Novel helical TiO2 nanotube arrays modi

Novel helical TiO2nanotube arrays modi?ed by Cu2O for enzyme-free

glucose oxidation

Mei Long,Lin Tan,Hongtao Liu,Zhen He,Aidong Tang n

School of Chemistry and Chemical Engineering,Central South University,Changsha410083,PR China

a r t i c l e i n f o

Article history:

Received29January2014

Received in revised form

8March2014

Accepted12March2014

Available online29March2014

Keywords:

Cu2O/TiO2

Nanotube array

Electrochemical property

Sensor

a b s t r a c t

A helical TiO2nanotube(TNT)array modi?ed with cuprous oxide(Cu2O)electrode was fabricated and

used for nonenzymatic glucose detection.The structure and morphology of Cu2O/TNT were character-

ized by X-ray diffraction and transmission electron microscopy.The electrocatalytic performance of

Cu2O/TNT electrode for glucose oxidation was investigated by cyclic voltammetry and chronoampero-

metry.At an applied potential oft0.65V versus SCE,a linear range was obtained within the

concentration range of3.0–9.0mM with a detection limit of62μM(signal/noise?3).The response

time was approximately3s after adding0.10mM glucose.Formate and gluconic acid were identi?ed as

the main products of the glucose oxidation using1H NMR spectrometry.A possible mechanism for

continuous glucose oxidation was also proposed.

&2014Elsevier B.V.All rights reserved.

1.Introduction

Glucose is a simple sugar that is extensively distributed in the

blood of living organisms.This simple sugar is often used as a

marker of diabetes,which has become one of the major diseases

worldwide.Moreover,glucose as a common food component is

also an indicator of food quality/acceptability.Therefore,the

quantitative determination of glucose level,not only in blood but

also in other sources such as foods and pharmaceuticals,is very

important in biological and clinical analysis(Chen,2013;Wang et

al.,2012).Glucose oxidase exhibits high sensitivity and selectivity

to glucose and is widely used as biosensors for glucose detection.

However,enzymatic glucose sensors are limited by their instabil-

ity,complex enzyme immobilization,and high sensitivity to

temperature,pH,and humidity.To overcome these drawbacks,

numerous efforts have been made to develop non-enzymatic

amperometric glucose sensors.These sensors are based on the

generation of electrons in catalyst-assisted glucose oxidation,

resulting in a detectable current response that is linearly corre-

lated with glucose concentration(Guo and Wang,2011).With

ongoing technical development,nanostructured metals,such as Pt

(Park et al.,2012),Au(Wang,et al.,2013a,2013b),Ag(Yang,et al.,

2013),and Ni(Pissinis et al.,2013),or metal-oxides such as NiO

(Cao et al.,2011;Zhu et al.,2013),Co3O4(Hou et al.,2012;Ensa?

et al.,2013),and Cu x O(Jiang and Zhang,2010;Wang et al.,2010a,

2010b;Luo et al.,2011;Yang et al.,2012;Zhang et al.,2012;

Dung et al.,2013;Sun et al.,2013)have been extensively explored

in constructing biosensors for the determination of glucose via

electrochemical oxidation(Rahman et al.2010).Compared to

noble metals and alloys,copper-based materials that are less

expensive exhibited comparable catalytic oxidation ability for

glucose(Zhang et al.,2009;Li et al.,2010;El Khatib and

Hameed,2011;Luo et al.,2012;Wang et al.,2012;Yec and Zeng,

2012;Zhou et al.,2012;Meng et al.,2013;Xu et al.,2013).One

promising strategy for Cu2O,used as a high-ef?ciency electro-

catalyst,is planting Cu2O nanoparticles to various supporting

materials such as polypyrrole(PPy)nanowire(Meng et al.,2013),

reduced graphene oxide(Zhang et al.,2009;Xu et al.,2013),and

straight multi-walled carbon nanotube(Zhou et al.,2012).The

Cu x O/PPy sensor showed excellent selectivity,reproducibility,and

stability(Meng et al.,2013).Furthermore,cuprous oxide-reduced

graphene oxide nanocomposite displayed better performance for

the catalytic reduction of H2O2,compared with the single compo-

nent Cu2O(Xu et al.,2013).Similarly,the as-prepared nanospin-

dle-like Cu2O/SMWNTs nanohybrids demonstrated much higher

electrocatalytic activity towards the oxidation of glucose than the

SMWNTs or Cu2O alone,which is attributed to the high catalytic

active sites provided by the nanospindle-like Cu2O,and the high

electron transfer rate delivered by an ef?cient electrical network

formed by Cu2O and SMWNTs(Zhou et al.,2012).Recently,the

encapsulation of individual nanoparticles in morphologically well-

de?ned inorganic tubes has received much attention because of

thermal and chemical stabilities in catalysis(Huo and Yang,2012).

The substrates of nonenzymatic sensors and their spatial structure

have been recognized as the main factors that in?uence the

analytical performance of biosensors(Meng et al.,2013).

Contents lists available at ScienceDirect

journal homepage:https://www.360docs.net/doc/fb416563.html,/locate/bios

Biosensors and Bioelectronics

https://www.360docs.net/doc/fb416563.html,/10.1016/j.bios.2014.03.032

0956-5663/&2014Elsevier B.V.All rights

reserved.

n Corresponding author.Tel./fax:t8673188879616.

E-mail address:tangaidong@https://www.360docs.net/doc/fb416563.html,(A.Tang).

Biosensors and Bioelectronics59(2014)243–250

Well-aligned TiO2nanotube arrays(TNT)with a large speci?c surface area and abundant active sites have attracted extensive interest because of their low cost,long-term chemical and thermal stability,excellent biocompatibility,and nontoxicity.Consequently, the TNT has been proposed as one of the ideal carriers for the immobilization of biomolecules(Rahman et al.,2010),metals (Wang,2010a,2010b;Li et al.,2013),and metal oxides.However, compared to electron conductors,such as PPy nanowire,reduced graphene oxide,and straight multi-walled carbon nanotube,TiO2 has very poor conductivity.We proposed that Cu2O in tandem with TiO2would be a good solution for this problem.The narrow-bandgap Cu2O nanoparticles,acting as active materials to promote the charge transfer to TiO2/Ti electrode,lead to an ef?cient charge carrier separation,thus improving the conductivity of TiO2/Ti electrode.Therefore,such p–n heterojunction electrodes com-posed of Cu2O-loaded TiO2nanotube arrays may exhibit enhanced electrocatalytic activities.Various methods have been adopted to obtain catalysts of different morphologies with high surface area. Previous studies on Cu2O/TiO2heterojunction nanoparticles have been reported(Huang et al.,2010;Zhang et al.,2011;Chen,2013; Wang,et al.,2013a,2013b).Electrochemical deposition is one of the most convenient and effective methods to deposit semicon-ductor nanoparticles onto the TNT structure.Recently,anodic TiO2 nanotubular arrays having high surface area and precisely con-trolled morphology have been widely studied as catalyst support. However,to the best of our knowledge,the helical TNTs are less studied,and no reports on Cu2O/TNT array for nonenzymatic glucose detection have been published.In this work,we success-fully fabricated helical Cu2O/TNT composites by incorporating the nano-sized polyhedral Cu2O into the entire TNT frameworks using an electrodeposition method.The synergy between TiO2nano-tubes and Cu2O nanopaticles may lead to an enhanced detection performance of nonenzymatic glucose sensors.The activity of Cu2O/TNT nanostructures may also be improved because of high catalytic active sites provided by Cu2O nanoparticles supported on the self-assembled and highly oriented TiO2nanotube arrays with a helical-like morphology.The electrochemical behavior of the obtained anodic curves toward electrocatalytic oxidation of glu-cose,including a proposal for the detection mechanism,is also discussed.

2.Experimental

2.1.Chemicals

All chemicals used in this study were of analytical grade. Glucose,CuSO4á5H2O,NaOH,NH4F,glycerol,lactic acid,and Ti foils(purity499.6%)were purchased from ChangSha Chemical Corp.in China.Glucose was used as received.Double-distilled water was used for the preparation of standard solutions.

2.2.Preparation of the Cu2O/TNT electrode

TNTs were fabricated through a two-step anodization.Before fabrication,Ti foils(purity499.6%,100mm?10mm in size, 0.14mm in thickness)were ultrasonically cleaned in acetone and alcohol.A Pt foil(purity499.9%)was used as the cathode and pure Ti foil was used as the anode.In the?rst step,anodization was carried out in a glycerol electrolyte containing0.5wt%NH4F. The voltage and oxidation time were20V and1h,respectively. Afterward,the pre-anodized Ti foil was ultrasonically cleaned in an acid solution containing HF and HNO3to remove the formed TiO2?lm.The cleaned Ti foil was used for the secondary anodiza-tion in a similar electrolyte with the addition of HF.The voltage and oxidation time were20V and4h,respectively.The as-prepared TiO2nanotubes were cleaned using distilled water, air dried,and then calcined in a muf?e furnace at5001C for3h.

Cu2O/TNT composites were prepared by electrochemical deposition of Cu2O in a three-electrode cell,using the TNT, saturated Hg/Hg2Cl2(SCE),and platinum foil as the working, reference,and counter-electrodes,respectively.A CHI660B elec-trochemical working station(ChenHua Instruments Co.Ltd., Shanghai,China)was used as the power source.The electrolyte was obtained by dissolving1mol Là1CuSO4in a3mol Là1lactic acid solution to form a copper lactate complex,and pH was further adjusted to12using5M NaOH solution.The electrolyte was stirred and kept at a constant temperature of351C.An electro-deposition charge of1C and a potential ofà0.7V versus saturated calomel electrode were used during the deposition process.After the electrochemical deposition,the Ti foil covered with Cu2O/TNT was thoroughly washed using distilled water,and air dried.

2.3.Characterization

X-ray diffraction(XRD)patterns of the fabricated products were recorded on a DX-2700X-ray diffractometer(Liaoning Dandong Hao Yuan Instrument Co.,Ltd.TD)at a scan rate of 0.051sà1with a2θrange from201to801,using high-intensity Cu Kαradiation(λ?0.15418nm).Scanning electron microscope

(SEM)images were obtained using a FEI Nova NanoSEM230?eld emission scanning electron microscope.Microstructures and morphologies were investigated using a Tecnai G2F20S-TWIN (FEI Company)transmission electron microscope(TEM)with a ?eld emission gun of200kV.1H NMR spectra were recorded using an AVANCE III500MHz Bruker spectrometer.Tetramethylsilane (TMS)was used as the internal standard(0.00ppm)and the residual solvent was D2O.

2.4.Electrochemical measurements

Electrochemical measurements were performed using a CHI 660B electrochemical workstation(ChenHua Instruments Co.Ltd., Shanghai,China)on a conventional three-electrode setup,with Cu2O/TNT as the working electrode,Pt foil as the counter-elec-trode,and SCE as the reference https://www.360docs.net/doc/fb416563.html,ing the modi?ed Cu2O/TNT working electrode,data on cyclic voltammetric(CV) and amperometric experiments were obtained in a mixture of 4mmol Là1glucose and0.1mol Là1NaOH.The CV measurements required operation of the electrode in a range of potential of 0–0.8V versus SCE.The measurements of amperometric curves required operation of the electrode at a constant applied potential of0.65V versus SCE under ambient temperature.Once the current reached a plateau in the absence of glucose,glucose was added every50s thereafter with constant stirring using a magnetic stirrer at20rpm.

