The high strain mechanical response of the wet Kelvin model for open-cell foams

The high strain mechanical response of the wet

Kelvin model for open-cell foams

https://www.360docs.net/doc/e69286137.html,ls *

Metallurgy and Materials,University of Birmingham,Birmingham B152TT,UK

Received 22November 2005;received in revised form 11April 2006

Available online 22April 2006

Abstract

Surface Evolver software was used to create the three-dimensional geometry of a Kelvin open-cell foam,to simulate that of polyurethane ?exible foams.Finite Element Analysis (FEA)with 3D elements was used to model large compressive deformation in the [001]and [111]directions,using cyclic boundary conditions when necessary,treating the polyurethane as an elastic or elastic–plastic material.The predicted foam Young’s moduli in the [001]direction are double those of foams with uniform Plateau border cross-section edges,for the same foam density and material properties.For compres-sion in the [111]direction,the normalized Young’s modulus increases from 0.9to 1.1with foam relative density,and the predicted stress–strain relationship can have a plateau,even for a linearly-elastic polymer.As the foam density increases,the predicted e?ects of material plasticity become larger.For foam of relative density 0.028,edge-to-edge contact is pre-dicted to occur at a 66%strain for [111]direction compression.The foam is predicted to contract laterally when the [111]direction compressive strain exceeds 25%.

ó2006Elsevier Ltd.All rights reserved.

Keywords:Foam;FEA;Modelling;Compression

1.Introduction

Lord Kelvin (Thomson,1887)proposed a tetrakaidecahedral cell model for the structure of soap foams with equal-sized bubbles,for which he claimed the surface energy was a global minimum.Each cell consists of six square and eight hexagonal faces,and every edge has the same length.The edges meet at tetrahedral vertices,and the cell centres are on a body centred cubic (BCC)lattice.Dement’ev and Tarakanov (1970)were the ?rst to predict the stress–strain relationship for the large strain compression of a Kelvin foam in the [001]lattice direction,expressing their results in terms of elliptic integrals.The edges,taken to have a constant square cross-section,were assumed only to bend.

In 1997,two independent analyses of Kelvin open-cell foams assumed the cell edges were uniform cross-section Euler–Bernoulli beams,in which the e?ects of shear were ignored.The vertices were taken to be 0020-7683/$-see front matter ó2006Elsevier Ltd.All rights reserved.doi:10.1016/j.ijsolstr.2006.04.014

*Tel.:+441214145185;fax:+441214145232.

E-mail address:

https://www.360docs.net/doc/e69286137.html,ls@https://www.360docs.net/doc/e69286137.html,

International Journal of Solids and Structures 44(2007)

51–65

https://www.360docs.net/doc/e69286137.html,ls/International Journal of Solids and Structures44(2007)51–65

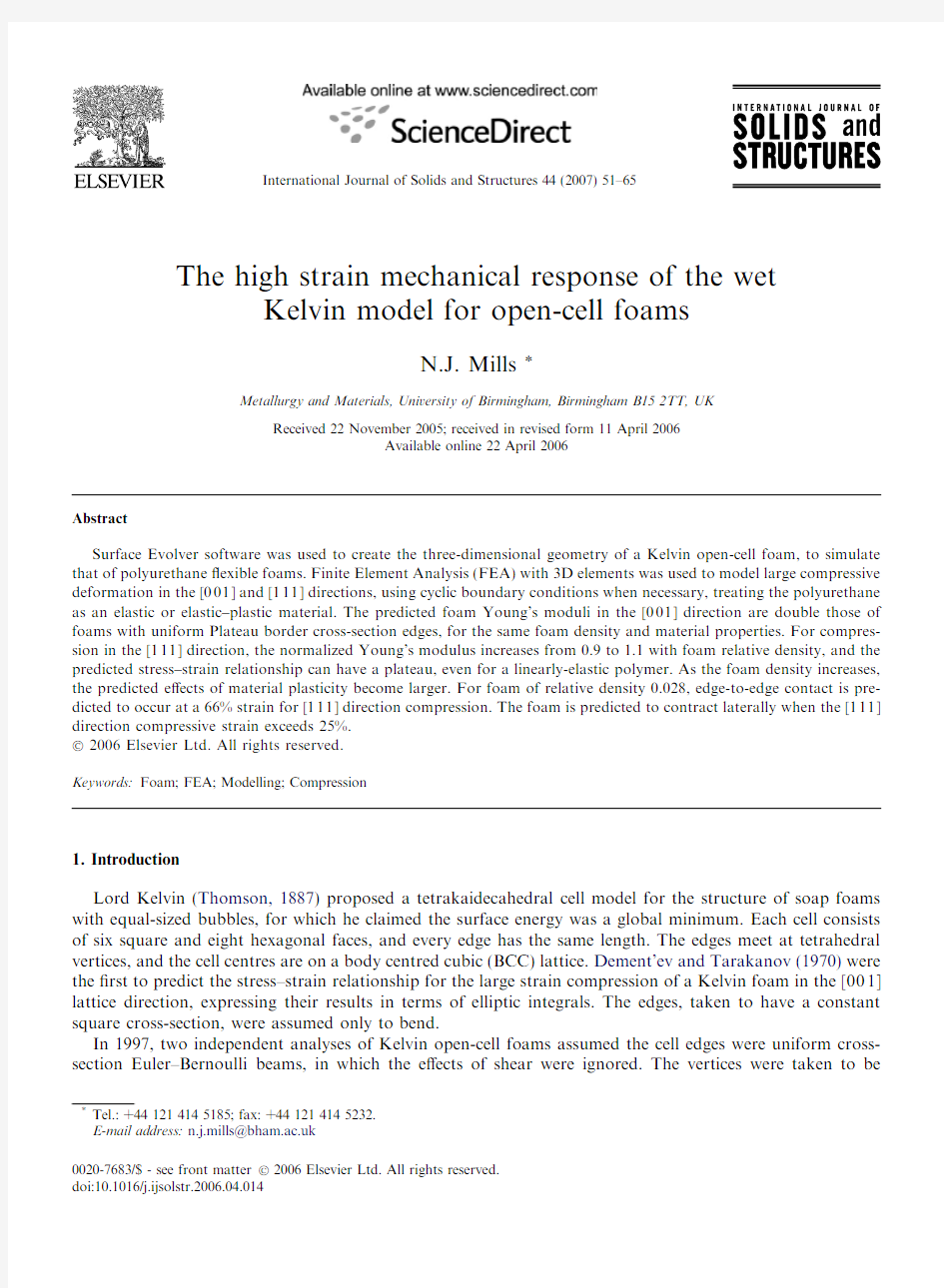

in?nitesimally-small and rigid.Hence the model geometry only approximates that of low-density?exible poly-urethane(PU)foams(Fig.1).Warren and Kraynik(1997)used matrix methods to consider the deformation of the unit cell of the Kelvin foam,and calculated the elastic moduli.They described edge deformation mech-anisms for compression in the[001]and[111]lattice directions,but neither showed detailed edge shapes,nor gave the compressive stress–strain relationships.Zhu et al.(1997a)con?rmed Dement’ev and Tarakanov’s analysis for compression in the[001]direction,and considered other edge cross-sections.For[111]direction compression,the equations for edge curvature and twist were solved numerically,and the edge shapes found.

A minor slip in the analysis was corrected by Mills and Gilchrist(2000),who considered the foam response in uniaxial tension.Their analysis will be referred to as the corrected Zhu model.Kraynik et al.(1999)con?rmed the[111]direction compressive stress–strain response using https://www.360docs.net/doc/e69286137.html,roussi et al.(2002)showed that multi-cell buckling modes,for[001]direction compression of the Kelvin foam,would cause a non-linear response;how-ever,they did not predict the shape of the compressive stress–strain curve.Gong and Kyriakides(2005)con-sidered representative unit cells containing2–20whole Kelvin cells in the[001]direction,1cell wide and1cell thick,with periodic boundary conditions.In general the cells were elongated in the rise direction,but they could be made isotropic.They used FEA with beam elements to represent Plateau border edges with non-uni-form cross-sections.They predicted for R=0.025,E P=69MPa,m=0.49(data for a polyester urethane foam)that collapse occurs by buckling when the normalized stress?0.15and the foam compressive strains ?0.2.At higher strains,the compressive stress was predicted to be nearly constant.Gong et al.(2005b)used a Bloch wave method to check the onset of instability in the Kelvin foam model.

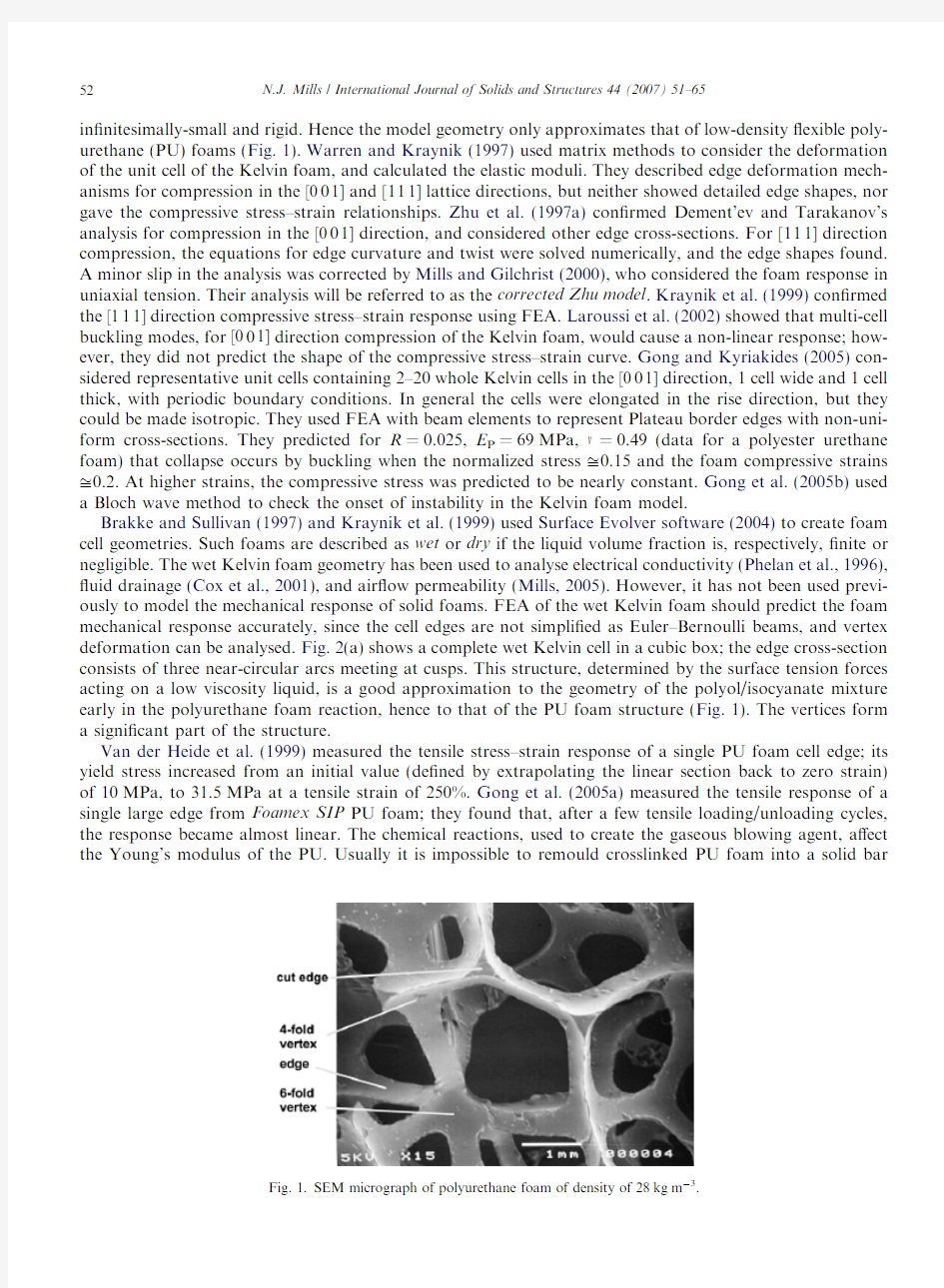

Brakke and Sullivan(1997)and Kraynik et al.(1999)used Surface Evolver software(2004)to create foam cell geometries.Such foams are described as wet or dry if the liquid volume fraction is,respectively,?nite or negligible.The wet Kelvin foam geometry has been used to analyse electrical conductivity(Phelan et al.,1996),?uid drainage(Cox et al.,2001),and air?ow permeability(Mills,2005).However,it has not been used previ-ously to model the mechanical response of solid foams.FEA of the wet Kelvin foam should predict the foam mechanical response accurately,since the cell edges are not simpli?ed as Euler–Bernoulli beams,and vertex deformation can be analysed.Fig.2(a)shows a complete wet Kelvin cell in a cubic box;the edge cross-section consists of three near-circular arcs meeting at cusps.This structure,determined by the surface tension forces acting on a low viscosity liquid,is a good approximation to the geometry of the polyol/isocyanate mixture early in the polyurethane foam reaction,hence to that of the PU foam structure(Fig.1).The vertices form a signi?cant part of the structure.

