大涡模拟的FLUENT算例2D

Tutorial:Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

Introduction

The purpose of this tutorial is to provide guidelines and recommendations for the basic setup and solution procedure for a typical aeroacoustic application using computational aeroacoustic(CAA)method.

In this tutorial you will learn how to:

?Model a Helmholtz resonator.

?Use the transient k-epsilon model and the large eddy simulation(LES)model for

aeroacoustic application.

?Set up,run,and perform postprocessing in FLUENT.

Prerequisites

This tutorial assumes that you are familiar with the user interface,basic setup and solution procedures in FLUENT.This tutorial does not cover mechanics of using acoustics model,but focuses on setting up the problem for Helmholtz-Resonator and solving it.It also assumes that you have basic understanding of aeroacoustic physics.

If you have not used FLUENT before,it would be helpful to?rst review FLUENT6.3User’s Guide and FLUENT6.3Tutorial Guide.

Problem Description

A Helmholtz resonator consists of a cavity in a rigid structure that communicates through a

narrow neck or slit to the outside air.The frequency of resonance is determined by the mass of air in the neck resonating in conjunction with the compliance of the air in the cavity.

The physics behind the Helmholtz resonator is similar to wind noise applications like sun roof bu?eting.

We assume that out of the two cavities that are present,smaller one is the resonator.The motion of the?uid takes place because of the inlet velocity of27.78m/s(100km/h).The ?ow separates into a highly unsteady motion from the opening to the small cavity.This unsteady motion leads to a pressure?uctuations.Two monitor points(Point-1and Point-2) act as microphone points to record the generated sound.The acoustic signal is calculated within FLUENT.The?ow exits the domain through the pressure outlet.

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA) Preparation

1.Copy the?les steady.cas.gz,steady.dat.gz,execute-by-name.scm,stptmstp4.scm,

ti-to-scm-jos.scm and stptmstp.txt into your working directory.

2.Start the2D double precision(2ddp)version of FLUENT.

Setup and Solution

Step1:Grid

1.Read the initial case and data?les for steady-state(steady.cas.gz and steady.dat.gz).

File?→Read?→Case&Data...

Ignore the warning that is displayed in the FLUENT console while reading these?les.

2.Keep default scale for the grid.

Grid?→Scale...

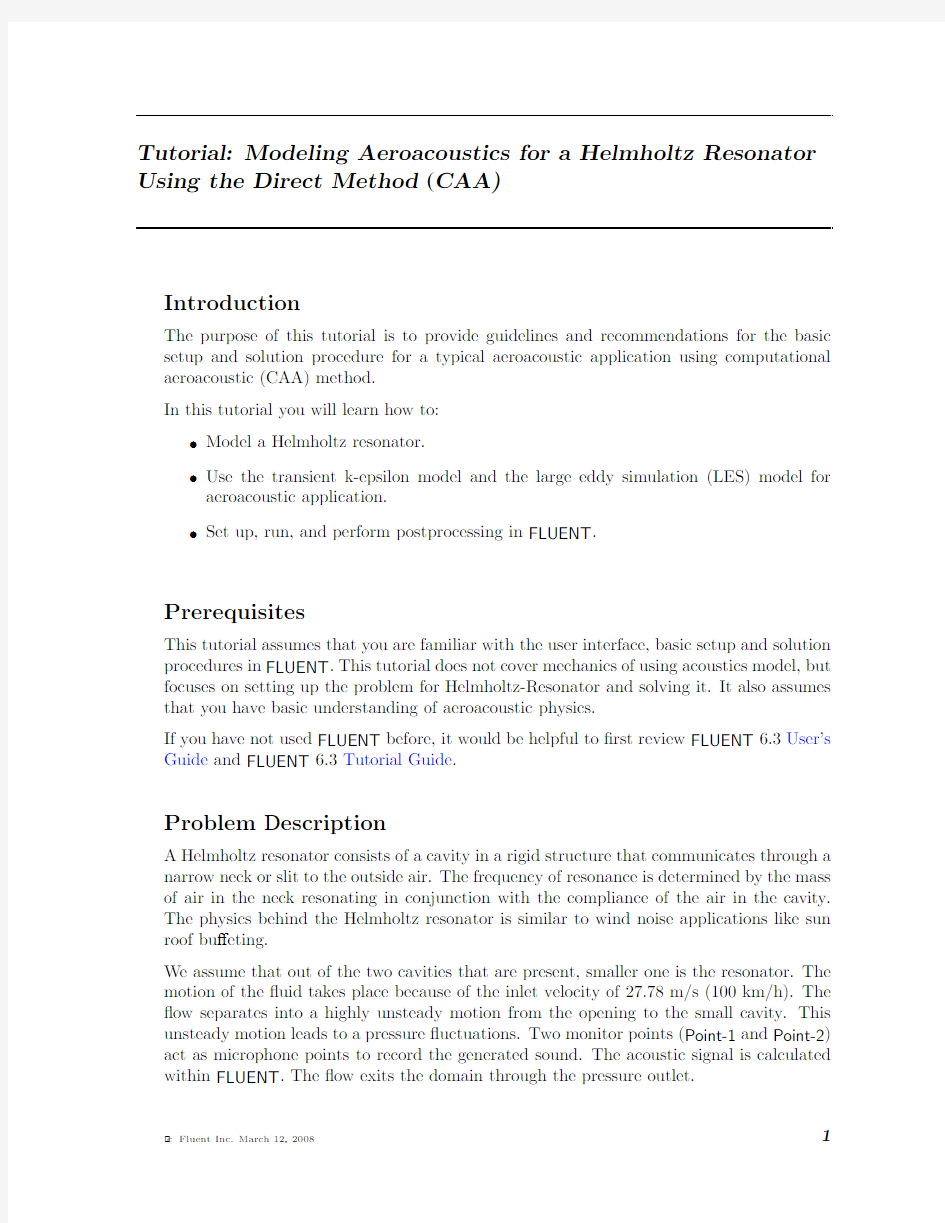

3.Display the grid and observe the locations of the two monitor points,Point-1and

Point-2(Figure1).

