Metal to ceramic joining via a metallic interlayer bonding technique

Journal of Materials Processing Technology 152(2004)

257–265

Metal to ceramic joining via a metallic interlayer bonding technique

A.K.Jadoon a ,?,

B.Ralph a ,P.R.Hornsby b

a

Department of Mechanical Engineering,Brunel University,Uxbridge,Middlesex UB83PH,UK b

The Wolfson Centre for Material Processing,Brunel University,Uxbridge,Middlesex UB83PH,UK

Accepted 15October 2003

Abstract

The lack of suitable joining techniques for dissimilar materials such as metal and ceramic for high-temperature applications and devices is a major hindrance to the utilization of their outstanding properties and lower costs.

This paper presents the results of joining between the high-temperature and corrosion resistant iron–chromium–aluminium alloy (Fe-cralloy)with silicon nitride by use of metallic interlayer.The primary objectives were to produce joints for high-temperature applications (above 500?C)and to observe the effects of processing parameters with regards to joint strength.

Joining by use of a thin (12.5?m)and non-remaining copper foil produced joints with an average maximum shear strength of 67.5MPa (±5)at 1100?C,30min dwell time at 9.5MPa,under vacuum.The processing conditions were found to play a very important role in the joining process and effected joint strength.The results suggest that a thin aluminium nitride,AlN,reaction product layer was present on the silicon nitride interface in the joined samples.This is an indication that reactive wetting was occurring.Iron,chromium,aluminium and copper were found to in?ltrate the silicon nitride,whilst silicon and nitrogen diffused into the Fecralloy.

Joining was also attempted using a Ti/Cu/Ti multilayer and its variations.Joining was not possible due to the formation of a brittle reaction product layer,highlighting that wetting and joining are not synonymous.?2003Elsevier B.V .All rights reserved.

Keywords:Metal–ceramic joining;Interfacial melting;In?ltration;Process parameters

1.Introduction

Silicon nitride is an attractive engineering ceramic due to its high strength and toughness,good thermal properties and chemical resistance at elevated temperatures [1].It ?nds use in a variety of applications including spark plugs,piston heads and rocker arms in automobile engines [2].Due to the brittle nature of ceramics,machining holes for riveting or bolting is not advisable and the use of bonding adhesives is avoided where service temperatures rise above 100?C.The popular choice for metal to ceramic joining tends to be active metal brazing.Joining of heat resistant alloys to silicon nitride using this method has been extensively studied and developed over the last decade [3–5].

There are numerous obstacles for successful metal–ceramic joining,the most important of which is the relative inert-ness of the ceramic and the coef?cient of thermal expansion (CTE)mismatch.The latter tends to be a major problem when joining any dissimilar material.Temperature changes induced during cooling from the joining temperature and

?

Corresponding author.

during subsequent service can generate high internal stresses due to the CTE mismatch and lead to poor joint strength or failure [6].It has been proposed that the use of a remaining ductile interlayer,such as in active metal brazing,can over-come or reduce the residual stress build up by deformation [7].

Like all techniques active metal brazing has its limita-tions and cannot join all combinations of metal–ceramic.More importantly the joints formed cannot be used for high-temperature applications with a ceiling limit of around 400?C [8].Thus,a need has been identi?ed to develop and study a technique(s)that can join metal–ceramic with a large CTE mismatch for potential high-temperature applications (above 500?C)by a simple process.

This study deals with the joining of silicon nitride to the high-temperature iron–chromium–aluminium alloy (com-mercially known as ‘Fecralloy’)using copper (Cu)and titanium (Ti)/Cu variant interlayers.Joining was performed under varying processing conditions and the optical pro-cessing conditions were determined by measuring the shear strength of the joints obtained.

Joining of Fecralloy–silicon nitride by another technique has been achieved and is reported elsewhere [9].

0924-0136/$–see front matter ?2003Elsevier B.V .All rights reserved.doi:10.1016/j.jmatprotec.2003.10.005

258 A.K.Jadoon et al./Journal of Materials Processing Technology152(2004)257–265

2.Experimental

2.1.Materials

The materials to be joined were Fecralloy(72.3Fe,22.0Cr, 5.0Al,0.3Si,0.02C,0.2Mn,0.1Y,0.1Zr,wt.%)and reaction bonded silicon nitride.They were supplied by Goodfellow Ltd.,UK in sheet form100mm×100mm×https://www.360docs.net/doc/ab18550051.html,ing a low speed diamond wheel they were cut into samples mea-suring10mm×10mm×5mm.The joining surface was manually ground to a planar1200grit?nish.Polishing to a 1?m?nish using6?m and then1?m diamond paste fol-lowed this.

The physical properties of the reaction bonded silicon nitride and Fecralloy are given in Table1.Foils of technically pure Cu and Ti were used for interlayer.The Cu foil(12.5 and50?m thickness)and Ti foil(12.5?m thickness)were cut into10mm×10mm squares.After polishing,the silicon nitride and Fecralloy substrates along with the Cu and Ti foil were all cleaned ultrasonically and stored in acetone until use.

2.2.Joining procedure

Joining was carried out in a purpose built high-temperature vacuum furnace,where temperatures of1200?C under a vacuum of5×10?4Torr were possible.Greater experimen-tal detail,including that of the high-temperature vacuum furnace has been reported previously[9].

The Cu foil was placed between the Fecralloy and silicon nitride in a butt joint con?guration.This con?guration was then placed into the high-temperature vacuum furnace using a graphite sample holder.

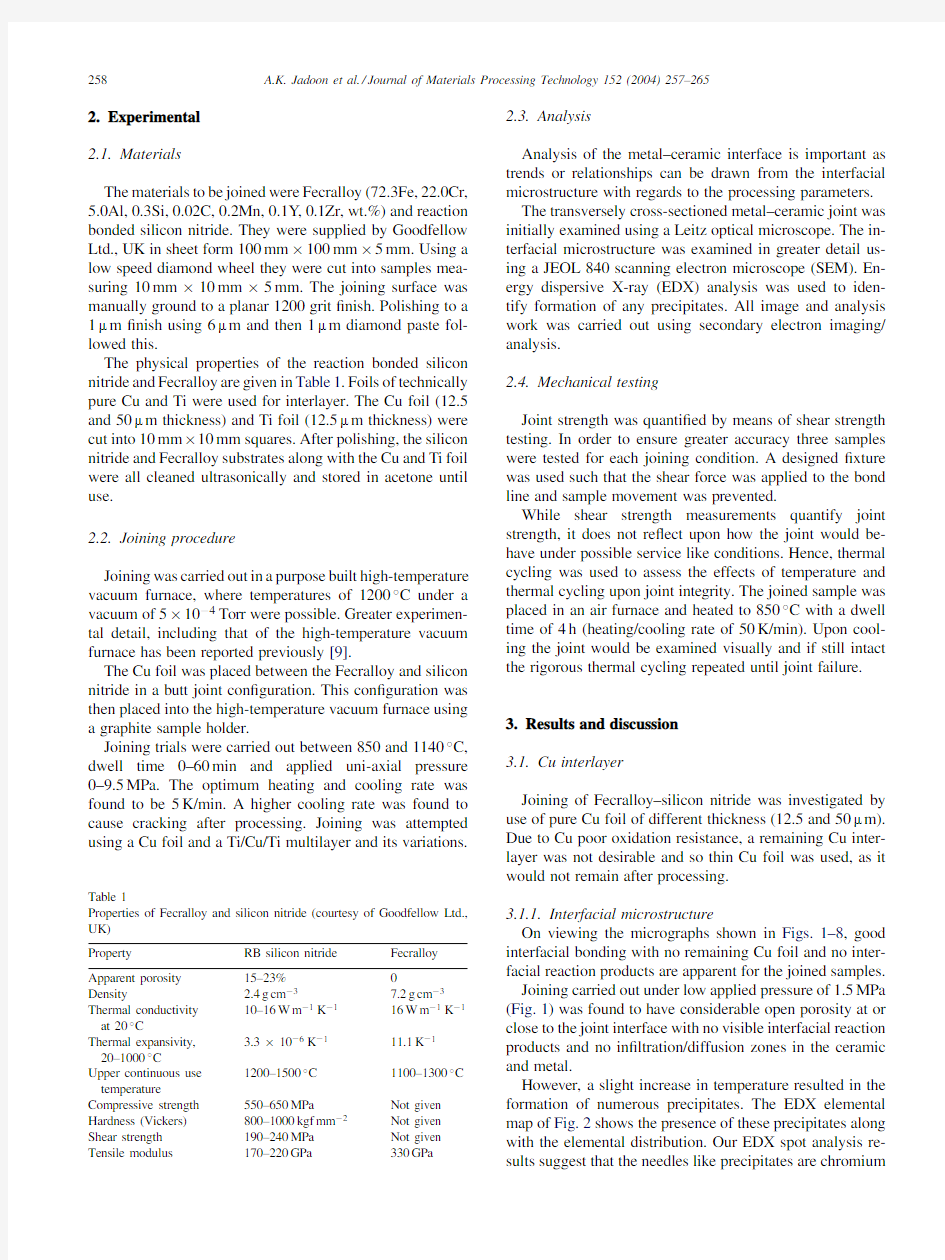

Joining trials were carried out between850and1140?C, dwell time0–60min and applied uni-axial pressure 0–9.5MPa.The optimum heating and cooling rate was found to be5K/min.A higher cooling rate was found to cause cracking after processing.Joining was attempted using a Cu foil and a Ti/Cu/Ti multilayer and its variations. Table1

Properties of Fecralloy and silicon nitride(courtesy of Goodfellow Ltd., UK)

Property RB silicon nitride Fecralloy Apparent porosity15–23%0

Density 2.4g cm?37.2g cm?3 Thermal conductivity

at20?C

10–16W m?1K?116W m?1K?1

Thermal expansivity,

20–1000?C

3.3×10?6K?111.1K?1

Upper continuous use

temperature

1200–1500?C1100–1300?C

Compressive strength550–650MPa Not given Hardness(Vickers)800–1000kgf mm?2Not given Shear strength190–240MPa Not given Tensile modulus170–220GPa330GPa 2.3.Analysis

Analysis of the metal–ceramic interface is important as trends or relationships can be drawn from the interfacial microstructure with regards to the processing parameters. The transversely cross-sectioned metal–ceramic joint was initially examined using a Leitz optical microscope.The in-terfacial microstructure was examined in greater detail us-ing a JEOL840scanning electron microscope(SEM).En-ergy dispersive X-ray(EDX)analysis was used to iden-tify formation of any precipitates.All image and analysis work was carried out using secondary electron imaging/ analysis.