Van der Heide et al.(1999)measured the tensile stress–strain response of a single PU foam cell edge;its yield stress increased from an initial value(de?ned by extrapolating the linear section back to zero strain) of10MPa,to31.5MPa at a tensile strain of250%.Gong et al.(2005a)measured the tensile response of a single large edge from Foamex SIP PU foam;they found that,after a few tensile loading/unloading cycles, the response became almost linear.The chemical reactions,used to create the gaseous blowing agent,a?ect

bar

the Young’s modulus of the https://www.360docs.net/doc/e69286137.html,ually it is impossible to remould crosslinked PU foam into a solid Array Fig.1.SEM micrograph of polyurethane foam of density of28kg mà3.

for subsequent mechanical property tests.However,Van der Schuur et al.(2004)compression moulded polye-ther (urethane–urea)foams at 200°C into solid plaques and measured the in-phase shear modulus at 25°C;this increased from 9MPa at 26wt%urea content to 25MPa at 35wt%urea content.

Gibson and Ashby (1988)attributed the stress increase at high compressive strains to densi?cation (a con-fusing term,since foam density increases continuously on compression),and used an empirical expression to describe the shape of the stress–strain curve.Although Gong and Kyriakides (2005)used a contact spring approximation to model contact between beam-element edges and predicted the upturn in the stress–strain curve at high strains,to date FEA of solid element models has not been used for this purpose.

Gong et al.(2005a)?tted the measured variation in Plateau border widths,along the edges of PU open-cell foams,with a forth-order polynomial.They placed,on the framework of a Kelvin foam,Plateau border edges with a width distribution that followed their experimental data.They used FEA,with nine quadratic beam elements simulating each edge,to predict that the Young’s modulus in the [001]direction was 69%higher

than Fig.2.Wet Kelvin foam,generated using Surface Evolver,with RUC for [001]direction compression outlined:(a)complete cell with edge spread S =0.2;(b)partial cell with S =0.3showing the boundary conditions for [001]compression.

https://www.360docs.net/doc/e69286137.html,ls /International Journal of Solids and Structures 44(2007)51–6553

for uniform edge cross-sections,for foam with a 0.02relative density (and 74%higher at a 0.05relative den-sity).They also used a 3D solid element model;as the cusps of the edges were misaligned by about 5°(their Fig.13)where they meet at a vertex,they had to remove some material.This model predicted a E 00122%higher than the beam element model prediction,for a foam relative density of 0.04.

The e?ect of non-linear elasticity on the foam mechanics depends on the local strain distribution in the polymer,hence on the edge and vertex shapes,and the foam density.If the e?ect is signi?cant,it should be included in micromechanics modelling.However,the e?ects of cell size distribution and non-regular cell shapes cannot be investigated using the Kelvin foam.Zhu et al.(2002),using Voronoi constructions,predicted a fully-random foam with edges of constant Plateau border cross-section would have a normalized Young’s modulus E *about 50%larger than the corresponding regular Kelvin foam.E *is de?ned,in terms of the foam relative density R ,the polymer modulus E P and the foam modulus E F ,by

E ??E F

E P R e1T

However Gan et al.(2005),who made similar computations for edges with circular cross-sections,predicted no increase in Young’s modulus with foam irregularity.Therefore there is doubt about the e?ects of foam irregularity.

The FEA of wet Kelvin foams in this paper investigates the e?ects of

(a)edge thickness variation and vertex deformation on the foam Young’s modulus and large strain com-

pressive response;

(b)non-linear elasticity or plasticity on the high strain response;

(c)edge-to-edge contact on the high strain response.

1.1.Generation of wet Kelvin foam geometry using surface evolver

In the Surface Evolver ?le twointor .fe ,the diametral distance D ,between two square faces,of a dry Kelvin foam cell is taken as 1unit.Hence the edge length L =0.25p 2.12vertices,24edges,14triangular facets (a number of facets make up a planar face),and 2bodies are repeated in toroidal space,to create the dry Kelvin foam.A command ?le wetfoam .cmd is used to create an initial wet structure;an edge spread parameter S determines the width of the nearly-equilateral triangular section edges,which replace the line edges of the dry foam.The triangle has one edge of length S /2and two of length ????????3=4p S =2;two angles are 54.736°,half the inter-edge angle at an ideal tetrahedral vertex.The initial wet structure was used to validate the FEA against the corrected Zhu model.The wet structure is evolved ,increasing the number of triangular faces that approximate the shape of the curved air–liquid interface,then minimising the surface energy.The sequence of commands gogo in the wetfoam ?le was used once,giving a good approximation to the foam shape without creating an excessive number of faces.gogo consists of {g 5;r ;g 5;Hessian;r ;g 5;Hessian;Hessian},where

g 5?ve iteration steps in which the vertices are moved.

r re?ne the triangulation;edges are divided in two,and faces into four.

Hessian the second derivative matrix for energy is solved to ?nd the minimum energy.

Table 1

Parameters of evolved wet Kelvin foam cells (Cell diameter =1unit)

Edge spread S

Edge width at mid length Relative density R Hexagonal face hole diameter Square face hole diameter 0.1

0.05400.006910.5400.3360.2

0.10720.02760.4780.2630.3

0.17100.06220.4090.1810.35

0.20330.08460.3760.1400.40.23850.11050.3400.095

https://www.360docs.net/doc/e69286137.html,ls /International Journal of Solids and Structures 44(2007)51–65

https://www.360docs.net/doc/e69286137.html,ls/International Journal of Solids and Structures44(2007)51–6555 In the evolved structure,the in?nitesimally-thin,?at,two-sided faces(those not listed in the.fe?le as density=0.5)were removed from the.fe data?les,creating holes(Fig.2).The edge spread parameter S determines the hole size and the foam relative density R(Table1).If the square-face hole diameter were to reach0.3536,it would?ll the face.In commercial open-cell PU foams,R ranges from0.02to0.1.If S>0.4,the square faces remain wet after evolution(a fact noted by Phelan et al.,1995),so no holes occur in these faces.

2.Finite element analysis

2.1.Representative unit cell and boundary conditions for[001]direction compression

The representative unit cell(RUC)for the initial elastic response during[001]direction compression of the foam structure was a triangular prism,with90°and45°angles,height D/2,and shorter horizontal sides of length D/2(Fig.2(b)).The deformed prism is assumed to have mirror symmetry boundary conditions on its top,base and side surfaces(Zhu et al.,1997b);such conditions were applied in the FEA program ABAQUS 6.5(2005)to the polymer surfaces that lie in the top,base,and smaller side surfaces of the prism.The larger side-surface of the prism,at45°to the coordinate axes,cuts two foam edges at symmetrical positions.A cou-pling constraint is used,that these cut surfaces have the same normal displacement;this keeps them in the45°plane,while allowing them to move freely normal to that plane.

The toroidal space used by Surface Evolver is not understood by ABAQUS or computer aided design (CAD)programs,which use Euclidian geometry.Consequently the?le,which describes the geometry of the evolved wet Kelvin structure,was converted by interpreting the torus edge-wrap conditions to give the Euclidian coordinates of vertices connected by an edge to a vertex inside the prism.Javaview(2004)was used to convert the resulting.fe?le to a Wavefront.obj?le,then Rhinoceros(2002)CAD used to convert this to an ACIS.sat?le that could be read by ABAQUS CAE.The resulting surface was cut by the boundaries of the RUC to create the required solid part,that represents the polymer structure.

2.2.Representative unit cell and boundary conditions for[111]direction compression

The RUC for[111]direction compression is a prism with an equilateral triangle cross-section.A threefold screw axis runs along its axis.Zhu et al.(1997a)showed that the vertices move directly towards the screw axis by equal amounts,maintaining their120°angular separation when viewed along the screw axis.The angles between the boundary planes at the sides of the prism also remain constant.Modelling was performed for a complete repeat unit of the helix of edges,having‘cut’half-edges at each end.The deformed shapes of these half edges should be the same as those of intervening complete edges.This prism(Fig.3)has periodically repeating boundary conditions on the top and bottom surfaces,which contain n matching vertices.

ABAQUS does not have the option of link-meshed boundaries,on which periodic boundary conditions can be imposed.Nevertheless,Grenestedt and Tanaka(1999)used multi-point constraint equations to create peri-odic boundary conditions for a‘small deformation’problem,in which the initial geometry does not change signi?cantly.The ABAQUS manuals do not clarify whether,when the large deformation option is used, multi-point equations applied to boundary nodes will constrain the surfaces in the intended way.Therefore a trial-and-error was used to?nd the appropriate boundary conditions.If the results of the corrected Zhu model could be reproduced,this would validate the boundary conditions and multi-point constraints used in the FEA solid element model.

Periodic boundary conditions were achieved by using constraint equations,for each j from1to n,of the form

U1etop;jT?U1ebase;jTe2aTU2etop;jT?U2ebase;jT?0e2bTU3etop;jT?U3ebase;jTtU3eC0Te2cT

The displacements U 1U 2U 3are de?ned in a 123coordinate system ?xed in space;3is along the helix axis,1points from the centre of the cut top edge towards the helix axis,and 2lies in the nearest bounding rigid plane (Fig.3(b)).Eq.(2a)allows the corresponding nodes on the cut edge to move directly towards the axis of the helix,and (2b)prevents them from shifting laterally.Eq.(2c)controls the axial compression of the RUC;this is equal to U 3(C 0),the displacement of a dummy point C 0,which is ramped from 0to 1.It was found that imposing the condition U 2(top,j )=U 2(base,j )allowed the top and base cut-edge surfaces,as they tilted,to move laterally in the 2direction.However,the stricter boundary condition U 2(top,j )=U 2(base,j )=0produced the required deformation pattern.

A set of points C j (j =1,n ),not connected to the model,were given zero displacement.According to the ABAQUS manual,the constraint equation

U 3etop ;j TàU 3ebase ;j TàU 3eC 0TàU 3eC j T?0e3

T

Fig.3.Undeformed representative unit cells for [111]direction compression,for edge width S =0.2:(a)perspective view of initial foam,showing some boundary conditions;(b)end view and (c)side view of evolved foam.The cut edges at the sides of the RUC are labelled C1,etc.,while those at the ends are E1and E2.(b)shows the local 1,2axes used for periodic boundary conditions.

https://www.360docs.net/doc/e69286137.html,ls /International Journal of Solids and Structures 44(2007)51–65

which replaces Eq.(2c),allows the reaction force at end node j to be found as the reaction force on dummy point C j .Nodes were selected manually on both periodic cut foam-edges and labelled,and the Python script-ing language used to speed the entry of the constraint Eqs.(2a)and (3).

The boundary conditions on the cut lateral cell-edges were achieved by using frictionless contact (which cannot break if tension is applied)between the element faces and a discrete-rigid plane (Fig.3(b))at the appro-priate prism side surface.Three such planes have a single degree of freedom;to move (by equal amounts)directly towards the prism axis.

The resolved force F along [111],acting on the cut end,is equal to the sum,for the j end nodes,of the components along the lattice 1axis of the reaction forces on C j (the sum of the 2or 3axis force components has the same value).The cross-sectional area A of the prism is 0.5D 2/p 3,where D is the cell diameter.Hence the compressive engineering stress in the foam is F /A .The lateral strain in the foam is 6U 1,where U 1is the lattice 1direction displacement of the bounding rigid plane in Fig.3(b)that contacts edges B1and B2.The initial length of the RUC is p (3/4)D ,hence the compressive strain can be evaluated.