Figure1:Graphics Display of the Grid

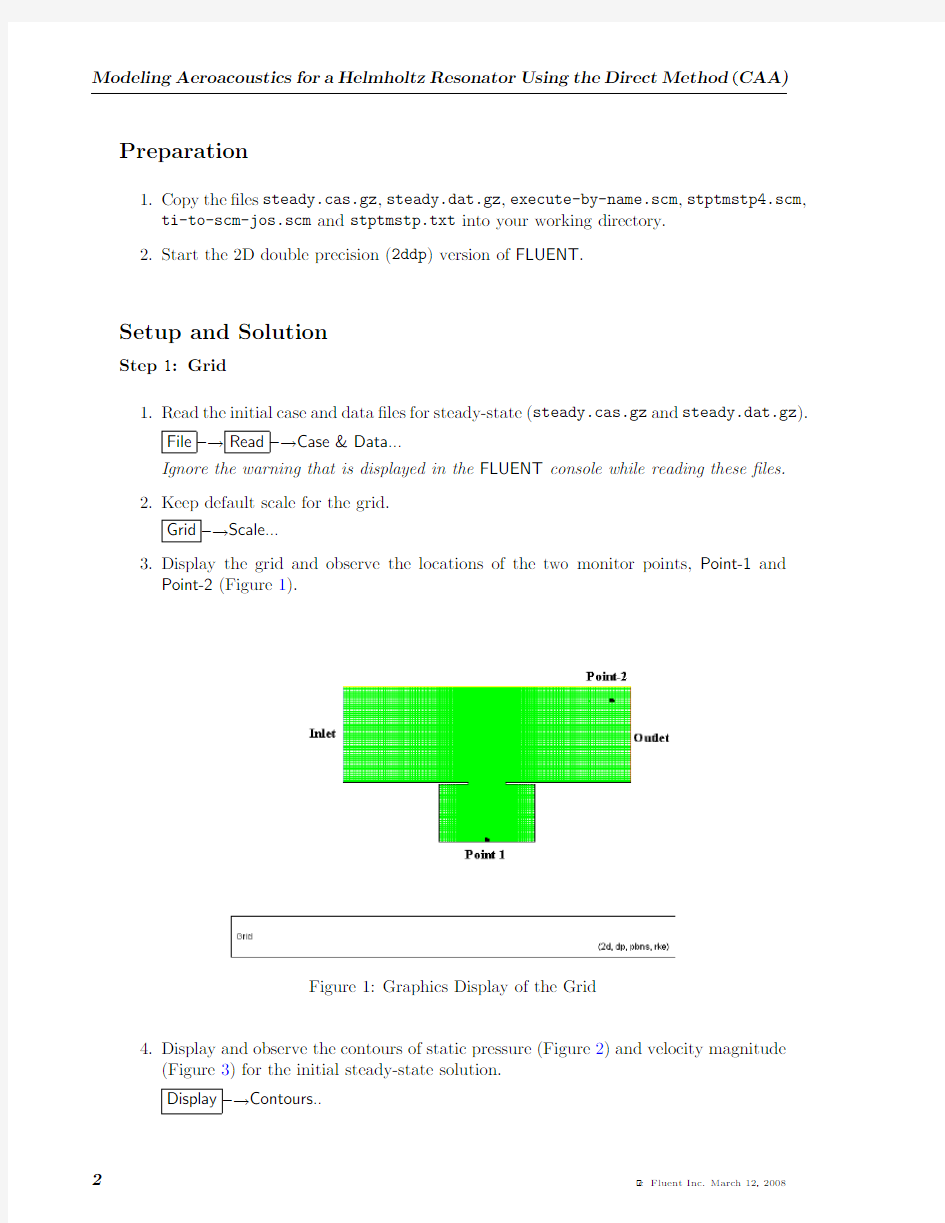

4.Display and observe the contours of static pressure(Figure2)and velocity magnitude

(Figure3)for the initial steady-state solution.

Display?→Contours..

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

Figure2:Contours of Static Pressure(Steady State)

Figure3:Contours of Velocity Magnitude(Steady State)

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA) Step2:Models

1.Select unsteady solver.

De?ne?→Models?→Solver...

(a)Select Unsteady in the Time list.

(b)Select2nd-order-implicit in the Unsteady formulation list.

(c)Retain the default settings for other parameters.

(d)Click OK to close the Solver panel.

2.De?ne the viscous model.

De?ne?→Models?→Viscous...

(a)Select Non-Equilibrium Wall Functions in the Near-Wall Treatment list.

(b)Retain the default settigns for other parameters.

(c)Click OK to close the Viscous Model panel.

Near-Wall Treatment predicts good separation and re-attachment points.

Step3:Materials

De?ne?→Materials...

1.Select ideal-gas from the Density drop-down list.

2.Retain the default values for other parameters.

3.Click Change/Create and close the Materials panel.

Ideal gas law is good in predicting the small changes in the pressure.

Step4:Solution

1.Monitor the static pressure on point-1and point-

2.

Solve?→Monitors?→Surface...

(a)Enter2for the Surface Monitors.

(b)Enable Plot and Print options for monitor-1and monitor-2.

(c)Select Time Step from the When list.

(d)Click De?ne...for monitor-1to open De?ne Surface Monitor panel.

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method

(CAA)

i.Select Vertex Average from the Report Type drop-down list.

ii.Select Flow Time from the X Axis drop-down list.

iii.Enter1for Plot Window.

iv.Select point-1from the Surfaces selection list.

(e)Similarly,specify the surface monitor parameters for point-2.

2.Start the calculations using the following settings.

Solve?→Iterate...

(a)Enter3e-04s for Time Step Size.

The expected time step size for this problem is of the size of about1/10th of the

time period.The time period depends on the frequency(f)which is calculated

using the following equation:

f=

c

2π

S

V[L+π

2

.D h

2

]

where,

c=Speed of sound

S=Area of the ori?ce of the resonator

V=Volume of the resonator

L=Length of the connection between the resonator and the free?ow area

D h=Hydraulic diameter of the ori?ce

For this geometry,the estimated frequency is about120Hz.

(b)Enter250for the Number of Time Steps.

(c)Enter50for Max Iterations per Time Step.

(d)Click Apply.

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

(e)Read the scheme?le(stptmstp4.scm).

File?→Read?→Scheme...

This?le activates a alternative convergence criteria.For acoustic simulations

with CAA it is obligatory that the pressure is completely converged at the reciever

position.FLUENT compares the monitor quantities within the last n-de?ned it-

erations to judge if the deviation is smaller than a y-de?ned deviation.

(f)Specify the number of previous iterations from which monitor values of each

quantity used are saved and compared to the current(latest)value(include the

paranthesis):

(set!stptmstp-n5)

(g)Specify the relative(the smaller of two values in any comparison)di?erence

by which any of the older monitor values(for a selected monitor qauntity)may

di?er from the newest value:

(set!stptmstp-maxrelchng1.e-02)

(h)De?ne the execute commands.

Solve?→Execute Commands

i.Enter(stptmstp-resetvalues)for the?rst command and select Time Step

from the drop-down list.

ii.Enter(stptmstp-chckcnvrg"/report/surface-integrals vertex-avg point-1 ()pressure")and select Iteration from the drop-down list.

iii.Click OK.

(i)Click Iterate to start the calculations.

