VW50160_En_062003

Vertragspartner erhalten die Norm nur über die zust?ndige Beschaffungsabteilung.

Confidential. All rights reserved. No part of this document may be transmitted or reproduced without the prior written permission of a Standards Department of the Volkswagen Group.

Parties to a contract can only obtain this standard via the responsible procurement department.

VOLKSWAGEN AG

N o r m v o r A n w e n d u n g a u f A k t u a l i t ?t p r üf e n / C h e c k s t a n d a r d f o r c u r r e n t i s s u e p r i o r t o u s a g e .

T h e E n g l i s h t r a n s l a t i o n i s b e l i e v e d t o b e a c c u r a t e . I n c a s e o f d i s c r e p a n c i e s t h e G e r m a n v e r s i o n s h a l l g o v e r n .

Page 2

VW 501 60: 2003-06

4.2 Type

ATF Dexron? III technology, based on mineral oils or unconventional and synthetic hydrocarbons, with additives to improve the friction, viscosity/temperature, wear protection, oxidation protection, foaming and corrosion protection properties.

A summary of the test report on the Dexron? III tests must be submitted.

4.3 Miscibility

Factory-fill-for-life automatic transmission fluids (ATF) according to this specification must be miscible with one another and with factory-fill-for-life automatic transmission fluids according to TL 521 62 in any ratio without limitation. The mixtures must also correspond to all requirements of this specification.

The documentation must be provided for a mixing ratio of 50 : 50.

