Degradation of diesel oil in soil using a food waste composting process (2)

(D2876)BR_Power_Diesel_EN

n o i t a r e n e g r e w o P r e w o P

Contents MAN diesel engines for power generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Servicing concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Application type and product range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Description of engines D2866 (6) D2876 (8) D2676 (10) D2848 (12) D2840 (14) D2842 (17) D2862 (20)

MAN diesel engines for power generation Power wherever needed MAN offers manufacturers of power generators all over the world a broad spectrum of 6-, 8-, 10- and 12-cylinder engines including radiators for peak load leveling as well as for supplying emergency power and base loads. Depending on their type of operation in PRP (Prime Power), ESP (Emergency Standby Power), COP (Continuous Power) or LTP (Limited Time Power), the engines can be run for a maximum of between 200 and 8?000 hours a year. Totally reliable and with dependable availability and exemplary economy, they provide limitless energy generation. Transforming night into day. Customer Benefits n n MAN is a strong and independent partner for packagers and offers high quality engines made in Germany n n Global after sales network guarentees short-term spare parts supply n n Eco-friendly operation as a result of lower con-sumption of fuel and lubricating oil n n MAN engines with high efficiency, reliability and low maintenace costs result in profitable prime power operation especially in emerging markets n n MAN engines for standby operation to pro-vide maximum power output with quick load a cceptance in case of power shortage n n Ideal balance between compact design and r obust construction allows smaller size of c ontainer gensets with high durability Servicing concept MAN offers power-unit manufacturers a tailor-made servicing concept. This is how MAN gives you the option of performing servicing for your end customers yourself, from start to finish. This is made possible by an extensive training offering which can be matched individually to your needs. Power – Diesel engines for power generation 3

DIESEL ENGINE OIL CF 15W-40柴油发动机油产品安全数据表(MSDS)

产品安全数据表(MSDS) 第一部分化学品及企业标识__________________________________________________________________________________________________________________________________________________ 化学品中文名称:DIESEL ENGINE OIL CF 15W-40柴油发动机油 化学品俗名或商品名:柴油机油 化学品英文名称:DIESEL ENGINE OIL CF 15W-40 企业名称:天津日石润滑油脂有限公司 地址:天津市滨海新区汉沽化工街5号 邮编:300480 电子地址邮件: 传真号码:(086) 022 — 67161104 或 67161107 企业应急电话:(086) 022 — 67161105 或 67161106 技术说明书编码:无 生效日期:2009年2月 国家应急电话:无 第二部分成分/组成信息 主要组成:润滑油:81%、添加齐IJ:19% 化学品名称:石油系润滑油和添加剂 外观:黄褐色透明液体___________________________________________________________________ 第三部分危险性概述 危险性类别:非危险品。 燃爆危险:无爆炸危险性,属可燃物品。 第四部分急救措施 皮肤接触:用肥皂水及清水彻底冲洗皮肤。 眼睛接触:立即用流动清水或生理盐水冲洗,严重情况下就医。 吸入:迅速脱离现场至空气新鲜处。保持呼吸道通畅。必要时就医。 食入:清理口腔遗留物,吐出饮入物,必要时就医。 第五部分消防措施— 危险特性:遇明火、高热能引起燃烧。 燃烧产物:CO、CO2 灭火方法及灭火剂:可用泡沫、二氧化碳、干粉、砂土扑救,用水灭火无效。_________________ 第六部分泄露应急处理 应急处理:切断火源。迅速撤离泄露污染区人员至安全地带,并进行隔离,严格限制出入。建议应急处理人员戴自给正压式呼吸器,穿防毒服。尽可能切断泄露源。防止进入下水道、排洪沟等限制性空间。小量泄露:尽可能将溢漏液收集在密闭容器内,用砂土、活性碳或其它惰性材料吸收残液。大量泄露:构筑围堤或挖坑收容。运至废物处理所处理。 第七部分操作处置与储存 搬运注意事项:避免撞击磕碰。 储存注意事项:常温下室内储存,如露天存放需有遮阳防雨措施。

DEC 公司及产品 简介

Diesel Emission Control Limited CONFIDENTIAL THE INFORMATION CONTAINED HEREIN IS PROPRIETARY AND MAY NOT BE REPRODUCED OR TRANSMITTED TO ANY THIRD PARTY WITHOUT THE EXPRESS PERMISSION OF D IESEL E MISSION C ONTROL L TD.