The iterations will take a long time to complete.You can skip this simulation af-

ter few time steps and read the?les(transient.cas.gz and transient.dat.gz)

provided with this tutorial.These?les contain the data for the?ow time of0.22

seconds.As seen in Figures4and5,no pressure?uctuations are present at this

stage.The oscillations of the static pressure at both monitor points has reached

a constant value.

The RANS-simulation is a good starting point for Large Eddy Simulation.If

you choose to use the steady solution as initial condition for LES,use the TUI

command/solve/initialize/init-instantaneous-vel provides to get a more realistic

instantaneous velocity?eld.The usage of LES for acoustic simulations is obliga-

tory.The next two pictures compare the static pressure obtained with RANS and

Large Eddy Simulation for a complete simulation until0.525seconds.Obviously,

the k-epsilon model underpredicts the strong pressure oscillation after reaching

a dynamically steady state(>0.3s)due to its dissipative character.Under-

predicted pressure oscillations lead to underpredicted sound pressure level which

means the acoustic noise is more gentle.

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

Figure4:Convergence History of Static Pressure on Point-1(Transient)

Figure5:Convergence History of Static Pressure on Point-2(Transient)

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA) Step5:Enable Large Eddy Simulation

1.Enter the following TUI command in the FLUENT console:

(rpsetvar’les-2d?#t)

2.Enable large eddy simulation e?ects.

The k-epsilon model cannot resolve very small pressure?uctuations for aeroacoustic

due to its dissipative https://www.360docs.net/doc/9b5522280.html,e Large Eddy Simulation to overcome this problem.

De?ne?→Models?→Viscous...

(a)Enable Large Eddy Simulation(LES)in the Model list.

(b)Enable WALE in the Subgrid-Scale Model list.

(c)Click OK to close the Viscous Model panel.

An Information panel will appear,warning about bounded central-deferencing be-

ing default for momentum with LES/DES.

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

(d)Click OK to close the Information panel.

3.Retain default discretization schemes and under-relaxation factors.

Solve?→Controls?→Solution...

4.Enable writing of two surface monitors and specify?le names as monitor-les-1.out and

monitor-les-2.out for monitor plots of point-1and point-2respectively.

Solve?→Monitors?→Surface...

To account for stochastic components of the?ow,FLUENT provides two algorithms.

These algorithms model the?uctuating velocity at velocity inlets.With the spec-

tral synthesizer the?uctuating velocity components are computed by synthesizing a

divergence-free velocity-vector?eld from the summation of Fourier harmonics.

5.Enable the spectral synthesizer.

De?ne?→Boundary Conditions...

(a)Select inlet in the Zone list and click Set....

i.Select Spectral Synthesizer from the Fluctuating Velocity Algorithm drop-down

list.

ii.Retain the default values for other parameters.

iii.Click OK to close the Velocity Inlet panel.

(b)Close the Boundary Conditions panel.

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA) Typically it takes a long time to get a dynamically steady state.Additionally,the

simulated(and recorded for FFT)?ow time depends on the minimum frequency in the

following relationship:

flowtime=

10

minimumfrequency

(1)

The standard transient scheme(iterative time advancement)requires a considerable amount of computaional e?ort due to a large number of outer iterations performed for each time-step.To accelerate the simulation,the NITA(non-iterative time advance-ment)scheme is an alternative.

6.Set the solver parameters.

De?ne?→Models?→Solver...

(a)Enable Non-Iterative Time Advancement in the Transient Controls list.

(b)Click OK to close the Solver panel.

7.Set the solution parameters.

Solve?→Controls?→Solution...

(a)Select Fractional Step from the Pressure-Velocity Coupling drop-down list.

(b)Click OK to close the Solution Controls panel.

8.Disable both the execute commands.

Solve?→Execute Commands...

9.Continue the simulation with the same time step size for1500time steps to get a

dynamically steady solution.

10.Write the case and data?les(unsteady-?nal.cas.gz and unsteady-?nal.dat.gz).

File?→Write?→Case&Data...

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

Figure6:Convergence History of Static Pressure on Point-1(Transient)

Figure7:Convergence History of Static Pressure on Point-2(Transient)

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA) Step6:Postprocessing

1.Display the contours of static pressure to visualize the eddies near the ori?ce.

2.Enable the acoustics model.

De?ne?→Models?→Acoustics...

(a)Enable Ffowcs-Williams&Hawkings from the Model selection list.

(b)Retain the default value of2e-05Pa for Reference Acoustic Pressure.

To specify a value for the acoustic reference pressure,it is necessary to activate

the acoustic model before starting postprocessing.

(c)Retain default settings for other parameters.

(d)Click OK to accept the settings.

A Warning dialog box appears.This is an informative panel and will not a?ect

the postprocessing results.

(e)Click OK to acknowledge the information and close the Warning panel.

3.Plot the sound pressure level(SPL).

Plot?→FFT...

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

(a)Click Load Input File...button.

(b)Select monitor plot?le for Point-1(monitor-les-1.out).

(c)Click Plot/Modify Input Signal....

i.Select Clip to Range,in the Options list.

ii.Enter0.3for Min and0.5for Max in the X Axis Range group box.

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

iii.Select Hanning in the Window drop-down list.

Hanning shows good performance in frequency resolution.It cuts the time

record more smoothly,eliminating discontinuities that occur when data is

cut o?.

iv.Click Apply/Plot and close the Plot/Modify Input Signal panel.

(d)Select Sound Pressure Level(dB)from the Y Axis Function drop-down list.

(e)Select Frequency(Hz)in the X Axis Function drop-down list.

(f)Click Plot FFT to visualize the frequency distribution at Point-1.

(g)Select Write FFT to File in the Options list.

Note:Plot FFT button will change to Write FFT.

(h)Click Write FFT and specify the name of the FFT?le in the resulting Select File

panel.

(i)Similarly write the FFT?le for monitor plot for point-2(Figure9).

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

Figure8:Spectral Analysis of Convergence History of Static Pressure on Point-1

Figure9:Spectral Analysis of Convergence History of Static Pressure on Point-2

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA) In Figures8and9,the sound pressure level(SPL)peak occurs at125Hz which is

close to the analytical estimation.Considering that this tutorial uses a slightly large

time step and a2D geometry,the result is?ne.

https://www.360docs.net/doc/9b5522280.html,pare the frequency spectra at point-1and point-2.

Plot?→File...

(a)Click Add...and select two FFT?les(point-1-fft.xy and point-2-fft.xy)

that you have saved in the previous step.

(b)Click Plot to visualize both spectra in the same window(Figure10).

Note that the peak for Point-1is a little higher than for Point-2.This is due to the dissipative behaviour of the sound in the domain.The bigger the distance between the reciever point and the noise source,the bigger is the dissipation of sound.This is the reason,why we use CAA method only for near?eld calculations.