2.3.Elements and meshing

Initially a check was made,for a uniform cross-section Plateau border edge under torsion and bending,of the mesh size needed to obtain a reasonable approximation of the analytical solution.The torsional sti?ness had been evaluated by Warren et al.(1997)by solving a two-dimensional heat ?ow problem on the edge cross-section.This gave the edge torsional sti?ness as

GJ ?0:08025GA 2e4Twhere G is the polymer shear modulus,J the polar second moment of area and A the edge cross-sectional area.The edge bending sti?ness was given by

E P I ?0:1338E P A 2e5TTable 2shows the predicted bending and torsional sti?ness of an edge of length ?ve times the Plateau border width b ,as a function of the mesh size.

Consequently,to keep the errors <5%,10-node quadratic tetrahedral elements C3D10M were used (M indicates a modi?ed version for contact problems).At the cut-edge ends of the wet Kelvin model,the number of triangular element faces across the section were 20,21and 22for edge spreads S =0.1,0.2and 0.3,respec-tively.Consequently,FEA should calculate the wet Kelvin model sti?ness to within 5%.There were typically 3000–4000elements in the models.The slender beams of the S =0.1initial foam structure required a small mesh size,as elements,close to vertices,lie in a rapidly varying stress ?eld.The use of quadratic elements e?ec-tively places additional linear element nodes midway between the existing nodes;since these extra nodes are not constrained by Eqs.(2b)and (3),the end surfaces tended to bulge at these nodes when the foam strain is high.Although this e?ect can be overcome by entering further constraint equations for the new nodes,this caused the FEA to become unstable at a lower maximum foam strain.Consequently,the additional constraint equations were not used.By St Venant’s principle,the e?ects of the distortion of the cut end are minor else-where in the edge helix.

The bending and torsional sti?ness of the nearly-equilateral triangle section of the initial Kelvin structure were evaluated using the meshing conditions of the last row of Table 2.The torsional sti?ness constant in Eq.

(4)was 1.4%lower than for the equilateral triangle section,whereas the bending sti?ness constant in Eq.(5)Table 2

Bending and torsional sti?ness as a fraction of the analytical solutions

Element type

Seeds in edge width Triangles in cross-section Relative bending sti?ness Relative torsion sti?ness Linear

518 2.23 6.18Linear

1046 1.325 2.49Quadratic

518 1.100.954Quadratic 10460.979 1.023

https://www.360docs.net/doc/e69286137.html,ls /International Journal of Solids and Structures 44(2007)51–6557

was18.4%lower when the neutral surface was parallel to,and23%higher when perpendicular to,the longest edge.The edge bending sti?ness is consequently no longer isotropic.

To achieve matching node positions at the ends of the[111]direction representative cell(Fig.3(c)),the edge helix was considered to consist of four sections,taken perpendicular to the prism axis.Two central sections each contain a whole edge,while two half-sized end sections each contain a half edge from the helix.The latter were created by cutting a central section in half.Virtual topology was used,on each cusp surface,to merge all the faces that met the end of the model,prior to meshing,to avoid the creation of very small faces.The Plateau border edges,at the ends of the model,were given six equally spaced seeds.Consequently,after meshing with tetrahedral elements,the end faces of the model have matching node positions.Orphan meshes,created from the meshed end sections,were instanced at both ends of the model,then merged with those for the rest of the model.If the whole model was meshed in one go,its ends tended to have non-matching node positions.

The symmetric solver in ABAQUS6.5Standard was used with the large deformation option.Stabilisation by dissipated energy fraction was not used.The PU properties were taken either as

(a)elastic,with Young’s modulus E P=50MPa,Poisson’s ratio m=0.45.These are consistent with the

E P=55MPa and m=0.5determined by Zhu et al.(1997a),and fall in the range found by Van der

Schuur et al.(2004).

(b)elastic–plastic,adding an initial yield stress of10MPa,which rises linearly to31.5MPa at a strain of2.5

(Van der Heide et al.,1999).

3.FEA predictions

3.1.The initial Kelvin foam compared with the corrected Zhu model

FEA of the high strain deformation of the initial Kelvin foam,in both the[001]and[111]directions,was compared with the corrected Zhu model,to validate the FEA.Both models have constant edge cross-sections, the former nearly-equilateral triangle and the latter equilateral triangle.The corrected Zhu model,which allows for axial strain in the edges but not for the e?ects of shear or the volume of the vertices,predicts normalized stress(stress divided by E P R2)https://www.360docs.net/doc/e69286137.html,pressive strain relations that are independent of the relative density R.The normalized Young’s modulus is predicted to be0.760in the[001]direction and0.670in the [111]direction(at1%strain).If the nearly-equilateral sections of the initial Kelvin structure were used in the Zhu model,the normalized moduli would be slightly smaller.

The corrected Zhu model ignores the e?ect of the polymer Poisson’s ratio on the edge bending sti?ness E P I. Elsewhere in engineering,the bending sti?ness of wide,rectangular cross-section beams is E*I,where the plane-strain Young’s modulus E*=E P/(1àm2).However,for equilateral-triangle edge cross-sections,FEA predicts a foam modulus E001for an initial wet Kelvin foam with S=0.1,that is1.2%higher for m=0.45than it is for m=0.0.Hence the conditions in the edges are close to plane stress.For Plateau border edge sections (see later),the e?ect of using m=0.45rather than0.0is to increase the foam Young’s modulus by4.5%.

The FEA predictions(Table3)approach those of the corrected Zhu model,as the relative density is reduced below0.01.Under that condition,the errors in the Zhu model,due to ignoring the vertex volume and edge shear,become negligible.The normalized Young’s moduli are higher for S=0.2than for S=0.1,due to the larger vertices.As the corrected Zhu model ignores vertices,at a relative density of0.03 it overestimates the edge length,hence overestimating the edge bending compliance.The normalized stress Table3

Normalized foam Young’s moduli(at1%strain)for compression of initial Kelvin foam with nearly-equilateral triangle edges, E P=50MPa,polymer Poisson’s ratio=0.45(values for m=0in brackets)

Edge spread S Relative density R E?

001E?111

0.10.006910.802(0.792)0.60(0.60) 0.20.02760.906(0.832)0.67(0.65) https://www.360docs.net/doc/e69286137.html,ls/International Journal of Solids and Structures44(2007)51–65

vs.strain curve,predicted by FEA for the [001]direction compression of a model with S =0.1,is 10%higher,over the range up to 0.7strain,than that predicted by the corrected Zhu model.For [111]direction compres-sion,the predictions of the two models are close up to a strain of 0.4,but FEA predicts a larger negative cur-vature at higher strains,and a plateau region at a strain of 0.6if m =0.45(Fig.4).In general,the FEA con?rms the earlier analysis,if the foam relative density is very low.Conversely,the earlier analysis con?rms that the boundary conditions of the FEA are valid.

3.2.The wet Kelvin foam compressed in the [001]direction

The predicted compressive stress–strain relationship is nearly linear for strains <2%.When the normalized secant modulus (stress/strain)was plotted as a function of strain,it was found to be a linearly decreasing func-tion of strain,in this strain range.The normalized Young’s modulus E ?001extrapolated to zero strain (Table 4)is in the range 2.13to 2.22,except the lower value for S =0.1.The Zhu et al.(1997b)theory predicts a value of 1.007,for edges of uniform Plateau border cross-section,at a low relative density.The bending moment M is largest close to the vertices,where the second moment of area I of the evolved edge is also largest,while it is zero at the mid-edge where I is lowest.Hence the lower edge curvature in the wet Kelvin foam explains its

higher modulus E ?001compared with the Zhu et al.(1997b)model.The slope of the graph of E ?001vs.strain

(Table 4)decreases as the edge spread increases.

Fig.5(a)shows the edge shape for a wet foam with S =0.3,at a foam compressive strain of 18%,close to the strain at which long-wavelength buckling is predicted (Gong and Kyriakides,2005).There are two waves along the cusp that borders the hexagonal face;the cusp has buckled as the face diameter has decreased.This buckling,ignored in the corrected Zhu model,has little e?ect on the foam mechanical response since the thin cusp region contributes very little to the edge bending sti?ness.There is only minor non-linearity in

the Fig.4.Predicted normalized stress vs.[111]compressive strain,for the initial wet Kelvin foam calculated for S =0.1,compared with the corrected Zhu theory.

Table 4

Normalized foam Young’s moduli for [001]direction compression of wet Kelvin foam

Edge spread S

Relative density R E P R 2kPa Zero strain E ?001Slope d E ?001/d e 0.1

0.00691 2.389 1.73à3.50.2

0.027638.09 2.15à3.20.3

0.0622193.4 2.22à1.70.35

0.0846357.9 2.17à1.00.40.1105610.5 2.13à0.3

https://www.360docs.net/doc/e69286137.html,ls /International Journal of Solids and Structures 44(2007)51–6559

predicted compressive stress–strain relationship for a linearly-elastic material (Fig.6),the conclusion reached by Zhu et al.(1997a)using the constant cross-section Euler–Bernouilli beam model.The relationship above a compressive strain of 0.2is only of academic interest,given that long-wavelength buckling allows a lower energy deformation mode.

3.3.The wet Kelvin foam compressed in the [111]direction

When the undeformed helix of edges is viewed down the cube [111]axis,there is only a clear view between the edges for models with S <0.3.Axial compression of the edge helix is related to the axial compression of a helical spring,for which the torque is constant along the length.As the torque on the foam edges is nearly constant along their length,and the torsional sti?ness is proportional to the 4th power of the edge width,edge width variations in the wet Kelvin model reduce the mean torsional sti?ness of the edge,hence the [111]axis compressive sti?ness of the edge helix ‘spring’.The normalized Young’s moduli in the [111]direction E ?001for evolved wet Kelvin foams are close to 1.0(Table 5).The increase with S suggests that edge torsion

becomes

Fig.5.The buckled cusp of the edges surrounding the hexagonal face of a wet Kelvin foam with S =0.3at a foam compressive strain of 18%in the [001]direction,with contours of von Mises stress in

MPa.

Fig.6.Predicted stress–strain relationship for [001]direction compression of evolved wet Kelvin foam with S =0.2.

https://www.360docs.net/doc/e69286137.html,ls /International Journal of Solids and Structures 44(2007)51–65

less important,and edge bending and axial compression more important,as S increases.At relative densities of 0.07or greater,the foam geometry is no longer similar to a network of slender beams;the edge beams are short and stubby while the vertices are huge.

Signi?cant non-linearity is predicted in the compressive stress–strain response in the [111]direction.There are plateaus in the normalized stress https://www.360docs.net/doc/e69286137.html,pressive strain curves;such a plateau was not predicted by Zhu et al.(1997a).For the S =0.1model the response for elastic and elastic–plastic materials are the same.In the S =0.2model,material plasticity a?ects the response at foam strains >0.3(Fig.7),and in the S =0.3model,at foam strains >0.2.The yield strain in the material model is 20%,and the peak material s train is lower than the foam strain.FEA predicts that yielding initiates at the mid-length of edges,on one of the cusps.Therefore FEA for elastic materials predicts that the stress–strain non-linearity changes slightly with foam density,whereas the corrected Zhu model predicts density independence.The e?ects of material plasticity also become greater as the foam density increases.The small e?ect of S on the shape of the normalized stress–strain graph shows that the edge length to width ratio is relatively unimportant.

Fig.8(a)and (b)compares end views of the helix of edges at compressive strains of 0%and 50%for S =0.1.The diameter of the ‘hole’along the axis of the helix enlarges when the foam is deformed.This increases the torque on the vertices for a given axial load on the RUC.Edge torsion is visible when the foam strain is 50%.The oblique view at a 66%compressive strain (Fig.8(c))shows a very small gap between an edge cusp and an edge,as touching is about to occur in an S =0.2model.Modelling at higher strains necessitates consideration of contact between edges,which is not easy for the orphan meshes used in the model.

The lateral strain is predicted to be a maximum of about 6%when the compressive strain is in the range 23–26%(Fig.9and Table 5).This phenomenon was also predicted by the Euler–Bernoulli beam model of Zhu et al.(1997a).

