Pickering suspension polymerization

Facile fabrication of nanocomposite microspheres with polymer cores and magnetic shells by Pickering suspension polymerization

Chaoyang Wang *,Chengjin Zhang,Yu Li,Yunhua Chen,Zhen Tong

Research Institute of Materials Science,South China University of Technology,Guangzhou 510640,China

a r t i c l e i n f o Article history:

Received 22February 2009

Received in revised form 4June 2009Accepted 5June 2009

Available online 10June 2009Keywords:

Magnetic polymer microspheres Nanocomposites Pickering emulsion

Suspension polymerization PS

a b s t r a c t

Pickering suspension polymerization was used to prepare magnetic polymer microspheres that have polymer cores enveloped by shells of magnetic nanoparticles.Styrene was emulsi?ed in an aqueous dis-persion of Fe 3O 4nanoparticles using a high shear.The resultant Pickering oil-in-water (o/w)emulsion stabilized solely by magnetic nanoparticles was easily polymerized at 70°C without stirring.Fe 3O 4nano-particles act as effective stabilizers during polymerization and as building blocks for creating the organic–inorganic hybrid nanocomposite after polymerization.The fabricated magnetic nanocomposites were characterized by FTIR,XRD,TGA,DSC,GPC,XPS and SEM.The structures of the polymer core and the nanoparticle shell were analyzed.We investigated the effects on the products of the weight of Fe

3O 4nanoparticles used to stabilize the original Pickering emulsions.Pickering suspension polymerization provides a new route for the synthesis of a variety of hybrid nanocomposite microspheres with supracol-loidal structures.

ó2009Elsevier Ltd.All rights reserved.

1.Introduction

Magnetic polymer microspheres have attracted considerable interest due to their extensive application in the ?elds of biosepa-ration and biomedicine,such as cell isolation,targeted drug deliv-ery,protein and enzyme immobilization,immunoassays,and DNA and RNA puri?cation [1–4].The main advantages of magnetic polymer microspheres are the ease with which they can be manip-ulated and the possibilities they provide for automation equipments and mini devices.Fast and cost-ef?cient separation by applying an external magnetic ?eld without ?ltration or centri-fugation makes magnetic microspheres even more useful [5,6].Many approaches have been employed to prepare magnetic polymer microspheres.The conventional method is to coat the magnetic particles with a linear polymer to form magnetic poly-mer microspheres by phase separation [7],solvent evaporation [8,9]and sol–gel transition [10,11].However,polymerization methods [1,2]are more widely used and include emulsion poly-merization [12],miniemulsion polymerization [13],microemul-sion polymerization [14],dispersion polymerization [15],suspension polymerization [16–20],seed polymerization [21],and the two-step swelling method [2,22–24].Magnetic polymer microspheres with a core-shell structure of magnetic cores embed-ded in a polymer shell are mostly fabricated by both the polymer coating method and a polymerization method [3].

Recently,self-assembly of solid particles at the liquid–liquid interface to stabilize so-called Pickering emulsion has been well documented and offers a straightforward pathway for the produc-tion of organized nanostructures [25–29].Pickering emulsion droplets are also used as versatile polymerization vessels to fabri-cate hybrid polymer spheres and capsules with supracolloidal structures [30–47].The solid particles ?rst self-assemble at the li-quid–liquid interface and act as effective stabilizers during the polymerization process,eliminating the need for any conventional stabilizers.After the polymerization process is complete,the parti-cles are captured at the surface of the resultant polymer beads where they are most effective for subsequent applications.Such a surfactant-free emulsion polymerization process,called Pickering emulsion polymerization,is more attractive for preparation of hy-brid beads than the conventional emulsion polymerization meth-od.Polymerizations based on Pickering emulsion include Pickering miniemulsion polymerization,Pickering suspension polymerization,Pickering dispersion polymerization and Pickering emulsion interface-initiated atom transfer radical polymerization (PEII-ATRP)[30–47].Magnetic microparticles with poly(methyl methacrylate)(PMMA)[35]or polyaniline (PANI)[44]cores and Fe 3O 4nanoparticle shells have been prepared by Pickering suspen-sion polymerization;polystyrene (PS)-Fe 3O 4microparticles have been produced by Pickering dispersion polymerization [36].The method based on the Pickering emulsion technique has many advantages [35].The nanoparticles are added as both a component and a stabilizer during the polymerization process.There is no need to use conventional organic stabilizers.There are also no

1381-5148/$-see front matter ó2009Elsevier Ltd.All rights reserved.doi:10.1016/j.reactfunctpolym.2009.06.003

*Corresponding author.Tel./fax:+862087112886.E-mail address:zhywang@https://www.360docs.net/doc/8313632037.html, (C.Wang).

Reactive &Functional Polymers 69(2009)750–754

Contents lists available at ScienceDirect

Reactive &Functional Polymers

j o ur na l h om e pa ge :w w w.e ls e v ie r.c om /lo c at e /re act

by-products produced in the process,and no unwanted contami-nants are left in the polymer[35].The?nal product has a polymer core with a nanoparticles shell,which can be used in catalysis, electronics,or sensing technologies.

We prepared microcapsules with alginate gel cores and shells of porous CaCO3microparticles using in situ gelation of Pickering emulsions in our previous work[48,49].We also fabricated ther-mo-sensitive hybrid poly(N-isopropylacrylamide)(PNIPAm) microcapsules with supracolloidal structures using Pickering sus-pension polymerization[45,46]and investigated the growth of lightly cross-linked poly(2-hydroxyethyl methacrylate)(PHEMA) brushes from silica nanoparticles and subsequent capsule forma-tion using PEII-ATRP[47].In the present work,magnetic polymer microspheres with polymer cores and magnetic shells were pre-pared using a novel approach based on Pickering suspension polymerization that differs from conventional polymerization, which produces microspheres consisting of magnetic cores embedded in a polymer shell.Polystyrene(PS)was chosen to be the model system.The polymerization factors and the mor-phology of the fabricated magnetic PS microspheres were analyzed.

2.Materials and methods

2.1.Materials

Styrene(Guanghua Chemical Industries Co.,China)was distilled and benzoyl peroxide(BPO)was recrystallized before use.Iron(II) chloride tetrahydrate(FeCl2á4H2O),iron(III)chloride hexahydrate (FeCl3á6H2O),2-propanol(HPLC grade),ammonium hydroxide, and methanol were bought from Guangzhou Chemical Factory, China and were used without further puri?cation.Water used in all experiments was puri?ed by deionization and?ltered with a Millipore puri?cation apparatus to a resistivity higher than 18.0M X cm.

2.2.Preparation of Fe3O4nanoparticles

Superparamagnetic nanoparticles were prepared by a co-pre-cipitation method.A0.5g sample of FeCl3á6H2O was added to 50mL of nitrogen-purged2-propanol.Then,0.25g of FeCl2á4H2O was added while the solution was continuously stirred.The tem-perature of the solution was gradually raised to50°C and8mL ammonium hydroxide was added.The mixture was allowed to react at50°C for30min.To speed up the precipitation of nano-particles,the resulting solution was placed in a refrigerator for 5h.The nanoparticles were subsequently washed with methanol three times and separated by centrifugation at10,000rpm for 5min.Finally,the black precipitate was collected by centrifuga-tion and dispersed in water to obtain superparamagnetic iron oxide nanoparticles having an average particle size of about 8nm.

2.3.Preparation of magnetic PS microspheres by Pickering suspension polymerization

Styrene(1mL)with BPO(0.1g)was emulsi?ed into an aque-ous dispersion(10mL)of a given weight of Fe3O4nanoparticles (3–30mg)by agitation using an IKA Ultra Turrax T25basic instrument at11,500rpm for3min with a30s pause after every minute.The resulting stable Pickering emulsion was polymerized at70°C for8h after having argon bubbled through for15min. The resulting magnetic PS microspheres were washed three times with methanol and water and dried under vacuum at room temperature.2.4.Characterization

Pickering emulsions were observed with an optical microscope (Carl Zeiss,German).The size and size distribution of Pickering emulsions were estimated by counting200emulsion droplets.

