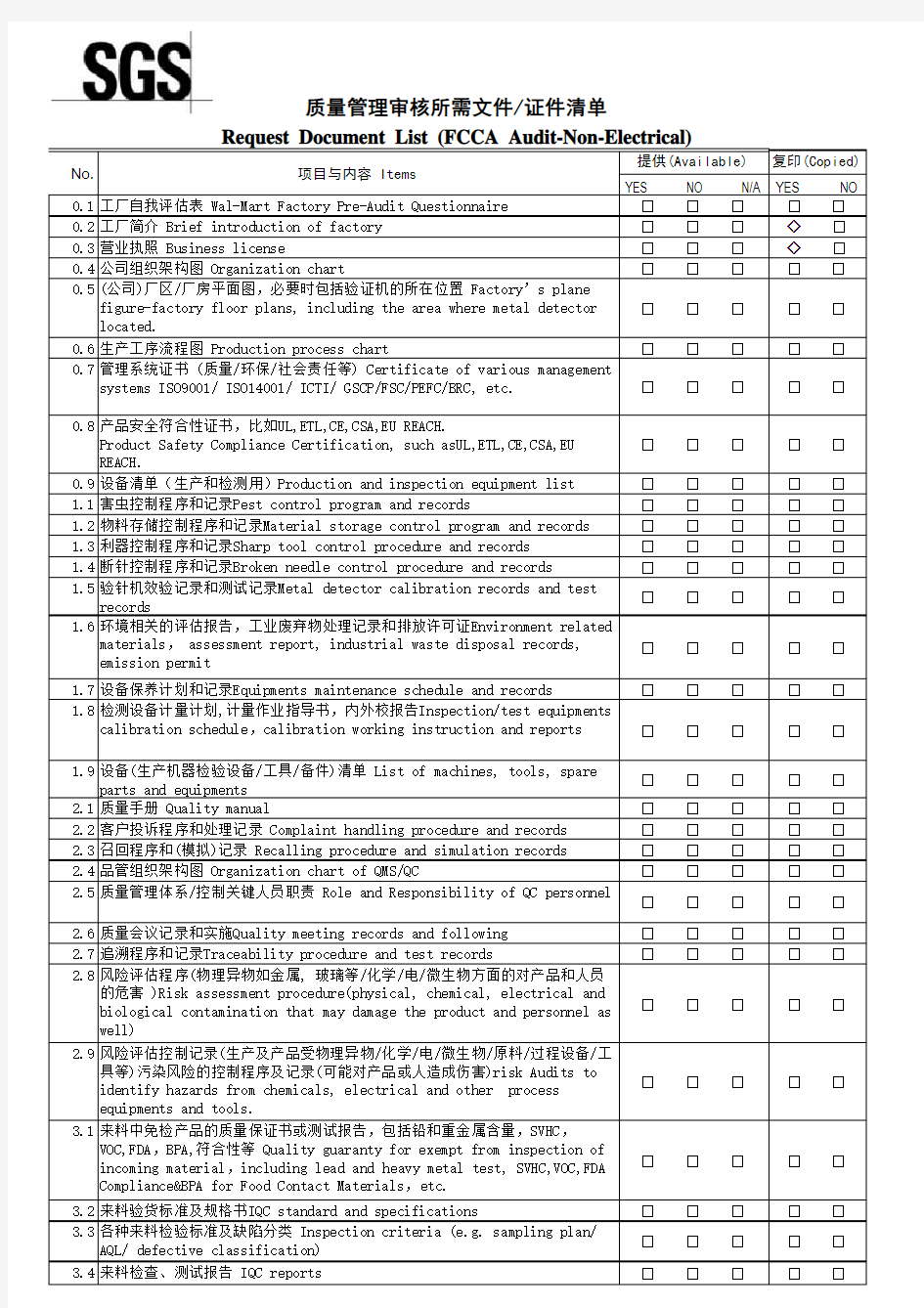

Wal mart-FCCA_验厂文件清单(130918)

提供(Available)复印(Copied) No.项目与内容 Items

YES NO N/A YES NO 0.1工厂自我评估表 Wal-Mart Factory Pre-Audit Questionnaire□ □ □□ □0.2工厂简介 Brief introduction of factory□ □ □◇ □0.3营业执照 Business license□ □ □◇ □0.4公司组织架构图 Organization chart□ □ □□ □0.5(公司)厂区/厂房平面图,必要时包括验证机的所在位置 Factory’s plane

figure-factory floor plans, including the area where metal detector

□ □ □□ □located.