Table 5

Data for [111]direction compression of wet Kelvin foam

Edge

spread S

Relative density R Normalized Young’s modulus E ?111Normalized stress at e =0.4elastic (elastic–plastic)kPa Contracts laterally when e >0.1

0.006910.880.106(0.106)0.250.2

0.0276 1.000.095(0.093)0.230.30.0622 1.090.114(0.102)

0.26

https://www.360docs.net/doc/e69286137.html,pressive normalized stress–strain responses of the wet Kelvin foam in the [111]direction.Where pairs of curves diverge,the lower one is for an elastic-plastic material.

https://www.360docs.net/doc/e69286137.html,ls /International Journal of Solids and Structures 44(2007)51–65

61

4.Discussion

The wet Kelvin model,with S in the range 0.2–0.3,simulates many of the geometric features of commercial ?exible PU open-cell foams.If a large number of re?ning steps are used with Surface Evolver,the foam geom-etry can be predicted with considerable accuracy.However,to keep the number of elements reasonable for FEA,and to make the imposition of periodic boundary conditions easy,the initial structure was only re?ned three times.Consequently,the edge width increases in a bi-linear fashion,from the mid-edge to the point where two edges join.Nevertheless,the e?ects of further geometry re?nement on the predicted foam mechan-ical properties are unlikely to be large.

The normalized Young’s modulus E *,predicted by Warren et al.(1997)and Zhu et al.(1997b),conve-niently con?rmed the value of approximately 1estimated by Gibson and Ashby (1988)from data for open-cell polymer foams.However the latter had no experimental data for the Young’s modulus of PU from foams,so the E *values for the PU foams must be in doubt.The experimental data for other polymer foams was extre-mely scattered;data was included for polystyrene and polyethylene foams,which were not available in open-cell form in the 1980s.Consequently the error bounds on their estimate must be large.The FEA in this paper shows,for evolved wet Kelvin foams,E ?001is in the range 2.1–2.2(except for S =0.1with the unrealistically

low R ),but E ?111ranges from 0.9to 1.1.E ?001appears to be independent of density for the wet Kelvin foam

(Table 4),whereas it increases with density for the initial wet foam (Table 3).The geometry of the

former

Fig.8.Kelvin wet foam with S =0.1compressed in the [111]direction:(a)initial end view,(b)end view at strain =41.5%,showing the expansion of the central ‘hole’,with von Mises stress contours in MPa,(c)oblique view of S =0.2model,with [111]axis vertical,showing cusp-to-edge contact at foam strain =66%.

https://www.360docs.net/doc/e69286137.html,ls /International Journal of Solids and Structures 44(2007)51–65

model is more appropriate to real PU foams.The signi?cant increase in E ?001,compared both with the analysis of Zhu et al.(1997b)and FEA of the initial wet foam,shows the sti?ening e?ect of the wet foam geometry compared with uniform edge cross-section models.Gong et al.(2005a),using an approximate vertex geometry and beam element models,predicted E ?001?1:7.Although they do not emphasise it,their limited 3D element FEA suggests E ?001?2:07at R =0.04,in agreement with the predictions of this paper.It is di?cult to make accurate comparisons of the E ?001predicted here by FEA with their analytical expressions for beam element models,due to uncertainties in ?tting the wet Kelvin foam geometry with a polynomial function for Plateau border width variation,calculating averages of edge width,and allowing for the vertex volume.

The elastic anisotropy factor A *of materials with cubic symmetry is de?ned as the ratio of the shear mod-ulus in the cube axes to that in the (110)[110]axes;it is 1.0for isotropic materials.Zhu et al.(1997b)showed,for the initial Kelvin foam model with Euler–Bernoulli beam edges and polymer Poisson’s ratio m =0.5A ??325EI tGJ 8EI tGJ

e6TFor the Plateau border cross-section and m =0.5,EI =5.002GJ ,and the foam is nearly isotropic with A *=0.91.For the wet Kelvin foam studied here,the anisotropy factor is considerably larger than 1.

The stress–strain non-linearity for [001]direction compression,predicted by FEA,is similar to that of the Euler–Bernouilli beam-element model using the same small representative unit cell.A small RUC is not appro-priate for large compression analysis in the [001]direction,since it cannot simulate long wavelength buckling.However,FEA predicts more non-linearity and a stress plateau for [111]direction compression.The wet Kelvin model,with realistic foam geometry and deformation mechanisms,is a better explanation of the com-monly-observed near-plateau in the compressive responses of polyurethane open-cell foams than the geomet-rically incorrect model of Gibson and Ashby (1988),which relies on the axial buckling of edges that are parallel to the applied stress direction.Furthermore,parameters such as the Young’s modulus and collapse stress are now predicted quantitatively either by the analysis given here,or by that of Gong et al.In contrast Gibson and Ashby needed to estimate the constants of proportionality from experimental data.Their value of 0.05in the collapse stress relationship appears,from the FEA performed here,to be too small by a factor of two.

The normalized stress plateau of 0.1,predicted for [111]direction compression by FEA,is smaller than the 0.15value predicted by Gong and Kyriakides (2005)for [001]direction compression by using beam elements.However,they state that,for an anisotropic cell shape,the use of 3D elements gave a collapse stress 30%lower than with beam elements.As relatively little elastic energy is stored in [111]compression,it is unlikely that

a Fig.9.Predicted lateral strain vs.[111]compressive strain for wet Kelvin foams with S values shown.

https://www.360docs.net/doc/e69286137.html,ls /International Journal of Solids and Structures 44(2007)51–6563

https://www.360docs.net/doc/e69286137.html,ls/International Journal of Solids and Structures44(2007)51–65

larger RUC will undergo long-wavelength buckling.Beam elements are more suited than3D elements to the analysis of large RUCs,due to the smaller number of elements,and the easier imposition of periodic boundary conditions.However,beam-element models neglect the deformation of cell vertices(even if the vertex volumes are considered when relating the foam relative density to the edge width)so tend to be in error at foam relative densities>0.02.It is likely that3D elements will eventually be used with the wet Kelvin foam or similar real-istic foam geometry and large RUCs to con?rm the long wavelength buckling response in[001]direction com-pression.The previous use of beam-element models to predict such buckling was necessitated by computing limitations;the use of3D elements should just re?ne the values of the collapse stresses.

It seems that material non-linearity(measured for the?rst loading of a single PU foam edge by Van der Heide et al.)plays little part in the compressive response of PU foams with relative densities R?0.02.Con-sequently the non-linearity of the foam response is mainly due to geometry changes on compression.However, at higher relative densities,material non-linearity plays an increasing part in the foam non-linearity.Edge-to-edge contact is not important in a wet Kelvin foam of relative density up to0.03,for strains<65%,for defor-mation along the[111]direction.Therefore hardening,at strains>0.3in the compressive stress–strain curve, should not automatically be attributed to edge-to-edge contact.

The Kelvin foam model has been successively re?ned,from the initial beam element models of constant edge cross-section,through the consideration of edge shear and long-wavelength buckling in[001]direction compression,to the consideration of non-uniform edge sections.For the latter,FEA predictions using3D ele-ments di?er from those of models using beam elements.The former should be used for FEA modelling of material non-linearity and viscoelasticity,phenomena that occur in polyurethane foams.

Cell size variation and cell shape irregularity could not be considered in the Kelvin model in which each RUC responds identically.In real foams,with a range of cell sizes,edge-to-edge contact phenomena will be more complex.Strain inhomogeneity is also likely to occur given the predicted slight stress drop in the [111]direction compressive response(Fig.7).In a larger model,once the average compressive strain exceeds about0.3(point A)a strain of about0.8(point B)will develop in one region,then this region will propagate through the foam.Consequently,a plateau in the stress vs.mean strain response is likely.There is experimen-tal evidence for inhomogeneous compression in some,but not for the majority of,PU foams.

Acknowledgements

To K.Braake for a copy of the wetfoam.cmd?le,for use with Surface Evolver.

To J.Grenestadt for a preprint on the use of periodic boundaries in ABAQUS.

To referees for helpful comments.

References

ABAQUS6.5,https://www.360docs.net/doc/e69286137.html,er’s manual(especially vol.3,Section20.2.1Linear Constraint Equations)Hibbitt,Karlsson and Sorensen Inc. Brakke,K.A.,Sullivan,J.M.,https://www.360docs.net/doc/e69286137.html,ing symmetry features of the Surface Evolver to study foams.In:Polthier,K.,Hege,H.C.(Eds.), Mathematics and Visualisation.Springer-Verlag,Berlin.

Cox,S.J.,Bradley,G.,Hutzler,S.,Weaire,D.,2001.Vertex corrections in the theory of foam drainage.J.Phys.:Condens.Matter13, 4863–4869.

Dement’ev,A.G.,Tarakanov,O.G.,1970.E?ect of cellular structure on the mechanical properties of plastic foams.Polym.Mech.6, 519–525.

Gan,Y.X.,Chen,C.,Shen,Y.P.,2005.Three-dimensional modelling of the mechanical property of linearly elastic open cell foams.Int.J.

Solids Struct.42,6628–6642.

Gibson,L.J.,Ashby,M.F.,1988.Cellular Solids.Pergamon,Oxford.

Gong,L.,Kyriakides,S.,https://www.360docs.net/doc/e69286137.html,pressive response of open-cell foams,Part2Initiation and evolution of crushing.Int.J.Solids Struct.

42,1381–1399.

Gong,L.,Kyriakides,S.,Jang,W.Y.,https://www.360docs.net/doc/e69286137.html,pressive response of open-cell foams,Part1Morphology and elastic properties.Int.J.

Solids Struct.42,1355.

Gong,L.,Kyriakides,S.,Triantafyllidis,N.,2005b.On the stability of Kelvin cell foams under compressive loads.J.Mech.Phys.Solids 53,771–794.

Grenestedt,J.L.,Tanaka,K.,1999.In?uence of cell shape variations on elastic sti?ness of closed cell cellular solids.Scripta Mater.40, 71–77.

Javaview,2004.Available from:

https://www.360docs.net/doc/e69286137.html,ls/International Journal of Solids and Structures44(2007)51–6565 Kraynik,A.M.,Neilsen,M.K.,Reinelt,D.A.,Warren,W.E.,1999.Foam micromechanics.In:Sadoc,J.,Rivier,N.(Eds.),Foams and Emulsions.Kluwer,pp.259–286.

Laroussi,M.,Sab,K.,Alaoui,A.,2002.Foam mechanics:nonlinear response of an elastic3D-periodic microstructure.Int.J.Solids Struct.39,3599–3623.

Mills,N.J.,2005.The wet Kelvin model for air?ow through polyurethane open-cell foams.J.Mater.Sci.40,5845–5851.

Mills,N.J.,Gilchrist,A.,2000.The high strain extension of open cell foams.J.Eng.Mater.Technol.,ASME122,67–73.

Phelan,R.,Weaire,D.,et al.,1996.The conductivity of a foam.J.Phys.:Condens.Matter8,L475–L482.

Phelan,R.,Weaire,D.,Brakke,K.,https://www.360docs.net/doc/e69286137.html,putation of equilibrium foam structures using the surface evolver.Exp.Math.4,181–191. Rhinoceros,nurbs modelling for Windows,2002.From Robert McNeel&Associates,Seattle.

Surface Evolver,2004.Available from:.

Thomson,W.,1887.On the division of space with minimum partitional area.Philos.Mag.24,503,reproduced in.In:Weaire,D.(Ed.), The Kelvin Problem.Taylor and Francis.

Van der Heide,E.,van Asselen,O.L.J.,Ingenbleek,G.W.H.,et al.,1999.Tensile deformation behaviour of the polymer phase of?exible polyurethane foams and polyurethane elastomers.Macromol.Symp.147,127–137.

Van der Schuur,M.,van der Heide,E.,et al.,2004.Elastic behaviour of?exible polyether(urethane–urea)foam materials.Polymer45, 2721–2727.

Warren,W.E.,Kraynik,A.M.,1997.Linear elastic behaviour of a low-density Kelvin foam with open cells.ASME J.Appl.Mech.64, 787–794.

Warren,W.E.,Neilsen,M.K.,Kraynik,A.M.,1997.Torsional rigidity of a Plateau https://www.360docs.net/doc/e69286137.html,mun.24,667–672.

Zhu,H.X.,Mills,N.J.,Knott,J.F.,1997a.Analysis of the high strain compression of open-cell foams.J.Mech.Phys.Solids45, 1875–1904.

Zhu,H.X.,Knott,J.F.,Mills,N.J.,1997b.Analysis of the elastic constants of open cell foams having tetrakaidecahedral cells.J.Mech.

Phys.Solids45,319–343.