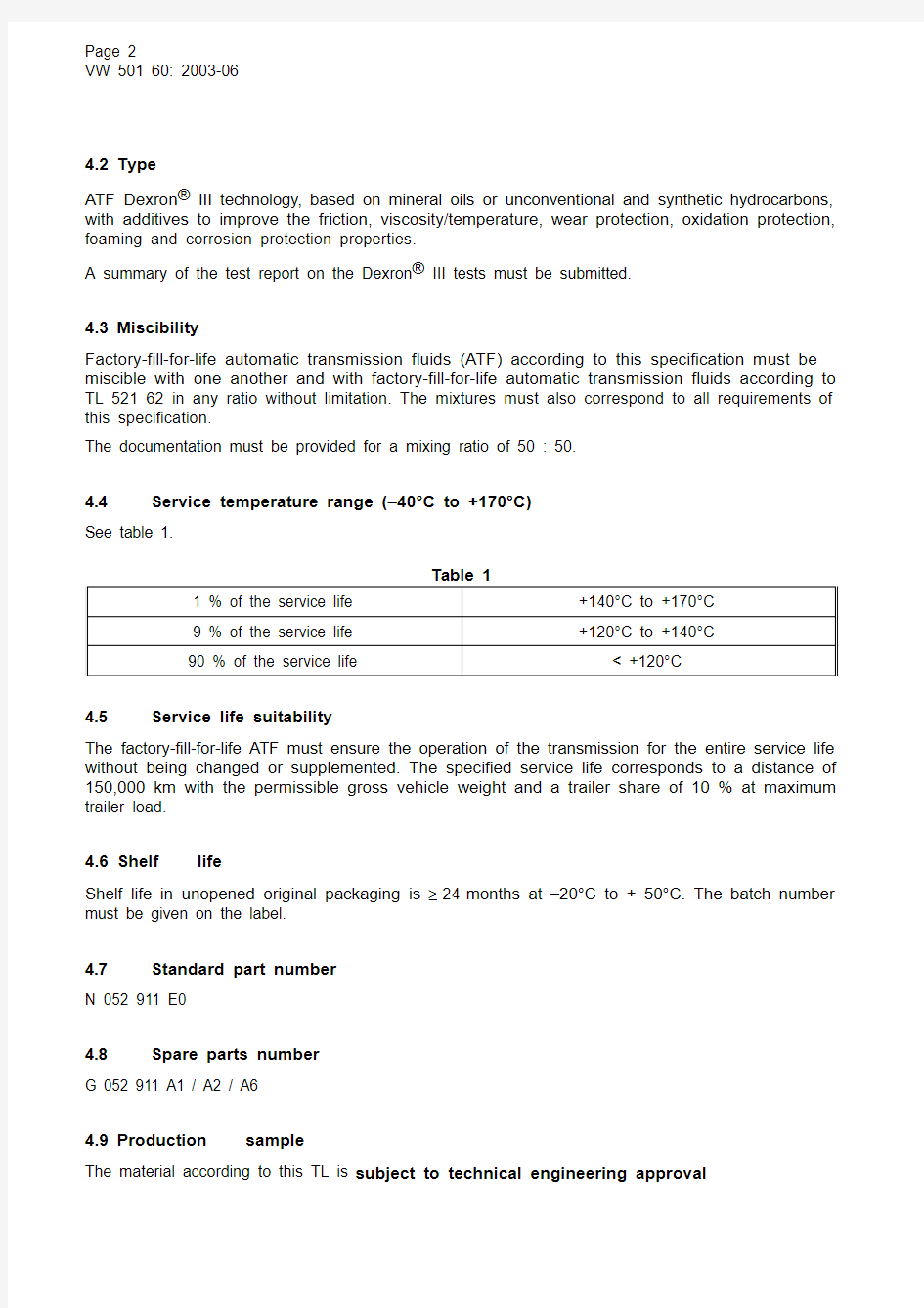

4.4 Service temperature range (–40°C to +170°C)

See table 1.

Table 1

1 % of the service life +140°C to +170°C

9 % of the service life +120°C to +140°C

90 % of the service life < +120°C

4.5 Service life suitability

The factory-fill-for-life ATF must ensure the operation of the transmission for the entire service life without being changed or supplemented. The specified service life corresponds to a distance of 150,000 km with the permissible gross vehicle weight and a trailer share of 10 % at maximum trailer load.

life

4.6 Shelf

Shelf life in unopened original packaging is ≥24 months at –20°C to + 50°C. The batch number must be given on the label.

4.7 Standard part number

N 052 911 E0

4.8 Spare parts number

G 052 911 A1 / A2 / A6

sample

4.9 Production

The material according to this TL is subject to technical engineering approval.

Page 3

VW 501 60: 2003-06 departments

4.9.1 Responsible

Volkswagen AG: EAGA

K-QS-33

procedure

5 Release

5.1 Additive batch testing

If the additive supplier mixes a certain quantity of the finished additive package, this total quantity is designated as an additive batch and given an additive batch number.

Each additive batch must be tested prior to use for mixing the end product. The additive batch is tested and the results documented by the supplier of the service ATF according to section 5.5.

The additive batch is released after the release cycle (Appendix A.1) by the Quality Assurance Department of the ATF supplier.

test

5.2 First-sample

For mixing a first sample, only a checked and released additive batch may be used (section 5.1). The supplier of the service ATF provides 40 liters of the end product mixed under standard production conditions to the Quality Assurance Department of the ordering plant with an Association of German Automotive Industry (VDA) first-sample test report.

This report must contain the results according to sections 6 to 10.

The first-sample release is issued by the Quality Assurance Department of the ordering plant.

5.3 Manufacturing batch testing

If the supplier of the service ATF mixes a certain quantity of the finished product, this total quantity is designated as a manufacturing batch and given a manufacturing report number.

For mixing a manufacturing batch, only a checked and released additive batch may be used (section 5.1).

The manufacturing batch is tested and the results documented by the supplier of the service ATF according to section 5.5.

The manufacturing batch release is issued after the release cycle (Appendix A.1) by the Quality Assurance Department of the service ATF supplier.

If different manufacturing batches (max. 2) are stored in one tank and the shipment is taken from this tank, both manufacturing batch numbers (section 5.4) are to be given on the delivery slip.

batch

5.4 Delivery

If the service ATF supplier removes one or more separate partial quantities from the total quantity of a manufacturing batch at different times and delivers them to the ordering party or stores them, each partial quantity is designated as its own fill batch and given a fill report number in addition to the manufacturing report number.

When delivering in drums, only clean drums must be used. For bulk deliveries, the tank car shall be cleaned before filling.

Page 4

VW 501 60: 2003-06

The Quality Assurance Department of the ordering plant receives a plant testing certificate (DIN EN 10 204) with each shipment. The plant testing certificate includes the manufacturing and

fill report numbers as well as the test values according to section 5.5.

5.5 Test

plan

See table 2.

