspection and compare these to the impurity profiles submitted in the Drug Master File.*

6.*在检查中所涉及到的每个活性药物成分生产工艺,获取一份杂质状况的复印件并与DMF中所提交的相对比。All Establishment Inspection Reports for API manufacturers must include:

所有的API厂检厂报告都应该包括:

1. History of business, and any corporate affiliations.

2. Names, titles, *and complete mailing address of most responsible officials who should receive correspondence from FDA.*

1.经营历史及任何合作经营

2.应该收到FDA回应的主要负责人的名字,称呼以及完整的通信地址。

3. A list of APIs manufactured (or categories of products if many) along with the general manufacturing process for each (for example, chemical synthesis non-sterile, fermentation, extraction of natural products, etc.).

3.生产的API产品列表(如果众多的话则列出种类)以及每个产品(例如,化学合成的非无菌产品,发酵产品,植物提取产品等)的一般生产过程

4. *For foreign API manufacturers, the names, titles, complete mailing address, telephone and Fax number of the firm's U.S. Agent, Regulatory Agent, and/or Importer/Broker.*

4.*对于海外API制造商,要有美国代理,注册代理或/和进口商/经纪人等的名称,完整的通信地址,电话及传真号。

5. *For foreign API manufacturers, a report of all active pharmaceutical ingredients imported into the United States in the last three years, their consignees, and an estimate of the frequency and quantity of shipments to these consignees.* 5.*对于海外API制造商,一份关于过去三年进入美国市场的活性药物成分的报告,它们的承销商以及对这些承销商运输的频率和质量的评估。

6. A description of areas/processes inspected (i.e., what areas, systems and processes were inspected, who was interviewed, what manufacturing activities were ongoing during the inspection).

6.对所检查区域/进程的描述(如,什么区域,系统和工艺被检查了,与谁面谈,在检查中进行了什么生产活动等)

7. A description of any non-drug manufacturing activities conducted by the firm, such as processing pesticides or other toxic chemicals. If non pharmaceuticals are processed in the same facility and/or equipment with APIs, report precautions taken by the firm to prevent or minimize the potential for crosscontamination.

7.对厂家进行的任何非药品生产活动进行描述,比如农药或别的有毒化学品的生产。如果非药品是在与生产API 相同的设备或/和装置中生产的,则要报告厂家对避免或减少交叉污染所采取的措施。

8. A description of all API micronizing or milling operations, whether conducted in-house or by a contract micronizer. Fully describe the precautions taken by the firm to prevent or minimize the potential for cross-contamination. During inspections of contract micronizers, obtain a complete list of all active pharmaceutical ingredients micronized and report the source (owners) of these materials.

8.对厂家进行制粒或磨粉的操作,不管它是由企业内部操作还是委托加工粉碎都要进行描述。对厂家所采取的避免或减少潜在的交叉污染的措施要进行完整地描述。对于委托加工粉碎,要拿到一份完整的关于所有的进行粉碎操作的活性药物成分列表并要报告这些物质的来源(所有者)

9. *A copy of the firm's process validation protocol. Report the status of all validation efforts. If not completed, obtain and submit the firm's written timetable showing when process validation will be completed.*

9.*厂家工艺验证方案的复印件。报告所有验证结果的状态。如果没完成,则要取得并提交厂家的书面报告时间表并且表明工艺验证将于何时完成。*

10. A report of any adverse findings as required by the Investigations Operations Manual (IOM).

10.任何与检查操作指南(IOM)不符的调查结果报告

SAMPLING

1.A profile sample of the active pharmaceutical ingredient should be collected for analysis by the Forensic Chemistry Center, FCC (HFR-MA500) and Northeast Regional Lab (NRL). These samples of the API

should not be confused with profile samples of actives collected together with finished product samples

under the Pre-Approval Inspections/Investigations Compliance Program, CP 7346.832。

取样

1.应收集一份活性药物成分的样品用于提供给法医化学中心,FCC(HFR-MA500)以及东北地区实验室(NRL)进行分析。这些API的样品不应与批准前检查/调查合格程序所收集到的终产品相混。

Depending upon the cost, the sample should consist of 25 - 50 grams of active drug substance from three different lots, collected in duplicate. Documentation that should accompany the sample must include:

- A flowchart and brief narrative description of the API manufacturing process;

- A material safety data sheet for the active pharmaceutical ingredient;

- A Certificate of Analysis *(COA)* for each lot; *in addition, a description of the computer system that was utilized to generate the COA and the precautions taken by the firm to safeguard the integrity of the computer data against employee manipulation.*

- A copy of any potential/established impurity profiles and applicable methodologies;

- The analytical methodology (if the inspection involves a new chemical entity).*

考虑到成本,所收集的样品应该包含从三批活性药物原料药中收集到的25-50g的两份样品。随样品一起的文件中应该包括以下内容:

-一份API生产过程的流程图以及简单描述。

-一份活性药物成分的材料安全数据

-每批的化验单(COA)。另外,还需对用于开出化验单的计算机系统以及厂家为保证计算机数据的安全针对员工操作采取的预防措施进行描述。

-对于任何潜在的/已建立的杂质状况以及所应该的方法的复印件

-分析方法(如果检查涉及到一个新分子实体)

2. *During foreign inspections, it is often difficult for the investigator to collect profile samples of APIs. If a sample is not collected, the investigator should identify the lot (s) to be sampled and instruct the manufacturer to collect and ship the sample and applicable records directly to the FCC. The FCC will prepare an annotated collection report and forward the duplicate portion and copy of records to the NRL. An information copy will also be sent to the lead investigator.* 2.*在海外检厂期间,检查官通常很难收集到API的全部样品。如果样品没有收集,则检查官应该确定要取样的批(批次)并告诉生产商收集好并将样品以及申请表直接递交给FCC。FCC将会准备一份带注解的收集报告并会把副本及记录复印件转给NRL。一份相关信息副本也将会送达主检查官手中*

3. *When collecting samples for profile analysis, protect these from trace contamination. In all instances, avoid using metal spatulas. Use a plastic container and closure for sampling and submit an empty container as a control sub. If a plastic spatula is used, also submit an unused spatula as a sub-sample. Identify each container with the sample number, the product name and lot number, manufacturer, date and initials of the sampler. Wear disposable, talc-free, polyethylene gloves during the sampling activity. The preferred sampling method is by direct transfer and replacing the gloves between each subsample. Multiple product lots may be submitted under one collection report.*

3.*当收集样品作简要表分析时,要避免受到轻微污染。所有情况下都要避免使用金属刮刀。用一个塑料的容器和包装来取样并提交一份空的包装以做为控制物质。如果使用到了塑料刮刀,也要提交一个没用过的刮刀作为物质样品。用样品号,产品名称以及批号,生产者,取样日期及取样者的字母来标示每个包装。在取样中要配戴一次性使用的,无滑石粉的,聚乙烯的手套。较好的取样方法是通过直接传递的方法并且在每次取样的时候都要更换手套。多个产品批号应该提交在同一份报告中。

4. To establish a labeling/container forensic data base, obtain the following information during inspections of foreign API firms. Identify this information with the firm's name, central file number (CF Number), and street address and send to *FDA/FCC, Bulk Drug Group, HFR-MA500, 1141 Central Pkwy., Cincinnati, Ohio 45202.*

4.为了建立一份标签/包装法医数据库,则在对海外API厂家检厂时要获得以下信息。用厂名,中心文件编号(CF 号)以及地址等信息来标识这个信息并且把它送到*FDA/FCC,Bulk Drug Group, HFR-MA500, 1141 Central Pkwy., Cincinnati, Ohio 45202.*

https://www.360docs.net/doc/6812093142.html,plete telephone and FAX number;

a. 完整的电话及传真号

b.Contact person with title;

b. 联系人及称呼

c. *Decoding of the *lot/batch numbering system;

c.*批/批号系统的解析

d.*List* of the actual quantities of each lot of API produced for the last three years. Explain any difference between

the batch and lot number. The records should reflect the total quantity *produced* and the amount shipped to the U.S.

d.过去三年所生产的每批API的实际数量的列表。解释批与批号之间的任何不同。记录应该反映出生产总量

以及运输到美国的数量。

e. Description *and/or* specimen of the container closure systems *(if easily obtained)* for APIs intended for U.S.

distribution, as domestic packaging is often different:

1) Description *or photograph* and dimension of the container. If the container is plastic, list the color.

What is the composition of the container bottom/lid?

2) Description *or photograph* of closure system. Is the lid sealed with a crimped

seal? If so, briefly describe the seal and whether it contains any unique identifier. Some companies will have

a product and/or company code visible in the crimped lead seal.

3) Provide a brief description *or photograph* of inner packaging (double or single plastic bag) and method

of inner bag closure.

