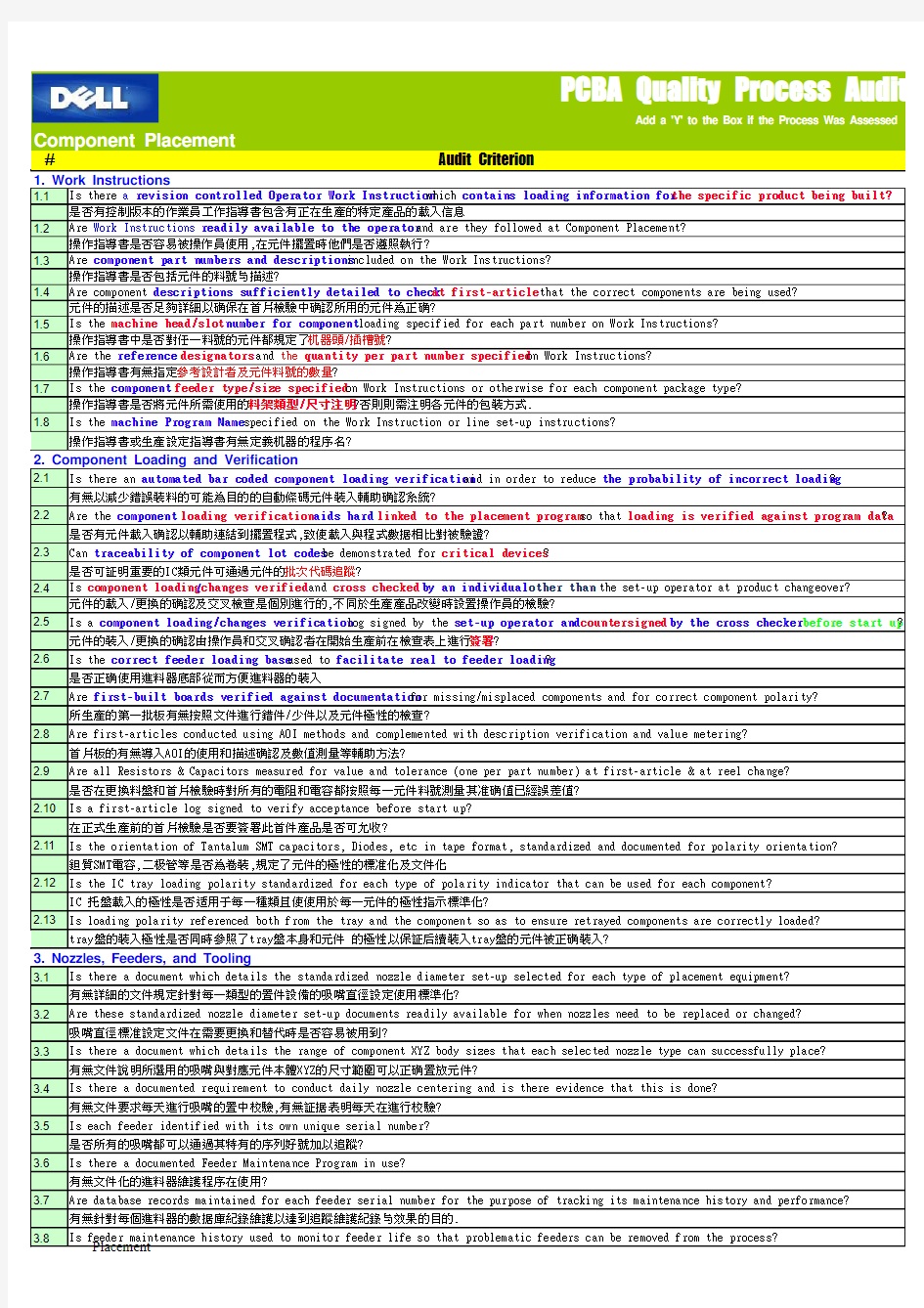

Dell DIMM Audit Process check list-中英经典

#Audit Criterion

1. Work Instructions

1.1Is there a revision controlled Operator Work Instruction which contains loading information for the specific product being built?

是否有控制版本的作業員工作指導書包含有正在生產的特定產品的載入信息

1.2Are Work Instructions readily available to the operator and are they followed at Component Placement?

操作指導書是否容易被操作員使用,在元件擺置時他們是否遵照執行?

1.3Are component part numbers and descriptions included on the Work Instructions?

操作指導書是否包括元件的料號与描述?

1.4Are component descriptions sufficiently detailed to check at first-article that the correct components are being used?

