PA66+30GB物性

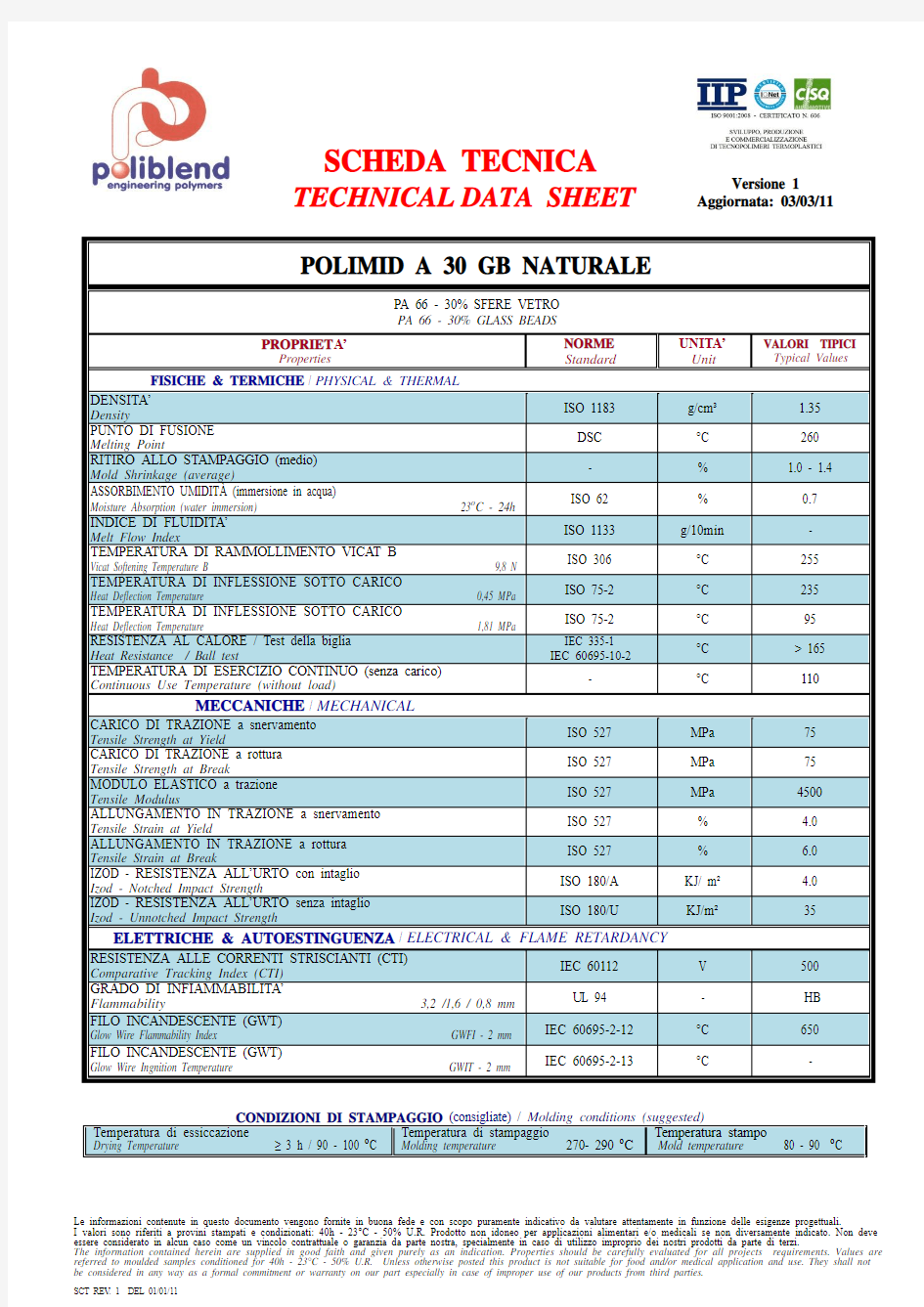

SCHEDA TECNICA

TECHNICAL DATA SHEET

Versione 1

Aggiornata: 03/03/11

Le informazioni contenute in questo documento vengono fornite in buona fede e con scopo puramente indicativo da valutare attentamente in funzione delle esigenze progettuali. I valori sono riferiti a provini stampati e condizionati: 40h - 23°C - 50% U.R. Prodotto non idoneo per applicazioni alimentari e/o medicali se non diversamente indicato. Non deve essere considerato in alcun caso come un vincolo contrattuale o garanzia da parte nostra, specialmente in caso di utilizzo improprio dei nostri prodotti da parte di terzi.