4) Provide an actual label specimen for each exported API *if easily obtained*. Has the label design

changed since 1991? If so, briefly describe. Does the labeling or

packaging contain any unique identifiers (i.e., embedded water marks)?

e.由于国内分装通常是不一样的,因此要说明并且/或者对卖到美国市场的产品包装系统进行取样(如果很容

易得到的话):

1)对容器的尺寸进行照相或进行描述。如果容器是塑料的,列出颜色。这个容器的底部及盖子是由什么组成的?

2)对包装系统进行拍照或说明。顶盖是否有胶圈密封?如果有,则不管它是否包含有任何唯一标识都要简单地描述密封圈。一些公司可能会拥有一个产品或/和公司代码在密封圈上标识出来。

3)对内包装(双层或单层塑料袋)进行描述或拍照,并说明内包装的包装方法。

4)如果很容易拿到的话,则对每一个出口的API都要提供标签样张。从1991年后标签设计是否有改变?

如果是,则简单地说明。标签或包装是否有唯一的标识(如是否嵌入水印)?

NOTE: Items (4.) (a - d) should be determined during the inspection. However, unless the firm has prepared summary reports that contain the information for (4.) (e), it is likely the data will not be available before completion of the inspection. This might also be true for (4.) (f) and other items. If so, provide the firm with a copy of Appendix B and obtain a commitment from a responsible individual stating when the information will be sent to FCC. Shipment by overnight carrier is recommended.

注意:第4项(a-d)中应该在检查中确定。然而,除非厂家对包含有(4)(e)项的信息的小结报告进行了准备,否则在检查中不可能获得这些数据。而这个对于(4)(f)项以及别的项来说也是如此。如果是这样的话,对厂家提供附录B的复印件并且要取得负责人的授权信以说明这些信息将会于何时交到FCC。推荐通过隔日递送来传递这些文件。

5. Collect samples to document any suspected adulteration and misbranding problems encountered during the inspection. Collect physical samples for suspected identity, potency, decomposition, contamination and/or labeling problems.

5.收集样品以证明任何在检查当中所遇到的掺杂及帖错标签问题。对所怀疑的鉴别,潜在性,分解或/和标签问题收集实际样品。

6. During foreign inspections, collect copies of analytical methods used by API manufacturers that are not from the United States Pharmacopeia. We do not have access to the pharmacopeial standards of other countries.

6.在海外检厂过程,收集API生产厂家采用的分析方法的复印件而不是美国药典的复印件。我们并不接受别的国家的药典标准。

7. If cross-contamination is suspected, collect samples of the API and samples of the materials that are the suspected

contaminants. Include with the Sample Collection Report (C/R) a description of the suspected route of contamination, or mechanism by which it is believed that contamination could have occurred. Any sample collected to document

cross-contamination must be protected from contamination during or as the result of collection.

7.如果被怀疑有交叉污染问题,收集API样品以及所怀疑的污染物的样品。在样品收集报告(C/R)中要包括一份对污染途径或者机制的描述以说明污染可能发生。任何所收集的来说明交叉污染的样品在收集过程或结束过程中都必须保护以避免再受污染。

PART IV - ANALYTICAL

ANALYZING LABORATORIES

1.Routine chemical analyses - For sample collections under PACs 56002F, 52R806, 56008A, and 56008H follow the

Servicing Laboratories guidance in the applicable compliance programs *and the ORA workplan*.

第四部分-分析

分析实验室

1.常规的化学分析—对于PACs 56002F, 52R806, 56008A, and 56008H中收集到的样品,按照适用的顺应性程序以及ORA工作计划中的实验室服务指南来操作

2.Routine Microbiological examinations - For sample collections under PACs 56002F and 56008A, follow the

Servicing Laboratories guideline in the applicable compliance programs *and the ORA workplan. *The current testing laboratories are ATL, MIN, NYK, DEN and SAN.*

2.常规微生物检测—对于PACs 56002F and 56008A中所收集到的样品,按照适用的顺应性程序以及ORA工作计划中的实验室服务指南来操作。当前的检测实验室是ATL, MIN, NYK, DEN 以及SAN。

3.Chemical cross-contamination analyses by mass spectrometry (MS) - NRL, DAL, SRL, DET, DEN, and LOS.

Non-mass spectrometry laboratories should call one of their own regional MS labs and/or the Division of Field Science (HFC-140) to determine the most appropriate MS lab for the determinations to be performed.

3.化学交叉污染分析可通过质谱(MS)来分析- NRL, DAL, SRL, DET, DEN, 以及LOS等实验室来分析。非质谱实验室应该让他们所在地区的MS实验室或/和Division of Field Science(HFC-140)来决定哪个MS实验室最适合来进行该项分析。

4. Antibiotic analyses:

a. Penicillin by cylinder plate method: All laboratories listed in paragraph number 2 above (microbiological examinations).

b. Other microbiological-based antibiotic analyses: DEN

c.Chemical analyses: NRL, BLT *(PHI after 12/99)*, DEN.

4.抗生素分析:

a.青霉素通过圆盘分析法来检测:上面第二段中列出的所有实验室都可以进行该项分析(微生物检测)

b.别的基于抗生素检测的分析:DEN

c.化学分析:NRL, BLT *(PHI after 12/99)*, DEN.

5. Bioassays (such as insulin and heparin tests):

-Division of Research and Testing (HFD-470)

5.生物测定(比如胰岛素和肝素检测):

- 研究和检测部(HFD-470)

6. Profile Analysis of API's:

- Quality Test Analysis of Bulk Pharmaceuticals (PAC 56008A) and Bulk Import Samples Collected at Domestic Manufacturers for Quality (PAC 56008H)

*Northeast Regional Lab (NRL): [NMR, MS, UV, IR]*

850 3rd Ave.

Brooklyn, NY 11232-1593

*Contact: Alfred C. King

Tel: (718) 340-7000 (Extension 5067)

FAX: (718) 340-7003

- Counterfeit Drug Analysis (PAC 56008A) and Bulk Import Samples Collected at Domestic Manufacturers for Fingerprinting (PAC 56008H)

Forensic Chemistry Center (FCC)

1141 Central Pkwy.

Cincinnati, Ohio 45202

*Contact: Either Robert Sharpnack (Ext.114) or Karen Wolnik (Ext.181)

Tel: (513) 684-3505

FAX: (513) 684-6082

6.API的简要分析:

-对原料药的质量检测分析(PAC56008)以及在国内厂家收集的进口原料药样品的质量分析(PAC-56008H)是由以下实验室来检测的:

*Northeast Regional Lab (NRL): [NMR, MS, UV, IR]*

850 3rd Ave.

Brooklyn, NY 11232-1593

*Contact: Alfred C. King

Tel: (718) 340-7000 (Extension 5067)

FAX: (718) 340-7003

-仿制药分析(PAC56008A)以及在国内厂家收集的进口原料药样品的指纹分析(PAC56008H)是由以下实验室来检测的

Forensic Chemistry Center (FCC)

1141 Central Pkwy.

Cincinnati, Ohio 45202

*Contact: Either Robert Sharpnack (Ext.114) or Karen Wolnik (Ext.181)

Tel: (513) 684-3505

FAX: (513) 684-6082

ANALYSIS

1. Examine samples for compliance with applicable specifications. Perform check analyses using the official compendial method, or when no official method exists, by other validated analytical procedures.

See Compliance Policy Guide (CPG) 7152.01.

分析

1.检测样品与申请规格的一致性。采用官方认可的方法来进行分析,或者如果没有官方的方法,则通过验证过的分析方法来检测。

见顺应性政策指南(CPG)7152.01

2. Confirm the presence of cross-contamination by a second method such as MS, UV, or IR. If a chromatographic procedure was used for the initial analysis, a second chromatographic method (HPLC, GC, TLC, etc.) may be employed provided the separation mechanism is different from that of the initial method.

2.采用如质谱,紫外或红外等二级方法来进行交叉污染的检验。如果一色谱方法在最初的分析中已经采用,则I 不同于最初的检测方法的二级的色谱方法(HPLC,GC,TLC等)可以用来进行分离检测.

3. Microbiological examinations should be based on appropriate sections of the United States Pharmacopeia (USP 23),

B.A.M., 7th Edition, and A.O.A.

C., Chapter 17.

