TS-INT-001-2012

TS-INT-001-2012

车用材料及零部件散发性能测试标准及要求

The Emission Test and Requirement for the Materials and Components in Vehicle

1 范围

该标准规定了车用材料及零部件散发性能测试标准及要求,适用于所有可能对车内空气质量产生影响的材料及零部件。 若中英文版本发生冲突,以中文为准。

2 参考标准

除非另有说明,只有最新颁布的引用文件适用于本标准。 GMW3205

车内装饰材料气味测试方法

GMW3235 车内装饰材料雾翳性能测试方法

GMW15634 车内装饰材料挥发性和半挥发性有机物测试方法 GMW15635

车内装饰材料醛酮类物质散发测试方法

TS-BD-003 车内零部件挥发性有机化合物的测试方法——袋子法 采样及试验方法参照TS-INT-001指导手册。

3 要求

3.1 样件/样品要求

待测样件/样品在交付SGM/PATAC 认可前,需满足以下条件:

1) 正式供货状态且下线时间不超过15天;

2) 不允许进行任何正式生产工艺之外的可能对试验结果产生影响的预处理或后处理,例如烘烤等;

3) 对于小零件提供能满足测试需求的数量;

4)对于可分离的复合总成零件(袋子法除外),应按均一材质进行分离测试;

对于不可分离的复合总成零件,可整体取材测试;

5)袋子法总成零件需用铝箔包装装箱,整体测试;

6)零件取样位置须以文字及图片形式进行记录,并作为试验报告附件提交;

7)电镀件无需执行此标准;

8)在整车中总质量少于10g、或总面积小于50cm2的零部件无需执行此标准;

9)零件供应商所提交零件级测试的样品必须是供货状态的完整零部件;

10)对于塑料粒子类的原材料统一打成塑料样板进行测试;

11)本标准涉及的实验(袋子法除外)必须在同一家实验室完成;

12)在3.6清单内的零部件,散发性能测试标准为:TS-BD-003、GMW3205、

GMW3235;不在3.6清单内的零部件,散发性能测试标准为:GMW15635、

GMW15634、GMW3205、GMW3235;