The information contained herein are supplied in good faith and given purely as an indication. Properties should be carefully evaluated for all projects requirements. Values are referred to moulded samples conditioned for 40h - 23°C - 50% U.R. Unless otherwise posted this product is not suitable for food and/or medical application and use. They shall not be considered in any way as a formal commitment or warranty on our part especially in case of improper use of our products from third parties.

SCT REV. 1 DEL 01/01/11

物性材料表

特性Feature 耐高温、耐冲击、高流动性、尺寸稳定。High temperature resistance, impact resistance, high liquidity, dimension stability. 用途Use 电子、电器零件、汽车部件等。Electronic, electrical parts, auto parts, etc. 注塑条件Injection conditions 预干燥温度Pre-drying temperature 预干燥时间Pre-drying time 进料区温度Feed zone temperature 压缩区温度Compression zone temperature 熔融区温度Melting zone temperature 喷嘴温度Nozzle Temperature 模具温度Mold 注射压力Injection pressure 物理机械性能Physical and mechanical properties 项目Project 单位unit 试验方法Test method 数值Value 密度Density 熔点Melting point 成型收缩率Mold Shrinkage 吸水率(24小时,23℃)Water Absorption (24 hours, 23 ℃) 熔融指数Melt Index 阻燃等级Flame Rating 拉伸断裂强度Tensile Strength 拉伸模量Tensile modulus 断裂伸长率Elongation at break 弯曲强度Bending 弯曲模量Bending modulus 悬臂梁(无缺口)冲击强度Izod (unnotched) impact strength 悬臂梁缺口冲击强度Izod notched impact strength 洛氏硬度Rockwell hardness 热变形温度(0.45MPa)Heat Deflection Temperature(0.45MPa) Dielectric Strength 绝缘破坏强度 Arc resistance 耐电弧性 Dielectric Constant 介电常数 Dielectric Losses 介电损耗 Characteristics 特性 平衡吸湿量Moisture Absorption at Equilibrium 线性成型收缩率,横向Linear Mould Shrinkage, Transverse 断裂伸长率Elongation at Break 屈服伸长率Elongation at Yield

PA10T材料物性表

P ROVISIONAL D ATA S HEET G RIVORY HT G RIVORY XE 4027 BLACK 9916 Product description Grivory XE 4027 black 9916 is a 30% glass-fibre reinforced flame retardant (UL 94 V-0) engineering thermoplastic material based on a semicrystalline, partially aromatic co-polyamide. Grivory XE 4027 black 9916 is free of halogens and red phosphorus. RoHS: Grivory XE 4027 black 9916 is in compliance with RoHS (2002/95/EC, Re-striction of Hazardous Substances). WEEE:Parts produced from Grivory XE 4027 black 9916 are not subject to "selec-tive treatment" according the Directive 2002/96/EC on Waste Electrical and Elec-tronic Equipment. ISO polymer designation: PA 10T/X ASTM designation: PPA, polyphthalamide The main distinguishing features of Grivory HT-PPA, when compared to other poly-amides, are its good performance at high temperatures providing parts which are stiffer, stronger, have better heat distortion and dimensional stability as well as excel-lent chemical resistance and low moisture absorption. Grivory XE 4027 black 9916 is especially suitable for injection moulded components in electrical and electronic applications which require a flame class acc. UL 94 V-0. The material is suitable for lead-free SMT reflow soldering acc. i.e. JEDEC J-STD-020C (peak temperature 260°C). Compo-nents conforming to JEDEC MSL1 are achievable.