2.4.Mechanical testing

Joint strength was quanti?ed by means of shear strength testing.In order to ensure greater accuracy three samples were tested for each joining condition.A designed?xture was used such that the shear force was applied to the bond line and sample movement was prevented.

While shear strength measurements quantify joint strength,it does not re?ect upon how the joint would be-have under possible service like conditions.Hence,thermal cycling was used to assess the effects of temperature and thermal cycling upon joint integrity.The joined sample was placed in an air furnace and heated to850?C with a dwell time of4h(heating/cooling rate of50K/min).Upon cool-ing the joint would be examined visually and if still intact the rigorous thermal cycling repeated until joint failure. 3.Results and discussion

3.1.Cu interlayer

Joining of Fecralloy–silicon nitride was investigated by use of pure Cu foil of different thickness(12.5and50?m). Due to Cu poor oxidation resistance,a remaining Cu inter-layer was not desirable and so thin Cu foil was used,as it would not remain after processing.

3.1.1.Interfacial microstructure

On viewing the micrographs shown in Figs.1–8,good interfacial bonding with no remaining Cu foil and no inter-facial reaction products are apparent for the joined samples. Joining carried out under low applied pressure of1.5MPa (Fig.1)was found to have considerable open porosity at or close to the joint interface with no visible interfacial reaction products and no in?ltration/diffusion zones in the ceramic and metal.

However,a slight increase in temperature resulted in the formation of numerous precipitates.The EDX elemental map of Fig.2shows the presence of these precipitates along with the elemental distribution.Our EDX spot analysis re-sults suggest that the needles like precipitates are chromium

A.K.Jadoon et al./Journal of Materials Processing Technology152(2004)257–265259 Fig.1.Micrograph of a Fecralloy–silicon nitride joint(1100?C,30min,1.5MPa).Good interfacial bonding is apparent with signs of reactive wetting (uneven joint interface).

nitride(Cr2N),while the smaller and more numerous pre-cipitates are iron silicide(Fe3Si).

The elemental maps also establish the presence of a thin reaction product layer at the silicon nitride joint interface for all the joined samples(average thickness of8?m).From the results obtained,this is most likely to be aluminium nitride, AlN.

The castrotropic effects of a high cooling rate can be seen in Fig.3,where interfacial cracking is apparent.The most likely reason for this is the large residual stresses build up due to the CTE mismatch.

Joining carried out using greater applied pressures of 5.5–9.5MPa all have a diffusion and in?ltration zone,as shown in Figs.4and5.The?rst diffusion zone at the Fe-cralloy interface is that of Si,where precipitates of Fe3Si are present.The second diffusion zone is that of N,where the needles like Cr2N precipitates exist.The chemical compo-sition of the in?ltrated compound in the silicon nitride was found to be similar to that of Fecralloy,in addition to small amounts of Cu,Si and N(<10wt.%).The size of the dif-fusion and in?ltration zone was found to vary according to the processing temperature and not pressure or time.This is because they are thermally assisted processes.

The use of a thicker Cu foil did not result in joining, as can be seen in Fig.6.The foil remained after process-ing adhering to the Fecralloy only.Failure was always at the ceramic–interlayer interface.The reason for this is be-lieved to be due to the formation of brittle phases at the ceramic–interlayer interface(mostly copper silicides).

The morphology of the metal–ceramic interface depends upon the type of interaction that has occurred.If only phys-ical interaction has occurred,the structure of the metal and ceramic is unchanged.However,if a chemical reaction oc-curs,the morphology is effected depending upon whether solid–solid or solid–liquid reactions occur and if new in-terfacial phases are formed.Formation of new interfacial phases not only alters the microstructure but also the phys-ical and mechanical properties.These interfacial phases or reaction product layers are a consequence of the reactions needed to cause wetting of the ceramic.One can consider the reaction product layer as chemical bridges between the metal and ceramic.

It is believed that the advantages or disadvantages of a re-action product layer vary from system to system and general-ization would be dif?cult.However,a thick reaction product layer tends to weaken the interface due to excessive growth stresses and brittle nature.Opinion is varied about the pres-ence of a reaction layer product.Some researchers believe they are very detrimental to joint strength[10],while oth-ers attribute interfacial failure due to a thin reaction layer product[11].

3.1.2.Effects of processing conditions

The primary variables in the joining process are pressure, temperature and time.These variables are not independent from each other and the effect of each variable is discussed outlining the important considerations associated with each variable.Table2presents the shear strength results for the varying processing conditions.

3.1.2.1.Pressure.In order to determine the optimum pro-cess conditions,the in?uence of applied bonding pressure on joint integrity was studied.Experiments were carried out with different pressures varying between0and9.5MPa.Fig. 7shows the plot of average shear strength(±5MPa)versus bonding pressure at1100and1140?C.

260 A.K.Jadoon et al./Journal of Materials Processing Technology152(2004)257–265 Fig.2.EDX elemental map showing presence of AlN reaction product layer and needle like Cr2N precipitates(1140?C,30min,1.5MPa).

It is clear that the applied pressure affects joint strength. At high-temperature and applied pressure the yield point of Fecralloy is lowered.The applied pressure causes partial de-formation of the Fecralloy at the joining interface,which is suf?cient to bring the Fecralloy into full contact with the sil-icon nitride on an atomic scale.Once full contact is made,further increase of pressure aids the diffusion/in?ltration process that is occurring at the interface.The liquid metal that in?ltrates the silicon nitride holds the substrate together by mechanical interlocking upon cooling.It follows that the more liquid metal that in?ltrates the silicon nitride,the stronger the joint.Of course there must be an applied pres-

A.K.Jadoon et al./Journal of Materials Processing Technology152(2004)257–265261 Fig.3.Micrograph of a failed joint due to high cooling rate(1100?C,30min,1.5MPa).

sure after which detrimental effects occur such as bulk de-formation of the metal,expulsion of the liquid metal,etc. This was not identi?ed in the present work.

The applied pressure also helps to break up surface oxides present at the joining interface.Fecralloy has a protective iron–chromium–aluminium oxide spinnel and a silicon ox-ide layer covers silicon nitride.These oxide layers present a barrier for wetting and also the diffusion/in?ltration pro-cess,giving rise to an incubation period for the interfacial reactions to begin.Quantitative data about the applied pres-sure required to promote the removal of these oxide layers is not available.

3.1.2.2.Temperature.This is an important variable and the dependence of strength on temperature can be explained by Fig.

4.Micrograph of Fecralloy–silicon nitride joint(1100?C,30min, 7.5MPa).considering the behaviour of the materials in the vicinity of both the metal and ceramic interface.Temperature increases interaction across the metal–ceramic interface by increasing the mobility of the atoms and also the mobility of disloca-tions in the metal during joining.

Diffusion and in?ltration are thermally assisted processes and so an increase in temperature is followed by an increase in their respective rates.

Increasing temperature can cause a non-wetting-to-wetting transition for liquid metals in contact with ceramics,usually at1100?C.This was found to be the case for an Al drop on silicon nitride[12].At low temperatures,large non-wetting angles were observed as both Al and silicon nitride had sur-face oxide layers.At higher temperatures(1100?C)contact angles of90?(i.e.wetting was occurring)were observed Fig.5.Micrograph of Fecralloy–silicon nitride joint(1140?C,30min, 7.5MPa).

262 A.K.Jadoon et al./Journal of Materials Processing Technology152(2004)257–265 Fig.6.Micrograph showing failed Fecralloy–silicon nitride joint using a

thicker Cu foil(1100?C,30min,1.5MPa).

and believed to be due to the breaking down of surface oxide layers and lowering of free surface energy.This is believed to be the case with our joining system,as joining was not possible below1100?C.