3.微生物检测应该按照美国药典(USP23)中的相应章节,B.A.M,第7版以及A.O.A.C,第17章的要求进行.

https://www.360docs.net/doc/6812093142.html,P testing methods may not be appropriate for detecting impurities generated from the synthesis routes of foreign

source APIs. Therefore, foreign source APIs should have impurity limit tests based on their synthesis. If this

information is lacking, contact the Division of Field Science (DFS) at 301-443-3007 for assistance.

https://www.360docs.net/doc/6812093142.html,P检测方法有可能并不适用于用来检测那些海外API生产商的合成路线中产生的杂质.因此,海外来源的的API 应该有基于它们合成方法的杂质限度检测。如果这些信息缺少,则致电Division of Field Science(DFS)

301-443-3007以获得帮助。

PART V - REGULATORY/ADMINISTRATIVE STRATEGY

*All Warning Letters with CGMP charges involving domestic active pharmaceutical ingredient manufacturers require CDER review and concurrence. See Chapter 4, Page 81, of the August 1995 FDA Regulatory Procedures Manual and Chapter I, Page 15, of the October 1994 ORA Warning Letter Reference Guide.*

第五部分—注册/管理策略

*所有涉及国内活性药物生产厂家的带有CGMP指控的警告信都要求CDER的审查与许可。见1995年8月出版的

FDA 注册程序手册(FDA Regulatory Procedures Manual)中的第4章,第81页以及1994年10月出版的ORA 警告信参考指南(ORA Warning Letter Reference Guide.*)中的第Ⅰ章第15页。

Send Warning Letter recommendations to CDER's Office of Compliance, Division of Manufacturing and Product Quality (HFD-320). Warning Letters to foreign API manufacturers will issue from CDER_s Division of Manufacturing and Product Quality, HFD-320.

将警告信建议书提交给CDER的Compliance 管理处,制造和生产质量部(HFD-320)。对海外API厂家的警告信将会从CDER的制造和生产质量部,HFD-320发出。

When recommending regulatory action, keep in mind that the CGMP regulations (21 CFR 210 and 211) do not apply to the production of active pharmaceutical ingredients (APIs) intended for further manufacturing. Nonetheless, the definition of "drug" in the Federal Food, Drug, and Cosmetic Act encompasses APIs and Section 501(a)(2)(B) of the Act requires that all drugs be manufactured, processed, packed, and held according to current good manufacturing practices. The Act makes no distinction between APIs and finished pharmaceuticals and failure of either to comply with CGMPs constitutes a violation of the Act.

当进行注册行动时,要记住CGMP条例((21 CFR 210 and 211)并不适用于那些要进一步制造的活性药物成分的生产过程。不过,联邦食品,药品和化妆品法规中对于“药品”的定义包含有API,而且,法规501(a)(2)(B)部分也要求所有被加工,生产,包装和持有的药品都应该按照当前优良质量管理规范来进行。法规并没有对API和药品进行任何的区别对待,因此不符合CGMP的行为都被认为是违背了法律。

Because of the lack of a GMP regulation specific to APIs, any regulatory action based upon CGMP noncompliance for APIs must closely relate the deviations with actual or potential product defects, product contamination, or product cross-contamination, more so than for finished pharmaceuticals. In addition, consider the critical product attributes of the API, its therapeutic significance, and intended use in finished drug products when recommending regulatory action.

因为缺少针对API的GMP管理条例,任何基于CGMP的管理条例如果不适用于API都必须地将偏差与实际的或可能的生产缺陷,产品污染或产品的交叉污染相联系,而这些联系要比药品要紧密得多。另外,在制定管理条例时要考虑API的关键产品属性,它的治疗意义以及在最终药品中的应用。

The following list represents examples of deficient practices that CDER believes may warrant issuance of Warning Letters, withholding application approvals, or other appropriate regulatory actions:

1. Contamination of APIs with filth, objectionable microorganisms, toxic chemicals, other chemicals, drug residues, or a reasonable potential for contamination (with demonstrated avenues of contamination) such as airborne contamination or product contact with unclean equipment.

以下列举说明了CDER认为的可能会发出警告信,扣留申请批准或者别的相应的管理措施的有缺陷的实际过程:1.将API中混入污物、令人讨厌的微生物、有毒化学品、别的化学物质、药品残留或者别的如空气污染或产品接触到了不洁容器而可能存在的污染(具有可见的污染途径)

2. Failure to show that API batches conform to established specifications, such as NDA, USP, customer specifications, and label claims. See Compliance Policy Guide (CPG) 7132.05.

2.不能证明API批能符合所建立的规格,比如NDA,USP,客户规格以及标签所标规格。见Compliance Policy Guide(CPG)7132.05。

3. Failure to comply with commitments in drug applications, including Drug Master Files (DMFs). These documents should be current and accurately reflect the current synthesis process, impurity profile, and other specifications or procedures associated with the manufacture of the API.

3.不能符合药品申请书包括在药物主文件(DMF)中所宣称的内容。这些文件应该是现行的并且能正确反映出当前的合成过程,杂质状况以及别的与厂家生产API相关的规格或操作。

4. Distribution of an API that does not conform to established specifications.

5.*Failure to determine actual yields and percentages of expected yields at the conclusion of appropriate phases of

manufacturing, processing, packaging, or holding of APIs.*

4.一个API的发放与所建立的规格不符

5.在加工,生产,包装或持有API的相应阶段进行总结时实际的收率及理论收率百分率不能确定。

6.Deliberate blending of API batches to dilute or hide filth or other noxious contaminants, or blending of a batch that

does not conform *with critical product attributes* with one meeting specifications in an attempt to obtain one blended batch meeting minimum specifications.

6.故意对API进行混批以冲淡或隐藏污垢或别的有毒污染物,或者将不符合关键产品属性的批与合格的批次相混合试图获得符合最低要求的合格批。

7.*Failure to demonstrate that process water used in the manufacture of active pharmaceutical ingredients is suitable

for its intended use and does not adversely alter the quality of the API.*

7.缺乏生产活性药物成分所用的工艺用水是适合它的要求并且不会改变API的质量的证明。

8.*Failure to validate reverse osmosis, ultrafiltration, deionized water, and distilled water systems that produce

process water used in the final isolation and purification steps of non-sterile and sterile APIs.*

8.对产出用于非无菌及无菌API最终的分离和纯化步骤的工艺用水的诸如反渗透,超滤,去离子水以及蒸馏水等水系统缺乏验证

9. Lack of a formal written program to validate API manufacturing processes or failure to follow a validation program. The FDA expects API manufacturers to be actively engaged in a validation program for all APIs and *to complete process validation in an expeditious manner in accordance with timetables stipulated in protocols and commitments made to the Agency.* Therefore, regulatory action should not be initiated where the firm has an adequate API validation program in place, including reasonable milestones, and is following the plan.

Regulatory action should be initiated, however, when:

(1) the firm has not established or is not following an adequate plan to validate all APIs;

OR

(2) there is evidence that an API process is not *valid* as demonstrated by repeated batch failures (product

non-conformance) due to manufacturing process variability not attributable to equipment malfunction or operator error. Refer to Compliance Policy Guides 7132c.08 and 7125.38.

9.缺乏正式的书面的生产工艺验证方案或者没有进行随后的验证程序。FDA希望API生产厂家积极地参与所有的API的验证程序并且以所期望的方式按照提交给FDA的方案或讨论中所制定的时间表完成工艺验证。因此,如果厂家拥有一个合适的充分的API验证,包括合理的进程并且正在按计划进行的话,则整改将不会发生

但如果发生以下情况时,则有可能要进行整改:

(1)厂家没有建立或没有按合适计划来验证所有的API;或者

(2)由于生产工艺的易变性而非设备故障或操作失误导致的重复批生产中失败(产品不合格),因此有证据表明这个API工艺是无效的

参见Compliance Policy Guides 7132c.08 and 7125.38.

10. *Conducting a retrospective process validation for an existing API process when the process has changed significantly, when the firm lacks impurity profile data, or when there is evidence of repeated batch failures caused by process variability.*

Retrospective validation may be acceptable if:

- critical product attributes and critical steps in API processes have been identified and

documented

- adequate in-process specifications and controls for critical processes have been established and documented

- there have been no significant changes to the manufacturing *components*, equipment or processes that could adversely affect the critical quality attributes of the API or the critical process parameters that affect these product quality attributes

- there are few process/product failures attributable to process variability

- complete impurity profiles have been established for existing API processes

- in-process and end-product test data show lot-to-lot consistency

10.*对于一个存在的API工艺,当工艺发生明显更改,或当厂家缺乏杂质状况数据或当由于工艺更改而导致重复性的批生产失败的时候,要对它进行回顾性工艺验证。

如果符合如下几点,则进行回顾性验证是可以接受的:

-API工艺中的关键产品参数及关键步骤已经确定并存档

-对关键工艺有足够的工序间规格及控制并且这些规格及控制都已经建立并存档

-对于会明显影响到API关键属性的生产组成,设备或工艺或关键工艺参数都已经没有显著改变

-很少有产品或工艺的失败是因为工艺改变而导致的

-对于存在的API工艺具有完整的杂质研究

-工序间及终产品的测试数据表明了批与批之间的一致性

11. Failure to demonstrate homogeneity of final blending/mixing operations in API processes where particle size distribution, surface area, or other physical attributes of the active pharmaceutical ingredient are critical to the dissolution and bioavailability of finished drug products. *Do not apply guidance intended for the blend uniformity of finished pharmaceuticals.*

11.在API工艺中的混粉/混合操作中,活性药物成分的质粒分布,表面积或别的对于药品成品的溶解性及生物利用度很关键的物理性质缺乏均一性。

12. *Failure to establish an impurity profile for each API process. FDA expects manufactures to establish complete impurity profiles for each API as part of the process validation effort. This includes collecting data on (1) actual and potential organic impurities that may arise during synthesis, purification, and storage of the API; (2) inorganic impurities that may derive from the API process; and (3) organic and inorganic solvents used during the manufacturing process that are known to carry over to the API.

