AC 7101.3C 材料实验室Nadcap审核准则 - 力学性能检测

PRI operating procedures provide that "This report is published by PRI to advance the state of technical, engineering, and quality sciences. The use of this report is entirely voluntary, and its applicability and suitability for any particular use, including any patent infringement arising there from, is the sole responsibility of the user."

161Thorn Hill Road

Warrendale, PA 15086-7527

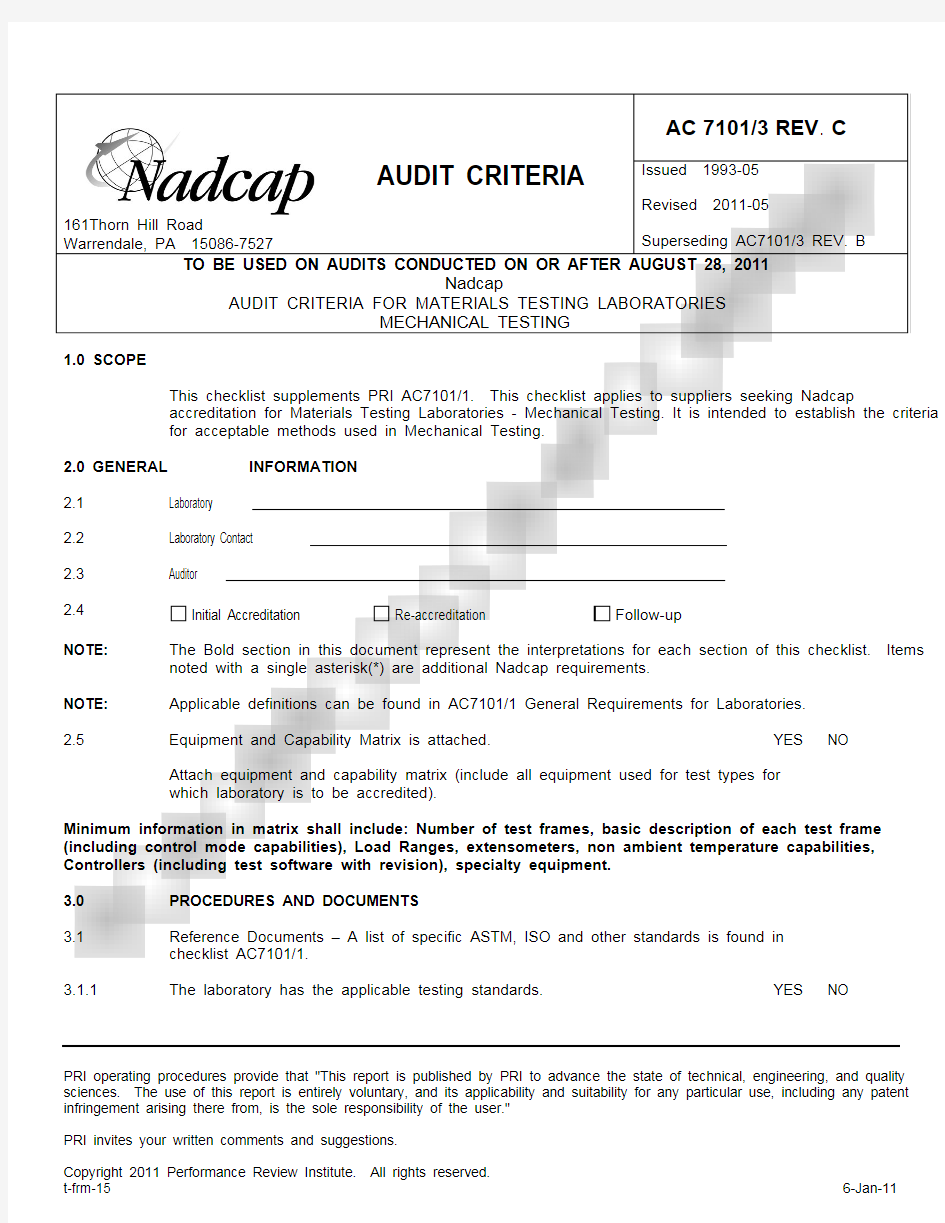

AUDIT CRITERIA

AC 7101/3 REV . C

Issued 1993-05

Revised 2011-05

Superseding AC7101/3 REV. B

TO BE USED ON AUDITS CONDUCTED ON OR AFTER AUGUST 28, 2011

Nadcap

AUDIT CRITERIA FOR MATERIALS TESTING LABORATORIES

MECHANICAL TESTING

1.0 SCOPE

This checklist supplements PRI AC7101/1. This checklist applies to suppliers seeking Nadcap

accreditation for Materials Testing Laboratories - Mechanical Testing. It is intended to establish the criteria for acceptable methods used in Mechanical Testing.

2.0 GENERAL INFORMATION

2.1 Laboratory 2.2 Laboratory Contact 2.3 Auditor 2.4 Initial Accreditation Re-accreditation Follow-up

NOTE:

The Bold section in this document represent the interpretations for each section of this checklist. Items noted with a single asterisk(*) are additional Nadcap requirements.

NOTE:

Applicable definitions can be found in AC7101/1 General Requirements for Laboratories. 2.5 Equipment and Capability Matrix is attached. YES NO Attach equipment and capability matrix (include all equipment used for test types for which laboratory is to be accredited).

Minimum information in matrix shall include: Number of test frames, basic description of each test frame (including control mode capabilities), Load Ranges, extensometers, non ambient temperature capabilities, Controllers (including test software with revision), specialty equipment.

3.0 PROCEDURES AND DOCUMENTS

3.1 Reference Documents – A list of specific ASTM, ISO and other standards is found in checklist AC7101/1.

3.1.1 The laboratory has the applicable testing standards. YES NO

3.1.2 The laboratory uses the latest applicable standards or as specified by customer. YES NO

AUDITOR NOTE: Verify revision of standard used for each test type to be accredited.

3.2

Laboratory Procedures – Laboratory has a system of written procedures for test types performed.

YES NO Written procedures are required which are detailed to be followed for the specific test requirement to be used and specific test to be performed, and shall conform to the applicable test standard.

AUDITOR

NOTE: Verify written procedure for each test type to be accredited.

4.0 PERSONNEL AND TRAINING

4.1 Verify personnel training for at least one Mechanical Testing test type.

Test Type ___________________________________ Equipment operated ___________________________________

4.2 Training is documented. YES NO 4.3 Training includes any methods specified in laboratory procedures. YES NO

5.0 FACILITIES AND EQUIPMENT

Refer to Capability and Equipment List if needed. 5.1

Ambient facility temperature and humidity are monitored and documented as required by individual test requirements.

YES NO For short term tests, a minumim of a single measurement shall be made within ? hour of the start of the test (e.g. application of force to the specimen) and documented. Short term testing is defined as testing that lasts one hour or less.

For long term tests, measurements shall be made at time intervals no greater then every half hour commencing within 30 minutes of the time of load application. Long term testing is defined as testing having a duration of more than one hour.

Humidity shall be monitored and recorded when required by customer or standard.

It is the intent of this requirement that the ambient temperature is measured in close proximity to the testing equipment; however that Nadcap MTLTG recognizes that this is often not practical. The temperature sensor should be in the general area of the test equipment and placed so as to avoid drafts and other airflow (i.e. do not place directly under a heat source or air conditioning register).