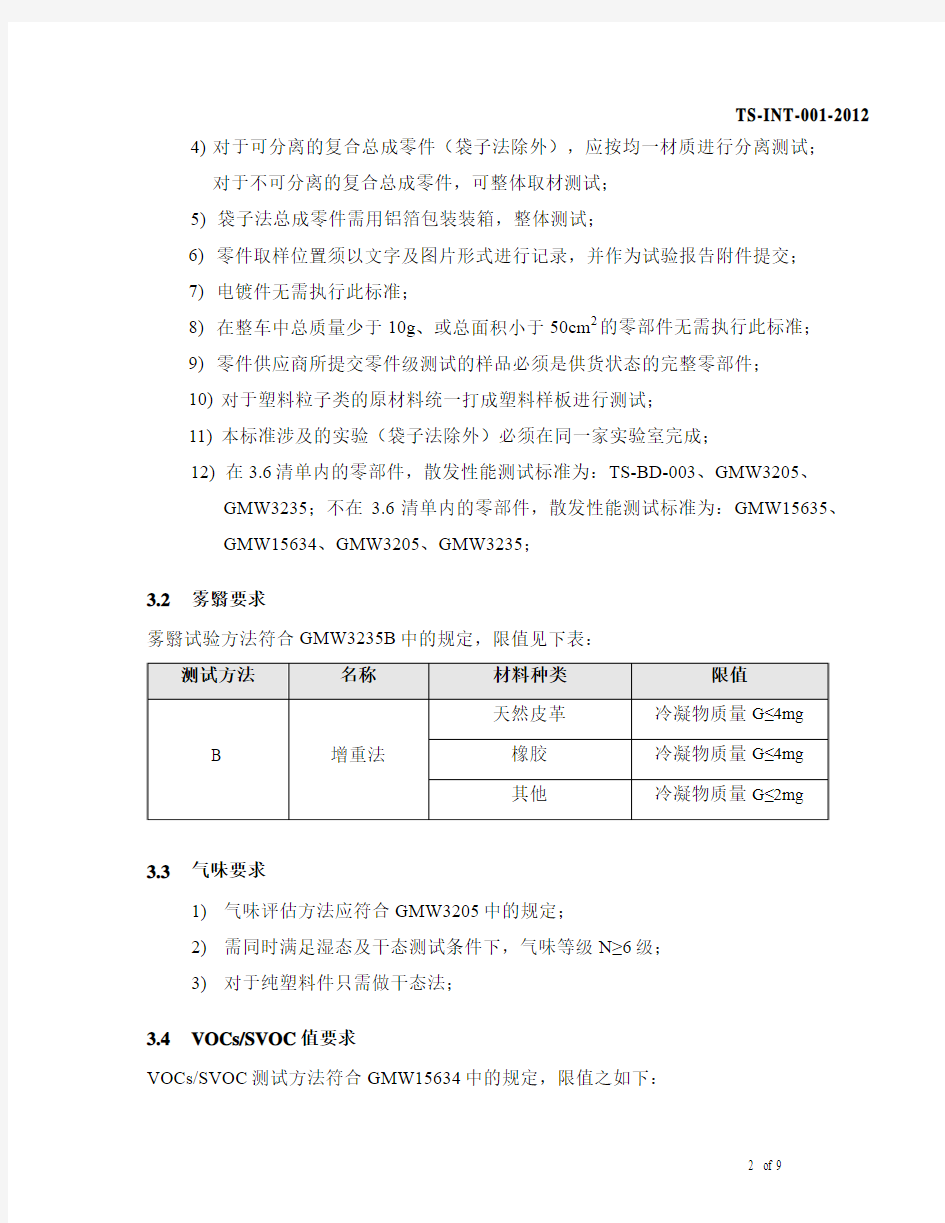

3.2雾翳要求

雾翳试验方法符合GMW3235B中的规定,限值见下表:

3.3气味要求

1)气味评估方法应符合GMW3205中的规定;

2)需同时满足湿态及干态测试条件下,气味等级N≥6级;

3)对于纯塑料件只需做干态法;

3.4VOCs/SVOC值要求

VOCs/SVOC测试方法符合GMW15634中的规定,限值之如下:

*备注:VOC和SVOC目前仅需Report,半年后更新。

3.5醛酮类物质要求

醛酮类物质测试方法符合GMW15635中的规定,限值之如下:

3.6袋子法限值要求

袋子法按照TS-BD-003中规定进行测试,限值如下表:

4标准号

此标准在SOR(要求声明)或图纸等文件中以下面的形式被引用:

TS-INT-001-2012

5发布与更新

5.1发布

此标准由泛亚汽车技术中心2004年5月起草,首次发布时间为2004年5月31日。

5.2更新

此标准2012-5-30由泛亚汽车技术中心更新,最新版本为005版。

5.3更新内容记录

1Scope

This standard defines the test specification and the limit of emission characteristics of materials and components which may influence the air quality in vehicle.

In the event of conflict between the English and domestic language, the domestic language shall take precedence.

2Referenced Standards

Only the latest approved standards are applicable unless otherwise specified.

GMW3205 Test Method for Determining the Resistance to Odor Propagation

of Interior Materials

GMW3235 Fogging Characteristics of Trim Materials

GMW15634 Determination of Volatile and Semi-Volatile Organic Compounds

from Vehicle Interior Materials

GMW15635 Determination of Aldehyde and Ketone Emissions from Interior

Materials

TS-BD-003 Determination of Volatile Organic Compounds from Vehicle

Interior Parts—Tedlar Bag Method

The sampling and testing method refer to the TS-INT-001guideline.

3Requirement

3.1Specimen/Sample Requirement

The specimen or sample need to meet the requirements listed below before delivered to lab:

1)The specimen should be kept the delivery state and taken within 15 days after

production;

2)It is forbidden to do any pre- or post-treatment outside of production process

that will affect the test results, such as baking;

3)For small parts , the quantity and size of specimens need to meet the test

requirement;

TS-INT-001-2012

4)It is necessary to do the test separately for detachable composite assembly parts

(Tedlar Bag Method exception); And it should be sampled and tested as a whole

for unseparated composite assembly parts;

5)The assembly parts tested by tedlar bag method should be packed with

aluminum foil and be tested as a whole.

6)The sampling point of parts need to be documented and taken picture, and

submitted as the attachment of test reports;

7)Electric coated parts need not execute the specification;

8)Those parts whose the weight is less than 10g or the total area is less than 50cm2

in vehicle don’t execute the specification;

9)The specimen that parts suppliers to submit for part-level testing must be

delivery state complete parts;

10)Plastic pellet raw material will be changed to plastic panel to do the test;

11)All experiments (Tedlar Bag Method exception) involved in this standard must

be done in the same laboratory;

12)The test standards of the parts which are in 3.6 list are TS-BD-003, GMW3205,

GMW3235; The test standards of the parts which arenot in 3.6 list are

GMW15634, GMW15635, GMW3205, GMW3235;

3.2Fogging Characteristics

The test method for evaluating fogging characteristics meets the requirement of GMW3235B. The limit value is as following:

3.3Odor

1)The test method for determining the resistance to odor propagation should meet

the requirement of GMW 3205;

2)Need to meet the requirement both of wet and dry condition: N ≥ grade 6;

TS-INT-001-2012

3)Pure plastic parts only require dry condition;

3.4VOCs/SVOC

The test method for determining VOCs/SVOC value should meet the requirement of GMW15634. The limit value is as following:

*Remark:VOC/SVOC only need to report at present,which will be updated after half of a year。

3.5Aldehyde and Ketone Emissions

The test method for determining aldehyde and ketone emissions value should meet the requirement of GMW15635. The limit value is as following:

3.6Tedlar Bag

Tedlar Bag Method meet the requirement of TS-BD-003. The limit value is as following:

TS-INT-001-2012

4Coding System

This specification shall be referenced in other documents, SOR or drawing as following:

TS-INT-001-2012

5Release and Revisions

5.1Release

This specification was first approved on May 2004 and published on May 31, 2004 by PATAC.

5.2Revisions

This specification is revised on Dec 1th, 2012 by PATAC, and the new version is 005.