Impurity profile testing of each batch or after a specified number of batches may detect new impurities that may appear because of a deliberate or nondeliberate change in the API manufacturing process.*

12.对每个API工艺没有建立杂质状况研究。FDA希望生产厂家对每一个API都要建立完整的杂质状况研究并作为工艺验证的一部分内容。包括在以下方面收集数据:(1)在合成,纯化及贮存API时产生的实际的及潜在的有机杂质;(2)API生产过程中可能产生的无机杂质以及(3)已知会被带到API成品中的生产过程中所用到的有机或无机的杂质。每一批的杂质项测试或者对于规定的批次都应该检测那些由于有意或无意的API工艺更改中可能出现的新的杂质。

13. *If reprocessing of APIs is performed and the manufacturer lacks data to show that reprocessing of API batches results in a product that complies with all established standards, specifications, and characteristics.*

13.如果对API进行了返工并且厂家缺乏相应的数据表明返工的批次产品的结果符合所有建立的标准,规格以及性质。

14. *Failure to test for residues of organic/inorganic solvents used during manufacturing that may carryover to the API using analytical procedures with appropriate levels of sensitivity.*

14.对生产中使用到的有可能被带到API中的残留的有机或无机溶剂没有采用具有合适灵敏度的分析方法进行检测

15. *Failure to have a formal process change control system in place to evaluate changes in components, facilities, support systems, equipment, processing steps, and packaging materials that may affect the production and quality of APIs.*

15.在评估组成,设施,维护系统,设备,生产步骤以及包装材料等会影响到API的产量及质量等的参数改变时缺乏正式的适当的更改控制系统

16. Failure to keep adequate batch records, including:

- Date (s) manufactured

- Quantity manufactured

- Lot number

- Test results and dates

- Labeling records and specimen of labels used

- The signature of person (s) responsible for accomplishing significant steps, including:

- determining yields

- examining labeled containers for correctness of labels

- testing for conformance to specifications

- blending, if required

- assuring conformance with established manufacturing procedure

- reviewing production and testing records and authorizing release for distribution

16.没有很好地保存足够的批生产记录,包括以下几点:

-生产日期

-产量

-批号

-检测结果及日期

-标签记录及所用的标签样本

-完成重要步骤时负责人的签名,包括:

-确定的产率

-检查贴标签处有正确的标签

-检测符合规格

-混批,如果需要的话

-确保与建立的生产规程相符

-审查和产和检测记录以及对放行进行授权

17. Failure to record distribution by lot number in a way that would permit prompt recall.

17.没有按批号来记录放行,在某种程度上会允许召回能有效进行

18. *Incomplete stability studies to establish API stability for the intended period of use, and/or failure to conduct forced degradation studies on APIs to isolate, identify and quantify potential degradants that may arise during storage. Expiration dates are not required, except for antibiotics, radiopharmaceuticals, and other APIs with expected expiry dates of two years or less.*

18.没有做完稳定性研究以评估API在以后阶段中使用时的稳定性,并且/或者没有对API进行强降解实验以对贮存过程中产生的潜在的降解产物进行分离,鉴别和定性。除了对抗生素,放射性药物以及别的希望的有效期在两年或以内的API以外,对别的API没有要求失效日期,

19. Use of laboratory test methods that are inadequate or have not been validated.

19.所使用的实验检测方法不充分或者没有验证过

20. *If there is a USP reference standard, failure to test each lot of an in-house (secondary reference standard) against the U.S.P primary reference standard before use.*

20.*如果有USP的对照品,对每一批的企业(二级对照品)标准品在使用前缺乏检测

21. Conducting packaging and labeling operations in a way that introduces a significant risk of mislabeling.

21.进行包装和贴标签时在某种程度上会有明显的贴错标签的危险

22. *Failure to submit to FDA a list of every drug, including APIs, in commercial distribution. In the case of foreign drug firms, failure to list all drugs imported or offered for import into the United States.

Refer to 21 CFR 207.40 for additional information on drug listing requirements for foreign drug establishments.* 22.没有向FDA递交在商业放行区的每个药品的列表,包括API的列表。如果是海外生产厂家,没有列出所有进口或提供进口到美国的所有药品。

对于海外药品供应商的药品列表要求的进一步的信息请参见21 CFR 207.40

PART VI - REFERENCE, ATTACHMENTS AND PROGRAM CONTACTS REFERENCES OR GUIDES

1. September 1991 FDA Guide to Inspection of Bulk Pharmaceutical Chemicals,

*Reformatted May 1994 with minor editorial changes*

2. FDA Guide to Inspections of Sterile Drug Substance Manufacturers, July 1994

3. FDA Biotechnology Inspection Guide, November 1991

4. FDA Guideline for Submitting Supporting Documentation in Drug Applications for the

Manufacture of Drug Substances, February 1987

5. FDA Regulatory Procedures Manual, Chapter 8-10

6. FDA Office of Regulatory Affairs Warning Letter Reference Guide, October 1994

7. Chapter 15, GWQAP Manual, revised August 1991

8. Drug Process Inspection Compliance Program, CP 7356.002

9. "Process Validation Requirements for Drug Products Subject to Pre-Market Approval,"

Compliance Policy Guides 7132c.08 and 7125.38, dated August 30, 1993

10. "Performance of Tests for Compendial Requirements on Compendial Products,_

Compliance Policy Guide (CPG) 7132.05, issued October 1, 1980

11. The United States Pharmacopeia/National Formulary (USP 23/NF 18), including

supplements.

12. *Draft Guidance for Industry - Manufacture, Processing or Holding of Active

Pharmaceutical Ingredients, released for discussion purposes on September 20, 1996.*

PROGRAM CONTACTS:

Office of Regional Operations (ORO)

1. *Division of Emergency and Investigational Operations, Drug Group

(HFC-130), ORO/DEIO

Telephone: (301) 827-5653

FAX: (301) 443-6919*

2. Division of Field Science (HFC-140), ORO/DFS

Telephone: (301) 443-3007

Office of Enforcement (OE)

1. Medical Products Quality Assurance Staff (HFC-240), OE/MPQAS

Telephone: (301) 443-3590

Center for Drug Evaluation and Research (CDER)

1. For questions relating to product quality, the application of CGMPs, and validation

of active pharmaceutical ingredient processes contact:

Edwin Rivera Martínez, Rick Friedman, or Patricia Alcock

Foreign Inspection Team, HFD-322

Division of Manufacturing and Product Quality, Office of Compliance

Telephone: (301) 594-0095

FAX: (301) 594-2202 or (301) 827-0145

Office of Regulatory Affairs (ORA)

1. *For questions on profile sampling of APIs contact:

Food and Drug Administration

Forensic Chemistry Center (HFR-MA500)

Telephone: (513) 684-3505, FAX: (513) 684-6082

Contact either Robert Sharpnack (Ext.114) or Karen Wolnik (Ext.181)*

PART VII- CENTER RESPONSIBILITIES

See Drug Process Inspection Compliance Program, 7356.002.