Figure10:Comparison of Frequency Spectra at Point-1and Point-2

A second issue is the dissipation of sound due to the in?uence of the grid size.This applies

especially for which the wave lengths are very short.Thus,a too coarse mesh is not capable of resolving high frequencies correctly.In the present example,the mesh is rather coarse in the far-?eld.Thus,the discrepancy between both spectra is more evident in the high frequency range.

This behaviour can be seen in Figure11.

For high frequencies,the monitor for Point-1generates much fewer noise than monitor for Point-2due to coarse grid resolution.

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

Figure11:Spectral Analysis of Convergence history of Static Pressure The deviation of sound pressure level between the?rst two maximum peaks(50Hz and132 Hz)is quite small.The postprocessing function magnitude in fourier transform panel is similar to the root mean square value(RMS)of the static pressure at these frequencies.

We can use the RMS value to derive the amplitude of the pressure?uctuation which is responsible for the SPL-peak.The resolution of frequency spectra is limited by the temporal discretization.With the temporal discretization,the maximum frequency is

f max=

1

2 t

(2)

This frequency is de?ned as Nyquist frequency.It is the maximum educible frequency.To resolve up to f max the maximum allowable time step size is

f max=

1

2×f max

(3)

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

Figure12:Spectral Analysis of Convergence History of Static Pressure on Point-1

An instability of the?uid motion coupled with an acoustic resonance of the cavity(helmholtz resonator)produces large pressure?uctuations(at132Hz).Compared to this dominant helmholtz resonance the pressure?uctuation at50Hz is quite small.

Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA)

Figure13:Spectral Analysis of Convergence History of Static Pressure on Point-2

Summary

Aeroacoustic simulation of Helmholtz resonator has been performed using k-epsilon model and Large Eddy Simulation model.The advantage of using LES model has been demon-strated.You also learned how the sound dissipation occurs in the domain by monitoring sound pressure level at two di?erent points in the domain.The importance of using CAA method has also been explained.

fluent 软件介绍

百科名片 Fluent是目前国际上比较流行的商用CFD软件包,在美国的市场占有率为60%,凡是和流体、热传递和化学反应等有关的工业均可使用。它具有丰富的物理模型、先进的数值方法和强大的前后处理功能,在航空航天、汽车设计、石油天然气和涡轮机设计等方面都有着广泛的应用。 简介 Fluent算例 CFD商业软件FLUENT,是通用CFD软件包,用来模拟从不可压缩到高度可压缩范围内的复杂流动。由于采用了多种求解方法和多重网格加速收敛技术,因而FLUENT能达到最佳的收敛速度和求解精度。灵活的非结构化网格和基于解的自适应网格技术及成熟的物理模型,使FLUENT在转换与湍流、传热与相变、化学反应与燃烧、多相流、旋转机械、动/变形网格、噪声、材料加工、燃料电池等方面有广泛应用。 基本特点 FLUENT软件具有以下特点: FLUENT软件采用基于完全非结构化网格的有限体积法,而且具有基于网格节点和网格单元的梯度算法; 定常/非定常流动模拟,而且新增快速非定常模拟功能; Fluent 前处理网格划分 FLUENT软件中的动/变形网格技术主要解决边界运动的问题,用户只需指定初始网格和运动壁面的边界条件,余下的网格变化完全由解算器自动生成。网格变形方式有三种:弹簧压缩式、动态铺层式以及局部网格重生式。其局部网格重生式是FLUENT所独有的,而

且用途广泛,可用于非结构网格、变形较大问题以及物体运动规律事先不知道而完全由流动所产生的力所决定的问题; FLUENT软件具有强大的网格支持能力,支持界面不连续的网格、混合网格、动/变形网格以及滑动网格等。值得强调的是,FLUENT软件还拥有多种基于解的网格的自适应、动态自适应技术以及动网格与网格动态自适应相结合的技术; FLUENT软件包含三种算法:非耦合隐式算法、耦合显式算法、耦合隐式算法,是商用软件中最多的; FLUENT软件包含丰富而先进的物理模型,使得用户能够精确地模拟无粘流、层流、湍流。湍流模型包含Spalart-Allmaras模型、k-ω模型组、k-ε模型组、雷诺应力模型(RSM)组、大涡模拟模型(LES)组以及最新的分离涡模拟(DES)和V2F模型等。另外用户还可以定制或添加自己的湍流模型; 适用于牛顿流体、非牛顿流体; 含有强制/自然/混合对流的热传导,固体/流体的热传导、辐射; 化学组份的混合/反应; 自由表面流模型,欧拉多相流模型,混合多相流模型,颗粒相模型,空穴两相流模型,湿蒸汽模型; 融化溶化/凝固;蒸发/冷凝相变模型; 离散相的拉格朗日跟踪计算; 非均质渗透性、惯性阻抗、固体热传导,多孔介质模型(考虑多孔介质压力突变); 风扇,散热器,以热交换器为对象的集中参数模型; 惯性或非惯性坐标系,复数基准坐标系及滑移网格; 动静翼相互作用模型化后的接续界面; 基于精细流场解算的预测流体噪声的声学模型; 质量、动量、热、化学组份的体积源项; 丰富的物性参数的数据库; 磁流体模块主要模拟电磁场和导电流体之间的相互作用问题; 连续纤维模块主要模拟纤维和气体流动之间的动量、质量以及热的交换问题; 高效率的并行计算功能,提供多种自动/手动分区算法;内置MPI并行机制大幅度提高并行效率。另外,FLUENT特有动态负载平衡功能,确保全局高效并行计算; FLUENT软件提供了友好的用户界面,并为用户提供了二次开发接口(UDF); FLUENT软件采用C/C++语言编写,从而大大提高了对计算机内存的利用率。 在CFD软件中,Fluent软件是目前国内外使用最多、最流行的商业软件之一。Fluent 的软件设计基于"CFD计算机软件群的概念",针对每一种流动的物理问题的特点,采用适合于它的数值解法在计算速度、稳定性和精度等各方面达到最佳。由于囊括了Fluent Dynamical International比利时PolyFlow和Fluent Dynamical International(FDI)的全部技术力量(前者是公认的在黏弹性和聚合物流动模拟方面占领先地位的公司,后者是基于有限元方法CFD软件方面领先的公司),因此Fluent具有以上软件的许优点 软件简介