Table 2

Tests Additive

batches

Manufacturing

batches

Delivery batch

Laboratory tests Table 3, No. 1,

No. 2 and No. 5 Table 3, No. 1,

No. 2 and No. 5

to No.10

Table 3, No. 1,

No. 2 and No. 5

to No.10

Pumpability Table 3, No. 12 1) Chemical luminescence analysis Table 4, No. 5.1 1)

Foaming behavior Table 4, No. 6 Air release property Table 4, No. 7 Steady-state temperature Table 5, No. 6.1 1)

DKA coefficient of friction behavior (5 HP-30)

Friction disk 1055 271 053 Coefficient of friction test

(NS 3,000) Section 9.1.1 1) Section

9.1.1

1)

DKA coefficient of friction behavior

(5 HP-24)

Friction disk 1058 270 029

Coefficient of friction test

(NS 3,000)

Section 9.1.2 Section 9.1.2 2)

DKA coefficient of friction behavior (VW AG 4)

Friction disk 095.323.241 A Endurance test (NS 15,000) Section

9.1.3

1)

ZF regulated converter clutch

override test

Section 9.2 Section 9.2

1) These tests must be performed 1 x per year.

2) These tests must be performed on each manufacturing batch.

Page 5

VW 501 60: 2003-06

6 Requirements for composition, density and viscosity

See table 3.

Table 3

No. Property Unit Requirement

1 Color/appearance

acc. to ASTM D 6045

≤ 3.5 / colorless, clear

2 IR spectrum

acc. to DIN 51 451

acc. to sample

3 Additive type acc. to sample, see section 10.1

3.1 Additive content % acc. to sample

4 Base oils

4.1 Type and content

(C A, C P, C N)

% to be specified

4.2 Compliance with VW environmental

standard VW 911 01

to be specified

4.3 PAH content acc. to VW 505 50

acc. to PV 1448

to be specified

4.4 Viscosity index of the base oil

acc. to DIN ISO 2909

≥ 145

5 Elements

(Mg, Ca, Ba, Zn, B, N, P, S, Cl)

to be specified

5.1 Calcium (Ca)

acc. to DIN 51 391-2

% 0.0030 ± 0.0005

5.2 Boron (B)

acc. to BAA 202 or PV 1442

% 0.014 ± 0.003

5.3 Nitrogen (N)

acc. to ASTM D 3228

% 0.10 ± 0.01

5.4 Phosphorous (P)

acc. to DIN 51 363

% 0.034 ± 0.004

5.5 Sulfur (S)

acc. to DIN EN ISO 14596

% 0.015 ± 0.005

6 Water content

acc. to PV 1459

mg/kg ≤ 500

7 Density at +15°C

acc. to DIN 51 757 kg/m3

acc. to sample

8 Pour point (P)

acc. to DIN ISO 3016-2 °C max.

-55

9 Dynamic viscosity

Page 6

VW 501 60: 2003-06

No. Property Unit Requirement 9.1 At –40°C

acc. to DIN 51 398

mPas ≤ 10,000

9.2 At –25°C

acc. to DIN 51 377

mPas ≤ 1,500

10 Kinematic viscosity

acc. to DIN 51 562-1

10.1 At +40°C mm2/s acc. to sample

10.2 At +100°C mm2/s 7.40 ± 0.30

11 Viscosity index

acc. to DIN ISO 2909

≥ 165

12 HTHS viscosity

acc. to CEC-L-36-A-90

mPas ≥ 2.7

13 Pumpability at –40°C (V

oil

/ R oil) acc. to PV 1460 cm3/s 20 % better than VW reference oil section 11.4

7 Characteristics

requirements

See table 4.

Table 4

No. Property Unit Requirement

1 Evaporation loss at +200°C

acc. to DIN 51 581

% ≤ 5

2 Flash point

acc. to DIN ISO 2592

°C ≥ 200

Oil purity

Microscopic particle count

acc. to ISO 4407

3

Purity class

acc. to ISO 4406

19 / 15

4 Corrosivity

acc. to PV 1425

Steel

4.1

Grade

max.

1 Copper

Grade

max.