3.1.2.3.Time.The dwell time at temperatures of1100?C or above effects the interfacial reactions and size of dif-fusion/in?ltration zones.At1100and1140?C we see the same pattern where there is a minimum time to initiate the reactions in order to produce a joint(10min),an optimum time that produces joints of maximum strength(30min) and a detrimental time that produces weak joints/no joints (60min).From this it is apparent that there is a minimum time to initiate the joining process and this is due to the breaking up of surface oxides and wetting of ceramic in-Fig.7.Graph showing dependence of average shear strength of joints with applied pressure(Cu interlayer).Fig.8.Micrograph of a failed sample during thermal cycling(Cu inter-layer).

terface.There is an optimum time,where suf?cient wet-ting/interfacial reactions have occurred that produce a thin reaction product layer and elemental diffusion/in?ltration to produce a good joint.Then there is a detrimental excess Table2

Results of joining trials and thermal cycling using Cu foil interlayer Temperature

(?C)

Dwell

time

(min)

Applied

pressure

(MPa)

Average shear

strength

(±5MPa)

No.of thermal

cycles till joint

failure 100010 1.500

100030 1.500

100060 1.500

110010000

110030000

110060000

110010 1.512.71

110030 1.549.63

110060 1.532.32

110030 3.556.10

110030 5.562.33

1100307.566.83

1100309.567.53

114010000

114030000

114060000

114010 1.516.11

114030 1.534.32

114060 1.511.81

114030 3.548.92

114030 5.557.42

1140307.563.83

1140309.562.23

A.K.Jadoon et al./Journal of Materials Processing Technology152(2004)257–265263

time,where the reactions proceed to form brittle products, usually silicides that cause a weak joint.

3.1.3.Mechanical testing

3.1.3.1.Shear testing.Table2presents the data for the average shear strength of the joined samples.Shear strength ranged from11.8to67.5MPa and are modest compared to those of metal–metal and ceramic–ceramic joining. Metal–ceramic joints tend to have inherently low shear strength values.The two main reasons for this are the resid-ual thermal stress due to the CTE mismatch and formation of brittle phases at the joint interface.Our shear strength values compare well to other metal–silicon nitride joints. Using an active metal braze,Lee[13]presented shear strength values of46.1–70.4MPa for Inconnel718–silicon nitride joints.Work by Vegeter and Den Ouden[14]pro-duced zirconia–silicon nitride joints using a Ni interlayer that had a maximum shear strength of57MPa.

The modest shear strength values obtained in this work can be attributed to the mentioned reasons along with the presence of interfacial defects such as cracks and pores. Processing conditions do affect the shear strength of the joint and the results reveal the following trends:

1.At a given joining time and pressure,the shear strength

increases with joining temperature,reaching a maximum and then decreasing with further temperature increase.

2.At a given joining temperature and pressure,the shear

strength increases with joining time,reaching a maxi-mum and then decreasing with further dwell time in-crease.

3.At a given joining time and temperature,the shear

strength increases with pressure.This work did not es-tablish the maximum pressure after which shear strength decreases.

These results establish that the optimum processing con-ditions to produce a Fecralloy–silicon nitride joint with the highest shear strength is1100?C,9.5MPa and30min.Dwell times greater than30min and temperatures greater than 1100?C,make the formation of brittle silicides at the ce-ramic interface likely and lower shear strength.

Lee and Kim[15]studied the residual stress in various metal–ceramic joints using an X-ray diffraction technique and compared these with analytical calculations of the resid-ual stress.They put forth a?gure of700MPa for a di-rectly joined316stainless steel–silicon nitride joint.This value is believed to be similar for Fecralloy–silicon nitride joints.While the exact?gure of residual stress is unsure, it is clear that it is considerably high.This explains why metal–ceramic joints tend to have low shear strength values.

3.1.3.2.Thermal cycling.Total reliance upon joint strength measurements to characterize the mechanical be-haviour of a metal–ceramic joint in service like conditions is incorrect.As mentioned in the previous section failure is mainly attributed to residual thermal stress and formation of brittle interfacial phases.Interfacial defects such as cracks and pores and the local variation of stresses governed by the geometry of the joint,the elastic and plastic properties of the metal/ceramic and loading conditions all in?uence joint failure.

It is therefore important to characterize mechanical be-haviour of the joint under service like conditions.One op-tion is to measure joint strength at temperature and this al-ways shows that joint strength decreases with temperature [16].The main reason for this tends to be the low melt-ing temperature of the active metal braze and an annealing effect at lower temperatures.Another option is thermal cy-cling,which was used in this work.This gives an indication to the durability of the joint to thermal cycling.Provided all the test conditions are kept the same,the results are reliable enough to serve as a means of comparison.

The temperature of850?C was chosen as it higher than the service temperature of most active metal braze joints. From Table2it can be seen that the thermal cycling results are quite encouraging.They can be directly related to the shear strength values,as the stronger joints tend to be able to withstand more thermal cycles.

It is the residual stress factor that comes into play leading to joint failure during thermal cycling.The stresses parallel to the interface are tensile in metals and compressive in ceramics showing a jump at the interface.Maximum tension in ceramics occurs near the free edge of the interface,where the stresses are singular.It is this tensile stress developed in the ceramic adherent that is thought to be the most important factor effecting joint failure.Fig.8shows the micrograph of a sample that failed after thermal cycling.Extensive cracking in the ceramic where the cracks initiate and propagate from the side can be seen.Failure was due to the excessive thermal stresses in the joint.

3.2.Ti/Cu/Ti multi-interlayer

Partial transient liquid phase(PTLP)bonding has been explored for ceramic–ceramic and metal–ceramic joining in recent years[17].This process offers the possibility of pro-ducing an interlayer with a high melting temperature and hence a joint that can possibly withstand high-temperatures. Iino[18]used this process to join silicon nitride with Ni us-ing a Ti foil.Zhang et al.[7]further increased the strength of this joint(four-point bend test)by the insertion of a Cu foil between the Ni metal and Ti foil.

The joining of Fecralloy–silicon nitride was investigated by use of a Ti/Cu/Ti multi-interlayer and its variations.The Ti/Cu/Ti system was selected as it has a eutectic point and a reaction between the inner insert(Cu)and outer inserts (Ti)would occur with the formation of a transient liquid. At1050?C the liquid phase formed at the Ti/Cu interface would disappear as the Cu diffused into the Ti.If the Cu concentration in the Ti is below30wt.%,this interlayer has a melting temperature of approximately1200?C,producing a high-temperature ductile interlayer.This system of a re-

264 A.K.Jadoon et al./Journal of Materials Processing Technology 152(2004)257–265

Table 3

Results of the joining trials using multi-interlayer foil system (no joining)Multilayer system Temperature (?C)Dwell time (min)Applied pressure (MPa)Ti/Cu/Ti

950302100030 1.5100030 3.5100060 1.5110010 1.5110030 3.5110030 5.5110060 3.5114030 1.5Cu/Ti/Cu

100030 1.51100

30

1.5

maining ductile interlayer would be compared to that of the previous section where the Cu interlayer does not remain.3.2.1.Results and discussion

3.2.1.1.Microstructure of interface.Table 3presents the results of the joining trials using the multi-interlayer sys-tems.Although varying processing conditions were used,joining was not possible at all as weak joints were produced that broke under handling.

Figs.9and 10show the trials carried out at 1100and 1140?C.From the Cu–Ti phase diagram [19]it is established that a eutectic reaction occurs at 1050?C,while at 1100?C,the Cu foil completely melts.The rough silicon nitride sur-face indicates that reactive wetting occurred during process-ing.EDX analysis of the interlayer found it to be mostly TiCu and Ti 2Cu 3both of which had dissolved Si.There were also small areas where pure Cu or Ti existed.EDX analy-sis of the silicon nitride interface determined the presence of two products.The ?rst was TiN,from the reaction of Ti with the silicon nitride.The second product contained Ti,Cu and Si with small amounts of N.This is believed to be

a

Fig.9.Micrograph of failed Fecralloy–silicon nitride joint using Ti/Cu/Ti interlayer (1100?C,30min,1.5MPa).

Ti–Cu Si–N compound and its presence along with that of TiN was also con?rmed by Suganuma et al.[20]in the join-ing of silicon nitride to itself using a Ti–Ag–Cu braze.From this it is apparent that reactive wetting and dissolution of the ceramic occurs,with small amounts of reactive in?ltration into the silicon nitride (Ti and Cu)and diffusion into the Fecralloy (Ti,Cu,Si and N).Joint failure can be attributed to the two reaction products that form in all the joints with varied processing conditions.This can be due to their brit-tle nature or excessive residual stresses that accompany the volume change with the formation of the reaction product.In order to overcome this problem and achieve joining two different methods were tried.The ?rst used a thinner Ti foil (12.5?m),as the thickness of the Ti foil determines the amount of liquid present.Weak joints were produced that broke under handling.EDX analysis identi?ed the presence of the Ti–Cu–Si–N compound,which is believed to cause failure.However,it should be noted that although these joints also broke under handling,considerably more force was re-quired with the Ti/Cu/Ti joints.From this it is apparent that as little Ti as possible should be used due to the formation of the brittle compound.

The second approach was a reversal of the multilayer,in that a Cu/Ti/Cu multilayer was used (12.5?m/20?m/12.5?m).Once again joining was not possible as the joints broke under handling but showed signs of reactive wetting at the silicon nitride interface.At the processing tempera-tures of 1050or 1100?C,the Cu foil would react with the free Si on the silicon nitride surface forming a Cu–Si liquid and would also react with the Ti foil forming a transient liquid.It is believed that a Ti–Cu–Si liquid was present at the silicon nitride interface,which is responsible for the ex-tensive reactive wetting (cratoring).Again the Ti–Cu–Si–N compound was present at the silicon nitride interface.One can conclusively attribute the presence of this compound to failure highlighting the dif?culties of metal–ceramic joining.

