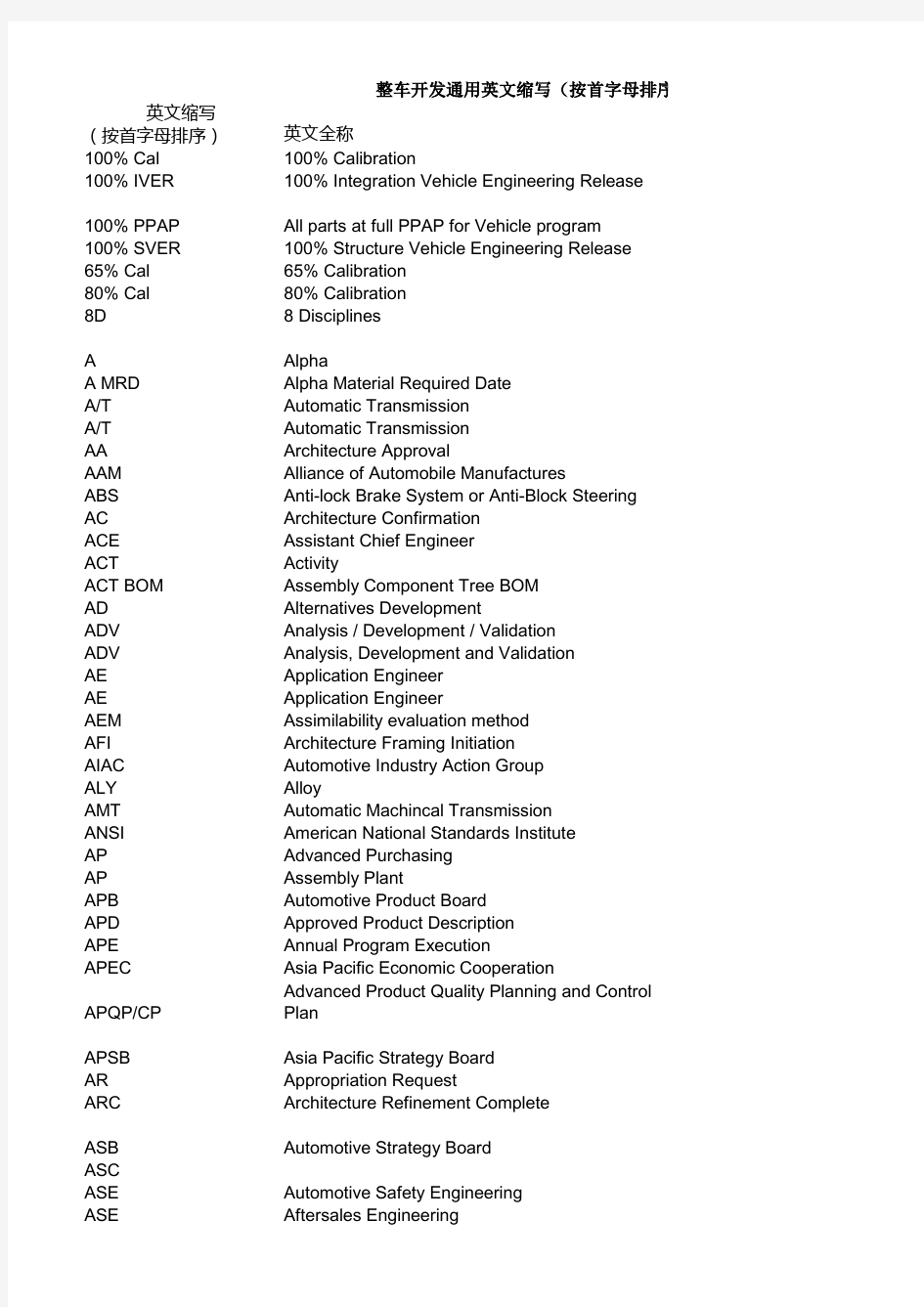

整车开发通用英文缩写(按首字母排序)-通用GVDP

英文缩写

(按首字母排序)

