天津高银117大厦_细长体型的结构解决方案

801

Peng Liu Goman Ho

Peng Liu, Goman Ho, Alexis Lee & Chao Yin Arup

3008, 30/F, Jing Guang Centre Beijing

China 100020

tel (电话): +86 10 5960 1188 fax (传真): +86 10 5960 1111

email (电子邮箱): peng.liu@https://www.360docs.net/doc/d514024005.html,; goman.ho@https://www.360docs.net/doc/d514024005.html,; alexis.lee@https://www.360docs.net/doc/d514024005.html,; chao.yin@https://www.360docs.net/doc/d514024005.html, https://www.360docs.net/doc/d514024005.html,

Dr. Peng Liu is an Associate Director at Arup and has substantial experience in tall building and seismic design. He is the specialist of structural optimisation in Arup East Asian region and the structural team leader of the Arup Beijing office.

刘鹏博士现为奥雅纳公司的联席董事,他在高层建筑设计和抗震设计上有着丰富的经验。他是奥雅纳东亚地区结构优化专家,现任奥雅纳北京办公室结构部负责人。

Dr. Goman Ho is a Director at Arup and visiting

Research Fellow at Hong Kong Polytechnic University. He was involved in the 597m tall Goldin Finance Tianjin 117 project.

何伟明博士是奥雅纳公司的董事,同时为香港理工大学的客座教授。并参与了 597米高的天津高银117大楼项目。

Mr. Alexis Lee is a Director at Arup. He has been responsible for delivering total engineering design of mixed-use complex developments, and arena type structures globally.

李志铨是奥雅纳公司的董事。他负责全球范围内综合性复杂项目的一体化和场馆类结构的设计。Mr. Chao Yin is a Senior Engineer at Arup. He has accumulated a significant amount of experience

from different types of civil and industrial engineering projects, including large office buildings, superall residences and five-star hotels

殷超现为奥雅纳公司高级结构工程师。他在以往的工作中积累了不同类别民用与工业建筑的工作经验,设计领域涵盖大型办公楼、高层住宅、五星级酒店等。

Abstract

With an architectural height of 597m, the Tianjin Goldin Finance 117 tower will have the highest structural roof of any building under construction in China, and will have a structural height-width ratio of approximately 9.5, making it very slender. To satisfy earthquake and wind-resisting requirements, the structure consists of a perimeter mega-braced frame and reinforced concrete core with composite steel plates. Based on the new requirements from the latest Chinese building seismic design codes, the design includes a number of new features and solutions in overall stiffness control, material and component type selection which are further evaluated by seismic performance-based design, mega-column design, robustness analysis as well as elastic-plastic time-history analysis. The design overcomes various structural challenges and satisfies the requirement of the architect and the client.

Keywords: Mega Frame, Seismic Zone, Mega Column, Composite Steel Plate Shear Wall

摘要

天津高银117大厦建筑高597米,是中国在建的屋顶高度最高的建筑物,结构高宽比达到约9.5,使其形态非常纤细。为满足抗震与抗风的技术要求,结构采用了含有巨型组合柱的外框架以及含有组合钢板混凝土混合的结构体系。结合新的抗震规范要求,在整体刚度控制、材料与构件选型、性能化设计、巨型柱设计、防倒塌及稳健性分析、弹塑性动力时程分析等方面均体现了许多新的特点和设计要求。在克服了结构设计种种挑战的同时,成功实现了建筑师及业主方的设计意图。关键词:巨型框架、地震带、巨型柱、组合钢板剪力墙

Engineering Background

Measured from the structural roof level, Tianjin Goldin 117 will be the tallest building in China. The tower is located in Tianjin, China, and will include class-A office spaces, a 6-star hotel and ancillary facilities with a gross floor area of approximately 370,000m2. The architectural height is approximately 597m with 117 stories (total of 126 structural stories). The project is financed by Goldin Properties Holdings Limited.

The mega tower has a square plan which reduces in size throughout the height and follows a tapered shape in elevation. The plan dimension is approximately 65m x 65m at the ground level and gradually reduces to 45m x 45m at the roof level (see Figure 1).

Design Challenges

The structural height of the tower is 584 meters and the height-to-width ratio is

approximately 9.5, significantly exceeding the limit of 7.0 imposed by Chinese seismic code. Accordingly, approval from a National Expert Review Panel is required.

工程学背景

高银117大厦从结构屋顶高度测量将会成为中国第一高楼。此项目位于天津市,为一幢写字楼为主附有六星级酒店及相关设施的大型超高层建筑。总建筑面积约37万平方米,建筑高度约为597米,共117层(地上结构楼层共126层),由天津海泰新星房地产开发有限公司投资开发。巨塔平面为正方形,外形随高度变化,各层周边建筑轮廓随着斜外立面逐渐变小,塔楼首层建筑平面尺寸约65米×65米,渐变至顶层时平面尺寸约45米×45米(见图1)。

设计挑战

塔楼结构高度为584米,高宽比约9.5,大大超过中国抗震规范7.0的限值要求,因此必须通过国家专家审查。

由于天津处于中国北方地震高烈度区(7度0.15g),且所在场地覆盖层较松软,根据中国规范要求必须采取更为严格的控制标准,因此结构抗震设计面临更为严峻的技术要求和条件。

Alexis Lee

Chao Yin

Tianjin Goldin Finance 117 Tower: The Solution to a Slender Geometry

天津高银117

大厦: 细长体型的结构解决方案

802

Tianjin is located in Northern China with high seismic intensity

(Intensity 7, 0.15g) with soft ground conditions. According to Chinese codes and practice, a more stringent set of controlling criteria had to be adopted, leading to more challenging technical requirements and conditions for the seismic design of the structure.

