新大化工院研究生专业英语

Membrane reactors for hydrogenation and dehydrogenation processes based on supported palladium

基于支撑的加氢\脱氢钯膜反应器

Abstract摘要

Membrane reactors applied to catalytic reactions are currently being studied in many places world-wide.

目前,应用于各类催化反应的膜反应器正受到世界范围内的广泛研究。

Significant developments in membrane science and the vision of process intensification by multifunctional reactors have stimulated a lot of academic and industrial research, which is impressively demonstrated by more than 100 scientific papers on catalytic membrane reactors being published per year.

膜科学的显著发展成果和通过多功能反应器强化过程工艺的前景激励了学术和应用领域的诸多研究。每年公开发表的关于催化膜反应器的科学论文超过100篇就强烈的证实了这一点。

Palladium as a noble metal with exceptional hydrogen permeation properties and, at the same time, broad applicability as a catalyst, first of all for hydrogenation is part of many of these developments. This paper discusses two different membrane reactor concepts which both rely on supported palladium, on the one hand as a permselective membrane material, and on the other hand as base component of a membrane-type hydrogenation catalyst .

作为一种贵金属,钯具有只允许氢渗透通过的性质,同时,又是广泛使用的催化剂。钯首先被应用于加氢过程是这一领域诸多研究成果的一部分。这篇论文讨论了两类不同的支撑型钯膜反应器。在此,金属钯一方面作为选择渗透性的膜材料,另一方面又是膜型加氢催化剂的主要成分。

Dense palladium composite membranes can be used for hydrogen separation from packed-bed catalysts in gas-phase hydrocarbon dehydrogenation reactions. Mesoporous membranes containing dispersed bimetallic Pd/X-clusters can be employed as so-called catalytic diffusers for liquid-phase hydrogenation, e.g. of nitrate and nitrite in water.

致密型复合钯膜能够用于从填料床气固相烃类脱氢反应中分离氢。含

有分散双金属串(Pd/X-clusters)的中空型钯膜,即所谓的催化扩散器,可用于液固相加氢反应。例如,硝酸盐与亚硝酸盐在水中的加氢反应。The principles of both concepts are introduced, recently obtained experimental data are evaluated in connection with literature results, and the perspectives for further development are highlighted.

本文介绍了这两类钯膜反应器的基本原理,结合文献结果结果评价了最新获得的实验数据,展望了钯膜反应器未来的发展前景. Keywords

Membrane reactor; 膜反应器

Composite palladium membrane; 复合钯膜

Catalytic membrane; 催化膜

Palladium catalyst; 钯催化剂

Liquid-phase hydrogenation; 液相加氢反应

Gas-phase hydrocarbon dehydrogenation;气相烃类脱氢反应Abbreviations

CMR: catalytic membrane reactor; 催化膜反应器

CNMR: catalytic non-permselective membrane reactor; 非选择性催化膜反应器

CSTR: continuous stirred tank reactor ; 连续搅拌槽反应器

CVD: chemical vapour deposition;化学汽相沉淀法

FBCMR: fluidised-bed catalytic membrane reactor; 流化床催化膜反应器

FBMR: fluidised-bed membrane reactor;流化床膜反应器

GHSV: gas hourly space velocity (m3 feed/m3 catalyst·h); 气体小时空速

HVOF: high-velocity oxy-fuel flame spraying; 高速氧燃料火焰喷射IMCR: inert membrane catalytic reactor;惰性膜催化反应器

IMR: inert membrane reactor;惰性膜反应器

LHSV: liquid hourly space velocity (m3 feed/m3 catalyst h); 液体小时空速

MOCVD: metal organic chemical vapor deposition; 金属有机化学汽相沉淀法

PBCMR: packed-bed catalytic membrane reactor; 填料床催化膜反应器PBMR: packed-bed membrane reactor; 填料床膜反应器

PEM:proton exchange membrane;质子交换膜

PV AL: polyvinyl alcohol; 聚乙烯醇

PVD: physical vapor deposition; 物理汽相沉淀法

S/O: steam to oil ratio (kg/kg or mol/mol); 汽/油比

SS, stainless steel,weighted sum of squares defined by Eq. (12); 由方程12定义的总面积的不锈钢重量和

WHSV: weight hourly space velocity (kgfeed/kg catalyst· h) 重量小时空速

1.Membrane reactor concepts膜反应器概念

According to the IUPAC definition a membrane reactor is a device that combines a membrane-based separation process with a chemical reaction step in one unit. Various possibilities exist for such a combination.

根据国际理论与应用化学联合会的定义,膜反应器是一个把膜分离过程与化学反应组合于一个单元的设备。基于这样一个结合,就存在多种结构的膜反应器

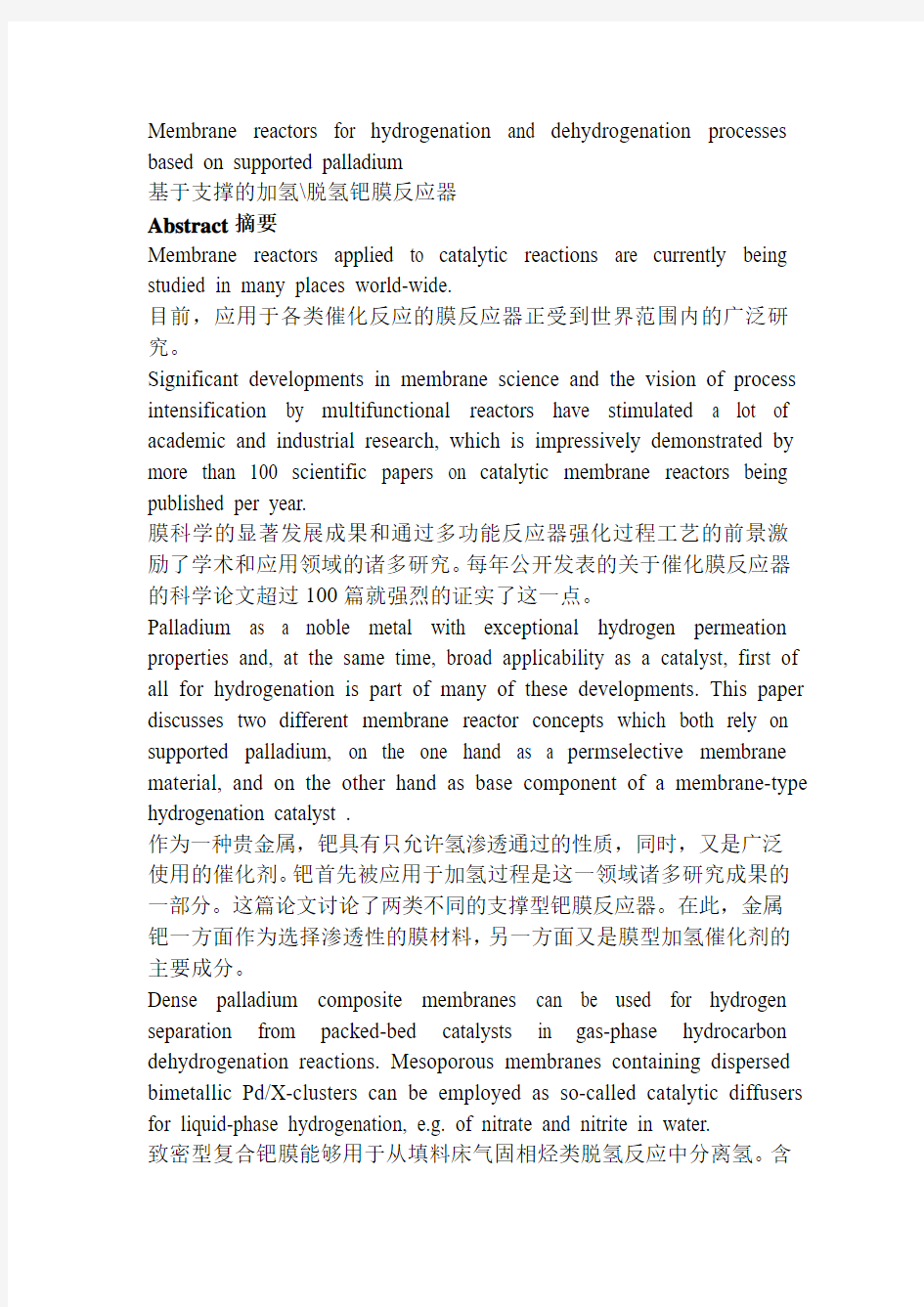

The most widely used concept is the selective removal of products from the reaction zone (cf. Fig. 1a), which is applied first of all to equilibrium limited reactions to increase the yield beyond the corresponding equilibrium value, or, generally speaking, to repress undesired secondary reactions of the products.

应用最为广泛的一类膜反应器是从反应区选择性移走反应产物,如图1a所示。这类膜反应器首先被应用于受平衡限制的反应,目的是提高低于相应平衡转化率的产率,或者,一般来说,抑制不期望产生的副反应产物。

In a different approach only particular reactants are supplied selectively via a membrane to the reaction zone (cf. Fig. 1b), e.g. to establish an optimum concentration profile along the reactor.

另一类膜反应器是通过膜把部分反应物选择性地送入反应区。如图1b所示。例如沿着反应器形成适宜的浓度分布。

A third concept refers to a membrane that creates a well-defined reaction interface (or region) between two reactant streams (cf. Fig. 1c).

第三类膜反应器指的是能够在两种反应物流之间提供确切的反应界

面或者反应区的膜,如图1c所示。The mass transport across a membrane can be permselective if only some components of a mixed stream permeate through the membrane (cf. Fig. 1a and b) or non-permselective if all species permeate at comparable rates (cf. Fig. 1c).