Fourier transform infrared spectroscopy(FTIR)spectra were re-corded using a Bruker Vector-33FTIR spectrometer under ambient conditions.The samples were grounded with KBr and then com-pressed into pellets.The spectrum was taken from400to 4000cmà1.Typically,64scans at a resolution of4cmà1were accu-mulated to obtain one spectrum.

Thermogravimetric analysis(TGA)and differential scanning cal-orimetry(DSC)were carried out with a TA-Q5000instrument. Samples were heated from20to700°C at a heating rate of 10°C/min in air.The total amount of Fe3O4uptake was obtained in a TGA measurement from the residual weight percentage at 700°C.

Gel permeation chromatography(GPC)was carried out with a Waters GPC instrument at40°C using tetrahydrofuran(THF)as the solvent and narrowly distributed polystryene(PS)as the stan-dard.Magnetic PS microspheres were dissolved in THF for48h with stirring.The solution was centrifuged and the supernatant was used for measurement.

X-ray photoelectron spectroscopy(XPS)was acquired on a Kra-tos Axis Ultra(DLD)X-ray photoelectron spectrometer using a monochromatic Al K a X-ray source(1486.6eV photons).The bind-ing energy was calibrated using the C1s hydrocarbon peak (284.6eV).The X-ray source ran at a power of150W(15kV and 10mA)and the pressure in the analysis chamber was maintained at1.33?10à6Pa.The surface element content was determined from the ratios of the spectral peak areas after calibrating with the experimentally determined sensitivity factors.

Powder X-ray diffraction(XRD)patterns were recorded using a Rigaku D/max-3Ainstrument(monochromated Cu K a radiation). Typically,the diffractogram was recorded in a2h range of5–90o C.

Scanning electron microscopy(SEM)was carried out with a Phi-lips XL30electron microscope equipped with a?eld emission elec-tron gun.Samples were sputter-coated with gold prior to measurement.

3.Results and discussion

3.1.Formation of Pickering emulsions stabilized by Fe3O4 nanoparticles

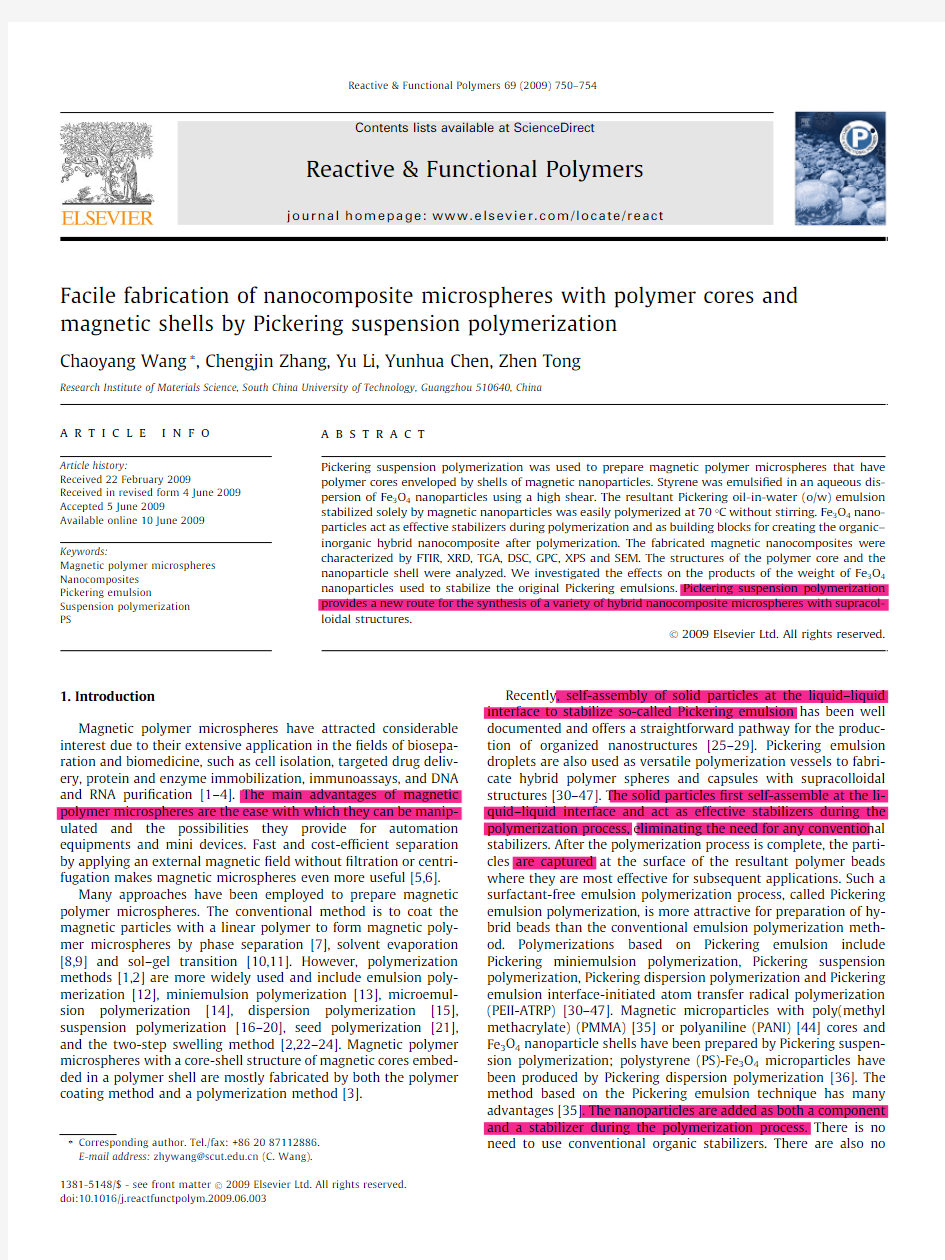

It is well known that colloidal particles can spontaneously local-ize to liquid–liquid interfaces to act as stabilizers for Pickering emulsions[25–29].Hydrophilic particles tend to form oil-in-water (o/w)emulsions whereas hydrophobic particles form water-in-oil (w/o)emulsions[25].However,Pickering emulsions cannot be formed if particles are highly hydrophilic.Here,we use Fe3O4 nanoparticles as stabilizers to generate styrene-in-water(o/w) Pickering emulsions.The zeta-potential of Fe3O4nanoparticles is 16.3mV,which is suitable for the preparation of Pickering o/w emulsions.Typical micrographs of Pickering emulsions stabilized by various amounts of Fe3O4nanoparticles are shown in Fig.1.Four kinds of emulsions were stable for more than1week.The styrene droplets had a wide size distribution from several micrometers to hundreds of micrometers.The average size of the styrene droplets decreased as the weight of Fe3O4nanoparticles used to stabilize emulsions https://www.360docs.net/doc/8313632037.html,ing3.0mg and6.8mg Fe3O4nanoparticles, the styrene droplets were spherical and?nely dispersed in water. With14.2mg Fe3O4nanoparticles,some styrene droplets bound together;the30.0mg Fe3O4nanoparticles formed styrene droplets where some magnetic particles were not adsorbed.

C.Wang et al./Reactive&Functional Polymers69(2009)750–754751

3.2.Preparation and characterization of magnetic PS microspheres Ensuring the formation of stable Pickering emulsions is neces-sary for the subsequent suspension polymerization to make func-tional microspheres.Polymerization can be easily carried out and needs no stirring after generation of a robust Pickering emulsion.Fe 3O 4nanoparticles act as effective stabilizers during polymeriza-tion and as building blocks for creating the organic–inorganic hy-brid nanocomposite after polymerization [30].We prepared magnetic polymer microspheres with PS cores and shells of Fe 3O 4nanoparticles using the Pickering suspension polymerization illustrated in Scheme 1.