大涡模拟

4.6.3大涡模拟LSE 大涡模拟LES 基本思想是:湍流运动是湍流运动是由许多大小不同尺度的涡旋组成,大尺度的涡旋对平均流动影响比较大,各种变量的湍流扩散、热量、质量、动量和能量的交换以及雷诺应力的产生都是通过大尺度涡旋来实现的,而小尺度涡旋主要对耗散起作用,通过耗散脉动来影响各种变量。不同的流场形状和边界条件对大涡旋有较大影响,使它具有明显的各向不均匀性。而小涡旋近似于各向同性,受边界条件的影响小,有较大的共性,因而建立通用的模型比较容易。据此,把湍流中大涡旋(大尺度量)和小涡旋(小尺度量)分开处理,大涡旋通过N-S 方程直接求解,小涡旋通过亚格子尺度模型,建立与大涡旋的关系对其进行模拟,而大小涡旋是通过滤波函数来区分开的。对于大涡旋,LES 方法得到的是其真实结构状态,而对小涡旋虽然采用了亚格子模型,但由于小涡旋具有各向同性的特点,在采用适当的亚格子模式的情况下,LES 结果的准确度很高。 大涡模拟LES 有四个一般的步骤: ①定义一个过滤操作,使速度分解u(x,t)为过滤后的成分(),u x t 和亚网格尺度成分u ’(x,t),这里要特别指出:过滤操作和Reynolds 分解是两个不同的概念,亚网格尺度SGS 成分u ’(x,t)与Reynolds 分解后的速度脉动值是两个不同的量。过滤后的三维的时间相关的成分()t x u ,表示大尺度的涡旋运动; ②由N-S 方程推导过滤后的速度场进化方程,该方程为一个标准形式,其中包含SGS 应力张量; ③封闭亚网格尺度SGS 应力张量,可采用最简单的涡黏性模型; ④数值求解模化方程,从而获得大尺度流动结构物理量。 (1)过滤操作 LES 方法和一般模式理论不同之处在于对N-S 方程第一步的处理过程不一样。一般模式理论方法是对变量取平均值,LES 方法是通过滤波操作,将变量分成大尺度量和小尺度量。对任一流动变量(),u x t 划分为大尺度量(,)u x t 和小尺度量(),u x t '(亚格尺度): (,)(,)(,)u x t u x t u x t '=+ 其中大尺度量是通过滤波获得:,过滤操作定义为: ()?-=dr t r x u x r G t x u ),(),(, (4.78) 式中积分遍及整个流动区域,(,)G r x 是空间滤波函数,它决定于小尺度运动的尺寸和结构。 滤波器G 要满足正规化条件 ?=1),(dr x r G (4.79) 亚网格尺度SGS 成分定义为 ),(),(),('t x u t x u t x u -= (4.80) 与Reynolds 分解不同的是,),(t x u 为一个随机的场分布,且 0),('≠t x u

FLUENT算例 (5)搅拌桨底部十字挡板的流场分析

搅拌桨底部十字挡板的流场分析搅拌设备在各个行业运用的十分广泛,搅拌就是为了更够更快速更高效的将物质与介质充分混合,发生充分的反应,而搅拌中存在着许多不利于混合的情况,比如液体旋流。为了解决这个问题,之前很多人提出在罐体的侧壁上增加挡板,可以抵消大部分旋流,然后大部分都是研究侧挡板的,对于底部挡板的研究十分少,本文就在椭圆底部挡板增加十字型挡板,对罐体中进行流场分析。 1.Gambit建模 首先用Gambit建模图形如下: 图1:Gambit建立的模型 分为两个区域,里面的圆柱为动区域,外面包着的大圆柱设为静区域,静区域划分网格大,划分粗糙,内部动区域划分网格小,划分精细。边界条件主要设置了轴,搅拌桨,底部挡板,上层液面。以下就是fluent进行数值模拟。 2.fluent数值模拟 2.1导入case文件

2.2对网格进行检查 Minimum volume的数值大于0即可。 图2网格检查2.3调节比例 单位选择mm单位。 图3比例调节2.4定义求解器参数 设置如图4所示

图4设置求解器参数2.5设置能量线 图5能量线 2.6设置粘度模型,选择k-e模型 k-e模型对该模型模拟十分实用。

图6粘度模型2.7定义材料 介质选择液体水。 2.8定义操作条件

由于存在着终于,建模时的方向向上,所以在Z轴增加一个重力加速度。 图8操作条件 2.9定义边界条件 在边界设置重,动区域如图所示,将材料设成水,motion type设成moving reference frame (相对滑动),转速设为10rad/s,单位可在Define中的set unit中的angular-velocity设置。而在在轴的设置中,如上图所示,将wall motion设成moving wall,motion设成Absolute,速度设成-10,由于轴跟动区域速度是相对的,所以设成反的。

FLUENT算例 (9)模拟燃烧

计算流体力学作业FLUENT 模拟燃烧 问题描述:长为2m、直径为0.45m的圆筒形燃烧器结构如图1所示,燃烧筒壁上嵌有三块厚为0.0005 m,高0.05 m的薄板,以利于甲烷与空气的混合。燃烧火焰为湍流扩散火焰。在燃烧器中心有一个直径为0.01 m、长为0.01 m、壁厚为0.002 m的小喷嘴,甲烷以60 m/s的速度从小喷嘴注入燃烧器。空气从喷嘴周围以0.5 m/s的速度进入燃烧器。总当量比大约是0.76(甲烷含量超过空气约28%),甲烷气体在燃烧器中高速流动,并与低速流动的空气混合,基于甲烷喷嘴直径的雷诺数约为5.7×103。 假定燃料完全燃烧并转换为:CH4+2O2→CO2+2H2O 反应过程是通过化学计量系数、形成焓和控制化学反应率的相应参数来定义的。利用FLUENT的finite-rate化学反应模型对一个圆筒形燃烧器内的甲烷和空气的混合物的流动和燃烧过程进行研究。 1、建立物理模型,选择材料属性,定义带化学组分混合与反应的湍流流动边界条件 2、使用非耦合求解器求解燃烧问题 3、对燃烧组分的比热分别为常量和变量的情况进行计算,并比较其结果 4、利用分布云图检查反应流的计算结果 5、预测热力型和快速型的NO X含量 6、使用场函数计算器进行NO含量计算 一、利用GAMBIT建立计算模型 第1步启动GAMBIT,建立基本结构 分析:圆筒燃烧器是一个轴对称的结构,可简化为二维流动,故只要建立轴对称面上的

二维结构就可以了,几何结构如图2所示。 (1)建立新文件夹 在F盘根目录下建立一个名为combustion的文件夹。 (2)启动GAMBIT (3)创建对称轴 ①创建两端点。A(0,0,0),B(2,0,0) ②将两端点连成线 (4)创建小喷嘴及空气进口边界 ①创建C、D、E、F、G点