若混合物流中的某些组分渗透通过膜,该质量传递便为选择性渗透,如图1a和b ;若所有组分以相当的速率通过膜,则为非选择性渗透,如图1c.

Permselective transport is found first of all in dense membranes.It is governed by a solution-diffusion mechanism. Non-permselective transport normally occurs in macro- and mesoporous membranes. In the latter Knudsen diffusion is often the dominating transport mechanism.

选择性传递首先是在致密性膜中发现的,此过程受溶解-扩散机理控制。非选择性传递一般发生在大孔和中空膜内,受努森扩散机理控制。Microporous membranes represent a bit of both: permselective and non-permselective transport is possible depending on the size of the permeating molecules in view of the pore size of the membrane (bottlenecks) as well as on the chemical nature of the permeating molecules and the membrane material.

微孔膜介于上述两者之间。究竟是选择性渗透还是非选择性渗透取决于膜孔径与渗透分子的相对大小以及渗透分子的化学性质与膜材料。

When the membrane reactor is used for carrying out a catalysed reaction the questions arises whether the membrane itself has a catalytic function or not. If the membrane acts as a catalyst we refer to this as a catalytic membrane reactor (CMR, cf. Fig. 1e and f), if not we have an inert membrane catalytic reactor (IMCR, cf. Fig. 1d).

当将膜反应器用于催化反应时,所提出的问题是膜自身是否具有催化功能。若该膜具有催化功能,则称为催化膜反应器,如图1e和f所示;若无催化功能,则称为惰性膜催化反应器,如图1d所示。

The CMR-case may be further subdivided into two categories, i.e. when the membrane acts as the sole catalyst (cf. Fig. 1e), and when a conventional catalyst is present in addition to the membrane (cf. Fig. 1f). 催化膜反应器又分为两种。一种是膜作为唯一的催化剂,如图1e;另一种是将催化剂担载于膜上,如图1f 。

other authors have introduced similar acronyms for an easy reference to the different membrane reactor types. Tsotsis et al. [1] refer to a catalytic non-permselective membrane reactor (CNMR) as to a reactor with a catalytic membrane which is not permselective but provides for a well-defined interface for two (or more) reactants flowing on opposite sides of the membrane (cf. Fig. 1c).

为了便于指代不同类型的膜反应器,其他作者还给出了类似的首字母缩略词。文献[1]用CNMR代表非选择性催化膜反应器,即其膜具有催化功能,而无选择性,但能够为流过膜两侧的两种或多种反应物提供确切的反应界面,如图1c 。

In contrast their definition of a catalytic membrane reactor (CMR) requires a permselective membrane (cf. Fig. 1e). In both cases the membrane acts as the sole catalyst.

相对而言,用CMR代表选择渗透膜反应器。这类反应器需要一种选择渗透性膜,如图1e。对于这两种反应器,膜是唯一的催化剂。The same authors assigned the acronyms PBMR and FBMR to the packed-bed and fluidised-bed membrane reactor where the membrane is permselective but not catalytic (cf. Fig. 1d). The opposite cases, i.e. with catalytic and permselective membrane, are referred to as PBCMR and FBCMR, respectively (cf. Fig. 1f).

文献[1]分别用PBMR 和FBMR代表填料床和流化床膜反应器。在这两种反应器内,膜只具备选择渗透性,而无催化性,如图1d;若同时具有催化性和选择渗透性,则分别用PBCMR 和FBCMR来表示,如图1f 。

Coronas and Santamaria [2] used the notations CMR and IMR to distinguish between the catalytic and the inert membrane reactor. According to their definition the CMR has no other type of catalyst except the membrane. Consequently a third category ―combined‖ is introduced to refer to membrane reactor configurations where the catalyst is placed both inside and outside the membrane.

文献[2]用CMR 和IMR来区分催化膜反应器和惰性膜反应器。根据其定义,CMR除膜外,无另外的催化剂。由此出现了第三种结构的膜反应器,即催化剂填装于膜的两侧。

No further distinction is made in view of the permselectivity, i.e. whether

the membrane performs a separation task, whether it provides a reaction interface for different reactant streams, or whether it acts only as a special type of catalyst support, e.g. to minimise the mass transport resistance when the whole feed stream is passed through it in cross-flow.

就选择性渗透而言,未进一步区别膜究竟是起分离作用,还是为不同反应物流提供反应界面,或只是充当一种特殊的催化剂载体,例如,全部进料以错流方式通过膜时,将传质阻力减到最小。

In the past 15 years many valuable reviews on membrane reactors have been published. It is not the intention of this paper to add one more to the list but rather to emphasise the use of palladium in this field.

在过去的15年里,已发表了许多关于膜反应器的有价值的文献。本文的目的不是在这众多文献中再增加一篇,而是为了进一步强调钯在这个领域里的用途。

2. Membrane reactors based on palladium allo membranes基于钯合金膜上的膜反应器

It is well established that dense palladium and palladium alloy membranes are permeable for hydrogen only. Two main possibilities arise from this feature to employ these in membrane reactors, namely

已完全证实只有H2能够渗透通过致密型的钯膜和钯合金膜。当把这两种膜应用于膜反应器时,就出现了两种主要的可能性,即,1. to promote a dehydrogenation reaction by removal of the produced hydrogen from a dehydrogenation catalyst through the membrane, i.e. preventing the establishment of the chemical equilibrium, or

1.通过钯膜从脱氢催化剂中除去生成的H2,促进脱氢反应,即阻止其化学平衡的建立;

2. to carry out a hydrogenation reaction on the palladium surface with supply of hydrogen through the membrane.

2.或者,通过钯膜提供氢气,在膜表面完成加氢反应。

The purpose of the use of the palladium membrane as well as its function differs considerable in both types of applications.

在这两类应用中,使用钯膜及其功能的目的是不径相同的。

In case(1) the aim is to increase the conversion of an equilibrium limited reaction by removal of one of the products.

1.在第一类应用中,目的是通过除去一种生成物提高被化学平衡所限制的反应转化率。

The dehydrogenation occurs in the gas phase over a conventional catalyst (e.g. a packed-bed) which is surrounded by the palladium membrane .

装有普通催化剂的气固相脱氢反应就是一例。例如填料床反应器,钯膜包裹着催化剂。

In principle the palladium surface could act as a dehydrogenation catalyst too, but then the reaction rate would be too small due to the low surface area. Hence, the membrane has no primary catalytic function.

从原理上说,金属钯的表面也能够充当脱氢催化剂。然而,因其表面积小,脱氢反应速率太低,故认为它基本无催化功能。

In case (2) the purpose can be two-fold; to promote a selective hydrogenation by deliberately dosing hydrogen through the membrane, or to utilize an existing diluted hydrogen gas to perform the hydrogenation. In both situations the palladium membrane has a catalytic function.

在第2类应用中,其目的又分为2种。其一,通过膜准确计量氢气流量,提高加氢反应的选择性。其二,利用已有的稀浓度氢气发生加氢反应。在这两种情况下,钯膜都具有催化作用。

From an engineering point of view case (2) has a limited potential, at least for gas-phase hydrogenations.

就工程角度而言,情况(2)的应用潜力受到限制,至少对于气相加氢反应的应用。

It is true that palladium is a versatile hydrogenation catalyst, but the reaction rate normally is proportional to the surface area of the catalyst, provided no diffusion limitation occurs and the active sites are uniformly distributed over the surface.

事实上,钯是一种多功能加氢催化剂,倘若不是扩散控制,反应活性点在钯膜的整个表面上均匀分布,则其加氢反应速率恰好与催化剂的表面积成正比。

Conventional hydrogenation catalysts have the palladium in highly dispersed form, e.g. as nanoscale metal clusters inside a porous pellet, and hence do offer a large palladium surface area. Compared to this the accessible surface area of a dense palladium membrane is small.

普通加氢催化剂含有高分散形状的金属钯,例如,在一个多孔的催化

剂圆柱内,含有多个纳米级的钯金属串,由此,确实提供了大的钯表面积。相对于这种钯催化剂,致密型钯膜的可用面积是小的。

If the hydrogenation is to be performed in the liquid phase the situation may be different because then the reaction rate is often controlled by the kinetics of hydrogen mass transfer, and the available active surface inside the porous catalyst is utilized anyway only in part.

如果加氢反应是在液相中进行,因为液相加氢反应速率往往受到氢的传质动力学控制,多孔催化剂内部的有效活性表面无论如何只能被利用一部分,情况有可能是不同。

Liquid-phase hydrogenations are carried out at high pressure due to the poor solubility of hydrogen in most organic liquids. Palladium membranes would allow for a simplification of the process design ,as they could take over both the catalytic function and the task of dosing hydrogen. High pressure operation could then be avoided.

由于氢在大多数有机液体中的溶解度都很小,故液相加氢反应都是在高压下完成的。假如这两种钯膜能够兼顾催化作用和准确计量氢气流量的话,或许可简化这一工艺过程,还可以避免高压操作。Combined with a clear benefit in selectivity there might be interesting applications of this concept in the fine chemicals area.

结合钯膜在选择性方面的明显好处,简化后的工艺可能在精细化学品生产领域中具有许多令人感兴趣的应用.

However, most of the recent studies using palladium-based membranes in literature are aimed at hydrogen removal from packed-bed catalysts either to boost the yield of industrially important dehydrogenation reaction ( propane , iso-butane/n-butane , ethyl-benzene , etc . )

然而,目前对于钯类膜的应用研究,大多数旨在从填料床催化剂中除去氢,或者提高具有工业重要性的脱氢反应的产率,例如:丙烷脱氢,异丁烷/丁烷脱氢,乙苯脱氢,等等。

or to provide pure hydrogen ( steam reformring of methane or methanol, water-gas-shift reaction),e.g. for use in low-temperature ( PEM ) fuel cell stack.Hence ,the discussion here is restricted to this type of application only.