1 4.2

Weight loss mg/cm2 ≤ 2.0

4.3 Sludge formation of the oil-water

mixture not

permissible

5 Oxidation stability

Page 7

VW 501 60: 2003-06

No. Property Unit Requirement

Chemical luminescence analysis

acc. to PV 1476

At 190°C s ≥ 850

5.1

At 220°C s ≥ 120

Oxidation test

acc. to CEC-L-48-A-97/B

(192 h; 5 l air/h; +170°C; 100 ml)

5.2

After testing is completed, the following requirements must be met:

5.2.1 Blotter-spot test / drippage area no solid or sticky residues

5.2.2 ? viscosity at +100°C

acc. to DIN 51 562-1

% ≤ 10

5.2.3 ? TAN

acc. to ASTM D 664 mg

KOH/g

to be specified

6 Foaming behavior

acc. to ASTM D 892

6.1 New oil

6.1.1 At +25°C / after 20 s ml ≤ 20 / 0 6.1.2 At +95°C / after 20 s ml ≤ 50 / 0 6.2 After aging

acc. to CEC-L-48-A-97/B

(24 h at +140°C)

6.2.1 At +25°C / after 20 s ml ≤ 20 / 0 6.2.2 At +95°C / after 20 s ml ≤ 50 / 0

Air release property at +50°C

acc. to DIN 51 381

After aging

per CEC-L-48-A-97/B

(24 h at +140°C)

Air-in-oil dispersion

(requirements based on

DIN 51 381)

After 0 min (extrapolated) vol. % ≤ 3.5

After 1 min vol. % ≤ 2.5

After 2 min vol. % ≤ 1.8

After 3 min vol. % ≤ 1.2

7

0.2 volume percent after min. ≤ 8

8 Shear stability

acc. to CEC L-45-A-99

Viscosity after shearing acc. to DIN 51 562-1 mm2/s ≥ 7.0

8.1

Shear loss % ≤ 5

Page 8

VW 501 60: 2003-06

No. Property Unit Requirement

HTHS viscosity

acc. to CEC L-36-A-90 after mechanical shearing acc. to CEC L-45-A-99 mPa.s ≥ 2.70

8.2

Shear loss % to be specified

8 Functional

requirements

See table 5.

Table 5

No. Property Unit Requirement

1 Elastomer compatibility

(static inclusion tests)

see section 9.2

Tensile strength

acc. to DIN 53 504

relative change

Test elastomer 1 % ± 25

Test elastomer 2 % ± 0 to –50

Test elastomer 3 (test temperature +100°C)% ± 0 to –50

Test elastomer 4 % ± 0 to –50

1.1

Test elastomer 5 % ± 30

Elongation at tear

acc. to DIN 53 504

Relative change

Test elastomer 1 ± 30

Test elastomer 2 ± 0 to –50

Test elastomer 3 (test temperature +100°C)± 0 to –50

Test elastomer 4 ± 0 to –30

1.2

Test elastomer 5 ± 35

1.3 Cracks at 100 % elongation not permissible

2 Elastomer compatibility

(dynamic radial shaft seal tests)

Test run with ACM radial shaft seal

see section 9.3

2.1

After testing is completed, the following requirements must be met:

2.1.1 Leakage

none

Page 9

VW 501 60: 2003-06 No. Property Unit Requirement

2.1.2 Sealing lip wear mm ≤ 0.4

2.1.3 Radial force loss % ≤ 30

2.1.4 Oil deposits and discoloration of the

radial shaft seal Slight, soft oil residues permissible

Cracks on the sealing lip at ~ 50 % elongation none

2.1.5

No indication specified, see VW 011 50 ff

3 Compatibility at 100°C with respect to

thrust washer composite material

acc. to PV 1471 μ1 > μ2≥ μ3

friction coefficient profile between μ1 and μ3

always ≥ μ3

3.1 PPA Friction-

oscillatio

n factor

≤ 0.12

4 Pitting load-bearing capacity (FZG

pitting test)

acc. to PT C/9/90 h ≥ 150

(3 trials/individual values must be

indicated)

Gray stippiness

VW reference oil see section 9.4 to be specified

Oil under test better than VW reference oil

section 9.4

4.1

Profile notes must be submitted

5 Limit of load capacity

(FZG test A/16.6/90)

acc. to DIN 51 354-2

SKS ≥ 11

6 Fuel economy

6.1 Steady-state temperature

acc. to PV 1454 > 5°C better than VW reference oil section 9.4

6.2 Loss coefficient V

G

acc. to PV 1456 5 % better than VW reference oil section 9.4

9 Functional requirements/friction behavior

9.1 DKA friction coefficient test

The friction coefficient test is performed on two selected clutches from the transmissions 5 HP-18 and 5 HP-30, made by Zahnradfabrik Friedrichshafen (ZF), and on one clutch from the VW transmission VW AG 4.