DEC Diesel Emission Control is a designer and supplier of diesel engine exhaust emission control systems. It has developed key electronic control technology to allow diesel engines to satisfy ever more stringent emission requirements. The already been widely used DE-Tronic controller is fast gaining acceptance within the industry with supplies being made to customers throughout Europe and North America. The modular approach together with advanced control strategies enable DE-Tronic to be used in the most complex of applications e.g. burner control, hydrocarbon and urea injection. DEC IP and Know-How Technical know-how Dec has extensive know-how in the field of electronic control units (ECUs), actuators, sensors and ECU and PC interface software including calibration function. DEC has in the past mainly focused on zero km, retrofit and aftermarket products for heavy duty, off-road and non road applications. Current activities are becoming more focused on products for the OEM market in which the DEC technology is proving to be viable. In the future OEM passenger car market might also be an option. Commercial know-how DEC has extensive knowledge of the world market in diesel emission related technologies at both system and component level. Licenses The following important licenses are held by DEC 1.License from Clean Diesel Technologies Inc. DEC holds a license from CDTI to practice CDT’s methods and apparatus for an airless urea injection system for emission control of diesel engines for retrofit and for original equipment manufacturers, known as CDT’s ARIS? System. The technology is covered by patents which can be seen on the attached document ‘Schedule A, Patents and Patent Applications, Clean Diesel Technologies Inc./ Diesel Emission Control Ltd.’ The territory covered is worldwide, excluding Japan. An additional lump sum entry fee of $50,000 shall be paid if the rights for Japan are required. 2.License from Forschungsgesellschaft für Verbrennungskraftmaschinen und Thermodynamik mbH, Graz, Austria DEC has been granted an exclusive, worldwide license to utilize the urea dosing control algorithms developed by Prof. Hausberger at the Institute for Internal Combustion Engines and Thermodynamics at Graz, Austria.

Lesson 3 Diesel Engine Construction(1)模板

Lesson 3 Diesel Engine Construction (1) 第3 课柴油机结构(1) Bedplate and Frame机座和机架 The bedplate, which in most cases is of the welded design, is bolted to the seating which forms a part of the double bottom of the ship. 在大多数情况下机座是焊接结构,用螺栓固定在构成船舶双层底的底座上。 It is secured in the transverse direction by means of bolts known as side-chock bolts and in longitudinal direction by means of end-chock bolts. 它在横向借助于侧楔垫螺栓,在纵向借助于端楔垫螺栓固定。 The crankshaft rests in bearings built into cross girders of the bedplate. These bearings, known as main bearings 曲轴安放在机座横梁的轴承上,这些轴承称作主轴承。 each consists of two shells which are supported in housings machined in the bedplate and secured by means of studs and bearing caps 每个轴承由两块轴瓦组成,两块轴瓦由在机座上加工出的瓦座支撑,用双头螺栓和轴承盖固定 The thrust block or thrust bearing, located at the aft end of the engine, may be integral with, or separate from the bedplate. 即推力轴承位于发动机的尾部,可同机座制成一体,也可同机座分开。 On the flat upper surface of the bedplate are arranged a number of A-shaped frames or entablatures which may be manufactured of cast iron or fabricated steel. The frames are mounted on and bolted to the bedplate cross girders. 在机座上平面装有若干铸铁或锻钢制成的A形机架,机架安装在机座的横梁上,并用螺栓固定。 At the top of the A-frames there is a strong cast iron frame called the scavenging air box A 形机架顶部有一个结实的框架结构叫扫气箱 which is built of a number sections provided with vertical flanges enabling them to be bolted together to form a block for 1-3 cylinders in front of the chain transmission, and a block with 4-6 cylinders aft of the chain transmission. 该扫气箱分若干段,每段均带有垂直法兰,通过螺栓可将它们在链传动装置前1~3 缸的部分连成一体,链传动装置后4 缸~6 缸的部分连成一体。 The chain transmission, forming the connection between the crankshaft and the camshaft, is enclosed in a cast iron casing known as the chain drive casing. 链传动装置将曲轴和凸轮轴连在一起,封闭在链传动箱的壳体内。 Cylinders and covers气缸和气缸盖 On top of scavenging air box is mounted strong cast iron frame for each cylinder. 在扫气箱上部,每个气缸装有一个坚固的铸铁框架。 These frames are known as cylinder blocks or cooling jackets, which are provided with vertical flanges enabling them to be bolted together in the foremost and aftmost groups in the same way as the scavenging air boxes. 这些框架称作气缸体或冷却水套,并带有垂直法兰,与扫气箱一样,可用螺栓将各框架连成首尾一组。 The bedplate, frames and cylinder blocks are secured together by long tie-rods to