或者是为低温燃料电池提供纯氢。例如,甲烷或甲醇的水蒸汽重整反

应,水煤气变换反应。因此,本文仅限于讨论膜反应器的这类应用。

2.1Working principle of an inert membrane catalytic reactor with removal of hydrogen

2.1一种能够移去氢的惰性膜催化反应器工作原理

The principle of a hydrogen permselective membrane reactor equipped with a packed-bed of catalyst and a surrounding palladium-based membrane has been described many times in literature. Fig. 2 illustrates the situation.

如图2所示,文献中已多次介绍过一种催化剂用钯类膜包裹着填料床式氢选择性渗透膜反应器的工作原理。

The dehydrogenation occurs on the packed-bed catalyst, and the produced hydrogen is withdrawn through the membrane. The transport through the membrane is driven by the hydrogen partial pressure difference between the packed-bed (i.e. retentate) side and the permeate side. Three different possibilities exist to create the driving force:

脱氢反应在固定床催化剂上发生,生成的氢通过膜取出。通过膜的传质推动力是反应区和渗透区间的氢气分压差。产生这一推动力的方式有三种:

1. Use of an inert sweep gas in the permeate compartment (e.g. nitrogen, helium, etc.).

2. Application of a pressure difference between retentate and permeate compartment (if necessary by evacuation of the permeate).

https://www.360docs.net/doc/f21194728.html,e of a reactive sweep gas to consume the permeated hydrogen (e.g. oxygen, air, carbon monoxide, unsaturated hydrocarbons, etc.).

1.在渗透区使用一种惰性吹扫气。例如N2, He, 等等。

2.利用反应区和渗透区的压差(必要时渗透区抽真空)。

3.使用一种活性吹扫气消耗透过的H2。如可使用O2,空气,CO或不饱和烃,等等。

Which of these possibilities is the best depends on the particular situation. In general, the worst case is the inert sweep gas because this has to be provided and compressed, and a diluted hydrogen gas is produced which can be used only as a fuel gas with low calorific value .

这3种措施究竟哪一个最好呢?这需要依据具体情况而定。一般来说,最糟糕的情况是使用惰性吹扫气。因为,这样做必须提供和压缩

所用的气体,且获得是低浓度氢气。这种氢气只能作为低热值燃料气使用。

If the kinetics of the hydrogen producing reaction do allow an operation at elevated pressure, for instance in the range of 1–3MPa, this becomes an attractive option because then the pressure difference is sufficiently large to flush out the permeated hydrogen.

若生成氢反应的动力学确实允许在提高压力条件下操作,例如反应压力在1-3MPa,则第二种情况就是一个具有吸引力的选择。因为,此时可提供足够大的压差,将所渗透的氢气全部排出。

The advantages are that no sweep gas is required and that pure hydrogen is obtained as a marketable product. On the other hand, the feed gas has to be compressed but the produced hydrogen is obtained at low pressure, which limits its usability and could make a recompression necessary.

第二个措施的优点是不需要吹扫气,可获得达到商品浓度氢。但缺点是必须压缩原料气,而且获得的是低压氢气。这就限制了氢气的用途,必要时还需对其进行二次压缩。

If pure hydrogen, e.g. for a fuel cell, is the target product of the membrane reactor, then an operation at elevated retentate pressure is the only viable option.

如果纯氢气,如用于燃料电池,是膜反应器的目标产品,那么提高反应物压力是唯一可行的选择。

The third option, i.e. reacting the permeated hydrogen with the sweep gas, is promising because it avoids the disadvantages of the other two.

第三种方式,即透过的氢气与吹扫气发生反应,是大有可为的。因为它避免了前两2者的缺点。

Moreover, since hydrogen producing reactions are endothermic in most cases (hydrocarbon dehydrogenation and hydrocarbon steam reforming) it is favourable to generate the required heat right in the permeate compartment.

而且,因为在大多数情况下生成氢的反应都是吸热反应,如烃类的脱氢反应和烃类湿法重整反应,渗透区恰好可产生反应所需的热量。这显然是有利的。

An exothermic hydrogen-consuming reaction can be carried out for this purpose, if possible employing the palladium membrane surface as a

catalyst.

为此,如果钯膜表面可作为催化剂使用,耗氢的放热反应便能够完成。Hydrogen oxidation with air or hydrogenation of an organic compound are candidates if they fit with the required reactor temperature. The disadvantage of hydrogen oxidation is that a high-valued product is used to heat the dehydrogenation.

只要能够适应这种反应器所需的温度,氢与空气的氧化反应或与某一有机物的加氢反应都是可考虑的对象。氢气氧化反应的缺点是用高附加值的氢提供脱氢反应所需要的热量。

The other case, coupling of the dehydrogenation process to a second synthesis, is difficult to run at optimized conditions in a commercial-scale reactor because of the reduced degree of freedom.

另一种情况,即把脱氢反应与二次合成组合起来,因这样做使过程的自由度减少,达到生产规模的膜反应装置难以在优化条件下运行。2.2 Development of palladium-based membranes 2.2 钯类膜的进展

First investigations of the hydrogen absorption and diffusion through palladium were reported by Graham in 1866. Today it is well known that hydrogen permeates with an infinite selectivity via a solution-diffusion mechanism through palladium and its alloys. The permeation is based on a multi-step process.

最早关于氢吸收扩散透过钯的研究是Graham于1866年公开发表的。如今,氢以溶解-扩散原理无限制性选择通过钯及其合金,已是众所周知。这种渗透基于多步过程。

First molecular hydrogen is adsorbed on the palladium surface, where the dissociation into atomic hydrogen takes place. Then the hydrogen atoms enter the palladium lattice and diffuse through the lattice, while the electrons interact with the metal lattice. On the adjacent side the hydrogen atoms leave the lattice and recombine on the surface, before they are finally desorbed as hydrogen molecules [23]。

第一步,分子氢吸附于钯的表面,解离为原子氢。然后, 原子氢进入钯的晶格。当氢电子与钯的晶格发生作用时,原子氢扩散穿过晶格,在另一侧与晶格脱离,在钯表面重新结合,最终,以氢分子的形式脱附。

It is also well known that the use of pure palladium membranes is hindered by the fact that palladium shows a transition from the α-phase (hydrogen-poor) to the β_-phase (hydrogen-rich) at temperatures below 300 ℃and pressures below 2MPa, which depends on the hydrogen concentration in the metal.

纯钯膜的使用受到如下原因的影响,即当温度<300 ℃和压力<2MPa时,钯表现出由α相(贫氢相)向β相(富氢相)的转变,且这一转变过程与氢在钯里的浓度有关。这也已是众所周知的。Since the lattice constant of the β-phase is 3% larger than that of the α-phase this transition leads to lattice strain and, consequently, after a few cycles to a distortion of the metal lattice .

因β相的晶格常数比α相的晶格常数大3%,这一转变过程会引起晶格应变,故此,当经过几次循环之后,钯的晶格就产生形变。Alloying the palladium, especially with silver, reduces the critical temperature for this embrittlement and leads to an increase of the hydrogen permeability.

对钯进行合金,特别是钯与银合金,可降低发生这种氢脆现象的临界温度,并且可提高氢的渗透能力。A maximum value of the hydrogen flow is reached for an alloy with approximately 23 wt.% silver [25,26]. Similar to Pd/Ag, other alloys, e.g. Pd/Y or Pd/Ce show high hydrogen permeability and good mechanical stability[27].

当钯银合金中银的质量分率约为23%时,氢的流量达到最大值。类似于钯银合金,其它合金,例如钯铱合金或钯鈰合金均表现出良好的氢渗透性和优异的机械稳定性。

Palladium-based membranes have been used for decades to provide ultra-pure hydrogen, e.g. in the semiconductors industry and for the operation of fuel cells [28,29] .

用钯类膜生产超纯度的氢气,例如半导体行业和燃料电池,已经几十年了。

They were exploited to extract tritium from liquid-metal tritium breeders. In recent years there has been a growing interest in the industrial application of palladium-based membranes for hydrogen producing reactions.

这两种用途都是利用钯类膜从液态金属氚的原子滋生反应器中萃取

氚。近年来,用于制氢反应钯类膜的工业应用受到日益关注。Extensive investigations were conducted for the employment of palladium-based membranes for hydrogen removal to shift thermodynamic (equilibrium) limitations towards higher conversions, e.g. during dehydrogenation of hydrocarbons,steam reforming of methane and the water-gas-shift reaction .

广泛探索了采用钯类膜移去氢气以改变热力学(平衡)限制,进一步提高转化率。例如,烃类的脱氢反应,甲烷水蒸汽重整反应和水煤气转换反应。

And it was shown that hydrogen feeding through palladium membranes can improve the selectivity of hydrogenation reactions .

还有,研究表明通过钯类膜供氢能够改善加氢反应的选择性。

Key requirements for the successful development of palladium-based membranes are low costs as well as high hydrogen permeability and permselectivity combined with good mechanical /thermal and long-term stability.

成功研发钯类膜的关键要求是在膜具有优异且长期稳定的机械/热力学性能前提下,成本要低,氢的渗透性能和选择渗透性能要好。

2.2.1 Dense palladium-based Membranes致密型钯膜

Early work focused on the application of relatively thick unsupported dense metal membranes prepared by conventional metallurgical processes.

早期的研究工作是针对采用传统冶金工艺制备的致密型金属膜的应用。这类膜相对较厚,无需支撑。In 1964 Johnson Matthey developed a hydrogen purification equipment which employed a Pd/Ag tube [39]. However, the use of these membrane reactors is limited by the low hydrogen flow which is inversely proportional to the thickness of the membrane.