0.6生产工序流程图 Production process chart□ □ □□ □0.7管理系统证书 (质量/环保/社会责任等) Certificate of various management

systems ISO9001/ ISO14001/ ICTI/ GSCP/FSC/PEFC/BRC, etc.□ □ □□ □

0.8产品安全符合性证书,比如UL,ETL,CE,CSA,EU REACH.

Product Safety Compliance Certification, such asUL,ETL,CE,CSA,EU

□ □ □□ □REACH.

0.9设备清单(生产和检测用)Production and inspection equipment list□ □ □□ □

1.1害虫控制程序和记录Pest control program and records□ □ □□ □1.2物料存储控制程序和记录Material storage control program and records□ □ □□ □1.3利器控制程序和记录Sharp tool control procedure and records□ □ □□ □1.4断针控制程序和记录Broken needle control procedure and records□ □ □□ □

1.5验针机效验记录和测试记录Metal detector calibration records and test

□ □ □□ □records

1.6环境相关的评估报告,工业废弃物处理记录和排放许可证Environment related

materials, assessment report, industrial waste disposal records,

□ □ □□ □emission permit

1.7设备保养计划和记录Equipments maintenance schedule and records□ □ □□ □1.8检测设备计量计划,计量作业指导书,内外校报告Inspection/test equipments

calibration schedule,calibration working instruction and reports□ □ □□ □

1.9设备(生产机器检验设备/工具/备件)清单 List of machines, tools, spare

□ □ □□ □parts and equipments

2.1质量手册 Quality manual□ □ □□ □2.2客户投诉程序和处理记录 Complaint handling procedure and records□ □ □□ □2.3召回程序和(模拟)记录 Recalling procedure and simulation records□ □ □□ □2.4品管组织架构图 Organization chart of QMS/QC□ □ □□ □2.5质量管理体系/控制关键人员职责 Role and Responsibility of QC personnel

□ □ □□ □2.6质量会议记录和实施Quality meeting records and following□ □ □□ □2.7追溯程序和记录Traceability procedure and test records□ □ □□ □2.8风险评估程序(物理异物如金属, 玻璃等/化学/电/微生物方面的对产品和人员

的危害 )Risk assessment procedure(physical, chemical, electrical and

□ □ □□ □biological contamination that may damage the product and personnel as

well)

2.9风险评估控制记录(生产及产品受物理异物/化学/电/微生物/原料/过程设备/工

具等)污染风险的控制程序及记录(可能对产品或人造成伤害)risk Audits to

□ □ □□ □identify hazards from chemicals, electrical and other process

equipments and tools.

3.1来料中免检产品的质量保证书或测试报告,包括铅和重金属含量,SVHC,

VOC,FDA,BPA,符合性等 Quality guaranty for exempt from inspection of

□ □ □□ □incoming material,including lead and heavy metal test, SVHC,VOC,FDA

Compliance&BPA for Food Contact Materials,etc.