大涡模拟的FLUENT算例2D

Tutorial:Modeling Aeroacoustics for a Helmholtz Resonator Using the Direct Method(CAA) Introduction The purpose of this tutorial is to provide guidelines and recommendations for the basic setup and solution procedure for a typical aeroacoustic application using computational aeroacoustic(CAA)method. In this tutorial you will learn how to: ?Model a Helmholtz resonator. ?Use the transient k-epsilon model and the large eddy simulation(LES)model for aeroacoustic application. ?Set up,run,and perform postprocessing in FLUENT. Prerequisites This tutorial assumes that you are familiar with the user interface,basic setup and solution procedures in FLUENT.This tutorial does not cover mechanics of using acoustics model,but focuses on setting up the problem for Helmholtz-Resonator and solving it.It also assumes that you have basic understanding of aeroacoustic physics. If you have not used FLUENT before,it would be helpful to?rst review FLUENT6.3User’s Guide and FLUENT6.3Tutorial Guide. Problem Description A Helmholtz resonator consists of a cavity in a rigid structure that communicates through a narrow neck or slit to the outside air.The frequency of resonance is determined by the mass of air in the neck resonating in conjunction with the compliance of the air in the cavity. The physics behind the Helmholtz resonator is similar to wind noise applications like sun roof bu?eting. We assume that out of the two cavities that are present,smaller one is the resonator.The motion of the?uid takes place because of the inlet velocity of27.78m/s(100km/h).The ?ow separates into a highly unsteady motion from the opening to the small cavity.This unsteady motion leads to a pressure?uctuations.Two monitor points(Point-1and Point-2) act as microphone points to record the generated sound.The acoustic signal is calculated within FLUENT.The?ow exits the domain through the pressure outlet.

大涡模拟的fluent算例

Introduction:This tutorial demonstrates how to model the2D turbu-lent?ow across a circular cylinder using LES(Large Eddy Simula-tion),and compute?ow-induced noise(aero-noise)using FLUENT’s acoustics model. In this tutorial you will learn how to: ?Perform2D Large Eddy Simulation(LES) ?Set parameters for an aero-noise calculation ?Save surface pressure data for an aero-noise calculation ?Calculate aero-noise quantities ?Postprocess an aero-noise solution Prerequisites:This tutorial assumes that you are familiar with the menu structure in FLUENT,and that you have solved or read Tu-torial1.Some steps in the setup and solution procedure will not be shown explicitly. Problem Description:The problem considers turbulent air?ow over a2D circular cylinder at a free stream velocity U of69.19m/s. The cylinder diameter D is1.9cm.The Reynolds number based on the?ow parameters is about90000.The computational do-main(Figure3.0.1)extends5D upstream and20D downstream of the cylinder,and5D on both sides of it.If the computational domain is not taken wide enough on the downstream side,so that no reversed?ow occurs,the accuracy of the aero-noise prediction may be a?ected.The rule of thumb is to take at least20D on the downstream side of the obstacle. c Fluent Inc.June20,20023-1

FLUENT算例 (3)三维圆管紊流流动状况的数值模拟分析

三维圆管紊流流动状况的数值模拟分析 在工程和生活中,圆管内的流动是最常见也是最简单的一种流动,圆管流动有层流和紊流两种流动状况。层流,即液体质点作有序的线状运动,彼此互不混掺的流动;紊流,即液体质点流动的轨迹极为紊乱,质点相互掺混、碰撞的流动。雷诺数是判别流体流动状态的准则数。本研究用CFD 软件来模拟研究三维圆管的紊流流动状况,主要对流速分布和压强分布作出分析。 1 物理模型 三维圆管长2000mm l =,直径100mm d =。 流体介质:水,其运动粘度系数6 2 110m /s ν-=?。 Inlet :流速入口,10.005m /s υ=,20.1m /s υ= Outlet :压强出口 Wall :光滑壁面,无滑移 2 在ICEM CFD 中建立模型 2.1 首先建立三维圆管的几何模型Geometry 2.2 做Blocking 因为截面为圆形,故需做“O ”型网格。

2.3 划分网格mesh 注意检查网格质量。 在未加密的情况下,网格质量不是很好,如下图 因管流存在边界层,故需对边界进行加密,网格质量有所提升,如下图

2.4 生成非结构化网格,输出fluent.msh等相关文件 3 数值模拟原理 紊流流动

当以水流以流速20.1m /s υ=,从Inlet 方向流入圆管,可计算出雷诺数10000υd Re ν ==,故圆管内流动为紊流。 假设水的粘性为常数(运动粘度系数62 110m /s ν-=?)、不可压流体,圆管光滑,则流动的控制方程如下: ①质量守恒方程: ()()()0u v w t x y z ρρρρ????+++=???? (0-1) ②动量守恒方程: 2()()()()()()()()()()[]u uu uv uw u u u t x y z x x y y z z u u v u w p x y z x ρρρρμμμρρρ??????????+++=++??????????'''''????+---- ???? (0-2) 2 ()()()()()()()()()()[]v vu vv vw v v v t x y z x x y y z z u v v v w p x y z y ρρρρμμμρρρ??????????+++=++??????????'''''????+- ---???? (0-3) 2 ()()()()()()()()()()[]w wu wv ww w w w t x y z x x y y z z u w v w w p x y z z ρρρρμμμρρρ??????????+++=++??????????'''''????+- ---???? (0-4) ③湍动能方程: ()()()()[())][())][())]t t k k t k k k ku kv kw k k t x y z x x y y k G z z μμρρρρμμσσμμρεσ????????+++=+++????????? ?+ ++-?? (0-5) ④湍能耗散率方程: 212()()()()[())][())][())]t t k k t k k u v w t x y z x x y y C G C z z k k εεμμρερερερεεεμμσσμεεεμρσ??????? ?+++=+++??????????+++-?? (0-6) 式中,ρ为密度,u 、ν、w 是流速矢量在x 、y 和z 方向的分量,p 为流体微元体上的压强。 方程求解:采用双精度求解器,定常流动,标准ε-k 模型,SIMPLEC 算法。 4 在FLUENT 中求解计算紊流流动 4.1 FLUENT 设置 除以下设置为紊流所必须设置的外,其余选项和层流相同,不再详述。

大涡模拟简单介绍

《粘性流体力学》小论文 题目:浅谈大涡模拟 学生姓名:丁普贤 学生学号:103911018 完成时间:2010/12/16

浅谈大涡模拟 丁普贤 (中南大学,能源科学与工程学院,湖南省长沙市,410083) 摘要:湍流流动是一种非常复杂的流动,数值模拟是研究湍流的主要手段,现有的湍流数值模拟的方法有三种:直接数值模拟、大涡模拟和雷诺平均模型。本文主要是介绍大涡模拟,大涡模拟的思路是:直接数值模拟大尺度紊流运动,而利用亚格子模型模拟小尺度紊流运动对大尺度紊流运动的影响。大涡模拟在计算时间和计算费用方面是优于直接数值模拟的,在信息完整性方面优于雷诺平均模型。本文还介绍了对N-S方程过滤的过滤函数和一些广泛使用的亚格子模型,最后简单对一些大涡模拟的应用进行了阐述。 关键词:计算流体力学;湍流;大涡模拟;亚格子模型