3.Results and discussion

3.1.Characterization of the Cu2O modi?ed TiO2nanotubes array electrode

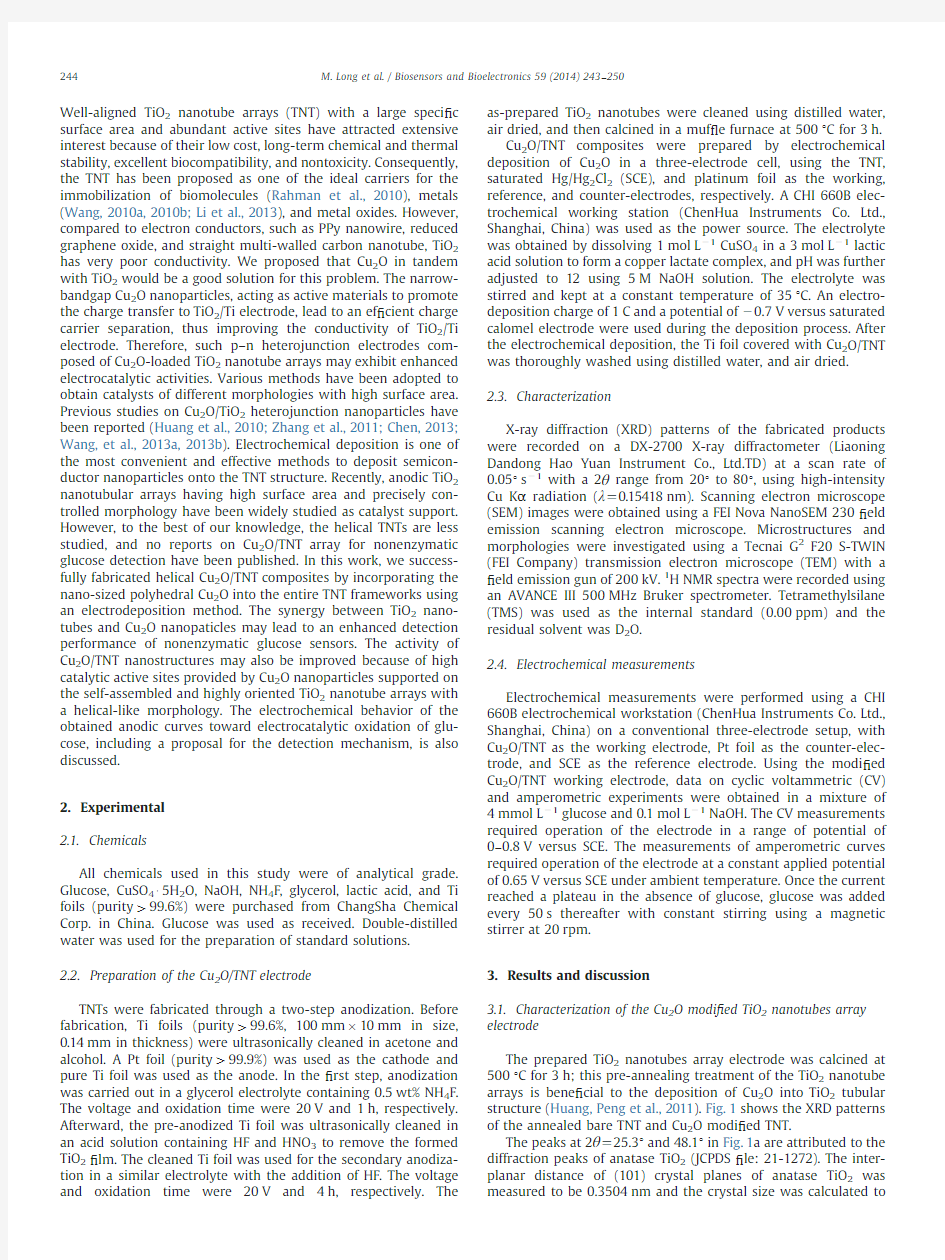

The prepared TiO2nanotubes array electrode was calcined at 5001C for3h;this pre-annealing treatment of the TiO2nanotube arrays is bene?cial to the deposition of Cu2O into TiO2tubular structure(Huang,Peng et al.,2011).Fig.1shows the XRD patterns of the annealed bare TNT and Cu2O modi?ed TNT.

The peaks at2θ?25.31and48.11in Fig.1a are attributed to the diffraction peaks of anatase TiO2(JCPDS?le:21-1272).The inter-planar distance of(101)crystal planes of anatase TiO2was measured to be0.3504nm and the crystal size was calculated to

M.Long et al./Biosensors and Bioelectronics59(2014)243–250 244

be about 34.18nm by the Scherrer equation (Yang et al.,2011).Three kinds of diffraction peaks can be identi ?ed from the XRD patterns in Fig.1b.The presence of Cu 2O in the sample after deposition can be con ?rmed by the characteristic re ?ection peaks at 36.51and 29.61,assigned to (111)and (110)crystal planes of the cubic Cu 2O (JCPDS ?le:65-3288).The interplanar distances of (111)and (110)crystal plane of cubic Cu 2O were measured to be 0.2456nm and 0.2978nm,and the crystal size of (111)crystal planes was calculated to be about 40.95nm by the Scherrer equation (Yang et al.,2011).Aside from the diffraction peaks of Ti substrate and TiO 2nanotubes,no other peak assigned to CuO or Cu phase was detected in the as-prepared sample.

Fig.2shows the morphologies and the crystal of the obtained Cu 2O/TNT.The top-view pro ?le-sectional FE-SEM images of the as-prepared TNT with a helical nanotube structure are shown in Fig.2a.Fig.2b illustrates the pro ?le-sectional TEM images of the Cu 2O/TNT.The Cu 2O modi ?ed TNT shows a highly ordered and open structure with a clearly helical-like morphology.The classic Cu 2O/TNT arrays with an outer diameter of about 105nm and wall thickness of 10nm in Fig.2c are highly arranged.

Fig.2d and e shows high resolution TEM (HRTEM)images of the as prepared Cu 2O/TNT.The observed lattice spacing of 0.35nm in the left portion of the image corresponds to (101)plane of anatase,showing that the wall consists of TiO 2.The observed 0.245and 0.296nm fringes of the wall correspond to (111)and (110)planes of Cu 2O,respectively.Results show that Cu 2O has been deposited into the outer pore wall of the TiO 2nanotubes.The small lattice distances difference between (110)planes of Cu 2O and (101)facets of TiO 2favors the (110)planes of Cu 2O nucleation on the surface of TiO 2nanotubes.HRTEM image of Cu 2O –TiO 2nanocomposites shows that the (110)planes of Cu 2O with d -spacing of about 0.296nm and the (101)facets of TiO 2with d -spacing of about 0.350nm intersect each other at the interfaces,which means that Cu 2O were epitaxially grown on the surfaces of TiO 2(Fig.2d).However,the large lattice mismatch between (111)planes of Cu 2O and (101)facets of TiO 2makes it very dif ?cult to form a desired heterogeneous nucleation on the TiO 2nanotubes surfaces (Fig.2e).Therefore,the interaction between TiO 2and Cu 2O is very likely attributed to the (110)facets Cu 2O epitaxially grown on the surfaces of TiO 2despite the necessity of further con ?rmation.TiO 2nanotube arrays clearly act as a support to facilitate the dispersion of Cu 2O nanoparticles.The TiO 2nanotubes have a well-ordered tubular structure with a high surface-to-volume ratio,which is bene ?cial for the attachment of Cu 2O nanoparticles and transport of electrical carriers along one con-trollable direction.Moreover,the helical tunnel structure and the

vertically aligned TiO 2nanotubes surrounded by numerous Cu 2O nanoparticles could improve the incorporation of analytes.3.2.Electrocatalytic oxidation of glucose on Cu 2O/TNT electrode The effect of pH on the glucose electrochemical property has been investigated on Cu 2O/MWCNTs modi ?ed electrode (Zhang et al.,2009).High pH is helpful to the mutarotation of glucose,which results in the increase of current.On the other hand,at high pH,glucose isomerization occurs and fructose and mannose will be formed,which results in the decrease of current.Therefore,we selected the NaOH concentration as 0.1M for nonenzymatic glucose detection.The electrocatalytic activities of bare TNT electrode and Cu 2O/TNT electrode towards the oxidation of glu-cose in 0.1M NaOH are shown in Fig.3A.In the presence of 4.0mM glucose,no obvious catalytic oxidation current on the bare TNT electrode (curve b)is observed compared with the absence of glucose (curve a).By contrast,the Cu 2O/TNT electrode shows obvious catalytic oxidation current (curve d)in the presence of 4.0mM glucose compared with the absence of glucose (curve c).The catalytic oxidation current is signi ?cantly higher than that of the Cu 2O/TNT electrode in the absence of glucose.The oxidation current rapidly increases,starting at about 0.35V with the appearance of an oxidation peak at around 0.55V and completing at about 0.75V.These results show that Cu 2O/TNT has good electrocatalytic activity toward the oxidation of glucose.Moreover,the catalytic currents gradually increase on the Cu 2O/TiO 2elec-trode with increasing glucose concentration (Fig.3B)and Fig.3C shows the cyclic voltammograms of the Cu 2O/TNT electrode recorded in 0.1M NaOH solution at different scan rates in the range of 20–200mV s à1.The oxidative peak current (the corre-sponding potential is 0.65V)is notably increased in a linear manner with increasing scan rates.

Fig.3C shows the cyclic voltammograms of the Cu 2O/TNT electrode recorded in 0.1M NaOH solution at different scan rates in the range of 20–200mV s à1.The oxidative peak current (the corresponding potential is 0.65V)linearly increased with the increasing scan rate in the range of 20–200mV s à1,as shown in the inset of Fig.3(C).A good linearity between scan rate and peak current is obtained,i (μAcm à2)??0.19t40.16ν(mVs à1),with a correlation coef ?cient (R 2)of 0.996.Further examinations about the dependence of scan rate on peak current at Cu 2O/TNT electrode illustrated a linear relationship between the voltam-metric peak current for glucose oxidation and the square root of the scan rate,àln i (μAcm à2)??1.51t0.026ν1/2(mV s à1)1/2,with a correlation coef ?cient (R 2)of 0.994.These results indicate that the glucose electrochemical oxidation is under diffusional control of glucose at scan rates lower than approximately 0.2V s à1.

To further clarify the effect of Cu 2O nanoparticles on electro-chemical properties of TiO 2nanotubes different Cu 2O/TNT electro-des were prepared at different deposition charges 1.0C and 1.5C,other conditions being the https://www.360docs.net/doc/fb416563.html,parison of their SEM images and CV curves is shown in Fig.3D.Different deposition charges would result in different amounts of Cu 2O nanoparticles being deposited onto TNT,which would generate different catalytic activities towards glucose oxidation at the prepared electrodes.As can be seen,Fig.3D(a,b)displays lots of Cu 2O particles with different morphologies decorated on the walls of TNT.Moreover,the response current of the Cu 2O/TNT electrode prepared at 1.5C is greater than that of 1.0C from Fig.3D(c,d),showing that more Cu 2O nanoparticles deposited onto TNT lead to higher response current.

To identify the products generated during glucose oxidation,1

H NMR spectrometry (Fig.4)was employed according to the method described by Farrell and Breslin (2004).For these mea-surements,glucose concentration was increased to 30

mM.