Marine Diesel Engines

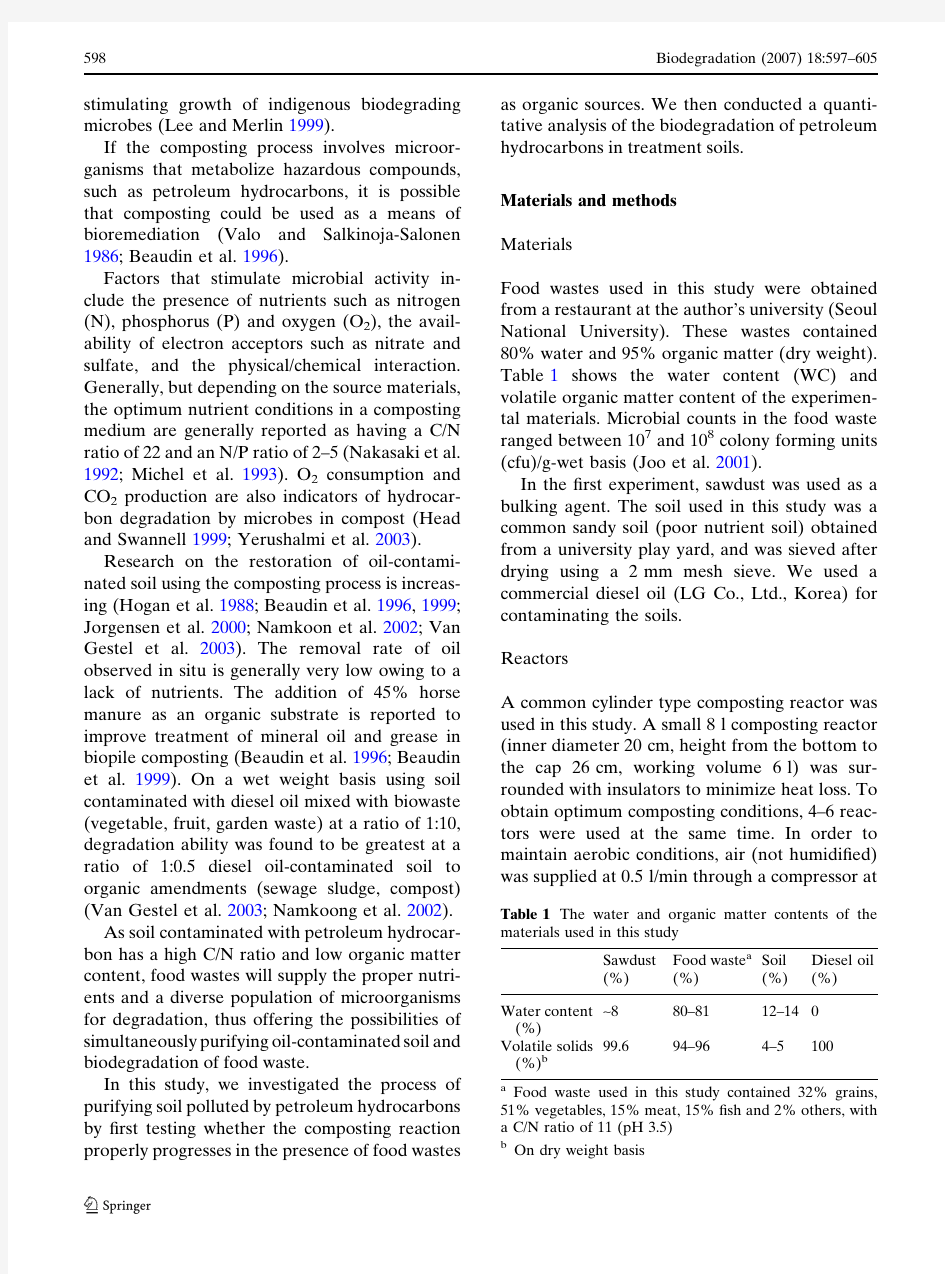

Chapter 7Marine Diesel Engines Edited by Kee-Rong Wu 7.1Prospects in Medium-Speed Diesel Engines 7.1.1Merits of Diesel Engines and Gas Turbine in Marine Propulsion This session will concentrates on diesel engines for cruise vessel applications with a total power requirement of approx. 60 MW each installation. A typical diesel-electric drive with five medium-speed diesel engines will be compared with the 58 MW COGES (Combined Gas Turbine and Steam Turbine Integrated Electric Drive System) [7.1]. In summer 2000, Celebrity Cruises' gas turbine-driven cruising vessel Millennium made her maiden voyage. The 91000 Ton vessel with a Pax capacity of 1950 (lower berth) denotes a technological shift in cruise ship design, primarily because she is the first cruise ship powered by a pure gas turbine plant. Apart from this, the ship has the biggest azimuth pods ever built (two Mermaid pods of 19.5 MW each). Currently there are three further cruise ships of this series under construction. This certainly is a milestone for gas turbine movers, the more so as four further new Vantage-class cruise ships for Royal Caribbean International (RCI) are also specified with turbine-based propulsion plants. Each plant consists of two General Electric LM2500+ aero-derived gas turbines of 25 MW each and an 8 MW back-pressure steam turbine. The steam turbine uses steam from the boilers fired by waste-heat from the gas turbines to generate additional electrical power. Depending