In this study,as shown in Table 1,four batches of varying weights of Fe 3O 4nanoparticles (batch 1:3mg;2: 6.8mg;3:14.2mg;4:30mg)were used to prepare magnetic nanocomposite PS microspheres.GPC of the PS in the nanocomposites is shown in Fig.2.The molecular weight (M n )and the polydispersity (PDI)of the PS are also listed in Table 1.The M n values of PS were similar from 8000to 10,000with similar PDI values from 2.0to 2.4for four batches,which is typical for suspension polymerization of styrene.Fig.3shows TGA curves of the magnetic PS microspheres.The total amount of Fe 3O 4uptake is 0.7wt%,1.1wt%,5.8wt%and 7.8wt%for batches 1–4,respectively,increasing with increasing weight of the magnetic nanoparticles used to stabilize the emulsions.The theoretical Fe 3O 4uptake in the nanocomposites calculated from the ratio of the reactants is 0.3wt%,0.75wt%,1.5wt%and

3.2wt%.The Fe 3O 4uptake from TGA is a little higher than the the-oretical Fe 3O 4uptake for all four batches.The experimental data suggests that the majority of the nanoparticles in the solution were harvested during the suspension polymerization and the polymer-ization conversion was less than 100%[32,33].DSC curves of the nanocomposites are shown in Fig.

4.T g from DSC listed in Table 1is 100.7°C,10

5.9°C,111.3°C and 112.0°C for batches 1–4,respectively,increasing with increasing weight of the magnetic nanoparticles used to stabilize the emulsions.This trend can be attributed to the inorganic shells protecting the PS cores.The

Table 1

Processing parameters

of Pickering suspension polymerization.Batch

Fe 3O 4

PS in products Fe 3O 4content (%)c

M n a

PDI a T g (°C)b 138000 2.4100.70.72 6.89000 2.0105.9 1.1314.29000 2.2111.3 5.84

30

10,000

2.3

112.0

7.8

Conditions:1mL styrene,0.1g BPO,10mL water,polymerization at 70°C for 8h.a

From GPC.b

From DSC.c

From TGA.

Fig.1.Light micrographs of Pickering emulsions stabilized with Fe 3O 4nanoparticles of (a)3mg,(b)6.8mg,(c)14.2mg and (d)30mg.

752 C.Wang et al./Reactive &Functional Polymers 69(2009)750–754

change in heat enthalpy at about300°C results from the crystal transformation of magnetic nanoparticles,and the change at about 400°C from heat degradation of PS.

Fe3O4nanoparticles,pure PS microspheres from emulsion polymerization and Fe3O4-PS nanocomposite made using Fe3O4 nanoparticles from batch2were analyzed by FTIR spectroscopy (Fig.5).The peak at580cmà1is the Fe–O vibration of Fe3O4. The bands at698and752cmà1can be attributed to?exural vibrations(d C–H)of the benzene ring and those at1450,1490,and1596cmà1can be attributed to benzene ring vibrations (m C–C)of polystyrene.All the major characteristic bands of Fe3O4-PS nanocomposite are present and there is no difference from the infrared spectrum of the polystyrene standard.This indicates that there is no or only very weak chemical bonding between the Fe3O4nanoparticles and polystyrene in the product; the presence of strong chemical bonding would shift the vibra-tional frequencies of the polymer.

The XRD results are shown in Fig.6.No obvious peaks from the Fe3O4nanoparticles were found in the XRD curve of the Fe3O4-PS nanocomposite made using Fe3O4nanoparticles from batch2.A possible reason for this is the small Fe3O4content of the batch.

We used XPS to analyze the surface elements of magnetic PS microspheres made using Fe3O4nanoparticles from batch4and the result is plotted in Fig.7.The binding energy(BE)of Fe2P is 710.8eV.The BE of O1S is529.8eV and that of C1S is283.8eV. The ratio of Fe to C atoms is1:6.4from the peak areas of XPS.If the magnetic nanoparticles are homogeneously dispersed within the polymer matrix,the theoretical ratio of Fe to C atoms calcu-lated from the ratio of the reactants is1:182.The higher Fe content in the surface of the product indicates that Fe3O4nanoparticles were covered on the microsphere surface and the core-shell struc-ture was successfully formed.

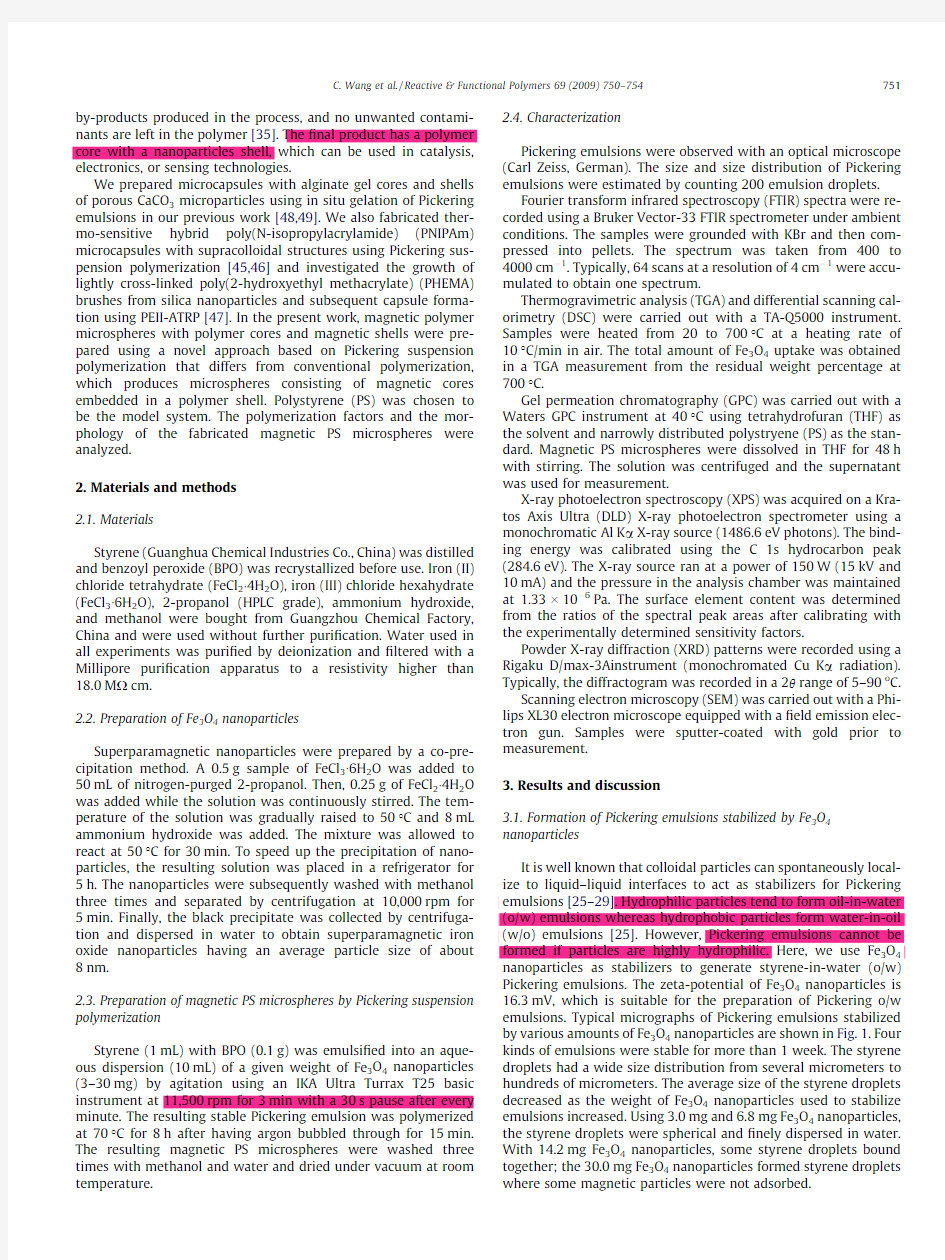

Fig.8shows SEM micrographs of the magnetic PS microspheres made using Fe3O4nanoparticles from batch4.The nanocomposites are spherical and have a size distribution as wide as that of the ori-ginal Pickering emulsion,indicating that the high stabilization ef?-ciency of the nanoparticles enabled successful suspension polymerization with controlled morphology.The microsphere sur-face is very rough due to the presence of entrapped magnetic nanoparticles.