APPENDIX A

附录A

The September 1991 Guide to Inspections of Bulk Pharmaceutical Chemicals lists various topics/areas that must be covered when conducting API inspections, to include the following:

在1991年9月出版的化学原料药检查指南中列出了很多在进行API检厂时要覆盖的内容,包括如下:

A. Inspection

1. Buildings and Facilities

- control of contamination/cross contamination

- water systems and suitability of process water for its intended use or specific synthesis step (i.e., whether used in early steps or later purification steps of a multi-stepAPI process)

-aseptic/sterile processing, if applicable (Refer to CP 7356.002A)

A.检查

1.厂房及设施

-对污染/交叉污染的控制

-水系统以及适用于进一步使用的或特定的合成步骤的工艺用水(如,在一多步API过程中,是用在早期还是用在后期纯化步骤中)

-防腐/无菌过程,如果要涉及到的话(参见CP7356.002A)

2. Equipment

- Multi purpose equipment

- cleaning and use logs

- located outdoors

- protected environment

- cleaning of product contact surfaces, including validation of equipment cleaning

procedures

2.设备

-多用途设备

-清洗和使用记录

-置于户外的

-环境保护

-对产品容器表面的清洗,包括设备清洗验证过程

3. Personnel training, qualifications, experience

3.人员培训,人员资格,经验

4. Raw Materials/Components and Intermediates

- storage/handling practices and controls over quarantined, released, and rejected

materials

- adequacy of specifications, and sampling/testing to determine conformance to

specifications

4.原材料/组成以及中间体

-贮存/处理操作以及对隔离、发放及拒收的控制

-合适的规格,以及取样/检测以决定是否符合规格

5. Production and Process Controls

- controls involving reuse of mother liquors

- validation of final API blending and mixing operations for API processes where particle size distribution, surface area, or other attributes of the active pharmaceutical ingredient are critical to the dissolution and bioavailability of finished drug products

- validation of API process and control procedures, with special emphasis on critical

process steps and synthesis and purification steps in the later stages of the API process that result in the formation of the active pharmaceutical ingredient or the removal of impurities

- procedures for reprocessing of APIs and types of reprocessing conducted (i.e.,

repeating a crystallization step), including whether these have been approved in the firm's

application or DMF

- process change control system

- characterization and control of impurities

- API micronizing/milling procedures, including precautions to prevent cross-contamination

5.生产和过程控制

-对母液再利用的控制

-因为质粒分布,表面积或别的对活性药物成分性质对于药品成品的溶解性以及生物利用度有关键性影响,因此需要对API成品混粉的以及混粉操作过程进行验证。

-对API工艺及控制操作进行验证,特别要对关键操作步骤以及在形成活性药物成分的或除去杂质的较后的合成及纯化步骤要进行验证。

-API返工操作以及返工类型(如,重复纯化步骤),包括这些是否是厂家的申请书或DMF中的内容

-工艺更改控制程序

-杂质的定性及控制

-API微粒/粉碎过程,包括避免交叉污染的预防措施

6. In-process Testing

- suitable batch sampling procedures employed and documented

- specified tests performed, recorded and within limits

- adequacy of instrument calibration procedures

6.中间工序检测

-使用的以及归档的合适的批取样程序

-所应用的,记录的特异检测以及内部限度

-合适的仪器校正过程

7. Packaging and Labeling Operations

- labeling controls

- lot numbering system

- conformance with labeling regulations

7.包装及贴标签操作

-标签控制

-批号系统

-标签一致性

8.expiration Dating/Re-Evaluation Dating Practices

8.失效日期/再评估日期操作

9. Laboratory Controls

- ability to conduct tests, adequacy of records

- adequacy of sampling/testing for raw materials, intermediates, and finished products, including tests for impurities in APIs

- drug reference standards (source, test results, equivalency with official standards)

- validation of analytical methods, as appropriate

- firm's performance of follow-up on unexpected analytical results to determine cause and make any necessary corrections (such as additional chromatographic graphic peaks, retention-time shifts, spectrophotometric maxima peaks, or melting point range changes)

- firm's quality assurance procedures for instruments and other laboratory equipment

FDA现场检查行业指南(中英文对照)

FDA行业指南 -药品现场检查中被认为是延迟、否认、限制或拒绝的情形

一、介绍 2012年7月9日,《美国食品和药物管理局安全及创新法案》(FDASIA)被签署成为法律。FDASIA章节707添加了501(j)到《食品、药品和化妆品法令》(FD&C Act),认为“任何从事生产、加工、包装或持有的生产企业、库房造成现场检查的延迟、否认、限制或拒绝的情况均被认为该产品为假劣药品”。该指南的目的是对“延迟、否认、限制或拒绝”的情形进行定义。 二、定义 1、延迟 A、检查计划安排的延迟 FDA将会根据当地的情况对检查计划进行适当的调整,例如天气、安保、节假日、其他非工作日、企业的生产计划等。以下延迟的情况将会被认为产品是假劣药品,包括但不仅限于: ●企业不同意建议的检查日期,但没有合理的解释。 ●在检查安排后,企业要求延迟检查日期,但没有合理的解释。

●企业不能回答为什么FDA联系不上企业指定的联系人。 下面给出了将不会被认为是假劣药品的潜在合理解释的一个例子,但不仅限于: ●企业没有正在生产,例如每个月只生产一次,企业要求检查日期另定, 以便FDA检查时生产正在进行中。 B、检查期间的延迟 以下检查期间的延迟情况将会被认为产品是假劣药品,包括但不仅限于: ●企业不允许FDA检查官进入某个区域直至一段时间过去之后,即使这个 区域是正在进行操作的并且是FDA有权检查的区域,对于这种行为没有 合理的解释。 ●企业长时间把FDA检查官单独撂在会议室,没有相应的文件或责任人供 审查和询问,从而干扰检查官完成其相应的检查。 下面给出了将不会被认为是假劣药品的潜在合理解释的一个例子,但不仅限于: ●企业不允许FDA检查官进入无菌工艺区域,直至检查官能满足企业的无菌 更衣程序要求。

FDA工厂检查心得

一,做一项工作,首先要问自己为什么做?怎么做?谁来做?什么时间做(包括完成的时间)? 二,评审文件;按QSIT方法——基于7个子系统 4个主要子系统(管理、设计、纠正预防、生产过程);3个支持子系统(文件、物料、生产工具和设备控制);FDA检查工作时会以点带面,抓住一点,可在一个问题上几个来回,也可能检查整个公司的质量管理体系。 三、在FDA官员来工厂检查前公司内部应进行多次的核查和确认;对任何公司来说,通过 FDA验厂最重要的条件是自己要严格执行已经确立的程序和作业流程,文件编制合理性及可操作性当然重要,检查官员对有文件不执行最反感。 四、FDA对工艺过程特别是特殊过程中的一些关键步骤的操作条件、方法及设备进行的验 证(Validation)非常重视。但他们更注重过程控制,应该有的作业指导书一定要准备好; 五、FDA非常重视对生产记录的检查,对原材料的入库、检验及发放、生产工艺过程的控 制、成品的质量检验以及各项重点项目的验证等均要求有完整的原始记录及整套的批记录,FDA官员在工厂检查要任意取样抽查批记录,批记录的真实性与完整性能具体体现工厂的GMP管理的水平。 六、FDA检查官对不合格品和顾客投诉的控制及处理方法、过程及相关的记录非常关注。 七、接待人员回答提问要有技巧,不清楚的事情切忌马上回答,可以先查文件,几个人商量 定下来再回答。更不要“灵机一动”,以为自己应付得了。 八、检查结果:什么都没有得到,这是最好的情况,但这恐怕不太可能。能接到无批评的 483表(无不合格项,只有观察项)已经是相当不错;到于做得不够好的企业也许会接到有批评的483表,这就危险啦,它可能导致:警告信(Warning letter)、自动滞留(Automatic Detention)、QSR扣留、(QSR Hold)撤回(Recall)、直至永久不得进入美国市场。 所以,凡是接美国FDA通知要来工厂的企业务请注意,需要全公司员工的非常重视,全员动员,全力准备,将可能出现的不符合减到最少,才能避免接到警告信 生产现场的标识不在乎以下几个方面: 1.1生产区域的标识。包括生产区域的总平面图,不同洁净级别区域的标志,按定置管理要求划分的 不同区域进入控制区的程序等 1.2生产设备容器和管线的标识,包括设备容器的名称、编号、型号规格和安装日期等,以及用不同 颜色区分不同类型的管线并标明流向。 1.3设备运转状态的标识、标明设备处于生产、清洗还是维修等。 1.4生产过程的各种物料的标识,包括原辅料、包装材料、半成品或中间体和成品的品名、批号、数 量、来源等标识及标明检验状态的标识(待验、合格或不合格) 2.仪器、仪表、量具和衡器的校验 生产和检验的仪器、仪表、量具和衡器等准备与否,关系到工艺参数的控制与检验结果的准确性,如其出现差错,在产品的生产和质量控制中操作者会产生错误的判断,产品质量难以保证,FDA官员对此非常重视,检查中特别关注厂房生产和检验的仪器、仪表、量具和衡器等的管理。

