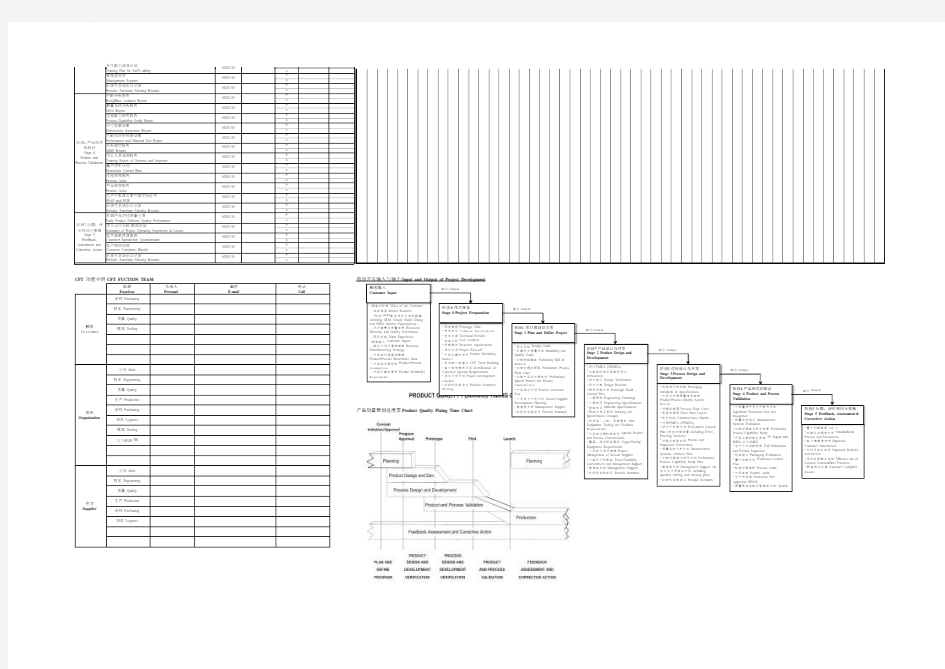

APQP项目管理进度表 APQP PROJECT MANAGEMENT TIMING CHART

APQP 项目管理进度表 APQP Project Management Timing Chart

车型年份:Model Year(s)项目名称:Program Name 供应商:Supplier 修订日期:Date Revised 项目经理:Project Manager

顾客及主机厂:Customer &OEM :

零件名:Part Name

供应商代码or 邓白氏号:Supplier Code or DUNS Number

制造地点:

Manufacturing Location

邮箱或电话:E-mail or Phone 项目停滞;项目运行超出计划;部分任务和问题未按时完成及关闭

Project Pending ;Project Running out schedule; Some task or open issue not completed and cloesd on time.

项目按计划运行;所有任务和问题都已完成及关闭

Project Running on schedule; All task and open issue completed and cloesd on time.

项目完成率:

绿色状态Green Status:红色状态Red Status:

A P A P A P A P A P A P A P A P A P A P A P A P A P A P A P A P A P A P A P A

CFT 功能小组 CFT FUCTION TEAM

项目开发输入与输出 Input and Output of Project Development

产品质量策划进度表 Product Quality Plaing Time Chart

顾客Customer

组织Organization

供方Supplier

生产 Production 采购 Purchasing 物流 Logistics

业务 Sales 技术 Engineering 质量 Quality

人力资源 HR

采购 Purchasing 物流 Logistics 模具 Tooling 技术 Engineering 质量 Quality 生产 Production

业务 Sales 质量 Quality

模具 Tooling

负责人Personal

电话Call

职能Funciton 采购 Purchasing 技术 Engineering 邮件E-mail

过程审核报告Process Audit 产品审核报告Product Audit

生产件批准及零件提交保证书PPAP and PSW

阶段性总结会议记录

Periodic Summary Meeting Records 早期产品交付质量业绩

Early Product Delivery Quality Performance 项目运行经验/教训总结

Summary of Project Operating Experience & Lesson 客户满意度调查表

Customer Satisfaction Questionnaire 客户抱怨处理

Customer Complaint Handle 阶段性总结会议记录

Periodic Summary Meeting Records

#DIV/0!#DIV/0!#DIV/0!