C.Wang et al./Reactive&Functional Polymers69(2009)750–754753

4.Conclusion

In summary,nanocomposite microspheres with PS cores and shells of Fe 3O 4nanoparticles were fabricated by Pickering suspen-sion polymerization of styrene stabilized by Fe 3O 4nanoparticles.The morphologies of magnetic PS microspheres are tunable and can be controlled via the method(s)by which the original Pickering emulsions are prepared due to their high stabilization during the suspension polymerization procedure.Suspension polymerization based on Pickering emulsion droplets opens up a new route to making a variety of hybrid nanocomposite microspheres with supracolloidal structures,allowing the synthesis of magnetic beads that have potential applications in bioseparation and biomedicine.Acknowledgements

This work was supported by the National Natural Science Foun-dation of China (20574023and 20874030),the Scienti?c and Tech-

nologic Program of Guangzhou Municipality (2007J1-C0351)and NCET-07-0306.References

[1]J.Ugelstad,A.Berge,T.Ellingsen,R.Schmid,T.N.Nilsen,P.C.M?rk,P.Stenstad,

E.Horenes,?.Olsvik,Prog.Polym.Sci.17(1992)87.

[2]J.Ugelstad,P.Stenstad,L.Kilaas,W.S.Prestvik,R.Herje,A.Berge,E.Hornes,

Blood Puri?cat.11(1993)349.

[3]D.Horak,M.Babic,H Mackova,M.J.Benes,J.Sep.Sci.30(2007)1751.[4]A.K.Gupta,M.Gupta,Biomaterials 26(2005)3995.[5]U.O.Hafeli,Int.J.Pharm.277(2004)19.

[6]S.Mornet,S.Vasseur,F.Grasset,E.Duguet,J.Mater.Chem.14(2004)2161.[7]J.Ren,H.Y.Hong,T.B.Ren,X.R.Teng,React.Funct.Polym.66(2006)944.[8]D.Tanyolac,A.R.Ozdural,React.Funct.Polym.45(2000)235.[9]D.Tanyolac,A.R.Ozdural,React.Funct.Polym.45(2000)279.

[10]J.Zhi,Y.J.Wang,Y.C.Lu,J.Y.Ma,G.S.Luo,React.Funct.Polym.66(2006)1552.[11]E.B.Denkbas,E.Kilicay,C.Birlikseven,E.Ozturka,React.Funct.Polym.50

(2002)225.

[12]J.J.Huang,H.Pen,Z.S.Xu,C.F.Yi,React.Funct.Polym.68(2008)332.[13]L.P.Ramirez,https://www.360docs.net/doc/8313632037.html,ndfester,Macromol.Chem.Phys.204(2003)22.

[14]Y.P.Wang,L.C.Li,J.Jiang,H.Liu,H.Z.Qiu,F.Xu,React.Funct.Polym.68(2008)

1587.

[15]X.B.Ding,Z.H.Sun,G.X.Wan,Y.Y.Jiang,React.Funct.Polym.38(1998)11.[16]S.S.Wei,Y.F.Zhu,Y.Zhang,J.R.Xu,React.Funct.Polym.66(2006)1272.

[17]K.R.Reddy,K.P.Lee,A.I.Gopalan,H.D.Kang,React.Funct.Polym.67(2007)

943.

[18]J.Jiang,L.C.Li,M.L.Zhu,React.Funct.Polym.68(2008)57.

[19]Z.Y.Ma,Y.P.Guan,H.Z.Liu,React.Funct.Polym.66(2006)618.

[20]C.L.Yang,Y.P.Guan,J.M.Xing,G.H.Jia,H.Z.Liu,React.Funct.Polym.66(2006)

267.

[21]P.Natalia,J.U.Michael,N.V.Evgeny,J.Appl.Polym.Sci.77(2000)1851.

[22]J.Ugelstad,T.Ellingsen,A.Berge,O.B.Helgee,US Patent 4654267,(31.03.87)[23]T.H.Chung,W.C.Lee,React.Funct.Polym.68(2008)1441.

[24]C.M.Yang,H.Y.Li,D.B.Xiong,Z.Y.Cao,React.Funct.Polym.69(2009)137.[25]R.Aveyard,B.P.Binks,J.H.Clint,Adv.Colloid Interf.Sci.100–102(2003)503.[26]B.P.Binks,R.Murakami,S.P.Armes,S.Fujii,A.Schmid,Langmuir 23(2007)

8691.

[27]O.D.Velev,K.Furusawa,K.Nagayama,Langmuir 12(1996)2374.

[28]Y.Lin,H.Skaff,A.Boker,A.D.Dinsmore,T.Emrick,T.P.Russell,Science 299

(2003)226.

[29]A.D.Dinsmore,M.F.Hsu,M.G.Nikolaides,M.Marquez,A.R.Bausch,D.A.Weitz,

Science 298(2002)1006.

[30]J.A.Balmer,A.Schmid,S.P.Armes,J.Mater.Chem.18(2008)5722.[31]A.Schmid,J.Tonnar,S.P.Armes,Adv.Mater.20(2008)3331.

[32]S.Cauvin,P.J.Colver,S.A.F.Bon,Macromolecules 38(2005)7887.[33]T.Chen,P.J.Colver,S.A.F.Bon,Adv.Mater.19(2007)2286.[34]S.A.F.Bon,S.Cauvin,P.J.Colver,Soft Matter 3(2007)194.

[35]T.Hasell,J.X.Yang,W.X.Wang,J.Li,P.D.Brown,M.Poliakoff,E.Lester,S.M.

Howdle,J.Mater.Chem.17(2007)4382.

[36]J.Yang,T.Hasell,W.X.Wang,J.Li,P.D.Brown,M.Poliakoff,E.Lester,S.M.

Howdle,J.Mater.Chem.18(2008)998.

[37]K.Q.Chen,Y.F.Yang,Q.N.Sa,L.Q.Shi,H.Y.Zhao,Polymer 49(2008)2650.[38]Y.N.Wu,J.Zhang,H.Y.Zhao,J.Polym.Sci.Polym.Chem.47(2009)1535.[39]J.Zhang,K.Q.Chen,H.Y.Zhao,J.Polym.Sci.Polym.Chem.46(2008)2632.[40]D.J.Voorn,W.Ming,A.M.van Herk,Macromolecules 39(2006)2137.

[41]J.Jeng,T.Y.Chen,C.F.Lee,N.Y.Liang,W.Y.Chiu,Polymer 49(2008)3265.[42]X.D.He,X.W.Ge,H.R.Liu,M.Z.Wang,Z.C.Zhang,J.Polym.Sci.Polym.Chem.45

(2007)933.

[43]B.Liu,W.Wei,X.Z.Qu,Z.Z.Yang,Angew.Chem.Int.Ed.47(2008)3973.[44]Q.Xiao,X.K.Tan,L.L.Ji,J.Xue,Syn.Met.157(2007)784.

[45]H.X.Liu,C.Y.Wang,Q.X.Gao,J.X.Chen,X.X.Liu,Z.Tong,Mater.Lett.63(2009)

884.

[46]Q.X.Gao,C.Y.Wang,H.X.Liu,C.H.Wang,X.X.Liu,Z.Tong,Polymer 50(2009)

2587.

[47]Y.H.Chen,C.Y.Wang,J.X.Chen,X.X.Liu,Z.Tong,J.Polym.Sci.Polym.Chem.47

(2009)1354.

[48]C.Y.Wang,H.X.Liu,Q.X.Gao,X.X.Liu,Z.Tong,Chem.Phys.Chem.8(2007)

1157.

[49]H.X.Liu,C.Y.Wang,Q.X.Gao,X.X.Liu,Z.Tong,Int.J.Pharm.351(2008)

104.

Fig.8.SEM micrographs of Fe 3O 4/PS nanocomposite microspheres made using Fe 3O 4nanoparticles from batch 4with (a)low and (b)high magni?cations.