Page 10

VW 501 60: 2003-06

9.1.1 Transmission 5 HP-18

9.1.1.1 Specimen parts 5 HP-18, clutches F/G

─Friction disk ZF no. 1056 277 036 / SD 1798 BM

─Steel disk ZF no. 1056 377 003

The specific references batches listed by ZF are to be used. The batch numbers of the friction and steel disk batches must be specified on the test log.

9.1.1.2 Measurement of dynamic, static and quasistic friction coefficients

─Short coefficient of friction test, measurement at shift number:

10, 20, 50, 100, 200, 300, 400, 500

─Coefficient of friction test, measurement at shift number:

10, 20, 50, 100, 200, 300, 400, 500, 1,000, 2,000, 3,000

─Endurance coefficient of friction test, measurement at shift number:

10, 20, 50, 100, 200, 300, 400, 500, 1,000, 2,000, ..., 10,000

The thickness of the friction disks is measured according to ZF-PRA 0000 700 875 before the beginning and after the end of the test.

9.1.1.3 Test conditions at 100 % load (testing note 10.8)

See table 6.

Table 6

Testing parameter Unit Short

coefficient

of friction test

Coefficient of

friction test

Endurance

coefficient of

friction test

Speed rpm 2,330

Disk pressure N/mm2 0.80

Specific work J/mm2 0.60

Number of friction

surfaces

8 Shift frequency h-1 120 Closing time s 5

Specific oil

flow rate

mm3/mm2/s 0.75

Oil flow rate l/min 1.0

Oil feed

temperature

°C 80 ± 3

Number of shift operations (NS) 500 or until

constant

coefficient of

friction reached,

see section 10.5

3,000 10,000

Total release

clearance

mm 1.4

Page 11

VW 501 60: 2003-06

9.1.1.4 Influence of the oil temperature and surface pressure on the coefficient of friction

A special temperature-pressure test (T-P test) is run according to section 10.9 to determine the dependence of the coefficient of friction on the oil temperature and the surface pressure.

9.1.1.5 Friction coefficient tolerances

─Dynamic coefficient of friction Shift no. 10 to 10,000 Shift operation start, see section 11.7 0.120 to 0.150

Shift operation end, see section 11.6 0.120 to 0.150

Friction coefficient difference within one shift operation ≤ 0.020

─Static coefficient of friction 0.130 to 0.170

─Quasistatic coefficient of friction 0.090 to 0.130

9.1.1.6 Wear limit values

Permissible decrease in thickness per friction disk (average of 5 measurements).

─After short coefficient of friction test (500 shift operations) ≤ 0.040 mm

─After coefficient of friction test (3,000 shift operations) ≤ 0.050 mm

─After endurance coefficient of friction test (10,000 shift operations) ≤ 0.060 mm

9.1.2 Transmission 5 HP-30

9.1.2.1 Specimen parts 5 HP-30, clutches B/D/E2

─Friction disk ZF no. 1055 271 053 / Dynax D-0580-30

─Steel disk ZF no. 1055 371 003

The specific references batches listed by ZF are to be used. The batch numbers of the friction and steel disk batches must be specified on the test log.

9.1.2.2 Measurement of dynamic, static and quasistic friction coefficients

─Short coefficient of friction test, measurement at shift number:

10, 20, 50, 100, 200, 300, 400, 500

─Coefficient of friction test, measurement at shift number:

10, 20, 50, 100, 200, 300, 400, 500, 1,000, 2,000, 3,000

─Endurance coefficient of friction test, measurement at shift number:

10, 20, 50, 100, 200, 300, 400, 500, 1,000, 2,000, ..., 10,000

The thickness of the friction disks is measured according to ZF-PRA 0000 700 875 before the beginning and after the end of the test.

9.1.2.3 Test conditions at 100 % load (testing note 10.10)

See table 7.