Zhu,H.X.,Hobdell,J.R.,Windle,A.,2002.E?ects of cell irregularity on the elastic properties of open-cell foams.Acta Mater.48, 4893–4900.

工作总结格式要求及范文

工作总结格式要求及范文 通常个人工作总结主要是对已做过的工作进行回顾、分析,并提到理论的高度,肯定已取得的成绩,指出应汲取的教训,以便今后做得更好些。下面由出国留学网小编为大家介绍工作总结格式要求及范文,仅供参考。 一、工作总结电子版格式要求 1、页面设置:A4 纵向 页码位置:下居中 页边距:上2厘米;下1.5厘米、左2.5厘米、右2厘米 2、字体、字号 标题:20xx年工作总结 部门人员:综合部***** 正文:宋体,四号,行距1.5倍,字距:默认 正文中标题:最多分三级,分级编号统一如下: 第一级:一、XXXXXXXXX 比如:一、出国留学网 第二级:1、XXXXXXX 比如:1、出国留学网 第三级:XXX 比如:出国留学网 二、工作总结手写版格式要求 标题:20xx年工作总结 正文: 署名及时间:写上自己的名字与写作时间 三、工作总结内容要求:

、20xx年度工作总结 1、请把你对自己所处的部门及工作岗位的理解,描述出来; 2、针对自己的工作岗位,请总结一下xx年度的工作,包括个人工作方法、工作态度、执行能力、沟通能力、学习能力、合作能力、团队建设、计划管理、组织协调能力、应变能力、开拓创新能力、工作效率等方面; 3、请大致对自己20xx年度的工作情况给予评定,包括个人取得了什么工作成绩和工作中得到哪些经验。 4、针对没有完成的指标和未按时完成的工作任务以及工作中的不足进行分析,要详细写出个人主要因素和外部主要因素。 、20xx年度工作计划 1、请结合你说出的部门和岗位,描述一下你对公司xy年度的发展方向、主要业务内容的理解; 2、请给出个人在20xx年的工作计划; 3、针对20xx年度,提出个人的发展愿望和提高计划; 、对公司的意见及建议 结合公司的发展方向和主要业务内容,提出您个人的看法和建议。内容可以是公司的发展方向、产品规划、销售、运营、管理等方方面面;如何改进团队管理方面也可以提出改进意见 范文精选:

个人年度总结的写作要求

个人年度总结的写作要求 个人年度总结对自身的发展带来的作用很强,那要如何正确、较好地把自己的年度总结写好呢? 首先,我们要清楚知道个人年终总结所包含的内容有哪些? 1)总结必须有情况的概述和叙述,有的比较简单,有的比较详细。这部分内容主要是对工作的主客观条件、有利和不利条件以及工作的环境和基础等进行分析。 2)成绩和缺点。这是总结的中心。总结的目的就是要肯定成绩,找出缺点。成绩有哪些,有多大,表现在哪些方面,是怎样取得的;缺点有多少,表现在哪些方面,是什么性质的,怎样产生的,都应讲清楚。 3)经验和教训。做过一件事,总会有经验和教训。为便于今后的工作,须对以往工作的经验和教训进行分析,研究,概括,集中,并上升到理论的高度来认识。 4)今后的打算。根据今后的工作任务和要求,吸取前一年工作的经验和教训,明确努力方向,提出改进措施等。 中间赘述业绩的段落中,不时要有“收到了很好的效果”、“受到了领导职工的好评和欢迎”、“迈上了一个新高度”、“又上了一个新台阶”等肯定性话语-- 如今是数字时代,故数据是多多益善,比如“业务增长率”、“顾客投诉减少率”、“接待了多少来访者”、“节约了

多少开支”、“义务加班多少次”、“平均每天接电话多少个”、“平均每年有多少天在外出差”、“累计写材料多少页”等等。 用好序列号序列号的最大好处是可以一句话拆成好几句说,还能几个字或半句当一句,在纸面上大量留白,拉长篇幅的同时,使总结显得很有条理。需要注意的是,一定要层层排序,严格按照隶属关系,不要给领导留下思路不清晰的印象撰写忌讳: “年终总结”切勿脱离实际,唱高调,拣好听的说,必须有一说一,有二说二,客观地评说,总的来说,这“年终总结”一定要杜绝“三忌”。 一忌夸夸其谈,夸大其词。 干了哪些工作,上级部门知晓,老百姓的心里也有数,自己也应如实汇报。干得好,群体心里有杆秤,自然能秤出其分量,干得好,要总结经验话得失。总之“有则改之,无则加勉”,切不要夸大政绩,欺上瞒下。 二忌避重就轻。 一些部门、单位在年终总结时往往“好大喜功”,对成绩大肆渲染,小事说成大事,芝麻说成了西瓜,摆功臣,讲苦功,好事说了一大堆,好话说了一大箩。而在总结过失和不足时,总是轻描淡写,几句话一带而过,有的甚至“大事化小,小事化

工作总结要求格式及范文_工作总结写作指导

工作总结要求格式及范文_工作总结写作指导 工作总结要求格式及范文s("fzoom");发布时间:2019-04-16s("hzh0");s("hzh1");s("hzh2");工作总结是做好各项工作的重要环节,通过它可以全面地,系统地了解以往的工作情况,可以明确下一步工作的方向。那么,这个工作总结格式是怎么样的,有什么要求呢?下面是工作总结要求格式及范文,欢迎阅读。更多资讯请继续关注工作总结格式栏目! 一、总结概论 总结是应用写作的一种,是对已经做过的工作进行理性的思考。它要回顾的是过去做了些什么,如何做的,做得怎么样。总结与计划是相辅相成的,要以工作计划为依据,订计划总是在总结经验的基础上进行的。其间有一条规律,就是:计划——实践——总结——再计划——再实践——再总结。 一、工作总结有如下特点: 1.自我性 总结是对自身社会实践进行回顾的产物,它以自身工作实践为材料,采用的是第一人称写法,其中的成绩、做法、经验、教训等,都有自指性的特征。 2.回顾性 这一点总结与计划正好相反。计划是预想未来,对将要开展的工作进行安排。总结是回顾过去,对前一段的工作进行检验,但目的还是为了做好下一段的工作。所以总结和计划这两种文体的关系是十分密切的,一方面,计划是总结的标准和依据,另一方面,总结又是制定下一步工作计划的重要参考。 3.客观性 总结是对前段社会实践活动进行全面回顾、检查的文种,这决定了总结有很强的客观性特征。它是以自身的实践活动为依据的,所列举的事例和数据都必须完全可靠,确凿无误,任何夸大、缩小、随意杜撰、歪曲事实的做法都会使总结失去应有的价值。 4.经验性 总结还必须从理论的高度概括经验教训。凡是正确的实践活动,总会产生物质和精神两个方面的成果。作为精神成果的经验教训,从某种意义上说,比物质成果更宝贵,因为它对今后的社会实践有着重要的指导作用。这一特性要求总结必须按照实践是检验真理的唯一标准的原则,去正确地反映客观事物的本来面目,找出正反两方面的经验,得出规律性认识,这样才能达到总结的目的。 二、工作总结的种类: 1、按总结的时间分,有年度总结、半年总结、季度总结、学期总结。进行某项重大任务时,还要分期总结或叫阶段总结。 2、按总结的范围分,有单位总结、个人总结、综合性总结、专题总结等。 3、按总结的性质分,有工作、生产、教学、科研、实习总结等。 三、总结撰写前的准备 有人说过:在应用写作中,要想总结写得好,必须总结作得好;要总结作得好,必须工作做得好,立场观点对头。这应该是写总结的经验之谈。好的总结是在做好总结工作的基础上写出来的,更是人民群众在实际中干出来的。在现实生活中,有的单位干得不怎么样,但总结时却“喷香水”,这对本单位的工作失去实际意义,不应该提倡。也有的单位工作有成绩却形成不了典型经验,这种情况说明总结工作没做好。上述两种情况都是应该避免的。搞好总结,是企业管理的一项重要工作,是增强干部、职工凝聚力的一种重要手段,需要认真对待。 总结究竟应该怎样做呢?从总体上说要发动群众,自下而上做总结。工作是群众做的,总结也应该由他们来做。不应撇开群众凑集政绩,绞尽脑汁制作观点。总结过程中能量化的

个人总结的写作要点

( 工作总结) 单位:____________________ 姓名:____________________ 日期:____________________ 编号:YB-BH-021752 个人总结的写作要点Writing points of personal summary

个人总结的写作要点 个人总结的写作要点 1.基本情况 这是对自身情况和形势背景的简略介绍。自身情况包括单位名称、工作性质、基本建制、人员数量、主要工作任务等;形势背景包括国内外形势、有关政策、指导思想等。 2.成绩和做法 工作取得了哪些主要成绩,采取了哪些方法、措施,收到了什么效果等,这些是工作的主要内容,需要较多事实和数据。 3.经验和教训 通过对实践过程进行认真的分析,找出经验教训,发现规律性的东西,使感性认识上升到理性认识。 4.今后打算 下一步将怎样发扬成绩、纠正错误,准备取得什么样的新成就,不必像计划那样具体,但一般不能少了这些内容。 工作总结的特点

总结的经验主要表现在自我性、客观性、经验性三个方面。 1.自我性 总结是对自身社会实践进行回顾的产物,它以自身工作实践为材料,采用的是第一人称写法,其中的成绩、做法、经验、教训等,都有自指性的特征。 2.回顾性 这一点总结与计划正好相反。计划是预想未来,对将要开展的工作进行安排。总结是回顾过去,对前一段的工作进行检验,但目的还是为了做好下一段的工作。所以总结和计划这两种文体的关系是十分密切的,一方面,计划是总结的标准和依据,另一方面,总结又是制定下一步工作计划的重要参考。 3.客观性 总结是对前段社会实践活动进行全面回顾、检查的文种,这决定了总结有很强的客观性特征。它是以自身的实践活动为依据的,所列举的事例和数据都必须完全可靠,确凿无误,任何夸大、缩小、随意杜撰、歪曲事实的做法都会使总结失去应有的价值。 4.经验性 总结还必须从理论的高度概括经验教训。凡是正确的实践活动,总会产生物质和精神两个方面的成果。作为精神成果的经验教训,从某种意义上说,比物质成果更宝贵,因为它对今后的社会实践有着重要的指导作用。这一特性要求总结必须按照实践是检验真理的惟一标准的原则,去正确地反映客观事物的本来面目,找出正反两方面的经验,得出规律性认识,这样才能达到总结的目的。 工作总结的分类 根据不同的分类标准,可将总结分为许多不同的类型。

秘书总结写作的基本要求

秘书总结写作的基本要求 含义和作用这里所说的总结,主要是就工作总结而言的,是事后对某一阶段的工作或某项工作的完成情况,包括取得的成绩、存在的问题及得到的经验和教训加以回顾和分析,为今后的工作提供帮助和借鉴的一种书面材料。总结与计划都是工作中常用的事务文书,两者对实际工作产生作用的方式不同。如果说计划主要是为了指导未来,那么总结则主要是回顾过去,而回顾过去,特别是从中引出规律性的东西,还是为了给今后的工作提供借鉴和帮助。同时,总结过去的工作情况本身,也是培养工作能力,提高认识水平的一种过程。种类从不同的角度,可将总结划分为不同的类别。比较常用的分类方法是按其性质和内容的不同,将总结分为综合性总结和专题性总结两类。所谓的综合性总结,是对总结对象在一定时期内的所有情况进行全面反映和评析的总结;所谓的专题性总结,则是对某项工作的情况或总结对象在某个时期的某个方面的情况进行专门反映和评析的总结。写法同计划一样,总结一般也是由三个部分构成的,即标题、正文和落款。1标题。标题的写法有两种,一种是包括单位名称、时间、总结对象和文种类别的标题,这种标题的写法同计划标题的写法相近;一种是新闻式标题,即概括总结的核心内容的标2正文。正文一般包括前言、主体和结语几个部分,分别写人基本情况、成绩与经验及问题与教训、今后的意见等几个方面的内容。“基本情况”也即“前言”部分,通常用以概述情况,或对工作背景和开展工作的条件,做一个简要交代。主体的第一个部分是“成绩与经验”部分,在此要用翔实的材料,将成绩及取得成绩的做法写明,最好要有实例,有数字,还要有体会,要能够从中找出规律性的东西。主体的第二个部分是“问题与教训”部分,在此要实事求是地把工作中的失误和问题写明,并深刻分析产生失误和问题的原因,指出应当吸取的教训。写主体部分,必须做到观点与材料相统一、情况与分析相结合,而且材料要具体,情况要真实,观点要正确,分析要深入,只有这样,写出的总结才会具有较高的价值。夹叙夹议或先叙后议,都是总结的主体部分常用的写法。把存在的问题和解决问题的措施放在一起,