5.1.1 Laboratory has a procedure for monitoring and recording ambient laboratory conditions.

YES NO

5.2 Laboratory has a written preventive maintenance plan in place. YES NO 5.2.1 The preventive maintenance plan is followed and logged. YES NO

5.3

Facility operations affecting specific testing – The laboratory procedures require notification of customers in the event of interruption due to power outage, or equipment failure that has an effect on the test results.

YES NO

If testing is interrupted due to power outage, equipment failure, etc. and the testing was not invalidated, testing records shall indicate the following: Date and time of interruption, description of malfunction, and corrective action taken, if required.

6.0 CALIBRATION/VERIFICATION

6.1 Equipment calibration/verification frequency is in accordance with Table 1 below. YES NO

Note all deviations from requirements.

Laboratories performing testing to ASTM based requirements shall use ASTM based calibrations. Laboratories performing testing to ISO based requirements shall use ISO based calibrations. Laboratories performing both types of testing shall have both types of calibrations.

TABLE 1 – Calibration/Verification Schedule

(Maximum Frequencies when not defined by standard methods or supplier requiements) (a),(e)

Code Test Type

Load Cell (c) Extensometer (d) Displacement (stroke) Crosshead/actuator Speed

STATIC TESTS A Room Temp. Tensile

1 year 1 year 1 year 1 year B Elev. Temp. Tensile 1 year 1 year 1 year 1 year C Stress Rupture (b) N/A N/A N/A XA Creep

(b) 1 year (f)

N/A N/A CYCLIC TESTS

O Load Control (High Cycle) Fatigue

1 year N/A N/A N/A Y Strain Control (Low Cycle) Fatigue

1 year 6 months N/A N/A P Fracture Toughness 1 year 6 months N/A N/A XE Crack Propagation 1 year COD gauge 6 months

N/A N/A

IMPACT – TYPE N 1 year (g)

1 year – Lateral Expansion gauge

N/A N/A

NOTE:

(a) Pull rod and adapter inspection takes place in individual test sections. (b) Weights: 5 years. Accuracy ± 0.5 %.

Load Frame – Lever Arm: 1 year. Accuracy ± 1.0%. See Table 2.

(c) Calibrate Load Cells in accordance with ASTM E4 or EN ISO 7500-1 Class 1 or better.

(d) Extensometers are calibrated for a particular system (i.e. the extensometer, cabling and signal conditioning must be included

and stay together as a unit). For the determination of all test types, the calibration shall be to at least Class B2 of ASTM E83 or at least Class 1 of EN ISO 9513 with the following exception: For the determination of Young’s Modulus of Elasticity, when required, Class B1 of ASTM E83 or Class 0.5 of EN ISO 9513 shall be used. Calibration of the Crack Opening Displacement (COD) gauge for fracture mechanics with the testing standard.

(e) Test machine alignment is considered a verification, not a calibration (i.e. it does not have a National Standards traceable

source) and is thus not addressed in the calibration section.

(f) For Creep indicators, the creep arms (sometimes referred to as “extensometer”) are required to have a visual inspection prior to

TABLE 2 – General Equipment Calibration Schedule

GENERAL EQUIPMENT REQUIRED FREQUENCY

(maximum)

Test temperature measurement Instruments and Recorders 3 Months

Laboratory Ambient Temperature/humidity measuring

Instruments

1 Year

Micrometers/Calipers 6

Months Creep Indicators (electronic – e.g. LVDT, Digital Glass Scale,

Capacitance, Digital Dial Indicators)

1 Year (Class B-2)

Creep Indicators (mechanical)

(This includes dial indicators.)

1 Month

Optical Comparator 1 Year

Oscilloscopes 1

Year Torque Testing Equipment 1 Year

Gauge Blocks 1 Year

Timers (rupture testing) – 0.1 Hr 1 Year

Load Frame – Lever Arm (Note “b” table 1) 1 Year

Weights (Note “b” table 1) 5 Year

All other Sensors and Instruments All other instruments shall be calibrated at an appropriate interval to ensure integrity of the test measurements.

Calibration cycles may be extended as defined by the NCSL (National Conference of Standards Laboratories), Recommended Practice 1, or other recognized statistical review process to support the extended time interval. Calibration frequencies defined by standard methods or supplier requirements shall not be extended. Calibration extension shall be allowed only if documented historical data and standard calibration practices substantiate the extension of calibration frequencies.

AUDITOR

NOTE:

Include documentation on all calibration extensions used.

7.0 TEST MACHINE AND TEST SPECIMEN ALIGNMENT

Proof of alignment capability is required for tests using axial loading. Calibration of elevated temperature test equipment may be performed at room temperature due to strain gauge temperature limitations.

Alignment verification for static testing is intended to be performed when the test machine is first set up and upon any major repairs from damage that might influence axiality of test load application.

Alignment verification for dynamic testing is far more likely to have an influence on test results and is intended to be performed upon setup of a particular gripping assembly (or program) as well as periodically during a dynamic fatigue testing program.

The intent of the test machine alignment check is to verify that the major components of the test machine load train are in alignment. Typically, the major components of a load train consist of a load cell, an actuator or crosshead, load rod or grip mounts, load rods and grips or grip bodies (creep and stress rupture machines do not require a load cell if calibrated dead weights are used). Reverification does not need to be performed upon the removal of the gripping mechanisms or specimen interface portions of the grips. These mechanisms include tapered wedges, collets, end cap housings, pins and clevises, anti-buckling supports, and threaded adapters. These mechanisms are typically characterized and identified by the fact that they are by design intended to routinely be inserted and removed from the grip bodies or load rods during normal operation of the grip.

7.1 Required

Capability

Laboratory demonstrates alignment capability for test frames used in Nadcap testing. YES NO

Maximum bending capability as calculated in accordance with ASTM E1012 shall be

demonstrated as follows:

Static Tests: 10% (requirement comes from ASTM test standards for static testing).

Dynamic (Cyclic) Tests: 5% (requirement comes from ASTM standards for dynamic

testing).

Acceptable alternate criteria - all gauges of each set within 100 micro strain of

average of that set for readings below 2000 micro strain.

Note – revision of ASTM E1012 will better clarify the alternate criteria. This document will be revised when that information becomes available.

Static and dynamic test equipment used in tension shall have an alignment verification performed in tension. Dynamic test equipment used in compression shall have an alignment verification performed in compression. Dynamic test equipment used in both tension and compression shall have an alignment verification performed in both tension and compression.

Note: there are no alignment requirements for static compression testing.

When bending calculations result in values greater than the stated requirements in 7.1, test equipment may be used at lower strain levels (i.e. below 2000 microstrain), if the bending calculation also includes a fixed strain gauge comparison, where the gauges are all within 100 microstrain of the average at the applied test forces of interest. A current revision of ASTM E1012 will better clarify the alternate criteria. This document will be revised when that information becomes available.

7.1.1 Loads During Evaluation

7.1.1.1 Static Test Alignment Verification

For static testing, an operational check that covers the general force range used for testing. Alignment verification shall include a minimum of three data points. Recommended data points at 10%, 20% and 40% of the load cell range or test machine capacity. Test set-up shall include the test machine and all rigid components of the load train assembly. Alternately, the alignment verification may be based on either of the following: ?The lowest maximum load as follows:

o Tensile tests – Lowest load required for yield strength determination

o Constant load tests – lowest load for producing specified stress.