互联网上的物性参数查询

互联网上的物性参数查询 1 化学工程师资源主页 该站点由西弗吉尼亚大学校友Christopher M.A.Haslego维护。该主页有非常丰富的化学工程方面的内容,其中包括一些查找物性数据比较好的站点:(https://www.360docs.net/doc/9319080788.html,/physinternetzz.shtml) 1.1 物性数据((https://www.360docs.net/doc/9319080788.html,/data.xls) 该数据库是浏览型数据库,含有470多种纯组分的物性数据,如分子量、冰点、沸点、临界温度、临界压力、临界体积、临界压缩、无中心参数、液体密度、偶极矩、气相热容、液相热容、液体粘度、反应标准热、蒸气压、蒸发热等。 1.2 聚合物和大分子的物理性质数据库(https://www.360docs.net/doc/9319080788.html,/~athas/databank/intro.html) 该数据库是浏览型数据库。含有200多种线性大分子的物性数据,如熔融温度、玻璃转换温度、热容等。该站点不仅提供物理性质,还提供一些供估计物质物理性质的软件,如PhysProps from G&P Engineering、Prode's thermoPhysical Properties Generator(PPP)等。 1.3 https://www.360docs.net/doc/9319080788.html,/~jrm/thermot.html 该站点可查294种组分的热力学性质,还可以根据Peng Robinson状态方程计算纯组分或混合物的性质:包括气液相图、液体与气体密度、焓、热容、临界值、分子量等数据。 1.4 https://www.360docs.net/doc/9319080788.html,/ G&P Engineering是一个软件,提供物质的28种物理性质并估算其它18种物理性质。 2 由美国国家标准技术研究院开发的数据库 2.1 标准参考数据库化学网上工具书(https://www.360docs.net/doc/9319080788.html,/chemistry/) 该数据库是一种检索型数据库,检索方法非常简单,可通过化学物质名称、分子式、部分分子式、CAS登记号、结构或部分结构、离子能性质、振动与电子能、分子量和作用进行检索,可检索到的数据包括分子式、分子量、化学结构、别名、CAS登记号、气相热化学数据、凝聚相热化学数据、液态常压热容、固态常压热容、相变数据、汽化焓、升华焓、燃烧焓、燃烧熵、各种反应的热化学数据、溶解数据、气相离子能数据、气相红外光谱、质谱、紫外/可见光谱、振动/电子能及其参考文献。 2.2 美国标准技术研究所物理网上工具书(https://www.360docs.net/doc/9319080788.html,/) 该站点包括物性常数、原子光谱数据、分子光谱数据、离子化数据、χ-射线、γ-射线数据、放射性计量数据、核物理数据及其它数据库。 3 化学搜索器

利用aspen-plus进行物性参数的估算

1 纯组分物性常数的估算 1.1、乙基2-乙氧基乙醇物性的输入 由于Aspen Plus 软件自带的物性数据库中很难查乙基2-乙氧基乙醇的物性参数, 使模拟分离、确定工艺条件的过程中遇到困难, 所以采用物性估算的功能对乙基2-乙氧基乙醇计算。 已知: 最简式:(C6H14O3) 分子式:(CH3-CH2-O-CH2-CH2-O-CH2-CH2-OH) 沸点:195℃ 1.2、具体模拟计算过程 乙基2-乙氧基乙醇为非库组分,其临界温度、临界压力、临界体积和临界压缩因子及理想状态的标准吉布斯自由能、标准吉生成热、蒸汽压、偏心因子等一些参数都很难查询到,根据的已知标准沸点TB,可以使用aspen plus软件的Estimation Input Pure Component(估计输入纯组分) 对纯组分物性的这些参数进行估计。 为估计纯组分物性参数,则需 1. 在 Data (数据)菜单中选择Properties(性质) 2. 在 Data Browser Menu(数据浏览菜单)左屏选择Estimation(估计)然后选Input(输入) 3. 在 Setup(设置)表中选择Estimation(估计)选项,Identifying Parameters to be Estimated(识别估计参数) 4. 单击 Pure Component(纯组分)页 5. 在 Pure Component 页中选择要用Parameter(参数)列表框估计的参数 6. 在 Component(组分)列表框中选择要估计所选物性的组分如果要为多组分估计