A simple study of Large Eddy Simulation DING Puxian (Central South University, School of Energy Science and Power Engineering, Changsha, Hunan, 410083) Abstract:Turbulent flow is a very complex flow, and numerical simulation is the main means to study it. There are three numerical simulation methods: direct numerical simulation, large eddy simulation,Reynolds averaged Navier-Stokes method. Large eddy simulation (LES) is mainly introduced in this paper. The main idea of LES is that large eddies are resolved directly and the effect of the small eddies on the large eddies is modeled by subgrid scale model. Large eddy simulation calculation in computing time and cost is superior to direct numerical simulation, and obtain more information than Reynolds averaged Navier-Stokes method. The Navier-Stokes equations filtering filter function and some extensive use of the subgrid scale model are simply discussed in this paper. Finally, some simple applications of large eddy simulation are told. Key words:computational fluid dynamics; turbulence; large eddy simulation; subgrid scale model

FLUENT算例(9)模拟燃烧(优选.)

最新文件---------------- 仅供参考--------------------已改成-----------word文本 --------------------- 方便更改 计算流体力学作业FLUENT 模拟燃烧 问题描述:长为2m、直径为0.45m的圆筒形燃烧器结构如图1所示,燃烧筒壁上嵌有三块厚为0.0005 m,高0.05 m的薄板,以利于甲烷与空气的混合。燃烧火焰为湍流扩散火焰。在燃烧器中心有一个直径为0.01 m、长为0.01 m、壁厚为0.002 m的小喷嘴,甲烷以60 m/s的速度从小喷嘴注入燃烧器。空气从喷嘴周围以0.5 m/s的速度进入燃烧器。总当量比大约是0.76(甲烷含量超过空气约28%),甲烷气体在燃烧器中高速流动,并与低速流动的空气混合,基于甲烷喷嘴直径的雷诺数约为5.7×103。 假定燃料完全燃烧并转换为:CH4+2O2→CO2+2H2O 反应过程是通过化学计量系数、形成焓和控制化学反应率的相应参数来定义的。利用FLUENT的finite-rate化学反应模型对一个圆筒形燃烧器内的甲烷和空气的混合物的流动和燃烧过程进行研究。 1、建立物理模型,选择材料属性,定义带化学组分混合与反应的湍流流动边界条件 2、使用非耦合求解器求解燃烧问题 3、对燃烧组分的比热分别为常量和变量的情况进行计算,并比较其结果 4、利用分布云图检查反应流的计算结果 5、预测热力型和快速型的NO X含量 6、使用场函数计算器进行NO含量计算 一、利用GAMBIT建立计算模型 第1步启动GAMBIT,建立基本结构

分析:圆筒燃烧器是一个轴对称的结构,可简化为二维流动,故只要建立轴对称面上的二维结构就可以了,几何结构如图2所示。 (1)建立新文件夹 在F盘根目录下建立一个名为combustion的文件夹。 (2)启动GAMBIT (3)创建对称轴 ①创建两端点。A(0,0,0),B(2,0,0) ②将两端点连成线 (4)创建小喷嘴及空气进口边界

(完整版)如何在gambit中提高网格质量

如何在gambit中提高网格质量 经常在网上看到一些网友为gambit划分不出好的网格质量而烦恼。 要生成一套好的网格,我觉得以下几点是很必要的: 1.选择一款好的网格生成软件; 2.确保实体尽量简洁; 3.合理布置线上节点; 但是,对于一些初学者来说,gridgen等专业点的网格划分软件在短时间内是很难掌握的,所以大部分人还是喜欢用gambit。对于gambit来说,有的时候满足了条件2,3,仍然有可能生成质量很差的网格,这个时候就需要手动调整以提高网格质量了。下面我将以一个例子来详细讲解一下如何在gambit中提高网格质量。 这个是个简单的楔形体,包括附面层网格。该网格满足实体简单,节点的布置也合理,但是生成的网格质量很差,主要是在楔形体尾部附面层网格与三角形网格交接的地方。 该图为放大图,从中可以看出有一个网格基本上已经退化成一条线了,从而导致整个网格最大的倾斜率超过了0.99。

解决方法一: 由于质量差的网格集中在附面层与三角形网格过渡的地方,可以从改变附面层网格分布入手。 改变楔形体三个顶点的类型,将其改为side,从而改变附面层网格。 改变附面层网格分布后,重新生成的网格质量提高了不少。 解决方法二: 改变三角形网格分布。

选择调整面网格的节点分布。 手动调整质量差的网格的节点,使其分布合理。

通过调整后,最大倾斜率小于0.91了。该质量的网格基本上就能导入fluent计算了,通过fluent中的smooth/swap功能,还能进一步提高网格质量。 以上例子只是给网友一个在gambit中调整网格的思路,希望能解决一部分人的问题。 其实,提高网格质量最好的办法就是将坏的网格merge到好的网格中,可惜我目前还没有在gambit中发现该功能。有机会再跟大家探讨一下在tgrid中如何用merge功能提高网格质量。