100% Cal

100% Calibration 100% IVER

100% Integration Vehicle Engineering Release 100% PPAP

All parts at full PPAP for Vehicle program 100% SVER

100% Structure Vehicle Engineering Release 65% Cal

65% Calibration 80% Cal

80% Calibration 8D

8 Disciplines A

Alpha A MRD

Alpha Material Required Date A/T

Automatic Transmission A/T

Automatic Transmission AA

Architecture Approval AAM

Alliance of Automobile Manufactures ABS

Anti-lock Brake System or Anti-Block Steering AC

Architecture Confirmation ACE

Assistant Chief Engineer ACT

Activity ACT BOM

Assembly Component Tree BOM AD

Alternatives Development ADV

Analysis / Development / Validation ADV

Analysis, Development and Validation AE

Application Engineer AE

Application Engineer AEM

Assimilability evaluation method AFI

Architecture Framing Initiation AIAC

Automotive Industry Action Group ALY

Alloy AMT

Automatic Machincal Transmission ANSI

American National Standards Institute AP

Advanced Purchasing AP

Assembly Plant APB

Automotive Product Board APD

Approved Product Description APE

Annual Program Execution APEC

Asia Pacific Economic Cooperation APQP/CP

Advanced Product Quality Planning and Control Plan APSB

Asia Pacific Strategy Board AR

Appropriation Request ARC

Architecture Refinement Complete ASB

Automotive Strategy Board ASC

ASE

Automotive Safety Engineering 整车开发通用英文缩写(按首字母排序)英文全称

ASN

Advanced shipping notice ASSI

Architecture Statement of Strategic Intent Assy PPAP

Assembly Line PPAP Assy PPV

Assembly Line Products and Process Validation Assy PPV

Assembly Line Production and Process Validation Assy Run-off

Assembly Line RUN-Off Assy Run-off MRD

Assembly Line RUN-Off Material Requied Date ATC

Auto Temperature Controller ATF

Automatic Transmission Fluid ATT

Attachment ATT

Actual takt time AVD

Advanced Vehicle Development AVDC

Advance Vehicle Development Center AVD-LT

Advanced Vehicle Development-Leadership Team AVDP

Advanced Vehicle Development Process (Time between DSI and VPI)AVPM

Advanced Vehicle Planning Manager B

Beta B

Build B MRD

Beta Material Required Date B+U

Building and Utility BAD

Build Authorization Document BC

Business Case BCM

Body Control Module BDC

Body Distributon Central BESC

Base Engine Steering Committee BIQ

Building in Quality BIR

Prototype Build Issue Report BIR

Build Issues Resolution BIR

Build Incident Report BIR

Bulding issue report BIW

Body-In-White BIW

Body in White BOD

Bill of Design BOE

Bill of Equipment BOM

Bill of Material BOM

Bill of Material BOM

Bill of Material BOM

Bill Of Material BOM

Bill Of Material BOM

Bill of Material Assy PPAP

Assembly Line PPAP Assy Check-in

Assembly Line Check-in Assy Run-Off

Assembly Line Run-Off

BOP Bill Of Process

BP Break Point

BPD Business Plant Deployment

BPP Best people practices

BPR Business plan recompose

BS Body Shop

BSD Build Site Direction

BUFFER Buffer

C/CAP Construction/Conversion and Acceleration Plan CAB Change Approval Board

CAC

CAFE Corporate Average Fuel Economy

Cal Calibration

CARE Customer acceptance review evaluation CARE Customer Acceptance & Review Evaluation CC Concept Confirmation

CC Consolidation Center

CC Confirmation Clinic

Cert LSO Certification Lift Stop Order

CET Cold Environment Test

CH Chassis Department

CI Concept Initiation

CIM Customer Interface Manager

CIP Continue Improve Process

CIP Continue Improve Process

CIT Continuous Improvement Team

CIT Compartment Integration Team

CMC Container Management Center

CME Change Management Engineer

Cmk N/A

Cmk Capability Machine Index

CMM

C-NCAP China New CAR Assessment Process

COC Centre of Competence

COE Center of Expertise

CP Control Plan

CPIT Current Product Improvement Team

Cpk Complex Process Capability

Cpk Process Capability Index

CPQE Current Product Quality Engineer

CPV Cost per Vehicle

CR/DN Change Request / Decision Notice

CR/DN Change Request/Decision Notice

CRB Change Review Board

CS Contract Signing

CS Contract Signing

CS1Controled Shipping 1

CS2Controled Shipping 2

CSC Controls Steering Committee

CSI Customer Satisfaction Index

CSN Current Sequence Number

CSO Contract Sign-Off

CSO Contract Sign-Off (VDP)