on the amount of steam required for onboard services, the complete COGES power plant is expected to achieve a combined- cycle efficiency of between 45 and 50%. This system will provide for all onboard power arrangements, such as propulsion, heating, cooling, lighting, ventilation, kitchen and laundry. However, with about 97% of all existing sea-going ships propelled by two and four-stroke diesel engines (Fig. 7.1)due to its comparably high thermal efficiency (Fig. 7.2),it seems their manufacturers have so far not seriously been affected by gas turbines in most of their traditional market areas. Fig. 7.1: A cross-sectional view of MAN B&W V40/50four-stroke Diesel engine Fig. 7.2:Power efficiency comparison at ISO 3046 [7.1] In general, diesel engines posses lower initial costs, fuel economy, weight and size as

FIRE_ESE_Diesel

AVL FIRE ESE Diesel

Advanced Simulation Technologies

TM001 10/02

AVL List GmbH

Advanced Simulation Technologies ast@https://www.360docs.net/doc/e711228515.html,

AVL FIRE ESE Diesel

2007-8-21 | Page 1

AVL FIRE

ESE Diesel

Advanced Simulation Technologies

ESE Diesel

ESE Diesel

handles standard Diesel simulation tasks (spray adjustment and segment model simulation) geometrical model description based on 2D curves automated two- and threedimensional grid generation

TM001 10/02

default simulation control files for all applications full access to all physical and chemical models of AVL FIRE IC engine specific result analysis and result database automated report generation