选择物性可单独选择附加组分或选择All(所有)估计所有组分的物性 7. 在每个组分的 Method(方法)列表框中选择要使用的估计方法可以规定一个以上的方法。 具体操作过程如下: 1、打开一个新的运行,点击Date/Setup 2、在Setup/Specifications-Global页上改变Run Type位property Estimation

物性表

Safety Data Sheet complies with:directive 91/155/EEC revision:2.0 ISO 11014-1:Safety data sheet for chemical products. revision date:02/02/1998date of issue: 26/02/1998 p 1. Product and company identification Product name:Stanyl ?Product code:TE250F3 Manufacturer: DSM Engineering Plastics P.O. Box 43,6130 AA Sittard The Netherlands Emergency number: The Netherlands +31 (0)46 4 76 55 55 2. Composition/Information on ingredients This chemical product is a preparation Chemical nature:(poly)amide PA 46CAS number:50327-22-5Components contributing to the hazard: The material contains Sb 2O 3 as a synergist with an average content of max. 7%. Sb 2O 3 is classified as a harmful (Xn) substance with a risk phrase R40 carcinogen class 3. However, the Sb 2O 3 is embedded in an impervious matrix of polymer and is therefore less biological available than the free Sb 2O 3 (see also Section 15). 3. Hazards identification Most important hazards:Hazard warning not required Specific hazards: Vapour and fumes released at elevated processing temperatures may be irritant for the eyes, the nose, the throat and the respiratory tract and in case of overexposure may cause nausea and headache. The material is not classified as being a dangerous preparation according to the EEC-Directive 88/379 and the subsequent amendments. See also Section 15.4. First-Aid measures Inhalation: When fumes of molten material have been inhaled;- Move person to fresh air as quickly as possible - rest in half upright position - loosen clothing - keep warm In case of respiratory problems move person to first aid station for medical treatment.Skin contact: Any molten material on the skin/burns should be cooled (off) as quickly as possible by means of cold water.Cover the wound with sterile cloth and move person to first aid station or hospital for medical treatment.Attention: never pull off the molten material from the wound.Eye contact: Any material entering the eye should be flushed out with copious volumes of water.Ingestion: No danger of toxicity, this material is biologically inactive (see also Section 11). 5. Fire-fighting measures Extinguishing media: Water, water/foam, CO 2, ABC fire extinguisher powder.Specific Hazards: Treat the material as a solid that can burn. Moulded parts or solid granules generally burn slowly with flaming drips.

物性参数网站大全

1 化学工程师资源主页 该站点由西弗吉尼亚大学校友Christopher M.A.Haslego维护。该主页有非常丰富的 化学工程方面的内容,其中包括一些查找物性数据比较好的站点:(https://www.360docs.net/doc/9319080788.html,/physinternetzz.shtml) 1.1 物性数据((https://www.360docs.net/doc/9319080788.html,/data.xls) 该数据库是浏览型数据库,含有470多种纯组分的物性数据,如分子量、冰点、沸点 、临界温度、临界压力、临界体积、临界压缩、无中心参数、液体密度、偶极矩、气相 热容、液相热容、液体粘度、反应标准热、蒸气压、蒸发热等。 1.2 聚合物和大分子的物理性质数据库(https://www.360docs.net/doc/9319080788.html,/~athas/da tabank/intro.html) 该数据库是浏览型数据库。含有200多种线性大分子的物性数据,如熔融温度、玻璃 转换温度、热容等。该站点不仅提供物理性质,还提供一些供估计物质物理性质的软件 ,如PhysProps from G&P Engineering、Prode's thermoPhysical Properties Genera tor(PPP)等。 1.3 https://www.360docs.net/doc/9319080788.html,/~jrm/thermot.html 该站点可查294种组分的热力学性质,还可以根据Peng Robinson状态方程计算纯组 分或混合物的性质:包括气液相图、液体与气体密度、焓、热容、临界值、分子量等数