1964年,由Johnson Matthey 研发了一套装有一根钯银合金管的氢气纯化装置[39]。然而,这类膜反应器的使用因氢流率小而受到限制。原因是氢流率与膜的厚度成反比。

Self supporting dense palladium-based membranes possess wall thicknesses greater than 50~100μm to keep a sufficient mechanical strength。

自撑式致密型钯膜的厚度超过50~100微米,才能保持足够的机械强度。

These membranes are too thick to obtain a satisfactory hydrogen flux. Besides the low permeance, thick palladium membranes are too expensive for an economic use, in particular since the price of palladium has tremendously increased over the last few years.

这类膜太厚了,以至于不能获得令人满意的氢气通量。除此之外,就经济性而言,各种厚型钯膜的价格太贵了,尤其是近年来钯价格猛涨。For practical use it is necessary to reduce the thickness of the palladium layer. Composite metal membranes and composite porous membranes seem to be an advisable choice to overcome these disadvantages.

要想实际使用钯膜,必须降低钯层的厚度。为了克服上述缺点,复合金属型钯膜和复合多孔钯膜似乎是一个明智的选择。

2.2.2 Palladium-based composite metal membranes 复合金属型的钯类膜

Palladium-based composite metal membrane consist of a thin layer of palladium or a palladium alloy coated on one or both sides of a hydrogen permeable base refractory metal such as niobium, vanadium or tantalum. These metals possess a high mechanical strength and are less expensive than palladium . Furthermore ,the hydrogen flow through these body-centred cubic metals is higher than through the face-centred cubic palladium.

复合金属钯类膜是将一薄层钯或钯合金单面或双面涂镀于氢可透过的耐熔金属,诸如铌、钒或钽,载体表面构成。铌、钒或钽这类金属机械强度高,比钯便宜。而且,这些金属是体心立方结构,钯是面心立方结构。故氢通过它们的流速比通过钯的大。

Unfortunately the direct replacement of palladium for these metals is not possible due to the formation of oxide layers and to surface reactions which reduce the hydrogen flow through the membrane [42].

可惜的是,不可能用这些金属直接替代钯。原因是会形成多个氧化层以及发生表面反应。由此,降低了氢通过膜的流率。

In 1967 Makrides et al. [43] filed a patent for plating foils of Group VB metals with thin layers of palladium using sputter deposition. However, it

has been reported that the hydrogen flux through palladium-based composite metal membranes decreases with time at high temperatures. 1967年,Makrides et al. [43] 申请了一项制备复合金属钯膜的专利。该专利是采用喷溅法在第五类副族元素的镀箔上沉积多层钯。然而,据报道这种复合金属膜的氢气流率高温下随时间而降低。Intermetallic between the metal layer and the base metal is the most likely reason for this notice [44]. To overcome this problem it was suggested to use a diffusion barrier between the base and the coating metal, e.g. thermal stable oxide layers such as alumina[44,45].

钯层与载体层间金属的相互作用是发生这一现象最有可能的原因。为了克服这个问题,曾建议在载体和钯膜之间增加扩散障碍物。例如,增加几层诸如氧化铝类的热稳定性能优异的氧化物。

2.2.3 Palladium-based composite porous membranes 钯类复合多孔膜Palladium-based composite porous membranes consist of a thin dense layer of palladium or a palladium alloy on a porous support. Tubes or discs of porous glass, porous ceramics or porous stainless steel can all be employed as supports.

复合钯类多孔膜就是将一层致密的钯或钯合金膜置于多孔载体上。多孔的玻璃管或盘、多孔陶瓷管或盘、多孔不锈钢管或盘都能作为载体使用。

Different techniques such as chemical vapor deposition [46,47], magnetron sputtering [46,48], electrodeposition [49] and spray pyrolysis [50] have demonstrated the ability to coat palladium-based films on porous substrates [51].

由文献[51]可知,把钯类膜涂敷在多孔载体上的方法有多种。例如,文献[46,47]提到的化学汽相沉积法,文献[46,48]提到的磁电管喷溅法,文献[49]所提到的电沉积法,文献[50]所提到的喷雾热解法。Each method has its advantages. However, due to its simplicity, relatively low costs and uniformity of the deposition, electroless plating is the most popular and most successful procedure so far [52–55].

每种方法各具优点。但由于无电电镀法操作简单、造价相对低廉、沉积均匀,故迄今为止,它是使用最为广泛、最为成功的方法。

It is based on the autocatalytic reduction of a metastable metallic salt complex on an activated substrate surface. New preparation methods

combine the electroless plating with reverse osmosis to obtain composite membranes with better thermal stability and higher permeance.

这种方法的基本原理是一种介稳态钯盐络合物在经过活化的载体表面上发生自催化还原反应。目前,新的制备方法是把无电电镀与反渗透相结合,将可获得具有更好热稳定性和更高渗透率的复合钯膜。Excellent results have been reported recently for ultrathin composite membranes prepared by a modified electroless plating method, where the classical substrate surface activation has been replaced by a new photocatalytic deposition method .

据最新的报道,用改进的无电电镀法可制备出超薄型的复合膜。在这种方法中,传统载体表面活性被一种新的光催化沉积物所取代。

2.3 Experimental

2.3.1 Preparation of palladium-based composite membranes钯类复合膜的制备

Many academic and industrial groups have developed palladium-based composite membranes in researach projects 。but so far no such products are available on a normal commercial basis .

许多学术的、企业的研究小组在其研究项目中开发了多种钯类复合膜。但迄今为止这类产品还未应用于实际生产。

For our studies on the dehydrogenation of hydrocarbons in palladium membrane reactors we too have looked at different techniques for the manufacture of hydrogen permselective palladium and palladium-silver composite membranes . Details are reported in [60,61] .

对于用钯膜反应器进行烃类脱氢反应的研究,我们已经考虑到有多种制备氢选择性渗透钯膜和钯银复合膜方法。详细内容可见参考文献[60] 和[61] 。

For the results presented in this paper mainly electroless plating was use. Asymmetric sintered porous stainless steel tubes supplied by GKN Sinter Metals Krebsoge Filters GmbH, Radevormwald (Germany), and asymmetric porous α—alumina tubes purchased from Inocermic GmbH, Hermsdorf (Germany), were employed as supports for the palladium plating.

本文所得结果主要采用无电电镀法。所用的镀钯载体非对称烧结多孔不锈钢管和非对称多孔α铝矾土管分别由德国GKN 和IGH公司提

供。

Both types have the same outer diameter of 10 mm and a comparable inner diameter of 6.5mm for the sinetered metal tubes and 7 mm for the ceramic tubes.

这两种载体管外径相同,均为10 mm,当量内径分别是烧结管 6.5 mm ,陶瓷管7mm。

The sintered metal tubes consist of two layers with different pore size. The nominal pore diameter of the fine layer, located on the shell side, is around 500 nm. The ceramic tubes have four layers with graded pore size. The finest layer has a mean pore diameter of 100 nm. The palladium was deposited always onto the layer with the finest pores.

金属烧结管由孔径不同的两层组成。小孔径层的公称孔径大约500纳米,且位于管外侧。铝陶瓷管由不同孔径尺度的4层组成。孔径最小层的平均孔径是100纳米。这样,钯总是可以沉积到这一层的最小孔上。

The porous substrates were first cut to 11 cm length and cleaned with ammoniac solution, isopropyl alcohol and de-ionised water. Following the cleaning the substrate surface was seeded with Pd nuclei, which initiates the auto-catalytic reduction of the palladium complex in the subsequent plating step.

首先,将多孔载体切割为11厘米长,用氨水、异丙醇和去离子水依次清洗。然后,在载体表面植入钯核。这样做是为了引发下一步电镀过程中钯络合物的自催化还原反应。

For this purpose the tubes were successively immersed at ambient temperature in a tin chloride solution followed by an acidic palladium chloride bath. This sequence was repeated 10 times.

为了植入钯核,在室温条件下,用氯化锡、酸性氯化钯溶液依次浸泡这些金属管。这一过程重复10次。Afterwards the palladium deposition was carried out at 60℃in a plating bath containing a palladium–amine complex as palladium source, hydrazine reducer and EDTA as stabilising agent (cf. Table 1).

接着,在温度为60 ℃的电镀槽内完成钯的沉积过程。如表1所示,钯胺络合物为钯源,联氨作还原剂,EDTA作稳定剂。

The plating solution was changed every hour to keep the plating rate

constant. Palladium deposition occurred according to Eq. (1).

2Pd 2+ + N2H4 + 4OH-→2Pd + N2 + 4H2O (1) After the plating the membranes were rinsed with de-ionised water and dried overnight at 120℃ in a drying oven.

每小时更换一次镀液,以保证钯的沉积速率不变。钯沉积反应按方程(1)进行。镀后,用去离子水冲洗,再置于120℃干燥箱内一个通宵。Palladium–silver composite membranes were prepared by successive deposition of palladium and silver on the porous supports followed by a heat treatment [53]. The first step was the preparation of a palladium layer as described above.

制备钯银复合膜是先将钯和银依次沉积在载体上,再热处理。第一步先镀钯层。方法同上,

Afterwards silver was deposited on the palladium film also by the electroless plating technique, which leads to the formation of a thin double layer of palladium and silver on the porous tube.

然后,也用无电电镀法,把银沉积在钯膜上,在载体表面形成一张薄的钯银双金属膜。

The silver plating solution consisted mainly of an EDTA stabilised silver–amine complex with hydrazine as reducing agent (cf. Table 1).