工作报告总结写作要求(精选多篇)

工作总结写作要求(精选多篇) 第一篇:工作总结的写作格式 总结,就是把某一时期已经做过的工作,进行一次全面系统的总检查、总评价,进行一次具体的总分析、总研究;也就是看看取得了哪些成绩,存在哪些缺点和不足,有什么经验、提高,工作总结的写作格式。 (一)基本情况。 1.总结必须有情况的概述和叙述,有的比较简单,有的比较详细。这部分内容主要是对工作的主客观条件、有利和不利条件以及工作的环境和基础等进行分析,工作总结《工作总结的写作格式》。 2.成绩和缺点。这是总结的中心。总结的目的就是要肯定成绩,找出缺点。成绩有哪些,有多大,表现在哪些方面,是怎样取得的;缺点有多少,表现在哪些方面,是什么性质的,怎样产生的,都应讲清楚。 3.经验和教训。做过一件事,总会有经验和教训。为便于今后的工作,须对以往工作的经验和教训进行分析、研究、概括、集中,并上升到理论的高度来认识。 今后的打算。根据今后的工作任务和要求,吸取前一时期工作的经验和教训,明确努力方向,提出改进措施等 (二)写好总结需要注意的问题

1.一定要实事求是,成绩不夸大,缺点不缩小,更不能弄虚作假。这是分析、得出教训的基础。 2.条理要清楚。总结是写给人看的,条理不清,人们就看不下去,即使看了也不知其所以然,这样就达不到总结的目的。 3.要剪裁得体,详略适宜。材料有本质的,有现象的;有重要的,有次要的,写作时要去芜存精。总结中的问题要有主次、详略之分,该详的要详,该略的要略。 第二篇:工作总结的写作方法 1.工作总结的概念 总结是对过去某一时期或某项工作的情况(包括成绩、经验和存在的问题)的总回顾、评价和结论,工作总结的写作方法。 2.工作总结的作用 认真进行工作总结是我党在长期革命斗争和建设中形成的一个好传统。其作用是: (1)总结是推动工作前进的重要环节任何一项工作,不管是个人或群体去进行都需要多次反复操作、辛勤劳动才能完成。每一次具体实践,都有成绩与失误、经验与教训,及时总结就会及时取得经验教训,提高认识和工作技能。不断实践,不断总结,那么人们对客观事物的认识也就越来越深刻,知识越来越广,智慧越来越高,所进行的事业通过总结才会不断发展、前进。

自我鉴定的写作要求

自我鉴定的写作要求 第一篇:自我鉴定写作用语 自我鉴定写作用语 本由自我鉴定提供参考阅读! 1、我习惯于学会分出必要的时间做点自己愿意的事。 2 、从事柔道是我一生中自觉自愿的事它不仅是一项运动而且似乎是一门哲学它教会我对待对手也要心怀敬意。 3 、学习英语--对我来说有点儿像智力体育节目。 4 、电影我也很喜欢看。 5、书--当然很重要但在你生活的周围还有更重要的东西--家庭和朋友。 6、至于信仰我倾向于任何时候都不要把这个问题拿到公众场合去讨论。 7 、全部生活都是由矛盾构成的哪里没有矛盾了哪里就将是一片荒芜。 8 、从某种意义上说人需要鲜明地体现出一种品质--这就是宽容依我看宽容常常是具有决定意义的东西。 9 、人应当是自由的...... 10 、我喜欢做的事我就欣然而为。 11 、我觉得没有弱点的人是没有的每一代新人都将是更优秀的。

12 、做事越多人就越会得出这样的结论:还有许多事没有做。 13 、我有一些很要的朋友。 14 、我现在的朋友基本上还是中学时代的或者是在大学学习期间的。 15、我从来不装样子。 16 、我希望公民把我看作雇来打工的人。 17 、求求你啦最别给我写小册子别塑半身像。 18 、我虽然经常注意但也不能总是露出一副令人愉快的笑脸。 19 、偶尔也有颓废之感。 20 、人首先应当遵从的不是别人的意见而是自己的良心。 章来源于:://haoword./ziwojianding/(作者:) 第二篇:自我鉴定写作举例的 本人丘__,自今年7月21日调到______有限公司工作的四个月里,坚持做到尊敬领导,团结同事,虚心向主管领导及部门同事学习专业知识及努力提高业务实操能力。认真完成公司领导分配给我的工作。 在船管部工作对我来说是一个新的工作领域,在新的工作岗位工作期间,我学到了许多以前没有接触过,没学过的知识,这一切都是公司领导对我的支持和信任,同时也给了我学习新专业知识和提高业务水平的机会。经过几天的学习,我现在能够独立,全面负责

总结和计划写作要求

一、工作总结 总结,就是把某一时期已经做过的工作,进行一次全面系统的总检查、总评价,进行一次具体的总分析、总研究;也就是看看取得了哪些成绩,存在哪些缺点和不足,有什么经验、提高。要有针对性:针对具体的活动,具体的问题来总结。 (一)基本情况。 1.总结必须有情况的概述和叙述,有的比较简单,有的比较详细。这部分内容主要是对工作的主客观条件、有利和不利条件以及工作的环境和基础等进行分析。 2.成绩和缺点。这是总结的中心。总结的目的就是要肯定成绩,找出缺点。成绩有哪些,有多大,表现在哪些方面,是怎样取得的;缺点有多少,表现在哪些方面,是什么性质的,怎样产生的,都应讲清楚。 3.经验和教训。做过一件事,总会有经验和教训。为便于今后的工作,须对以往工作的经验和教训进行分析、研究、概括、集中,并上升到理论的高度来认识。 今后的打算。根据今后的工作任务和要求,吸取前一时期工作的经验和教训,明确努力方向,提出改进措施等(二)写好总结需要注意的问题 1.一定要实事求是,成绩不夸大,缺点不缩小,更不能弄虚作假。这是分析、得出教训的基础。

2.条理要清楚。总结是写给人看的,条理不清,人们就看不下去,即使看了也不知其所以然,这样就达不到总结的目的。 3.要剪裁得体,详略适宜。材料有本质的,有现象的;有重要的,有次要的,写作时要去芜存精。总结中的问题要有主次、详略之分,该详的要详,该略的要略。 二、工作计划 工作计划大体分为标题、正文、结尾三部分。 (1)标题。由单位名称、适用时期、内容和文种构成。(2)正文。由前言和计划事项构成。 1)计划的前言,要简明扼要说明制定计划的目的或依据,提出工作的总任务或总目标。前言常用“为此,今年(或某一时期)要抓好以下几项工作”作结,并领起下述的计划事项。 2)计划事项,是总的计划下面的各个分计划项目。这部分一般要分项来写,有时,大的项目下有小的项目,大的项目是一个大的方面要做的工作,小的项目是在大的方面要做的每一项工作。 工作计划是一个单位或团体在一定时期内的工作打算。写工作计划要求简明扼要、具体明确,用词造句必须准确,不能含糊。 具体格式如下 1.计划的名称。包括订立计划单位或团体的名称和计

工作总结写作的基本要求

工作总结写作的基本要求 含义和作用 这个地方所说的总结,要紧是就工作总结而言的,是事后对某一时期的工作或某项工作的完成事情,包括取得的成绩、存在的咨询题及得到的经验和教训加以回忆和分析,为将来的工作提供帮助和借鉴的一种书面材料。 总结与打算基本上工作中常用的事务文书,两者对实际工作产生作用的方式别同。 假如说打算要紧是为了指导以后,那么总结则要紧是回忆过去,而回忆过去,特别是从中引出规律性的东西,依然为了给将来的工作提供借鉴和帮助。并且,总结过去的工作事情本身,也是培养工作能力,提高认识水平的一种过程。 种类从别同的角度,可将总结划分为别同的类别。比较常用的分类办法是按其性质和内容的别同,将总结分为综合性总结和专题性总结两类。所谓的综合性总结,是对总结对象在一定阶段内的所有事情进行全面反映和评析的总结;所谓的专题性总结,则是对某项工作的事情或总结对象在某个阶段的某个方面的事情进行特意反映和评析的总结。 写法 同打算一样,总结普通也是由三个部分构成的,即标题、正文和降款。 1。标题。标题的写法有两种,一种是包括单位名称、时刻、总结对象和文种类别的标题,这种标题的写法同打算标题的写法相近;一种是新闻式标题,即概括总结的核心内容的标 2。正文。正文普通包括前言、主体和结语几个部分,分别写人基本事情、成绩与经验及咨询题与教训、将来的意见等几个方面的内容。 基本事情也即前言部分,通常用以概述事情,或对工作背景和开展工作的条件,做一具简要交代。 主体的第一具部分是成绩与经验部分,在此要用翔实的材料,将成绩及取得成绩的做法写明,最好要有实例,有数字,还要有体味,要可以从中寻出规律性的东西。 主体的第二个部分是咨询题与教训部分,在此要实事求是地把工作中的失误和咨询题写明,并深刻分析产生失误和咨询题的原因,指出应当吸取的教训。写主体部分,必须做到观点与材料相统一、事情与分析相结合,而且材料要具体,事情要真实,观点要正确,分析要深入,惟独如此,写出的总结才会具有较高的价值。夹叙夹议或先叙后议,基本上总结的主体部分常用的写法。把存在的咨询题和解决咨询题的措施放在一起,在咨询题与教训部分之后写出,也是比较常见的写法。 在将来的意见也即结语部分,要结合经验和教训,提出改进工作的方法或下一步努力的方向。有的总结是在最后展望前景,表明决心。这部分内容也能够别写。篇幅较长的总结,常常要在每个部分之前加上序码,或者加上序码和小标题。 3降款。总结的降款同打算的降款写法彻底相同。

工作总结写作要求(多篇范文)

工作总结写作要求 总结,就是把某一时期已经做过的工作,进行一次全面系统的总检查、总评价,进行一次具体的总分析、总研究;也就是看看取得了哪些成绩,存在哪些缺点和不足,有什么经验、提高,工作总结的写作格式。 (一)基本情况。 1. 总结必须有情况的概述和叙述,有的比较简单,有的比较详细。这部分内容主要是对工作的主客观条件、有利和不利条件以及工作的环境和基础等进行分析,工作总结《工作总结的写作格式》。 2. 成绩和缺点。这是总结的中心。总结的目的就是要肯定成绩,找出缺点。成绩有哪些,有多大,表现在哪些方面,是怎样取得的;缺点有多少,表现在哪些方面,是什么性质的,怎样产生的,都应讲清楚。 3. 经验和教训。做过一件事,总会有经验和教训。为便于今后的工作,须对以往工作的经验和教训进行分析、研究、概括、集中,并上升到理论的高度来认识。 今后的打算。根据今后的工作任务和要求,吸取前一时期工作的经验和教训,明确努力方向,提出改进措施等 (二)写好总结需要注意的问题 1. 一定要实事求是,成绩不夸大,缺点不缩小,更不能弄虚作假。这是分析、得出教训的基础。

2. 条理要清楚。总结是写给人看的,条理不清,人们就看不下去,即使看了也不知其所以然,这样就达不到总结的目的。 3. 要剪裁得体,详略适宜。材料有本质的,有现象的;有重要的,有次要的,写作时要去芜存精。总结中的问题要有主次、详略之分,该详的要详,该略的要略。 第二篇:工作总结的写作方法 1.工作总结的概念 总结是对过去某一时期或某项工作的情况(包括成绩、经验和存在的问题)的总回顾、评价和结论,工作总结的写作方法。 2.工作总结的作用 认真进行工作总结是我党在长期革命斗争和建设中形成的一个好传统。其作用是: (1)总结是推动工作前进的重要环节任何一项工作,不管是个人或群体去进行都需要多次反复操作、辛勤劳动才能完成。每一次具体实践,都有成绩与失误、经验与教训,及时总结就会及时取得经验教训,提高认识和工作技能。不断实践,不断总结,那么人们对客观事物的认识也就越来越深刻,知识越来越广,智慧越来越高,所进行的事业通过总结才会不断发展、前进。 (2)总结是寻找工作规律的重