据。 1.4 https://www.360docs.net/doc/9319080788.html,/ G&P Engineering是一个软件,提供物质的28种物理性质并估算其它18种物理性质。 2 由美国国家标准技术研究院开发的数据库 2.1 标准参考数据库化学网上工具书(https://www.360docs.net/doc/9319080788.html,/chemistry/) 该数据库是一种检索型数据库,检索方法非常简单,可通过化学物质名称、分子式 、部分分子式、CAS登记号、结构或部分结构、离子能性质、振动与电子能、分子量和作 用进行检索,可检索到的数据包括分子式、分子量、化学结构、别名、CAS登记号、气相 热化学数据、凝聚相热化学数据、液态常压热容、固态常压热容、相变数据、汽化焓、 升华焓、燃烧焓、燃烧熵、各种反应的热化学数据、溶解数据、气相离子能数据、气相 红外光谱、质谱、紫外/可见光谱、振动/电子能及其参考文献。 2.2 美国标准技术研究所物理网上工具书(https://www.360docs.net/doc/9319080788.html,/) 该站点包括物性常数、原子光谱数据、分子光谱数据、离子化数据、χ-射线、γ- 射线数据、放射性计量数据、核物理数据及其它数据库。 3 化学搜索器(https://www.360docs.net/doc/9319080788.html,/' target=_blank>https://www.360docs.net/doc/9319080788.html,/) Chemfinder化学搜索器是免费注册使用的数据库,是目前网上化合物性质

材料物性表

EXTRUSION APPLICATION

Introduction Responsible for a long line of accomplishments in outstanding engineering plastics, UBE NYLON products have won the trust and respect of users the world over. UBE NYLON – NYLON 6, NYLON COPOLYMERS – is in wide use throughout industry with their unique properties utilized to their fullest potential. UBE NYLON 6 has a number of excellent properties as follows: Excellent in impact strength and rigidity Having a smaller friction coefficient, thus excellent in abrasion resistance Excellent in resistance to oils, solvents and chemicals Superior in heat resistance Appropriate to mass production, contributing to cost reduction Summary 1. Introduction 2. Nomenclature 3. Monofilament Applications 4. Film Applications 5. TERPALEX Polyamide 6/66/12 Copolymer Nomenclature The first 2 digits in the code indicate the type of Polyamide. The third and fourth digits indicate the molecular weight level for 1000 series. In case of copolymer, the third digit shows the viscosity level. The co-polymerization ratio can be roughly calculated from the fourth digit multiplying by 5. “T” means the basic grade for monofilament application and the grade contain some additives for maintain good process stability and high trans-parency. In case of “MT”, means monomer con-taining grade offering good flexibility and softness. 10: Polyamide 6 homopolymer 50: Polyamide 6/66 copolymer 70: Polyamide 6/12 copolymer Ex. 1022FDX04: : c.a. 22 x 1,000 = 22,000 Ex. 5034MTX1: : level = 3 (high viscosity) : c.a. 80/20(4 x 5 = 20et%) : monomer-contain type 2 Introduction

天然气高压物性参数计算

摘要 天然气的压缩因子、体积系数、压缩系数、粘度等高压物性参数随气藏压力和温度的变化而变化,定量描述和预测这些参数的变化规律具有十分重要的实际意义。通过电脑程序将天然气高压物性的相关经验公式转变为程序计算,能够很快的得到计算结果以及对计算结果的图形分析,通过最后的图形分析我们能很直观的看出高压物性参数之间的关系,有利于确定合理的开发速度和规模,节省投资,将资金投向回报率高的方案上。 本文中首先介绍了天然气高压物性参数的相关经验及半经验公式,再利用excelVBA 实现公式的程序计算,只要输入原始数据,点击相应的高压物性计算按钮就能得到计算结果,数据分析窗体能够自动输出高压物性与相关参数的图形。 关键字:高压物性偏差系数粘度压力温度

ABSTRACT Gas compressibility factor, volume factor, compressibility, viscosity and other physical parameters with high pressure gas reservoir pressure and temperature changes, quantitatively describe and predict the variation of these parameters has a very important practical significance. Through a computer program related to the physical properties of high pressure natural gas into a program to calculate the empirical formula, can quickly get the results and the calculation results of the graphical analysis, graphical analysis through the last we can see the pressure very intuitive relationship between the physical parameters will help determine a reasonable pace and scale of development, reduce investment, high return on the capital investment program on. This paper first introduces the gas pressure in the physical parameters relevant experience and semi.empirical formulas to achieve reuse excelVBA program calculates the formula, as long as the input raw data, click on the appropriate button to be able to calculate the physical properties of high pressure to get results, analysis of data form can be automatically output pressure properties and related parameters graphics. Keywords: PVT variation ;coefficient of viscosity;pressure ;temperature ;coefficient of volume.