如表1所示,银镀液主要由EDTA 、银铵络合物和联氨组成。EDTA 作稳定剂,联氨作还原剂。

Silver deposition occurred according to Eq. (2).After the plating the membranes were heated up to 700℃for 12 h under an atmosphere of argon. These high temperatures lead to the formation of a homogeneous palladium–silver film by thermal diffusion [53].

4Ag+ + N2H4 + 4OH-→ 4Ag + N2 + 4H2O(2)

银沉积反应按方程式(2)进行。镀后,在氩气环境下,将制备的膜加热到700℃,保持12 h。这样的高温,在热扩散作用,形成的钯-银膜均匀一致。

The thickness of the palladium and palladium–silver layers was determined from SEM micrographs and from the weight difference before and after the plating combined with the densities of the metals and under the assumption of uniform coverage.

用电子扫描显微镜和镀膜前后质量差除以金属的密度与面积两种方

法,确定所制两种膜的厚度。在此,假定膜表面均匀。

2.3.2 Permeation measurements渗透测定值

The separation behaviour of the palladium composite membranes was investigated in the permeation apparatus shown schematically in Fig. 3.

钯复合膜分离特性的考察是在如图3所示的渗透装置中完成的。Details of the permeation unit are given in Fig. 4. The experiments were conducted with pure hydrogen and pure nitrogen as well as with a binary gas mixture of hydrogen with nitrogen.

图4给出了渗透器的详细信息。实验中使用了纯氢、纯氮以及氢氮二元混合气体。

The temperature was varied between350 and 650℃, and the pressure difference reached up to 400 kPa. Measurements were carried out with no sweep gas at atmospheric or low pressure on the permeate side and with nitrogen as sweep gas at atmospheric pressure. The heating rate was 1 K/min and below 300℃both sides of the membrane were kept under nitrogen to void hydrogen embrittlement.

测定条件:温度在350和650℃间变化,压差增加到400 kPa,渗透区常压或低压,无吹扫气;常压,有氮气作吹扫气;加热速率为1K/分钟。氮气环境下,保持膜两侧的温度低于300 ℃,避免发生氢脆现象。The desired feed gases were introduced with the aid of thermal mass flow controllers. The pressures on the retentate and permeate sides of the membrane were adjusted with back pressure controllers. The axial temperature profile of the reactor was monitored with thermocouples. The temperature variation over the whole length of the membrane did not exceed ±4℃.

所要求的原料气通过热式质量流量控制器输入。膜两侧的压力用反馈式压力控制阀调节。膜反应器的轴向温度分布用热电偶监测。沿膜长的温度变化不超过±4℃。

The gas flows leaving the reactor were measured by a thermal mass flow meter or a digital soap bubble flow meter. A gas chromatograph was used to analyse the composition of the permeate and the retentate. The membrane was installed in the reactor by sealing both ends of the tube with graphite rings.

从反应器两侧离开的气体流量用热式质量流量计或数字皂泡流量计

计量,其组成用气相色谱分析。安装在反应器里。膜反应管两端用石墨环密封。

2.4 Results and discussion结果与讨论

2.4.1 Characterisation of the composite membranes by SEM用扫描电镜表征所制备的复合膜

The surface morphology of an electroless deposited palladium film is shown in Fig.5.

图5给出了无电沉积法制备的钯膜表面形态。

It can be seen that the palladium film is composed of fine palladium grains. These grains are grown well together and form a dense palladium layer on the support. The minimum thickness of the palladium layer must be about 3μm or greater with the above technique to get layers without pinholes.

由图5可见,该膜由细小的钯粒组成。这些钯粒完全生长在一起,在载体上形成了一层致密的钯膜。用无电沉积法制备钯膜,最小厚度必须超过3微米或更大,才能获得无气孔膜。

Fig. 6 shows a SEM micrograph of a palladium–silver surface after the final heat treatment.

图6给出了热处理后的钯银膜SEM图像。

X-ray diffraction patterns of the surface of this membrane before (a) and after (b) the heat treatment are given in Fig. 7.

图7分别给出了热处理前(a)和后(b)这个膜的X射线衍射图。After the plating the reflection peaks of pure silver and pure palladium can be seen among the peaks of the alumina support. After the heat treatment the peaks of the pure metals have disappeared and peaks of the palladium–silver alloy can be observed.

镀后,在载体Al2O3的群峰之间,可见到银和钯的衍射峰。热处理后,钯、银的衍射峰都消失了,只能见到钯银合金的衍射峰。These peaks lie between those for silver and palladium and shift with higher palladium contents to higher diffraction angles.

这些峰都位于银和钯的衍射峰之间,且钯的含量越高,转换的衍射角越大。

2.4.2 Permeation behaviour of the composite membranes 复合钯膜的渗透性质

化学专业英语(修订版)翻译

01 THE ELEMENTS AND THE PERIODIC TABLE 01 元素和元素周期表 The number of protons in the nucleus of an atom is referred to as the atomic number, or proton number, Z. The number of electrons in an electrically neutral atom is also equal to the atomic number, Z. The total mass of an atom is determined very nearly by the total number of protons and neutrons in its nucleus. This total is called the mass number, A. The number of neutrons in an atom, the neutron number, is given by the quantity A-Z. 质子的数量在一个原子的核被称为原子序数,或质子数、周淑金、电子的数量在一个电中性原子也等于原子序数松山机场的总质量的原子做出很近的总数的质子和中子在它的核心。这个总数被称为大量胡逸舟、中子的数量在一个原子,中子数,给出了a - z的数量。 The term element refers to, a pure substance with atoms all of a single kind. T o the chemist the "kind" of atom is specified by its atomic number, since this is the property that determines its chemical behavior. At present all the atoms from Z = 1 to Z = 107 are known; there are 107 chemical elements. Each chemical element has been given a name and a distinctive symbol. For most elements the symbol is simply the abbreviated form of the English name consisting of one or two letters, for example: 这个术语是指元素,一个纯物质与原子组成一个单一的善良。在药房“客气”原子的原子数来确定它,因为它的性质是决定其化学行为。目前所有原子和Z = 1 a到Z = 107是知道的;有107种化学元素。每一种化学元素起了一个名字和独特的象征。对于大多数元素都仅仅是一个象征的英文名称缩写形式,一个或两个字母组成,例如: oxygen==O nitrogen == N neon==Ne magnesium == Mg

应用化学专业英语第二版万有志主编版课后答案和课文翻译

Unit 1 The RootsofChemistry I.Comprehension. 1。C 2. B3.D 4. C 5. B II。Make asentence out of each item by rearranging the wordsin brackets. 1.Thepurification of anorganic compoundis usually a matter of considerabledifficulty, and itis necessary to employ various methods for thispurpose。 2.Science is an ever-increasing body ofaccumulated and systematized knowledge and isalsoan activity bywhic hknowledge isgenerated。 3.Life,after all, is only chemistry,in fact, a small example of c hemistry observed onasingle mundane planet。 4.Peopleare made of molecules; someof themolecules in p eople are rather simple whereas othersarehighly complex。 5.Chemistry isever presentin ourlives from birth todeathbecause without chemistrythere isneither life nor death. 6.Mathematics appears to be almost as humankindand al so permeatesall aspects of human life, although manyof us are notfully awareofthis. III。Translation. 1.(a)chemicalprocess (b) natural science(c)the techni que of distillation 2.Itis theatoms that makeupiron, water,oxygen and the like/andso on/andsoforth/and otherwise. 3.Chemistry hasa very long history, infact,human a ctivity in chemistrygoes back to prerecorded times/predating recorded times. 4.According to/Fromthe evaporation ofwater,people know /realized that liquidscan turn/be/changeinto gases undercertain conditions/circumstance/environment。 5.Youmustknow the propertiesofthe materialbefore y ou use it. IV.Translation 化学是三种基础自然科学之一,另外两种是物理和生物.自从宇宙大爆炸以来,化学过程持续进行,甚至地球上生命的出现可能也是化学过程的结果。人们也许认为生命是三步进化的最终结果,第一步非常快,其余两步相当慢.这三步

化学专业英语翻译1

01.THE ELEMENTS AND THE PERIODIC TABLE 01元素和元素周期 表。 The number of protons in the nucleus of an atom is referred to as the atomic number, or proton number, Z. The number of electrons in an electrically neutral atom is also equal to the atomic number, Z. The total mass of an atom is determined very nearly by the total number of protons and neutrons in its nucleus. This total is called the mass number, A. The number of neutrons in an atom, the neutron number, is given by the quantity A-Z. 原子核中的质子数的原子称为原子序数,或质子数,卓电子数的电中性的原子也等于原子序数Z,总质量的原子是非常接近的总数量的质子和中子在原子核。这被称为质量数,这个数的原子中的中子,中子数,给出了所有的数量 The term element refers to, a pure substance with atoms all of a single kind. To the chemist the "kind" of atom is specified by its atomic number, since this is the property that determines its chemical behavior. At present all the atoms from Z = 1 to Z = 107 are known; there are 107 chemical elements. Each chemical element has been given a name and a distinctive symbol. For most elements the symbol is simply the abbreviated form of

