电眼线标意思

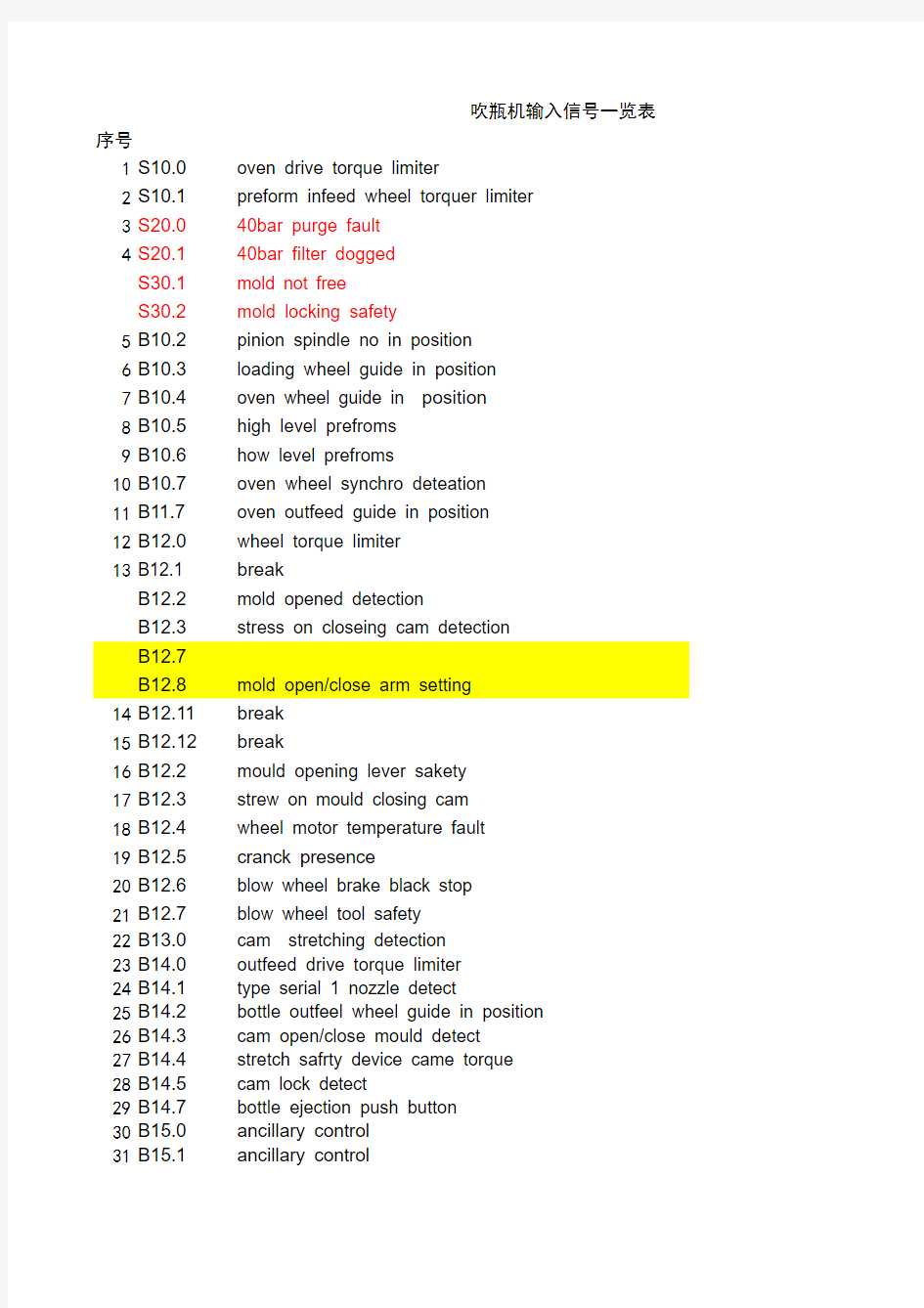

吹瓶机输入信号一览表序号

1S10.0oven drive torque limiter

2S10.1preform infeed wheel torquer limiter

3S20.040bar purge fault

4S20.140bar filter dogged

S30.1mold not free

S30.2mold locking safety

5B10.2pinion spindle no in position

6B10.3loading wheel guide in position

7B10.4oven wheel guide in position

8B10.5high level prefroms

9B10.6how level prefroms

10B10.7oven wheel synchro deteation

11B11.7oven outfeed guide in position

12B12.0wheel torque limiter

13B12.1 break

B12.2mold opened detection

B12.3stress on closeing cam detection

B12.7

B12.8mold open/close arm setting

14B12.11break

15B12.12break

16B12.2mould opening lever sakety

17B12.3strew on mould closing cam

18B12.4wheel motor temperature fault

19B12.5cranck presence

20B12.6blow wheel brake black stop

21B12.7blow wheel tool safety

22B13.0cam stretching detection

23B14.0outfeed drive torque limiter

24B14.1type serial 1 nozzle detect

25B14.2bottle outfeel wheel guide in position

26B14.3cam open/close mould detect

27B14.4stretch safrty device came torque

28B14.5cam lock detect

29B14.7bottle ejection push button

30B15.0ancillary control

31B15.1ancillary control

32B15.2ancillary control

33B30.0machine pitch

34B30.1mould not free

35B30.2mould locking axif fault

36B30.3bottle transfer arm spring break B31.0

37B31.1nozzle not free

38B31.2preform transfer arm spring break

39B31.3base mould roller detector

40B32.0preform loading safety

41B32.1machine infeed level detection

42B32.2oven pitch

43B32.3oven initialization

44B40.5blow wheel initialization

45B40.6 streching safety 1#

46B40.7 streching safety 2#

47B41.0 streching safety 3#

48B41.1 streching safety 4#

49B41.2 streching safety 5#

50B41.3 streching safety 6#

51B41.4 streching safety 7#

52B41.5 streching safety 8#

53B41.6 streching safety 9#

54B41.7 streching safety 10#

55B42.0 streching safety 11#

56B42.1 streching safety 12#

57B42.2 streching safety 13#

58B42.3 streching safety 14#

59B42.4 streching safety 15#

60B42.5 streching safety 16#

61B42.6 streching safety 17#

62B42.7 streching safety 18#

63B43.0 streching safety 19#

64B43.1 streching safety 20#

65B1000external temperature

66B1002oven temperature

67B1004oven water temperature

68B1008preform temperature

69B1010water flow on oven

70B1100 neck/base mold fluid temperature (output) 71B1102mold fluid temperature (output)

72B1104neck/base mold fluid flow

73B1106mold fluid flow

74B1108blow pressure after pressure reducer

75B1112blow pressure befor pressure reducer

76B1114cylinder movement pressure