Development of Structural Systems and Member Design Building Plan

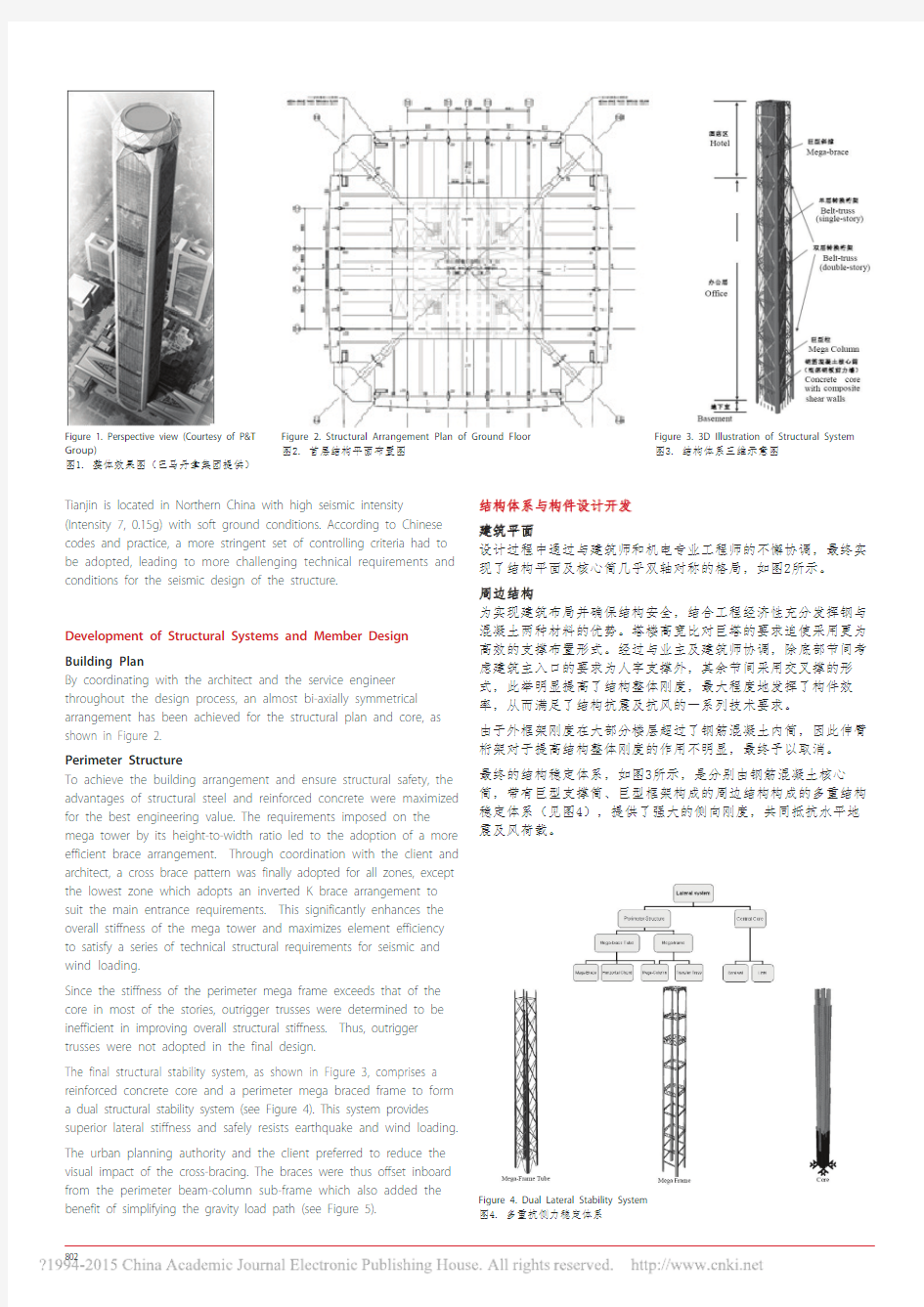

By coordinating with the architect and the service engineer throughout the design process, an almost bi-axially symmetrical arrangement has been achieved for the structural plan and core, as shown in Figure 2.

Perimeter Structure

To achieve the building arrangement and ensure structural safety, the advantages of structural steel and reinforced concrete were maximized for the best engineering value. The requirements imposed on the mega tower by its height-to-width ratio led to the adoption of a more efficient brace arrangement. Through coordination with the client and architect, a cross brace pattern was finally adopted for all zones, except the lowest zone which adopts an inverted K brace arrangement to suit the main entrance requirements. This significantly enhances the overall stiffness of the mega tower and maximizes element efficiency to satisfy a series of technical structural requirements for seismic and wind loading.

Since the stiffness of the perimeter mega frame exceeds that of the core in most of the stories, outrigger trusses were determined to be inefficient in improving overall structural stiffness. Thus, outrigger trusses were not adopted in the final design.

The final structural stability system, as shown in Figure 3, comprises a reinforced concrete core and a perimeter mega braced frame to form a dual structural stability system (see Figure 4). This system provides superior lateral stiffness and safely resists earthquake and wind loading.The urban planning authority and the client preferred to reduce the visual impact of the cross-bracing. The braces were thus offset inboard from the perimeter beam-column sub-frame which also added the benefit of simplifying the gravity load path (see Figure 5).

结构体系与构件设计开发

建筑平面

设计过程中通过与建筑师和机电专业工程师的不懈协调,最终实现了结构平面及核心筒几乎双轴对称的格局,如图2所示。周边结构

为实现建筑布局并确保结构安全,结合工程经济性充分发挥钢与混凝土两种材料的优势。塔楼高宽比对巨塔的要求迫使采用更为高效的支撑布置形式。经过与业主及建筑师协调,除底部节间考虑建筑主入口的要求为人字支撑外,其余节间采用交叉撑的形式,此举明显提高了结构整体刚度,最大程度地发挥了构件效率,从而满足了结构抗震及抗风的一系列技术要求。

由于外框架刚度在大部分楼层超过了钢筋混凝土内筒,因此伸臂桁架对于提高结构整体刚度的作用不明显,最终予以取消。最终的结构稳定体系,如图3所示,是分别由钢筋混凝土核心筒,带有巨型支撑筒、巨型框架构成的周边结构构成的多重结构稳定体系(见图4),提供了强大的侧向刚度,共同抵抗水平地震及风荷载。

Figure 1. Perspective view (Courtesy of P&T Group)

图1. 整体效果图(巴马丹拿集团提供)

Figure 2. Structural Arrangement Plan of Ground Floor 图2. 首层结构平面布置图Figure 3. 3D Illustration of Structural System 图3. 结构体系三维示意图

Figure 4. Dual Lateral Stability System 图4. 多重抗侧力稳定体系

803

To prevent potential progressive collapse if the lower part of the

columns of the sub-frame is damaged, an alternative load path for the upper portion is provided by connecting the columns with the belt truss above via a long slotted joint which will be activated if a lower column were ever to fail (see Figure 6). The belt truss is designed for high horizontal/vertical seismic load combination demand, and this simple structural detail enhances the robustness and safety of the gravity system without extra cost.

Core

The core extends from the top of the pile cap up to the roof of the mega tower, passing through the full height of the building. The core is rectangular in plan with dimensions of about 34m x 32m at the base, and an approximate square on Level 67 up to the roof.

The core adopts steel-reinforced concrete shear walls with embedded steel sections. At the low zone, alongside steel sections, steel plates are added to form composite steel plate walls (C-SPW) to prevent shear failure of the concrete walls in case of a severe earthquake, as shown in Figure 7. This system has been widely adopted for supertall buildings in China since its first introduction in the China World Trade Centre Phase 3A project. Once the wall is proved to be strong in shear, the ductility of a reinforced concrete shear wall can be guaranteed. At the same time, this kind of C-SPW will not induce any sound during oscillation like a pure steel plate shear wall. The use of this type of composite wall increases the compressive and shear capacity of the element, efficiently reducing the self-weight of the structure and hence the mass.

The core wall thickness gradually reduces from 1400mm thick at the base of the tower to 300mm at the top. Steel plate arrangements within the wall panels vary from two 35mm thick steel plates at the base to a single 25mm steel plate at about Level 32.

Mega-Columns

Mega columns are strategically located at the four corners of the building plan and extend to the top of the tower, connecting beams, transfer trusses and mega braces at each zone. The plan shape of the mega columns satisfies the architectural profile and structural connection requirements, resembling a six-sided polygon with a cross sectional area of about 45m2 at the bottom (see Figure 8). The mega columns reduce in size at zones along the height of the tower with the exterior face of the columns held flush.