A.K.Jadoon et al./Journal of Materials Processing Technology152(2004)257–265265 Fig.10.Micrograph of failed Fecralloy–silicon nitride joint using Ti/Cu/Ti interlayer(1140?C,30min,1.5MPa).

4.Conclusions

It has been possible to join Fecralloy with silicon nitride using a thin Cu interlayer foil.Good interfacial bonding is achieved and mechanical interlocking forces hold the joints together that exhibit the highest shear strength.Joining re-sults in a thin reaction product layer at the silicon nitride interface(results suggest AlN),diffusion of Cu,Si and N into the Fecralloy and in?ltration of Fe,Cr,Al and Cu into the silicon nitride.

The shear strength values are very modest but compare well to other metal–ceramic joints,where the CTE mismatch is also large.The thermal stresses that are induced in the silicon nitride during the process cooling are believed to be the main cause of the modest shear strength values and reason for failure during rigorous thermal cycling.

To overcome this problem,the use of a remaining and high-temperature ductile interlayer was looked in to by use of Ti/Cu/Ti multi-interlayer and its variations.However, joining was not possible and this was attributed to the pres-ence of a Ti–Cu–Si–N brittle compound.Although Ti is an active element aiding the wetting of ceramics,in large concentrations it tends to be detrimental as it can form brittle compounds.This is one of the main reasons why its concentration is low in active metal brazes.

References

[1]M.G.Nicholas,Joining of Ceramics,Chapman&Hall,London,

1990,p.207.

[2]https://www.360docs.net/doc/ab18550051.html,rson,J.W.Adams,L.R.Johnson,A.P.S.Teotia,L.G.Hill,

Ceramic materials for advanced heat engines,Noyes(1985)87. [3]J.F.Groves,H.N.G.Wadley,Functionally graded materials synthesis

via low vacuum directed vapour deposition,Composites B28(1–2) (1997)57–69.

[4]A.Bronson,Reactive liquid processing in ceramic joining,JOM

(1999)43.

[5]T.Shimoo,K.Okamura, D.Shibata,Reaction of Si3N4with

25%Cr–20%Ni austenitic stainless steel under nitrogen or argon at-mosphere,J.Mater.Sci.35(2002)5485–5492.

[6]G.Cam,M.Kocak,Progress in joining of advanced materials,Int.

Mater.Rev.43(1)(1998)1–39.

[7]J.X.Zhang,R.S.Chandel,Y.Z.Chen,H.P.Seow,Effects of resid-

ual stress on the strength of an alumina–steel joint by partial tran-sient liquid phase bonding(PTLP)brazing,J.Mater.Proc.Technol.

122(2–3)(2002)220–225.

[8]L.Esposito,A.Bellosi,G.De Portu,Joining of ceramic oxides by

liquid wetting and capillarity,J.Mater.Sci.33(1998)1827–1838.

[9]A.K.Jadoon,Employing reactive synthesis for metal to ceramic

joining for high-temperature applications,J.Mater.Sci.,in press.

[10]M.G.Nicholas,Joining of Ceramics,Chapman&Hall,London,

1990,p.175.

[11]M.Panlasto,G.Ceccone,S.D.Peteves,Joining of silicon nitride via

transient liquid,Scripta Mater.36(10)(1997)1175–1178.

[12]N.Eustathpoulos,M.G.Nicholas,B.Drevet,Wettability at High

Temperatures,Pergamon Materials Series,1999,p.294.

[13]W.C.Lee,Joint strength and interfacial microstructure in silicon

nitride/nickel-based Inconel718alloy bonding,J.Mater.Sci.32 (1997)221–230.

[14]R.H.Vegeter,G.Den Ouden,Diffusion bonding of zirconia to silicon

nitride using nickel interlayers,J.Mater.Sci.33(1998)4525–4530.

[15]S.B.Lee,J.H.Kim,Finite element analysis and x-ray measurement of

the residual stresses of ceramic/metal joints,J.Mater.Proc.Technol.

67(1–3)(1997)167–172.

[16]S.D.Peteves,M.Paulasto,G.Ceccone,V.Stamos,The reactive

route to ceramic joining:fabrication,interfacial chemistry and joint properties,Acta Mater.46(7)(1998)2407–2414.

[17]N.Eustathpoulos,M.G.Nicholas,B.Drevet,Wettability at High

Temperatures,Pergamon Materials Series,1999,p.306.

[18]Y.Iino,Partial transient liquid-phase metals layer technique of

ceramic–metal bonding,J.Mater.Sci.Lett.10(1990)104–106. [19]Alloy phase diagrams,in:ASM Handbook,vol.3,ASM International,

1992.

[20]K.Suganuma,T.Okamoto,Y.Miyamoto,M.Shimada,M.Koizumi,

Joining Si3N4to type405steel with soft metal interlayers,J.Mater.

Sci.Technol.(1986)156–1161.

Meta分析的完整步骤

Meta分析的完整步骤 根据个人的体会,结合战友的经验总结而成,meta的精髓就是对文献的二次加工和定量合成,所以这个总结也算是对战友经验的meta分析吧。 —、选题和立题 (一)形成需要解决的临床问题: 系统评价可以解决下列临床问题: 1?病因学和危险因素研究; 2.治疗手段的有效性研究; 3.诊断方法评价; 4.预后估计; 5.病人费用和效益分析等。 进行系统评价的最初阶段就应对要解决的问题进行精确描述,包括人群类型(疾病确切分 型、分期)、治疗手段或暴露因素的种类、预期结果等,合理选择进行评价的指标。 (二)指标的选择直接影响文献检索的准确性和敏感性,关系到制定检索策略。 (三)制定纳入排除标准。 二、文献检索 (一)检索策略的制定 这是关键,要求查全和查准。推荐Mesh联合free word 检索。 (二)文献检索,获取摘要和全文 国内的有维普全文VIP, CNKI,万方数据库,外文的有medline ,SD ,OVID等。 (三)文献管理 强烈推荐使用endnote ,procite ,noteexpress 等文献管理软件进行检索和管理文献。 查找文献全文的途径: 在这里,讲一下找文献的过程,以请后来的战友们参考(不包括网上有电子全文的): 1.查找免费全文: (1 )在pubmed center 中看有无免费全文。有的时候虽然没有显示free full text ,但是 点击进去看全文链接也有提供免费全文的。我就碰到几次。

(2 )在google 中搜一下。 少数情况下,NCBI没有提供全文的,google 有可能会找到,使用“学术搜索”。本人虽然没能在google 中找到一篇所需的文献,但发现了一篇非常重要的综述,里面包含了所有我需要的文献(当然不是数据),但起码提供了一个信息,所需要的文献也就这么多了,因为老外的综述也只包含了这么多的内容。这样,至U底找多少文献,找什么文献,心里就更有底了。 (3)免费医学全文杂志网站。Www.freemedicaljournals. 。提供很过超过收费期的免费 全文。 2.图书馆查馆藏目录: 包括到本校的,当然方便,使用pubmed 的linkout看文献收录的数据库,就知道本校的 是否有全文。其它国内高校象复旦、北大、清华等医学院的全文数据库都很全,基本上都 有权限。上海的就有华东地区联目、查国内各医学院校的图书馆联目。这里给出几个: (1)中国高等院校医药图书馆协会的地址: server14.library.imicams.ac.c n/xiehui/che ngyua n. htm ,进入左侧的“现干刊联目”, 可以看到有“现刊联目查询”和“过刊联目查询”,当然,查询结果不可全信,里面有许多错误。本人最难找的两篇文章全部给出了错误的信息(后来电话联系证实的)。 (2)再给出两个比较好的图书馆索要文献的email地址(有偿服务),但可以先提供文献, 后汇钱,当然做为我们,一定要讲信誉吆。一是解放军医学图书馆信息部: xxbmlplas ina. ,:; (3)二是复旦大学医科图书馆(原上医):https://www.360docs.net/doc/ab18550051.html, ,联系人,周月琴,王蔚之, 郑荣,,2,需下载文献传递申请表(202.120.76.225/ill.doc )。其他的图书馆要么要求 先交开户费,比如协和(500元),要么嫌麻烦,虽然网上讲过可提供有偿服务,在这里我就不一一列出了。 3.请DXY战友帮忙,在馆藏文献互助站中发帖,注意格式正确,最好提供linkout的多个 数据库的全文链接,此时为帮助的人着想,就是帮助自己。自己也同时帮助别人查文献,一来互相帮助,我为人人,人人为我。二则通过帮助别人可以积分,同时学会如何发帖和下载全文,我就感觉通过帮助别人收获很大,自己积分越高,获助的速度和机会也就相应增加。现在不少免费的网络空间(我常用爱存www.isload..c n ),比发邮件简便

