JED-019M

JED-019M : 2005-10 Page 2

3 Thermal range of application

Continuous operational temperature range: -60 °C t o +250 °C

For the thermal range of application of the finished parts the range of application of a possibly

applied surface coating has to be taken into consideration.

4 Properties

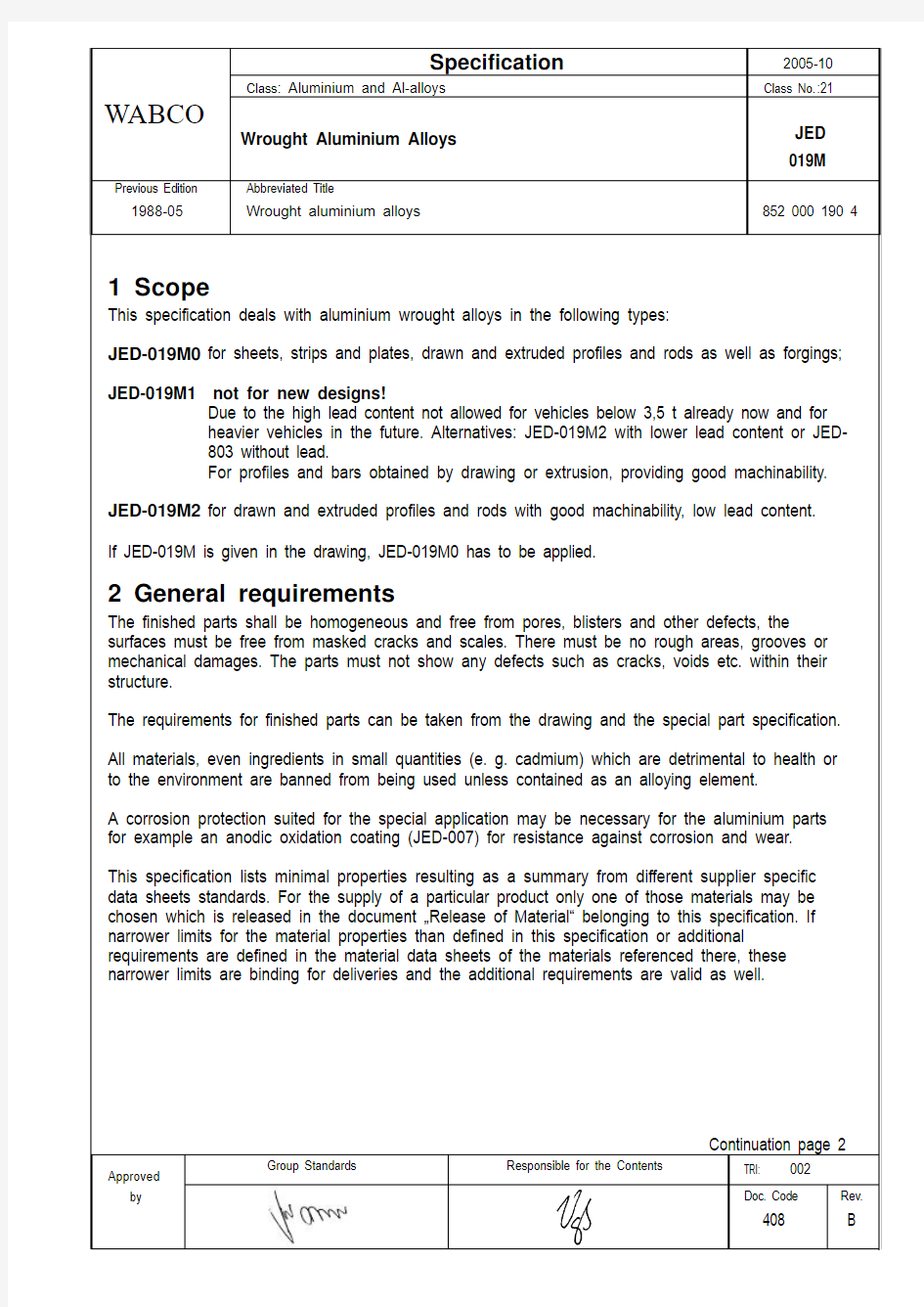

4.1 Mechanical properties

JED-019M0 JED-019M1 JED-019M2

Tensile strength (ISO 6892): > 270 > 260 > 310 (N/mm2) 0.2 % proof stress (ISO 6892): > 200 > 200 > 260 (N/mm2) Elongation at break (ISO 6892): > 6 > 8 > 8 (%)