?A customer requested loading regime

7.1.1.2 Dynamic (cyclic) Test Alignment Verification

Cyclic tests: verification shall cover the range used in normal testing without causing permanent deformation to the alignment through the lower strain or load levels to be used in testing are acceptable for higher strain or load levels.

?For negative R testing, verification in both tension and compression shall be used.

?For R=0, the data point at zero load (grips clamped) adequately represents the lowest peak stress or strain.

?For positive R testing, loads shall cover the entire test range.

Test set-up shall include the test machine and grips. Calibration is performed under static load conditions, but

7.2 Alignment verification for uniaxial testing is in accordance with ASTM E1012, using

YES NO the strain gauge method.

The test machine alignment verification includes zeroing the strain gauge readings with the specimen hanging

free, a data point with the grips engaged at zero applied force (i.e. a clamped at zero load point), a bending

calculation at the lowest force range used on the machine (for reporting or establishing test results or

conditions) and shall include at least two additional bending calculations at higher applied force levels. For the

clamped at zero applied force data point, bending calculations are not necessary.

NO 7.3 Alignment Specimens – meets guidelines of ASTM E10231012. YES Calibration Specimen(s): Bars shall represent the typical reduced section lengths to be tested. A strain gauge set

comprises axial strain gauges located at either 90° or 120° intervals around the circumference of the specimen

reduced section. The number of sets is as defined in ASTM E 1012.

For static testing where a number of test sample configurations are used, any standard ASTM E8 specimen may

be used provided that no more than one adapter coupling is used on each end of the specimen to connect to

machine pull rods.

7.4 Alignment Frequencies are acceptable. YES NO

7.4.1 Static Testing Machines (those used in sections 11,12 and 15 of this checklist) - upon

setup, if the equipment is moved or if any damage occurs to the machine from

unexpected events.

7.4.2 Dynamic Testing Machines (those used in testing covered in sections 17, 18, 19 and

21) - every 6 months or when changing test setups for new specimen geometry

(whichever comes first). Note - if testing is underway when an alignment verification is

due, the test may be allowed to run to completion before the alignment verification is

performed.

7.5 Alignment Verification Records YES NO

Alignment verification records may be curves showing % bending as a function of the applied load, or they may

be tabular listing of data points (3 minimum for tension and 3 minimum for compression).

For Clevis loaded specimen testing such as CT specimens for crack growth or fracture toughness, a test

machine alignment verification using dimensional measurements or setup gauges (Machine Alignment as

defined in ASTM E1012) is acceptable (may be done to internal procedure). For this case, a specimen alignment

using a standard uniaxial specimen (eliminating the clevises) is also acceptable.

8.0 INCOMING SPECIMEN INSPECTION AND MATERIAL CONTROL

8.1 Incoming test specimens receive a general quality inspection. All specimens have

YES NO specific identification.

Machined test specimens may enter the testing area either from in house (captive) machine shop or from an

outside (independent) supplier. Either method requires quality inspections of the specimens. This includes: ?Measurement of dimensions that are used in the calculation of test results

?Visual inspection

?Verification of specimen identification

Nadcap MTL Task Group recognizes that inspection may be best performed in a facility other than the laboratory

(e.g. machine shop or inspection area). It is the expectation that the inspection will be performed using the best

8.2 The laboratory inspection procedure requires inspection to the specimen drawing or customer requirement. YES NO

8.2.1 Inspect and record dimensions that are used in the calculation of test results for all specimens. YES NO

8.3 Describe quality inspection methods: YES NO

Same inspection methods applied to ALL specimen types. Different inspection methods applied to different specimen types. Requires process control (SPC). Audits process control.

8.4 For CYCLIC TESTS (Codes O, Y) and when required by standard, the machining source is qualified to Specimen Preparation Code Z1 for Low Stress Grinding and Specimen Preparation Code Z2 for Low Stress Grinding and Polishing.

YES NO

8.5 Non-cyclic specimen machining is controlled (e.g. Drawing/Procedure/Machining Guidelines). YES NO

Testing laboratory performs its own specimen machining.

8.6

Outside specimen machining source(s) comply with the Nadcap requirements

regarding specimen machining, and are listed on AC7101/1 Figure 3 with test codes and specimen types. If outside specimen machining sources are not accredited to AC7101/7, then laboratory has a procedure for verifying the outside specimen machining source is compliant with AC7101/7. YES NO

AUDITOR

NOTE: Be sure AC7101/1 lists machining sources.

9.0 TEMPERATURE MEASUREMENT

9.1 Thermocouples (T/Cs) Thermocouple selection shall be according to ASTM E230. Thermocouple tolerances (correction factors or deviations) shall meet the special tolerances for base metal thermocouples and the standard tolerances for noble metal thermocouples. List types and uses: ___________________________________________________________________ 9.1.1

Control and recording thermocouples shall have a calibration certificate that identifies

the source of the calibration data, nominal calibration temperatures, actual calibration temperature readings, and calibration technique for each calibration temperature traceable to NIST (or other National Standardization body). Calibration technique shall comply with ASTM E220 or other recognized standard.

YES NO

Thermocouples shall not be used outside the calibration range. Extrapolation of correction factors shall not be performed. Calibration temperature intervals shall be within the following:

?Noble metal (e.g. type R, S) thermocouples: 200°F (111°C) Requirement from AMS 2750

?Base metal (e.g. type K, N) thermocouples: 100°F (56°C) Requirements meet suggested ASTM E220 of every 200 degrees F and AMS 2750D requirement of not to exceed 250 degrees F

Thermocouples produced from calibrated rolls may be used in lieu of individually calibrated thermocouples. Rolls up to and including 1000 ft (305 meters) in length may be sampled at one end; rolls over 1000 ft (305 meters) shall be sampled at both ends of the roll and at 2000 ft (610 meter) increments. Calibrations shall be performed per ASTM E220.

The difference between correction factors at opposite ends of rolls shall not exceed 2o F (1.1o C). It is permissible to divide the roll into shorter length rolls when the end-to-end tolerance is exceeded. These then become individual rolls and require their own calibration and correction factors.

It is permissible to use thermocouples that have been calibrated individually.

Non expendable thermocouples and devices that are used for purposes other than to record test temperatures (i.e. furnace over-temp thermocouples) are exempt from calibration requirements.

Non expendable thermocouples and devices that record data (i.e. laboratory ambient temperature monitor thermocouples) shall be calibrated and are limited to use below 500o F (260o C). This includes thermocouples that are used for cryogenic testing applications.

AUDITOR NOTE:Review at least one calibration report for every T/C type material used. Attach each report reviewed.

9.1.2 Correction factors (deviations) are applied to all non ambient temperature testing. YES NO Thermocouple correction factors shall not exceed + 2o F (+1.1°C) or 0.4% of the reading, whichever is greater.

For thermocouples produced from rolls calibrated at each end, the correction factor shall be the average of the values at each end.

Thermocouple correction factors and recording/display equipment correction factors shall be applied algebraically to each non room temperature test. These may be applied either manually or with an automated control system.

For additional information on applying Thermocouple Correction Factors, please see example located under Public Documents section of Materials Testing Laboratories within eAuditNet.

AUDITOR NOTE:Review test and work instruction to verify that correction factors were calculated and applied correctly.

9.1.3 Thermocouples are only be used within ranges defined in ASTM E230. YES NO Temperature measurements for testing outside these temperatures require customer approval.

AUDITOR

NOTE:

Verify laboratory work instructions for this requirement.