总结写作的要求

总结写作的要求(一) 总结的基本要求 1.总结必须有情况的概述和叙述,有的比较简单,有的比较详细。这部分内容主要是对工作的主客观条件、有利和不利条件以及工作的环境和基础等进行分析。 2.成绩和缺点。这是总结的中心。总结的目的就是要肯定成绩,找出缺点。成绩有哪些,有多大,表现在哪些方面,是怎样取得的;缺点有多少,表现在哪些方面,是什么性质的,怎样产生的,都应讲清楚。 3.经验和教训。做过一件事,总会有经验和教训。为便于今后的工作,须对以往工作的经验和教训进行分析、研究、概括、集中,并上升到理论的高度来认识。 今后的打算。根据今后的工作任务和要求,吸取前一时期工作的经验和教训,明确努力方向,提出改进措施等。 总结的注意事项

1.一定要实事求是,成绩不夸大,缺点不缩小,更不能弄虚作假。这是分析、得出教训的基础。 2.条理要清楚。总结是写给人看的,条理不清,人们就看不下去,即使看了也不知其所以然,这样就达不到总结的目的。 3.要剪裁得体,详略适宜。材料有本质的,有现象的;有重要的,有次要的,写作时要去芜存精。总结中的问题要有主次、详略之分,该详的要详,该略的要略。 总结的基本格式 1、标题 2、正文 开头概述情况,总体评价;提纲挈领,总括全文。 主体分析成绩缺憾,总结经验教训。 结尾分析问题,明确方向。

3、落款 署名,日期 总结写作的要求(二) 总结写作的要求(三) 总结写作的要求(四) 总结写作与要求 一、总结概论 总结是对已经做过的工作进行理性的思考。它要回顾的是过去做了些什么,如何做的,做得怎么样。总结与计划是相辅相成的,要以计划为依据,订计划总是在总结经验的基础上进行的。其间有一条规律,就是计划——实践——总结——再计划——再实践——再总结。 二、总结的特点

工作总结写作要求

工作总结写作要求 在这样一个大家庭里,以前没有管理经验,除了给员工灌输公司下达的任务外,最重要的是和员工一起学习,沟通心态等方面的问题。让大家了解我们上班的目的和公司对我们的要求,所以要大家除了能学到一些技能外,更重要的是学习做人的道理。要鼓励员工人人做优秀员工,个个都是最棒的。 一、个人工作总结一般的格式为标题、主体、结尾三部分。 标题 存在的问题虽不在每一篇工作总结中都写,但思想上一定要有个正确的认识。每篇工作总结都要坚持辩论法,坚持一分为二的两点论,既看到成绩又看到存在的问题,分清主流和枝节。这样才能发扬成绩、纠正错误,虚心谨慎,继续前进。 总结的标题大体上有两类构成形式:一类是公文式标题;一类是非公文式标题。公文式标题由单位名称、时间、事由、文种组成,如《××村2020年度工作总结》《××镇2020年党建工作总结》,有的只写《工作总结》等。非公文式标题则比较灵活,有的为双行标题,如《增强体质,全面贯彻执行教育方针——开展多种形式的体育活动》,有的为单行标题,如《推动人才交流,培植人才资源》等。 正文 总结正文的结构由前言、主体、结尾组成。 1、前言。即正文的开头,一般简明扼要地概述基本情况,交代背景,点明主旨或说明成绩,为主体内容的展开做必要的铺垫。例如:“群众富不富,关键在支部;干部强不强,关键在班长”。能否选配好支部“一把手”,是加强农村基层党组织建设的核心。在工作中,我们积极围绕支部班子建设这个重点,紧紧抓住配好支部书记这个关键,着力走好“选人”“育人”“用人”这三步棋,努力把工作引向深入。 2、主体。这是总结的核心部分,其内容包括做法和体会,成绩和问题,经验和教训等。这一部分要求在全面回顾工作情况的基础上,深刻、透彻地分析取得成绩的原因、条件、做法、以及存在问题的根源和教训,揭示工作中带有规律性的东西。回顾要全面,分析要透彻。 不同类型的总结,内容有所侧重,全面性总结其主体包括两个层次,即成绩和经验,存在的问题和教训。对于一般的工作总结,重点放在成绩和经验上。 总结正文的结构,主要采用逻辑结构形式。全面性总结根据过去一段工作中的成绩和问题,或者经验和教训的内在联系去组织材料。专题性总结以经验为轴心去组织材料。

总结写作要求

总结写作要求 (一)总结的标题 总结的标题有种种形式,最常见的是由单位名称、时间、主要内容、文种组成,如 《××市财政局1999年工作总结》、《××厂2000年上半年工作总结》。 有的总结标题中不出现单位名称,如《创先争优活动总结》、《1999年教学工作总结》。 有的总结标题只是内容的概括,并不标明“总结”字样,但一看内容就知道是总结, 如《一年来的谈判及前途》《周恩来选集》上卷,人民出版社1980年版,第251页。、《走活三步棋,选好一把手》《先锋》1996年第5期。等。 还有的总结采用双标题。正标题点明文章的主旨或重心,副标题具体说明文章的内容 和文种,如《构建农民进入市场的新机制――运城麦棉产区发展农村经济的实践与总结》、《加强医德修养树立医疗新风――南方医院惠侨科精神文明建设的经验》。 (二)总结的正文 和其他应用文体一样,总结的正文也分为开头、主体、结尾三部分,各部分均有其特 定的内容。 1.开头 总结的开头主要用来概述基本情况。包括单位名称、工作性质、主要任务、时代背景、指导思想,以及总结目的、主要内容提示等。作为开头部分,要注意简明扼要,文字不可 过多。 2.主体 这是总结的主要部分,内容包括成绩和做法、经验和教训、今后打算等方面。这部分 篇幅大、内容多,要特别注意层次分明、条理清楚。 主体部分常见的结构形态有三种。 第一,纵式结构。就是按照事物或实践活动的过程安排内容。写作时,把总结所包括 的时间划分为几个阶段,按时间顺序分别叙述每个阶段的成绩、做法、经验、体会。这种 写法的好处是事物发展或社会活动的全过程清楚明白。 第二,横式结构。按事实性质和规律的不同分门别类地依次展开内容,使各层之间呈 现相互并列的态势。这种写法的优点是各层次的内容鲜明集中。

工作总结写作要领及注意事项

工作总结写作要领及注意事项 工作总结是论说性的应用文。好的工作总结应有一定深度的理论概括,但又不同于评论。它主要是从工作实践中,抽象出带有规律 性的经验教训。 一、工作总结的基本要素 写总结是没有公式可套用的,也就是我们常说的“水无定势,文 无定法”。写工作总结也可不拘泥于某种“格式”和“框框”,但是有一 些基本的要素是应该具备的,比如要有标题、正文、日期。 工作总结的正文一般可分为五个部分:一是情况概述;二是成绩;三是经验和教训;四是存在的问题;五是今后工作或努力的方向。 其中,着笔较多的主要是“成绩和经验”部分,因为它是总结的主要 部分,所以一定要写好写实。另外,存在的问题和教训部分也要努 力写准。存在的问题是指工作中的不足之处,或在实践中感受到的 应当解决而解决得不好、或暂时没有解决、或不具备条件解决的问题。教训是由于思路不对路,方法不得当,或由于一些其他原因出 现失误而得出的反面经验。 容。它是工作总结的引言,便于把后述的内容引出来。一般只需要很短的一段文字即可。但这段文字要高度概括,语言要十分精炼。 (二)工作成绩部分。这是工作总结的中心。总结的目的就是要肯定成绩。因此要写明成绩有哪些,有多大,表现在哪些方面,是 怎样取得的;要写明工作任务、完成的步骤、采取的措施和取得的 成效;要写得详细、具体,对取得的成效要表达得形象、生动。在 写工作回顾的过程中,还要有意识地照应到下一部分的经验教训, 使之顺理成章地引出来,不至于造成前后不一的感觉。 (三)经验教训部分。应从总结工作中很自然地归纳提炼出来。一定要写得丰富、充实,并选用具体事例适当地展开议论,使总结

出来的经验和教训,有论点,有论据,有血有肉,鲜明生动,确实 能给人以启发和教益。可以说,这是总结最难写的部分。 (四)存在问题部分。在总结成绩的同时,要找出存在的问题。问题有多少,表现在哪些方面,有什么性质的,怎样产生的,都应 该讲清楚。 (五)今后工作或努力的方向部分。主要写明今后的打算或下一步的工作思路。这部分应写得简明扼要一些。 二、写好工作总结需要注意的问题 (一)情况要吃透。起草总结前要充分拥有和认真消化有关材料,最好通过不同的形式,听取各方面的意见,全面了解有关情况。或 者把总结的想法、意图提出来,同有关的同志一起商量。一定要避 免领导出观点,然后起草者再去找事实的写法。 (二)条理要清楚。总结是写给人看的,条理不清,别人看 不下去,即使看了也会不得要领、不知其所以然,这样就达不到总结的目的。特别要防止下笔千言,离题万里。 (三)剪裁要得体。材料有本质的,有现象的,有重要的,有次要的,写作时就要去粗取精、去莠存良。总结中的问题要有主次、 详略之分,该写的要详,该略的要略,特别要注意强调重点,突出 亮点。在实际撰写中,经常会出现信马由缰、事无巨细,把做过的 所有工作都一一罗列出来的现象。比如什么时间做了什么事,有哪 些人参加等。这样写出来的总结就成了一本流水账,让人看起来很 费力,或看了也不知所云。 (四)观点要正确。总结必须实事求是,不能夸大其词,一定要以党和国家的方针、政策作为衡量工作的主要标准。观点正确,是 总结能否站得住脚的关键。同时还要注意,光有正确的观点还不够,还需要有能够说明观点的丰富素材和具体内容,这样的总结别人才 喜欢看,看后也能有所收获。

总结写作的基本要求

总结写作的基本要求 含义和作用 这里所说的总结归纳,主要是就工作总结归纳而言的,是事后对某一阶段的工作或某项工作的完成情况,包括获得的成绩、存在的问习题及得到的经验和教训加以回忆和分析,为今后的工作提供帮助和借鉴的一种书面材料。 总结归纳与计划都是工作中常用的事务文书,两者对实际工作产生作用的方式不同。 假如说计划主要是为了指导将来,那么总结归纳则主要是回忆过去,而回忆过去,特别是从中引出规律性的东西,还是为了给今后的工作提供借鉴和帮助。同时,总结归纳过去的工作情况自己,也是培养工作能力,提高认识水平的一种过程。 品种从不同的角度,可将总结归纳划分为不同的类别。比较常用的分类方法是按其性质和内容的不同,将总结归纳分为综合性总结归纳和专习题性总结归纳两类。所谓的综合性总结归纳,是对总结归纳对象在一定时期内的所有情况进行全面反映和评析的总结归纳;所谓的专习题性总结归纳,则是对某项工作的情况或总结归纳对象在某个时期的某个方面的情况进行专门反映和评析的总结归纳。 写法 1/ 3

同计划一样,总结归纳一般也是由三个部分构成的,即题目、正文 和落款。 1。题目。题目的写法有两种,一种是包括单位名称、时间、总结归纳对象和文品种别的题目,这种题目的写法同计划题目的写法相近;一种是新闻式题目,即概括总结归纳的核心内容的标 2。正文。正文一般包括前言、主体和结语几个部分,分别写人基本情况、成绩与经验及问习题与教训、今后的意见等几个方面的内容。“基本情况”也即“前言”部分,通常用以概述情况,或对工作背景和开展工作的条件,做一个简要交代。 主体的第一个部分是“成绩与经验”部分,在此要用翔实的材料,将成绩及获得成绩的做法写明,最好要有实例,有数字,还要有领会,要能够从中找出规律性的东西。 主体的第二个部分是“问习题与教训”部分,在此要实事求是地把工作中的失误和问习题写明,并深刻分析产生失误和问习题的原因,指出应当吸取的教训。写主体部分,必须做到观点与材料相统一、情况与分析相结合,而且材料要详细,情况要真实,观点要正确,分析要深入,只有这样,写出的总结归纳才会具有较高的价值。夹叙夹议或先叙后议,都是总结归纳的主体部分常用的写法。把存在的问习题和解决问习题的措施放在一起,在“问习题与教训”部分之后写出,也是比较常见的写法。 在“今后的意见” 也即“结语”部分,要结合经验和教训,提出改 良工作的规定或下一步努力的方向。有的总结归纳是在最后展望前景,2/ 3