Fig.1.XRD patterns of TiO 2nanotube arrays (a)and Cu 2O/TiO 2nanotube arrays (b).

M.Long et al./Biosensors and Bioelectronics 59(2014)243–250245

The glucose solution was oxidized at an applied potential of 0.65V/(SCE)for a 16h period and then analyzed using TMS as the internal standard.

For the starting material,the expected absorptions for glucose in 2.8–3.8ppm region were demonstrated.The peak centered at 8.3ppm is attributed to formate and has been previously observed by Luo and Baldwin (1995).Absorption in the 3.75–4.75ppm region represents gluconic acid formation.Therefore,gluconic acid and formate were identi ?ed as the main products of the glucose oxidation reaction in 0.1M alkaline solution,detected using 1H NMR spectrometry.The obtained results indicate that the major products,gluconic acid and formate,are in agreement with the ?ndings of Marioli and Kuwana (1992),who concluded that glucose oxidation may proceed beyond the formation of gluconic or glucuronic acids to give lower molecular weight products and fragmentation of the carbohydrate carbon skeleton.3.3.Electrochemical sensing properties

Fig.5shows the amperometric measurement of the Cu 2O/TNT electrode in 0.1M NaOH solution at 0.65V versus SCE,with successive additions of glucose.The steady-state currents are obtained at a 3s response time and are plotted as the calibration curve,which shows the lowest limit of detection,62μM,for glucose.This observation may be attributed to the enhanced nano-size effect realized by the highly well dispersed self-assembly nanostructure.The sensor electrode exhibits linearity for glucose sensing that ranged from 3mM to 9mM,with a correlation coef ?cient of 0.992(illustrated by the right inset in Fig.5).The electrode sensitivity calculated from the slope of the calibration curve is 14.56μA cm à2mM à1.The Cu 2O/TNT electrode exhibits improved characteristics in terms of sensitivity and limits of detection,which is induced by the nano-size effect in a well dispersed self-assembly nanostructure.

As shown in Fig.6,to evaluate the selectivity of the Cu 2O/TNT electrode,the current responses to several possible interfering biomolecules,such as ascorbic acid (AA),uric acid (UA),and fructose,which normally coexist with glucose in human blood,were examined.Considering that the concentration of glucose in the human blood is more than 30times of interfering materials (Luo et al.,2011),the interference experiment was conducted at Cu 2O/TNT arrays electrode by successive addition of 4.0mM glucose and 0.40mM interfering materials into the 0.10M NaOH solution.The results show an apparent response to glucose and insubstantial responses to interfering materials.The interferences current responses range from 5.47%(AA)to 6.66%(fructose)and (UA)9.61%with respect to the current response to 4.0mM glucose at t0.650V (versus SCE).Hence it can be concluded that the Cu 2O/TNT electrode can demonstrate high selectivity for glucose detection.Although Cu-based electrode materials were used for very high potential in biosensor performance,the applied poten-tial of 0.65V for our obtained Cu 2O/TNT electrodes is not very high compared with the literature.For a glassy carbon electrode modi ?ed with CuO nanowires and a Na ?on ?lm,the

maximum

Fig.2.Top-view pro ?le-sectional FE-SEM images of the as-prepared TNT (a);the pro ?le-sectional TEM images of the Cu 2O/TNT (b);and the HRTEM images of the Cu 2O/TNT (c)–(e).

M.Long et al./Biosensors and Bioelectronics 59(2014)243–250

246

response current with a good signal/noise ratio was achieved at 0.80V(Zhang et al.,2012).In addition,for a copper nanocluster/ multiwall carbon nanotube-modi?ed glassy carbon electrode,the maximum response current was observed at0.65V and a good signal/noise ratio can be offered that is the same as our results. When the sensor was applied for the determination of glucose in real blood serum samples,the results are in agreement with those determined by the hospital(Kang et al.,2007).It can be seen that the Cu-based modi?ed electrode materials including our obtained Cu2O/TNT electrodes present excellent anti-interference ability against the commonly coexisting species such as uric acid(UA) and ascorbic acid(AA)in real samples.

Most of the electrochemical nonenzymatic glucose sensors based on noble metal are reported to easily lose their activities because of the poisoning by chloride ions,which are abundant in physiological?uids.Thus,the amperometric responses of the Cu2O/TNT electrode to4.0mM glucose in a0.10M NaOH solution and a0.10M NaOH solution containing0.20M NaCl are examined to be89.70μA cmà2and93.5μA cmà2,respectively.The results prove that change in current responses can be enhanced by4.23% in the presence of chloride,implying that the Cu2O/TNT electrode is hardly poisoned by chloride ions.

The reproducibility and stability of the Cu2O/TNT electrode response current were tested.The current density responses (89.32,88.4,95.93,93.55,and92.45μA cmà2)to the addition of 4.0mM of glucose at the same Cu2O/TNT electrode for?ve times minimally changed.The relative standard deviation is 2.89%, indicating that the Cu2O/TNT electrode is stable and can hence be repeatedly used.

The sensor was exposed to air at room temperature.The current density response to the addition of2.0mM glucose at the Cu2O/TNT electrode after26d retained98.61%of its original density of 73.90μA cmà2.The results demonstrated that the electrode can be used in long-term applications.The good reproducibility and long-term stability of Cu2O/TNT electrode can be attributed to both the good stability of Cu2O modi?ed TiO2nanotube arrays in the base solution and to good chemical stability of the materials.

3.4.Discussion for electrocatalytic oxidation of glucose over

Cu2O/TNT electrode

From the CV of the Cu2O/TNT electrode in0.1M NaOH solution with absence of glucose(Fig.3A(c)),a broad and weak oxidation current plateau from about0.30to0.75V is observed,which

can

Fig.3.(A)CVs of bare TNT electrode(a and b)and Cu2O/TNT electrode(c and d)in the absence(a and c)and presence(b and d)of4mM glucose in0.10M NaOH;(B)CVs of the Cu2O/TiO2electrode in0.1M NaOH in different concentrations of glucose:0(a),3.0(b),5.0(c)and8.0mM.Scan rate:50mv/s;(C)CVs of Cu2O/TiO2electrode obtained in0.10M NaOH solution containing2mM glucose at different scan rates(inner to outer):20,50,80,100,120,150,180,and200mV sà1,and the dependence of the oxidation peak current density(at650mV)of glucose on scan rate(left inset).(D)SEM images and CVs of the as-prepared Cu2O/TNTs electrode prepared at different deposition charges:1.0C(a and c)and1.5C(b and d)in the absence and presence of2mM glucose in0.1M NaOH.

M.Long et al./Biosensors and Bioelectronics59(2014)243–250247

be mainly attributed to the formation of different surface species of Cu(I)hydroxide,Cu(II)oxide,or hydroxides.The surface copper hydroxides are easily formed in highly alkaline electrolyte.The appearance of a reversible response at 0.75–0.8V,just prior to the onset of oxygen gas evolution,is assumed to be associated with a Cu(II)/Cu(III)transition,probably in an oxide deposit on the electrode surface.Evidence for the reduction of Cu(III)species has been available for the appearance of an obvious cathodic counterpart at 0.668V in the negative sweep (Fig.3A(c)).We believe that this reduction peak is due to the reduction of Cu(III)species.Similarly,Fleischmann et al.claimed that the copper II/III transition occurs at potentials of 0.65V versus SCE in 0.1M KOH,which is too close to bulk oxygen evolution to be studied in detail.However,the presence of Cu(III)in the apparent charge under the peaks had a clear indication (Wang,et al.,2013a,2013b ).Further-more,the thermodynamic data for copper in an aqueous base are summarized in terms of the following equations:

2CuO t2H tt2e à?Cu 2O tH 2O,E θ

?0.4275V (0.5055)V versus SCE (1)CuO t2H tt2e -?Cu tH 2O,E θ

?0.3285V (0.3675)V versus SCE(2)Cu 2O t2H tt2e -?2Cu tH 2O,E θ?0.2285V versus SCE

(3)

The potential value is quoted in terms of the SCE scale;those in

parentheses refer to cases of the hydrated oxide,CuO ?H 2O or Cu (OH)2.The data outlined above show that the maximum potential reduction of CuO or Cu(OH)2should be no more than 0.5055V,versus SCE.Therefore,the peak at 0.688V cannot be attributed to a Cu(III)/Cu(II)transition.

Upon adding 4.0mM glucose,the broad anodic peak with upward shoulder rapidly increases,which represents glucose irreversible oxidation,as shown in Figs.3A(d)and B.The process involved is clearly irreversible,and no obvious cathodic counterparts in the negative sweep were observed.Moreover,with increasing of glucose concentration,the catalytic currents gradually increase on the Cu 2O/TiO 2electrode (Fig.3B).A decrease in the peak current for the reduction of Cu(III)is found upon increasing glucose concentration.Under these conditions,glucose oxidation may be assumed to be catalyzed by Cu(III)species.The overall behavior observed here is relatively simple,and is somewhat similar to the results on the copper-modi ?ed polyaniline (Farrell and Breslin,2004)and the CuO-modi ?ed TiO 2nanotubes array electrode (Luo et al.,2011)under the same conditions.However,the oxidation currents were higher for Cu 2O/TNT than in Cu/polyaniline and CuO/TNT (Farrell and Breslin,2004;Luo et al.,2011).Based on the above analysis,a schematic illustration of the preparation of Cu 2O/TNT electrode and reaction mechanism of glucose at Cu 2O/TNT electrode is pre-sented in Fig.7

.

Fig.3.(continued )

M.Long et al./Biosensors and Bioelectronics 59(2014)243–250

248

Fig.7describes direct electron transfer between the glucose and the Cu 2O/TNT electrode via oxidation and reduction of Cu 2O/TNT,wherein Cu 2O/TNT acts as a better electron acceptor in the strong alkaline solution.A possible complexation –oxidation pro-cess for glucose oxidation at Cu 2O/TNT electrodes in 0.1M NaOH solute has been proposed on the basis of the cyclic voltammetry data and 1H NMR spectrometry.The broad upward anodic peaks in CVs can be attributed to the adsorption of glucose.Subsequently,the complex intermediate is continuously oxidized on the elec-trode.Finally the glucose is further oxidized at more positive potentials in the strong alkaline solution.

The possible mechanism is presented in Fig.7a –c and described as follows.(a)Glucose in strongly alkaline solutions can be transformed into the enediol compound.This reaction is a slow process that consists of a hydride ion transfer.(b)This enediol structure of glucose may react with cuprous ions to form a complex intermediate,which in turn can be subsequently oxidized at higher potentials (Marioli and Kuwana,1992).The complex of the enediolic structure with surface species of copper was con-tinuously oxidized under the drive of electric ?eld force.The ?rst process involves the oxidation of a complex intermediate.Soluble species were not observed in the CV curves due to the limited effect of the Cu 2O nanoparticle immobilized on the TiO 2nanotube arrays.The second process operates at higher potentials and involves the catalytic oxidation participation of Cu(III),leading to the formation of gluconic acid.(c)Formic acid product is obtained through the cleavage of the gluconic acid C 1–C 2bond in the strong alkaline solution.The continuous oxidation of the glucose complex produces gluconic acid,which further decomposes into formic acid in the 0.1M NaOH solution.The proposed mechanism for the oxidation of glucose at Cu 2O/TNT in alkaline solution is consistent with most experimental ?ndings (Marioli and Kuwana,1992;Luo et al.,2011;Wang et al.,2012;Meng et al.,2013).Difference in reactivity of different electrodes is related to their composition and spatial structure.The Cu 2O/TNT electrodes exhibit numerous attractive features,including high electrocatalytic activity,low detection,good selectivity,stability,and reproducibility.These features are ascribed to three aspects:(a)the large electroactive surface area of Cu 2O modi ?ed helical TiO 2ordered arrays;(b)the excellent synergistic effect due to the combination of Cu 2O nanoparticles and TiO 2nanotube arrays;and (c)the limited effect of the Cu 2O nanoparticle immobilized on the TiO 2nanotube arrays.