CSO HC Contract Sign-Off Health Check

CSO HC Contract Sign-Off Health Check

CT Cycle Time

CT Cycle time

CT Creativity Teams

CT Critical Test

CTS Component Technical Specification

CTT Common Timing Template

CVER Concept Vehicle Engineering Release

CVER LL Concept Vehicle Engineering Release Long Lead CVIS Completed Vehicle Inspection Standards

CVQC Completed vehicle quality ceter

CVQCB Completed vehicle quality ceter board

CVT Continuously Variable Transmission

D.Q.R

DAS Design & Analysis Section

DC Deliver Charter

DCN Design Change Notice

DCN Design Change Notice

DCP Dimension Control Plan

DCS Design Concept Sheet

DCT Double Clutch Transmission

DD Direct Delivery

DDSP Driver Door Switch Pack

DEI Die Engineering Integration

DFA Design for Assembly

DFM Design for Manufacturability

DFMEA Design failure mode and effects analysis DFMEA Design FMEA

DIFF Differential

DL 3b Design Level 3b

DMS Dealer Manage System

DOL Dealer On Line

DP Demand Plan

DPV Defects per vehicle

DPV Defect per Vehicle

DQ&V Design Quality & Validation

DR Direct run

DRC Design Review Committee

DRE Design Responsible Engineer

DRE Design Release Engineer

DRE Design release engineer

DRL Direct run loss

Drop Off Drop Off

DS44HIGH SPEED DURABILITY TEST

DSG Direct shift gearbox

DSI Document of Strategic Intent

DSO Design Sign Off

DTA Design Theme Alternatives

DTC Diagnostic Trouble Code

DV Design Validation

DV Design Validation

DVP Design Validation Plan

DVT Dynamic vehicle test

E/T/C Engine/Transmission/Controller

EBA Emergency Brake Assistant

EBD Electronical Brake Distribute

EBOM Engineering BOM

EC Embedded Controller

ECC ERP Central Component

ECR Engineering Change Request

ECR Engineering Change Request

ECR Engineering Change Request

ECR Engineering Change Request

ECS Engineering Change Summary

ECT Emission Control System

EDS Electronic Data Systems

EEVC European Enhanced Vehicle-Safety Committee EFEO Emissions & Fuel Economy

EGM Engineering Group Manager

EI&S Electronics Integration & Software

ELV End of life vehicle

EMlS Emission

EMS Engine Management System

ENB Build-Test Section

E-NCAP Euro New Car Assessment Process

ENG Engineer

EOA End of Acceleration

EOLT End of Line Test

EP Engineering Prototype

EPA Environmental Protection Agency

EPC Engineering Program Committee

EPN Engineering Project Number

ERD Early Requirement Document

ESB European Strategy Board

ESO Engineering Sign Off

ESO Engineering Sign Off

ESO Engineering Sign-off

ET Engineering Technology

EV Engineering Vehicle

EWO Engineering Work Order

EWO Engineering Work Order

EWO Engineering workorder

Exp Cal Experimental Calibration

FA Final Approval

FATG Final Approval to Grain

FBIW First Body in White Complete

FE Functional Evaluation

FE LSO Fuel Economy Label Lift Stop Order

FIVC First Integration Vehicle Complete

FIVC First Integration Vehicle Complete

FLO Factory Layout

FM

FM Finance Manager

FMC First Mule Complete

FMC

FMEA Failure model effectiveness analysis

FMEA Failure model effectiveness analysis

FMEA Failure Mode and Effects Analysis

FMEA Failure mode and effects analysis

FMEA Failure Mode and Effect Analysis

FMS Flexible manufacturing systems

FMVSS Federal Motor Vehicle Safety Standards FPPV BIW First Product/Process Body in White Complete

FPPVC First Product/Process Validation Vehicle Complete

FPS Fixed Point Stop

FTC First Time Capability

FTP/FTQ First time pass/quality

FTQ First time quality

FWD Four Wheel Drive

G Gamma

G MRD Gamma Material Required Date

G/L Group leader

GA General Assembly

GA General Assembly

GADT Global Architecture Development Team GBOM Global Bill of Material

GMNA General Motors North America

GMPT General Motors Powertrain

GPDC Global Product Development Council GPDP Global Powertrain Development Process GPDS Global Product Description System GSD Global Segment Director