9.1.4 Control T/Cs are of equivalent or better precision, accuracy, and durability to YES NO

9.1.5 Requirements specific to Types K and N Thermocouples. YES NO Requirements for type N thermocouples are the same as for type K thermocouples except that Type N thermocouples shall not be used above 2000°F (1093°C).

9.1.5.1 T/C wires are not twisted prior to the weld bead or the crimp tips. YES NO

9.1.5.2 For long duration, high temperature tests, the procedure addresses T/C degradation. YES NO

Wire stability for all long term testing (greater than 25 Hr for temperature measurement) above 1600°F (871°C) shall be determined by the comparison method of ASTM E 220. The exposure temperature shall equal or exceed the maximum temperature at which the wire will be used; exposure time shall be the greater of the standard minimum or 25 hours. If the standard minimum is unknown, the exposure time for stability shall be limited to 150 Hr. The wire is acceptable provided the indicated temperature does not drift more than 5°F (3°C) during exposure.

For additional information on applying Thermocouple Correction Factors, please see example located under Public Documents section of Materials Testing Laboratories within eAuditNet.

YES NO 9.1.5.3 T/Cs are not re-used unless all heat affected wire and all kinked wire have been

removed and a new junction made.

The laboratory shall have a procedure addressing reuse of type K thermocouples. Thermocouples shall not be re-used unless all wire previously exposed at temperatures above 1000°F (538°C) has been removed and a new junction made. For reuse of type K thermocouples at any non ambient temperature, kinked wire and any damaged junctions shall be removed and replaced.

This requirement is intended to apply to recording and control thermocouples.

9.1.6 Requirements Specific to Noble metal Thermocouples

YES NO N/A 9.1.6.1 The laboratory has a procedure addressing use and reuse of type R, S and B

thermocouples. This shall include any recalibration periods used.

Recalibration requirements are as follows:

?For temperatures at or below 1112o F (600o C) – 4 years

?For temperatures from 1112 o F (600o C) to 1472o F (800o C) – 2 years

?For temperatures above 1472o F (800o C)- 1 year

?Note – these come from ISO 204.

Type B thermocouples shall not be used below 1600°F (593°C).

Type R and S thermocouples shall not be used above 2700°F (1482°C).

Temperature measurements for testing above this temperature require customer approval.

Type R and S thermocouple junctions - Welded junctions in Types “R” and “S” may be used as long as welding processes prevent contact with foreign metal vapor (e.g. laser welding or arc welding with inert gas).

9.1.7 Thermocouple selection and use complies with requirements. YES NO

Thermocouples (T/C) shall be selected in accordance with customer criteria. Bare wire thermocouples are preferred although if the lab can prove that all requirements of this standard are met Mineral insulated metal

Traceability information for control and recording T/Cs used for elevated and cryogenic temperature tests shall be maintained in laboratory records.

9.1.7.1 Thermocouple attachment methods comply with requirements. YES NO Thermocouple attachment methods shall be in accordance with the test standard or with customer criteria. If no specific criteria are provided, use ASTM E633 for creep and stress rupture (this also may be used for tensile testing).

Thermocouple attachment by welding directly on the gauge section of the specimen is prohibited. Methods of attachment are test type and material type dependent. Specific thermocouple attachment requirements are described in the specific test sections. Revision note – be sure this is included.

The T/C junction shall be in intimate contact with the test specimen.

The contact between the thermocouple junction and the test piece shall be shielded from radiation effects of the furnace elements. This may either be done through furnace design, where a high temperature material blocks the direct radiation from the furnace elements or by the use of high temperature insulation applied directly to the external surface of the contact point, also blocking direct radiation from the furnace elements.

If used, Mineral insulated metal sheathed (MIMS) thermocouple junctions shall be grounded to the sheath for acceptable intimate contact. Procedures shall identify standard attachment practice.

9.2 Thermocouple extension wire use conforms to requirements. YES NO Extension wire shall conform to ASTM E230 or other recognized standard.

Extension wire shall not be spliced. Connectors, plugs, jacks and terminal strips are permitted if they are the compatible type, i.e. they have thermoelectric properties conforming to the characteristics of the corresponding thermocouple type – ASTM E1129 may be used as a guide for round-pin connectors.

9.3 Temperature measurement instrumentation conforms to requirements. YES NO Output of thermocouples shall be converted to temperature through the use of readouts, recorders and controllers. These shall be calibrated against a standard traceable to NIST (or other National Standardization body).

Calibration accuracy requirements for readouts, recorders and controllers shall be +2°F (or for laboratories using SI temperature units +1 °C is acceptable).

Readouts, recorders and controllers shall be digital with a minimum readability to 1°F or 1o C.

10.0 TEST CERTIFICATES, REPORTS AND RECORDS

Test Certificates, Test Reports and Test Records are defined in AC7101/1. Additional report requirements are contained within AC7006 and ISO17025.

This section is intended to audit the overall method used by the laboratory for establishing how results are reported. Audit checks of specific reports are included in the various test sections of AC7101/3.

In the case of a laboratory sharing raw test data with a customer for purposes other than generating a report, this data is not considered a report in and of itself.

10.1 Test records include all pertinent information from the test. YES NO

It is the intent of the Nadcap MTL TG that a test Certificate/Report can be recreated using information contained in the Test Record.

Test records shall include customer required information, items from the following list required by standard and other information from which reported results are determined:

?Stress/strain or load/displacement curve or data (tensile), and creep curve or data (creep-rupture), from which values may be determined.

?Equipment identification, including testing machine, extensometer, furnace, and thermocouples.

?Measured test temperature and time, including ramp, soak, and test.

?Measured specimen critical dimensions.

?Invalid test results, and reason for invalidation

?Ambient temperature

?Reason for replacement of specimens

?Extensometer attachment method

?Test operator

?Test date or and start date, time and duration of test (multiple day tests)

?Test load and lever ratio (rupture)

?Incremental loading curves, if required (creep-rupture)

?Initial shoulder diameter, notch diameter, and notch radius (notched-rupture test)

?Test atmosphere, if different than laboratory air.

10.2 Test Certificates/ Reports include mandatory reporting information. YES NO

Test certificates/reports shall include standard/specification and customer required information and applicable items from the following list:

?Results that are required by the customer (typically UTS, 0.2% Yield Strength, %elongation, %creep, life, absorbed energy, lateral expansion, fracture appearance, etc.).

?Specimen identification

?Material identification

?Specified test temperature

?Heat treat condition if applicable

?Specimen type or reference to specimen type (e.g. drawing, ASTM E8, etc.)

?Stress (rupture)

?Uploaded or discontinued tests (rupture)

?Fracture location, if outside of center half of gauge length (tensile, rupture)

?Standard/source of requirements

10.3 Rounding – Lab procedures are governed by a standardized approach to rounding. YES NO

It is the intent of the MTL Task Group to allow rounding as per the test standard used. Unless otherwise specified in the test standard, numerical values are rounded in accordance with ASTM E29.

11.0 TENSILE TESTING (Codes A and B) N/A

11.1 Check which are being accredited.

A – Room Temperature Tensile

B – Elevated Temperature Tensile, to a maximum temperature of _______ .

There are several tensile test methods covered under tensile testing. The certification issued to the laboratory

will list the methods for which the laboratory is approved.