Page 12

VW 501 60: 2003-06

Table 7

Testing parameter Unit Short

coefficient

of friction test

Coefficient of

friction test

Endurance

coefficient of

friction test

Speed rpm 2,500

Disk pressure N/mm2 0.5

Specific work J/mm2 0.60

Number of friction

surfaces

6

Testing parameter Unit Short

coefficient

of friction test

Coefficient of

friction test

Endurance

coefficient of

friction test

Shift frequency h-1 120 Specific oil

flow rate

mm3/mm2/s 0.75

Oil flow rate l/min 1.7

Oil feed

temperature

°C 80 ± 3

Number of shift operations (NS) 500 or until

constant

coefficient of

friction reached,

section 10.5

3,000 10,000

Total release

clearance

mm 1.1

9.1.2.4 Influence of the oil temperature and the surface pressure on the coefficient of

friction

A special temperature-pressure test (T-P test) is run according to section 10.11 to determine the dependence of the coefficient of friction on the oil temperature and the surface pressure.

9.1.2.5 Friction coefficient tolerances

─Dynamic coefficient of friction Shift no. 10 to 10,000

Shift operation start, see section 11.7 0.130 to 0.190

Shift operation end, see section 11.6 0.115 to 0.155

Diff. betw. max. friction coeff. at shift start and min. friction coeff. ≤ 0.050

Diff. betw. max. friction coeff. at shift end and min. friction coeff. ≤ 0.015

Friction coefficient difference within one shift operation ≤ 0.020

─Static coefficient of friction 0.135 to 0.160

─Quasistatic coefficient of friction 0.095 to 0.120

9.1.2.6 Wear limit values

Permissible decrease in thickness per friction disk (average of 5 measurements).

─After short coefficient of friction test (500 shift operations) ≤ 0.040 mm

─After coefficient of friction test (3,000 shift operations) ≤ 0.050 mm

Page 13

VW 501 60: 2003-06

─After endurance coefficient of friction test (10,000 shift operations) ≤ 0.060 mm

9.1.3 Transmission VW AG 4

9.1.3.1 Specimen parts VW AG 4, clutches

─Friction disk VW no. 095.323.241 A

─Steel disk VW no. 095.323.139

The batch numbers of the friction and steel disk batches must be specified on the test log.

9.1.3.2 Measurement of dynamic, static and quasistic friction coefficients

─Endurance coefficient of friction test, measurement at shift number:

100, 200, 500, 1,000, 2,500, 5,000, 7,500, 10,000, 12,500, 15,000

The thickness of the friction disk is measured before the beginning and after the end of the test.

9.1.3.3 Test conditions at 100 % load (section 10.12)

See table 8.

Table 8

Testing parameter Unit Endurance coefficient

of friction test

Speed rpm 6,300 Disk pressure N 2,000

Specific work J/mm2 0.50

Number of friction surfaces 10

Shift frequency h-1 120

Oil flow rate l/min 1.0

Oil feed temperature °C 120 ± 3

Number of shift operations (NS) 15,000

Total release clearance mm 1.5

9.1.3.4 Friction coefficient tolerances

─Dynamic coefficient of friction

─Shift operation start, see section 10.7 0.130 to 0.190

─Shift operation end, see section 10.6 0.115 to 0.155

─Diff. betw. max. friction coefficient at

shift start and min. friction coefficient ≤ 0.050

─Diff. betw. max. friction coefficient at

shift end and min. friction coefficient ≤ 0.015

─Static coefficient of friction 0.135 to 0.160

─Quasistatic coefficient of friction 0.095 to 0.120

9.1.3.5 Wear limit values

Page 14

VW 501 60: 2003-06

Permissible decrease in thickness per friction disk (average of 5 measurements):

─After endurance coefficient of friction test (15,000 shift operations) ≤ 0.060 mm

9.2 ZF Sachs regulated converter clutch override test

(or section 9.3; ZF regulated converter clutch override test)

Schematic representation see section 10.13.1.

parts

9.2.1 Specimen

─Friction disk ZF Sachs no. 0784 063 000 (BW SD 1473-2)

The batch numbers of the friction and steel disk batches must be specified on the test log.