GSS Global Sales and Service

GVDP Global Vehicle Development Process GVDP Global Vehicle Development Process GVDP Global Vehicle Development Process GVDP Global Vehicle Development Process GVDP Global Vehicle Development Process GVDP Global Vehicle Development Process GVLE Global Vehicle Line Executive

GVW Gross Vehicle Weight

GW Gateway

HRC

Hardware Release Center ICD

Interface Control Document IDR

Initial Data Release IDSR

Integration Driven Subsystem Requirement ILP

Inbound Logistic Planning IMES

Integration Manufacturing Executive System Initial Cal

Initial Calibration IOM

Inspection operator method IOS

Inspection operator summary IPPE

integrated Product and Process Engineering IPTV

Incident per Thousand Vehicles IPTV

Incidents Per Thousand Vehicles IPTV

Incidents Per Thousand Vehicles IPTV

Incidents Per Thousand Vehicles IR

Incident Report IRP

Issue Resolution Process IRR

Internal Rate of Return ISO

International Standard Organization IV

Integration Vehicle IV MRD

Integration Vehicle Material Required Date IVBR

Integration Vehicle Build Readiness Review IVER

Integration Vehicle Engineering Release JIS

Just In Sequence JIS

Just In Sort JIS

Job Instruction Sheet JIT

Just In Time JIT

Just In Time JPH

Job per Hour JRS

Joint Ride Session JSC

JSC-GP

Joint Sourcing Committee - General purchase Kcc

Key Control Characteristic KCC

Key Control Character KCDS

Key Characteristic Designation System KO

Kick-Off Kpc

Key Product Characteristic KPC

Key Product Characteristic KPC

Key product characteristic KPC

Key product characteristic KPC

Key process control KPC

Key process control LAAMSB

Latin America, Africa, Middle East Strategy Board LCL

Lower Control Limit LCS

Logistic Confirmation Sheet LL

Learning Loop LL

Long Lead LLPR

Long Lead Production Release LM

Launch Manager LOU

Line of Usage BOM LSL

Lower Specification Limit

LTR Launch Team Release

LWO Logistic Work Order

M+E Machine & Equipment

MAC

MBOM Manufacturing BOM

MDS Materiel Data Sheet

ME Manufacture Engineer

ME Machine and Electronic

ME Manufacturing Engineering

ME Manufacturing Engineering

MEC

MEIS Manufacturing Engineering Info System

MES Manufacturing Execution System

MES Manufacturing Execution System

MFG Site Dec Manufacturing Site Decision

MIC Marketing Information Center

MILKRUN Milkrun

MKT Marketing

MMR Manufacturable Math Release

MO Manufacturing Operations

MP OTS 100%100% Made Parts in OTS

MP OTS 100%100% Made Parts in OTS

MP PPAP Made Parts PPAP

MP PPAP Made Parts PPAP

MP PPV Made Parts Production and Process Validation MP PPV Made Parts Production and Process Validation MPS Master Planning System

MPV Multi-Purpose Vehicle

MR Manufacturing Requirements

MRD Material Required Date

MRD Material Requirement Date

MRD Material Required Date (for physical builds) MRD Math Required Date (for virtual builds)

MRE Manufacturing Responsible Engineer

MS Manufacturing Studies

MSA Measurement System Analysis

MSA Measurement System Analysis

MSA Measure System Analyse

MSA Measurement system analysis

MSS Market Segment Specification

MSS

MSS Market Segment Specification

MT Manual Transmission

MT&E Machines, Tools and Equipment

MTS Manufacturing Technical Specification

MVB Manufacturing Validation Build

MVB Manufacturing Validation Build

MVB (ns)Manufacturing Validation Build (non saleable)

MVB (s)Manufacturing Validation Build (saleable) MVBns Manufacturing Validation Build Non-Salable MVBs Manufacturing Validation Build Salable MVSS Motor Vehicle Safety Standards