材料物性表

Product Data Sheet CHARACTERISTICS TEST METHOD Physical Properties Specific Gravity ASTM D792 1.20 1.20 Mould Shrinkage ASTM D9550.1-0.3%0.001-0.003in/in Mechanical Properties Tensile Strength ASTM D63890MPa 13050psi Flexural Strength ASTM D790125MPa 18125psi Flexural Modulus ASTM D7906500MPa 943ksi Notched Izod Impact Strength (3.2mm) ASTM D256 85 J/m 1.6 ft-lb/in Thermal Properties Heat Deflection Temperature @ 1.82MPa (264 psi) ASTM D648145°C 293°F Electrical Properties Surface Resistivity ASTM D2571E15ohms 1E15ohms Description: Glass Fiber Reinforced Polypropylene PPR 40G NC702 Product Code: 5218702Internal Code: NATURAL Colour: Maxxam TM NOMINAL VALUE (SI)NOMINAL VALUE (ENGLISH)Flammability Properties Flame Rating @ 0.8mm Internal HB HB Processing Conditions PP Barrel Temperature 200-240 °C 392-464°F Mould Temperature 30-60 °C 86-140°F Drying Temperature 80-85 °C 176-185°F Drying Time 2-3 Hour 2-3 Hour Injection Pressure Hold Pressure Screw Speed Back Pressure Rev #: 0, Revision Date: 6/8/2010 PRINTED IN SHENZHEN LHM 33587 Walker Road,Avon Lake,Ohio 44012, USA, Tel 1-440-930 1000 WHEN YOU HAVE QUESTION WITH ENGINEERING PLASTICS, WE COMPOUND THE ANSWER. No.1, Qihang Industrial Park,Haoxiang Road, Shajing Town, Baoan,Shenzhen, P.R.China,Tel:86-755-29692888MODERATE MED-HIGH MED-HIGH THIS IS NOT A PRODUCT SPECIFICATION LOW THE INFORMATION PRESENTED HEREIN IS PRESENTED IN GOOD FAITH AND TO THE BEST OF OUR KNOWLEDGE IS TRUE AND ACCURATE. IT IS INTENDED AS A GUIDE AND IS OFFERED FOR USE AT YOUR DISCRETION AND RISK. POLYONE DOES NOT GUARANTEE RESULT AND DISCLAIM ANY LIABILITY INCURRED IN CONNECTION WITH THE USE OF THE PRODUCTS DESCRIBED OR THE INFORMATION PRESENTED Tel: 86-755-29692888