总结写作与要求

总结写作与要求 一、总结概论 总结是对已经做过的工作进行理性的思考。它要回顾的是过去做了些什么,如何做的,做得怎么样。总结与计划是相辅相成的,要以计划为依据,订计划总是在总结经验的基础上进行的。其间有一条规律,就是:计划——实践——总结——再计划——再实践——再总结。 二、总结的特点: 1、工作总结要求人们对以往做过的工作进行冷静的反思。通过反思,提高认识,获得经验,为进一步做好工作打下思想基础。 2、强调科学性。总结经验不能就事论事,“跟着感觉走”。而要就事论理,辩证分析,力求得出科学结论,这样才能促进工作的转化。 3、表述上叙议结合,有评有论。工作总结除了叙述、说明外,还要议论,通过典型材料的介绍及分析评议,阐明作者的观点,使经验教训条理化、理论化,避免空洞无物和堆砌材料两种偏向。 三、工作总结的种类: 1、按总结的时间分,有年度总结、半年总结、季度总结。进行某项重大任务时,还要分期总结或叫阶段总结。 2、按总结的范围分,有单位总结、个人总结、综合性总结、专题总结等。 3、按总结的性质分,有工作、生产、教学、科研总结等。 四、总结撰写前的准备 有人说过:要总结写得好,必须总结作得好;要总结作得好,必须工

作做得好,立场观点对头。这应该是写总结的经验之谈。好的总结是在做好总结工作的基础上写出来的,更是人民群众在实际中干出来的。在现实生活中,有的单位干得不怎么样,但总结时却“喷香水”,这对本单位的工作失去实际意义,不应该提倡。也有的单位工作有成绩却形成不了典型经验,这种情况说明总结工作没做好。上述两种情况都是应该避免的。搞好总结,是企业管理的一项重要工作,是增强干部、职工凝聚力的一种重要手段,需要认真对待。 总结究竟应该怎样做呢?从总体上说要发动群众,自下而上做总结。工作是群众做的,总结也应该由他们来做。不应撇开群众凑集政绩,绞尽脑汁制作观点。总结过程中能量化的要量化,把定性分析和定量分析结合起来考察,从客观事实出发,防止感情用事,以免总结流于形式。 此外,搞好总结还要注意以下几点: 1、重视调查研究,熟悉情况 总结的对象是过去做过的工作或完成的某项任务,进行总结时,要通过调查研究,努力掌握全面情况和了解整个工作过程,只有这样,才能进行全面总结,避免以偏概全。 2、热爱本职工作,熟悉业务 热爱本职工作,事业心强,是做好工作的前提,也是搞好总结的基础。写总结涉及本职业务,如果对业务不熟悉,就难免言不及义。 3、坚持实事求是的原则 总结是对以往工作的评价,必须坚持实事求是的原则,就像陈云同志

个人总结需要书写的内容

1、主要内容 1、总结必须有情况的概述和叙述,有的比较简单,有的比较详细。这部分内容主要是对工作的主客观条件、有利和不利条件以及工作的环境和基础等进行分析。 2、成绩和缺点。这是总结的中心。总结的目的就是要肯定成绩,找出缺点。成绩有哪些,有多大,表现在哪些方面,是怎样取得的;缺点有多少,表现在哪些方面,是什么性质的,怎样产生的,都应讲清楚。 3、经验和教训。做过一件事,总会有经验和教训。为便于今后的工作,须对以往工作的经验和教训进行分析,研究,概括,集中,并上升到理论的高度来认识。 4、今后的打算。根据今后的工作任务和要求,吸取前一年工作的经验和教训,明确努力方向,提出改进措施等。 2、分类 年终总结大体分为:单位总结、个人总结、综合性总结、专题总结等。 从性质、时间、形式等角度可划分出不同类型的总结,从内容分主要有综合总结和专题总结两种。综合总结又称全面总结,它是对某一时期各项工作的全面回顾和检查,进而总结经验与教训。专题总结是对某项工作或某方面问题进行专项的总结,尤以总结推广成功经验为多见。总结也有各种别称,如自查性质的评估及汇报、回顾、小结

等都具总结的性质。 3、意义作用 年终总结是对一年内所有工作加以总结,分析和研究,肯定成绩,找出问题,得出经验教训,摸索事物的发展规律,用于指导下一阶段工作的一种书面文体。它所要解决和回答的中心问题,不是某一时期要做什么,如何去做,做到什么程度的问题,而是对某种工作实施结果的总鉴定和总结论,是对以往工作实践的一种理性认识。 总结是做好各项工作的重要环节。通过它,可以全面地,系统地了解以往的工作情况,可以正确认识以往工作中的优缺点;可以明确下一步工作的方向,少走弯路,少犯错误,提高工作效益。 总结还是认识世界的重要手段,是由感性认识上升到理性认识的必经之路。通过总结,使零星的,肤浅的,表面的感性认识上升到全面的,系统的,本质的理性认识上来,寻找出工作和事物发展的规律,从而掌握并运用这些规律。毛泽东同志曾指出:领导者的责任,就是不断指出斗争的方向,规定斗争的任务,而且必须总结具体的经验,向群众传播这个经验,使正确的获得推广,错误的不致重犯。 4、写作方法:年终总结“六要点” 一、要充分认识到总结的要义。总结是最好的老师,没有总结就没有进步,总结是一面镜子,通过总结可以全面地对自己的成绩与教训、长处与不足、困难与机遇进行客观评判,为下一步工作理清思路,明确目标,制订措施,提供参考和保障。所以总结不仅仅是给领导看

专业技术总结写作规范及要求

专业技术总结写作规范及要求 (包括学习经历、工作经历、实际成就和传授技艺等四个方面) 一、学习经历: 主要反映报考人在学历方面的状况,多年来参加培训的情况以及自学课程及掌握的程度。 1、学历:何时、何专业、什么学校毕业: 2、培训:何时、何地参加什么培训班,学习时间,主要课程; 3、自学:自学那些课程,教材、层次(大学、中专、技校)自订专业杂志。 二、工作经(资)历: 主要反映报考人的工龄、担任的工作职务、参与各种工程施工的经历、主持或参与的技术工作项目,主持或参与的技术攻关项目以及QC项目等方面的情况。 1、工龄情况:从事本工种或相关工种年限 2、职务年限:担任工班长、领工员、安全员、组长、项目负责人、技术攻关负责人、QC小组长等方面的情况; 3、工作经历:历年参加或主持制造、修理的机器型号、数量。主持或参与修建的工程项目,特别是重点工程项目。主持或参与四新技术(新技术、新工艺、新材料、新方法)的应用经历。主持或参与的技术攻关、QC 小组的项目等。 4、其他工作经历:特别是相关工种的工作经历,掌握技术的程度。 三、实际成就:

主要反映报考人解决关键技术问题的能力,本人高超的技能,主持或参与的技术革新、技术攻关、提出的合理化建议,应用四新技术合理组织施工生产取得的效益以及历年所获奖励等方面的情况。 1、解决关键技术问题(应从四个方面叙述): 1)、问题的提出,现象应表述清楚; 2)、理论分析,问题产生的原因,涉及的领域,参考的资料,最好能图文并茂; 3)、解决的措施和方法及手段; 4)、实际效果,经济效益; 2、利用本人高超的技能解决的实际技术难题,也应详述; 3、主持或参与技术革新、技术攻关、QC小组、提出的合理化建议的具体内容,本人负责的项目,解决的问题; 4、应用四新技术合理组织施工生产取得的效益,新、老的对比,经济效益的分析; 5、历年所获奖励情况,应附奖状等证明材料的复印件。 四、传授技艺: 主要反映报考人发挥传、帮、带作用的情况。 1、是否在各类学校、夜校、培训班授课(包括理论和实作指导),担任的课程、课时、传授的主要内容;带徒情况,传授技术时传授的项目、方法以及传艺的效果,学员或徒弟目前的技术水平,实际成就等。

计划和总结(格式要求-写作重点)(1)doc资料

(一)计划 1、计划的含义、特点及作用 (1)含义 计划是计划类文书的总称,因为计划涉及内容和期限的不同,计划文书还有不同的叫法,工作中常见的“规划”、“设想”、“纲要”、“要点”、“打算”、“安排”、“方案”等也属于这一文体。 “计划”,既是一个具体的文种,又是一个泛称,使用频率最高。作为一个具体的文种,它的内容相对比较具体,时间较短,多为一年或半年,是对长远规划的补充,它侧重于定任务、定指标、定措施、定时间,具有很强的现实性、规定性和可操作性。 “规划”是对较长时间的工作所作的具有全局性、方向性、战略性、概括性的宏观计划。与计划相比,一是内容不同。“规划”的内容一般比较重大,并着重于全局性部署,“计划”既有比较重大的内容,也有一般性的,着重于实施具体任务的方案;二是时间不同。“规划”是较长一个时期发展的科学展望,一般是三至五年、七至八年甚至更长时间的设想与安排。“计划”一般是当年的,甚至一个季度、一个月、一个星期的工作安排;三是要求不同。规划是在总体上、原则上定方向、定规模,展望远景,富于理想,表达比较概括,计划侧重于定任务、定指标、定措施、定时间,富于现实性、规定性和可操作性,表达相对具体;四是从关系上看,规划是产生各个时期计划的重要依据,是计划的基础;而计划既服从于规划,又根据形势的进展对规划进行补充和修正。 “设想”是对长远工作的初步的、非正式的富有创新性的计划,设想时间跨度多在十年以上,是对工作任务粗线条、不太成熟的安排,属于工作的初步构想,具有较大的可变性; “纲要”是既具有远景发展设想,又具有较强的政策性、思想性、指导性的提纲挈领式的计划性文件。与其他计划性文书相比,其突出特点是:在时间上,不象设想的跨度那么大,也不象计划的跨度那么小,多在五至十年之间;在空间上,范围比较大,多用于全局性工作或某一重要工作的发展设计;在内容上,多为经济和社会发展方面的,文字表述多为条款式。 “要点”是上级对下级布置工作任务时对主要内容做出的概括而简明扼要的计划,是工作计划的主要之点。要点是原则性、指导性较强的计划,与一般计划相比,要点表现为以下特点:内容上,“要点”是工作的主要方面,重要之点,表达简要、概括,而“计划”则要兼顾各个方面,写得比较具体;形式上,“要点”分条列项,一目了然,一般不写具体做法和过多的讲道理,而“计划”则要有具体做法和详细说明;行文方向上,“工作要点”一般下行或行于机关内部,而“计划”则在下达给下属单位的同时,也适用于上报上级机关,而上级机关也多要求下级报送工作计划。 “安排”与“打算”都是本单位、本部门对短期或近期内工作任务所作的考虑与布置,相比较而言,“安排”的任务明确,内容较单一,措施较具体,它是对已有“计划”的具体化,是“计划”的分解与消化。“打算”是要点式的短期计划、设想,它提出工作任务,但其中的指标、措施较粗略。 “方案”是本单位、本部门对近期要做的具体工作(某项任务或课题)的实施,从工作目标、要求、具体的措施办法进行全面部署的计划。 3、计划的写法 从文本形式看,计划有条文式、表格式和条文表格结合式,其结构一般由标题、正文和落款组成。 标题。标题的写法可分为全称式和简称式。全称式标题由计划单位名称、计划期限、计划内容和计划名称构成,如《××市税务局二00四年税收工作计划》、《××县二000年至二00五年经济发展规划》,综合性计划或须上报的计划常用这种写法。简称式标题是将全称式标题中的某个要素省略就形成简称式标题,或省略计划单位名称,或省略计划单位名称和计划期限,如《1999年信贷计划》、《税收计划》,单位内部计划和专项计划多用这种写法。要注意的是,对于不成熟的非正式计划或还未正式通过的计划应在标题后或正下方用圆括号标明“初稿”、“草案”、“讨论稿”、“征求意见稿”等字样。 正文。正文一般由前言、主体、结尾组成。 前言,是计划的开头部分,要说明制定计划的指导思想,概括单位的基本情况及制定计划的政策依据;或说明制订计划的目的、缘由。这部分是整个计划的纲.要,要说明“为什么做”的问题,表达上要简明扼要,点到为止,不宜过多展开。这部分结尾常用承启语“为此,特制订计划如下”或“特制订本计划”、“为此,要具