MWO Manufacture Work Order

MY Model Year

MYM Model Year Manager

NAO North American Operations

NEO New Employee Orientation

NOA Notice of Authorization

NOD Notice of Decision

NOD Notice of Decision

NPV Net Present Value

NRD Normal Road

NSB North American Strategy Board

OBD On Board Diagnostics

OEM Original Equipment manufacturers

OEM Run-Off Original Equipment Manufacturer Run-Off OEM Run-off Original Equipment Manufacturer Run-off OJT On Job Training

OPO Office of Product Operations

ORS Occupant Restraint System

OT Overtime

OTD Order to Delivery

OTP On Time Performance

OTS

OTS Off-tool Sample

OTS Off-tool Sample

OTS Off-tool Sample

OTS OFF-TOOL-SAMPLE

OTS QV OTS Quality Valve

OTS QV OTS Quality Valve

OTS TG2Off Tooling Samples Tooling Go Level 2 OTS TGL2Off Tooling Samples Tooling Go Level 2

P Pilot

P Pilot

PA Production Approval

PA Program Administrator

PaC Physical Alpha for Customer

PACK Packaging

PAD Product Assembly Documentation

PAM Product Assemble Manual

PAM Product Assemble Manual

PAPIR Product and Process Integration Review

PAS Parking Aid System

PAS Parking Aid System

PbC Physical Beta for Customer

PBS Painted Body Store

PC Deliver Pilot to Customer

PC Pullcord

PC Problem Communication

PC&L Production Control and Logistics

PCL Production Control Manager

PCM Powertrain Control Module

PCM Process Control Manager

PCN Project Cost Change Notice

PCN Project Costbook Change Notice

PCR Problem communication report

PCR Problem communication report

PCR Problem Communication Report

PCR Problem Communication Report

PDC Parking Distance Control

PDC Parking Distance Control

PDCA Plan、Do、Check、Action

PDCA Plan-Do-Check-Action

PDI Product delivery inspection

PDI Preliminary Data Indicator

PDI Pre-delivery Inspection

PDS Product Data Structure

PDT Product Development Team

PDT Product Development Team

PDT Product Development Team

PDT Product Development Team

PDT Product Development Team

PE Product Engineering

PET Program Executive Team

PET Program Execution Team

PET Program Execution Team

PFI Program Framing Initiated

PFMEA Process failure mode and effectsanalysis PFMEA Process FMEA

PFMEA Process failure mode & effects analysis PFSE Product Focus Systems Engineer

PG3Powertrain Gateway

PgC Physical Gamma for Customer

PGM Program Management / Project Management PGM Program Management

PGM Program Management

Pilot Pilot

Pilot Pilot

Pilot QV Pilot Quality Valve

Pilot MRD Pilot Material Requied Date

PIM

Powertrain Interface Manager PLM

Production Launch Manager PLP

PM

Programme Manager PM

Program Manager PM

Program Manager PM

Plan maintain PM

Prevention Maintenance PM

Program Manager PMO

Program Management Office PMP

PMT

Product Management Team PN

Part NO.PP

Pre-pilot PP

Pre-Pilot PP

Pre-pilot P-P

Pre-Pilot PP PPAP

Purchased Parts Production Parts Approval Process PP ESO

Purchased Parts Engineering Sign Off PP OTS 100%

100% Purchased Parts in OTS PP OTS 80%

80% Purchased Parts in OTS PP OTS 80%

80% Purchased Parts in OTS PP PPAP

Purchased Parts PPAP PPA

Product Planning Approval PPAP

Production Parts Approval Process PPAP

Production Part Approval Process PPAP

Production Part Approval Process PPAP

Production Part Approval Process PPAP

Production Parts Approval Process PPAP

Production Part Approval Process PPAP

Production Part Approval Process PPAP

Production Part Approval Process PPC

Deliver Pre-Pilot to Customer PPC

Product Program Content PPH Problems per Hundred

PP Appr.