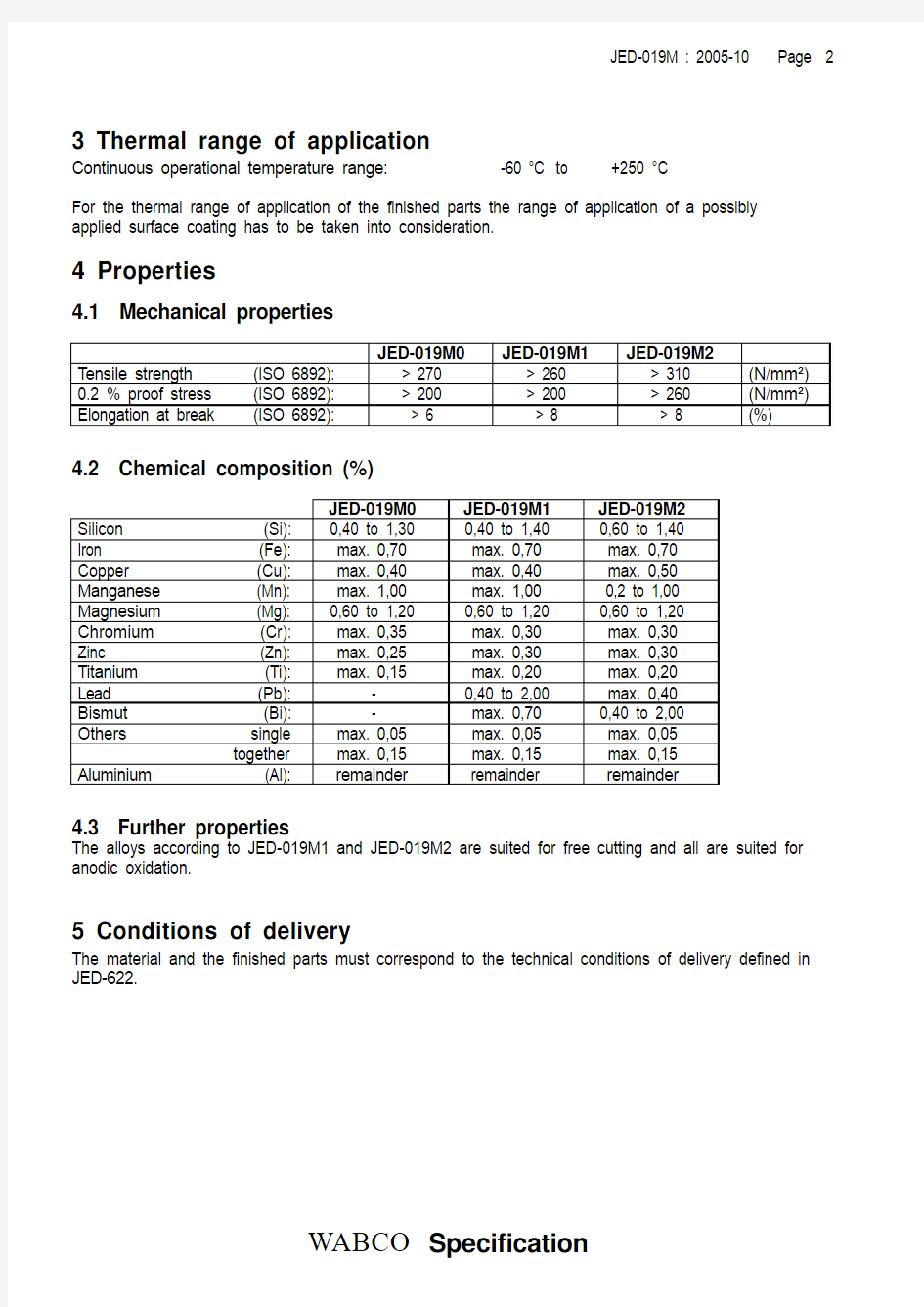

4.2 Chemical composition (%)

JED-019M0 JED-019M1 JED-019M2

Silicon (Si): 0,40 to 1,30 0,40 to 1,40 0,60 to 1,40

Iron (Fe): max. 0,70 max. 0,70 max. 0,70

Copper (Cu): max. 0,40 max. 0,40 max. 0,50

Manganese (Mn): max. 1,00 max. 1,00 0,2 to 1,00

Magnesium (Mg): 0,60 to 1,20 0,60 to 1,20 0,60 to 1,20

Chromium (Cr): max. 0,35 max. 0,30 max. 0,30

Zinc (Zn): max. 0,25 max. 0,30 max. 0,30

Titanium (Ti): max. 0,15 max. 0,20 max. 0,20

Lead (Pb): - 0,40 to 2,00 max. 0,40

Bismut (Bi): - max. 0,70 0,40 to 2,00

Others single max. 0,05 max. 0,05 max. 0,05

together max. 0,15 max. 0,15 max. 0,15

Aluminium (Al): remainder remainder remainder

4.3 Further properties

The alloys according to JED-019M1 and JED-019M2 are suited for free cutting and all are suited for anodic oxidation.

5 Conditions of delivery

The material and the finished parts must correspond to the technical conditions of delivery defined in JED-622.

WABCO Specification