The mega columns are connected to the transfer trusses and mega braces. Initial designs of the columns were envisioned to be steel reinforced columns (SRC), however it was determined that polygonal concrete filled tubes would ultimately be required. The normal practice

由于城市规划部门和业主弱化交叉支撑视觉效果的要求,因此设计中采取了将斜撑与周边次框架在平面上错开的方案,这还可简化重力荷载路径(见图5)。

为防止可能的连续倒塌,一旦副架的下层柱遭到破坏,上部需有另一条传力路径,通过长圆孔节点来连接柱体和带状桁架,一旦下层柱失效,节点则会被激活(见图6)。带状桁架设计用于横向/竖向高地震荷载的综合要求。而且这一简单的构造在不增加额外成本的同时,还提升了重力系统的鲁棒性与安全性。核心筒

核心筒从承台面向上伸延至大厦顶层,贯通建筑物全高,其平面基本呈长方形。底部尺寸约为34米×32米,直至核心筒于层67完全呈现正方形。

塔楼核心筒采用内含钢骨的型钢混凝土剪力墙结构,并在下部采用内嵌钢板的组合钢板剪力墙结构,以防止大震下的剪切破坏,如图7所示。此体系自北京国贸三期在国内首次采用后在超高层建筑中得到了广泛的应用。一旦证明墙体的抗剪强度很高,可以改善普通混凝土墙的延性,同时组合墙体也不像纯钢板墙在受力时可能发出声音。组合墙体的采用提高了构件抗压、抗剪承载力,有效降低结构自重及质量。

核心筒周边墙体厚度由1400mm从下至上逐步均匀收进至顶部300mm;墙体内的钢板布置由底部的两块35mm厚钢板到约层32处的单块25mm钢板。

巨型柱

巨型柱位于建筑物平面四角并贯通至结构顶部,在各区段分别与水平杆、转换桁架及巨型斜撑连接。其平面轮廓结合建筑及结构构造连接要求,呈六边菱形,底部截面约为45m 2(见图8),沿高度并配合建筑要求分多段内收,柱体外侧平齐。

巨型角柱与转换桁架及巨型斜撑连接,其设计也经过了不断的演化,特别是对型钢混凝土柱和钢管混凝土柱之间进行了各方面的比对,权衡利弊。根据相关试验结论,柱内各孤立的钢骨间必须采取全高的强连接的方式,避免出现类似格构柱的分离式的布置,确保柱的整体延性。最终考虑将钢板在周边外置,内部钢板根据构造要求相互连接,独立分割,如图所示,形成了多腔体的6边形钢管混凝土组合构件,获得巨大的拉压弯及抗剪扭承载力,以抵抗竖向荷载及风、地震产生的侧向荷载。

巨形柱非节点区整体含钢率约为4%~6%,钢材采用Q345GJ(或Q390GJ)。由底至顶内填高强混凝土,强度C70~C50。各腔体内布设钢筋,在提高构件强度的同时,有效降低混凝土收缩徐变产生的不利影响。在各腔体内侧对称布设纵向内肋板,并用水平拉结钢筋连接,约束钢板面外屈曲。

巨型柱结构设计,综合平衡了建筑布局、结构整体刚度、构件受

力性能、节点连接、工程造价、制作加工、施工可行性等各方面

Figure 5. Illustration of Mega Frame and Mega Brace connection – double-story truss

图5. 巨型框架与巨型支撑连接示意图 – 双层桁架Figure 6. Elevation of perimeter frame and slotted joint at the top 图6. 周边框架立面布置图和顶部滑动连接节点

804

of discrete steel sections in SRC columns was considered to have

insufficient ductility based on results of previous tests in other projects. The requirement of a full-height inter-connection of all steel sections resulted in a closed continuous steel. The final design is an external steel plate enclosure with internal inter-connected plates forming separate chambers in accordance with the detailing requirements (as shown). The six-sided polygonal concrete filled tube composite member has sufficient capacity to resist axial, bending and shear forces generated by earthquake and wind loads.

The overall steel percentage of the mega columns outside the

connection zone is about 4~6%, using Q345GJ (or Q390GJ) grade steel with high-strength concrete infill of grade C70~C50. Reinforcing steel is distributed within each compartment, enhancing the strength of the member while minimizing the undesirable effects of creep and shrinkage of concrete. Vertical stiffeners are arranged symmetrically on the inner face of the compartments, and linked with reinforcement ties to restrain out-of-plane buckling of the steel plates.

The structural design of the mega columns was a compromise

between various factors including architectural arrangement, overall structural stiffness, element performance under loading, connection design, construction cost, production and constructability, and achieving the best overall economic and technical performance.Mega Brace and Transfer Issues

The mega braces are arranged on the four elevations of the tower, using welded steel box sections and are connected to the mega columns. Since the mega braces are separated from the perimeter beam-column frame, lateral support was provided for in the floor system to restrain out of plane buckling of the mega braces.

Transfer trusses were coordinated with architectural and services

requirements and were located at mechanical and refuge floors. There are nine sets of trusses, distributed evenly at approximately every 12 to 15 floors. The transfer trusses resist the gravity loading from each zone and transfer the loads to the corner mega columns. The transfer trusses also create a frame with the corner mega columns, enhancing the torsional stiffness of the tower. Under severe seismic activity, the transfer trusses are a vital component of the structural system in preventing progressive collapse of the floors and ensuring safety. Vertical earthquake action has also been considered for the long-span trusses and its performance criteria has been increased to prevent yielding under severe seismic activity.

Floor System

Outside the core of the tower, a composite floor system is adopted with simply supported steel beams that are spaced at 3 meters on center with spans ranging from 6 meters at the top of the tower to 13 meters at the bottom of the tower. The office slab floor is 120mm thick and the hotel floor is 130mm thick including the metal decking.To ensure reliable transfer of diaphragm forces between the core and external frame, the main tower and the podium wings, and the main structure and the basement, specific floors were strengthened by thickening to 200~300mm and by introducing in-plane bracing.Foundation System

Underneath the 4-story 26-meter deep basement, the tower is

supported by a 6.5m thick raft which is in turn supported by 941 cast-in-situ bored piles. The raft is 86m x 86m in plan with C50 concrete strength. The piles are one meter in diameter and are founded at 100 meters below ground, while the effective length is approximately 76 meters. Post pressure grouting for pile shaft and toe was used to increase the pile capacity and reduce the settlement. Piles were zoned

的要求,达到最优的综合经济技术性能。

巨型支撑和转换桁架

巨型支撑设置于大厦四边的垂直立面上,采用焊接箱形钢截面并与巨型柱连接。巨型斜撑与边梁柱相互脱开,为楼面系统提供了侧向支持以控制巨型支撑平面外的屈曲。

转换桁架配合建筑及机电专业要求,设置于避难及设备层。由9组沿塔楼每12~15层均匀分布。转换桁架承担其间隔楼层竖向荷载并将其转换至角柱,并与四角的巨型柱共同作用,提供部分抗侧刚度,增加大厦的抗扭性能。在罕遇地震下,转换桁架将成为防止楼面局部倒塌,确保安全的重要构件,还考虑了大跨结构竖向地震作用,提高其性能化设计水准至大震不屈服。楼板体系

塔楼核心筒外,楼面梁采用了常见的组合楼板体系,间距为三米的简单支撑钢梁,跨度由高至低约为6~13m,两端铰接,钢梁典型间距为3m,包括金属面板在内的总楼板厚度办公楼层为120mm、酒店楼层为130mm。

为确保水平剪力在核心筒与外框架、主塔楼与裙楼间以及主体结构和结构大底盘之间的可靠传递,楼板固层厚度为200~300mm。基础体系

结构共有4层地下室,埋深约26米.塔楼采用钻孔灌注桩-平板式筏板基础,筏板尺寸为86m*86m,厚度6.5m,混凝土强度C50.塔楼下总桩数941根,有效桩长约76m, 桩径1m,混凝土强度C50.为进一步提高单桩承载力并控制沉降,桩侧桩底采用了后压浆,结合塔楼下不均匀桩反力分布,单桩设计承载力采用分区设计,巨型柱下最大单桩承载力特征值达到1650吨以满足抗震和抗风的设计要求。

Figure 7. Diagram of composite steel plate shear walls.图7. 复合钢板剪力墙图表

Figure 8. Typical low zone 45m 2 Mega Column section detail 图8. 底部典型楼层巨型角柱45m 2截面构造示意图

805

with different design capacities in which the maximum characteristic value of single pile capacity is 16500kN.