11.2 Round robin completed per AC7101/1. YES NO

11.3 Facilities and Equipment (Specific to Tensile Test)

11.3.1 Test machine calibrations meet the requirements in table 1 at frequencies indicated. YES NO

11.3.2 Test machine alignment verification meets the static testing requirements provided in

section 7 of AC7101/3.

YES NO

Verification is required for frame and grips after installation of the frame, and when alignment is suspect (e.g. movement of machine, multiple radius failures, etc.).

11.3.3 Ambient conditions – Testing is conducted between 50°F (10°C) and 100°F (38°C)

unless otherwise specified in the applicable standard.

YES NO

11.3.4 Tensile equipment has the capability to perform at the rates and in the control mode

required for the test standard.

YES NO

11.3.4.1 For testing to ASTM B557 (aluminum or magnesium alloys), strain rate control is not

required. Tensile equipment has the capability to run in a displacement control mode

and the lab has the capability to determine a displacement rate based on the rate of

stressing defined in ASTM B557.

YES NO

11.3.4.2 For all other tensile testing certifications, tensile equipment has capability to perform a

test in strain rate control at a controlled strain rate of 0.003 to 0.007 per minute

through yield, with a controlled crosshead speed of 0.04 to 0.06 per minute times the

nominal length of the reduced section until rupture.

YES NO

11.3.5 If elevated temperature tensile tests are performed, furnaces are:

Circulating hot air

Resistance

Other type approved during customer certification

Number of zones in each furnace:

_________________________________________

11.3.5.1 For elevated temperature testing, induction heating prohibited/not used for Tensile

Testing unless permitted by customer. YES NO

11.3.5.2 For elevated temperature testing, sufficient thermocouples are used to assure that the

uniformity of the temperature gradient along the reduced section of the test piece

conforms to the following:

For ≤ 1000° C ± 3°C (1800°F ± 5°F); For >1000°C ± 6°C (1800°F ± 10°F).

YES NO

11.3.5.3 Furnace design and practice prevents specimen over-temperature outside the

measured section.

YES NO

Specimen shall be in the approximate center of the furnace and operated in such a manner so as to prevent the areas outside the gauge section to be hotter than the gauge section.

11.3.6 Extensometers – Appropriate extensometer is used. YES NO Extensometer is rated to at least Class B2 of ASTM E83 or at least Class 1 of EN ISO 9513 for standard tensile testing. For the determination of Young’s Modulus of Elasticity, when required, Class B1 of ASTM E83 or Class 0.5 of EN ISO 9513 shall be used.

Non-contact extensometers are subject to the same requirements as contact extensometers. The strain measurement method shall use measurement points as close as practical to the gauge length used for elongation measurement. If non contact extensometers are used, Laboratory records shall show comparison and stability studies to compare with contact extensometers.

11.4 Tensile Testing Procedures

AUDITOR NOTE: Verify test procedure is in accordance with applicable standards and that procedures are followed (witness test).

11.4.1Appropriate test procedures are being used. YES NO Tensile testing shall be performed in accordance with one of the test standards listed in AC 7101/1, unless otherwise specified.

11.4.1.1Room Temperature Tensile YES NO AUDITOR

NOTE:

List standard used: _________________________________________________

11.4.1.2Elevated Temperature Tensile YES NO AUDITOR

NOTE:

List standard used: _________________________________________________

Other procedures are acceptable if required by customer.

Other written procedure(s): Describe below:

____________________________________________________________________

11.4.2 Adapters and pull bars are visually inspected before and after each test program. YES NO

The inspection may be performed by the test technician to verify that the adapters and bars are in good working condition and are suitable for performing the test. There is no need to record the inspection.

11.4.3 Specimens are inspected in accordance with AC7101/3 section 8. YES NO 11.4.3.1 Specimens are visually inspected for surface damage immediately prior to testing. YES NO 11.4.4 Laboratory procedures guide extensometer selection. YES NO The laboratory shall have a procedure that describes the method of choosing an appropriate extensometer type, size and attachment method.

11.4.4.1 The Extensometer is attached directly to the reduced section of the Specimen unless otherwise approved by customer requirements.

YES NO

Contact extensometers shall be attached to the gauge section used for elongation measurement unless otherwise approved by customer requirements and shall be as close as practical to the gauge length used for elongation measurement. Extensometers may be attached to the grip section of the specimen, to grips or adapters when not prohibited by customer requirements; however, this is not recommended. This also requires the use of an “effective gauge length” as described in ASTM E21.

AUDITOR

NOTE: Indicate if extensometer is attached to points outside the gauge section.

Shoulder attachment is used.

Contact extensometers may be removed at any point after yield to prevent damage to the extensometer.

11.4.5 For elevated temperature testing, the specimen is soaked at temperature for 30 minutes minimum.

YES NO

11.4.6 Correct testing speed is used. YES NO 11.4.6.1 For tensile testing to ASTM B557 (or AMS 2355) the test speed up to the specified yield strength is corresponds to a stress rate of less than 100,000 psi/min. Test speed after yield does not exceed 0.5 in/in gauge length per minute.

YES NO

11.4.6.2 For all testing not covered by ASTM B557 (or AMS 2355) - unless otherwise specified, testing speeds for both Room Temperature and Elevated Temperature Tensile tests are a controlled strain rate of 0.003 to 0.007 per minute through yield, with a controlled crosshead speed of 0.04 to 0.06 per minute times the nominal length of the reduced section until rupture.

YES NO

There are several other test speed and control mode callouts in related test standards. These are acceptable only if the material specification/standard or the customer requirements specifically call them out.

11.4.7 Tensile Testing Curves are reviewed as part of the testing process. YES NO All tensile curves shall be reviewed. The laboratory shall provide training to operators on identification of invalid tensile curves.

11.4.8 Laboratory procedures define the method of calculation of each result and measurement accuracy.

YES NO

11.4.9 Tensile Strength (alternately known as Ultimate Tensile Strength) is calculated using the formula: (Maximum Load) (Original Cross-Sectional Area).

YES NO

11.4.10 Yield Strength is measured at 0.2% Offset, unless otherwise specified. YES NO

Indicate if other than 0.2% offset method used.

AUDITOR

NOTE:

When offset Yield Strength determination is performed, the laboratory shall have a procedure for determining this manually or electronically. The procedure shall take into account initial and subsequent nonlinearity and other imperfections in the stress strain (load displacement) curve. Curves from which Yield Strength has been automatically determined via software shall be reviewed and changes to incorrectly calculated Yield Strength made.

YES NO 11.4.11 Both Percent Elongation and the relationship of the gauge length to test piece cross

section dimensions (Proportionality) are measured and reported in accordance with

the material specification/standard or customer requirement.

*Autographic measurement (elongation at fracture as defined in ASTM E8) is acceptable if it includes only the plastic portion of the strain (i.e. elastic strain is subtracted out of total strain). Extensometer must meet the gauge marking restrictions (i.e. 4X dia. for ASTM, 5X dia. for ISO testing) shown in 12.2.11.1 of AC7101/3.

For cases of low ductility or when the data acquisition does not have enough resolution to correctly determine plastic strain at fracture, then the traditional method of fitting the ends together and measuring the final gauge length shall be used.

11.4.11.1 Acceptable Elongation marking method used (punch, scribe or ink mark). YES NO

In order to accurately measure elongation to a multiple of the gauge length, a method of marking the gauge length shall be used. Acceptable methods are punches, scribe marks, or ink marks, provided the marking is readable after completion of the test. Fractures that occur on the gauge marks shall be indicated as such on the report. Specimens that fail on or outside the gauge marks and fail to meet the property requirements may be invalidated (elongation only).

