Value Stream VSM Template

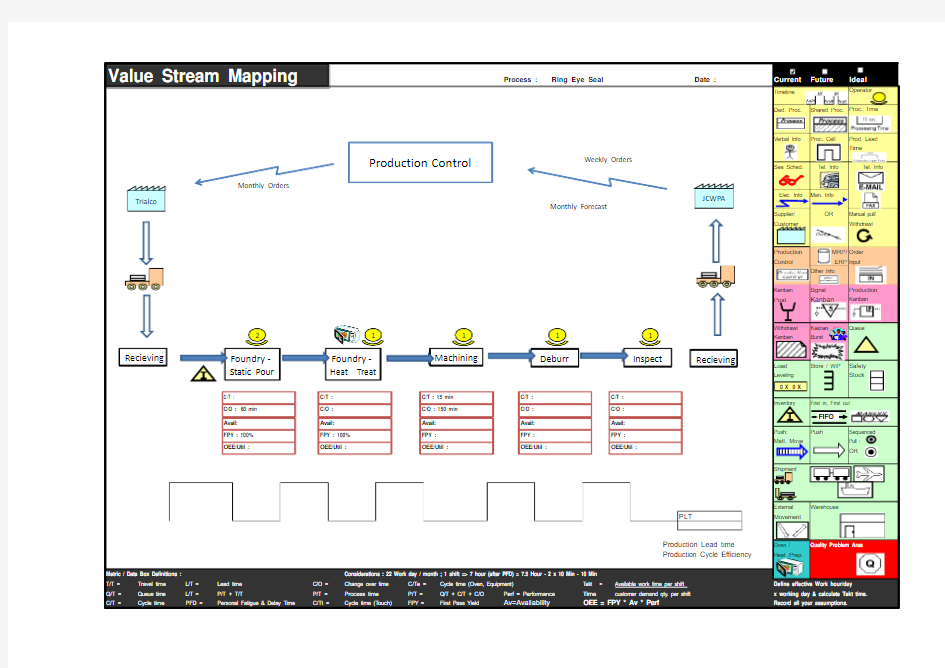

Value Stream Mapping

Process :Ring Eye Seal Date :Current

Future

Ideal

Timeline

Operator

Ded. Proc.

Shared Proc.Proc. Time

Verbal Info Proc. Cell Prod. Lead Time

See Sched.Tel. Info Tel. Info

Elec. Info Man. Info

Supplier/OR

Manual pull/Customer Withdrawl

Production MRP/Order Control ERP Input

Other Info Kanban Signal

Production Post Kanban

Kanban

Withdrawl Kaizan Queue

Kanban

Burst

Load Store / WIP Safety Leveling

Stock

Inventory First in, First out

Push:Push

Sequenced Matl. Move

Pull :OR

Shipment

External

Warehouse

PLT

Movement

Production Lead time

Oven /Quality Problem Area

Production Cycle Efficiency

Heat /Prep. Metric / Data Box Definitions :Considerations : 22 Work day / month ; 1 shift => 7 hour (after PFD) = 7.5 Hour - 2 x 10 Min - 10 Min

T/T = Travel time L/T = Lead time C/O =Change over time C/Te =Cycle time (Oven, Equipment)Takt =Available work time per shift Define effective Work hour/day Q/T =Queue time L/T = P/T + T/T

P/T =Process time P/T =Q/T + C/T + C/O Perf = Performance

Time

customer demand qty. per shift

x working day & calculate Takt time. C/T =

Cycle time

PFD =

Personal Fatigue & Delay Time

C/Tt =

Cycle time (Touch)

FPY =

First Pass Yield

Av=Availability OEE = FPY * Av * Perf

Record all your assumptions.

0 X 0 X

FIFO

C/T : C/O : 60 min

Avail:

FPY : 100%OEE/Util :

Trialco

JCWPA

Production Control

Recieving

Foundry -Static Pour

Foundry -Heat Treat

Machining

2111Weekly Orders

Monthly Forecast

Monthly Orders

Deburr 1

Inspect

C/T :C/O :

Avail:

FPY : 100%OEE/Util :

C/T : 15 min C/O : 150 min

Avail:

FPY :OEE/Util :

C/T :C/O :

Avail:

FPY :OEE/Util :

C/T :C/O :

Avail:

FPY :OEE/Util :

Recieving

Check

Check

Check