Elastic Analysis of Overall Performance

Basic Parameters

The design reference period and working life recurrence interval is 50-years, and the durability design recurrence interval is 100-years. The seismic fortification intensity is 7.0 with a design peak acceleration of ground motion at 0.15g.

The wind loading for the main tower is determined by wind tunnel testing with wind speeds of 50-year and 100-year return periods for displacement and strength checking, respectively.

Seismic Performance-Based Design Requirement

Since the structure exceeds prescriptive code requirements

considerably, seismic performance objectives have been established for the overall structural behaviour and element performance according to performance-based design principles and numerous discussions with the expert review panel. Elasto-plastic time-history analysis was used to confirm that the seismic performance objectives were met for severe earthquakes.

Elastic Analysis

For the elastic analysis, ETABS and MIDAS were used. For elastic-plastic analysis, LS-DYNA was adopted while ABAQUS was selected by the independent review engineer.

The first three modal periods of the structure are 9.06s, 8.97s and 3.46s, with the first two modes being translational modes and the third being a torsional mode.

Overturning Moment, Story Shear and Shear-Gravity Ratio The distribution of shear under frequently occurring earthquakes and wind is shown below. The seismic story drift, scaled according to the minimum base shear, was found to be larger than the wind load. Accordingly, it was determined that seismic loads controlled the design (see Figure 9).

Displacement

As shown in Figure 10, the maximum inter-story drift is 1/667 for a 50-year wind event, while inter-story drift under frequently occurring earthquakes, magnified per the allowable shear-gravity ratio and considering vertical earthquake response, is 1/516 (1/614 before magnification) at Level 97, which is within the 1/500 limit of the Chinese code.

整体性能弹性分析

基本参数

塔楼结构设计基准期及设计使用年限为50年,耐久性为100年,建筑抗震设防烈度7度,地震加速度为0.15g。

塔楼主体结构风荷载的确定,按照“强度控制按100年规范风速风洞试验,位移控制按50年规范风速风洞试验荷载”原则进行。抗震性能化设计要求

由于结构超限较多,按照性能化设计的思想,经过与超限审查专家组的多次讨论,明确了结构整体和各构件抗震目标。对于弹塑性时程分析明确了大震下的抗震性能目标。

弹性分析

弹性分析采用了ETABS和MIDAS。弹塑性分析除采用LS-DYNA,同时应用ABAQUS进行了第三方的比对分析。

结构前三个自振周期分别为9.06,8.97,3.46s,前两振型均为平动,第三振型为扭转。

倾覆弯矩、层剪力和剪重比

小震和风荷载作用下底部剪力如下所示。结构地震下的位移根据最小底部剪力进行了调整,大于风荷载下的位移。因此结构的侧向刚度主要受地震荷载控制(见图9)。

位移

如图10所示,采用50年一遇的风荷载,最大层间位移角为1/667,小震下层间位移角计算考虑了剪重比和竖向地震放大的影响,最大层间位移角为1/516(放大前为1/614),均处于建筑层97,在中国设计规范限制的1/500以内。

小震弹性时程分析

小震分析采用了七组强震加速度记录作为动力时程分析,其中两组为人工波,其余五组为天然波。七条时程曲线的基底剪力均大于反应谱法的65%,平均值大于反应谱法的80%,满足规范要求。结构设计取时程波在各层的平均值,在反应谱基础上将内力值进行放大调整,进行构件的补充验算。

内外框架剪力与倾覆力矩

外框筒承担了标准楼层约70%以上的剪力,明显大于核心筒(见图11)。在结构加强层,由于外框筒刚度在该楼层的显著增大,导致外框筒吸收的地震剪力出现突变,同时伴随水平力在内外筒

间进行传递。

Figure 9. Story shear and frequent earthquake shear-gravity ratio distribution

图9. 楼层剪力和小震剪重比分布图Figure 10. Inter-story drift under earthquake and wind 图10. 地震及风作用下层间位移角

806

Elastic Time-History Analysis of Level 1 Seismic

Seven sets of earthquake acceleration records have been studied in the

frequent seismic dynamic time-history analysis, in which two sets are artificial records and five sets are natural

records. All seven sets of records have base shears greater than 65% of that obtained from the response spectrum analysis, with an average value greater than 80%, which satisfies Code

requirements. In the structural design, an average value of the story shear has been used to magnify the story shear obtained from the response spectrum analysis.

Shear and Overturning Moment

distribution between Internal and External Frame

The external tube carries over 70% of

the story shear on typical floors, which

is considerably greater than that taken by the core (see Figure 11). At

the strengthened floors, the sudden increase in stiffness of the external tube results in a sharp increase in shear force taken by the external

frame with a horizontal force transfer between the internal and the

external tube.About 80% of the total overturning moment is taken by the perimeter structure.

These distributions of shear and overturning moments between the internal and external tube indicates that the perimeter mega-structure provides the majority of stiffness while the internal core becomes a “secondary” system. The advantage of this arrangement is that the core can be designed for a relatively low demand.

Wind Comfort Analysis

Wind tunnel tests for the tower were independently completed by BMT Fluid Mechanics and Shantou University Wind Tunnel Laboratory. Results from both laboratories are consistent and indicate an estimated peak acceleration of 20.3mill-g at the highest occupied level, which satisfies the national code requirements.

Axial Shortening Analysis

Tall buildings will shorten under the gravity load, elastically as well as under the effect of shrinkage and creep. An initial construction program simulation analysis was carried out to estimate the amount of the axial shortening and evaluate the additional forces incurred. The internal forces of the mega braces were found to be increased due to the shortening of the mega columns which has been allowed properly in the member capacity checking.

Elastic-Plastic Time-History Analysis of Level 3 Seismic

To achieve the seismic performance objective of no collapse under a severe earthquake, the design adopts the member plasticity

development limits and analysis methods and procedures suggested in FEMA356 and ATC40. The non-linear seismic analysis was carried out with the general non-linear dynamic finite element analysis software LS-DYNA considering geometric non-linearity as well as material non-linearity.

As for the composite steel plate shear wall, the steel plates and

reinforced concrete shear walls are separately modelled as non-linear

外框筒分担了各层约80%的倾覆力矩。

从层剪力和倾覆力矩内外筒分担比例分析看,带有巨型支撑的巨型框架结构体系提供了大部分刚度,而内部核心筒则成为“次

级”体系。这种布置的好处是对内部核心筒的抗震性能要求可以降低。风舒适度分析 塔楼风洞试验分别由英国BMT公司和汕头大学风洞试验室完成,两个试验结果是一致的,显示本工程的最高住人楼层加速度为20.3mill-g,满足国家规范要求。

轴向缩短分析

高层建筑在重力荷载下高度会有所缩短,并且在收缩和徐变效应下也会弹性化的变化。初步的建设方案模拟分析被用于估算轴向缩短量并评估额外产生的受力。其结果显示,巨型框架的内力由于巨型柱的缩短而增大,而这些巨型柱已被进行适当的受力能力检查。

罕遇地震弹塑性时程分析

为实现在罕遇地震作用下防倒塌的抗震设计目标,工程采用了美国FEMA356(建筑抗震修复预标准及其说明)和ATC40 所提供的结构构件弹塑性变形可接受限值,以及所建议的结构非线性地震分析方法与步骤。结构的非线性地震反应分析采用了通用非线性动力有限元分析软件LS-DYNA 进行计算,考虑了几何非线性与材料的非线性。