754 C.Wang et al./Reactive &Functional Polymers 69(2009)750–754

废乳化液处理

废乳化液处理 Prepared on 22 November 2020

废乳化液 机械制造工业中,金属切削加工使用大量乳化液作为润滑冷却之用,乳化液经过一段时间使用后,就会变成废水排出。 乳化液中主要含有机油和表面活性剂,是用乳化油根据需要用水稀释再加入乳化剂配制而成的。在机床切削使用的乳化液中为了提高乳化液的防锈性,还加入了亚硝酸钠等。 由于乳化剂都是表面活性剂,当它加入水中,使油与水的界面自由能大大降低,达到最低值,这时油便分散在水中。同时表面活性剂还产生电离,使油珠液滴带有电荷,而且还吸附了一层水分子固定着不动,形成水化离子膜,而水中的反离子又吸附再其外表周围,分为不动的吸附层和可动的扩散层,形成双电层.这样使油珠外面包围着一层有弹性的、坚固的、带有同性电荷的水化离子膜,阻止了油珠液滴互相碰撞时可能的结合,使油珠能够得以长期地稳定在水中,成为白色的乳化液。 配制的乳化液pH值一般再8~9之间,有的甚至高达10~11. 乳化液废水水质如表1-1所示:

2. 乳化液废水处理原理 根据乳化液的性质,进行乳化液废水的处理需经过二个步骤: 破乳剂油;(2)水质净化去除表面活性剂等物质。 破乳方法种类较多,有盐析法、乳酸法、凝聚法、顶替法、高压电法、吸附法等等。一般常用的采用盐析凝聚混合法,现介绍如下 在乳化液中加入电解质,电解质的离子在乳化液中发生强烈的水化作用即争水作用,使乳化液中的自由水分子减少了,对油珠产生脱水作用,从而破坏了乳化液油珠的水化层,中和了油珠的电性,破坏了它的双电层结构,因而油珠失去了稳定性,产生凝聚现象(电解质一般分为二、三价的钙、镁、铝等盐类),其反应式如下: 2C17H33COONa+2MgCl2-→(C17H33COO)2Mg+2NaCl 油酸皂镁皂 2C17H33(OSO3Na)COONa+2CaCl2-→(C17H32)2(OSO3)2Ca(COO)2+4NaCl 磺化蓖麻油 2R-SO3Na+CaCl2-→[R-SO3]2Ca+2NaCl(R为烷基) 石油酸钠石油磺酸钙 加入混凝剂,则加快起到油水分离的目的。 在实际使用中,应注意调整水的pH值,将pH值调整为较好。 四种破乳方法比较见表2-1:

汽车零部件中英文对照

仪表板Instrument Panel 中央置物箱Console 孔塞Grommet Plug 地毯Floor Mat 安全带Seat Belt 车门扶手Door Armrest 车门把手Door Handle 车门锁Door Lock 车顶内衬Roof Lining 车窗升降摇柄Window Lifter Handle 车窗升降机Window Lifter 防水衬条Weather strip 油量表Fuel Gauge 门饰板Door Trim 室内镜Room Mirror 音响喇叭盖Speaker Cover (电动)座椅(Electric) Seat 顶蓬Headlining 烟灰缸Ashtray 各类隔音垫All Kinds of Silencer 饰板/饰条Garnish / Trim 仪表饰板Instrument Panel Garnish 遮阳板Sun visor 压条Moulding 点烟器Cigar Lighter 备胎板Trim for Spare Tire 天窗Sun Roof 后置物板Rear Parcel Shelf 后舱室饰板Rear Trunk Trim 仪表板支架 Instrumental Panel Mounting 其它Others 随车工具Tools

千斤顶Jack 尼龙绳、特多龙绳Nylon Rope 生产、检测及涂装设备 Production, Test & Painting Equipment 各类孔盖Cap、Cover 扣具Cargo Lash 夹片、管束Clamp, Clip 油土与基准模型 Clay Model and Master Model 油封Oil Seal 门铰链Door Hinge 故障标志Reflector 玻璃类Glass 修理业Repairing & Maintenance 粉末冶金Powder Metallurgy 轴承Bearing 塑料件Plastic Parts 隔热材Heat Insulator 电子件Electrical Parts 垫片类 Seal、Gasket、Washer、Packing 碳刷Carbon Brush 管类Pipe, Hose, Tube 铜套类Bushing 弹簧Spring 橡胶件Rubber Parts 帮浦类Pump 螺帽/螺栓/螺丝Nut/Bolt/Screw 锻造件(加工) Forging Parts (Processing) 滤清器类Filter 锁Lock 镜类> Mirror

英语作文关于共享单车的篇精编

(一) 假定你是红星中学初三学生李华。你的美国朋友Jim在给你的邮件中提到他对中国新近出现的一种共享单车“mobike”很感兴趣,并请你做个简要介绍。请你给Jim回信,内容包括: 1. 这种单车的使用方法(如:APP查看车辆、扫码开锁等); 2. 这种单车的优势; 3. 你对这种单车的看法。 注意:1. 词数不少于80; 2. 开头和结尾已给出,不计入总词数。 提示词:智能手机smartphone, 二维码the QR code 参考范文 Dear Jim, I’m writing to tell you more about the new form of sharing bike mobike mentioned in your latest letter. It’s very convenient to use if you have a smartphone. What you do is find a nearest mobikethrough the APP, scan the QR code on the bike, and enjoy your trip. Compared to other forms of sharing bike, the greatest advantage of mobike is that you can easily find one and never worry about where to park it. It is becoming a new trend as a means of transportation, which relieves the traffic pressure and does good to the environment as well. Hope to ride a mobike with you in China. Yours, Li Hua (二) 最近很多大城市都投放了共享单车(shared bikes),比如摩拜单车(Mobike)、Ofo共享单车等。由于它们方便停放,骑车也能起到锻炼身体的作用,作为代步工具很受大家欢迎。但是,各地也出现了很多毁车现象,比如刮掉车上的二维码(QR code)、上私锁等。 你对这种现象怎么看?你对共享单车公司有什么建议吗?写一篇符合逻辑的英语短文,80词左右。 参考词汇:bike-sharing companies 共享单车公司,Mobike 和Ofo 是两家共享单车公司,convenience 方便,register登记 参考范文 The shared bikes like Mobike and Ofo bring great convenience to people. You needn’t lock them by simply using your smart phone. They can take you where the subway and bus don’t go. And they can be left anywhere in public for the next user. However, bad things happen. Some people damage the QR code on the bike, or use their own lock, which causes trouble to other users. In my opinion, it’s difficult to turn these people’s ideas in a short time. Therefore, bike-sharing companies like Mobike and Ofo need to do something. For example, those who damage the bike should pay for their actions. Also, because people use their real name toregister as a user, it’s a good way to connect to one’s personal credit. In the end, what I want to say is to take good care of public services. (三) 共享单车(bicycle sharing)已成为时下最热的话题之一,请你就这一话题写一篇短文。内容须包括三方面:1. 共享单车蓬勃发展,成为社会热潮;2. 共享单车带来便利,但也存在问题;3. 我对解决问题的建议。 参考范文 Bicycle Sharing With the development of technology, bicycle sharing comes into people's lives. It becomes more and more popular and much news reported it. At the same time, we should see that there are some problems caused by bicycle sharing. On one side, bicycle sharing makes it very convenient of people traveling. You can find a bicycle anywhere at any time when you want to go out for a cycling, and the price of one trip is very low. It can save time for people. On the other side, its management is not perfect. Even kids can open the lock and ride the bicycle, there is no doubt that such behavior is very dangerous.