Meta-分析的森林图及临床意义

Meta-分析的森林图及临床意义 作者:刘关键, 吴泰相 作者单位:四川大学华西医院中国循证医学中心,成都,610041 刊名: 中国循证医学杂志 英文刊名:CHINESE JOURNAL OF EVIDENCE-BASED MEDICINE 年,卷(期):2004,4(3) 被引用次数:19次 参考文献(6条) 1.Cochrane Collaboration open learning material for reviewers 2002 2.Austrahan Cochrane Center The Cochrane Handbook Summary Points & Libraries of Examples,September 1998 3.Australian Cochrane Center The Cochrane Handbook Summary Points & Libraries of Examples,September 1998 4.刘关键临床科研中正确抉择统计方法 2001 5.徐秦;鲁瑞萍关于"Cochrane协作网标志及其意义"中的一点异议[期刊论文]-中国循证医学杂志 2004(01) 6.Clarke M;Oxman AD;editors Cochrane Reviewers' Handbook 4.1.6 引证文献(20条) 1.陈灼AF内固定治疗胸腰段脊柱骨折疗效的Meta分析[期刊论文]-右江民族医学院学报 2010(2) 2.陈友浩.李章华.崔西龙.柳铭.刘天舒.肖思杰强骨胶囊治疗原发性骨质疏松症的系统评价[期刊论文]-中国骨质疏松杂志 2010(9) 3.张永.刘玉敏.郭新彪室内外PM2.5质量浓度(重量法)的Meta分析[期刊论文]-首都公共卫生 2010(5) 4.尹宏.钱卫庆外固定支架和小夹板外固定治疗桡骨远端不稳定性骨折疗效的Meta分析[期刊论文]-江苏医药2010(24) 5.孟宪民.周叶华.朱东辉.金甬嘉桡骨远端关节内骨折内固定与外固定疗效的meta分析[期刊论文]-中国当代医药2010(5) 6.周海鹰.胡雅君.刘荣波.尚兰.银文杰乏脂肪肾血管平滑肌脂肪瘤与肾细胞癌鉴别诊断中主要CT征象价值的系统评价[期刊论文]-中国循证医学杂志 2009(6) 7.汤建华.苏峰.徐今宁.董玫.安毛毛.王睿放射免疫法检测血清神经元特异性烯醇酶诊断小细胞肺癌价值的系统评价[期刊论文]-中国循证医学杂志 2009(5) 8.尹小磊.袁容娣.叶剑儿童白内障三种手术方式与后发障关系的Meta分析[期刊论文]-中国斜视与小儿眼科杂志2009(2) 9.谷贵山.张进.王铁军.王刚锁骨骨折手术与非手术治疗的Meta分析[期刊论文]-实用骨科杂志 2009(3) 10.仇瑶琴.袁长蓉.贺佳Meta分析论文写作的质量控制要点[期刊论文]-中国实用护理杂志 2009(23) 11.王睿.汤建华.李然.唐惠林.安毛毛.蔡芸.梁蓓蓓.张桂云.龙丽艳.陈良安EIA法检测血清神经元特异性烯醇酶诊断小细胞肺癌价值的系统评价[期刊论文]-中国循证医学杂志 2008(10) 12.唐健元.马莉Meta分析与药物评价[期刊论文]-药物流行病学杂志 2008(4) 13.仇瑶琴.贺佳国内护理期刊有关Meta分析论文的质量分析[期刊论文]-解放军护理杂志 2008(23) 14.林丛笑.苏银法.杜乐燕Excel软件在药效评价Meta分析中的应用[期刊论文]-实用药物与临床 2008(3)

Stata在meta分析中的应用

1 定量资料两组比较的meta分析 2 定性资料两组比较的meta分析 实例: 分类资料的meta分析 为了探讨用Aspirin预防心肌梗塞(myocardial infarction,MI)后死亡的发生。美国在1976——1988年问进行了7个关于Aspirin 预防MI后死亡的研究,详细结果见表1,其中6项研究的结果表明Aspirin组与安慰剂组的MI后死亡率的差别无统计学意义。只有1项结果表明Aspirin预防MI后死亡有效并且差别有统计学意义。现根据表1提供的结果进行meta分析 表1 Aspirin预防心肌梗塞死亡的临床试验结果 研究发表年份 Aspirin组安慰剂组 总例数死亡例数总例数死亡例数 MRC-1 1974 615 49 624 67 CDP 1976 758 44 771 64 MRC-2 1979 832 102 850 126 GASP 1979 317 32 309 38 PARIS 1980 810 85 406 52 AMIS 1980 2237 246 2257 219 ISIS-2 1988 8587 1570 8600 1720 操作步骤 1 把数据输入stata软件

2 变量的解释 Study 纳入的研究 Year 年份 Death1 Aspirin组的死亡人数 Live1 Aspirin组的存活人数 Death2 安慰剂组的死亡人数 Live2 安慰剂组的死亡人数 3 进行meta分析 metan death1 live1 dead2 live2, or label(namevar=study, yearvar=year) 结果:

Meta分析的完整步骤

Meta分析的完整步骤 Meta分析的完整步骤,根据个人的体会,结合战友的经验总结而成,meta的精髓就是对文献的二次加工和定量合成,所以这个总结也算是对战友经验的meta分析吧。 一、选题和立题 (一)形成需要解决的临床问题: 系统评价可以解决下列临床问题: 1.病因学和危险因素研究; 2.治疗手段的有效性研究;? 3.诊断方法评价; 4.预后估计; 5.病人费用和效益分析等。 进行系统评价的最初阶段就应对要解决的问题进行精确描述,包括人群类型(疾病确切分型、分期)?、治疗手段或暴露因素的种类、预期结果等,合理选择进行评价的指标?。 (二)指标的选择直接影响文献检索的准确性和敏感性,关系到制定检索策略。(三)制定纳入排除标准。 二、文献检索 (一)检索策略的制定 这是关键,要求查全和查准。推荐Mesh联合free?word检索。 (二)文献检索,获取摘要和全文 国内的有维普全文VIP,CNKI,万方数据库,外文的有medline?,SD,OVID等。

(三)文献管理 强烈推荐使用endnote,procite,noteexpress等文献管理软件进行检索和管理文献。 查找文献全文的途径: 在这里,讲一下找文献的过程,以请后来的战友们参考(不包括网上有电子全文的): 1.查找免费全文: (1)在pubmed?center中看有无免费全文。有的时候虽然没有显示free?full?text,但是点击进去看全文链接也有提供免费全文的。我就碰到几次。 (2)在google中搜一下。 少数情况下,NCBI没有提供全文的,google有可能会找到,使用“学术搜索”,进入左侧的“现刊联目”,可以看到有“现刊联目查询”和“过刊联目查询”“我的论坛”中查看帖子,有的很快就把下载链接发过来了,不要一味只看邮箱。 4.实在不行,给作者发email。这里给出一个查作者email的方法,先在NCBI中查出原文献作者的所有文章,注意不要只限于第一作者,display,abstract,?并尽可能显示多的篇数,100,200,500。然后在网页内查找“@”,一般在@前的字母会与人名有些地方相似。再根据地址来确定是否是同一作者。 5.查找杂志的网址,给主编发信求取全文。这里我就不讲查找的方法了,DXY中有许多帖子。我的一篇全文就是这样得到的。 6.向国外大学里的朋友求助。国外大学的图书馆一般会通过馆际互借来查找非馆藏文献,且获得率非常高。我的三篇文献是通过这一途径得到的。

关于Meta分析中的森林图解析

关于Meta分析中的森林图解析: 1、OR在统计学中是指比值比、优势比,英文全称是(odds ratio).它的具体意思是在病例-对照研究中,描述疾病与危险因素关联的指标。OR通常适用于病例对照研究。由于在病例对照研究中无法获得病例组与对照组的确切发病率,只能获得病例组和对照组的暴露频率,因此不能直接用相对危险度描述疾病与危险因素的关系。如: 病例组暴露某一事件的优势(odds)=a/b 对照组暴露某一事件的优势(odds)=c/d 病例组和对照组暴露某一事件的优势比为OR=(a/b)/(c/d)=ad/bc a表示在病例组中暴露某一事件后得病得人,b表示在病例组中没有得病的人 c表示在对照组中暴露某一事件后得病得人,d表示在病例组中没有得病的人 >1 暴露与疾病的危险度增加正相关 <1 暴露与疾病的危险度减少负相关 =1 暴露与疾病的危险度无关无相关 2、OR,即比值比(odds ratio),是病例对照研究中表示疾病与暴露之间联系强度的指标,又称为比数比,优势比,交叉乘积比。 楼上说描述疾病与危险因素关联的指标是不准确的,因为这个暴露不一定是危险因素,也可能是保护因素或者既不是保护因素也不是危险因素。 暴露史病例对照合计 有a b a+b=n1 无c d c+d=n0 合计a+c=m1 b+d-m0 a+b+c+d=T 从表可见,病例对照研究对比的是病例组的曾暴露率即a/(a+c)和对照组的曾暴露率b/(b+d),如a/(a+c)>b/(b+d),并经统计学检验证实差异有统计学意义,则暴露与疾病有联系(为危险因素);如a/(a+c)(完整word版)用stata进行单个率meta分析程序总结,推荐文档