对于组合钢板剪力墙,把钢板和混凝土剪力墙分别建成共节点的非线性壳单元,保证钢板与混凝土协同作用。大震对弹塑性整体分析模型的质量及周期振型等信息与ETABS模型相比较,确保了弹性兼容性的动力特性。

图12显示了罕遇地震下,7条时程波在弹塑性动力分析中,结构整体在X和Y方向上层间位移角的分布情况,均满足规范1/100的要求。

设计研究和建议

整体刚度控制与结构选型

塔楼结构高近600m,在风及地震作用下,整体刚度合理定量控制成为结构设计最重要的内容之一。因而刚重比、剪重比、结构层间位移角及风载顶点加速度(舒适度)这4项指标同时成为结构整体刚度的控制性因素,特别是超高层建筑“剪重比不能超越规

Figure 11. Distribution of shear and overturning moment between internal and external frame

图11. 剪力及倾覆弯矩在内外框架分布示意图

shell elements in space with common nodes, ensuring compatibility between the steel plates and reinforced concrete. Parameters such

as overall mass and period of the elastic-plastic model under severe seismic activity are calibrated with the ETABS results to ensure the elastic compatibility of the dynamic properties.

Figure 12 indicates the inter-story drift response in the X and Y directions for the seven sets of time-history records under severe seismic activity, and each response satisfies the code requirement of

1/100.

Design Study and Recommendations

Overall Stiffness Control and Selection of Structural Form

The structural height of the tower reaches almost 600 meters. The overall stiffness of the tower, therefore, was key to resisting the demanding wind and earthquake loads, and was driven by the stiffness-gravity ratio, shear-gravity ratio, inter-story drift, and peak acceleration of the top level under wind (comfort). The major design effort was focused on reducing the structure self-weight and to improve the structural efficiency. The steel-reinforced concrete composite structural system adopted for the tower maximizes the technical advantages of a steel structure, provides superior structural stiffness and fire proofing resistance, while taking advantage of

the relatively low cost of concrete. All of these characteristics are advantageous when compared to a pure steel structure, and ultimately provides an economical and reasonable structural form.

Material Selection

Analysis revealed that 30% of the seismic mass originates from

the concrete core, and that the shear wall is controlled by axial

stress throughout the height of the building. Considering ductility requirements, the concrete grade was kept no higher than C60 for the shear wall. As a result, steel plates were added to provide composite action and to increase overall stiffness, shear resistance and ductility. Selection of Structural Form for External Frame

The overall stiffness of the external frame is significantly greater than the internal tube due to the cross mega brace configuration.

Similar flexural deformations for both the perimeter structure and the internal core occurred because of the increase of the external frame’s stiffness, which provided further confirmation that the external frame dominated the overall tower stiffness. Accordingly, outriggers were determined to be unnecessary due to this deformation consistency. Performance-Based Design

For seismic design of code-exceeding buildings in China, the code-based prescriptive method, or “seismic concept design”, is still the major design method used which is supplemented by the verification from a nonlinear elastic-plastic analysis and shake table test for the severe earthquake event. Important members were identified and designed for the elevated design criteria. For example, different criteria in severe earthquakes have been considered for various components of the mega columns, transfer trusses, core walls and mega braces were designed to remain elastic under the fortification level earthquake. In the axial-moment analysis of mega columns under various internal force combinations, mega columns are in compression for the fortification earthquake event (1 in 475 years), the frequent earthquake event (1 in 50 years), and the 100-year return period wind event. Under severe earthquake, compression in the mega columns is overcome

by axial tension induced by lateral action, and the mega columns are under a tension-bending state for most height. This phenomenon happens in high-rise buildings in high earthquake intensity regions 范限值太多”的要求下,控制结构整体重量,采用更高效的抗侧力体系和构件布局成为设计的关键性因素。结构整体采用钢-混凝土混合结构,有效地将钢及混凝土进行组合,既具有钢结构的技术优势又具备混凝土造价相对低廉的特点,结构刚度大,防火性能好,与纯钢结构相比具有明显的优势,成为了塔楼最为经济合理的结构形式。

材料选择

经统计,结构地震质量的30%来源于混凝土核心筒,剪力墙轴压比成为核心筒全高的控制性指标。考虑一定的延性要求,混凝土材料等级被控制在C60,因此嵌入钢板的这种构造,提高了结构整体刚度、抗剪及延性等性能。

外框架结构形态选择

由于塔楼采用巨型框架+交叉支撑的结构形式,外框架整体刚度明显大于内筒。

外筒刚度的增大,使得内外筒均呈现整体弯曲变形的特征,两者变形相对协调,伸臂桁架对协调两者变形的效能降低,对结构整体刚度几乎无贡献。

性能化设计

在规范体系框架下,采用抗震概念设计并辅以罕遇地震下弹塑性时程分析和整体模型振动台试验仍旧是中国对于复杂超限建筑抗震设计主要的方法,对于重要构件的强度要求则根据特点相应采用更高的抗震性能目标。例如本塔楼巨型柱、转换桁架要求满足大震性能,而核心筒(拉压弯)和巨型斜撑则按照中震性能进行复核。对于巨型柱的拉压弯构件校核,则分别考虑了小震、中震以及百年风作用不同的内力组合,而在大震下,结构自重不能平衡地震作用产生的轴拉力,因而使巨型柱在大部分高度范围内出现受拉工况。随着地震设计内力水准的显著提高,高震区超高层建筑中拉弯作用有可能成为相关构件设计的控制性因素,因而巨

型柱的型钢和钢筋同时根据校核结果设计抵御此轴拉作用。此外Figure 12. Overall inter-story drift under severe earthquake elastic-plastic time-history analysis

图12. 罕遇地震弹塑性动力时程分析结构整体层间位移角

807

after the seismic force magnification and would possibly become the controlling criteria for element design. The steel section and rebar have been checked to resist this tension force and relevant stiffness degradation is modelled in a non-linear analysis.

Conclusion

For the structural design of the slender tower of Tianjin Goldin Finance 117, the Chinese codes, together with the prescriptive performance-based design principles, guided the entire design process. Extensive linear and non-linear spectrum-based and time-history-based analyses have been carried out for different levels of earthquake events as

well as wind events to ensure that the structure meets performance objectives. There are still obstacles within the code system and

within the industry before a true performance-based design can be performed and accepted. However, we understand that the current approach is pragmatic in the current environment in China of fast-track construction of supertall buildings.