4.Conclusions

(a)A non-enzyme glucose sensor was developed using a simple and controllable electrodeposition method.An examination of the morphology suggested that Cu 2O/TNT composites were helical TiO 2nanotube arrays loaded with well-dispersed Cu 2O nanopar-ticles.(b)The synergetic effect of the composite can be attributed to the large speci ?c surface area of Cu 2O loaded on the helical TiO 2nanotubes and the strong electron transfer rate from the Cu 2O/TNT electrode to the glucose.A possible mechanism for glucose continuous oxidation has been proposed on the basis of cyclic voltammetry data and 1H NMR spectrometry.

(c)The nonenzymatic glucose sensing properties of Cu 2O/TNT electrodes exhibited higher sensitivity (14.56μA cm à2mM à1)towards glucose oxidation when compared to electrodes of pure TNT.These properties also exhibited the lowest limit of detection at 62μM,as well as good reproducibility,selectivity,and quick response characteristics.The overall characterization results demon-strate that the Cu 2O/TNT array electrode has high potential for glucose detection.It is found that the catalytic activity of the biosensors depended strongly on the size,morphology,distribution of nanoparticles and the nature of substrate.Therefore,in

the

Fig.4.1H NMR spectra of 30mM glucose solution (a)prior to electrolysis and (b)after a 16h electrolysis period at 0.65V versus SCE at the Cu 2O/TNT

electrode.

Fig.5.Amperometric measurement of Cu 2O/TNT electrode responses to successive addition of 0.5mM glucose in 0.10M NaOH solution at t0.65V.Inset is the calibration curve of the current response versus glucose

concentration.

Fig. 6.Amperometric measurement of the Cu 2O/TNT electrode responses to successive addition of 4mM glucose,0.4mM fructose,0.4mM AA,and 0.4mM UA in 0.10M NaOH solution at t0.65V.

M.Long et al./Biosensors and Bioelectronics 59(2014)243–250249

future work,it is necessary to systematically study the effects of fabrication parameters and morphologies of TiO 2and/or Cu 2O on electrocatalytic oxidation of glucose.Acknowledgments

This work was supported by the National Natural Science Foundation of China (No.51374250)and Hunan Provincial Natural Science Foundation for Innovative Research Groups (No.2013-2).References

Cao,F.,Guo,S.,Ma,H.Y.,Shan,D.C.,Yang,S.X.,Gong,J.A.,2011.Biosens.Bioelectron.

26,2756–2760.

Chen,L.C.,2013.Mater.Sci.Semicon.Process.16,1172–1185.

Dung,N.Q.,Patil,D.,Jung,H.,Kim,D.,2013.Biosens.Bioelectron.42,280–286.El Khatib,K.M.,Hameed,R.M.A.,2011.Biosens.Bioelectron.26,3542–3548.Ensa ?,A.A.,Jafari-Asl,M.,Rezaei,B.,2013.Talanta 103,322–329.Farrell,S.T.,Breslin,C.B.,2004.Electrochim.Acta 49,4497–4503.Guo,S.J.,Wang,E.K.,2011.Nano Today 6,240–264.

Hou,C.T.,Xu,Q.,Yin,L.N.,Hu,X.Y.,2012.Analyst 137,5803–5808.

Huang,L.,Peng,F.,Wang,H.J.,Yu,H.,Geng,W.,Yang,J.,Zhang,S.Q.,Zhao,H.J.,2011.

Mater.Chem.Phys.130,316–322.

Huang,L.,Zhang,S.,Peng,F.,Wang,H.,Yu,H.,Yang,J.,Zhang,S.,Zhao,H.,2010.Scr.

Mater.63,159–161.

Huo,C.,Yang,H.,2012.J.Colloid Interface Sci.384,55–60.

Jiang,L.C.,Zhang,W.D.,2010.Biosens.Bioelectron.25,1402–1407.Kang,.X.,Mai,Z.,Zou,.X.,2007.J.Anal Biochem.363,143–150.

Li,C.L.,Su,Y.,Zhang,S.W.,Lv,X.Y.,Xia,H.L.,Wang,Y.J.,2010.Biosens.Bioelectron.

26,903–907.

Li,X.,Yao,J.,Liu,F.,He,H.,Zhou,M.,Mao,N.,Xiao,P.,Zhang,Y.,2013.Sens.

Actuators B:Chem.181,501–508.

Luo,M.Z.,Baldwin,R.P.,1995.J.Electroanal.Chem.387,87–94.

Luo,S.,Su,F.,Liu,C.B.,Li,J.X.,Liu,R.H.,Xiao,Y.,Li,Y.,Liu,X.N.,Cai,Q.Y.,2011.Talanta

86,157–163.

Luo,Z.J.,Han,T.T.,Qu,L.L.,Wu,X.Y.,2012.Chin.Chem.Lett.23,953–956.Marioli,J.M.,Kuwana,T.,1992.Electrochim.Acta 37,1187–1197.

Meng,F.H.,Shi,W.,Sun,Y.N.,Zhu,X.,Wu,G.S.,Ruan,C.Q.,Liu,X.,Ge,D.T.,2013.

Biosens.Bioelectron.42,141–147.

Park,S.,Park,S.,Jeong,R.A.,Boo,H.,Park,J.,Kim,H.C.,Chung,T.D.,2012.Biosens.

Bioelectron.31,284–291.

Pissinis,D.E.,Sereno,L.E.,Marioli,J.M.,2013.J.Electroanal.Chem.694,23–29.Rahman,M.M.,Ahammad, A.J.S.,Jin,J.H.,Ahn,S.J.,Lee,J.J.,2010.Sensors 10,

4855–4886.

Sun,C.L.,Cheng,W..L,Hsu,T.K.,Chang,C.W.,Chang,J.L.,Zen,J.M.,https://www.360docs.net/doc/fb416563.html,mun.30,91–94.

Wang,C.,Yin,L.,Zhang,L.,Gao,R.,2010a.J.Phys.Chem.C 114,4408–4413.

Wang,G.F.,He,X.P.,Wang,L.L.,Gu,A.X.,Huang,Y.,Fang,B.,Geng,B.Y.,Zhang,X.J.,

2013a.Microchim.Acta 180,161–186.

Wang,G.F.,Wei,Y.,Zhang,W.,Zhang,X.J.,Fang,B.,Wang,L.,2010b.Microchim.Acta

168,87–92.

Wang,L.,Fu,J.Y.,Hou,H.Q.,Song,Y.H.,2012.Int.J.Electrochem.Sci.7,

12587–12600.

Wang,M.Y.,Sun,L.,Lin,Z.Q.,Cai,J.H.,Xie,K.P.,Lin,C.J.,2013b.Energy Environ.Sci.6,

1211–1220.

Xu,F.G.,Deng,M.,Li,G.Y.,Chen,S.H.,Wang,L.,2013.Electrochim.Acta 88,59–65.Yang,J.H.,Zhang,K.T.,Ma,D.,2013.Mater.Lett.97,133–136.

Yang,Z.Y.,Feng,J.S.,Qiao,J.S.,Yan,Y.M.,Yu,Q.Y.,Sun.,KN.,2012.Anal.Methods —UK

4,1924–1926.

Yang,H.M.,Zhang,X.C.,Ouyang,J.,2011.Low-Dimens.Metal Oxide Nanomater.18.Yec,C.C.,Zeng,H.C.,2012.Chem.Mater.24,1917–1929.

Zhang,P.,Zhang,L.,Zhao,G.C.,Feng,F.,2012.Microchim.Acta 176,411–417.

Zhang,S.S.,Zhang,S.Q.,Peng,F.,Zhang,H.M.,Liu,H.W.,Zhao,H.J.,https://www.360docs.net/doc/fb416563.html,mun.13,861–864.

Zhang,X.J.,Wang,G.F.,Zhang,W.,Wei,Y.,Fang,B.,2009.Biosens.Bioelectron.24,

3395–3398.

Zhou,X.M.,Nie,H.,Yao,Z.,Dong,Y.,Yang,Z.,Huang,S.,2012.Sens.Actuators B:

Chem.168,1–7.

Zhu,X.H.,Jiao,Q.F.,Zhang, C.Y.,Zuo,X.X.,Xiao,X.,Liang,Y.,Nan,J.M.,2013.

Microchim.Acta 180,477–483

.

Fig.7.Schematic illustration of the preparation of Cu 2O/TNT electrode and the reaction mechanism of glucose at Cu 2O/TNT electrode.

M.Long et al./Biosensors and Bioelectronics 59(2014)243–250

250

生物膜法在污水处理方面的研究进展

生物膜法在污水处理方面的研究进展 摘要:本文先简单的介绍了生物膜法概念及历史,然后简述了解了生物膜技术 和各自的应用,最后从生物膜法在具体事例中的应用及其前景。 关键词:生物膜法技术应用污水处理 引言:生物膜法是令微生物附着在惰性滤料上,形成膜状的生物污泥,从而对污水起到净化效果的生物处理方法。生物膜法的特点主要有对废水水质、水量变化适应性强,操作稳定性好不会发生污泥膨胀,运转管理较方便生物膜中的物相丰富,且沿水流方向膜中生物种群具有一定分布剩余污泥量较少采用自然通风供氧.在运行方面灵活性较差,设备容积负荷有限,空间效率较低。其作用机制是利用生物膜的强吸附性和吸水性,通过将微生物细胞固定于反应器内的载体上,实现了微生物停留时间和水力停留时间的分离,从而达到目的的一种手段。一般所用到的技术有:生物接触氧化法、生物流床技术、移动床生物膜反应器等。污水,通常指受一定污染的、来自生活和生产的排出水,污水的主要污染物有病原体污染物,耗氧污染物,植物营养物,有毒污染物等。生物膜法处理污水就是通过惰性材料的粘着性使微生物附着其上,以达到污水处理的目的。 20世纪50年代以前,生物膜法一直未被重视,其主要原因是它以碎石为原料,微生物附着困难,并且操作不方便,而50年代,塑料工业的发展及其向生物膜处理技术的引用克服了滤料堵塞等困难。生物膜技术的核心就是滤料【1】。滤料可以是天然的,也可以是经过加工的石英砂、无烟煤、大理石、白云石、磁铁矿石、石榴石、锰砂等颗粒物质,还可以是人造聚苯乙烯发泡塑料球、高效纤维束和陶瓷滤料。它的选择特点有:机械强度高,化学稳定性好,密度适宜,形状规则,易成膜,但无毒无味,无异物脱落,不会产生二次污染;取材方便,价格便宜。再生性强.Allant等【2】人研究结果表明:上浮式滤料比沉没式滤料对SS(悬浮颗粒物)、有机物的去除率高,更耐有机负荷和水力负荷冲击。由此可见,滤料的好坏关系着生物膜的脱落和附着情况,进而影响了曝气生物滤池运行的稳定和处理效果。下面,我们具体的了解生物膜法的应用。 1生物膜在污水处理中的具体应用 1.1生物膜法除无机元素 1.1.1生物膜法除磷 磷是生物生长必需的元素之一,但水体中磷含量过高可造成藻类的过度繁殖,引起严重的水质富营养化问题【3】。国内外对控制水体中的磷含量均十分重视,经济、高效地降低排放废水的磷含量已成为防治水体富营养化的重要途径之一。污水中磷的去除有化学和生物两种途径【4】:化学途径是指投加Ca2+、Al3+和Fe3+形成金属磷酸盐沉淀;生物途径是指微生物对磷的吸收,磷最终通过沉淀池排放剩余污泥得以去除。微生物对磷的吸收又分为两种【5】:①微生物生长的生理需要,对磷的正常吸收,普通活性污泥微生物细胞干重含磷2%~3%;②生物强