Purchased Parts Approved Pilot QV

Pilot Quality Valve

排序)

中文含义

100%标定

100%集成车工程发布

为了整车项目,所有零件须完全通过

PPAP

100%结构车工程发布

65%的动力总成标定

80%的动力总成标定

问题解决8步法

Alpha阶段(动力总成产品开发的一个阶

段)

Alpha样件需求日期

自动变速器

自动变速器

架构批准

汽车制造商联盟

防抱死制动系统

架构确认

总工助理

工艺路线

总成件树形BOM

主题开发

分析/开发/验证

分析,开发和认证

应用工程师

应用工程师

可装配性评估方法

架构框架启动

美国汽车工业行动集团

铝合金

机械式自动变速器

美国国家标准协会

提前采购

总装厂

汽车产品委员会

批准的产品描述

年度项目执行

亚太经济联盟

先期产品质量规划和控制计划

亚太战略委员会(通用汽车的高层管理组织)

项目预算

架构优化完成

汽车战略委员会(通用汽车的高层管理组织)

经销商售后管理系统

汽车安全工程

战略意向的架构陈述

装配线进场

启动现场安调

装配线

通过PPAP

装配线通过PPAP

装配线交付后的产品工艺验证

装配线交付后产品工艺验证

装配线试装

交样日期

装配线整线打通,启动试装,允许手工装配

装配线

自动空调控制器

自动变速箱油

附件

实际单件工时

先期车辆开发

先期车辆开发中心

前期整车开发-领导小组

先期车辆开发流程(在DSI与VPI之间)先期车辆计划经理

Beta阶段(动力总成产品开发的一个阶段)

制造

Beta样件需求日期

土建公用

试制授权文档

业务计划

车身控制器

车辆调配中心

发动机总成战略转向委员会

制造质量

试制问题报告

试制问题

装车问题报告

造车问题报告

白车身

白车身

设计清单

设备清单

物料清单

物料清单

物料清单

物料清单

物料清单

物料清单

断点

业务计划实施

最佳人员准则

业务流程重组

车身车间

试制现场指导书

线边缓存区

土建/改造和生产提速计划更改审批会

服务热线专员

公司平均油耗

动力总成标定

整车报交检查

用户接受度和审查评估

验证概念

集散中心

确认临床

通过排放认证通知

寒区试验

底盘部

提出项目概念

客户服务经理

持续改进

持续改进

不断改进小组

车厢集成小组

空箱管理中心

更改管理工程师

临界机器能力指数

机器设备能力

三坐标测量

中国标准新车评估体系

能力中心

经验总结中心

控制计划

现有产品改进小组

过程能力指数

稳定过程的能力指数

现有产品质量工程师

单车成本

更改决议

变更申请/决议通知

更改评审小组

动力总成签署项目合同

合同签订

一级受控发运

二级受控发运

控制模块战略转向委员会用户满意度指标

合同签署

整车签署项目合同(VDP术语)合同签署健康检查

合同签署健康检查

制程周期

周期时间

创造性工作小组

关键试验

零部件技术标准

标准2级进度模板

概念车工程发布

概念车工程发布--长周期

整车检验标准

整车质量中心

整车质量目视板

无级变速器

合格率概况

设计分析科

递交项目章程

设计更改通知

设计更改通知

尺寸控制计划

概念设计表

双离合器变速箱

直接投线

驾驶席门控开关

模具工程集成

装配工艺性设计

制造工艺性设计

设计失效模式和效果分析

设计失效模式分析

差速器

设计阶段3b

经销商管理系统

经销商在线系统

需求计划

单车缺陷数

单车缺陷数

设计质量和验证

直接通过率

设计评审委员会

设计和发布工程师

设计发布工程师

设计发布工程师

直接通过损失率

停产

高速耐久试验(MGRES 标准)双离合器变速箱

战略意向书

设计主题选项

诊断故障码

设计验证

产品设计验证

设计验证计划

整车综合动态测试

发动机/变速器/控制模块

紧急制动辅助系统

电子制动力分配系统

工程BOM

控制模块

ERP核心组建

工程更改请求

工程更改请求

工程更改申请

工程项目变更申请

工程变更摘要

电子控制自动变速器

电子数据系统

欧洲提高车辆安全性委员会

排放和燃料经济

产品工程小组经理

电器零件集成和软件

整车寿命结束

排放

发动机管理系统

试制试验科

欧洲标准新车评估体系

工程师

生产提速的完成

生产线试验结束

工程样车(件)

环境保护厅

工程项目委员会

工程项目数目

早期的要求文件

欧洲战略委员会(通用汽车的高层管理组织)