77E70.0elevator motor safety

78E70.1conveyor belt circuit breaker fault

79E70.2hopper box 24V power supply

80E70.3elevator circuit breaker fault

81E71.0elevator high door safety

82E71.1elevator low door safety

83E71.2hopper right emergency

84E71.3hopper left emergency

85E72.0hopper box fan fanlt

86E72.1emergncy stop + door safeties relay

87E72.2low level hopper call

88E72.3hopper loading request cell

89E78.0elevator loading door safety

90E78.1hopper emptying door safety

91E78.2hopper conveyor motor safety sensor

92E78.3hopper conveyor belt on (start)

93E100.0recycling motor safety sensor

94E100.1little hopper elevator motor safety sensor 95E100.2emergency stop + doors safetyies relay 961KB rollers box 24 power supply

97E101.0paddle wheel fault

98E101.1recycling converoy fault

99E101.2orientator fault

100E101.3rollers box fan fault

101E102.0rollers outfeed cell

102E102.1rollers and elevator stop

103E102.2fit preform cell

104E102.3gangway preform feeder start

105E103.0gangway preform feeder stop

106E103.1gangway preform emergency stop

107E103.2

108E103.3rollers anticipation starting cell

109E104.0paddle wheel door safety

110E104.1rollers door 1 safety

111E104.2rollers door 2 safety

112E105.0high counter cell

113E3.5oven emergency stop

114E3.6wheel blow emergency stop

115E3.7wheel blow emergency stop

116E6.0door security

117E6.1door security

118E6.2door security

119E6.3door security

120E6.4door security

121E6.5door security

122E6.6door security

123E6.7door security

124E40.0solenoid valve breakers 24v fault

125E40.01solenoid valve breakers 24v fault

126E40.02solenoid valve breakers 24v fault

127E40.03solenoid valve breakers 24v fault

128E40.04solenoid valve breakers 24v fault

129E40.1G1EA power supply secondary fault

130E40.2G1EA power supply primary fault

131E40.4fans boxes breaker fault

132E40.5intintialization of wheel

133EW1400mould pressure No.1

134EW1402mould pressure No.2

135EW1404mould pressure No.3

136EW1406mould pressure No.4

137EW1408mould pressure No.5

138EW1410mould pressure No.6

139EW1412mould pressure No.7

140EW1414mould pressure No.8

141EW1416mould pressure No.9

142EW1418mould pressure No.10

143EW1420mould pressure No.11

144EW1422mould pressure No.12

145EW1424mould pressure No.13

146EW1426mould pressure No.14

147EW1428mould pressure No.15

148EW1430mould pressure No.16

149EW1448mould pressure No.17

150EW1450mould pressure No.18

151EW1452mould pressure No.19

152EW1454mould pressure No.20

153EW1432preblow pressure

154EW1434air relief/preblow/blow valve control pressure monitoring 155EW1436stretching pressure