─Converter cover ZF Sachs no. 0083 014 980 (flange cover)/bypass Grooves, made from ZF Sachs no. 0783 181 000 (used for max. 10 test runs)

─Converter piston ZF Sachs no. 0784 062 100 (new)

Test conditions (section 10.13) See table 9.

Table 9

Testing parameter Unit Endurance coefficient

of friction test

Speed rpm 800 to 0

Clutch pressure bar 3.5

Disk pressure N/mm2 2.5

Specific work J/mm2 0.6

Number of friction surfaces 2

Shift frequency h-1 120 Oil feed temperature °C 110 ± 5

Number of shift operations (NS) 5; 505 or to constancy of the

coefficient of friction Total release clearance mm 0.3

Recording of the coefficient of friction of switching actuation 5 and 505 at speed:

550, 400, 120, maximum value between 50 and 0 or no maximum value at 50 and 1.2 rpm

9.2.2 Specific coefficient of sliding friction test (regulated converter clutch override test)

a) Test conditions

See table 10.

Table 10

Testing parameter Unit Endurance coefficient

of friction test

Speed rpm 0 to 100

Clutch pressure No. 1 bar approx. 2.8

Disk pressure No. 1 N/mm2 1.9

Clutch pressure No. 2 bar approx. 1.6

Page 15

VW 501 60: 2003-06 Testing parameter Unit Endurance coefficient

of friction test

Disk pressure No. 2 N/mm2 1.1

Torque rate of rise Nm/s 100

Number of friction surfaces 2

Shift frequency h-1 120 Oil feed temperature °C 110 ± 5

Number of shift operations (NS) 3

Total release clearance mm 0.3

With a closed converter clutch and at constant pressure, the torque is increased steadily until the converter clutch breaks away and the speed reaches 100 rpm. Torques and speeds are recorded.

The measurements are taken after shift operations 5 and 505 at clutch pressures no. 1 and no. 2.

The coefficient of sliding friction test is conducted 3 times in succession for each setting. The friction coefficient profile is assessed at shift operation no. 3 between 0 and 100 rpm for the evaluation.

b) Limit values (section 10.16)

─Coefficient of friction at 5 rpm 0.120 to 0.125

(Clutch pressure no. 1, shift operation 505)

─Profile until speed 120 rpm monotonically rising

9.3 ZF regulated converter clutch override test

Schematic representation see section 10.7.

parts

9.3.1 Specimen

─Friction disk ZF no. 9907 870 120 (BW SD 1473-2)

The batch numbers of the friction and steel disk batches must be specified on the test log.

─Converter cover ZF Sachs no. 0783 181 000/bypass grooves

─Converter piston ZF Sachs no. 0784 062 100/bypass grooves

conditions

9.3.2 Test

See table 11.

Table 11

Testing parameter Unit Endurance coefficient of friction

test

Difference speed rpm 40

Disk pressure N/mm2 0.9

Clutch torque Nm 160

Oil feed temperature °C 120 ± 5

Permanent slip time min. 20

Flushing and cooling time min. 1

Page 16

VW 501 60: 2003-06

9.3.3 Vibration behavior measurement

The drive torque with superimposed friction vibrations is to be measured throughout the entire test.

Page 17

VW 501 60: 2003-06

9.3.4 Limit values (sections 10.16 and 10.17)

─Vibration time at start of test ≤ 3 min

─Subsequent vibration-free time ≥ 25 h

─Friction coefficients at 5 rpm 0.120 to 0.125

10 Notes on testing, explanations

The requirement "according to sample" is a quality specification of a released sample.

The requirement "to be specified" is for the general information of the sample presented, from

which a concrete requirement can be derived later.

10.1 Released additive types

"Hitec 403" by Ethyl Mineral?l-Additive GmbH

10.2 Sources of supply for reference elastomers

Test specimens: S3A according to DIN 53 504; test duration: 192 h; test temperature: +150°C;

specimen/oil ratio according to PV 3323: 1:80.

─Test elastomer 1: “70 ACM/121433” by Freudenberg Dichtungs- und

Schwingungstechnik

KG

─Test elastomer 2: "FKM E-281" by Parker-Pr?difa GmbH

─Test elastomer 3: "NBR 28" by Bayer AG

─Test elastomer 4: "VMQ E-151" by Bayer AG

─Test elastomer 5: “AEM 11621” by Dichtungstechnik Bruss GmbH

10.3 Test run with ACM radial shaft seal

See table 12.