AVL FIRE ESE Diesel 2007-8-21 | Page 2

热机循环对比Comparison_of_Otto,Diesel,dual_cycles

4.7 Comparison of Otto, Diesel and Dual Cycles: The important variable factors which are used as the basis for comparison of the cycles are compression ratio, peak pressure, heat addition, heat rejection and the net work. In order to compare the performance of the Otto, Diesel and Dual combustion cycles, some of the variable factors must be fixed. In this section, a comparison of these three cycles is made for the same compression ratio, same heat addition, constant maximum pressure and temperature, same heat rejection and net work output. This analysis will show which cycle is more efficient for a given set of operating conditions. Case 1: Same Compression Ratio and Heat Addition: The Otto cycle 1-2-3-4-1, the Diesel cycle 1-2-3'-4'-1 and the Dual cycle 1-2-2”-3”-4”-1 are shown in p-V and T-θ diagram in Fig.4.7.1 (a) and (b) respectively for the same compression ratio and heat input. (a) Volume Isentropic Process 1 2 2'33" 3' 44'4"

内燃机diesel engine

内燃机diesel engine 1.柴油机在四个冲程中,只有一个冲程即第二冲程产生功率,这就是为什么柴油机需要有若干个汽缸,其数目从用于小功率调车机车的4缸,到用于大功率干线机车的16缸或16缸以上。各个汽缸的曲柄互相排列成一定的角度,把柴油机工作周期划分为相应数目的相等部分,这样就保证了曲轴的扭矩十分均匀 It is during one stroke only out of the four, the second, that the engine develops its power, and this is why the diesel engine requires a number of cylinders, from four in a small shunter to sixteen or more in a main line unit of high power, with their cranks set at angles which divided up the circle into a corresponding number of equal parts, so ensuring a perfectly even torque of the crankshaft. 2.较大功率的汽缸往往按V形排列,汽缸在中线的左侧或右侧,以一定角度交错安排,汽缸以V形排列的柴油机比全部汽缸单列的柴油机更能缩短其总长度。 In the V-type cylinder arrangement, often adopted in the larger diesel engines, setting the cylinders alternately at angle right or left of the centre-line, in a “V” formation, makes possible a reduction in total length as compared with an engine that has all the cylinders in line. 3.也有两冲程的柴油发动机,它的工作循环仅由活塞用一个来回的行程就完成了。 There is also the two-stroke engine, in which the cycle of operation is completed in a single return stroke of the piston. 4.当接近燃烧冲程的末端时,活塞打开一个排气孔,让已用过的废气排出去,活塞再进一步运动,打开进气孔,空气通过进气孔随着活塞在压力下进入汽缸。一旦活塞在回程中通过了这两个气孔,就开始压缩空气,刚好在活塞到达上止点之前,喷射燃油。 Near the end of the combustion stroke the piston uncovers an exhaust port, which allows the spent gases to escape, and a further piston movement uncovers the inlet port, through which a charge of air under pressure enters the cylinder behind the piston. As soon as the piston has passed the two ports on the return stroke compression begins, and the oil is injected just before the piston reaches the top of the stroke. 5.两冲程发动机的活塞每次回程都产生燃烧,不像四冲程的活塞每隔一次回程才产生燃烧,但其功率并不是按比例增大,因为两冲程发动机的效率比四冲程的效率要低。 The power of a two-stroke engine does not go up in proportion to the fact that combustion takes place on every return stroke of the piston, instead of on every alternate return stroke, because the two-stroke engine is less efficient than the four-stroke. 6.在柴油机的复杂设备中,实际上其核心部分是喷油泵。它是由主轴通过独立轴上的一系列凸轮驱动的,每个凸轮推动一个汽缸喷油泵的柱塞,那柱塞封住少量的燃油,并以细雾状射入汽缸活塞上方,然后喷油泵的弹簧使柱塞回到“停止”位置。 Of the complicated equipment of a diesel engine, the most important constituent—in effect, the nerve centre—is the fuel injection pump. It is driven off the main crankshaft by a series of cams on an independent shaft, and each cam actuates the plunger of one of the cylinders. This plunger traps a small quantity of fuel oil, and delivers it as fine spray into the cylinder above the prison, after which a spring restores the plunger to its out-of-action position. 7.每隔冲程喷射燃油的数量可以变化,这就使发动机产生的功率发生相应的变化。 The amount of fuel delivered per stroke can be varied, with a proportionate variation in the power developed by the engine. 8.两冲程发动机的凸轮轴转动速度与主轴旋转速度相同,而四冲程发动机则为主轴转速的一半。另外有一根凸轮轴控制气阀,它准确、及时的打开与关闭汽缸的进气气孔。 In a two-stroke engine the camshaft is rotated at the same speed as the main crankshaft, and in a four-stroke engine at half the speed. Another camshaft works the valves which open and close the cylinder ports at precisely the right moments. 9.校正定时的工作是极其重要,而准确的精密度也是极其重要的,对喷油泵与气阀某些部件的研磨精密度可达到两万分之一英寸。 Correct timing is of the utmost importance, and also extreme accuracy, down to a twenty-thousandth part of an inch, in