染料敏化太阳能电池

染料敏化太阳能电池 物理科学与技术学院化学物理学交叉培养班张玲玲 2011213434 摘要染料敏化太阳电池主要是模仿光合作用原理,研制出来的一种新型太阳电池,其主要优势是原材料丰富、成本低、工艺技术相对简单,在大面积工业化生产中具有较大的优势,同时所有原材料和生产工艺都是无毒、无污染的,部分材料可以得到充分的回收,对保护人类环境具有重要的意义。本文主要从染料敏化太阳能电池的原理和电解质来进行介绍。 关键词染料敏化太阳能电池原理制备 一、染料敏化太阳能电池的基本结构 染料敏化太阳能电池主要由纳米多孔半导体薄膜、染料敏化剂、氧化还原电解质、电极和导电基底等几部分组成。纳米多孔半导体薄膜通常为金属氧化物(TiO2、SnO2、ZnO等),聚集在有透明导电膜的玻璃板上作为染料敏化太阳能电池的负极。对电极作为还原催化剂,通常在带有透明导电膜的玻璃上镀上铂。敏化染料吸附在纳米多孔二氧化钛膜面上。正负极间填充的是含有氧化还原电对的电解质,最常用的是I3/I-。 图1染料敏化太阳能电池的基本结构 二、染料敏化太阳能电池的工作原理 当太阳光照射在染料敏化太阳能电池上,染料分子中基态电子被激发,激发态染料分子将电子注入到纳米多孔半导体的导带中,注入到导带中的电子迅速富集到导电玻璃面上,传向外电路,并最终回到对电极上。而由于染料的氧化还原

电位高于氧化还原电解质电对的电位,这时处于氧化态的染料分子随即被还原态的电解质还原。然后氧化态的电解质扩散到对电极上得到电子再生,如此循环,即产生电流。电池的最大电压由氧化物半导体的费米能级和氧化还原电解质电对的电位决定。 图2 染料敏化太阳能电池的工作原理示意图 2.1纳米晶多孔薄膜 作为太阳能电池半导体材料,首要条件为光照下性能稳定。考虑到只有禁带宽度Eg ﹥ 3eV 的宽带隙半导体才满足这一条件,因此可以用作DSC 半导体材料的禁带宽度必须大于3eV 。TiO2禁带宽度为3. 2eV ,是性能最优、使用最广泛的DSC 半导体电极材料。所有的太阳能电池都是依靠光电效应将光能转化为电能. 半导体的截止波长由下式计算: g E 1240g =λ 式中: Eg 为半导体禁带宽度,λg 为半导体的截止吸收波长. 则禁带宽度为3eV 半导体材料截止波长为413 nm ,而太阳光主要分布在可见光区域,而可见光光谱范围为390 ~770 nm ,因此基本不能被吸收. 为了使宽带隙半导体材料能够吸收可见光,必须通过某种方法将截止波长红移至红外区. 吸附于半导体表面的染料可以使半导体的吸收边强烈红移。 2.2染料分子

染料敏化太阳能电池

新能源课程 染料敏化太阳能电池(DSSC)装置的制作教学实验报告 电气01 王平09041020 4/22 Monday

《染料敏化太阳能电池(DSSC)装置的制作》教学实验 一、研究背景: 随着工业发展和技术进步,人类对能源的需求与日俱增。因此开发新的绿色能源,减少对环境的冲击影响,是迫切需要研究的课题。绿色能源种类很多,本实验将针对染料敏化太阳能电池(DSSC)进行实验制作,以了解其设计原理及机制。 二、实验目的: 了解染料敏化太阳能电池(DSSC)发电原理,掌握DSSC基本制作方法和的电池性能测定;理解决定DSSC性能的材料方面的影响因素,实验比较不同燃料、不同光线对电池性能的效果。 三、实验技能: 学习研磨制样、材料的选择、万用电表的使用、涂布coating及组装、测试太阳能电池。 四、工作原理: 本实验所制备的染料敏化太阳能电池(DSSC),是一个电化学反应过程装置。由正极、负极、电解质液组成。其中正极为涂布有石墨的导电玻璃;负极为涂布有二氧化钛的导电玻璃;二氧化钛为多孔纳米结构,吸附有染料或光敏剂;电解液为含碘化合物,能够产生I2/I-,被填充在正、负极之间。 DSSC太阳能电池是由一系列电子传递过程完成光能-电能转换的。当光线照在负极侧,染料吸收光能发生电子跃迁,染料被氧化,电子经二氧化钛半导体传导,流动到负极的导电玻璃片进入外电路;电子到达正极后,电解液中的I2/I-氧化还原作用使得染料被还原到原始状态。这样构成电子回路,产生电。 五、实验准备: 1.材料: A.导电玻璃:具有高透过率、导电率,如ITO、FTO B.正极:导电能力强、有一定催化活性,如炭、铂 C.二氧化钛:具有催化能力,高活性、比表面积大、分散均匀

染料敏化太阳能电池学术发展简史

染料敏化太阳能电池学术发展简史 2016-05-07 13:13来源:内江洛伯尔材料科技有限公司作者:研发部 基于钌化合物的染料敏化太阳能电池 1839年,Becquerel发现氧化铜或卤化银涂在金属电极上会产生光电现象,证实了光电转换的可能。 1960年代,H.Gerischer,H.Tributsch,Meier及R.Memming发现染料吸附在半导体上并在一定条件下产生电流的现象,成为光电化学电池的重要基础。 1980年代, 光电转换研究的重点转向人工模拟光合作用,美国州立Arizona大学的Gust和Moore研究小组成功模拟了光合作用中光电子转换过程,并取得了一定的成绩。Fujihia等将有机多元分子用L B 膜组装成光电二极管,开拓了这方面的工作。 1970年代到90年代,R.Memming,H.Gerischer,Hauffe,H.Tributsh等人大量研究了各种染料敏化剂与半导体纳米晶间光敏化作用,研究主要集中在平板电极上,这类电极只有表面吸附单层染料,光电转换效率小于1%。 1991年,Graetzel M.于《Nature》上发表了关于染料敏化纳米晶体太阳能电池的文章以较低的成本得到了>7%的光电转化效率,开辟了太阳能电池发展史上一个崭新的时代,为利用太阳能提供了一条新的途径。 1993年,Graetzel M.等人再次研制出光电转换效率达10 %的染料敏化太阳能电池, 已接近传统的硅光伏电池的水平。 1997年,该电池的光电转换效率达到了10%-11%,短路电流达到18mA/cm2,开路电压达到720mV。 1998年,采用固体有机空穴传输材料替代液体电解质的全固态Gr?tzel电池研制成功,其单色光电转换效率达到33%,从而引起了全世界的关注。 2000年,东芝公司研究人员开发含碘/碘化物的有机融盐凝胶电解质的准固态染料敏化纳米晶太阳能电池,其光电能量转换率7.3 % 。 2001年, 澳大利亚STA 公司建立了世界上第一个中试规模的DSC 工厂。 2002 年, STA建立了迄今为止独一无二的面积为200m2 DSC 显示屋顶,集中体现了未来工业化的前景;PengWang等人用含 1-methyl-3-propylimidazoliumiodide 和poly(viylidenefloride

染料敏化太阳能电池关键材料的制备与表征

实验一 染料敏化太阳能电池关键材料的制备与表征 在众多新能源中,太阳能因具有清洁、环保、无污染、取之不尽、用之不竭等诸多优点,被认为是未来最有希望的新能源之一。太阳能电池是通过光电效应或光化学效应直接把光能转化成电能的装置。太阳能电池产业,已成为世界主要国家抢占新一轮经济和科技发展制高点的重大战略之一。 在众多太阳能电池中,硅基太阳能电池技术最为成熟,但制作工艺复杂、价格昂贵、设备要求较高而不适合开展大学生实验。纳米二氧化钛(TiO 2)晶体太阳能电池是最近发展起来的一种新型太阳能电池,其优点在于其低廉的成本、简单的工艺以及相对稳定的性能。其光电效率稳定在10%以上,而制作成本仅为硅太阳能电池的1/5~1/10,寿命却能达到20年以上。但是TiO 2的禁带宽度为3.2eV ,只能吸收波长小于375nm 的紫外光。为了使其吸收红移至可见光区,增大对全光谱范围的响应,1991年,瑞士洛桑高等工业学院(EPFL )的Gratzel 研究小组开发了染料敏化太阳能电池(Dye Sensitized Solar Cell ,简称DSSC ),它由 吸附了染料光敏化剂(过渡金属钌的有 机化合物)的纳米TiO 2多孔薄膜制成, 其光电转换效率可达7.1%。1993年,他 将光电转换效率提高到了10%,1998年, 该研究组进一步研制出全固态DSSC , 使用固体有机空穴传输代替液体电解质, 单色光光电转化效率达到33%,引起了全世界的科学家对DSSC 的关注。近年来,染料敏化太阳能电池的研究主要集中在阳极材料的改性、染料的改进、电解质的研究、以及阴极对DSSC 的影响等方面。 “染料敏化太阳能电池的制备、组装及测试”实验涵盖材料制备实验(水热反应制备TiO 2纳米颗粒、热解法制备Pt 催化剂、丝网印刷技术制备光阳极薄膜、玻璃工操作、材料热处理等)、仪器分析实验(台阶仪测量薄膜厚度、X 射线衍射仪表征材料的结构与成分、扫描电子显微镜观测形貌、紫外-可见吸收光谱测试光谱吸收效果)等多种实验方法。由于实验步骤繁多、周期较长,因此根据其 图1 Gratzel 研究小组开发的 DSSC