用stata进行单个率meta分析程序总结 感谢版主对我的方法进行验证,这里整理一下方面大家研究 谷歌的程序(标红部分,分批录入stata12.0.可得到结果。)clear input study cases total 1 20 1000 2 40 5000 3 30 1500 4 2 5 3300 end gen p = . gen se = . // get proportions and std errors forv i =1(1)4 { cii total[`i'] cases[`i']

qui replace p = r(mean) in `i' qui replace se = r(se) in `i' } // get the inverse variance-weighted proportion // use the official Stata -vwls- command gen cons =1 vwls p cons, sd(se) // use the user written -metan- command // for fixed-effects meta-analysis metan p se, nograph fixed // for random-effects meta-analysis metan p se, nograph random 我的数据,用谷歌方法运行的命令:clear input study cases total

1 76 451 2 86 202 3 2 4 97 4 401 2502 end gen p = . gen se = . forv i =1(1)4 { cii total[`i'] cases[`i'] qui replace p = r(mean) in `i' qui replace se = r(se) in `i' } gen cons =1 vwls p cons, sd(se) metan p se, nograph fixed metan p se, nograph random

meta分析简介

Meta分析 在医学研究中,绝大多数的医学现象都呈一定的随机性,因此医学研究的结果都受随机抽样误差影响而有所差异。所以对于同一研究问题的多个研究结果往往不全相同,有些研究的结论甚至相反。因此如何从结果不一的同类研究中综合出一个较为可靠的结论是医学研究中常常需要面临的问题。Meta分析就是研究如何综合同类研究结果的一种统计分析方法。 Meta分析就是把相同研究问题的多个研究结果视为一个多中心研究的结果,运用多中心研究的统计方法进行综合分析。Meta统计分析可以分为确定性模型分析方法和随机模型分析方法。较常用的确定性模型Meta分析有Mantel-Haeszel统计方法(仅适用于效应指标为OR)和General-V ariance-Based统计方法。然而所有的确定性模型统计方法都要求Meta分析中的各个研究的总体效应指标(如:两组均数的差值等)是相等的,并称为齐性的(Homogeneity),而随机模型对效应指标没有齐性要求。因此Meta分析可以采用下列分析策略: 1)如果各个研究的效应指标是齐性的,则选用确定性模型统计方法: ●效应指标为OR,则采用Mantel-Haeszel统计方法 ●效应指标为两个均数的差值、两个率的差值、回归系数、对 数RR等近似服从正态分布的效应指标,则采用General- V ariacne-Based方法进行Meta统计分析。 2)如果各个研究的效应指标不满足齐性条件或者研究背景无法用

确定性模型进行解释的,则采用随机模型进行Meta 统计分析。 为了使读者较容易地掌握Meta 分析方法,以下将结合STA TA 软件的Meta 分析操作命令,通过实例介绍Meta 分析步骤和软件操作以及相应的统计分析结果解释,然后对Meta 分析中所涉及的统计公式进行分类汇总小结。 确定性模型的Meta 分析方法 例1:为了研究Aspirin 预防心肌梗塞(MI)后死亡的发生,美国在1976年-1988年间进行了7个关于Aspirin 预防MI 后死亡的研究,其结果见表1,其中6次研究的结果表明Aspirin 组与安慰剂组的MI 后死亡率的差别无统计意义,只有一个研究的结果表明Aspirin 在预防MI 后死亡有效并且差别有统计意义。现根据表1所提供的资料作Meta 分析。 表1 Aspirin 预防心肌梗塞后死亡的研究结果 研究 Aspirin 组 安慰剂组 编号 观察人数 死亡人数 死亡率P E (%) 观察人数 死亡人数 死亡率P C (%) P 值 OR * 1 615 49 7.97 624 67 10.74 0.094 0.720 2 758 44 5.80 771 64 8.30 0.057 0.681 3 832 102 12.26 850 126 14.82 0.125 0.803 4 317 32 10.09 309 38 12.30 0.382 0.801 5 810 85 10.49 40 6 52 12.81 0.229 0.798 6 226 7 246 10.85 2257 219 9.70 0.204 1.133 7 8587 1570 18.28 8600 1720 20.00 0.004 0.895 注:11E C E C P P O R P P =--。可以证明:OR>1对应P E >P C ;OR<1对应P E

Meta分析的完整步骤

Meta 分析的完整步骤,根据个人的体会,结合战友的经验总结而成, 量合成,所以这个总结也算是对战友经验的 meta 分析吧。 一、选题和立题 (一)形成需要解决的临床问题: 系统评价可以解决下列临床问题 : 1. 病因学和危险因素研究 ; 2. 治疗手段的有效性研究 ; 3. 诊断方法评价 ; 4. 预后估计 ; 5. 病人费用和效益分析等。 进行系统评价的最初阶段就应对要解决的问题进行精确描述 , 包括人群类型 (疾病确切分型、 分期 ) 或暴露因素的种类、预期结果等 , 合理选择进行评价的指标 。 (二)指标的选择直接影响文献检索的准确性和敏感性,关系到制定检索策略。 (三)制定纳入排除标准。 、文献检索 一)检索策略的制定 meta 的精髓就是对文献的二次加工和定 、治疗手段

这是关键,要求查全和查准。推荐Mesh 联合free word 检索。 (二)文献检索,获取摘要和全文 国内的有维普全文VIP , CNKI,万方数据库,外文的有medline ,SD , OVID等。 / ■ X 卜TB (三)文献管理 强烈推荐使用endnote ,procite ,noteexpress 等文献管理软件进行检索和管理文献。查找文献全文的途径:在这里,讲一下找文献的过程,以请后来的战友们参考(不包括网上有电子全文的): 1. 查找免费全文: (1)在pubmed center 中看有无免费全文。有的时候虽然没有显示free full text ,但是点击进去看全文链接也有提供免费全文的。我就碰到几次。 (2)在google 中搜一下。 少数情况下,NCBI没有提供全文的,google有可能会找到,使用“学术搜索”。本人虽然没能在google中找到一篇所需的文献,但发现了一篇非常重要的综述,里面包含了所有我需要的文献(当然不是数据),但起码 提供了一个信息,所需要的文献也就这么多了,因为老外的综述也只包含了这么多的内容。这样,到底找多少文献,找什么文献,心里就更有底了

Meta分析的步骤.doc

Meta 分析的完整步骤 Meta 分析的完整步骤,根据个人的体会,结合战友的经验总结而成,meta 的精髓就是对文献的二次加工和定量合成,所以这个总结也算是对战友经验的meta 分析吧。 一、选题和立题 (一)形成需要解决的临床问题: 系统评价可以解决下列临床问题: 1.病因学和危险因素研究; 2.治疗手段的有效性研究; 3.诊断方法评价 ; 4.预后估计 ; 5.病人费用和效益分析等。 进行系统评价的最初阶段就应对要解决的问题进行精确描述,包括人群类型 (疾病确切分型、分期 ) 、治疗手段或暴露因素的种类、预期结果等,合理选择进行评价的指标。 (二)指标的选择直接影响文献检索的准确性和敏感性,关系到制定检索策略。 (三)制定纳入排除标准。 二、文献检索 (一)检索策略的制定 这是关键,要求查全和查准。推荐Mesh 联合 free word 检索。 (二)文献检索,获取摘要和全文 国内的有维普全文VIP,CNKI,万方数据库,外文的有medline ,SD, OVID 等。 (三)文献管理 强烈推荐使用endnote , procite , noteexpress 等文献管理软件进行检索和管理文献。 查找文献全文的途径: 在这里,讲一下找文献的过程,以请后来的战友们参考(不包括网上有电子全文的):1.查找免费全文: (1)在 pubmed center 中看有无免费全文。有的时候虽然没有显示 free full text ,但是点击进去看全文链接也有提供免费全文的。我就碰到几次。 (2)在 google 中搜一下。 少数情况下, NCBI 没有提供全文的, google 有可能会找到,使用“学术搜索”。本人虽然没能在google 中找到一篇所需的文献,但发现了一篇非常重要的综述,里面包含了所有我需要的文献(当然不是数据),但起码提供了一个信息,所需要的文献也就这么多了,因为老 外的综述也只包含了这么多的内容。这样,到底找多少文献,找什么文献,心里就更有底了。(3)免费医学全文杂志网站。。提供很过超过收费期的免费全文。 2.图书馆查馆藏目录: 包括到本校的,当然方便,使用pubmed 的linkout 看文献收录的数据库,就知道本校的是否有 全文。其它国内高校象复旦、北大、清华等医学院的全文数据库都很全,基本上都有权限。上 海的就有华东地区联目、查国内各医学院校的图书馆联目。这里给出几个: (1)中国高等院校医药图书馆协会的地址:,进入左侧的“现刊联目” ,可以看到有“现刊联 目查询”和“过刊联目查询” ,当然,查询结果不可全信,里面有许多错误。本人最难找 的两篇文章全部给出了错误的信息(后来电话联系证实的)。 (2)再给出两个比较好的图书馆索要文献的email 地址(有偿服务),但可以先提供文献,后汇钱,当然做为我们,一定要讲信誉吆。一是解放军医学图书馆信息部:,电话:;

Meta分析的完整步骤,DOC

Meta分析的完整步骤,根据个人的体会,结合战友的经验总结而成,meta的精髓就是对文献的二次加工和定量合成,所以这个总结也算是对战友经验的meta分析吧。 一、选题和立题 (三)制定纳入排除标准。 二、文献检索 (一)检索策略的制定 这是关键,要求查全和查准。推荐Mesh联合freeword检索。