Acknowledgements

The preliminary design of Goldin Finance 117 was approved by the National Review Panel for Seismic Design of Code-exceeding Buildings in October 2010. The authors would like to thank the local design institute ECADI for their support in the statutory submission process. The authors are grateful to the following experts and parties involved in this design: experts of the National and Tianjin Code Exceeding Seismic Design Expert Panel, Xu Peifu, Wang Yayong, Dai Guoyin, Cheng Maokun, Chen Fusheng, Wu Xuemin, Ke Changhua, Lin Tong, Ling Guangrong, Ding Yongjun, Wen Libin, Huang Zhaowei, Zhou Yuming, etc; from RBS, Rong Baisheng, Li Shengyong, Li Zhishan; from ECADI, Wang Dasui, Lu Daoyuan; and the experts of wind engineering review: Zhang Xiangting, Gu Ming, Gu Zhifu, Lou Wenjuan.在非线性分析中,同时考虑了巨型柱内由于混凝土受拉开裂构件刚度退化产生的相应影响。

总结

对于天津高银117大厦这样一个高纤细建筑的结构设计,在中国规范基础上采用相应的抗震性能化设计贯穿了整个设计过程。基于大量的线性与非线性反应谱和动力时程进行的抗震分析与抗风工况分析确保了整个结构满足相应的性能目标。在现有中国规范体系下,实施并接受真正的性能化设计仍旧存在一些障碍。但考虑当前中国建造超高层建筑急速发展的环境,目前的设计方法是在现行规范下较为实际和稳妥的。

致谢

天津高银117大楼的初步设计已于2010年10月通过了全国及天津市超限高层建筑工程抗震设防审查专家委员会的联合审查。

致谢:全国及天津市超限高层建筑工程抗震设防审查专家组徐培福、王亚勇、戴国莹、程懋堃、陈富生、吴学敏、柯长华、林桐、凌光容、王承春、丁永君、文礼彬、黄兆伟、周玉明以及广州容柏生建筑工程设计事务所容柏生、李盛勇、李志山,华东建筑设计研究院汪大绥、陆道渊,风工程审查专家组张相庭、顾明、顾志福、楼文娟等对本工程结构设计给予的大力帮助,并为工程设计提供了许多宝贵意见,在此表示忠心感谢!

References (参考书目):

ARUP (2010). Structural feasibility study report on Tianjin Goldin 117 office tower code limits exceeding design.

ATC40 (1996). Seismic evaluation and retrofit of concrete buildings. Applied Technology Council.

FEMA 356 (2000). Pre-standard and commentary for the seismic rehabilitation of buildings. Federal Emergency Management Agency, Washington D. C.

GB50011-2010(2010) Code for seismic design of buildings. China Architecture & Building Press, Beijing, China.

808

天津117大厦工程介绍

需要截取视频起止时间1:48——39:30 1:48 京畿南望,紫气东来。在中国经济增长的第三级天津宝地,高银天下,巍峨耸立,傲视群雄,成就富国神话。 工程概况:天津高新区和服务外贸基地综合陪同区,中央商务区一期工程由117层的117塔楼,37层的总部办公楼,23层的商业廊及两层的精品商业廊。该工程总建筑面积84.7万平方米,其中地上部分49.7万平方米。117塔楼总高度597,结构高度596.2米,是中国结构第一高,为钢筋混凝土核心筒加矩形框架的结构体系。大楼首层65米乘65米,4200平方米,向上以0.88度的角度逐层缩小。顶层46米乘46米,2100平方米,是一幢集甲级办公、六星级酒店、旅游观光、精品商业为一体的特大型超高层摩天大楼。117大厦擎天巨钻,至尊闪耀。 工程特点与施工关键控制点:在中国所有的摩天大楼中,117大厦塔楼结构最高,体量最大,工期最紧,由此带来的施工关键控制点有—— 1. 确保塔楼工期节点是第一要务,对施工组织安排提出的难度最大。 2. 垂直运输是117塔楼施工的大动脉,塔吊、施工电梯的投入和合理安排是大动脉的保障。 3. 全力以赴确保32层以下提前运营,科学组织将运营与施工的影响降到最低。 4. 厚钢板剪力墙、大吨位矩形柱制作加工与吊装焊接,复杂钢筋的穿插与避让,高强混凝土超高泵送等施工难题需逐项攻克。 5. 深化设计总包协调管理是快速顺畅施工的保障。 垂直运输与总平面布置: 裙楼和商业房利用第5标段已安装的8台塔吊进行上部结构施工,总部办公楼利用第5标段已安装的两台SCT293塔吊进行上部结构施工,117塔楼核心筒1-4夹层结构利用已安装ZSL270塔吊进行施工,然后在核心筒巨形柱外侧共安装6台大型动力塔吊,其中两台ZSL2700塔吊负责巨形柱,转换桁架,巨形斜撑大型机械设备等重型器械的吊装,两台ZSL1250塔吊和两台zsL380塔吊负责型钢梁,压型钢板幕墙板块等次构件的吊装,6台动力塔吊随核心筒巨形柱施工交替爬升,塔楼外框106层施工完成后用ZSL1250塔吊拆除ZSL2700塔吊,并用ZSL1250塔吊补装结构间后。用3号塔吊拆除6号塔吊,用4号塔吊拆除3号塔吊,用5号塔吊拆除4号塔吊,然后在屋面安装SDD20-15屋面吊拆除ZSL380塔吊,安装ZSL60屋面吊,拆除SDD20-15屋面吊,最后人工拆除ZSL60屋面吊,用施工电梯运送至地面。 施工电梯选型与布置: 117塔楼共设置9台便捷施工电梯,共16个梯笼。为施工人员和材料提供垂直运输,核心筒在4夹层安装顶升模架安装后在安装1号2号3号高速电梯,外框组合楼板施工至94层后再安装9号中速电梯与3号电梯接力。完成94层至屋顶层施工人员、材料运输,结构封顶后拆除核心筒内4部施工电梯。核心筒施工至30层,开始安装通道塔和4号5号高速施工电梯;核心筒施工至64层,开始安装6号7号8号高速施工电梯;在塔楼装上货梯与永久电梯形成对接后,再拆除施工电梯和通道塔,部分永久电梯提前运行计划,117塔楼施工后期,计划提前运行13部永久电梯,其中3部F1中区办公转换电梯,用于32层至93夹层人员运输,3部F2高区办公转换电梯,用于94层至屋顶人员中转运输,2部F3酒店区转换电梯,2部HH1酒店电梯及1部HH2餐厅电梯,用于94层至屋顶后期收尾。SL5,SL8办公中高区服务电梯,主要用于31层至93夹层后期收尾。 总平面规划: 施工现场总平面依据建筑计划安排、垂直运输和提前运营要求。结合现场条件,共分、管路敷设技术通过管线敷设技术,不仅可以解决吊顶层配置不规范问题,而且可保障各类管路习题到位。在管路敷设过程中,要加强看护关于管路高中资料试卷连接管口处理高中资料试卷弯扁度固定盒位置保护层防腐跨接地线弯曲半径标高等,要求技术交底。管线敷设技术中包含线槽、管架等多项方式,为解决高中语文电气课件中管壁薄、接口不严等问题,合理利用管线敷设技术。线缆敷设原则:在分线盒处,当不同电压回路交叉时,应采用金属隔板进行隔开处理;同一线槽内,强电回路须同时切断习题电源,线缆敷设完毕,要进行检查和检测处理。、电气课件中调试对全部高中资料试卷电气设备,在安装过程中以及安装结束后进行高中资料试卷调整试验;通电检查所有设备高中资料试卷相互作用与相互关系,根据生产工艺高中资料试卷要求,对电气设备进行空载与带负荷下高中资料试卷调控试验;对设备进行调整使其在正常工况下与过度工作下都可以正常工作;对于继电保护进行整核对定值,审核与校对图纸,编写复杂设备与装置高中资料试卷调试方案,编写重要设备高中资料试卷试验方案以及系统启动方案;对整套启动过程中高中资料试卷电气设备进行调试工作并且进行过关运行高中资料试卷技术指导。对于调试过程中高中资料试卷技术问题,作为调试人员,需要在事前掌握图纸资料、设备制造厂家出具高中资料试卷试验报告与相关技术资料,并且了解现场设备高中资料试卷布置情况与有关高中资料试卷电气系统接线等情况,然后根据规范与规程规定,制定设备调试高中资料试卷方案。 、电气设备调试高中资料试卷技术电力保护装置调试技术,电力保护高中资料试卷配置技术是指机组在进行继电保护高中资料试卷总体配置时,需要在最大限度内来确保机组高中资料试卷安全,并且尽可能地缩小故障高中资料试卷破坏范围,或者对某些异常高中资料试卷工况进行自动处理,尤其要避免错误高中资料试卷保护装置动作,并且拒绝动作,来避免不必要高中资料试卷突然停机。因此,电力高中资料试卷保护装置调试技术,要求电力保护装置做到准确灵活。对于差动保护装置高中资料试卷调试技术是指发电机一变压器组在发生内部故障时,需要进行外部电源高中资料试卷切除从而采用高中资料试卷主要保护装置。