第五章 污水的生物处理方法(二)——生物膜法

第五章污水的生物处理方法(二)——生物膜法 教学要求: 1)掌握生物膜法的微生物学特征和工艺特征 2)掌握高负荷生物滤池、曝气生物滤池、塔式生物滤池以及生物转盘三相传质和工艺运行 特点。 3)掌握生物接触氧化特点及其工艺设计 第一节概述 生物膜——是使细菌、放线菌、蓝绿细菌一类的微生物和原生动物、后生动物、藻类、真菌一类的真核微生物附着在滤料或某些载体上生长繁殖,并在其上形成膜状生物污泥。 生物膜法:污水经过从前往后具有细菌→原生动物→后生动物、从表至里具好氧→兼氧→厌氧的生物处理系统而得到净化的生物处理技术。 一、生物构造及其对有机物的降解 1 生物膜的构造特征 生物膜(好氧层+兼氧层+厌氧层)+附着Array水层(高亲水性)。 2 降解有机物的机理 1)微生物:沿水流方向为细菌——原生动物— —后生动物的食物链或生态系统。具体生物 以菌胶团为主、辅以球衣菌、藻类等,含有 大量固着型纤毛虫(钟虫、等枝虫、独缩虫 等)和游泳型纤毛虫(楯纤虫、豆形虫、斜 管虫等),它们起到了污染物净化和清除池 内生物(防堵塞)作用。 2)污染物:重→轻(相当多污带→α中污带→ β中污带→寡污带). 3)供氧:借助流动水层厚薄变化以及气水逆向 流动,向生物膜表面供氧。 4)传质与降解:有机物降解主要是在好氧层进 行,部分难降解有机物经兼氧层和厌氧层分解,分解后产生的H2S,NH3等以及代谢产物由内向外传递而进入空气中,好氧层形成的NO3--N、NO2--N等经厌氧层发生反硝化,产生的N2也向外而散入大气中。 5)生物膜更新:经水力冲刷,使膜表面不断更新(DO及污染物),维持生物活性(老化 膜固着不紧)。 二、生物膜的主要特征 1 微生物相方面的特征 1)参与净化反应微生物多样化; 2)食物链长,污泥产率低; 3)能够存活世代较长的微生物; 4)可分段运行,形成优势微生物种群,提高降解能力。 2 工艺方面的特征 1)对水质水量变动有较强适应性;

染料敏化太阳能电池的结构与工作原理

染料敏化太阳能电池的结构与工作原理 染料敏化太阳能电池主要由表面吸附了染料敏化剂的半导体电极、电解质、Pt 对电极组成,其 结构如图1-1。 图1-1 染料敏化太阳能电池结构图 当有入射光时,染料敏化剂首先被激发,处于激发态的染料敏化剂将电子注入半导体的导带。氧化态的染料敏化剂被中继电解质所还原,中继分子扩散至对电极充电。这样,开路时两极产生光 电势,经负载闭路则在外电路产生相应的光电流(图1-2)。 图1-2 染料敏化太阳能电池工作原理图 通过超快光谱实验可得出染料敏化太阳能电池各个反应步骤速率常数的数量级[12]: ①染料(S)受光激发由基态跃迁到激发态(S*): S + hυ→S* ②激发态染料分子将电子注入到半导体的导带中: S* →S+ + e-(CB),k inj = 1010~1012s-1 ③I-离子还原氧化态染料可以使染料再生: 3I- + 2S+ →I3 - + 2S,k3 = 108s-1 ④导带中的电子与氧化态染料之间的复合:

S+ + e-(CB) →S,k b = 106s-1 ⑤导带中的电子在纳米晶网络中传输到后接触面(back contact ,BC)后而流入到外电 路中: e-(CB) →e-(BC),k5 = 103~100s-1 ⑥纳米晶膜中传输的电子与进入TiO2 膜的孔中的I3 -离子复合: I3 - + 2e-(CB) →3I-,J0 = 10-11~10-9A cm-2 ⑦I3 -离子扩散到对电极上得到电子使I-离子再生: I3 - + 2e-(CE) →3I-,J0 = 10-2~10-1A cm-2 激发态的寿命越长,越有利于电子的注入,而激发态的寿命越短,激发态分子有可能来不及将 电子注入到半导体的导带中就已经通过非辐射衰减而返回到基态。②、④两步为决定电子注入效率 的关键步骤。电子注入速率常数(k inj)与逆反应速率常数(k b)之比越大(一般大于三个数量级), 电子复合的机会越小,电子注入的效率就越高。I-离子还原氧化态染料可以使染料再生,从而使染料 不断地将电子注入到二氧化钛的导带中。步骤⑥是造成电流损失的一个主要原因,因此电子在纳米 晶网络中的传输速度(k5)越大,电子与I3 -离子复合的交换电流密度(J0)越小,电流损失就越小。步骤 ③生成的I3 -离子扩散到对电极上得到电子变成离子I-(步骤⑦),从而使I-离子再生并完成电流循环。 DSC的结构组成:主要由纳米多孔半导体薄膜、染料敏化剂、氧化还原电解质、对电极和导电基底等几部分组成。纳米多孔半导体薄膜通常为金属氧化物(TiO2、SnO2、ZnO等),聚集在有透明导电膜的玻璃板上作为DSC的负极。对电极作为还原催化剂,通常在带有透明导电膜的玻璃上镀上铂。敏化染料吸附在纳米多孔二氧化钛膜面上。正负极间填充的是含有氧化还原电对的电解质,最常用的是I3/I-。 DSC工作原理如下图所示: ⑴染料分子受太阳光照射后由基态跃迁至激发态; ⑵处于激发态的染料分子将电子注入到半导体的导带中; ⑶电子扩散至导电基底,后流入外电路中; ⑷处于氧化态的染料被还原态的电解质还原再生; ⑸氧化态的电解质在对电极接受电子后被还原,从而完成一个循环; ⑹和⑺分别为注入到TiO2 导带中的电子和氧化态染料间的复合及导带上的电子和氧化态的电解质间的复合

染料敏化太阳电池

染料敏化太阳电池主要是模仿光合作用原理,研制出来的一种新型太阳电池,其主要优势是:原材料丰富、成本低、工艺技术相对简单,在大面积工业化生产中具有较大的优势,同时所有原材料和生产工艺都是无毒、无污染的,部分材料可以得到充分的回收,对保护人类环境具有重要的意义。自从1991年瑞士洛桑高工(EPFL)M. Grtzel教授领导的研究小组在该技术上去的突破以来,欧、美、日等发达国家投 染料敏化太阳能电池的研究历史可以追溯到19世纪早期的照相术。1837年,Daguerre制出了世界上第一张照片。两年后,Fox Talbot将卤化银用于照片制作,但是由于卤化银的禁带宽度较大,无法响应长波可见光,所以相片质量并没有得到很大的提高。1883年,德国光电化学专家Vogel 发现有机染料能使卤化银乳状液对更长的波长敏感,这是对染料敏化效应的最早报导。使用有机染料分子可以扩展卤化银照相软片对可见光的响应范围到红光甚至红外波段,这使得“全色”宽谱黑白胶片乃至现在的彩色胶片成为可能。1887年,Moser将这种染料敏化效应用到卤化银电极上,从而将染料敏化的概念从照相术领域延伸到光电化学领域。1964年,Namba 和Hishiki发现同一种染料对照相术和光电化学都很有效。这是染料敏化领域的重要事件,只是当时不能确定其机理,即不确定敏化到底是通过电子的转移还是通过能量的转移来实现的。直到20世纪60年代,德国的Tributsch发现了染料吸附在半导体上并在一定条件下产生电流的机理,才使人们认识到光照下电子从染料的基态跃迁到激发态后继而注入半导体的导带的光电子转移是造成上述现象的根本原因。这为光电化学电池的研究奠定了基础。但是由于当时的光电化学电池采用的是致密半导体膜,染料只能在膜的表面单层吸附,而单层染料只能吸收很少的太阳光,多层染料又阻碍了电子的传输,因此光电转换效率很低,达不到应用水平。后来人们制备了分散的颗粒或表面积很大的电极来增加染料的吸附量,但一直没有取得非常理想的效果。1988年,Grätzel小组用基于Ru的染料敏化粗糙因子为200的多晶二氧化钛薄膜,用Br2/Br-氧化还原电对制备了太阳能电池,在单色光下取得了12 %的转化效率,这在当时是最好的结果了。直到1991年,Grätzel在O’Regan的启发下,应用了O’Regan制备的比表面积很大的纳米TiO2颗粒,使电池的效率一举达到7.1 %,取得了染料敏化太阳能电池领域的重大突破。应当说,纳米技术促进了染料敏化 结构组成 主要由纳米多孔半导体薄膜、染料敏化剂、氧化还原电解质、对电极和导电基底等几部分组成。纳米多孔半导体薄膜通常为金属氧化物(TiO2、SnO2、ZnO等),聚集在有透明导电膜的玻璃板上作为DSC的负极。对电极作为还原催化剂,通常在带有透明导电膜的玻璃上镀上铂。敏化染料吸附在纳米多孔二氧化钛膜面上。正负极间

生物膜法处理污水

生物膜法处理工业废水 摘要:目前化工产业的发展十分迅速,但随之而来的化工污染状况也十分严重,化工废水成分复杂、水质水量变化大,随着国家对其处理达标要求越来越严格,其处理技术也在不断发展。生物膜法是与活性污泥法平行发展的一种污水处理技术方法,实质是使细菌类微生物和原生动物、后生动物类的微型动物附着在滤料或某些载体上,并在其上形成膜状生物污泥,即生物膜。生物膜法是土壤自净过程的人工强化,主要去除废水中溶解性的和胶体状的有机污染物,同时对废水中的氨氮还具有一定的硝化能力。生物膜法在处理工业废水中有着广泛应用。 关键词:生物膜,废水,净化 生物膜法是属于好养生物处理的方法,它是将废水通过好氧微生物和原生动物,后生动物等在载体填料上生长繁殖形成的生物膜,吸附和降解有机物,使废水得到净化的方法。根据装置的不同,生物膜法可分为生物滤池、生物转盘、接触氧化法和生物流化床等四类。在石油和化学工业的废水处理中,其中应用最多的是接触氧化法。 一、生物膜法的机理 1、生物膜法的发展 在20世纪50年代以前,生物膜法却一直未被人们重视,其原因主要是因为生产中最早采用的生物膜法构筑物是以碎石为填料的滴滤池。碎石的比表面积小,能够为微生物附着生长的表面积小,因而滴滤池的负荷不可能很大,使其占地面积较大,卫生状况也不好。 50年代,由于塑料工业的发展以及塑料填料引入生物膜处理系统,使生物膜法出现了许多具有重要意义的发展。因此,出现了许多新型的生物膜法设备。 20世纪70年代末,为强化生物膜法反应器中的传质,流化床系统被引人生物膜处理中,称为生物流化床。生物流化床兼有活性污泥法和生物膜法的待点,又称为半生物膜和半悬浮生长系统。 2、生物膜法的基本流程 下图为生物膜法处理系统的基本流程:废水经初次沉淀池后进入生物膜反应器,废水在生物膜反应器中经需氧生物氧化去除有机物后,再通过二次沉淀池出水。

