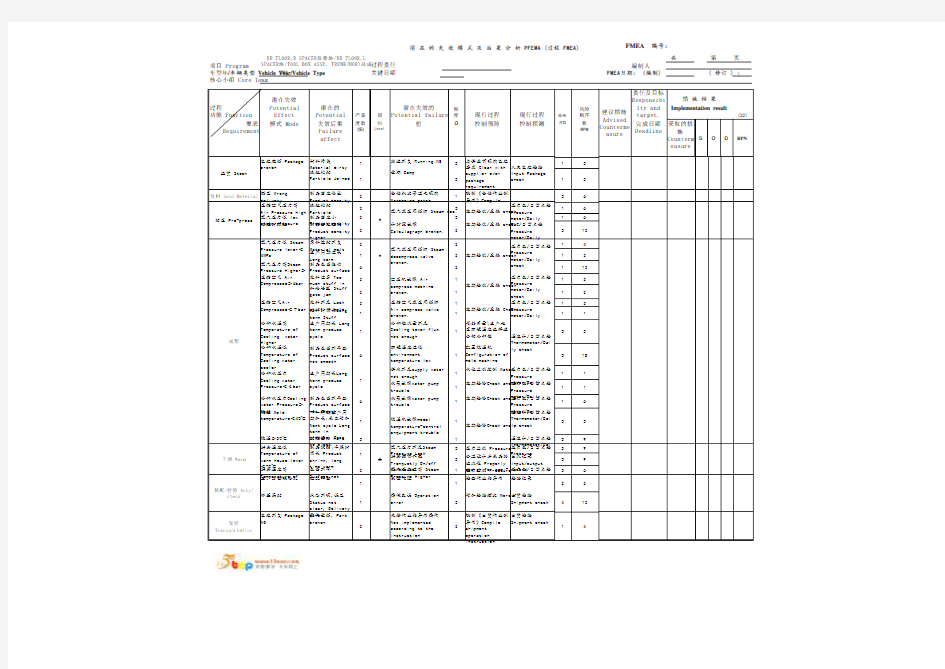

PFMEA潜在失效模式及后果分析

DFV/QD/SQS Supplier Program Management Document

潜 在 的 失 效 模 式 及 后 果 分 析 PFEMA (过程 FMEA)FMEA 编号: 共 第页项目 Program 过程责任

编制人车型年/车辆类型 Vehicle Year/Vehicle Type DB1关键日期FMEA日期: (编制) ( 修订 ) :核心小组 Core Team 过程功能 Function 潜在失效Potential Effect 潜在的Potential 严重级潜在失效的Potential failure 频度现行过程现行过程探测风险

顺序责任及目标

Responsibi lty and target.措 施 结 果

Implementation result

(22)

要求Requirement 模式 Mode 失效后果Failure affect 度数(S)别Level 想O 控制预防控制探测度D 数RPN 完成日期Deadline 采取的措

施

Counterm easure

S O D RPN

材料污染Material dirty 1转运不良 Running NG 313

珠粒粘结Particle Joined 1受潮 Damp

313

发料 Send Material 错发 Wrong delivery 制品密度偏差Product density 2仓储批次管理未明确Warehouse patch 1编制《仓储作业制

导书》Compile 36

压缩空气压力高Air Pressure High 珠粒粘结Particle 2316

蒸汽压力低 low steam pressure 制品密度小Product density 23

16

预压时间短制品密度过大Product density higher 2计时器故障Calculagraph broken.2定期检测/更换 check PLC/日常点检

Pressure meter/Daily

312

原料熔结不良

Material melt 22

14

生产周期过长

Long term 1212

蒸汽压力高Steam Pressure Higher>制品表面烧伤Product surface 62112

充料过多 Too

much stuff in 2112

料枪堵塞 Stuff gate jam 2112

充料不足 Lack stuff in mold 2112

充料时间长Long term Stuff 1111

冷却水温高Temperature of Cooling water Higher 生产周期长 Long term produce

cycle 1冷却塔流量不足Cooling tower flux not enough 1根据用量\生产地

区环境温度选择适

合的冷却塔33

冷却水温低Temperature of Cooling water cooler

制品表面不平整Product surface not smooth 6环境温度过低environment temperature low 1配置模温机Configuration of mold machine

318

供水不足supply water not enough 1水位监测控制 Water 压力表/日常点检

Pressure meter/Daily 11

水泵故障water pump trouble 1定期检修Check and m 压力表/日常点检

Pressure meter/Daily 11

冷却水压力Cooling water Pressure>6bar 制品表面不平整

Product surface not smooth 6水泵故障water pump trouble 1定期检修Check and m 压力表/日常点检

Pressure meter/Daily 16

模温 Mold temperature<40℃下一周期生产周期加长;成本增加

Next cycle Long term in produce, Cost 11温度计/日常点检

Thermometer/Dai

ly check 33

模温>50℃脱模困难 Hard to eject.31温度计/日常点检Thermometer/Dai 39

蒸汽压力不足Steam Pressure Lack

3压力监测 Pressure i 压力表/日常点检Pressure 39

烘房频繁开关Frenquetly On/off warmhouse 3合理设计半成品转运流程 Properly design for semi-出入记录

Input/output record 39

烘房温度高Temperature of 表面不平Surface not 2蒸汽压力过高 Steam Pressure Higher

1压力监测 Pressure i 压力表/日常点检36

左、右垫块修孔装配干涉1成型飞边1检查作业指导书检验记录22

标签漏贴状态不明,误发Status not clear, Delivery

error 1操做失误 Operation error 3增加检验频次 More f 出货检验

Shipment check 412

发运Transportation 包装不良 Package NG 零件受损, Part broken 2未按作业指导书操作Not implemented according to the instruction 2编制《出货作业制导书》Compile shipment operation

instruction 出货检验

Shipment check

14

成型蒸汽压力低 Steam Pressure lower<4MPa ★装配/检验 Assy/

check 干燥 Warm 烘房温度低Temperature of warm house lower <70℃制品收缩;干燥时间长 Product shrink, long time warm 压缩空气Air Compressed<7bar 压缩空气减压阀损坏Air compress valve broken.RR FLOOR,R SPACER后垫块/RR FLOOR,L SPACER块/TOOL BOX ASSY, TRUNK(NOR)总成★1

;

模温机故障model temperature-control enquipment trouble

定期检修Check and m 压力表/日常点检

Pressure meter/Daily 定期检测/更换 check 压力表/日常点检Pressure

meter/Daily check 进货 Stock 包装破损 Package broken 与供应商明确包装

要求 Clear with supplier over package requirement

冷却水压力Cooling water Pressure<4bar 生产周期长Long term produce cycle 预压 Pre-press ★蒸汽减压阀损坏 Steam decompress valve broken.

压缩空气 Air Compressed>6bar 空压机故障 Air compress machine broken.温度计/日常点检Thermometer/Dai

ly check

1

建议措施Advised Counterme asure 入库包装检验Input Package

check 定期检测/更换 check 定期检测/更换 check 压力表/日常点检Pressure

meter/Daily

check 定期检测/更换 Check 蒸汽减压阀损坏 Steam dec 压力表/日常点检Pressure

meter/Daily 1/1