《化学工程与工艺专业英语》课文翻译 完整版

Unit 1 Chemical Industry 化学工业 1.Origins of the Chemical Industry Although the use of chemicals dates back to the ancient civilizations, the evolution of what we know as the modern chemical industry started much more recently. It may be considered to have begun during the Industrial Revolution, about 1800, and developed to provide chemicals roe use by other industries. Examples are alkali for soapmaking, bleaching powder for cotton, and silica and sodium carbonate for glassmaking. It will be noted that these are all inorganic chemicals. The organic chemicals industry started in the 1860s with the exploitation of William Henry Perkin‘s discovery if the first synthetic dyestuff—mauve. At the start of the twentieth century the emphasis on research on the applied aspects of chemistry in Germany had paid off handsomely, and by 1914 had resulted in the German chemical industry having 75% of the world market in chemicals. This was based on the discovery of new dyestuffs plus the development of both the contact process for sulphuric acid and the Haber process for ammonia. The later required a major technological breakthrough that of being able to carry out chemical reactions under conditions of very high pressure for the first time. The experience gained with this was to stand Germany in good stead, particularly with the rapidly increased demand for nitrogen-based compounds (ammonium salts for fertilizers and nitric acid for explosives manufacture) with the outbreak of world warⅠin 1914. This initiated profound changes which continued during the inter-war years (1918-1939). 1.化学工业的起源 尽管化学品的使用可以追溯到古代文明时代,我们所谓的现代化学工业的发展却是非常近代(才开始的)。可以认为它起源于工业革命其间,大约在1800年,并发展成为为其它工业部门提供化学原料的产业。比如制肥皂所用的碱,棉布生产所用的漂白粉,玻璃制造业所用的硅及Na2CO3. 我们会注意到所有这些都是无机物。有机化学工业的开始是在十九世纪六十年代以William Henry Perkin 发现第一种合成染料—苯胺紫并加以开发利用为标志的。20世纪初,德国花费大量资金用于实用化学方面的重点研究,到1914年,德国的化学工业在世界化学产品市场上占有75%的份额。这要归因于新染料的发现以及硫酸的接触法生产和氨的哈伯生产工艺的发展。而后者需要较大的技术突破使得化学反应第一次可以在非常高的压力条件下进行。这方面所取得的成绩对德国很有帮助。特别是由于1914年第一次世界大仗的爆发,对以氮为基础的化合物的需求飞速增长。这种深刻的改变一直持续到战后(1918-1939)。 date bake to/from: 回溯到 dated: 过时的,陈旧的 stand sb. in good stead: 对。。。很有帮助

蓝梅主编 给排水科学与工程专业英语部分课文翻译中文版

第四单元给水系统 一般来说,供水系统可划分为四个主要组成部分:(1)水源和取水工程(2)水处理和存储(3)输水干管和配水管网。常见的未处理的水或者说是原水的来源是像河流、湖泊、泉水、人造水库之类的地表水源以及像岩洞和水井之类的地下水源。修建取水构筑物和泵站是为了从这些水源中取水。原水通过输水干管输送到自来水厂进行处理并且处理后的出水储存到清水池。处理的程度取决于原水的水质和出水水质要求。有时候,地下水的水质是如此的好以至于在供给给用户之前只需消毒即可。由于自来水厂一般是根据平均日需求流量设计的,所以,清水池为水需求日变化量提供了一个缓冲区。 水通过输水干管长距离输送。如果输水干管中的水流是通过泵所产生的压力水头维持的,那么我们称这个干管为增压管。另外,如果输水干管中的水流是靠由于高差产生的可获得的重力势能维持的,那么我们称这个干管为重力管。在输水干管中没有中间取水。与输水干管类似,在配水管网中水流的维持要么靠泵增压,要么靠重力势能。一般来说,在平坦地区,大的配水管网中的水压是靠泵提供的,然而,在不平坦的地区,配水管网中的压力水头是靠重力势能维持的。 一个配水管网通过引入管连接配水给用户。这样的配水管网可能有不同的形状,并且这些形状取决于这个地区的布局。一般地,配水管网有环状或枝状的管道结构,但是,根据当地城市道路和街区总体布局计划,有时候环状和枝状结构合用。城市配水管网大多上是环状形式,然而,乡村地区的管网是枝状形式。由于供水服务可靠性要求高,环状管网优于枝状管网。 配水管网的成本取决于对管网的几何形状合适的选择。城市计划采用的街道布局的选择对提供一个最小成本的供水系统来说是重要的。环状管网最常见的两个供水结构是方格状、环状和辐射状;然而,我们不可能找到一个最佳的几何形状而使得成本最低。 一般地,城镇供水系统是单入口环状管系统。如上所说,环状系统有一些通过系统相互连接的管道使得通过这些连接接的管道,可以供水到同一个需水点。与枝状系统不同,在环状系统中,由于需水量在空间和时间上的变化,管道中的水流方向并非不变。 环状管网可为系统提供余量,提高系统应对局部变化的能力,并且保证管道故障时为用户供水。从水质方面来说,环状形状可减少水龄,因此被推广。管道的尺寸和配水系统的设计对减少水龄来说是重要的因素。由于多方向水流模式和系统中流动模式随时间的变化,水不会停留在一个地方,这样减少了水龄。环状配水系统的优缺点如表4.1所述。 优点:1.Minimize loss of services.as main breaks can be isolated due to multidirectional flow to demand points.2.Reliability for fire protection is higher due to redundancy in the system.3.Likely to meet increase in water demand -higher capacity and lower velocities.4.Better residual chlorine due to in line mixing and fewer dead ends. 5.Reduced water age. 在文献中曾记载过,只考虑最低成本设计的环状管网系统会转化成树状似的结构,这一做法导致在最终的设计中失去最初的几何形状。环状保证了系统的可靠性。因此,一个只考虑最低成本为依据的设计打败了在环状管网中所提供的基本功能。有文献记载设计环状管网系统的方法。尽管这个方法也是仅以考虑最低成本为基础,它通过对管网中所有管道最优化规划从而保持了管网的环状结构。

英语研究生专业分类

与其他不少考研热门专业一样,英语专业研究生招生的研究方向设置非常细,不同学校的方向设置类别不一,名称也各异。 比如上海外国语大学英语语言文学专业下设有语言方向、文学方向、教学法方向、翻译学方向、口译学方向、英语国家文化方向、跨文化交际方向7个方向。而同样是外语类专业院校,北京外国语大学该专业设置的研究方向明显不同,广东外语外贸大学该专业设置的8个研究方向更与前两所学校无一相同。 在这种情况下,不少备考英语专业的同学对“如何选择研究方向”这样的问题一头雾水,也就不足为怪了。 就英语专业考研而言,外国语言文学下设置的二级学科很多,包括英语语言文学、俄语语言文学、法语语言文学、德语语言文学、日语语言文学、印度语言文学、阿拉伯语语言文学、欧洲语言文学、亚非语言文学、外国语言学及应用语言学、翻译学11个学科。其中,涉及英语专业的二级学科主要有3个:英语语言文学、外国语言学及应用语言学、翻译学。 一般院校的英语专业多设置英语语言文学和外国语言学及应用语言学两个专业,所以,英语专业考研的专业设置其实比较简单,一般就是两大专业。不过,这两个专业被不同学校细化研究方向以后,就变得复杂了。如前面说到的上海外国语大学英语语言文学专业下设有7个方向,这7个方向进一步细分,小的研究方向达37个之多。 英语专业的研究方向虽名目众多,却也并非杂乱无章,其设置仍是遵循一定规律的。粗略分析,这些研究方向可分为传统研究方向和新兴研究方向两大类。 传统研究方向 传统研究方向,顾名思义,指的是设置多年的老牌研究方向,这些研究方向一般学校都有开设。 1. 文学方向 开设学校:全国绝大部分招收英语专业研究生的学校。据2007年的招生统计,仅有17所招收英语专业研究生的学校没有开设文学方向。 研究内容:主要研究英美文学研究领域中的重大问题,目的在于提高文学素养、理论水平和研究能力。 就业方向:此方向开设学校多,招生人数较多,就业范围非常广泛,一般为教师、研究人员。所学课程:西方文论、美国经典文学、美国现当代文学、英国经典文学、文学批评、英国文学选读、美国文学选读、17~19世纪英国文学研究、希腊戏剧研究、英国长篇小说选读、美国长篇小说选读、英国诗歌选读、美国诗歌选读、英美散文鉴赏、王尔德戏剧欣赏、英国短篇小说欣赏、美国短篇小说鉴赏、英美戏剧鉴赏、中国文学史、中国古典文学选读等。 2. 语言学 开设学校:全国绝大部分招收英语专业研究生的学校。据2007年的招生统计,仅有9所招收英语专业研究生的学校没有开设语言学方向。 研究内容:语言学是我国高校近年来普遍设置的一个综合性的语言研究学科。主要学习语言学理论及语言在各种学科中的应用,不同学校侧重点有所不同。 通过大量阅读有关文献、论文和最新的研究成果报告,使学生对于语言学的形成和发展有进一步的了解,并了解现代语言学的最新动向和最新发展。语言学特别强调和重视研究生的广泛阅读,包括专业的外语期刊和近几年的语言学相关论文。 就业方向:该专业理论性较强,主要面向大中专教师及研究人员。 所学课程:语言学概论、语用学与话语分析、应用语言学、现代语法学、语义学、语用学、英语语体学与文体学、语篇分析等。 3. 英美文化研究 开设学校:南京大学、上海外国语大学、天津师范大学等。