染料敏化太阳能电池-化学与物理电源基础实验讲义1

天然染料敏化TiO2太阳能电池的制备及光电性能测试 太阳能电池是通过光电效应或者光化学效应直接把光能转化成电能的装置。纳米TiO2晶体化学能太阳能电池是最近发展起来的,优点在于其廉价的成本和简单的工艺及稳定的性能。其光电效率稳定在10%以上,制作成本仅为硅太阳电池的1/5~1/10.寿命能达到20年以上。但是TiO2的禁带宽度为3.2eV,只能吸收波长小于375nm的紫外光,为了使其吸收红移至可见光区,增大对全光谱范围的响应,1991年,瑞士洛桑高等工业学院(EPFL) Gratzel研究小组开发了染料敏化太阳能电池(Dye Sensitized Solar Cell,简称DSSC),它是由吸附染料光敏化剂(过渡金属钌的有机化合物染料)的纳米二氧化钛(TiO2)多孔薄膜制成的新型光化学电池。其光电转换效率达7.1%。1993年,他再次报道了光电转换效率达10%的TiO2染料电池,1998年,该研究组进一步研制出全固态DSSC,使用固体有机空穴传输代替液体电解质,单色光光电转化效率达到33%,从而引起了全世界的科学家对染料敏化太阳能电池的关注。近年来,染料敏化太阳能电池的研究主要集中在阳极材料的改性、染料的改进、电解质的研究、以及阴极对染料敏化太阳能电池的影响等。本实验主要研究不同的染料敏化剂和不同的敏化方法对TiO2太阳能电池光电转换效应的影响。 【实验目的】 (1)了解染料敏化纳米TiO2太阳能电池的工作原理及性能特点。 (2)掌握合成纳米TiO2溶胶的方法、染料敏化太阳能电池光阳极的制备方法以及电池的组装方法。 (3)掌握评价染料敏化太阳能电池性能的方法。 【实验原理】 一、DSSC结构和工作原理 DSSC结构:染料敏化太阳能电池的结构是一种“三明治”结构, 如图1所示,主要由以下几个部分组成: 导电玻璃、染料光敏化剂、多孔结构的TiO2半导体纳米晶薄膜、电解质和铂电极。其中吸附了染料的半导体纳米晶薄膜称为光阳极,铂电极叫做对电极或光阴极。 DSSC电池的工作原理:电池中的TiO2禁带宽度为3.2 eV,只能吸收紫外区域的太阳光,可见光不能将它激发,于是在TiO2膜表面覆盖一层染料光敏剂来吸收更宽的可见光,当太阳光照射在染料上,染料分子中的电子受激发跃迁至激发态,由于激发态不稳定,并且染料与TiO2薄膜接触,电子于是注入到TiO2导带中,此时染料分子自身变为氧化态。注入到TiO2导带中的电子进入导带底,最终通过外电路流向对电极,形成光电流。处于氧化态的染料分子在阳极被电解质溶液中的I-还原为基态,电解质中的I3-被从阴极进入的电子还原成I-,这样就完成一个光电化学反应循环。但是反应过程中,若电解质溶液中的I-在光阳极上被TiO2导带中的电子还原,则外电路中的电子将减少,这就是类似硅电池中的“暗电流”。整个反应过程可用如下表示: (l) 染料D受激发由基态跃迁到激发态D*: D + hv→ D* (2) 激发态染料分子将电子注入到半导体导带中:D*→ D+ + e- (3) I-还原氧化态染料分子:3I- + 2D+→ I3- + 2D (4) I3-扩散到对电极上得到电子使I-再生:I3- +2e- → 3I- (5) 氧化态染料与导带中的电子复合:D+ + e- → D (6) 半导体多孔膜中的电子与进入多孔膜中I3-复合:I3- +2e-→ 3I- 其中,反应(5)的反应速率越小,电子复合的机会越小,电子注入的效率就越高;反应(6)是造成电流损失的主要原因。 光阳极 目前,DSSC常用的光阳极是纳米TiO2。TiO2是一种价格便宜,应用广泛,无污染,稳定且抗腐蚀性能良好的半导体材料。TiO2有锐钛矿型(Anatase)和金红石型(Rutile)两种不同晶型,其中锐钛矿型的TiO2带隙(3.2eV)略大于金红石型的能带隙(3.l eV),且比表面积略大于金红石,对染料的吸附能力较好,因而光

染料敏化太阳能电池

染料敏化太阳能电池 摘要:与硅基太阳能电池相比,染料敏化太阳能电池(DSSC)具有成本低、制备工艺简单、理论光电转化效率高、制备过程无毒无污染等优点,因而迅速成为该领域的研究热点,目前染料敏化太阳能电池的最高转化效率已达到12%以上,被认为是实现下一代光伏器件大规模利用的主要候选者,是极具研发潜力的太阳能电池之一。 关键词:太阳能电池,染料敏化,光阳极 前言 染料敏化太阳能电池被人们称为神奇的人造树叶,因此以天然植物色素作为光敏剂的太阳能电池一直都被各国所关注。染料敏化太阳能电池是1991年由瑞士科学家O’Regan与Gr?ztel首先发明的,并发表在Nature上,其报道了光电转化效率达7.1%的染料敏化太阳能电池。染料敏化太阳能电池具有原材料丰富、成本低、制作工艺简单及生产过程都是无毒无害等优点,成为最有发展前景的太阳能电池之一。染料敏化剂是染料敏化太阳能电池的重要组成部分,它通过吸收太阳光将基态的电子激发到激发态中产生光电子,然后再注入半导体的导带上。因此,染料敏化剂的好坏对染料敏化太阳能电池的光电性能起着决定性的作用。目前,已开发的染料敏化剂主要有金属配合物染料和纯有机染料。染料敏化太阳能电池是仿照光合作用原理研制出来的,因此天然染料作为纯有机染料的一部分,从染料敏化太阳能电池研究初期就引起各国专家的注意。1997年,Gr?ztel从黑莓中提取天然染料作为敏化剂敏化太阳能电池,得到的光电转化效率为0.56%。为了提高天然染料敏化太阳能电池的光电转化效率,研究者们在天然染料分子的基础上进行了改性,经过不断努力,Hara等合成了光电转化效率7.6%由香豆素衍生染料敏化太阳能电池,使天然染料敏化太阳能电池的光电性能得到了很大提高,更增加了人们研究天然染料的信心。天然染料原材料丰富分布广泛种类繁多,可以直接从天然的植物中提取,制备过程简单无污染,大大降低了染料敏化太阳能电池的生产成本[1]。 一、染料敏化太阳能电池(DSSC)的结构与原理 DSSC的基本结构如图1所示,主要包括:TCO透明导电玻璃(光阳极)、TiO2纳米晶粒薄膜、光敏染料、电解液以及对电极。当太阳光照射在染料敏化太阳能电池上,染料分子中基态电子被激发,激发态染料分子将电子注入到纳米多孔半导体的导带中,注入到导带中的电子迅速富集到导电玻璃面上,传向外电路,并最终回到对电极上。而由于染料的氧化还原电位高于氧化还原电解质电对的电

染料敏化太阳能电池实验报告(共9篇)

染料敏化太阳能电池实验报告(共9篇) 染料敏化太阳能电池实验 天然染料敏化TiO2太阳能电池的制备及光电性能测试姓名:蓝永琛班级:新能源材料与器件学号:20112500041 一、实验目的 1. 了解染料敏化纳米TiO2太阳能电池的工作原理及性能特点。 2. 掌握合成纳米TiO2溶胶的方法、染料敏化太阳能电池光阳极的制备方法 以及电池的组装方法。 3. 掌握评价染料敏化太阳能电池性能的方法。 二、实验原理 略 三、仪器与试剂 一、仪器设备 可控强度调光仪、紫外-可见分光光度计、超声波清洗器、恒温水浴槽、多功能万用表、电动搅拌器、马弗炉、红外线灯、研钵、三室电解池、铂片电极、饱和甘汞电极、石英比色皿、导电玻璃、镀铂导电玻璃、锡纸、生料带、三口烧瓶(500mL)、分液漏斗、布氏漏斗、抽虑瓶、容量瓶、烧杯、镊子等。 二、试剂材料 钛酸四丁酯、异丙醇、硝酸、无水乙醇、乙二醇、乙腈、碘、碘化钾、TBP、丙酮、石油醚、绿色叶片、红色花瓣、去离子水

四、实验步骤 一、TiO2溶胶制备 目前合成纳米TiO2的方法有多种,如溶胶-凝胶法、水热法、沉淀法、电化 学沉积法等。本实验采用溶胶-凝胶法。 (1)在500mL的三口烧瓶中加入1:100(体积比)的硝酸溶液约100mL,将三口烧瓶置于60-70oC的恒温水浴中恒温。 (2)在无水环境中,将5mL钛酸丁酯加入含有2mL异丙醇的分液漏斗中,将混合液充分震荡后缓慢滴入(约1滴/秒)上述三口烧瓶中的硝酸溶液中,并不断搅拌,直至获得透明的TiO2溶胶。 二、TiO2电极制备 取4片ITO导电玻璃经无水乙醇、去离子水冲洗、干燥,分别将其插入溶胶中浸泡提拉数次,直至形成均匀液膜。取出平置、自然晾干,再红外灯下烘干。最后在450oC下于马弗炉中煅烧30min 得到锐态矿型TiO2修饰电极。可用XRD粉 末衍射仪测定TiO2晶型结构。 三、染料敏化剂的制备和表征 (1) 叶绿素的提取 采集新鲜绿色幼叶,洗净晾干,去主脉,称取5g剪碎放入研钵,加入少量石油醚充分研磨,然后转入烧杯,再加入约20mL石油醚,超声提取15min后过滤,弃去滤液。将滤渣自然风干后转入研钵中,再以同样的方法用20mL丙酮提取,过滤后收集滤液,即得到

生物膜法的基本原理

生物膜法的基本原理 1、生物膜在载体上的生长过程:当有机污水或由活性污泥悬浮液培养而成的接 种液流过载体时,水中的悬浮物及微生物被吸附于固相表面上,其中的微生物利用有机底物而生长繁殖,逐渐在载体表面形成一层粘液状的生物膜。这层生物膜具有生物化学活性,有进一步吸附、分解污水中呈悬浮、胶体和溶解状态的污染物。 2、生物膜的降解机理 (1)物质的传递 1)空气中的氧溶解于流动水层中,通过附着水层传递给生物膜; 2)有机污染物则由流动水层传递给附着水层,然后进入生物膜; 3)微生物的代谢产物如H2O等则通过附着水层进入流动水层,并随其排走; 4)CO2及厌氧层分解产物如H2S、NH3以及CH4等气态代谢产物则从水层逸出进入空气中。 (2)膜的生长与脱落 1)生物膜降解有机物的过程,也是膜生长的过程; 2)好氧层与厌氧层的平衡稳定关系; 3)厌氧层加厚,生物膜老化、脱落。 二、生物膜的主要特征 1、生物相方面的特征: (1)微生物多样化 (2)生物的食物链长 (3)能够存活世代时间较长的微生物 (4)分段运行与优占种属 2、处理工艺方面的特征: (1)对水质、水量变动有较强的适应性 (2)污泥沉降性能良好,宜于固液分离 (3)能够处理低浓度的污水 4)易于维护运行、节能 三、生物滤池 1、生物滤池法的特征: 生物滤池法是在砂滤池的基础上发展起来的一种生物膜处理方法,它利用滤料表面形成的一层生物膜来净化污水。在滤池内,污水由于重力作用自上而下地连续流经滤料,滤料表面的微生物借助酶的作用,使被吸附和吸收的有机物在氧气的参与下进行氧化分解,同时微生物又以有机物为营养进行自身繁殖。老化的微生物附着力差,在污水冲刷会不断脱落,脱落后随水流出滤池,同时新的生物膜不断生长,因而处理可连续进行。 2、典型构造 生物滤池主要由池壁、池底、滤料、布水器等部分组成。 滤料:组成滤层的过滤材料。常以花岗石、安山岩、闪绿岩等较硬的岩石以及无烟煤等材料制成。