Diesel Emission Control in review

400 Commonwealth Drive, Warrendale, PA 15096-0001 U.S.A. Tel: (724) 776-4841 Fax: (724) 776-0790 Web: https://www.360docs.net/doc/e711228515.html, 2007-01-0233 Diesel Emission Control in Review Timothy V. Johnson Corning Incorporated Reprinted From: Diesel Exhaust Emission Control, 2007 (SP-2080) 2007 World Congress Detroit, Michigan April 16-19, 2007

By mandate of the Engineering Meetings Board, this paper has been approved for SAE publication upon completion of a peer review process by a minimum of three (3) industry experts under the supervision of the session organizer. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SAE. For permission and licensing requests contact: SAE Permissions 400 Commonwealth Drive Warrendale, PA 15096-0001-USA E mail: permissions@https://www.360docs.net/doc/e711228515.html, Fax: 724-776-3036 Tel: 724-772-4028 For multiple print copies contact: SAE Customer Service Tel: 877-606-7323 (inside USA and Canada) USA) (outside Tel: 724-776-4970 Fax: 724-776-0790 E mail: CustomerService@https://www.360docs.net/doc/e711228515.html, ISSN 0148-7191 Copyright ? 2007 SAE International Positions and opinions advanced in this paper are those of the author(s) and not necessarily those of SAE. The author is solely responsible for the content of the paper. A process is available by which discussions will be printed with the paper if it is published in SAE Transactions. Persons wishing to submit papers to be considered for presentation or publication by SAE should send the manuscript or a 300 word abstract of a proposed manuscript to: Secretary, Engineering Meetings Board, SAE. Printed in USA

Diesel Generating Set

Diesel Generating Set HP300 Model HP300 Standby Power (50Hz) 280 KW / 350 kV A Prime Power (50Hz) 240 KW / 300 kV A Standard Features: General Features: ● Perkins Engine (2206C-E14TAG1); ● Radiator 40 oC max, fans are driven by belt, with safety guard; ● 24V charge alternator; ● Alternator (Marathon MP-240-4), single bearing alternator, protection class IP22, insulation class H/H; ● Absorber; ● Dry type air filter, fuel filter, oil filter; ● Main line circuit breaker; ● Standard control panel; ● Two12V batteries, rack and cable; ● Flexible exhaust bellows, exhaust elbow, flange, muffler; ● User manual. Generator Ratings: Voltage (V) Frequency (Hz) Phase PF Standby Current (A) Standby Power (KW/KV A) Prime Power (KW/KV A) 440/254 50 3 0.8 459 280/350 240/300 415/240 50 3 0.8 487 280/350 240/300 400/230 50 3 0.8 505 280/350 240/300 380/220 50 3 0.8 532 280/350 240/300 Prime Power (PRP): Prime power is available for an unlimited number of annual hours in variable load application, in accordance with GB/T2820-97(eqv ISO8528); A 10% overload capability is available for a period of 1 hour within a 12-hour period of operation. Standby Power Rating (ESP): The standby power rating is applicable for supplying emergency power for duration of a utility power interruption. No overload, utility parallel or negotiated outage operation capability is available at this rating. Warranty: Hengjin Power provides a full line of brand new and high quality products. Each and every unit is strictly factory tested. Warranty is according to our standard conditions: 12 months or 1,000 running hours, subject to the earlier one. Service and parts are available from Hengjin Power or distributors in your location.