Pickering乳液的制备及应用研究

西安科技大学 硕士学位论文Pickering乳液的制备及应用研究 姓名:刘登卫 申请学位级别:硕士 专业:化学工艺 指导教师:贺拥军 2011

论文题目:Pickering乳液的制备及应用研究 专 业:化学工艺 硕 士 生:刘登卫(签名) 指导教师:贺拥军(签名) 摘 要 Pickering乳液是以固体粒子替代传统化学乳化剂制得的热力学和动力学均稳定的分散体系。Pickering乳液由于其成本低、无毒和环保等特性,在食品、医药和化妆品等领域具有重要的应用价值。本文以固体粒子为乳化剂制备了稳定的Pickering乳液,考察了影响Pickering乳液形成和稳定性的因素,并研究了Pickering乳液作为分离介质的应用性能。 采用St?ber法制备了SiO2粒子,用直接沉淀法制备了ZnO粒子和MgO粒子,利用晶相生长逐层包覆的方法制备了SiO2/ZnO复合粒子,讨论了反应物浓度、滴加方式和滴加速度等因素对固体粒子形貌和分散性的影响。SEM测试表明,SiO2粒子分散性良好,平均粒径约为300 nm;ZnO粒子呈针状结构,平均直径为20 nm;ZnO在SiO2表面分布不均,改变锌盐溶液的浓度和滴加速度,可以得到ZnO组分含量不同的SiO2/ZnO复合粒子;MgO粒子有球形和立方晶形结构,平均粒径约为100 nm。FTIR检测表明,SiO2、ZnO、SiO2/ZnO和MgO粒子表面均有大量的羟基。XRD分析证明,MgO结晶度较高。 以SiO2、ZnO、SiO2/ZnO和MgO粒子为乳化剂,制备了O/W型Pickering乳液,考察了固体粒子种类、复合粒子组分含量、油水体积比、连续相中电解质和表面活性剂等因素对乳液稳定性的影响。以三氯甲烷为油相时,基于SiO2和ZnO制备的乳液很不稳定,而SiO2/ZnO和MgO均能得到稳定的乳液,且SiO2/ZnO中ZnO组分含量越高,乳液滴越小。在MgO稳定的三氯甲烷/水乳液中,增加油水体积比,乳液稳定性下降,但没有发生相转变。当连续相中电解质浓度增加时,乳液稳定性下降,且Na2CO3比NaCl 的作用强。给MgO稳定的三氯甲烷/水乳液中加入表面活性剂,乳液滴变小且更稳定;给表面活性剂稳定的三氯甲烷/水乳液中加入固体粒子,乳液滴平均直径增大而稳定性也增加。 以SiO2/ZnO稳定的三氯甲烷-苯乙烯/水乳液为介质,进行了静态和动态分离甲基紫的研究。在静态分离下,Pickering乳液在30 min内就趋于分离饱和,温度对分离效果的影响不大,而增加乳液量和增大甲基紫水溶液浓度可以提高乳液分离能力,分离前后乳液滴的形貌变化不大。在动态分离下,增加Pickering乳液量、降低甲基紫溶液进水

汽车零部件中英文对照表

汽车类Automobile English 整车Finished Automobile 轿车Passenger Car 休旅车Recreational Vehicle (RV) 小型商用车(3.5吨以下) Light Duty Commercial Car (Less Than 3.5 Tons) 大型商用车(3.5吨以上) Heavy Duty Commercial Car (More Than 3.5 Tons) 散装车Bulk Truck 搅拌车Mixer Truck 环境卫生车Garbage Truck 液罐车Refueling Truck 倾卸车Dumper Truck 曳引车Tractor Truck 消防车Fire Fighting Truck 堆高机Forklift 拖板车Pallet Truck 运钞车Armor Cash Carrier 冷气客车Air-Conditioned Car 冷冻车Freezer Car 拖车Trailer 车体打造(改装) Car Body Building (Refitting) 瓦斯车LPG Car 底盘车Chasis Truck 引擎零件Engine Parts 引擎Engine 引擎波司Engine Bush 引擎修理包Engine Gasket Kits 引擎零件Engine Parts 凸轮轴Camshaft 凸轮轴链轮Sprocket Camshaft 皮带张力器Tensioner 曲轴Crankshaft 曲轴皮带盘Crankshaft Pulley 曲轴轴承片Crankshaft Bearing 汽门Valve 汽门座Valve Seat 汽门摇臂Valve Arm 汽门摇臂盖Rocker Cover 汽门弹簧Valve Spring 汽门导管Valve Guide 汽缸头(盖) Cylinder Head 汽缸衬套Cylinder Liner 汽缸体Cylinder Block 波司垫片Washer 活塞Piston 活塞肖Piston Pin 活塞环Piston Ring 活塞衬套Piston Liner 飞轮Flywheel 飞轮环齿轮Ring Gear of Flywheel 时规炼条/皮带Timing Chain/Belt 连杆Connecting Rod 连杆轴承片Connecting Rod Bearing 摇臂轴Rocker Arm Shaft 汽门锁Valve Cotter 止推垫片Thrust Washer 共鸣箱Resonator 喷油嘴Injection Nozzle 燃料系统Fueling System 油箱Fuel Tank 油箱浮筒Gauge Fuel Tank 空气滤清器Air Cleaner 空气滤清器盖Air Cleaner Cover 空气滤清器导管Air Intake Tube 空气滤蕊Air Cleaner Element 消音器Exhaust Muffler 排气歧管Exhaust Manifold 排气管Exhaust Pipe 进气歧管Intake Manifold

汽车利弊英语作文4篇

[标签:标题] 篇一:关于汽车的英语作文 好的 Nowadays, with the rapid improvement of people’s living standards, cars have become an indispensable part of people's lives,so that more and more people have a car of their own, especially in cities. It brings some benefits for us but also causes many problems at the same time. For one thing,there’s no doubt that cars provide much convenience for people to go where they want to quickly and easily. Especially on weekday,driving a car can save a lot of time for us to go to work.When some places are too far away from our home, driving our own car is also convenient, we can go wherever we want. However,for another, too many cars will lead to the pressure of public transport, a series of problems will appear.First of all,it will bring about more air pollution,a large amount of polluted air given off by cars do great harm to our health.What’s more, as the existing roads are not so wide for the increasing number of cars,undoubtedly,traffic jams will become more and more serious. Last but not least, cars also place burden on the public facilities in providing more parking lots. As far as I am concerned,everything has its advantages and disadvantages. It’s high time that effective action must be token to limit the ever growing number of cars, the government should take measures to control the air pollution from the cars. Some roads should be widened and more new roads should be constructed. Only in this way,will people benefit from the popularity of cars. 坏的 Nowadays, with the rapid improvement of people's living standards, cars have become an indispensable part of people's lives,so that more and more people have a car of their own, especially in cities.It brings some benefit for us but also causes many problems at the same time. For one thing,it's no doubt that that cars provide much convenience for people to go where they want to quickly and easily. Especially on weekday,driving a car can save a lot of time for us to go to work.When some places are too far away from our home, driving our own car is also convenient, we can go wherever we want. However,for another, too many cars will lead to the pressure of public transport, a series of problems will appear.First of all,it will bring about more air pollution,a large amount of polluted air given off by cars do great harm to our health .What's more, as the existing roads are not so wide for the increasing number of cars,undoubtedly,traffic jams will become more and more serious. Last but not least, cars also place burden on the public facilities in providing more parking lots. As far as I am concerned,everything has its advantages and disadvantages. It's high time that effective action must be token to limit the ever growing number of cars, the government should take measures to control the air pollution from the cars. Some roads should be widened and more new roads should be constructed. Only in this way,will people benefit from the popularity of cars. 篇二:雅思作文高分范文:私家车的利与弊 智课网IELTS备考资料 雅思作文高分范文:私家车的利与弊

废乳化油的破乳方法

废乳化油的破乳方法,主要有酸化法和聚化法两种。 酸化法就是往废乳化液中加入酸(如盐酸或硫酸)。 所加入的酸可利用工业废酸。 由于在目前的乳化液配方中,多数选用阴离子型乳化剂(如石油磺酸钠、磺化蓖麻油),所以遇到酸就会破坏,乳化生成相应的有机酸,使油水分离,而酸中氢离子的引入,也有助于破乳的过程。 酸的用量是待处理乳化液重量的0.2%,浓度为37%; 如果采用废酸时,则酸的用量应适当加大。 聚化法就是在废乳化油中添加盐类电解质(如0.4%氯化钙)和凝聚剂(如0.2%明矾),以达到乳化液破乳的目的。酸化法的优点是油质较好,成本低廉,水质也好,水质中含油量一般在20mg/L以下,化学耗氧量(COD)值也比其它破乳方法低;其缺点是沉渣较多。聚化法的优点是投药量少,一般工厂均有条件使用,但油质较差。 针对难处理乳化油破乳过程中存在的问题,通过对现有油水分离技术的总结和各种破乳方案的比较,提出了微波破乳—离心分离的新工艺。该工艺处理沉降罐中间层难处理乳化油技术指标优越,可有效解决该部分液压支架乳化油的破乳问题。 通过对现有离心机特点的分析,提出了适用于油、水、渣分离的BKD-1000三相立式离心机的设计方案,该机具有分离区整体旋转的特点,流体获得了较高的离心加速度。 微波破乳器的试验室模拟试验表明,采用微波破乳—离心分离工艺处理模拟乳化油,可使模拟乳化油油水有效分离,油中含水率由50.0%降至5.51%, 油的回收率达到98.33%。BKD-1000三相立式离心机的工业试验表明, 处理油田干化池含油污水可使油中含水率降至3.56%,油的回收率达到85.26%,排渣浓度达到62.18%,达到了现场提出的工业试验要求。