#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!#DIV/0!阶段5 反馈,评价和纠正措施

Stage 5Feedback,Assessment and Corrective Action

阶段4 产品和过

程验证Stage 4Product and Process Validation

员工能力培训计划

Training Plan for Staff's ability 管理者支持

Management Support 阶段性总结会议记录

Periodic Summary Meeting Records 产能分析报告

Run@Rate Analysis Report 测量系统分析报告MSA Report

过程能力研究报告

Process Capability Study Report 尺寸检查结果

Dimensions Inspection Report 性能和材料检查结果

Performance and Material Test Report 材料提交报告MDS Report

作业人员培训报告

Training Report of Operator and Inspector 量产控制计划

Production Control Plan ? 顾客的呼声Voice of the Customer -市场调查Market Research

(包含OEM 整车节点及市场期望including OEM Vehicle Build Timing and OEM Volume Expectations)-历史背景及质量信息Historical Warranty and Quality Information -团队经验Team Experience ? 顾客输入Customer Inputs

-商务计划及营销策略Business Plan/Marketing Strategy -产品和过程基础数据

Product/Process Benchmark Data -产品和过程设定Product/Process Assumptions

-产品可靠性需求Product Reliability Requiements

顾客输入

Customer Input

? 原型数据Prototype Data

? 技术规范Technical Specifications ? 技术评审Technical Review ? 成本分析Cost Analysis

? 资源需求Resource requirements ? 项目立项Project Kick-off

? 产品可靠性研究Product Reliability Studies

? 多功能小组建立CFT Team Building ? 客户特殊要求识别Identification of Customer Special Requirements

? 项目开发计划Project development schedule

? 阶段性总结会议Periodic Summary Meeting

阶段0 项目准备

Stage 0Project Preparation

? 设计目标Design Goals

? 可靠性及质量目标Reliability and Quality Goals

? 初始物料清单Preliminary Bill of Material

? 初始过程流程图Preliminary Process Flow Chart

? 初始产品及过程特性Preliminary Special Product and Process Characteristics

? 产品保证计划Product Assurance Plan

? 二次供方开发计划Second Supplier Development Planning

? 管理者支持Management Support ? 阶段性总结会议Periodic Summary

阶段1 项目策划及立项

Stage 1Plan and Define Project

? 设计FMEA (DFMEA)? 可制造性和可装配性设计DFM&DFA

? 设计验证Design Verification ? 设计评审Design Reviews

? 样件控制计划Prototype Build -Control Plan

? 工程图纸Engineering Drawings ? 工程规范Engineering Specifications ? 材料规范Material Specifications ? 图纸及规范更改Drawing and Specification Changes

? 新设备、工装、设施需求New Equipment, Tooling and Facilities Requirements

? 产品和过程特殊特性Special Product and Process Characteristics

? 量具、测试设备需求Gages/Testing Equipment Requirements ? 二次供方项目管理Project Management of Second Supplier ? 小组可行性承诺Team Feasibility Commitment and Management Support ? 管理者支持Management Support ? 阶段性总结会议Periodic Summary

阶段2 产品设计与开发

Stage 2 Product Design and Development

? 包装规范和规格Packaging Standards & Specifications ? 产品及过程质量体系审核Product/Process Quality System Review

? 过程流程图Process Flow Chart ? 场地布局图Floor Plan Layout ? 特性矩阵Characteristics Matrix ? 过程FMEA (PFMEA)

? 试生产控制计划Pre-Launch Control Plan (包含防错装置including Error-Proofing Devices)

? 过程及检验说明Process and Inspection Instructions

? 测量系统分析计划Measurement Systems Analysis Plan

? 初始过程能力研究计划Preliminary Process Capability Study Plan

? 管理者支持Management Support (包含作业人员培训计划including operator staffing and training plan)? 阶段性总结会议Periodic Summary

阶段3 过程设计与开发Stage 3Process Design and Development

? 小批量试产及生产能力评估Significant Production Run and Run@Rate

? 测量系统验证Measurement Systems Evaluation

? 初始过程能力研究结果Preliminary Process Capability Study

? 产品及材料验证报告PV Report and IMDS or CAMDS

? 全尺寸及功能检测Full Dimensions and Fuction Inspection

? 包装验证Packaging Evaluation ? 量产控制计划Production Control Plan

? 制造过程审核Process Audit ? 产品审核Product Audit ? 生产件批准Production Part Approval (PPAP)

? 质量策划总结及管理者支持Quality

阶段4 产品和过程验证

Stage 4 Product and Process Validation

? 量产初期管理GP-12

? 标准化流程和文件Standardized Process and Documents

? 客户满意度改进Improved Customer Satisfaction

? 交付及服务改进Improved Delivery and Service

? 项目经验教训总结Effective use of Lessons Learned/Best Practices

? 顾客抱怨处理Customer Complain Handle

阶段5 反馈,评价和纠正措施Stage 5 Feedback, Assessment & Corrective Action

输出Output

输出Output

输出Output

输出Output

输出Output

输出Output