染料敏化太阳电池光电能量转换效率的测定实验报告

染料敏化太阳电池光电能量转换效率的测定 一、实验目的 1.了解染料敏化太阳电池的基本工作原理,学习CHI630电化学工作 站的基本功能和调谐方法(或恒电位仪测量光电流的方法); 2.了解染料敏化太阳电池的基本结构,测定方法; 3.掌握利用I-V曲线计算染料敏化太阳电池的能量转换效率 二、实验原理 太阳能的利用是一个永恒的课题。染料敏化纳米晶光电化学电 池以其低成本和高效率而成为硅太阳能电池的有力竞争者。 染料敏化太阳电池是由透明导电玻璃、TiO2多孔纳米膜、电解质 溶液以及镀铂镜对电极构成的“三明治”式结构。 图1 染料敏化太阳电池的结构示意图 与p-n结固态太阳能电池不同的是,在染料敏化太阳电池中光 的吸收和光生电荷的分离是分开的。图2是染料敏化太阳电池的能 级分布和工作原理图。

图2 染料敏化纳米晶太阳能电池的工作原理Ecb半导体的导带边;Evb半导体的价带边; D’,D’’ 是氧化还原电解质。对电极表面镀一层金属铂分别是染料的基态和激发态; I-,I- 3 上图表示在光照射太阳电池后,电池内的电子直接转移过程。(1)染料分子的激发。(2)染料分子中激发态的电子注入到TiO2的导带,CB和VB 分别表示TiO2的导带底和价带顶。从图中可以看出染料分子的能带最好与TiO2的能带重叠,这有利于电的注入。(3)染料分子通过接受来自电子 供体- I的电子,得以再生。(4)注入到TiO2导带中的电子与氧化态染料之3 间的复合,此过程会减少流入到外电路中电子的数量,降低电池的光电流。(5)注入到TiO2导带中的电子通过TiO2网格,传输TiO2膜与导电玻璃 的接触面后流入到外电路,产生光电流。(6)在TiO2中传输的电子与- I间 3 的复合反应。(7) - I离子扩散到对电极被还原再生,完成外电路中电流循 3 环。 太阳能电池的性能测试系统主要分为五部分,分别为光源,透镜,电池器件,电化学工作站(恒电位仪),计算机,通过对太阳能电池光照下的电流/电压曲线的分析,来测试染料敏化TiO2纳米晶光电化学电池的

柔性染料敏化太阳能电池

· 25 ·第38卷第1期 柔性染料敏化太阳能电池材料制备工艺参数的优化 赵晓冲1,杨盼2,林红1,李鑫1,许晨阳2,李建保1 (1. 清华大学材料科学与工程系,新型陶瓷与精细工艺国家重点实验室,北京 100084;2. 中国矿业 大学(北京)材料科学与工程系,北京 100083) 摘要:采用水热法制备TiO2纳米浆,与P25粒子和TiO2散射大粒子混合制成级配浆料。将所得的浆料涂敷在铟掺杂氧化锡–聚苯二甲酸乙二醇酯导电聚合物基板上,并在120~150℃进行热处理制成光阳极薄膜。利用溅射法制备Pt对电极,将其组装成柔性的染料敏化太阳能电池(dye-sensitized solar cell,DSC)。研究了对电极溅射时间、TiO2薄膜热处理温度、膜厚以及级配浆料中的酸添加量对电池光电性能的影响。结果表明:当对电极Pt 溅射时间为30s,TiO2薄膜热处理温度为150℃,膜厚为10.5μm,浆料添加0.05 mol/L HNO3时,柔性DSC的光电性能最好,光电转换效率可达4.05%。 关键词:染料敏化太阳能电池;柔性;二氧化钛薄膜;铂对电极 中图分类号:O484 文献标志码:A 文章编号:0454–5648(2010)01–0025–04 OPTIMIZATION OF FABRICATION PARAMETERS OF FLEXIBLE DYE-SENSITIZED SOLAR CELLS ZHAO Xiaochong1,YANG Pan2,LIN Hong1,LI Xin1,XU Chenyang2,LI Jianbao (1. State Key Laboratary of New Ceramics and Fine Processing, Department of Material Science and Engineering, Tsinghua University, Beijing 100084; 2. Department of Material Science and Engineering, China University of Mining and Technology, Beijing 100083, China) Abstract: A binder-free paste with a graded structure, which was composed of titania (TiO2) nano-particles synthesized by hydro-thermal method, titania particles named P25 and scattering large particles, was prepared. The TiO2 photoanode film was prepared on a conductive indium-tin oxide -coated polyethylene naphthalate plastic sheet in a temperature range of 120–150℃ by a doctor-blade method. The Pt counter electrode was prepared by an ion sputtering method. The effects of sputtering time of Pt counter electrode, heat-treatment temperature, thickness of TiO2 film and the acid content of the paste on the photovoltaic performance of the flexible dye-sensitized solar cell (DSC) fabricated from the above materials were discussed. The results show that the flexible DSC has the highest light-to-energy conversion efficiency of 4.05% when the Pt sputtering time is 30 s, the acid content is 0.05 mol/L, the heat-treatment temperature is 150℃and the film thickness is 10.5μm. Key words: dye-sensitized solar cells; flexible; TiO2 film; Pt counter electrode 自从Graetzel等[1]提出以染料敏化二氧化钛纳米薄膜作光阳极的光伏电池以来,染料敏化太阳能电池(dye-sensitized solar cell,DSC)以其低成本、无污染、工艺简单等优点被认为是未来光伏发电最有前景的发展方向之一。[2]具有可折叠性、便携性等优点的柔性DSC进一步拓宽了电池的应用范围,有较高的研究价值。 Zhang 等[3]通过优化柔性DSC的前驱体材料和辐射工艺,取得 3.27%的光电转换效率。Miyasaka 等[4]调整了薄膜制备工艺,采用刮涂法进行薄膜的低温制备获得了5.8%的光电转换效率。新工艺的不断研发为柔性DSC在工业生活中的应用提供了广阔前景。近期莫纳什大学[5]的研究人员研发出一款适于大规模生产的超薄柔性太阳能电池。 收稿日期:2009–08–06。修改稿收到日期:2009–10–09。基金项目:国家自然科学基金(50672041);国家“863”计划(2006AA03Z218) 资助项目。 第一作者:赵晓冲(1985—),男,博士研究生。 通讯作者:林红(1964—),女,博士,副教授。Received date:2009–08–06. Approved date: 2009–10–09. First author: ZHAO Xiaochong (1985–), male, postgraduate student for doctor degree. E-mail: zxc08@https://www.360docs.net/doc/fb416563.html, Correspondent author: LIN Hong (1964–), female, Ph.D., associate pro- fessor. E-mail: hong-lin@https://www.360docs.net/doc/fb416563.html, 第38卷第1期2010年1月 硅酸盐学报 JOURNAL OF THE CHINESE CERAMIC SOCIETY Vol. 38,No. 1 January,2010

生物接触氧化法 biological contact oxidation process 从生物膜法派生出来的一种废水生物处理法

生物接触氧化法biological contact oxidation process 从生物膜法派生出来的一种废水生物处理法,即在生物接触氧化池内装填一定数量的填料,利用栖附在填料上的生物膜和充分供应的氧气,通过生物氧化作用,将废水中的有机物氧化分解,达到净化目的。19世纪末,德国开始把生物接触氧化法用于废水处理,但限于当时的工业水平,没有适当的填料,未能广泛应用。到20世纪70年代合成塑料工业迅速发展,轻质蜂窝状填料问世,日本、美国等开始研究和应用生物接触氧化法。中国在70年代中期开始研究用此法处理城市污水和工业废水,并已在生产中应用。生物接触氧化法是以附着在载体(俗称填料)上的生物膜为主,净化有机废水的一种高效水处理工艺。具有活性污泥法特点的生物膜法,兼有活性污泥法和生物膜法的优点。在可生化条件下,不论应用于工业废水还是养殖污水、生活污水的处理,都取得了良好的经济效益。该工艺因具有高效节能、占地面积小、耐冲击负荷、运行管理方便等特点而被广泛应用于各行各业的污水处理系统。生物处理是经过物化处理后的环节,也是整个循环流程中的重要环节,在这里氨/氮、亚硝酸、硝酸盐、硫化氰等有害物质都将得到去除,对以后流程中水质的进一步处理将起到关键作用。如果能配合JBM新型组合式生物填料使用,可加速生物分解过程,具有运行管理简便、投资省、处理效果高、最大限度地减少占地等优点。一、生物接触氧化法的反应机理 生物接触氧化法是一种介于活性污泥法与生物滤池之间的生物膜法工艺,其特点是在池内设置填料,池底曝气对污水进行充氧,并使池体内污水处于流动状态,以保证污水与污水中的填料充分接触,避免生物接触氧化池中存在污水与填料接触不均的缺陷。该法中微生物所需氧由鼓风曝气供给,生物膜生长至一定厚度后,填料壁的微生物会因缺氧而进行厌氧代谢,产生的气体及曝气形成的冲刷作用会造成生物膜的脱落,并促进新生物膜的生长,此时,脱落的生物膜将随出水流出池外。生物接触氧化法具有以下特点:1、由于填料比表面积大,池内充氧条件良好,池内单位容积的生物固体量较高,因此,生物接触氧化池具有较高的容积负荷;2、由于生物接触氧化池内生物固体量多,水流完全混合,故对水质水量的骤变有较强的适应能力;3、剩余污泥量少,不存在污泥膨胀问题,运行管理简便。特点生物接触氧化法具有生物膜法的基本特点,但又与一般生物膜法不尽相同。一是供微生物栖附的填料全部浸在废水中,所以生物接触氧化池又称淹没式滤池。二是采用机械设备向废水中充氧,而不同于一般生物滤池靠自然通风供氧,相当于在曝气池中添加供微生物栖附的填料,也可称为曝气循环型滤池或接触曝气池。三是池内废水中还存在约2~5%的悬浮状态活性污泥,对废水也起净化作用。因此生物接触氧化法是一种具有活性污泥法特点的生物膜法,兼有生物膜法和活性污泥法的优点。生物接触氧化法净化废水的基本原理与一般生物膜法相同,就是以生物膜吸附废水中的有机物,在有氧的条件下,有机物由微生物氧化分解,废水得到净化。生物接触氧化池内的生物膜由菌胶团、丝状菌、真菌、原生动物和后生动物组成。在活性污泥法中,丝状菌常常是影响正常生物净化作用的因素;而在生物接触氧化池中,丝状菌在填料空隙间呈立体结构,大大增加了生物相与废水的接触表面,同时因为丝状菌对多数有机物具有较强的氧化能力,对水质负荷变化有较大的适应性,所以是提高净化能力的有力因素。处理装置按结构分为分流式和直接式两类,其结构如图生物接触氧化池所示分流式的曝气装置在池的一侧,填料装在另一侧,依靠泵或空气的提升作用,使水流在填料层内循环,给填料上的生物膜供氧。此法的优点是废水在隔间充氧,氧的供应充分,对生物膜生长有利。缺点是氧的利用率较低,动力消耗较大;因为水力冲刷作用较小,老化的生物膜不易脱落,新陈代谢周期较长,生物膜活性较小;同时还会因生物膜不易脱落而引起填料堵塞。直接式是在氧化池填料底部直接鼓风曝气。生物膜直接受到上升气流的强烈扰动,更新较快,保持较高的活性;同时在进水负荷稳定的情况下,生物膜能维持一定的厚度,不易发生堵塞现象。一般生物膜厚度控制在1毫米左右为宜。