汽车零部件中英文对照

汽车零部件中英文对照 车轮系统Wheeling System Wheel Hub轮毂 轮胎Tire 轮胎汽门嘴ValveTire 轮圈DiskWheel 轮圈盖CoverWheel 内胎((Flap)含内衬)TireInner 车轮系统Wheeling System 电装品PartsElectrical

电瓶Battery 中央门控LockDoorCentral 分电盘Distributor 火星塞PlugSpark 汽车用电子钟Digital Clock 汽车音响AudioCar 防盗器Alarm BurglarCar 雨刷及雨刷连杆WiperLinkage/保险丝座FuseSeat 保险丝Fuse 洗涤壶Windshield Washer Wire配线Harness

Motor马达类 Ignition Cable高压线组 Horn喇叭 Alternator(Components)(发电机零件) Switch开关类 Buzzer蜂鸣器 Plug预热塞Glow MeterCombination仪表 Bulb灯泡 Lamp灯类 Coil点火线圈Ignition

Relay继电器 SensorReverse倒车雷达Charger电池充电器Battery Flasher闪光器 Unit省电器Saving Energy Terminal端子 Unit Power Seat电动座椅装置Components马达零件Motor Parts电装品Electrical 汽车用光盘Car CD Car LCD汽车用液晶显示器

调整器Regulator 整流器Rectifier 电子点火器ModuleIgnition 倒车显示器View DisplayRear 定速器CruiseController HID Set车灯安定器组合HIDBallast Complete for Headlights LED灯LED Lamp Lighting Controller车灯控制器 点火线圈模块ModuleIgnition Coil 外装品PartsExterior

汽车的重要性《英语作文》

汽车的重要性《英语作文》 The automobile has become one of the most important means/ways of transportation in the world since it was invented. The automobile has completely changed the lifestyles of almost all the people in the world. In the past, animals like horses and camels were used for traveling and transporting goods. Automobiles are more comfortable and faster. Automobiles have also made it possible for us to transport large quantities of goods and people at the same time. Besides, the invention of the automobile has provided jobs for millions of people all over the world. 翻译: 汽车已经成为世界上最重要的交通工具之一,因为它是发明的。汽车已经完全改变了世界上几乎所有的人的生活方式。 在过去,像马和骆驼的动物被用来运送货物。汽车更舒适,更快速。汽车也使我们能够在同一时间运送大量货物和人。 此外,汽车的发明为全世界上百万的人提供了工作。

废乳化液处理

精心整理 废乳化液 机械制造工业中,金属切削加工使用大量乳化液作为润滑冷却之用,乳化液经过一段时间使用后 , 就会变成废水排出。 乳化液中主要含有机油和表面活性剂,是用乳化油根据需要用水稀释再加入乳化剂配制而成的。在机床切削使用的乳化液中为了提高乳化液的防锈性 , 还加入了亚硝酸钠等。

2. 2.1 乳化液废水处理原理 根据乳化液的性质,进行乳化液废水的处理需经过二个步骤: 破乳剂油; (2) 水质净化去除表面活性剂等物质。 破乳方法种类较多,有盐析法、乳酸法、凝聚法、顶替法、高压电法、吸附法等等。一般常用的采用盐析凝聚混合法,现介绍如下 在乳化液中加入电解质,电解质的离子在乳化液中发生强烈的水化作用即争水作用,使乳化 液中的自由水分子减少了 , 对油珠产生脱水作用,从而破坏了乳化液油珠的水化层,中和了油珠

的电性,破坏了它的双电层结构,因而油珠失去了稳定性,产生凝聚现象 ( 电解质一般分为二、三价的钙、镁、铝等盐类 ) ,其反应式如下: 2C 17 H 33 COONa + 2MgCl 2 -→ (C 17 H 33 COO) 2 Mg+2NaCl 油酸皂镁皂 2C 17 H 33 (OSO 3 Na) COONa+2CaCl 2 -→ (C 17 H 32 ) 2 (OSO 3 ) 2Ca (COO) 2 +4NaCl 磺化蓖麻油

2-2 所示: 2.2 处理工艺流程选择及设备

图 2-1 原乳化液处理机处理工艺流程图

上述处理工艺流程中存在以下问题 : a. 由于乳化液中油、SS、COD含量较高,一级气浮只能除去大部分油、SS、COD,残留的部分只能靠石英砂滤罐、两级活性炭吸附来保证出水达标,因此石英砂滤罐及两级活性炭滤罐负荷较重,造成经常反冲和活性炭很快饱和失去吸附作用需要更换的情况发生。 b.气浮设备进气未设自控装置,靠人工调整,很难达到良好的气浮效果,工人操作难度大。

汽车零部件中英文对照

车轮系统WheelingSystem 轮毂WheelHub 轮胎Tire 轮胎汽门嘴TireValve 轮圈WheelDisk 轮圈xxWheelCover 车轮系统WheelingSystem 电装品ElectricalParts 电瓶Battery 中央门控CentralDoorLock 分电盘Distributor 火星塞SparkPlug 汽车用电子钟DigitalClock 汽车音响CarAudio 防盗器CarBurglarAlarm 雨刷及雨刷连杆Wiper/Linkage 保险丝座FuseSeat 保险丝Fuse 洗涤壶WindshieldWasher 配线WireHarness xx类Motor

高压线组IgnitionCable 喇叭Horn 发电机(零件)Alternator(Compon ents) 开关类Switch 蜂鸣器Buzzer 预热xxGlowPlug 仪表CombinationMeter 灯泡Bulb 灯类Lamp 点火线圈IgnitionCoil 继电器Relay 倒车xxReverseSensor 电池充电器BatteryCharger 闪光器Flasher 省电器EnergySavingUnit 端子Terminal 电动座椅装置PowerSeatUnit xx零件MotorComponents 电装品ElectricalParts汽车用光盘CarCD 汽车用液晶显示器CarLCD调整器Regulator

整流器Rectifier 电子点火器IgnitionModule倒车显示器RearViewDisplay定速器CruiseController HID车灯安定器组合HIDBallastCompleteSetforHeadlightsLED灯LEDLamp 车灯控制器LightingController点火线圈模块IgnitionCoilModule 外装品ExteriorParts 水箱饰罩RadiatorGrille 天线Antenna 车身护条SideProtector 防撞护垫BumperPad 后视镜DoorMirror 装饰贴纸、标志OrnamentMark轮弧FenderTrim 挡泥板MudGuard 扰流板Spoiler 前防撞杆GuardAssy(Front)后防撞杆GrardAssy(Rear)内装品InteriorParts 仪表板InstrumentPanel中央置物箱Console xxGrommetPlug 地毯FloorMat xxSeatBelt 车门扶手DoorArmrest 车门把手DoorHandle

汽车英文演讲稿

汽车英文演讲稿 篇一:汽车英语演讲稿 Good morning everyone ,today, the topic of my lecture(演讲) is “Do you love automobiles('tmbilz)”. before I start my speech ,I want to ask a question,did there anybody present had seen the movie”the Fast and the Furious['fjrs]”.There are many cars of different styles in the movie,for example ,when you see the movie,you can find roadsters(跑车) just like Porsche(保时捷) GT3,sports utility (通用的)vehicles (车)SUV such as Volkswagen ['f:lks,va:gn]Touareg ['twɑ:reɡ](大众途锐),even armored cars ,all of them are so powerful and beautiful. When I was a child,I dreamed I can have a car like FORD GT 40,this racing bike(跑车) is amazing and fantastic,but as time goes on ,my hobby is changing,now my favorite car is Jeep Rubicon,this is a car I really want ,it’s dynamic performance(性能) and off-road (越野) performance is top-ranking(一流的) ,which other ordinary SUV is unable to compare; the shape and color of this car is magnificent (华丽的) [mg'nfs()nt],and it’s gear-shift system(齿轮转