3.2来料验货标准及规格书IQC standard and specifications□ □ □□ □3.3各种来料检验标准及缺陷分类 Inspection criteria (e.g. sampling plan/

AQL/ defective classification)□ □ □□ □3.4来料检查、测试报告 IQC reports□ □ □□ □

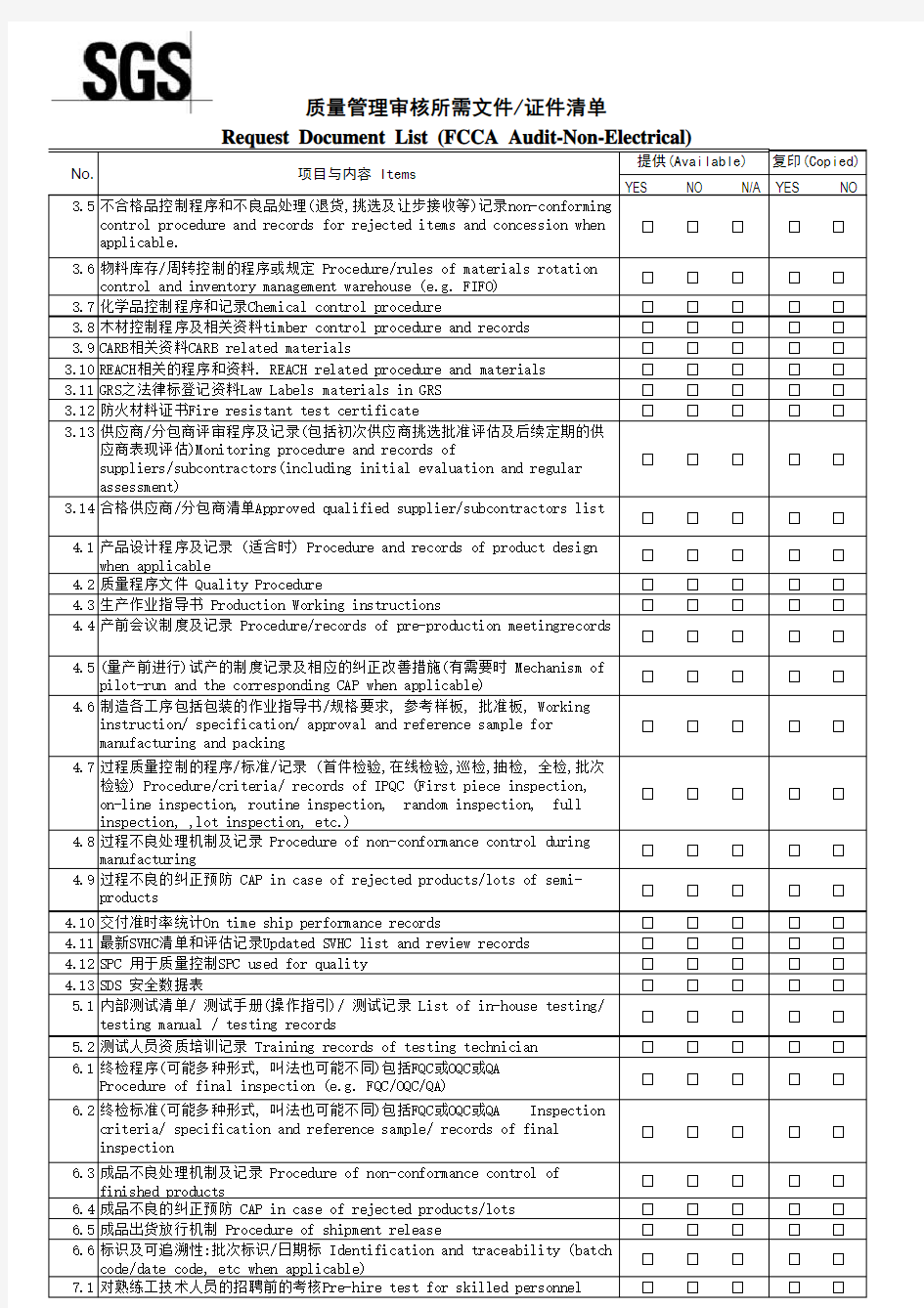

提供(Available)复印(Copied) No.项目与内容 Items

YES NO N/A YES NO

提供(Available)复印(Copied) No.项目与内容 Items

YES NO N/A YES NO 。