138-张宏、田春雨等-天津117大厦振动台试验研究

天津高银117大厦模型振动台试验研究 张宏,田春雨,肖从真曹进哲郝伟李建赢 (中国建筑科学研究院,北京,100013) 提要:天津高银117 大厦地上共117 层,建筑高度597m,塔楼结构由钢筋混凝土核心筒,带有巨型支撑、巨型框架构成的周边结构,构成了多重抗侧力体系。为确认结构在地震作用下的安全性,对地上塔楼结构进行了模拟地震振动台试验。试验模型比例为1:40,主要采用微粒混凝土及黄铜制作。试验结果表明,结构可以满足规范的抗震设防要求,基本达到了设计要求的抗震性能目标,试验结果与原型结构的计算结果基本符合。在试验及分析结果基础上,对结构设计提出了改进意见与措施,进一步保证了结构的抗震安全性。试验为国内外类似的超高层建筑的结构抗震设计提供了参考。 关键词:超高层结构;振动台试验;抗震设计;天津高银117大厦 1工程概况 天津高银 117 大厦是一幢以甲级写 字楼为主,并且附有六星级豪华商务酒店 及相关设施的大型超高层建筑,总建筑面 积约 37 万平方米。塔楼高 597 米,大大 超过中国高层建筑设计规范限值,为超 B 级高度的建筑。塔楼地面以上 117 层,地 面以下 3 层。结构平面布局呈正方形,其 尺寸沿竖向逐渐内收,办公层平面边长由 65 米逐渐收进至 50 米,酒店则由 50 米 收进至 45 米。结构平面长宽比为 1:1, 钢筋混凝土核心筒位于结构正中,整体结 构布置规则、对称,无凹进。 本工程塔楼采用了多重结构抗侧力体 系,该体系由钢筋混凝土核心筒、带有巨 型支撑的巨型框架构成多道设防的结构体 系,提供必要的侧向刚度,共同抵抗水平 地震及风荷载。其中,巨型支撑筒和核心 筒占主要作用。塔楼结构存在高度超限、 加强层等超限内容,且抗震设防类别为乙 类,为了确保塔楼结构在地震作用下满足 规范要求,了解其结构特性和地震效应, 对地上塔楼结构进行模拟地震振动台试 验。 图1 建筑效果图图2 计算模型图3 振动台试验模型

117大楼工程概况(含周大福大楼)

天津117大厦以其597米的高度以及创下的一连串“国内第一”成为建筑业的焦点。该工程体量巨大、结构复杂,施工组织难度高、工期异常紧张。日前,地下室结构顺利封顶,四台“巨无霸”塔机已经正式上岗,整个工程全面进入地上施工阶段。按照计划117大厦将于2014年11月底32层以下将实现提前营业,届时,天津市民将提前走进这座令世界瞩目的世界摩天大楼。这座117层、总高度达到597米的大厦目前稳坐"亚洲第一高楼"位置。 “巨无霸”塔吊春节前就位 一台赫赫有名ZSL2700动臂塔机目前已矗立在由中建三局承建的天津高银117大厦项目建设现场,进行主塔楼钢结构的施工吊装。不过很快又将有1台同型号的“兄弟”以及两台稍小型号的“朋友”加入到主结构的吊装工作中。以确保年内现场内共有4台“巨无霸”塔吊参与主塔楼施工过程中原材料的运输和钢构件的吊装。117项目使用的ZSL2700塔机是全国第4台,华北地区第一台。据介绍,这种塔吊为动臂式、内燃机动力、全液压控制、无级调速的重型塔机,六节起重臂总长为60米,最大起重量100吨/2倍率,在最大起吊半径60米处,吊重为31.9吨。最大起升高度超过600米。

项目关键技术破解世界难题 承担钢结构施工的中建钢构项目负责人介绍说,天津高银117大厦工程钢结构体量大,施工难度大,现场焊缝和巨柱尺寸均为世界之最,超长超厚钢板剪力墙焊接量大,焊接变形难以控制。近日,经由中国工程院院士马克俭、外籍院士许溶烈等8名业内知名专家组成的鉴定委员会鉴定,项目采用的《超长超厚钢板剪力墙变形控制关键技术》、《超高层(300 米以上)钢框架-芯筒结构伸臂桁架施工关键技术》与《超高层空间网格结构三维递归匹配、动态纠偏技术》均达国际领先水平。解决了施工过程中的世界级难题,提高了施工效率,将确保项目工期如期完成。 32层以下主要为写字楼 高银金融117大厦是滨海高新区高银金融CBD中标志性建筑,计划于2014年11月底32层以下实现提前营业;2015年8月30日实现大厦主体结构封顶;2015年12月底,外幕墙封闭完成;预计2016年8月底全部施工完毕并投入使用。提前营业的部分功能主要以写字楼为主。记者了解,大厦92层以下为超甲级国际商务办公楼,93层以上为超五星级酒店,其中115层为空中高级会所,配有目前本市唯一的空中游泳池;116层为视野开阔的大型餐厅、117 层为可旋转的特色酒吧和咖啡厅,整体结构为一幢集甲级办公、酒店、旅游观光、精品商业于一体的特大型超高层摩天大楼。春节后,117大厦的主体建设将逐渐加速,最初阶段盖一层可能需要十几天的时间,但之后将有望缩短至一周一层。 游泳池建在597米顶层

中银117大厦

中国117大厦 中国117大厦位于天津高新区,地下3层,地上117层,总设计高度在570米以上,占地83万平方米,规划建筑面积183万平方米,预计投资270多亿元人民币。中国117大厦集高档商场、写字楼、商务公寓和六星级酒店于一身,建成后将是高新区乃至天津市极具代表性的标志性建筑。 117资料 【建设地点】:中国天津 【占地面积】:占地83万平方米 【建筑面积】:规划建筑面积183万平方米 【建筑造价】:预计投资270多亿元人民币 【建筑层数】:地下3层地上117层 【建筑高度】:597M 117概况 天津享有独特的经济和地理环境优势,已被国家定为北方经济中心。 目前,天津乃中国经济发展最快城市之一,滨海新区的规划令天津极具潜力成为继深圳及上海后,引领中国经济高银金融117走上第三波快速发展的火车头。未来,天津势必成为中国北方的金融中心,预期将有更多投资者于天津设立办事处,到天津旅游和工作的人数也会不断增加。这些都将带动当地对优质物业的需求。 「天津高银Metropolitan」(中国117大厦乃其地标建筑)将发展具备新核心商业区(CBD)及社区概念的大型项目。该核心商业区建成后,将拥有一幢建议楼高117层甲级办公大楼,并将成为天津市的中心地标。