FDA现场检查注意事项

注意事项 永远要讲实话。 这是药厂在针对现场检查的公司声明材料中,必须强调的内容,任何人要回答FDA的问题,都需要进行事先培训知道这些程序和原则。 不要答非所问,超出提问要求回答的内容和范畴。 先考虑好如何回答问题,确信保您正确理解它,并知道如何给出你要的答案。如果您不能确定具体问的是什么,请与调查人员澄清。如果FDA的检查员没有反应,耐心等到他或她作出解释为止。如果FDA检查员对你的回答没有发表评论,等待其作出评论。正常的社交规则不适用现场考察过程。通常情况下,FDA检查员通常会让你等待不耐烦,试图提示您主动谈更多情况。不要中其诱饵。 澄清被要求回答的问题。如果你不明白FDA问什么,试图问清提问的含义或目的。如果这个问题似乎过于宽泛,可以要求FDA更明确具体为题所问。最重要 的是,如果所涉的问题有错误,与检查员澄清问题的范围或给出不妥的理由。 尽力限制钓鱼式的敏捷。美国FDA往往要求你回答很广泛的问题。尽力缩小回 答的范围。例如,如果现场考察人员说,“我想看看您的申诉材料和文件。”你可以回应说:“你要的是哪一年材料?”或想看哪类“产品?”或“您是否正在寻找一个特定类型的投诉?“ 在回答同问题的同时反问FDA检查员问题,可以在 两方面帮助您。首先,您表示出您愿意帮助查看FDA检查员寻找的申诉文件。 其次,检查员无法简单给你回复的是或否的答案,让你更加有数他们到底想看什么。请记住,现场考察人员有权要求所有的档案,但更多情况下是,提出你的问题将有助于完善你的理解和回答。 如果你不知道某一个问题的答案,就坦率这么说。一时不知道答案这没关系。最佳对策是要找到知道问题答案的人或发现这一问题答案,如果适合您这样做的话。

FDA检查员指导手册

Food and Drug Administration Compliance Program Guidance Manual FDA检查员指导手册:7356.002F 56002F- Active Pharmaceutical Ingredient Process Inspections (Drug Quality Assurance) 56002F-原料药生产检查(药品质量保证)

目录 现场检查报告要求 (55) 第I部分背景 (56) 第II部分实施 (57) 第III部分检查 (58) 第IV部分分析 (63) 第V部分法规/行政策略 (65) 第VI部分参考资料,附件和联系接触方式 (68) 第VII部分中心的职责 (69) 附件A (69) 附件B (72)

现场检查报告要求 工艺专论报告 在API检查时,要使用下列的分类进行报告所检查的工艺情况1.Non Sterile API by Chemical Synthesis CSN 化学合成非无菌原料CSN 2.Sterile API by Chemical Synthesis CSS 化学合成无菌原料药CSS 3.Non Sterile API by Fermentation CFN 发酵生产的非无菌原料CFN 4.Sterile API by Fermentation CFS 发酵生产的无菌原料CFS 5.Plant/Animal Extraction API CEX 植物/动物提取原料药CEX 6.Biotechnology API CBI 生物技术生产的原料药CBI

第I部分――背景 至八十年代后期以来,美国食品与药品管理局以强化了其对原料药(API)生产企业的检查内容。从部分方面来说,这归咎于对原料药质量在制剂的质量、效力、和安全方面所起的重要作用认识的提高。例如,在配制成固体口服制剂,混悬剂和局部用药时原料药的化学特性会对制剂的溶出度/生物利用度产生不利影响。另外,原料中的少量没有鉴别出的杂质或其特性未知的杂质会给病人造成的严重不良反应。 FDA长期以来一直认为,收载在制剂药品生产质量管理规范规定(21 CFR 210 and 211)中的CGMP概念对原料药生产工艺同样有效。这些概念包括,与其他一起,产品质量是生产出来的,雇佣能够胜任和经过培训的员工,建立适宜的书面程序和管理规定,建立一套在线测试和产品测试系统,工艺验证,和保证原料药在预期的使用期内质量稳定。 FDA在1991年出版的化学原料药检查指南,在1994年经过少量的编辑变化,包含有原料药生产的GMP/验证概念应用和范围方面的基本指南,并包含了FDA对杂质和杂质专论方面的要求。在对国内和国外原料药进行检查时均必须使用该指南,以促进检查的一致性和均一性。 目前,FDA希望生产企业在API生产的全过程实施CGMP,即从起始原料的使用开始,到对原料药质量和纯度产生影响的关键工艺步骤的验证。该方法认为所需的控制方法完全依赖于实际的生产工艺且随着合成步骤从早期的中间阶段向最终分离和纯化步骤的延伸控制水平也在不断加强。该方法允许依据工艺本身(即,化学合成工艺和发酵工艺)及特殊工艺步骤的风险性和关键性采取适宜水平的控制方法。 该“控制所有步骤,验证关键工艺步骤”方法包含在FDA的《原料药制造,加工和储存指南》草案内,其在1996年9月20日公布供公众讨论。后者可以从CDER的网站下载:https://www.360docs.net/doc/6812093142.html,/cder/api.htm.。

FDA 行业指南 中英对照 待完成

Guidance for Industry Container Closure Systems for Packaging Human Drugs and Biologics Chemistry, Manufacturing and Controls Documentation 行业指南 人用药品及生物制品的包装容器和封装系统:化学,生产和控制文件 指南发布者:美国FDA下属的CDER及CBER 发布日期:May 1999 TABLE OF CONTENTS目录 I. INTRODUCTION介绍 II. BACKGROUND 背景 A. Definitions 定义 B. CGMP, CPSC and USP Requirements on Containers and Closures. CGMP, CPSC和 USP对容器和密封的要求 C. Additional Considerations 其他需要考虑的事项 III. QUALIFICATION AND QUALITY CONTROL OF PACKAGING COMPONENTS包装组件的合格要求以及质量控制 A. Introduction 介绍 B. General Considerations 通常要求 C. Information That Should Be Submitted in Support of an Original Application for Any Drug Product 为支持任何药品的原始申请所必须提供的信息 D. Inhalation Drug Products 吸入性药品 E. Drug Products for Injection and Ophthalmic Drug Products 注射剂和眼科用药 F. Liquid-Based Oral and Topical Drug Products and Topical Delivery Systems 液体口服 和外用药品和外用给药系统 G. Solid Oral Dosage Forms and Powders for Reconstitution 口服固体剂型和待重新溶解 的粉末 H. Other Dosage Forms 其他剂型 IV. POSTAPPROVAL PACKAGING CHANGES 批准后的包装变更 V. TYPE III DRUG MASTER FILES 药品主文件第III类 A. General Comments 总体评述 B. Information in a Type III DMF 第III类DMF中包括的信息 VI. BULK CONTAINERS 大包装容器 A. Containers for Bulk Drug Substances 用于原料药的容器 B. Containers for Bulk Drug Products 用于散装药品的容器 ATTACHMENT A 附件A REGULATORY REQUIREMENTS 药政要求

FDA检查员指导手册--中文译

FDA检查员指导手册CP 7356.002:药品生产检查程序

目录 对现场报告的要求 (35) 第一部分背景 (36) 第二部分执行 (36) 2.1.目的 (36) 2.2.策略 (36) 2.2.1.对生产企业两年一度的检查(包括重新包装商、合同实验室等) (36) 2.2.2.系统性检查 (37) 2.2.3.对原料药及制剂生产的系统性检查计划 (38) 2.2.3.1.质量系统 (38) 2.2.3.2.厂房设施与设备系统 (38) 2.2.3.3.物料系统 (38) 2.2.3.4.生产系统 (38) 2.2.3.5.包装和贴签系统 (38) 2.2.3.6.实验室控制系统 (39) 2.3.程序管理指导 (39) 2.3.1.定义 (39) 2.3.1.1.监督性检查 (39) 2.3.1.2.达标检查 (40) 2.3.1.3.受控状态 (40) 2.3.1.4.药品工艺 (40) 2.3.1.5.药品生产检查 (41) 第三部分检查 (41) 3.1.检查活动 (41) 3.1.1.总则 (41) 3.1.2.检查方法 (42) 3.1.2.1.全面性检查的选择 (43) 3.1.2.2.简略性检查的选择 (43) 3.1.2.3.综合性检查范围 (43) 3.1.3.系统性检查范围 (43)

3.1.3.1.质量系统 (44) 3.1.3.2. 厂房设施与设备系统 (44) 3.1.3.3.物料系统 (45) 3.1.3.4.生产系统 (46) 3.1.3.5.包装和贴签系统 (47) 3.1.3.6.实验室控制系统 (48) 3.1.4.取样 (49) 3.1.5.检查组组成 (49) 3.1.6.报告 (49) 第四部分分析 (50) 第五部分法律性/行政性策略 (50) 5.1.质量系统 (51) 5.2.厂房设施和设备 (51) 5.3.物料系统 (51) 5.4.生产系统 (52) 5.5.包装和贴签系统 (52) 5.6.实验室控制系统 (52)