基于Pickering乳液构建的多级孔材料及其应用研究

基于Pickering乳液构建的多级孔材料及其应用研究 多级孔结构在自然界无处不在。尤其是在生命有机体中,多级孔结构在细胞、组织甚至器官的构建中都起着非常重要的作用。 迄今为止,受大自然的启发,科学家们已经成功地制备了大量具有多级孔道结构的材料,在材料的设计、合成和应用等方面都取得了巨大的进展。然而与自然界中的多级孔结构相比,“人造的”多级孔材料还有许多方面需要提高。 譬如,孔道结构比较简单、机械强度比较差和功能比较单一等。因此,如何设计制备结构丰富、应用广泛和性能良好的多级孔材料,依然是该领域研究的一个热点。 在本论文中,我们设计开发了一种基于Pickering乳液的多重模板法,结合溶胶凝胶和分子自组装技术,成功地合成了一系列孔道结构丰富、孔径分布可调的多级孔材料,并探索了这些多级孔材料在超级电容器等领域的应用。与传统乳液相比,Pickering乳液(即固体颗粒稳定的乳液),不但稳定性高,而且具有双重模板的特性。 该多重模板法工艺简单、易于放大,且具有广泛的适用性和灵活性。本论文的主要研究内容可分为四个部分,具体结论概括如下:1.基于水包油Pickering 乳液模板制备多级孔二氧化硅微胶囊的研究设计开发了一种基于水包油Pickering乳液的多重模板法。 该方法以碳酸钙棒稳定的油滴为软模板,碳酸钙棒为硬模板,辅以十六烷基三甲基溴化铵(Hexadecyltrimethylammonium bromide,CTAB)胶束模板,成功地合成了具有微孔-介孔-大孔多级孔结构的二氧化硅微胶囊。该微胶囊含有5种不同的孔道结构,其孔径分布从1 nm到100μm,横跨多达5个数量级。

乳化液

近几年来,我国切削液生产发展较快,新产品不断推出,但归纳起来,它们的基本成分都是由油、水和各种化学添加剂配制而成。生产中常用的切削液有切削油、乳化液和水溶液三大类。切削油润滑和防锈性好,但冷却和清洗性较差,切削时在切削区会形成油雾,造成环境 污染,同时油资源消耗多,生产成本高。水基切削液的冷却和清洗性较好,但防锈性较差。乳化液具有一定的润滑性、冷却性、清洗性和防锈性,是目前生产中使用最广泛的一种切削液。但它的使用寿命短,废液多,排放时水质污染较严重,因此必须进行净化和废液回收处理。现就乳化液的组成及其净化方法,废液的回收处理,以及如何延长乳化液使用寿命等问题,介绍如下。 乳化液的组成及其净化方法 1.乳化液的组成 乳化液是用矿物油、乳化剂(如石油磺酸钠、磺化蓖麻油等)及添加剂预先配制好的 乳化油,加水稀释而成。因为油不溶于水,为了使两者混合,所以必须加入乳化剂。 乳化剂是一种表面活性剂,它的分子是由极性基团和非极性基团两部分组成。前者 亲水,可溶于水;后者亲油,可溶于油。把油在水中搅拌成细粒时,乳化剂分子能 定向地排列吸附在油水两界面上,把油和水连接起来,使分离的细粒不再因凝聚而 浮游在水中,成为浮浊液。乳化液中含乳化油少,即浓度低的(如浓度为3%~5%),冷却和清洗作用较好,适于粗加工和磨削;浓度高的(如浓度为10%~20%),润滑作 用较好,适于精加工(如拉削和铰孔等)。为了进一步提高乳化液的润滑性能,还可 加入一定量的氯、硫、磷等极压添加剂,配制成极压乳化液。 2.乳化液的净化方法 近几年来研究表明,如将切削液中的杂质(如碎屑、砂轮粉末等)从40μm降低到10μm,刀具耐用度可延长1~3倍。由于人们的肉眼看不见小于40μm的微粒,所以当切削 液中的杂质,尺寸小于20μm,常被人们所忽视,然而这些不可见的杂质对金属切削 加工有着不可低估的影响。在切削加工时,它们将进入到刀具前刀面与切屑以及刀 具后刀面与工件接触区的界面上,产生强烈摩擦,使切削温度增加,并使刀具耐用 度大大降低,同时使加工表面质量变差。因此,目前的研究认为,无论是精密加工, 还是在钻削、扩孔、铰孔和镗孔等普通加工中,为了提高刀具耐用度和可靠性,改 善零件加工质量,均应使用净化的切削液。此外,清洁的切削液还可防止微生物的 生长。乳化液的使用寿命短、易变质,与在乳化液中微生物的生长有重要关系。在 乳化液中微生物的繁殖十分惊人。乳化液含细菌量的标准是不超过1000个/mL,当 细菌繁殖到大于0.1×105~1×106个/mL时,乳化液就会变质发臭,并会污染周围环 境,使空气中含有硫化氢和二氧化碳等有害气体,影响工人健康。保持乳化液的清

(完整版)关于汽车的零部件名称中英文大全

关于汽车的零部件名称中英文大全 座杆束SeatPostClamp 座杆SeatPost 座垫套SaddleCover 座垫Seat 座垫Saddles 自行车类Bicycle 自排车用滤油器OilFilterforAutomaticTransmission 自排变速箱修理包AutomaticTransmissionGasketKits 自动变速箱油AutomaticTransmissionOil 装饰贴纸、标志OrnamentMark 转向总成SteeringAssembly 转向主干SteeringStemComp 转向连杆SteeringLinkage 转向节臂Knuckle 转向机柱SteeringColumn 转向齿轮箱SteeringGearBox 铸造件(加工)CastingParts(Processing) 主轴、副轴Mainshaft/Countershaft 主脚架MainStand 主滑动模轮组件PrimarySheaveAssembly 轴承Bearing 中轴组件(天心)BottomBracketParts 中央置物箱Console 中央门控CentralDoorLock 中心盖CenterCover 置物袋CarriageBag 趾夹带ToeStrap 止推垫片ThrustWasher 支柱总成StrutAssembly 支架Bracket 整流器Rectifier 整车FinishedMotorcycle 整车FinishedBicycle 蒸发器Evaporator 折叠式自行车FoldingBicycle 遮阳板Sunvisor 运钞车ArmorCashCarrier 越野车TrekkingBicycle 预热塞GlowPlug 雨刷及雨刷连杆Wiper/Linkage 油压感应器OilPressureSensor

英语作文:关于共享单车的4篇范文

英语作文:关于共享单车的4篇范文 共享单车确实是今年最热的话题之一,很多小伙伴们留言问共享单车要怎么写英语作文,这一份写作指南想必大家都很需要。 词汇篇 bicycle-sharing /sharing bike /shared bikes 共享单车 bicycle /bike /cycle 自行车 ride a bicycle /take a ride /cycling /cycle /bicycle /bike 骑自行车 park 停车 Bluegogo 小蓝单车 Ofo bicycle 小黄车 Mobike 摩拜单车 APP 应用程序(全称为application) scan the QR code

扫描二维码 unlock the smart lock 解开智能锁 timer 计时器 user 用户 smartphone 智能手机 keep fit 健身 environmental protection/ environment friendly/ help the environment 环保的 In full swing 如火如荼 brightly coloured 色彩鲜艳 The combination of technology, creativity and market forces 科技、创意、市场力量的结合 has changed the image of the city 改变了城市形象

curb carbon dioxide emissions 减少二氧化碳排放 reduce road congestion 减少道路拥堵的情况 random parking 随机停车 illegal parking 乱停乱放 bicycle damage 车辆损坏 traffic violation 违章 social mind 公德心 quality 素质 范文篇 (一) 假定你是红星中学初三学生李华。你的美国朋友Jim在给你的邮件中提到他对中国新近出现的一种共享单车“mobike”很感兴趣,并请你做个简要介绍。请你给Jim回信,内容包括: 1. 这种单车的使用方法(如:APP查看车辆、扫码开锁等);