元件的描述是否足夠詳細以确保在首片檢驗中确認所用的元件為正确?

1.5Is the machine head/slot number for component loading specified for each part number on Work Instructions?

操作指導書中是否對任一料號的元件都規定了机器頭/插槽號?

1.6Are the reference designators and the quantity per part number specified on Work Instructions?

操作指導書有無指定參考設計者及元件料號的數量?

1.7Is the component feeder type/size specified on Work Instructions or otherwise for each component package type?

操作指導書是否將元件所需使用的料架類型/尺寸注明?否則則需注明各元件的包裝方式.

1.8Is the machine Program Name specified on the Work Instruction or line set-up instructions?

操作指導書或生產設定指導書有無定義机器的程序名?

2. Component Loading and Verification

2.1Is there an automated bar coded component loading verification aid in order to reduce the probability of incorrect loading?

有無以減少錯誤裝料的可能為目的的自動條碼元件裝入輔助确認系統?

2.2Are the component loading verification aids hard linked to the placement program so that loading is verified against program data?

是否有元件載入确認以輔助連結到擺置程式,致使載入與程式數据相比對被驗證?

2.3Can traceability of component lot codes be demonstrated for critical devices?

是否可証明重要的IC類元件可通過元件的批次代碼追蹤?

2.4Is component loading/changes verified and cross checked by an individual other than the set-up operator at product changeover?

元件的載入/更換的确認及交叉檢查是個別進行的,不同於生產產品改變時設置操作員的檢驗?

2.5Is a component loading/changes verification log signed by the set-up operator and countersigned by the cross checker before start up?

元件的裝入/更換的确認由操作員和交叉确認者在開始生產前在檢查表上進行簽署?

2.6Is the correct feeder loading base used to facilitate real to feeder loading?

是否正确使用進料器底部從而方便進料器的裝入

2.7Are first-built boards verified against documentation for missing/misplaced components and for correct component polarity?

所生產的第一批板有無按照文件進行錯件/少件以及元件極性的檢查?

2.8Are first-articles conducted using AOI methods and complemented with description verification and value metering?

首片板的有無導入AOI的使用和描述确認及數值測量等輔助方法?

2.9Are all Resistors & Capacitors measured for value and tolerance (one per part number) at first-article & at reel change?

是否在更換料盤和首片檢驗時對所有的電阻和電容都按照每一元件料號測量其准确值已經誤差值?

2.10Is a first-article log signed to verify acceptance before start up?

在正式生產前的首片檢驗是否要簽署此首件產品是否可允收?

2.11Is the orientation of Tantalum SMT capacitors, Diodes, etc in tape format, standardized and documented for polarity orientation?

鉭質SMT電容,二极管等是否為卷裝,規定了元件的極性的標准化及文件化

2.12Is the IC tray loading polarity standardized for each type of polarity indicator that can be used for each component?

IC 托盤載入的極性是否适用于每一種類且使使用於每一元件的極性指示標準化?

2.13Is loading polarity referenced both from the tray and the component so as to ensure retrayed components are correctly loaded?

tray盤的裝入極性是否同時參照了tray盤本身和元件 的極性以保証后續裝入tray盤的元件被正确裝入?

3. Nozzles, Feeders, and Tooling

3.1Is there a document which details the standardized nozzle diameter set-up selected for each type of placement equipment?

有無詳細的文件規定針對每一類型的置件設備的吸嘴直徑設定使用標準化?

3.2Are these standardized nozzle diameter set-up documents readily available for when nozzles need to be replaced or changed?

吸嘴直徑標准設定文件在需要更換和替代時是否容易被用到?

3.3Is there a document which details the range of component XYZ body sizes that each selected nozzle type can successfully place?

有無文件說明所選用的吸嘴與對應元件本體XYZ的尺寸範圍可以正确置放元件?

3.4Is there a documented requirement to conduct daily nozzle centering and is there evidence that this is done?

有無文件要求每天進行吸嘴的置中校驗,有無証据表明每天在進行校驗?

3.5Is each feeder identified with its own unique serial number?

是否所有的吸嘴都可以通過其特有的序列好號加以追蹤?

3.6Is there a documented Feeder Maintenance Program in use?

有無文件化的進料器維護程序在使用?

3.7Are database records maintained for each feeder serial number for the purpose of tracking its maintenance history and performance?

有無針對每個進料器的數据庫紀錄維護以達到追蹤維護紀錄与效果的目的.

3.8Is feeder maintenance history used to monitor feeder life so that problematic feeders can be removed from the process?

Placement

#Audit Criterion

#Audit Criterion

Placement