When customer requirements prohibit the use of gauge marks or materials are sensitive to gauge marks, the adjusted gauge method described in ASTM E21 may be used. Records shall include the actual gauge length that was used.

Elongation calculated using the adjusted gauge length method will typically be lower than when calculated using the 4D or 5D method, as the gauge length will be longer than 4D or 5D.

11.4.12 Reduction of Area is determined in accordance with the test standard. YES NO

11.4.13 Test data is reported per AC7101/3 section 11. YES NO

YES NO 11.4.14 Rounding of test results per appropriate test standard required in procedure and

demonstrated in job audit.

Rounding for data from Room Temperature Tensile per ASTM E8, EN2002-1, EN10002, ISO 6892 or BS4A4. Rounding for data from Elevated Temperature Tensile per ASTM E21, ISO 2002-2 or ISO 783. Rounding of data not established in the test standards per ASTM E29.

11.5 Specific Reporting Requirements meet the following requirement. YES NO

11.5.1 As a minimum the report includes the following:

(unless any of these are by specification/standard not required for the specific test)

NO Temperature YES

11.5.1.2 Test

Strength YES NO 11.5.1.3 Yield

NO strength YES

11.5.1.4 Ultimate

11.5.1.5 Elongation YES NO 11.5.1.6 Reduction of area YES NO Specific reporting requirements are often supplied by the customer and take precedent over the list above when applicable.

12.0 STRESS RUPTURE AND CREEP TESTING (Codes C and XA) N/A

C = Stress Rupture (S/R). Questions apply to S/R. Creep (C/R). XA = Creep Only.

12.1 Check which tests are being accredited:

Room Temperature S/R only

___________________

Elevated Temperature S/R to maximum temperature of ________________________

Creep to maximum temperature of

________________________________

12.2 Round robin completed per AC7101/1. YES NO

12.2.1 Facilities and Equipment (Specific to Stress and Creep Rupture Testing)

12.2.1.1 Test machine calibrations meet the requirements in table 1 at frequencies indicated. YES NO

YES NO 12.2.1.2 Test machine alignment verification meets the static testing requirements provided in

section 7 of AC7101/3.

Verification is required for frame and grips after installation of the frame, and when alignment is suspect (e.g. movement of machine, multiple radius failures, etc.).

YES NO 12.2.1.3 For creep testing only, shifts in ambient temperature are accounted for in strain

measurement.

Laboratory may address this through one of the following methods:

?Extensometer stability data showing no effect on strain measurement with normal shift in ambient temperature.

?ASTM E139 requirements – Extensometer readings should be taken only when ambient temperature is within ± 5 degrees F of the ambient temperature at the start of the test.

? A temperature correction applied when the ambient temperature exceeds ± 5 degrees F of the ambient temperature at the start of the test as described in ASTM E139.

?Record ambient temperature concurrently with creep data. Assess whether ambient temperature exceeds ASTM E139-06 requirements and determine whether the creep curve is affected at times

required by specification/standard.

12.2.1.4 Furnaces

are: YES NO Circulating hot air

Resistance

Other type approved during customer certification

Number of zones in each furnace:

_________________________________________

12.2.1.4.1 Induction heating prohibited/not used for Stress Rupture or Creep Testing unless

permitted by customer.

YES NO

AUDITOR

NOTE:

Indicate if induction heating is used.

12.2.1.4.2 Furnace design and practice prevents specimen over-temperature outside the

measured section.

YES NO

Specimen shall be in the approximate center of the furnace and operated in such a manner so as to prevent the areas outside the gauge section to be hotter than the gauge section.

12.2.1.5 Specimen temperature measurement

12.2.1.5.1 Laboratory procedures define the number, location, and attachment method of

thermocouples that are attached to the specimen.

YES NO 12.2.1.5.2 The number of thermocouples meets the customer requirements. YES NO

Laboratories should be able to provide evidence of the source of customer requirements. If no customer requirements exist, the laboratory shall define the minimum number of thermocouples. ASTM E139 requires three (3) thermocouples for specimens with ≥ 50 mm reduced section and two (2) thermocouples for specimens with < 50 mm reduced section length. It is recognized that it may be difficult to attach two (2) thermocouples to extremely small specimens, so engineering judgment may be required.

12.2.1.5.3 The minimum and maximum Indicated specimen temperature tolerances during soak

and testing meet customer requirements.

YES NO

Most customer requirements revert to ATSM E139 temperature tolerances. ASTM E139 tolerances are: For a nominal temperature ≤1000°C (1800°F) the tolerance shall be ± 2°C (± 3°F); for a nominal temperature > 1000°C (1800°F) the tolerance shall be ± 3°C (± 5°F). The material specification/standard or other customer requirements may differ.

12.2.1.5.4 The laboratory has a procedure that provides requirements for review and disposition

of tests with occurrences of indicated temperature that are outside of the customer-

required tolerances.

YES NO

It is recognized that temperature deviations may occur during rupture testing. At minimum, the laboratory should have a procedure that provides guidance or instructions for common occurrences and/or requires review and disposition by a Metallurgist or equivalent. Additional guidance is provided in ASTM E139.

12.2.1.5.5 Extensometers – Appropriate extensometer system is used. YES NO

Many creep extensometers are different from other mechanical test extensometers in that they use a frame that attaches to the specimen (usually outside the gauge section). This frame is often referred to as the Creep Arm Assembly with the attachment to the specimen at the Creep Arms. These require a functional inspection before every test (e.g. assembly slides smoothly) but not a calibration. The strain sensor attaches to the creep arm assembly and is the element of the system that requires calibration to AC7101/3 Tables 1 and 2. Other extensometers are acceptable as long as they meet AC7101/3 Table 1 and 2 requirements.

12.3 Stress Rupture and Creep Testing Procedures

AUDITOR

NOTE:

Verify test procedure is in accordance with applicable standards and that procedures are followed (witness test). 12.3.1 Appropriate test procedures are being used. YES NO

Stress Rupture and Creep testing shall be performed in accordance with one of the test standards listed in AC7101/1, unless otherwise specified.

AUDITOR

NOTE:

Stress Rupture Testing – List standard used:______________________________

AUDITOR

NOTE:

Notched Stress Rupture Testing – List standard used:_______________________

AUDITOR

NOTE: Creep Testing – List standard used:_____________________________________

Other procedures are acceptable if required by customer. Other written procedure(s). Describe:_______________________________________

12.3.2 Creep arms, adapters and pull bars are visually inspected before and after each test program.

YES NO

The inspection may be performed by the test technician to verify that the adapters and bars are in good working condition and are suitable for performing the test. There is no need to record the inspection.

12.3.3 Specimens are inspected in accordance with AC7101/3 section 8. YES NO 12.3.3.1 For the case of Notch Stress Rupture testing, root radius is measured to the nearest 0.0005 in (0.01 mm) prior to testing. (ASTM E292 Notch).

YES NO

12.3.3.2 For the case of Notch Stress Rupture, notch profile is verified using a 10X minimum magnification (e.g. optical comparator).

YES NO

12.3.3.3 Specimens are visually inspected for surface damage immediately prior to testing. Note magnification if used. ______________________________________________

YES NO

12.3.4 Laboratory procedures guide extensometer selection. YES NO

The laboratory shall have a procedure that describes the method of choosing an appropriate extensometer type, size and attachment method.