发动机整机

工程签署

工程签署

工程签署

工程技术

工程样车

工程工作指令

工程更改号

工程更改流程

尝试性标定

批准正式生产

生产最终批准

第一轮白车身完成

功能评估

通过油耗认证的通知

第1辆集成车制造完毕

第一轮集成车完成

工厂布局

功能尺寸

财务经理

第一轮骡子车完成

区域售后支持

失效模式分析

失效模式分析

潜在失效模式及后果分析

失效模式和后果分析

失效模式和影响分析

柔性制造系统

联邦汽车安全标准

第一轮产品/工艺白车身完成

第一轮产品/工艺验证车辆完成

固定停止位置

首次能力

一次通过合格率

下线合格率

四轮驱动

Gamma阶段(动力总成产品开发的一个阶段)

Gamma样件需求日期

工段长

总装

总装

全球架构开发小组

全球物料清单

通用汽车北美分部

通用汽车动力总成分部

全球产品开发理事会

全球动力总成开发流程

全球产品管理系统

全球细分主管

全球销售和服务

全球整车开发流程

整车开发流程

整车开发流程

全球汽车开发流程

全球整车开发流程

整车开发流程

整车平台执行

车辆总重

网关

硬件发布中心

接口控制文件

初始数据发布

集成驱动子系统要求

入厂物流规划

生产执行系统

初始标定

检验操作方法

检验操作概要

集成产品与工艺工程

每千辆车的故障率

每一千台车事故率

每千辆车的故障率

千辆车故障率

事故报告

问题解决流程

内含报酬率

国际标准化组织

集成车

集成车的物料需求日期

集成车制造准备评审

集成车工程发布

排序供货

供应商排序供货方式

岗位指导书

及时供货

供应商及时供货方式

生产节拍

联合评审

生产采购委员会

联合采购委员会-一般采购

关键过程控制特性

关键控制特性

产品关键特性定义系统

启动

关键产品特性

关键产品特性

主要产品特性

主要产品特性

关键过程控制

关键过程控制

通用的拉美,非洲,中东战略委员会管制下限

物流确认单

学习周期

长周期

长周期的产品发布

启动经理

整车BOM行

规格下限

启动小组释放

物流属性更改号

机器设备

区域经理

制造BOM

物料数据单

样车试制工程师或生产线制造工程师

电器设备

制造工程

制造工程

区域市场支持

制造工程信息系统

制造执行系统

制造执行系统

确定生产厂址

市场信息中心

循环取货

营销

制造数模发布

生产管理部门

100%自制件达到OTS状态

100%自制件达到OTS状态

自制件

通过PPAP

自制件通过PPAP

自制件生产线交付后的产品工艺验证

自制件生产线交付后的产品工艺验证

主计划系统

多用途轿车

制造要求

交样日期

物料需求日期

物料需求日期(用于制造样机)

数模需求日期(用于虚拟制造)

制造工程师

制造车间

测量系统分析手册

测量系统分析

测量系统分析

测量系统分析

市场细分规范

区域销售支持

市场分割规范

手动变速箱

机床,工装和设备

制造技术标准

用于认证制造工艺的整车制造

制造验证造车

用于认证制造工艺的整车制造(不可销售的)

用于认证制造工艺的整车制造(可销售的)

非销售制造验证造车

销售制造验证造车

汽车安全标准

制造属性更改号

年度款

车型年经理

通用的北美分部

新员工培训

授权书

决议

决议通知

净现值

一般公路

通用的北美传略委员会(通用的高层管理组织)

车载诊断系统

原始设备制造商(主机厂)

零件供应商

工装设备具备试生产条件

零件供应商工装设备具备试生产条件

在岗培训

产品高层管理组织

乘员约束系统

加班

订单到货时间

及时性能

装车评审

工装样件

工装样件

工装样件

工装样件

OTS质量阀

OTS交付状态满足质保的开阀要求

OTS质量阀,OTS交付状态满足质保的开阀要求

OTS设计达到TG2阶段,发布图纸用于供应商启动工装和设备投入

OTS设计达到TG2阶段

批量试生产

小批量生产

批准正式生产

项目管理专员

提交客户的Alpha样机

包装规划

产品装配文件

样车装配指南

产品装配手册

产品和工艺集成会议