化工主要物性参数

1化学工程师资源主页 该站点由西弗吉尼亚大学校友Christopher M.A.Haslego维护。该主页有非常丰富的 化学工程方面的内容,其中包括一些查找物性数据比较好的站点: (https://www.360docs.net/doc/9319080788.html,/physinternetzz.shtml) 1.1物性数据((https://www.360docs.net/doc/9319080788.html,/data.xls) 该数据库是浏览型数据库,含有470多种纯组分的物性数据,如分子量、冰点、沸点、临界温度、临界压力、临界体积、临界压缩、无中心参数、液体密度、偶极矩、气相 热容、液相热容、液体粘度、反应标准热、蒸气压、蒸发热等。 1.2聚合物和大分子的物理性质数据库(https://www.360docs.net/doc/9319080788.html,/~athas/da tabank/intro.html) 该数据库是浏览型数据库。含有200多种线性大分子的物性数据,如熔融温度、玻璃转换温度、热容等。该站点不仅提供物理性质,还提供一些供估计物质物理性质的软件 ,如PhysProps from G&P Engineering、Prode's thermoPhysical Properties Genera tor(PPP)等。 1.3https://www.360docs.net/doc/9319080788.html,/~jrm/thermot.html 该站点可查294种组分的热力学性质,还可以根据Peng Robinson状态方程计算纯组分或混合物的性质:包括气液相图、液体与气体密度、焓、热容、临界值、分子量等数据。 1.4https://www.360docs.net/doc/9319080788.html,/ G&P Engineering是一个软件,提供物质的28种物理性质并估算其它18种物理性质。 2由美国国家标准技术研究院开发的数据库 2.1标准参考数据库化学网上工具书(https://www.360docs.net/doc/9319080788.html,/chemistry/) 该数据库是一种检索型数据库,检索方法非常简单,可通过化学物质名称、分子式 、部分分子式、CAS登记号、结构或部分结构、离子能性质、振动与电子能、分子量和作用进行检索,可检索到的数据包括分子式、分子量、化学结构、别名、CAS登记号、气相热化学数据、凝聚相热化学数据、液态常压热容、固态常压热容、相变数据、汽化焓、 升华焓、燃烧焓、燃烧熵、各种反应的热化学数据、溶解数据、气相离子能数据、气相 红外光谱、质谱、紫外/可见光谱、振动/电子能及其参考文献。 2.2美国标准技术研究所物理网上工具书(https://www.360docs.net/doc/9319080788.html,/) 该站点包括物性常数、原子光谱数据、分子光谱数据、离子化数据、χ-射线、γ- 射线数据、放射性计量数据、核物理数据及其它数据库。 3化学搜索器(https://www.360docs.net/doc/9319080788.html,/' target=_blank>https://www.360docs.net/doc/9319080788.html,/) Chemfinder化学搜索器是免费注册使用的数据库,是目前网上化合物性质数据最全 面的资源。可通过分子式、化学物质名称、分子量或化合物的结构片段来检索,检索结 果包括化合物的同义词、结构图形及物理性质,如熔点、沸点、蒸发速率、闪点、折射率、CAS登记号、比重、蒸汽密度、水溶性质及特征等。该数据库目前含有75 000种化合

物性表

DuPont ? Zytel ? nylon resin Zytel ? 101L NC010 Value DAM 50%RH Identification Resin Identification ISO 1043PA66 Part Marking Code ISO 11469>PA66< Mechanical Yield Stress ISO 527MPa (kpsi) 82 (11.9)55 (8.0) Strain at Break ISO 527% 50mm/min 45 Nominal Strain at Break ISO 527%25>100 Yield Strain ISO 527% 4.525 Tensile Modulus ISO 527MPa (kpsi)3100 (450) 1400 (200) Tensile Creep Modulus ISO 899 MPa (kpsi) 1h 1400 (200) 1000h 820 (119) Poisson's Ratio 0.41 Flexural Modulus ISO 178MPa (kpsi)2800 (410) 1200 (174) Notched Charpy Impact Strength ISO 179/1eA kJ/m 2 -30°C (-22°F) 4.53 23°C (73°F) 5.515 Unnotched Charpy Impact Strength ISO 179/1eU kJ/m 2 -30°C (-22°F)400NB 23°C (73°F) NB NB Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated. The DuPont Oval Logo, DuPont?, The miracles of science? and Zytel? are trademarks or registered trademarks of DuPont Company. Copyright? 2005. 050630/050630 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise. The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publication is to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. Caution: Do not use this product in medical applications involving permanent implantation in the human body. For other medical applications see "DuPont Medical Caution Statement", H-50102. https://www.360docs.net/doc/9319080788.html, Zytel ? 101L NC010 is a lubricated polyamide 66 resin for injection molding. Property Test Method Units