(二)文献检索,获取摘要和全文 国内的有维普全文VIP,CNKI,万方数据库,外文的有medline,SD,OVID等。 (三)文献管理 强烈推荐使用endnote,procite,noteexpress等文献管理软件进行 了一篇非常重要的综述,里面包含了所有我需要的文献(当然不是数据),但起码提供了一个信息,所需要的文献也就这么多了,因为老外的综述也只包含了这么多的内容。这样,到底找多少文献,找什么文献,心里就更有底了。

2.图书馆查馆藏目录: 包括到本校的,当然方便,使用pubmed的linkout看文献收录的数据库,就知道本校的是否有全文。其它国内高校象复旦、北大、清华 根据地址来确定是否是同一作者。 5.查找杂志的网址,给主编发信求取全文。这里我就不讲查找的方法了,DXY中有许多帖子。我的一篇全文就是这样得到的。

6.向国外大学里的朋友求助。国外大学的图书馆一般会通过馆际互借来查找非馆藏文献,且获得率非常高。我的三篇文献是通过这一途径得到的。 如果还是找不到,那就……我也没辙了,还有朋友如有其他的方法, 法”; ⑤各组病人的年龄、性别、职业等是否相似; ⑥除进行研究的治疗手段不同外,其它的治疗是否一致; ⑦治疗作用大小; ⑧治疗效果的评价是否准确;

META分析步骤

(1)明确简洁地提出需要解决的问题。 (2)制定检索策略,全面广泛地收集随机对照试验。 (3)确定纳入和排除标准,剔除不符合要求的文献。 (4)资料选择和提取。 (5)各试验的质量评估和特征描述。 (6)统计学处理。 a.异质性检验(齐性检验)。 b.统计合并效应量(加权合并,计算效应尺度及95%的置信区间)并进行统计推断。 c.图示单个试验的结果和合并后的结果。 d.敏感性分析。 e.通过“失安全数”的计算或采用“倒漏斗图”了解潜在的发表偏倚。 (7)结果解释、作出结论及评价。 (8)维护和更新资料。 提高国内随机对照试验Meta-分析的质量 何成奇,赵晓玲 (四川大学华西医院康复中心,四川省成都市610041) [摘要] 高质量的随机对照试验(RCT)的Meta-分析结果与国际公认的大样本RCT结果一起被各国列为最高等级的证据,可为临床实践和卫生决策提供更真实的科学依据,引导临床医师在实践中做出正确的决策。但质量差的Meta-分析反而可能导致错误的结论。国外Meta-分析方法的应用已趋于成熟和规范。然而目前国内由于应用时间不长,且缺乏统一规范的实施标准,文献质量参差不齐,很多方面还存在着较为严重的缺陷。探讨如何提高国内RCT Meta-分析的质量,尽快与国际接轨,以便为循证医学、药学提供更科学真实的证据。以进行RCT Meta-分析的步骤为线索,对国内Meta-分析存在的问题和解决的办法进行了综述。具体内容包括:提出一个好问题(研究目的),全面收集相关的RCT,制定严格的纳入/排除标准,正确提取数据资料,对符合纳入标准的RCT进行质量评价,应用正确的统计方法,必须进行敏感性分析,根据结果做出正确、全面的结论。一篇理想的RCT Meta-分析应当纳入当前所有的高质量的同质研究,无发表偏倚,使用正确的模型和统计学方法,并对结果做出全面的论述。也就是说只有尽量满足进行Meta-分析每一步所需的条件,才能逐步提高Meta-分析的质量,

META分析:手把手教你使用RevMan软件绘制森林图

META分析:手把手教你使用RevMan软件绘制森林图 要做好一篇meta分析至少要掌握一些基本的技能,绘制一幅清晰明了、美观直接的森林图就是一项必备技能。笔者在这里不打算探讨什么高深的统计学理论,本文将以图示的形式展示如何用RevMan 5.3软件做一幅符合SCI杂志投稿要求的森林图。下图是一篇正式发表的森林图,下面我们将采用RevMan软件做出一幅一样的图形。 第一步,准备工作 分为安装Revman软件和数据提取。 首先是安装RevMan5.3软件,这是一个完全免费的软件,管你什么Windows,Mac OS X或者Linux统统可以搞定。这个软件完全视窗操作,简便易学,适合初学者,关键是虽然简单但是基本可解决大部分的meta 分析的统计学处理,其实很强大。(需要软件的朋友,可以向解螺旋微信助手索要,助手微信号:helixlife0。) 其次就是数据的准备工作了,采用Excel管理数据足矣。RevMan最新版本软件是支持直接复制粘贴数据的,我们按要求整理好数据,直接从Excel复制上去就好了。我们首先看看RevMan来处理二分类数据(所谓二分类数据,就是取值只有是或否两种可能)。

So,在Excel上我们就如上图这样录入数据就好了。其中r1 、r2分别代表的是干预组和对照组的事件发生数,n1、n2则是它们各自的总人数。这里可能会碰到一组或者两组的事件发生数为零,不要紧,软件会帮我们处理的,不需要我们去校正这个零。 第二步,添加研究 在打开我们的软件之后,我们新建一个文件,点击“create a new review”(新建),接下来创建一个最普通的“Intervention review”(勾选),我们进行相关项目的填写(如果仅仅是使用该软件的统计分析功能,可以不填),选择制作“Full Review” 然后点击Finish就ok了。如果我们的目标仅仅是画纳入研究的质量评估图或者是流程图,我们可以选择Protocol而不去使用软件的计算功能,Protocol状态下不能使用其统计计算功能。然后如下图所示,在屏幕左边的条目里依次点击至Included studies。

Meta分析的完整步骤修订稿

M e t a分析的完整步骤内部编号:(YUUT-TBBY-MMUT-URRUY-UOOY-DBUYI-0128)

Meta分析的完整步骤 Meta分析的完整步骤,根据个人的体会,结合战友的经验总结而成,meta的精髓就是对文献的二次加工和定量合成,所以这个总结也算是对战友经验的meta分析吧。 一、选题和立题 (一)形成需要解决的临床问题: 系统评价可以解决下列临床问题: 1.病因学和危险因素研究; 2.治疗手段的有效性研究; 3.诊断方法评价; 4.预后估计; 5.病人费用和效益分析等。 进行系统评价的最初阶段就应对要解决的问题进行精确描述,包括人群类型(疾病确切分型、分期)、治疗手段或暴露因素的种类、预期结果等,合理选择进行评价的指标。 (二)指标的选择直接影响文献检索的准确性和敏感性,关系到制定检索策略。(三)制定纳入排除标准。 二、文献检索 (一)检索策略的制定

这是关键,要求查全和查准。推荐Mesh联合freeword检索。 (二)文献检索,获取摘要和全文 国内的有维普全文VIP,CNKI,万方数据库,外文的有medline,SD,OVID等。(三)文献管理 强烈推荐使用endnote,procite,noteexpress等文献管理软件进行检索和管理文献。 查找文献全文的途径: 在这里,讲一下找文献的过程,以请后来的战友们参考(不包括网上有电子全文的): 1.查找免费全文: (1)在pubmedcenter中看有无免费全文。有的时候虽然没有显示 freefulltext,但是点击进去看全文链接也有提供免费全文的。我就碰到几次。(2)在google中搜一下。 少数情况下,NCBI没有提供全文的,google有可能会找到,使用“学术搜索”,进入左侧的“现刊联目”,可以看到有“现刊联目查询”和“过刊联目查询”“我的论坛”中查看帖子,有的很快就把下载链接发过来了,不要一味只看邮箱。 4.实在不行,给作者发email。这里给出一个查作者email的方法,先在NCBI中查出原文献作者的所有文章,注意不要只限于第一作者,display,abstract,并尽可能显示多的篇数,100,200,500。然后在网页内查找“@”,一般在@前的

Meta分析的基本方法和步骤

Meta分析基本步骤 (一)提出问题,拟定研究计划。 选择临床热点问题:注意时效性 (二)检索相关文献。 (三)根据纳入、排除标准筛选文献 (四)提取纳入文献的数据信息 a)一般要求2人进行 b)事先设计表格 (五)纳入研究的质量评价 a)达不到分值标准可以排除 (六)资料的统计学处理 (七)敏感性分析 (八)结果分析和讨论 一、选题与立题 a)形成需要解决的临床问题 i.疾病的病因学探讨: ii.治疗方法效果评价:某方法是否优于另一种方法; iii.诊断方法评价:某因子在某肿瘤方面的预测作用; iv.生存预后分析 进行系统评价的最初阶段就应对要解决的问题进行精确描述,包括人群特征 (疾病分型、分期)、治疗手段或暴露因素的种类、预期结果等,合理选择进 行评价的指标。 b)结合自己的研究方向、平时阅读文献、科研讨论、参加学术会议等获得好的选题; 及时去Pubmed检索他人是否已发表 i.注意有无类似分析发表 ii.已发表结果评价,是否有再次分析的意义:(1)结果有无重大变化;(2)已发表结果有无缺陷 iii.对已发表2周内的文献进行评价(Letter) 二、文献检索 (一)检索策略的制定 要求查全和查准。推荐自由词(text word search)或医学主题词(medical subject headings(Me SH))检索 (二)文献检索,获取全文 国内的有维普全文VIP、CNKI、万方数据库