该旗舰项目属于高档综合发展项目,总计划建筑面积约160万平方米,将发展国际中央商务中心、高档住宅项目、高级消费零售商业设施及国际级马球会。 天津高新区国家软件及服务外包产业基地综合配套服务区首个建设项目——中国117大厦(又名高银金融117)举行奠基仪式,标志着被列入天津市发展现代服务业20项重点工程之一的天津高新区国家软件及服务外包产业基地已全面进入建设阶段。中国117大厦地下3层,地上117层,总设计高度在600米以上,占地83万平方米,规划建筑面积183万平方米,预计投资270多亿元人民币,产业主导区已于今年10月开工建设。综合配套服务区由数幢企业总部大厦、金融服务中心、会展中心以及商业配套设施等建筑物组成,计划五年内建成,将实现产值超千亿元,安排就业10万人。 中国117大厦集高档商场、写字楼、商务公寓和六星级酒店于一身,建成后将是天津高新区一张亮丽的“城市名片”成为高新区乃至天津市极具代表性的标志性建筑。 项目主要分为三大范畴,包括中央商务区、高级豪华住宅及天津环亚国际马球会,分别占地约57.27公顷(572,700平方米)、49.46公顷(494,600平方米)及89.88公顷(898,800平方米)。各个区域均有全天候走廊连接,令出入更为方便。 中央商务区设有四大功能,包括商务及名店购物设施、文化娱乐、酒店会展及服务式公寓。 中央商务区包括项目中的标志性建筑及未来中国地标性建筑物──建议楼高约600米、共117层的高银金融117。高银金融117最高部份超过十层,将设有六星级商务酒店。

天津中国117大厦

天津中国117大厦 ? 天津高银117大厦从其设计之初到开工建设吸引了人们关注的目光,这栋建筑拥有10项工程之最:结构高度中国之最:597米,单体建筑面积中国之最:83万平方米,单 体建筑基坑土方开挖之最:200万立方米,民用建筑工程桩长度之最:117大楼工程桩桩长 为100米以上,民用建筑工程桩长细比之最:120,民用建筑工程水下浇注混凝土之最:C55 水下浇注,民用建筑工程桩钢筋规格之最:直径50毫米三级钢,底板C50大体积混凝土体 量最大:7万立方米,自密实砼强度之最:C70,钢结构巨型钢柱尺寸世界之最:24米*22.8 米。 基本信息 ?中文名称 天津高银117大厦 ?高度 570米 ?中国中国最新在建高楼排名 第五名 ?建筑面积 83万平方米 ?投资 180亿元 ?位置 天津滨海高新技术产业园区 ?获奖情况 争创国优工程奖、天津市建设工程“海河杯”奖、美国LEED白金认证和全国AAA级安全文明样板工地 ?亮点 攻克复杂地基施工难题,诞生多项新技术,项目关键技术破解世界难题,32层以下主要为写字楼,游泳池 建在597米顶层 目录 展开

1亚洲第一高楼 中国在建高楼排名第四——【中国最新在建高楼TOP.10】1、深圳平安国际金融大厦646米2、上海中心大厦632米3、武汉绿地中心606米4、天津罗斯洛克国际金融中心588米5、天津中国117大厦570米6、广州东塔539.2米7、天津周大福滨海中心530米8.防城港亚洲国际金融中心528米9、大连绿地中心518米9.台北101大厦509米(已成)、9、上海环球金融中心492米10、深圳华润总部大厦460米11、苏州国际金融中心450米) 2项目概况 117大厦由高银地产(天津)有限公司投资兴建,中建三局承建,总建筑面积为83万平方米,总投资为180亿元。其中,大厦塔楼地下4层,地上117层,建筑高度597米。工程位于天津滨海高新技术产业园区。工程自开工之初就确定了争创国优工程奖、天津市建设

天津高银117大厦超长超大直径锚栓群施工技术

2015年1月下第44卷第2期 施工技术 CONSTRUCTION TECHNOLOGY 9 DOI :10.7672/sgjs2015020009 天津高银117大厦超长超大直径锚栓群施工技术 * 陈志刚1,2, 叶建2 (1.武汉大学土木建筑工程学院,湖北武汉430072;2.中建三局集团有限公司工程总承包公司,湖北武汉430064) [摘要]随着钢板-混凝土组合剪力墙、钢管混凝土柱、型钢混凝土柱等构件形式愈加广泛地应用于超高层建筑结构中,上述构件与基础筏板连接时面临的超长超大直径锚栓群施工问题愈发突出。基于天津高银117大厦巨型钢柱及钢板-混凝土组合剪力墙底部超长超大直径锚栓群施工实际,通过模拟试验,分析得出大体积混凝土水化过程中混凝土自身应变对锚栓初始应力的影响在设计允许范围内;基于这一结果,将带套筒的锚栓优化为直埋式的锚栓,保证了施工质量,加快了工期;通过设置锚栓支撑架、分段分片吊装,保证了锚栓的精准定位以及固定的可靠性。通过上述研究,形成了大直径锚栓群定位技术、大直径锚栓群安装施工技术、大体积混凝土应变对超长大直径高强锚栓初始应力影响分析等超长超大直径锚栓群施工关键技术。[关键词]高层建筑;锚栓;初始应力;定位;吊装[中图分类号]TU758.11 [文献标识码]A [文章编号]1002- 8498(2015)02-0009-06Construction of Super-long and Super-large Diameter Anchor Bolts in Tianjin Gaoyin 117Building Chen Zhigang 1,2,Ye Jian 2 (1.School of Civil and Architectural Engineering ,Wuhan University ,Wuhan ,Hubei 430072,China ;2.General Construction Company of CCTEB Group Co.,Ltd.,Wuhan ,Hubei 430064,China ) Abstract :With the wider application of steel plate concrete shear wall ,concrete filled steel tubular column and steel reinforced concrete column in super high-rise building ,construction issues of super-long and super-large diameter anchor bolts are more prominent when the above members are connected to the foundation raft.Based on the construction practice of super-long and super-large diameter anchor bolts of the giant steel column and steel plate concrete shear wall of Tianjin Gaoyin 117Building ,it is concluded that the effect of the concrete strain on initial stress of anchor bolts is in design range through test analysis.According to the result above ,the anchor bolt with sleeve is optimized to the directly-embedded anchor bolt ,which increases the quality of the project and reduces the schedule ;positioning accuracy and fixation reliability of anchor bolt are assured by means of bracing frame and segmentation lifting of the anchor bolts.Based on the research above ,construction of super-long and super-large diameter anchor bolts is got ,which consists of technology of locating anchor bolt ,technology of hoisting anchor bolt ,analysis of the effect of mass concrete strain on initial stress of super-long and super-large diameter anchor bolts. Key words :tall buildings ;bolts ;initial stress ;location ;hoists *中建三局研发课题项目(CSCEC3B-2011-39) [作者简介]陈志刚,副总经理,高级工程师,E-mail :380827210@qq.com [收稿日期]2014-09-10 钢板-混凝土组合剪力墙(混凝土内包钢板和劲 性钢骨)、钢管混凝土柱、型钢混凝土柱等由于其优越的抗震及抗火性能而广泛用于超高层建筑结构中。我国结构设计中仅在钢管柱或劲性柱中设置 有锚栓,在剪力墙中设置钢板并预埋锚栓的,目前国内尚属初步使用阶段;在巨型柱锚栓应用方面,尚无直径超过50mm 、长度超过5m 的锚栓相关应用;对于长度、直径均特别大,锚栓数量多的超长超 大直径锚栓群施工,国内外尚无较全面的研究 [1-6] 。因此, 超长超大直径锚栓群定位及安装等施工技术难题亟待解决。 本文基于天津高银117大厦巨型柱及钢板剪力