12.3.4.1 Laboratory performs pre-test functionality check of strain measurement components (extensometer, mechanisms for clamping to specimen and strain measurement YES NO

12.3.4.2 Method of Extensometer attachment is documented (Code XA). YES NO

Most creep extensometers are not attached directly to the gauge section of the specimen and require the use of an “Effective Gauge Length” measurement as defined in ASTM E139. Attachment directly to the specimen gauge section is acceptable.

12.3.4.3 Correction factor used for shoulder attachment. YES NO

12.3.5 Specimen soaked at temperature not less than 1 hour. (ASTM E139) YES NO

Soak time shall be recorded on test report if other than 1 hour.

YES NO 12.3.5.1 Maximum time that the specimen is held at temperature before test load applied is 24

Hr.

The intent of the Nadcap MTLTG is that tests are started immediately upon completion of the soak. While it is recognized that this is not always possible, the load application should not be delayed.

12.3.6 Care is taken in applying the test load, in order to prevent shock loads or overloading. YES NO

Describe loading technique. (ASTM E139) __________________________________

12.3.7 Creep Testing Curves are reviewed as part of the testing process. YES NO

All creep curves shall be reviewed. The laboratory shall provide training to operators on identification of invalid creep curves.

YES NO 12.3.8 Laboratory procedures define the method of calculation of each result and

measurement accuracy.

12.3.9 Both Percent Elongation and the relationship of the gauge length to test piece cross

YES NO section dimensions (Proportionality) are measured and reported in accordance with

the material specification/standard or customer requirement.

Unless otherwise specified, elongation shall be measured after fracture.

12.3.9.1 Acceptable Elongation marking method used (punch, scribe or ink mark). YES NO

In order to accurately measure elongation to a multiple of the gauge length, a method of marking the gauge length shall be used. Acceptable methods are punches, scribe marks, or ink marks, provided the marking is readable after completion of the test. Fractures that occur on the gauge marks shall be indicated as such on the report. Specimens that fail on or outside the gauge marks and fail to meet the property requirements may be invalidated.

When customer requirements prohibit the use of gauge marks or materials are sensitive to gauge marks, the adjusted gauge method described in ASTM E139 may be used. Records shall include the actual gauge length that was used.

Elongation calculated using the adjusted gauge length method will typically be lower than when calculated using the 4D or 5D method, as the gauge length will be longer than 4D or 5D.

12.3.10 Reduction of Area is determined in accordance with the test standard. YES NO AUDITOR ROA is not always required by material specifications/standard. If this is the case of

12.4 Specific Reporting Requirements meet the following requirement. YES NO

12.4.1 As a minimum the report includes the following:

(unless any of these are by specification/standard not required for the specific test)

12.4.1.1 Specimen

ID YES NO 12.4.1.2 Test

Temperature YES

NO 12.4.1.3 Test

Duration YES NO

12.4.1.4 Times to strain levels indicated in customer PO YES NO

12.4.1.5 Elongation YES NO 12.4.1.6 Reduction of area YES NO Specific reporting requirements are often supplied by the customer and take precedent over the list above when applicable.

13.0 BEND

TESTING(Code XN) N/A

There are no calibration, alignment or round robin requirements for Bend Testing.

13.1 Facilities and Equipment (Specific to Bend Testing)

13.1.1 Ambient conditions for ISO 7438 testing only. Testing is conducted between 50°F

(10°C) and 95°F (35°C) unless otherwise specified in the applicable standard.

YES NO

13.1.2 Controlled conditions for ISO 7438 testing only. Testing is conducted between 64°F

(18°C) and 82°F (28°C).

YES NO There are no specified ambient conditions for testing to ASTM E290.

13.2 Bend Testing Procedures

AUDITOR NOTE:Verify test procedure is in accordance with applicable standards and that procedures are followed (witness test).

13.2.1 Appropriate test procedures are being used. YES NO

Bend Testing shall be performed in accordance with one of the test standards listed in AC7101/1, unless otherwise specified.

AUDITOR

NOTE:

List standard used: __________________________________________________

Other procedures are acceptable if required by customer.

Other written procedure(s). Describe: ______________________________________

13.2.2 Bend Test methods used are in accordance with customer requirements. YES NO

材料力学实验报告标准规定答案解析

力学实验报告标准答案

长安大学力学实验教学中心 目录 、拉伸实验? 、压缩实验? 三、拉压弹性模量E测定实验? 四、低碳钢剪切弹性模量G测定实验? 五、扭转破坏实验-10

六、纯弯曲梁正应力实验? 12 七、弯扭组合变形时的主应力测定实验? 15 八、压杆稳定实验"8

、拉伸实验报告标准答案实验目的: 见教材 实验仪器 见教材实验结果及数据处理:例:(一)低碳钢试件

服应力 (T s = P s /A _273.8 _MP a 屈度极限 (T b = P b /A _411.3 MP a 强试验前 试验后 最小平均直径d= 10.16 mm 最小直径d= 10.15 mm 截面面积A= 81.03 mm 2 截面面积A1= 80.91 mm 2 计算长度L= 100 mm 计算长度L 忤 100 mm 试验前草图 试验后草图 1 ' 1 ''1 1 最大载荷P b =__14.4 KN P s =_22.1 KN P b =_33.2 ____ KN 塑性指标: 伸长率 厘100% L 68.40 % 33.24 % A A 1 面积收缩率 - 100% A 低碳钢拉伸图:

强度极限c b= P b / A = _ 177.7 — M P a 问题讨论: 1、为何在拉伸试验中必须采用标准试件或比例试件,材料相同而长短不同的试件 延伸率是否相同? 答:拉伸实验中延伸率的大小与材料有关,同时与试件的标距长度有关.试件局部变形较大的断口部分,在不同长度的标距中所占比例也不同.因此拉伸试验中必须采用标准试件或比例试件,这样其有关性质才具可比性. 材料相同而长短不同的试件通常情况下延伸率是不同的(横截面面积与长度存在某种特殊比例关系除外). 2、分析比较两种材料在拉伸时的力学性能及断口特征. 答:试件在拉伸时铸铁延伸率小表现为脆性,低碳钢延伸率大表现为塑性;低碳钢具有屈服现象,铸铁无.低碳钢断口为直径缩小的杯锥状,且有45 0的剪切唇, 断口组织为暗灰色纤维状组织。铸铁断口为横断面,为闪光的结晶状组织

陶瓷材料的力学性能检测方法

陶瓷材料力学性能的检测方法 为了有效而合理的利用材料,必须对材料的性能充分的了解。材料的性能包括物理性能、化学性能、机械性能和工艺性能等方面。物理性能包括密度、熔点、导热性、导电性、光学性能、磁性等。化学性能包括耐氧化性、耐磨蚀性、化学稳定性等。工艺性能指材料的加工性能,如成型性能、烧结性能、焊接性能、切削性能等。机械性能亦称为力学性能,主要包括强度、弹性模量、塑性、韧性和硬度等。而陶瓷材料通常来说在弹性变形后立即发生脆性断裂,不出现塑性变形或很难发生塑性变形,因此对陶瓷材料而言,人们对其力学性能的分析主要集中在弯曲强度、断裂韧性和硬度上,本文在此基础上对其力学性能检测方法做了简单介绍。 1.弯曲强度 弯曲实验一般分三点弯曲和四点弯曲两种,如图1-1所示。四点弯曲的试样中部受到的是纯弯曲,弯曲应力计算公式就是在这种条件下建立起来的,因此四点弯曲得到的结果比较精确。而三点弯曲时梁各个部位受到的横力弯曲,所以计算的结果是近似的。但是这种近似满足大多数工程要求,并且三点弯曲的夹具简单,测试方便,因而也得到广泛应用。 图1-1 三点弯曲和四点弯曲示意图 由材料力学得到,在纯弯曲且弹性变形范围内,如果指定截面的弯矩为M ,该截面对中性轴的惯性矩为I z ,那么距中性轴距离为y 点的应力大小为: z I My = σ 在图1-1的四点弯曲中,最大应力出现在两加载点之间的截面上离中性轴最远的点,其大小为: =??? ? ???= z I y a P max max 21σ???? ?圆形截面 16矩形截面 332D Pa bh Pa π