外文的有Pubmed、OVID、Embase(Scopus可能包含,可以替代)等 获取全文途径: Pubmed Goole学术搜索 给通讯作者发email 向国外朋友求助 零点花园(https://www.360docs.net/doc/ab18550051.html,/bbs/)、丁香园等文献求助版块 (三)文献管理 推荐使用endnot、noteexpress和医学文献王等文献管理软件进行检索和管理文 献 三、纳入和排除标准 1、制定标准考虑四个方面 a)研究对象:疾病类型、年龄、性别、病情严重程度等作出明确规定; b)研究设计类型:明确规定哪些类型的设计可以纳入: c)暴露或干预措施:暴露或处理的程度、一致性;干预措施的剂量、强度、病例 依从性等; d)研究结局:量化的、可比的研究结局、随访年限。 另外:类似文献的标准可作参考 2、筛选文献严格按照标准筛选文献。两名研究人员完成。 四、文献质量评价和数据收集 (一)研究的质量评价 RCT研究:包括改良版Jadad量表(1-3分视为低质量,4-7分视为高质量)和Cochrane Handbook 5.0 RCT 质量评价等。 改良版Jadad量表: 1.随机序列的产生: a)恰当:计算机产生的随机数字或类似方法(2分) b)不清楚:随机实验但未描述随机分配的方法(1分) c)不恰当:采用交替分配的方法如单双号(0分) 2.随机化隐藏: a)恰当:中心或药房控制分配方案,或用序列编号一致的容器,现场计算机 控制,密封不透光的信封或其他使临床医生和受试者无法得知分配序列的 方法(2分) b)不清楚:只表明使用随机数字表或其他随机分配方案(1分) c)不恰当:交替分配、病例号、星期日数、开放式随机号码表、系列编码信 封以及任何不能防止分组的可预测性的措施(0分) d)不使用(0分) 3.盲法:

meta分析与森林图的作业

2013级《循证医学》平时作业 班级:临床9班 姓名:学号: 姓名:学号: 一、森林图 二、参考文献 1小剂量秋水仙碱与非甾体类药物联合治疗痛风急性关节炎的疗效观察2痛风消方加减治疗痛风性关节炎40例 3秋水仙碱联合别嘌醇治疗急性痛风性关节炎疗效分析 4加味四妙散联合秋水仙碱治疗急性痛风性关节炎的观察 5秋水仙碱两种给药方案治疗痛风急性发作的临床观察 6小剂量秋水仙碱联合依托考昔治疗急性痛风观察 7秋水仙碱联合金黄散冷敷治疗急性痛风性关节炎44例观察 8秋水仙碱加别嘌醇治疗痛风性关节炎80例临床疗效观察 三、数据提取(见附表) (不同秋水仙碱给药方案治疗有效情况) 编号 文献出处 发表 时间 发表 地区 研究对象 干预措施 研究设计 疗效

完全缓解 原发病 试验组 对照组 试验组 对照组 实验组 对照组 1 周荣珍 2013 广西 痛风 48 32 秋水仙碱加别嘌醇秋水仙碱 RCT

48 31 2 黄浔芳,姬森国,张徐明,刘炬,胡玲2013 江西 痛风 20 20 加味四妙汤和秋水仙 秋水仙碱 RCT 18 16 3 陈珺秋 2012 云南 痛风 18 56

秋水仙碱与非甾体类药物 秋水仙碱 RCT 18 28 4 丁煜 2011 江苏 痛风 40 36 痛风消方加减治疗痛风性关节炎痛风消方 RCT 38 28 5 李爱平,王振青 2014 河北

痛风 30 30 秋水仙碱联合别嘌醇 秋水仙碱 RCT 29 25 6 袁小波,许代福 2015 四川、重庆 痛风 44 38 秋水仙碱联合金黄散冷敷秋水仙碱联合体温金黄散RCT 43 32 7

mate分析森林图快速的解读知识分享

m a t e分析森林图快速 的解读

何瑶全科医学 201530130606 题目一:请解读如下森林图。要求:500字左右。 这张森林图,我们又可以叫它meta分析,它是对研究设计相同或者相似且具有相同目的的,但是又相互独立的多个研究结果(证据)进行系统的综合定量分析,计算其合并效应量,并作出结果解释。 如上图,gao2014的实验中实验组(experimental total)样本量为293,而其中有31个问题样本(experimental events),对照组(control total)样本量为289,问题样本(control events)为40,权重(weight)为16.0%,比值比(OR)为0.74,95%可信区间(95%CI)为(0.45,1.21),其横线与OR=1相交,表示无统计学意义;由此类推,我们不难分析出hu2001的实验结果、li2009年的实验结果和wang2009的实验结果,他们的实验中横线都与OR=1相交,表示无统计学意义。zang2011的实验中实验组(experimental total)样本量为812,而其中有84个问题样本(experimental events),对照组(control total)样本量为815,问题样本(control events)为152,权重(weight)为60.3%,比值比(OR)为0.5,95%可信区间(95%CI)为(0.38,0.67),其横线与OR=1不相交,表示有统计学意义。有分析图可见, li2009的实验样本量最小,权重最小,zang2011的实验样本量最大,权重最大,结果较其他组准确。实验组(experimental total)样本数为1693,对照组(control total)样本数为1358,问题样本数中,实验组(experimental events)为180,对照组(control events)为249,权重(weight)100%,比值比OR=0.57,95%可信区间(95%CI)为(0.46,0.70),其可信区间表现为菱形,位于图中竖线左侧,与竖线不相交,有统计学意义。 异质性检验(heterogeneity)为:卡方检验(ChI2)结果为2.65,自由度(df)为 4,P=0.62>0.1,没有异质性;I z=0%没有异质性意义,所以有统计学意义。合并效应量(test for overall effect)的检验Z = 5.22, P < 0.00001,我们可以认为外界因素或施加因素效果差异性大。 参考文献:1王建华《流行病学》第8版.人民卫生出版社.78-79,186-188。

meta分析sas程序

七:Meta分析 (一)几个概念 在讨论Meta分析的时候有必要先说明几个相关的概念,并明确他们之间的关系。 1 循证医学: 指医护人员利用发表的文献证据解决临床问题对证据进行严格分级,提供指导对医学文献评价分级的实践指南,并充分考虑病人的需求和意愿解决具体临床问题和其他健康问题的医疗实践活动。 这里已发表的文献证据分级指: ?一级:所有RCT的系统评价/Meta-分析。 ?二级:单个样本量足够大的RCT。 ?三级:设有对照组但未用随机方法分组的研究。 ?四级:无对照的系列病例观察。 ?五级: 专家意见。 上述的分级我们发现最好的证据是系统评价/Meta-分析,那么就有了下面的概念。 2 Systematic reviews(系统评价): 是循证医学重要的手段。是根据某一具体的临床问题,采用系统、明确的方法收集、选择和评估相关的临床原始研究,筛选出合格者并从中提取和分析数据,为疾病的诊治和预防提供科学的依据。 3 Meta分析: 是在系统性综述时为了合并多个独立的研究结果,所使用的统计方法。可以将针对同一问题的,多个独立的研究结果进行定量分析。目前,国外文献常常将系统评价与Meta-分析交叉使用。 (二)Meta analysis原理和基本思想 在用样本信息推断总体参数时,是存在抽样误差的,并且抽样误差的大小与样本量的大小有关,样本量较大时抽样误差较小。统计学用抽样分布的理论来描述样本统计量的变化规律,从一个总体中的多次随机抽样,样本的均数和标准差服从正态分布。所以所有的点以样本量较大时的均数为轴,左右是基本对称的。 用方差分析的方法对不同的样本所对应的总体均数是否相等进行检验,结果说明这多个样本对应的总体均数是相同的。用这些样本的信息来估计总体的均数和标准差,使总体的样本量增大,这样做的结果是提高了估计的精度。 理想状态下我们把不同作者对相同问题进行的研究可以看作从同一总体中进行抽样得到的一个随机样本,如果他们都是按照相同的设计得到的研究结果,并且我们可以找到每一项研究的结果,这样就可以根据上面的原理得到一个更为可靠的结果。 实际情况是不同作者:所使用的设计方案会有一定的差别,选择的实验对象有所不同,研究结果不一定都能发表到专业杂志上。因此实际能够得到的资料可能是不完整的,甚至是有偏性的,如阳性结果的文章,以及和目前大家普遍能够接受的观点一致的文章可能更容易发表在专业杂志上。 Meta analysis的目的就是: ①增加统计功效。 ②解决各研究结果的不一致性。 ③寻求新的假说。 (三)实例分析---戒烟对肺功能的影响 肺功能的检测是COPD诊断和病程进展评估的最为重要的指标,因此戒烟对COPD发病和死亡的影响作用可以通过肺功能的研究得到一个初步结论。目前戒烟的作用相比持续吸烟者来说,不同研究的结论有所差异。而且在一些人群中认为,如果是长期吸烟者,突然戒烟会造成机体功能紊乱,死亡时间可能提早。因此,本文将应用系统综述的方法,对中国大陆地区所有已发表在专业杂志上的有关文献进行相关meta分析,对戒烟对肺功能 FEV1,FEV1%,FVC,MMEF ,MVV和RV/TLC%等肺功能指标的影响进行了定性和定量的分析。