接受FDA检查的几点体会

接受FDA 检查的几点体会 郝运杰 (河北省石家庄市华曙制药厂 050031) 摘要 本文简要叙述了我厂化学原料药接受FDA 检查的过程,对FDA 检查中特别重视的几个G MP 管理问 题进行了深入分析,从而为完善原料药G MP 管理,促进我国的原料药打入美国市场提供参考。关键词 化学原料药 FDA 检查 G MP 管理 中图分类号:R95 文献标识码:A 文章编号:1002-7777(2002)12-0745-03R ealizing form FDA I nspection Hao Y unjie (Shijiazhuang Huashu Pharmaceutical Factory ,Hebei Province ,050031)ABSTRACT The procedure for FDA inspection bulk pharmaceutical chemicals (BPCs )is briefly instructed.Several queations for G MP management from FDA inspection are described.This article provide a reference for strengthening the G MP management and for prom oting BPCs enter to US market. KE Y WOR DS bulk pharmaceutical chemical ;FDA inspection ;G MP management 在当前日益激烈的国际市场竞争中,医药产品如果能够打入美国市场,无疑是获得了一张竞争王牌,不仅药品的生产质量管理得到认可,产品的售价也会有所提高。而绝大多数医药产品进入美国前,必须通过美国FDA 的检查。FDA 是美国食品药品管理局(F ood and Drug Administration )的简称,是美国卫生和人类健康服务部下设的公共卫生署的 一个下属机构,其宗旨是确保工业产品完全符合联邦管理法的法规,以保证食品、药物(包括兽用药品、生物制品)、医疗器械、化妆品等安全、有效。药品进入美国市场首先要有美国用户,用户的需要是申请FDA 检查的必要条件。申请时,首先编写DMF (Drug Master File 药品管理档案),阐明产品制造的相关资料,包括工厂概况、成品质量标准、检验方法、产品的生产过程、生产设备、所用原辅材料和包装材料质量标准及检验方法、产品的稳定性试验、杂质论述、验证和厂区平面图等资料。FDA 接到DMF 后,将发函告知DMF 已收到,给定DMF 的分配号,同时提醒厂家对DMF 中变更的内容按年度通知FDA ,并作好接受FDA 现场检查的准备。 FDA 一般在现场检查前1~2个月通知生产厂, 时间非常紧。故一旦申报,生产厂应严格按照cG MP (Current G ood Manufacturing Practice )要求提 前作好各项基础管理工作,尤其要保证实际情况与DMF 声称的内容相一致。FDA 官员来厂后,常常以批为线索,对照DMF 和厂方的生产质量管理文件,通过查阅各种记录、查看现场、对操作人员或管理人员提出问题、让操作人员现场演示等方式进行检查并记录。在检查结束前,FDA 官员将一份Inspectional Observations 表,即我们通常所说的 “483文件”交给厂方,提出检查中发现的问题。厂方应及时整改并以书面的形式答复上述问题。FDA 对检查结果及提出问题的答复进行汇总和综合 评估,如认为该产品可以进入美国市场,会在给厂方的信中表明该产品的生产质量管理按cG MP 要求进行,并提醒厂方这并不意味着完全符合cG MP ,应不断加强管理。 产品进入美国市场后并不是一劳永逸,每2~3年还要进行一次复查,复查程序与初次检查程序 基本相同。 近年来,FDA 加强了对出口到美国药品的检查,到现场检查的官员和检查时间相应增加,由原来1人检查3天,改为2人检查5天。而且2人进行了明确分工,一人侧重于生产现场,另一人侧重于试验室控制。笔者经历了华曙药厂土霉素碱的1998年7月的初次检查和2001年5月的复查及盐 酸土霉素的初次检查,明显感觉到FDA 现场检查 ? 547?中国药事2002年第16卷第12期

2007 FDA固体制剂制造商cGMP的检查指南02

备注: 本文件是供检查员和其他的FDA人员的参考。并不限制FDA,并不获取任何利益,义务,权利,或豁免某人 I简介 本文件旨对制药厂CGMP检查提供一个概括性指导。这个指导应该结合其它IOM(Investigations Operations Manual)的指南,其他的药物检查指导,和应遵循的规定。IOM的第十章,所列的一些指导如下: 1 原料药视察指导 2 高纯水系统视察的指导 3 QC实验室视察的指导 4 微生物QC实验室的指导 5 冻干注射剂视察的指导 6 清洁验证视察的指导 7 制药过程中的计算机系统的视察的指导 8 工艺过程验证通则的指导 II CGMP 处方和非处方 所有的药物的生产过程要遵守CGMP否则就被认为违反FD&C(食品药品化妆品法案) 501(a)(2)(B)条款。 依据704(a)(1)(B)章, 处方药物的记录一定要随时备查。如果是NDA或ANDA所列的OTC药物,根据FDC 505(k)(2)规定,FDA可以审查,复制,核对。然而,如果视察员是根据FDC 704条款到厂检查,则没有法律要求厂方,把那些在FDA没注册过的OTC 药物记录提供给视察者。所有的处方药和OTC 药的Note: This document is reference material for investigators and other FDA personnel. The document does not bind FDA, and does no confer any rights, privileges, benefits, or immunities for or on any person(s). I. INTRODUCTION This document is intended to be a general guide to inspections of drug manufacturers to determine their compliance with the drug CGMPR's. This guide should be used with instructions in the IOM, other drug inspection guides, and compliance programs. A list of the inspection guides is referenced in Chapter 10 of the IOM. Some of these guides are: o Guide to Inspections of Bulk Pharmaceutical Chemicals. o Guide to Inspections of High Purity Water Systems. o Guide to Inspections of Pharmaceutical Quality Control Laboratories. o Guide to Inspections of Microbiological Pharmaceutical Quality Control Laboratories. o Guide to Inspections of Lyophilization of Parenterals. o Guide to Inspections of Validation of Cleaning Processes. o Guide to Inspections of Computerized Systems in Drug Processing. o Guideline on General Principles of Process Validation. II. CURRENT GOOD MANUFACTURING PRACTICE REGULATIONS Prescription vs. Non-prescription All drugs must be manufactured in accordance with the current good manufacturing practice regulations otherwise they are considered to be adulterated within the meaning of the FD&C Act, Section 501(a)(2)(B). Records relating to prescription drugs must be readily available for review in accordance with Sec. 704(a)(1)(B) of the FD&C Act. If the product is an OTC drug which is covered by an NDA or ANDA, FDA may review, copy and verify the records under Sec. 505(k)(2) of the FD&C Act. However, if the product is an OTC drug for which there is no application filed with FDA, the firm is not legally

FDA检查员指导办法

FDA检查员指导手册 7356.002F 原料药生产检查(药品质量保证)

第一部分背景 总则 法案的501(a)(2)(B)条款要求所有药品的生产都必须遵守现行GMP 的要求,而原料药也不例外。关于原料药和制剂这两者的要求,法案并没有区不对待,而任何原料药或制剂方面的GMP缺陷都构成了对法案的偏离。关于原料药或药物成分来讲,FDA并没有为此而专门公布cGMP法规文件(就像我们现在有的制剂cGMP法规一样)。因此,本文提到的“cGMP”指的是法案要求,而并非美国联邦法规(CFR)第21部分210和211条款中关于制剂的要求。 事实上,FDA早就意识到cGMP对制剂的要求(美国联邦法规第21部分210、211条款)在理念上关于原料药生产来讲同样适用且有效。这些理念包括使用合适的设备;聘用通过培训且通过资质确认的人员;建立充分合理的书面程序和操纵,确保生产工艺和操纵的有效性,从而保证产品质量;建立一套中间体和最终药品检测方法的体系,确保药品在规定的使用期限内保持质量的稳定性。2001年,FDA在人用药物注册技术要求国际协调会议(ICH)上与其他政府监管部门共同努力,采纳了针对API 行业cGMP的国际性指南,也确实是ICH Q7A,活性药物成分的药品质量治

理的指南。ICH Q7A正体现了FDA关于原料药现行GMP体系的要求。因此,遵循该指南要求的API及其相关生产和检验设施是符合法定cGMP要求的。然而,只要是能符合法案501(a)(2)(B)的要求,并能确保API符合其纯度、均一性和质量特性的方法都能够采纳。 在本程序中所使用的术语“活性药物成分”(原料药)的含义与ICH Q7A 中的定义一致。在ICH Q7A中活性药物成分被定义为“旨在用于药品生产的任何物质或混合物,当用于药品生产时,这些物质即成为药品中的活性成分。这种物质被用来提供药学活性或在诊断、治疗、止痛、缓解、处理或疾病预防中起着直接作用或用于阻碍机体结构和功能。”目前,FDA 和原料药行业也会采纳其它术语来表示原料药。“药物成分”和“BPC”最常用,而BPC则表示非活性成分。这些术语和那个地点所使用的“API”意义等同。 FDA希望API厂家从起始原料的使用开始,到对原料药质量和纯度产生阻碍的关键工艺步骤的验证,即在API生产的全过程实施cGMP。越接近API 最终成品工序,就越要加强对物料质量的操纵。所需的操纵程度要紧取决于生产过程,且随着生产过程从起始中间体到最终的分离和纯化步骤而逐渐加强。操纵的强度还需依照每一步具体工序的风险性或关键性而定。 为了在合适的系统下生产原料药,并做好原料药的质量治理工作,ICH

fda检查员指导手册--药品生产检查程序(doc75页)(1)