156EW1438nozzle pressure

157EW1440compensation pressure

158EW1442push up pressure

159EW1444raising cam differential pressure

160EW1446HR wheel air regenerating pressure

加热炉扭拒限制器

瓶坯进入星轮扭拒限制器

40bar压缩空气过滤器失效

40bar压缩空气过滤器失效

模具未空

模具未锁

芯轴脱轨

瓶坯入口星轮护栏位置正常

加热炉星轮护板位置正常

瓶坯位置高

瓶坯位置低

加热炉星轮同步检测

加热炉出口护板位置正常

主电机输出轴扭拒限制器

刹车盘位置检测

模具未关闭检测

合模凸轮应力检测

使用底模拆卸接头two b12.7开合模臂位置设置

刹车盘位置检测

刹车盘位置检测

模具合模位置正常

开合模凸轮出口检测

主电机温度过高

手动摇柄检测

吹瓶轮制动销在位

开合模臂位置调整工具在位

出口星轮扭拒限制器

瓶子出口星轮护板位置正常

拉伸杆未上升检测

机器步进

模具不空

瓶胚加载不良

瓶子传送臂弹簧断裂

模具未锁

吹嘴未上升

瓶胚传送臂弹簧断裂

底模转子断裂检测

瓶胚进入检测

加热炉步进

加热炉位置初始化

吹瓶星轮位置初始化

拉伸汽缸上升到位检测1#拉伸汽缸上升到位检测2#拉伸汽缸上升到位检测3#拉伸汽缸上升到位检测4#拉伸汽缸上升到位检测5#拉伸汽缸上升到位检测6#拉伸汽缸上升到位检测7#拉伸汽缸上升到位检测8#拉伸汽缸上升到位检测9#拉伸汽缸上升到位检测10#拉伸汽缸上升到位检测11#拉伸汽缸上升到位检测12#拉伸汽缸上升到位检测13#拉伸汽缸上升到位检测14#拉伸汽缸上升到位检测15#拉伸汽缸上升到位检测16#拉伸汽缸上升到位检测17#拉伸汽缸上升到位检测18#拉伸汽缸上升到位检测19#拉伸汽缸上升到位检测20#室温检测

加热炉温度检测

加热炉冷却水温度检测

瓶坯温度检测

加热炉冷却水流量

底模出口冷却水温度检测侧模出口冷却水温度检测底模冷却水流量检测

侧模冷却水流量检测

减压阀后的压力

减压阀前的压力

所有汽缸压力

瓶坯提升马达过热检测

瓶坯输送带刹车失败

料斗控制柜24V电源正常

瓶坯提升传送带刹车失败

瓶坯提升传送带高位安全门关闭

瓶坯提升传送带低位安全门关闭

料斗右侧急停开关

料斗左侧急停开关

料斗控制柜风扇失败

急停开关和安全门继电器正常(料斗)料斗瓶坯低位检测

料斗清空安全门检测

料斗传送带电机安全传感器

料斗传送带运转开始

瓶坯回收电机安全传感器

急停开关和安全门继电器正常(理坯机)理瓶坯机控制柜24V电源正常

未整列瓶坯清理毛刷电机故障

瓶坯回收传送带故障

取向辊故障

理坯机控制柜风扇故障

取向辊出口电眼

取向辊及提升机停止

整列不良瓶坯检测电眼

理坯机启动按钮

理坯机停止按钮

理坯机紧急停止按钮

取向辊启动检测电眼

未整列瓶坯清理毛刷电机安全门

整列机1#安全门

整列机2#安全门

高速计数电眼

加热炉紧急停止按钮

吹瓶轮紧急停止按钮1

吹瓶轮紧急停止按钮2

安全门1关闭

安全门2关闭

安全门3关闭

安全门4关闭

安全门5关闭

安全门6关闭

安全门7关闭

安全门8关闭

G1EA 电源模块次要故障G2EA 电源模块严重故障

吹瓶轮位置初始化

1#吹瓶模具吹瓶压力检测2#吹瓶模具吹瓶压力检测3#吹瓶模具吹瓶压力检测4#吹瓶模具吹瓶压力检测5#吹瓶模具吹瓶压力检测6#吹瓶模具吹瓶压力检测7#吹瓶模具吹瓶压力检测8#吹瓶模具吹瓶压力检测9#吹瓶模具吹瓶压力检测10#吹瓶模具吹瓶压力检测11#吹瓶模具吹瓶压力检测12#吹瓶模具吹瓶压力检测13#吹瓶模具吹瓶压力检测14#吹瓶模具吹瓶压力检测15#吹瓶模具吹瓶压力检测16#吹瓶模具吹瓶压力检测17#吹瓶模具吹瓶压力检测18#吹瓶模具吹瓶压力检测19#吹瓶模具吹瓶压力检测20#吹瓶模具吹瓶压力检测预吹压力检测

先导气压力检测

拉伸汽缸压力检测

吹嘴压力检测

补偿压力检测

回收气压力检测