应用化学专业英语翻译完整篇

1 Unit5元素周期表 As our picture of the atom becomes more detailed 随着我们对原子的描述越来越详尽,我们发现我们陷入了进退两难之境。有超过100多中元素要处理,我们怎么能记的住所有的信息?有一种方法就是使用元素周期表。这个周期表包含元素的所有信息。它记录了元素中所含的质子数和电子数,它能让我们算出大多数元素的同位素的中子数。它甚至有各个元素原子的电子怎么排列。最神奇的是,周期表是在人们不知道原子中存在质子、中子和电子的情况下发明的。Not long after Dalton presented his model for atom( )在道尔顿提出他的原子模型(原子是是一个不可分割的粒子,其质量决定了它的身份)不久,化学家门开始根据原子的质量将原子列表。在制定像这些元素表时候,他们观察到在元素中的格局分布。例如,人们可以清楚的看到在具体间隔的元素有着相似的性质。在当时知道的大约60种元素中,第二个和第九个表现出相似的性质,第三个和第十个,第四个和第十一个等都具有相似的性质。 In 1869,Dmitri Ivanovich Mendeleev,a Russian chemist, 在1869年,Dmitri Ivanovich Mendeleev ,一个俄罗斯的化学家,发表了他的元素周期表。Mendeleev通过考虑原子重量和元素的某些特性的周期性准备了他的周期表。这些元素的排列顺序先是按原子质量的增加,,一些情况中, Mendeleev把稍微重写的元素放在轻的那个前面.他这样做只是为了同一列中的元素能具有相似的性质.例如,他把碲(原子质量为128)防在碘(原子质量为127)前面因为碲性质上和硫磺和硒相似, 而碘和氯和溴相似. Mendeleev left a number of gaps in his table.Instead of Mendeleev在他的周期表中留下了一些空白。他非但没有将那些空白看成是缺憾,反而大胆的预测还存在着仍未被发现的元素。更进一步,他甚至预测出那些一些缺失元素的性质出来。在接下来的几年里,随着新元素的发现,里面的许多空格都被填满。这些性质也和Mendeleev所预测的极为接近。这巨大创新的预计值导致了Mendeleev的周期表为人们所接受。 It is known that properties of an element depend mainly on the number of electrons in the outermost energy level of the atoms of the element. 我们现在所知道的元素的性质主要取决于元素原子最外层能量能级的电子数。钠原子最外层能量能级(第三层)有一个电子,锂原子最外层能量能级(第二层)有一个电子。钠和锂的化学性质相似。氦原子和氖原子外层能级上是满的,这两种都是惰性气体,也就是他们不容易进行化学反应。很明显,有着相同电子结构(电子分布)的元素的不仅有着相似的化学性质,而且某些结构也表现比其他元素稳定(不那么活泼) In Mendeleev’s table,the elements were arranged by atomic weights for 在Mendeleev的表中,元素大部分是按照原子数来排列的,这个排列揭示了化学性质的周期性。因为电子数决定元素的化学性质,电子数也应该(现在也确实)决定周期表的顺序。在现代的周期表中,元素是根据原子质量来排列的。记住,这个数字表示了在元素的中性原子中的质子数和电子数。现在的周期表是按照原子数的递增排列,Mendeleev的周期表是按照原子质量的递增排列,彼此平行是由于原子量的增加。只有在一些情况下(Mendeleev注释的那样)重量和顺序不符合。因为原子质量是质子和中子质量的加和,故原子量并不完全随原子序数的增加而增加。原子序数低的原子的中子数有可能比原子序数高的原

化学化工专业英语(课本内容)

第二章科技英语构词法 词是构成句子的要素,对词意理解的好坏直接关系到翻译的质量。 所谓构词法即词的构成方法,即词在结构上的规律。科技英语构词特点是外来语多(很多来自希腊语和拉丁语);第二个特点是构词方法多,除了非科技英语中常用的三种构词法—转化、派生及合成法外,还普遍采用压缩法、混成法、符号法和字母象形法。 2.1转化法(Conversion) 由一种词类转化成另一种词类,叫转化法。例如: water(n.水)→water(v.浇水) charge(n.电荷) →charge(v.充电) yield(n.产率) →yield(v.生成) dry(a.干的) →dry(v.烘干) slow(a.慢的) →slow(v.减慢) back(ad.在后、向后) →back(v.使后退、倒车) square(n.正方形) →square(a.正方形的) 2.2派生法(Derivation) 通过加前、后缀构成一新词。派生法是化工类科技英语中最常用的构词法。 例如“烷烃”就是用前缀(如拉丁或希腊前缀)表示分子中碳原子数再加上“-ane”作词尾构成的。若将词尾变成“-ane”、“-yne”、“-ol”、“-al”、“-yl”,则分别表示“烯”、“炔”、“醇”、“醛”、“基”、等。依此类推,从而构成千成种化学物质名词。常遇到这样的情况,许多化学化工名词在字典上查不到,全若掌握这种构词法,能过其前、后缀分别代表的意思,合在一起即是该词的意义。下面通过表1举例说明。需要注意的是,表中物质的数目词头除前四个另有名称外,其它均为表上的数目词头。 本书附录为化学化工专业常用词根及前后缀。此外还可参阅《英汉化学化工词汇》(第三版)附录中的“英汉对照有机基名表”、“西文化学名词中常用的数止词头”及“英汉对照有机词尾表”。 据估计,知道一个前缀可帮助人们认识450个英语单词。一名科技工作者至少要知道近50个前缀和30个后缀。这对扩大科技词汇量,增强自由阅读能力,提高翻译质量和加快翻译速度都是大有裨益的。 2.3合成法(Composition) 由两个或更多的词合成一个词,叫合成法。有时需加连字符。 如副词+过去分词well-known 著名的 名词+名词carbon steel 碳钢 rust-resistance 防锈 名词+过去分词computer-oriented 研制计算机的 介词+名词by-product 副产物 动词+副词makeup 化妆品 check-up 检查 形容词+名词atomic weight 原子量 periodic table 周期表 动词+代词+副词pick-me-up 兴奋剂 副词+介词+名词out-of-door 户外 2.4压缩法(Shortening) (1)只取词头字母 这种方法在科技英语中较常用。