fluent简介

简介: ?? CFD商业软件介绍之一——Fluent 通用CFD软件包,用来模拟从不可压缩到高度可压缩范围内的复杂流动。由于采用了多种求解方法和多重网格加速收敛技术,因而FLUENT能达到最佳的收敛速度和求解精度。灵活的非结构化网格和基于解的自适应网格技术及成熟的物理模型,使FLUENT在转捩与湍流、传热与相变、化学反应与燃烧、多相流、旋转机械、动/变形网格、噪声、材料加工、燃料电池等方面有广泛应用。 编辑本段基本特点 FLUENT软件具有以下特点: ☆ FLUENT软件采用基于完全非结构化网格的有限体积法,而且具有基于网格节点和网格单元的梯度算法; ☆定常/非定常流动模拟,而且新增快速非定常模拟功能; ☆ FLUENT软件中的动/变形网格技术主要解决边界运动的问题,用户只需指定初始网格和运动壁面的边界条件,余下的网格变化完全由解算器自动生成。网格变形方式有三种:弹簧压缩式、动态铺层式以及局部网格重生式。其局部网格重生式是FLUENT所独有的,而且用途广泛,可用于非结构网格、变形较大问题以及物体运动规律事先不知道而完全由流动所产生的力所决定的问题; ☆ FLUENT软件具有强大的网格支持能力,支持界面不连续的网格、混合网格、动/变形网格以及滑动网格等。值得强调的是,FLUENT软件还拥有多种基于解的网格的自适应、动态自适应技术以及动网格与网格动态自适应相结合的技术; ☆ FLUENT软件包含三种算法:非耦合隐式算法、耦合显式算法、耦合隐式算法,是商用软件中最多的; ☆ FLUENT软件包含丰富而先进的物理模型,使得用户能够精确地模拟无粘流、层流、湍流。湍流模型包含Spalart-Allmaras模型、k-ω模型组、k-ε模型组、雷诺应力模型(RSM)组、大涡模拟模型(LES)组以及最新的分离涡模拟(DES)和V2F模型等。另外用户还可以定制或添加自己的湍流模型; ☆适用于牛顿流体、非牛顿流体; ☆含有强制/自然/混合对流的热传导,固体/流体的热传导、辐射; ☆化学组份的混合/反应; ☆自由表面流模型,欧拉多相流模型,混合多相流模型,颗粒相模型,空穴两相流模型,湿蒸汽模型; ☆融化溶化/凝固;蒸发/冷凝相变模型; ☆离散相的拉格朗日跟踪计算; ☆非均质渗透性、惯性阻抗、固体热传导,多孔介质模型(考虑多孔介质压力突变); ☆风扇,散热器,以热交换器为对象的集中参数模型; ☆惯性或非惯性坐标系,复数基准坐标系及滑移网格; ☆动静翼相互作用模型化后的接续界面; ☆基于精细流场解算的预测流体噪声的声学模型; ☆质量、动量、热、化学组份的体积源项; ☆丰富的物性参数的数据库; ☆磁流体模块主要模拟电磁场和导电流体之间的相互作用问题; ☆连续纤维模块主要模拟纤维和气体流动之间的动量、质量以及热的交换问题; ☆高效率的并行计算功能,提供多种自动/手动分区算法;内置MPI并行机制大幅度提

(完整word版)大涡模拟亚格子模型

众所周知,求解紊流问题的困难主要来自于两方面,一是紊流的非线性特征难以数值模拟,二是紊流脉动频率谱域极宽,数值模拟技术难以模拟出连续变化的各级紊流运动。由于工程应用中人们对紊流运动的时间平均效应较为关心,所以目前常用的紊流模型,大都以雷诺时间平均为基础而获得的。雷诺时均的过程抹平了紊流运动的若干微小细节,模型模化过程带有很多人为因素。因此,封闭雷诺时均方程的各类紊流模型对复杂精细的紊流结构例如绕流体的流动分离、卡门涡街等流动现象的模拟能力还很有限。随着计算机的计算速度和计算容量的大幅度提高,已有一些研究机构对Navier-stokes方程不作任何形式的模化和简化,利用极为细密的网格直接数值求解N-S 方程,这就是直接数值模拟(Directly Numerical Simulation,简称DNS)。但目前普通的研究者尚无法实现DNS ,而介于DNS 和雷诺时均方法之间的大涡模拟(Large Eddy Simulation,简称LES)方法,由于其较雷诺时均理论更为精细且在常规的计算机上即可实现,因而已在计算流体力学(Computational Fluid Dynamics,简称CFD)界逐渐兴起并发展成为最有发展潜力的紊流数值求解方法[1-6]。 目前对温度振荡的研究多采用大涡模拟(LES)和直接模拟(DNS)方法,直接数值模拟(DNS)方法就是直接用瞬时的纳维斯托克斯方程对湍流进行数值计算。直接数值模拟的最大好处是无需任何简化或近似湍流流动,理论上可以得到较准确的计算结果。但是实验测试表明,直接数值模拟对计算机的要求非常高,目前的硬件条件无法满足大区域的计算,只能应用于小区域简单湍流计算,尚未用于大规模的工程计算,而LES方法相对来讲已得到成熟的发展。因此,本文选取LES方法及Smagoringsky-Lilly亚格子尺度模型来模拟温度振荡现象。 大涡模拟是介于直接数值模拟(DNS)与Reyno1ds平均法(RANS)之间的一种湍流数值模拟方法。在数值模拟湍流运动时,只计算比网格尺寸大的漩涡,通过纳维斯托克斯方程直接算出来,小尺度涡则可以用一个模型来表现出来,仅起到耗散作用,它们几乎是各项同性的。因此LES方法旨在用非稳态的N-S方程模拟大尺度涡,但不直接计算小尺度涡,小涡对大涡的影响通过近似模型来考虑,这种影响可以用一个湍流粘性系数来描述。 大涡数值模拟的基本思想是直接计算大尺度脉动,用近似模型计算小尺度脉动,实现大涡数值模拟最重要的就是将直接大尺度脉动和小尺度脉动分离。

FLUENT算例 9模拟燃烧

资料收集于网络,如有侵权请联系网站删除 计算流体力学作业FLUENT 模拟燃烧 问题描述:长为2m、直径为0.45m的圆筒形燃烧器结构如图1所示,燃烧筒壁上嵌有三块厚为0.0005 m,高0.05 m的薄板,以利于甲烷与空气的混合。燃烧火焰为湍流扩散火焰。在燃烧器中心有一个直径为0.01 m、长为0.01 m、壁厚为0.002 m的小喷嘴,甲烷以60 m/s的速度从小喷嘴注入燃烧器。空气从喷嘴周围以0.5 m/s的速度进入燃烧器。总当量比大约是0.76(甲烷含量超过空气约28%),甲烷气体在燃烧器中高速流动,并与低速流动的3。105.7×空气混合,基于甲烷喷嘴直径的雷诺数约为CH+2OCO+2HO假定燃料完全燃烧并转换为:→2422反应过程是通过化学计量系数、形成焓和控制化学反应率的相应参数来定义的。利用FLUENT的finite-rate化学反应模型对一个圆筒形燃烧器内的甲烷和空气的混合物的流动和燃烧过程进行研究。 1、建立物理模型,选择材料属性,定义带化学组分混合与反应的湍流流动边界条件 2、使用非耦合求解器求解燃烧问题 3、对燃烧组分的比热分别为常量和变量的情况进行计算,并比较其结果 4、利用分布云图检查反应流的计算结果 5、预测热力型和快速型的NO含量X 6、使用场函数计算器进行NO含量计算 一、利用GAMBIT建立计算模型 第1步启动GAMBIT,建立基本结构 分析:圆筒燃烧器是一个轴对称的结构,可简化为二维流动,故只要建立轴对称面上的二维结构就可以了,几何结构如图2所示。 (1)建立新文件夹 在F盘根目录下建立一个名为combustion的文件夹。 (2)启动GAMBIT 只供学习与交流.