Table 12

Drawing No. 02M 301 189 B

Number 6 Running time h 245 (10 cycles) Radial runout deviation mm ≤ 0.15

One test cycle consists of 3 steps according to table 13.

Table 13

Step no. Test duration

h : min.

Temperature

°C

Speed

rpm

Direction

of rotation

1 14 : 00 +110 2,000 right or left

2 06 : 00 +130 2,000 right or left

3 04 : 00 +25 0 at rest

After the temperature stage of +130°C in the 5th cycle, a peak temperature of +150°C is to be reached one time for 5 h. The entire run time is thus 245 h.

Page 18

VW 501 60: 2003-06

10.4 VW reference oil

“LT 71 141” by EXXON-MOBIL.

10.5 Friction coefficient constancy

Friction coefficient constancy is reached when the coefficient of friction does not change in form or

amount by more than 2% over 100 consecutive shift operations at full load.

For the first-sample test, coefficients of friction are also determined in the partial load range

(20 to 50 % load) (section 10.10).

10.6 Friction coefficient profile

The entire friction coefficient profile must be within the specified tolerance range, which is defined

by the combination of the upper and lower limit values.

10.7 Friction coefficient profile

The entire friction coefficient profile must be within the specified tolerance range, which is defined

by the combination of the upper and lower limit values. The entire friction coefficient profile must

rise monotonically.

10.8 Test conditions for coefficient of friction test (disk size: 5 HP-18 FL / F,G)

See tables 14 and 15.

Table 14

Number of friction disks 4

ZF friction disk no. 1055 277 036

ZF steel disk no. 1056 377 044

Steel disk thickness mm 1.8

Number of friction surfaces 8

Lining outside/inside diameter mm 135.00 / 121.00

Friction surface mm2 2,815

Mean radius m 0.0641

Release clearance per friction

mm 0.17 surface

Clutch release clearance mm 1.4

Page 19

VW 501 60: 2003-06

Table 15

Parameter

Unit

100 % load

50 % load

20 % load

Dynamic coefficient of friction

dn rpm 2,330 4,590 1,890

c m

m/s 15.6 30.79 12.68

J kgm2 0.453 0.078 0.172

Additional flywheel mass

27 KW DKA 2 + 3 - 5+6 50 KW DKA

J2D

-

J1A

p R N/mm2 0.80 0.35 0.35

F s N 2,250 990 990

μm 0.14 0.15 0.15

q A J/mm2 0.60 0.40 0.15

q 0.1 W/mm2 1.25 1.08 0.44

t R s 0.69 0.49 0.45

t S

s 30 30 30

Static coefficient of friction

dn rpm 2 2 2

c m m/s 0.01 0.01 0.01

p R N/mm2 0.80 0.35 0.35

F s N 2,250 990 990

Oil

th oil

°C

80

100

100

v. mm/s 0.75 0.75 0.75 v. l/min 1.0 1.0 1.0

Number of shift

operations

500 500 500

─ Lining thickness measurement New condition, after 500 shift operations ─ Visual inspection

After test completion

─

Calculation of friction coefficients

10, 20, 50, 100, 200, ..., 500

Page 20

VW 501 60: 2003-06

10.9 Temperature-pressure test (disk: 5 HP-18 F, G) See table 16.

Table 16

Shift operation

Dyn.

friction

coefficie

nt

100 %

load

Static

coeffici

ent of

friction

Pressure (N/mm2) Temperature (°C)

No. Qty. 8.0 4.0 1.2 30 50 80 100 120

1 10 X X

11 1 X X X

12 1 X X X

13 1 X X X

14 10 X X

24 1 X X X

25 1 X X X

26 1 X X X

27

10 X X

37 1 X X X

38 1 X X X

39 1 X X X

40

500 X X

540

10 X X

550

1 X X X

551 1 X X X

552

1 X X X

553

10 X X

563 1 X X X

564 1 X X X

565 1 X X X

566

10 X X

576

1 X X X

577 1 X X X

578

1 X X X

579 10 X X

589 1 X X X

590 1 X X X

591 1 X X X

592

10 X X 602

1 X X X 603 1 X X X 604

1 X X X