《化学工程与工艺专业英语》课文翻译

Unit1化学工业的研究和开发 One of the main发达国家化学工业飞速发展的一个重要原因就是它在研究和开发方面的投入commitmen t和投资investmen t。通常是销售收入的5%,而研究密集型分支如制药,投入则加倍。要强调这里我们所提出的百分数不是指利润而是指销售收入,也就是说全部回收的钱,其中包括要付出原材料费,企业管理费,员工工资等等。过去这笔巨大的投资支付得很好,使得许多有用的和有价值的产品被投放市场,包括一些合成高聚物如尼龙和聚脂,药品和杀虫剂。尽管近年来进入市场的新产品大为减少,而且在衰退时期研究部门通常是最先被裁减的部门,在研究和开发方面的投资仍然保持在较高的水平。 化学工业technology industry是高技术工业,它需要利用电子学和工程学的最新成果。计算机被广泛应用,从化工厂的自动控制a utomatic control,到新化合物结构的分子模拟,再到实验室分析仪器的控制。 Individual manufacturing一个制造厂的生产量很不一样,精细化工领域每年只有几吨,而巨型企业如化肥厂和石油化工厂有可能高达500,000吨。后者需要巨大的资金投入,因为一个这样规模的工厂要花费2亿5千万美元,再加上自动控制设备的普遍应用,就不难解释为什么化工厂是资金密集型企业而不是劳动力密集型企业。 The major大部分化学公司是真正的跨国公司multinational,他们在世界上的许多国家进行销售和开发市场,他们在许多国家都有制造厂。这种国际间的合作理念,或全球一体化,是化学工业中发展的趋势。大公司通过在别的国家建造制造厂或者是收购已有的工厂进行扩张。 Unit 2工业研究和开发的类型 The applied通常在生产中完成的实用型的或有目的性的研究和开发可以分为好几类,我们对此加以简述。它们是:(1)产品开发;(2)工艺开发;(3)工艺改进;(4)应用开发;每一类下还有许多分支。我们对每一类举一个典型的例子来加以说明。在化学工业的不同部门内每类的工作重点有很大的不同。 (1)产品开发。product development产品开发不仅包括一种新药的发明和生产,还包括,比如说,给一种汽车发动机提供更长时效的抗氧化添加剂。这种开发的产品已经使(发动机)的服务期限在最近的十年中从3000英里提高到6000、9000现在已提高到12000英里。请注意,大部分的买家所需要的是化工产品能创造出来的效果,亦即某种特殊的用途。,或称聚四氟乙烯()被购买是因为它能使炒菜锅、盆表面不粘,易于清洗。(2)工艺开发process development。工艺开发不仅包括为一种全新的产品设计一套制造工艺,还包括为现有的产品设计新的工艺或方案。而要进行后者时可能源于下面的一个或几个原因:新技术的利用、原材料的获得或价格发生了变化。氯乙烯单聚物的制造就是这样的一个例子。它的制造方法随着经济、技术和原材料的变化改变了好几次。另一个刺激因素是需求的显著增加。因而销售量对生产流程的经济效益有很大影响。早期的制造就为此提供了一个很好的例子。 The ability of能预防战争中因伤口感染引发的败血症,因而在第二次世界大战(1939-1945)中,pencillin的需求量非常大,需要大量生产。而在那时,只能用在瓶装牛奶表面发酵的方法小量的生产。英国和美国投入了巨大的人力物力联合进行研制和开发,对生产流程做出了两个重大的改进。首先用一个不同的菌株—黄霉菌代替普通的青霉,它的产量要比后者高得多。第二个重大的流程开发是引进了深层发酵过程。只要在培养液中持续通入大量纯化空气,发酵就能在所有部位进行。这使生产能力大大地增加,达到现代容量超过5000升的不锈钢发酵器。而在第一次世界大战中,死于伤口感染的士兵比直接死于战场上的人还要多。注意到这一点不能不让我们心存感激。 Process development for a new product对一个新产品进行开发要考虑产品生产的规模、产生的副产品以及分离/回收,产品所要求的纯度。在开发阶段利用中试车间(最大容量可达100升)获得的数据设计实际的制造厂是非常宝贵的,例如石油化工或氨的生产。要先建立一个中试车间,运转并测试流程以获得更多的数据。他们需要测试产品的性质,如杀虫剂,或进行消费评估,如一种新的聚合物。 Note that by-products注意,副产品对于化学过程的经济效益也有很大的影响。酚的生产就是一个有代表性的例子。早期的方法,苯磺酸方法,由于它的副产品亚硫酸钠需求枯竭而变的过时。亚硫酸钠需回收和废置成为生产过程附加的费用,增加了生产酚的成本。相反,异丙基苯方法,在经济效益方面优于所有其他方法就在于市场对于它的副产品丙酮的迫切需求。丙酮的销售所得降低了酚的生产成本。 A major part对一个新产品进行工艺开发的一个重要部分是通过设计把废品减到最低,或尽可能地防止可能的污染,这样做带来的经济利益和对环境的益处是显而易见的。 Finally it should be noted that最后要注意,工业开发需要包括化学家、化学工程师、电子和机械工程师这样一支庞大队伍的协同合作才能取得成功。 (3)process improvement工艺改进。工艺改进与正在进行的工艺有关。它可能出现了某个问题使生产停止。在这种情形下,就面临着很大的压力要尽快地解决问题以便生产重新开始,因为故障期耗费资财。 然而,更为常见的commonly,工艺改进是为了提高生产过程的利润。这可以通过很多途径实现。例如通过优化流程提高产量,引进新的催化剂提高效能,或降低生产过程所需要的能量。可说明后者的一个例子是在生产氨的过程中涡轮压缩机的引进。这使生产氨的成本(主要是电)从每吨6.66美元下降到0.56美元。通过工艺的改善提高产品质量也会为产品打开新的市场。 然而,近年来in rencent years,最重要的工艺改进行为主要是减少生产过程对环境的影响,亦即防止生产过程所引起的污染。很明显,有两个相关连的因素推动这样做。第一,公众对化学产品的安全性及其对环境所产生影响的关注以及由此而制订出来的法律;第二,生产者必须花钱对废物进行处理以便它能安全地清除,比如说,排放到河水中。显然这是生产过程的又一笔费用,它将增加所生产化学产品的成本。通过减少废物数量提高效益其潜能是不言而喻的。 然而,请注意note,with a plant对于一个已经建好并正在运行的工厂来说,只能做一些有限的改变来达到上述目的。因此,上面所提到的减少废品的重要性应在新公厂的设计阶段加以考虑。近年来另一个当务之急是保护能源及降低能源消耗。 (4)application development应用开发。显然发掘一个产品新的用处或新的用途能拓宽它的获利渠道。这不仅能创造更多的收入,而且由于产量的增加使单元生产成本降低,从而使利润提高。举例来说,早期是用来制造唱片和塑料雨衣的,后来的用途扩展到塑料薄膜,特别是工程上所使用的管子和排水槽。 我们已经强调emphasis了化学产品是由于它们的效果,或特殊的用途、用处而得以售出这个事实。这就意味着化工产品公司的技术销售代表与顾客之间应有密切的联系。对顾客的技术支持水平往往是赢得销售的一个重要的因素。进行研究和开发的化学家们为这些应用开发提供了帮助。33的制造就是一个例子。它最开始是用来做含氟氯烃的替代物作冷冻剂的。然而近来发现它还可以用作从植物中萃取出来的天然物质的溶解剂。当它作为制冷剂被制造时,固然没有预计到这一点,但它显然也是应用开发的一个例子 。 Unit3设计 Based on the experience and data根据在实验室和中试车间获得的经验和数据,一组工程师集中起来设计工业化的车间。化学工程师的职责就是详细说明所有过程中的流速和条件,设备类型和尺寸,制造材料,流程构造,控制系统,环境保护系统以及其它相关技术参数。这是一个责任重大的工作。 The design stage设计阶段是大把金钱花进去的时候。一个常规的化工流程可能需要五千万到一亿美元的资金投入,有许多的事情要做。化学工程师是做出很多决定的人之一。当你身处其位时,你会对自己曾经努力学习而能运用自己的方法和智慧处理这些问题感到欣慰。 设计阶段design stage的产物是很多图纸: (1)工艺流程图flow sheets。是显示所有设备的图纸。要标出所有的流线和规定的条件(流速、温度、压力、构造、粘度、密度等)。 (2)管道及设备图piping and instrumentation。标明drawings所有设备(包括尺寸、喷嘴位置和材料)、所有管道(包括大小、控制阀、控制器)以及所有安全系统(包括安全阀、安全膜位置和大小、火舌管、安全操作规则)。 (3)仪器设备说明书equipmen specification sheet s。详细说明所有设备准确的空间尺度、操作参数、构造材料、耐腐蚀性、操作温度和压力、最大和最小流速以及诸如此类等等。这些规格说明书应交给中标的设备制造厂以进行设备生产。 3.建造construction After the equipment manufactures当设备制造把设备的所有部分都做好了以后,这些东西要运到工厂所在地(有时这是后勤部门颇具挑战性的任务,尤其对象运输分馏塔这样大型的船只来说)。建造阶段要把所有的部件装配成完整的工厂,首先要做的就是在地面打洞并倾入混凝土,为大型设备及建筑物打下基础(比如控制室、流程分析实验室、维修车间)。 完成了第一步initial activities,就开始安装设备的主要部分以及钢铁上层建筑。要装配热交换器、泵、压缩机、管道、测量元件、自动控制阀。控制系统的线路和管道连接在控制室和操作间之间。电线、开关、变换器需装备在马达上以驱动泵和压缩机。生产设备安装完毕后,化学工程师的职责就是检查它们是否连接完好,每部分是否正常工作。

非英语专业研究生英语(第一外语)教学大纲

非英语专业研究生英语(第一外语) 教学大纲 -、总则 (—)为了保证达到《中华人民共和国学位条例暂行实施办法》中规定的外国语学习要求,进行非英语专业研究生英语课程的教学工作,特制定本大纲。 (二)研究生英语教学的宗旨是为了使学生掌握英语这门工具进行本专业的学习、研究与国际交流,为我国的社会主义建设服务,在教学中要坚持从实际出发、学以致用的原则,培养和提高研究生运用英语的能力。 二、硕士研究生的英语教学与考试 (一)教学对象 本大纲的教学对象是非英语专业的硕士研究生(以下简称硕士生)。硕士生入学时应达到以下水平: (1)掌握4000个左右常用单词及370个左右常用词组(能正确识别词类,选择词义),对其中1500个左右基本词能复用性掌握(即能正确识别词类,选择词义,英汉互译,熟悉某些常用搭配和用法)并具有初步的构词知识; (2)掌握基本语法知识(具备大学英语覆盖的语法知识); (3)能阅读一般难度(相当于大学英语四级课文的难度)的英语读物,理解基本正确,阅读速度为每分钟50词左右。 1

(4)能将一般难度的英语短文译成汉语,理解基本正确,译文达意;能将一般难度的汉语句子译成英语,内容表达与语法基本正确; (5)具有初步的写作能力。 硕士生中有一定数量单独考试入学的学生,其入学水平亦应逐步达到上述要求。 (二)教学目的 硕士生英语教学目的是培养学生具有较熟练的阅读能力,一定的写、译能力和基本的听、说能力,能够以英语为工具进行本专业的学习和研究。对听、说能力要求较高的专业,可根据需要,加强听、说能力的培养。 (三)教学要求 硕士生的英语教学包括基础英语和专业英语两部分。 1、基础英语部分 (1)词汇 理解性掌握5000个左右的常用单词及500个左右常用词组,复用性掌握其中2000个左右的基本词。认知120个左右常用词根和词缀,并能根据构词法识别派生词。 (2)语法 能较熟练地运用语法知识,能理解语法结构复杂的长难句。 (3)读 2

化学专业英语修订版翻译

. 01 THE ELEMENTS AND THE PERIODIC TABLE 01 元素和元素周期表 The number of protons in the nucleus of an atom is referred to as the atomic number, or proton number, Z. The number of electrons in an electrically neutral atom is also equal to the atomic number, Z. The total mass of an atom is determined very nearly by the total number of protons and neutrons in its nucleus. This total is called the mass number, A. The number of neutrons in an atom, the neutron number, is given by the quantity A-Z. 在一个原子核中的质子数量被称为原子序数,或质子数,Z。在一个电中性原子中的电子数量也等于原子序数,Z。一个原子的总质量被测定是非常接近于原子核中质子和中子的总数。这个总数被称为质量数,A。在一个原子中的中子数量等于A –Z的数量。 The term element refers to, a pure substance with atoms all of a single kind. To the chemist the kind of atom is specified by its atomic number, since this is the property that determines its chemical behavior. At present all the atoms from Z = 1 to Z = 107 are known; there are 107 chemical elements. Each chemical element has been given a name and a distinctive symbol. For most elements the symbol is simply the abbreviated form of the English name consisting of one or two letters, for example: 这个术语(指chemical element)也可以指由相同质子数的原子组成的纯化学物质。对化学家来说,这类原子通过原子数来说明,因为它的性质是决定其化学行为。目前,从Z = 1 到Z = 107的所有原子是知道的;有107种化学元素。每一种化学元素起了一个名字和独特的象征。对于大多数元素都仅仅是一个象征的英文名称缩写形式,由一个或两个字母组成,例如:oxygen==O nitrogen == N neon==Ne magnesium == Mg 氧= =O 氮= = N氖= = Ne 镁= =Mg .. . Some elements,which have been known for a long time,have symbols based on their Latin names, for example: 很久以来就已经知道一些元素,根据他们的拉丁名字符号命名,例如: iron==Fe(ferrum) copper==Cu(cuprum) lead==Pb(plumbum) 铁= =铁(铁) 铜= =铜(铜) 铅= =铅(铅)