利用aspenplus进行物性全参数地估算

实用文案 1 纯组分物性常数的估算 1.1、乙基2-乙氧基乙醇物性的输入 由于Aspen Plus 软件自带的物性数据库中很难查乙基2-乙氧基乙醇的物性参数, 使模拟分离、确定工艺条件的过程中遇到困难, 所以采用物性估算的功能对乙基2-乙氧基乙醇计算。 已知: 最简式:(C6H14O3) 分子式:(CH3-CH2-O-CH2-CH2-O-CH2-CH2-OH) 沸点:195℃ 1.2、具体模拟计算过程 乙基2-乙氧基乙醇为非库组分,其临界温度、临界压力、临界体积和临界压缩因子及理想状态的标准吉布斯自由能、标准吉生成热、蒸汽压、偏心因子等一些参数都很难查询到,根据的已知标准沸点TB,可以使用aspen plus软件的Estimation Input Pure Component(估计输入纯组分) 对纯组分物性的这些参数进行估计。 为估计纯组分物性参数,则需 1. 在Data (数据)菜单中选择Properties(性质) 2. 在Data Browser Menu(数据浏览菜单)左屏选择Estimation(估计)然后选Input(输入) 3. 在Setup(设置)表中选择Estimation(估计)选项,Identifying Parameters to be Estimated(识别估计参数) 4. 单击Pure Component(纯组分)页 5. 在Pure Component 页中选择要用Parameter(参数)列表框估计的参数

6. 在Component(组分)列表框中选择要估计所选物性的组分如果要为多组分估计选择物性可单独选择附加组分或选择All(所有)估计所有组分的物性 7. 在每个组分的Method(方法)列表框中选择要使用的估计方法可以规定一个以上的方法。 具体操作过程如下: 1、打开一个新的运行,点击Date/Setup 2、在Setup/Specifications-Global页上改变Run Type位property Estimation

常用材料物性表

常用材料物性表 清洗要求 压力速度 ABS 210℃-245℃90℃≥2H 25℃-75℃中高压中高速高温下材料会分解,正常温度下半小时后需清洗螺杆。 压中速正常温度下材料也会分解,停机十分钟需排料。 ABS+玻纤220℃-250℃90℃≥3H 50℃-80℃中高压中高速正常温度下材料也会分解,停机十分钟需排料。 ABS+AS 220℃-240℃90℃≥3H 60℃-85℃中高压中高速高温下材料会分解,正常温度下半小时后需清洗螺杆。 ABS+PC 240℃-280℃110℃≥4H 50℃-100℃中高压高速长期高温下材料会分解,正常温度下半小时后需排料。 PA6 240℃-270℃105℃≥8H 80℃-90℃中高压高速高温下材料会分解,正常温度下半小时后需清洗螺杆。 PA6+玻纤250℃-280℃110℃≥8H 80℃-90℃中高压高速高温下材料会分解,正常温度下半小时后需清洗螺杆。 PA12 240℃-290℃85℃≥5H 30℃-40℃中压高速高温下材料会分解,正常温度下半小时后需清洗螺杆。 PA12+玻纤240℃-270℃85℃≥5H 80℃-90℃中压高速高温下材料会分解,正常温度下半小时后需清洗螺杆。

压高速高温下材料会分解,正常温度下半小时后需清洗螺杆。 PA66+玻纤260℃-280℃105℃≥12H 70℃-90℃中压高速高温下材料会分解,正常温度下半小时后需清洗螺杆。 PBT 240℃-270℃140℃≥4H 25℃-50℃中压高速长期高温下材料会分解,正常温度下半小时后需排料。 PBT+玻纤240℃-265℃140℃≥4H 25℃-50℃中压高速长期高温下材料会分解,正常温度下半小时后需排料。 PC 260℃-300℃120℃≥4H 70℃-120℃高压高速、低速无需清洗,320℃高温下不会分解,如出现变色需排料。 PC+玻纤250℃-290℃125℃≥4H 70℃-120℃高压高速无需清洗,280℃高温下不易分解,如出现变色需排料。 PC+PBT 235℃-285℃130℃≥4H 35℃-95℃中高压高速长期高温下材料会分解,正常温度下半小时后需排料。 PE-HD 200℃-230℃/ / 50℃-95℃低压高速无需清洗,高温下不会分解,长期高温下流动性会增加。 PE-LD 180℃-220℃/ / 20℃-40℃中高压高速无需清洗,高温下不会分解,长期高温下流动性会增加。 PEI 340℃-400℃150℃≥4H 100℃-175℃中高压高速无需清洗,高温下不易分解,正常温度下半小时后需排料。 PEI+玻纤340℃-420℃150℃≥4H 100℃-175℃中高压高速无需清洗,高温下不易分解,正常温度下半小时后需排料。