FDA检查员指导手册CP 7356.002: 药品生产检查程序 对现场报告的要求 (35) 第一部分背景 (36) 第二部分执行 (36) 2.1. 目的 (36) 22 策略 (36) 221. 对生产企业两年一度的检查(包括重新包装商、合同实验室等) (36) 2.2.2. 系统性检查 (37) 2.2.3. 对原料药及制剂生产的系统性检查计划 (38) 2.2.3.1. 质量系统 (38) 2.2.32 厂房设施与设备系统 (38) 2.2.33 物料系统 (38) 2.2.34 生产系统 (38) 2.2.3.5. 包装和贴签系统 (38)

2.2.3.6. 实验室控制系统 (39) 2.3. 程序管理指导 (39) 2.3.1. 定义 (39) 2.3.1.1. 监督性检查 (39) 2.3.1.2. 达标检查 (40) 2.3.1.3. 受控状态 (40) 2.3.1.4. 药品工艺 (40) 2.3.1.5. 药品生产检查 (41) 第三部分检查 (41) 3.1. 检查活动 (41) 3.1.1. 总则 (41) 3.1.2. 检查方法 (42) 3.1.2.1. 全面性检查的选择 (43) 3.1.2.2. 简略性检查的选择 (43) 3.1.2.3. 综合性检查范围 (43) 3.1.3. 系统性检查范围 (43) 3.131. 质量系统 (44) 3.1.32厂房设施与设备系统 (44) 3.1.3.3. 物料系统 (45) 3.1.3.4. 生产系统 (46) 3.1.3.5. 包装和贴签系统 (47) 3.1.3.6. 实验室控制系统 (48) 3.1.4. 取样 (49) 3.1.5. 检查组组成 (49) 3.1.6. 报告 (49) 第四部分分析 (50) 第五部分法律性/行政性策略 (50) 5.1. 质量系统 (51) 5.2. 厂房设施和设备 (51)

FDA认证检查的六大系统

1 QUALITY SYSTEM质量保证系统 1.1 Product reviews (annual) 产品审查(年度) 1.2 Complaint reviews (quality and medical) 投诉审查(质量和医疗) 1.3 Discrepancy and failure investigations 不一致和失败的调查 1.4 Document Control 文件控制 1.5 Batch release 批放行 1.6 Change Control变更控制 1.7 Reprocess/Rework再加工/返工 1.8 Returns/Salvages 退回/补救 1.9 Rejects 拒收 1.10 Stability Failures稳定性失败 1.11 Quarantine 待验 1.12 Validation: computer, equipment, process, laboratory methods, cleaning 验证:计算机、设备、工艺、实验方法、清洁 1.13 Training/qualification 培训/资质 1.14 internal Audit Program内审规程 1.15 Supplier Audit Program 供应商审计规程 2 FACILITIES AND EQUIPMENT SYSTEM 厂房设施与设备系统 I Facilities 厂房设施 2.1 cleaning and maintenance 清洁与维护保养 2.2 facility layout and air handling systems厂房设施布局与空气处理系统 2.3 general air handling systems 全面的空气处理系统 2.4 control system for implementing changes in the building实施在厂房方面变更的控制系统

资产财务检查工作指引

资产财务检查工作指引 一、抽查事项 (一)行政、事业单位国有资产管理及财务管理情况。 (二)企业、社会团体财务管理情况。 二、检查内容和方法 (一)检查内容 1、是否制定单位国有资产管理具体办法或规章制度,并组织实施,制度包括对国有资产配置、使用、处置等环节的具体规定。 2、是否有专门部门、专人负责国有资产的管理工作,包括账卡管理、资产信息系统管理、财产清查登记、统计报告及日常监督检查等工作。 3、是否按规定出租、出借和处置国有资产。 4、是否定期处理往来账务(应收应付款项)和挂账业务(应列支出未列支挂往来账)、是否每年定期进行内部资产清查。 5、是否存在浪费、流失国有资产现象;是否存在超标准配置资产。

(二)检查方法 1、查看国有资产管理制度建立情况和执行情况; 2、国有资产台账和国有资产账簿记录是否一致; 3、查看资产信息系统的卡片是否规范,项目填写是否完整、真实与国有资产账簿记录是否一致; 4、查看国有资产会计处理是否有长期未处理的往来款项或挂账,行政事业单位是否按机关事务管理局批复处置资产,是否形成国有资产损失; 5、根据资产台账或卡片抽查单位实有资产是否存在,是否造成国有资产损失等。 三、检查依据 (一)《财政部门监督办法》(财政部令第69号) 第十六条财政部门依法对下列事项实施监督: (一)财税法规、政策的执行情况; (二)预算编制、执行、调整和决算情况; (三)税收收入、政府非税收入等政府性资金的征收、管理情况; (四)国库集中收付、预算单位银行账户的管理使用情况; (五)政府采购法规、政策的执行情况;

(六)行政、事业单位国有资产,金融类、文化企业等国有资产的管理情况; (七)财务会计制度的执行情况; (八)外国政府、国际金融组织贷款和赠款的管理情况; (九)法律法规规定的其他事项。 对会计师事务所和资产评估机构设立及执业情况的监督,由省级以上人民政府财政部门依法实施。 (二)《行政单位国有资产管理暂行办法》(财政部令第35号) 第八条各级财政部门是政府负责行政单位国有资产管理的职能部门,对行政单位国有资产实行综合管理。其主要职责是: (一)贯彻执行国家有关国有资产管理的法律、法规和政策; (二)根据国家国有资产管理的有关规定,制定行政单位国有资产管理的规章制度,并对执行情况进行监督检查; (三)负责会同有关部门研究制定本级行政单位国有资产配置标准,负责资产配置事项的审批,按规定进行资产处置和产权变动事项的审批,负责组织产权界定、产权纠纷调处、资产统计报告、资产评估、资产清查等工作; (四)负责本级行政单位出租、出借国有资产的审批,负责与行政单位尚未脱钩的经济实体的国有资产的监督管

中美药品检查员队伍情况

中美药品检查员队伍情况 一、FDA的检查员队伍情况 (一)、FDA的基本情况 美国食品和药物管理局(Food and Drug Administration,简称FDA),FDA 是美国政府在健康与人类服务部(DHHS) 和公共卫生部(PHS) 中设立的执行机构之一。在国际上FDA被公认为是世界上最大的食品与药品管理机构之一,世界许多国家都通过寻求协助或参考FDA 的先进经验以提高本国产品的质量和安全水平。 FDA有员工9000余人,遍及全国167个城市。整个FDA 按工作职能分为局长办公室、生物制品审评与研究中心、药品审评与研究中心、食品安全与营养中心、医疗器械与放射性产品健康中心、兽药中心、国家毒理学研究中心、监督管理办公室(ORA)等8个主要监管机构。 (二)、FDA药品检查员情况 作为FDA所有药品检查工作的主管部门,ORA的首要任务就是调查(investigation)和检查(inspect)被监管公司以确定它们对公众健康法律的遵守情况,保证在FDA监管下的产品符合相应的公众健康法律和规章。ORA监管工作原则为:向相关产业提供指导信息;指出显著违法的领域及其对公众健康的影响;优先考虑并将目标定位于高风险领域监管。

FDA通过ORA直接对药品进行日常监督管理,ORA对个FDA各大区分局实行垂直领导,这种对检查的统一组织及管理形式有助于统一药品监督管理的标准,提高工作效率。ORA下设立了4个中央办公室和5个地方大区办公室,分别为:资源管理办公室、执行办公室、地区运行办公室、犯罪案件调查办公室、中部地区办公室、东北部地区办公室、太平洋地区办公室、东南地区办公室、西南地区办公室,另外还有13个药品检验所。ORA 在全国各地建立了众多的派出机构,各派出机构的人员数量约占FDA总人数的三分之一(约3000人),是FDA履行职责和掌握情况的重要部门。 ORA作为FDA检查员队伍的核心,指导并派出药品检查员实施各项检查工作,并与各州和地方公众健康机构和监管者共同协作,为公众的用药安全建立了可靠的保障。 1、FDA药品检查员数量、分级和管理 FDA设立了一套完整的检查员评估体系对检查员的实际工作进行考核和评估,检查员根据上述的各系统的综合评定结果划分为三个级别: 一级药品检查员(Level I certification audits),FDA通过对检查员上一年的工作表现和能力体现进行评估,符合要求者评为该级检查员。授予此级检查员资格的目的是确保新入职的检查员能够胜任FDA各类检查工作的职能,目前此级药品检查员数量约为1700人。

FDA 11

CFR - Code of Federal Regulations Title 21

Page 1 of 6

U.S. Food & Drug Administration