其中P 为载荷的大小,a 为两个加载点中的任何一个距支点的距离,b 和h 分别为矩形截面试样的宽度和高度,而D 为圆形截面试样的直径。因此当材料断裂时所施加载荷所对应的应力就材料的抗弯强度。 而对于三点弯曲,最大应力出现在梁的中间,也就是与加载点重合的截面上离中性轴最远的点,其大小为: =??? ? ???= z I y a P l max max 4σ???? ?圆形截面 8矩形截面 2332D Pl bh Pl π 式中l 为两个支点之间的距离(也称为试样的跨度)。 上述的应力计算公式仅适用于线弹性变形阶段。脆性材料一般塑性变形非常小,同弹性变形比较可以忽略不计,因此在断裂前都遵循上述公式。断裂载荷所对应的应力即为试样的弯曲强度。 需要注意的是,一般我们要求试样的长度和直径比约为10,并且在支点的外伸部分留足够的长度,否则可能影响测试精度。另外,弯曲试样下表面的光洁度对结果可能也会产生显著的影响。粗糙表面可能成为应力集中源而产生早期断裂。所以一般要求表面要进行磨抛处理。当采用矩形试样时,也必须注意试样的放置方向,避免使计算中b 、h 换位得到错误的结果。 2.断裂韧性 应力集中是导致材料脆性断裂的主要原因之一,而反映材料抵抗应力集中而发生断裂的指标是断裂韧性,用应力强度因子(K )表示。尖端呈张开型(I 型)的裂纹最危险,其应力强度因子用K I 表示,恰好使材料产生脆性断裂的K I 称为临界应力强度因子,用K IC 表示。金属材料的K IC 一般用带边裂纹的三点弯曲实验测定,但在陶瓷材料中由于试样中预制裂纹比较困难,因此人们通常用维氏硬度法来测量陶瓷材料的断裂韧性。 陶瓷等脆性材料在断裂前几乎不产生塑性变形,因此当外界的压力达到断裂应力时,就会产生裂纹。以维氏硬度压头压入这些材料时,在足够大的外力下,压痕的对角线的方向上就会产生裂纹,如图2-1所示。裂纹的扩展长度与材料的断裂韧性K IC 存在一定的关系,因此可以通过测量裂纹的长度来测定K IC 。其突出的优点在于快速、简单、可使用非常小的试样。如果以P C 作为可使压痕产生雷文的临界负荷,那么图中显示了不同负荷下的裂纹情况。 由于硬度法突出的优点,人们对它进行了大量的理论和实验研究。推导出了各种半经

材料力学实验报告册概要

实验日期_____________教师签字_____________ 同组者_____________审批日期_____________ 实验名称:拉伸和压缩试验 一、试验目的 1.测定低碳钢材料拉伸的屈服极限σs 、抗拉强度σb、断后延伸率δ及断 面收缩率ψ。 2.测定灰铸铁材料的抗拉强度σb、压缩的强度极限σb。 3.观察低碳钢和灰铸铁材料拉伸、压缩试验过程中的变形现象,并分析 比较其破坏断口特征。 二、试验仪器设备 1.微机控制电子万能材料试验机系统 2.微机屏显式液压万能材料试验机 3.游标卡尺 4.做标记用工具 三、试验原理(简述) 1

四、试验原始数据记录 1.拉伸试验 低碳钢材料屈服载荷 最大载荷 灰铸铁材料最大载荷 2.灰铸铁材料压缩试验 直径d0 最大载荷 教师签字:2

五、试验数据处理及结果 1.拉伸试验数据结果 低碳钢材料: 铸铁材料: 2.低碳钢材料的拉伸曲线 3.压缩试验数据结果 铸铁材料: 3

4.灰铸铁材料的拉伸及压缩曲线: 5.低碳钢及灰铸铁材料拉伸时的破坏情况,并分析破坏原因 ①试样的形状(可作图表示)及断口特征 ②分析两种材料的破坏原因 低碳钢材料: 灰铸铁材料: 4

6.灰铸铁压缩时的破坏情况,并分析破坏原因 六、思考讨论题 1.简述低碳钢和灰铸铁两种材料的拉伸力学性能,以及力-变形特性曲线 的特征。 2.试说明冷作硬化工艺的利与弊。 3.某塑性材料,按照国家标准加工成直径相同标距不同的拉伸试样,试 判断用这两种不同试样测得的断后延伸率是否相同,并对结论给予分析。 5

七、小结(结论、心得、建议等)6

工程材料力学性能答案

工程材料力学性能答案1111111111111111111111111111111111111 1111111111111111111111111111111111111 111111 决定金属屈服强度的因素有哪 些?12 内在因素:金属本性及晶格类型、晶粒大小和亚结构、溶质元素、第二相。外在因素:温度、应变速率和应力状态。试举出几种能显著强化金属而又不降低其塑性的方法。固溶强化、形变硬化、细晶强化试述韧性断裂与脆性断裂的区别。为什么脆性断裂最危险?21韧性断裂是金属材料断裂前产生明显的宏观塑性变形的断裂,这种断裂有一个缓慢的撕裂过程,在裂纹扩展过程中不断地消耗能量;而脆性断裂是突然发生的断裂,断裂前基本上不发生塑性变形,没有明显征兆,因而危害性很大。何谓拉伸断口三要素?影响宏观拉伸断口性态的

因素有哪些?答:宏观断口呈杯锥形,纤维区、放射区和剪切唇三个区域组成,即所谓的断口特征三要素。上述断口三区域的形态、大小和相对位置,因试样形状、尺寸和金属材料的性能以及试验温度、加载速率和受力状态不同而变化?断裂强度与抗拉强度有何区别?抗拉强度是试样断裂前所承受的最大工程应力,记为σb;拉伸断裂时的真应力称为断裂强度记为σf; 两者之间有经验关系:σf = σb (1+ψ);脆性材料的抗拉强度就是断裂强度;对于塑性材料,于出现颈缩两者并不相等。裂纹扩展受哪些因素支配?答:裂纹形核前均需有塑性变形;位错运动受阻,在一定条件下便会形成裂纹。2222222222222222222222222222222222 2222222222222222222222222222222222 2222 试综合比较单向拉伸、压缩、弯曲及扭转试验的特点和应用范围。答:单向拉伸试验的特点及应用:单向拉伸的应力状态较硬,一般用于塑性变形

常用材料力学性能.

常用材料性质参数 材料的性质与制造工艺、化学成份、内部缺陷、使用温度、受载历史、服役时间、试件尺寸等因素有关。本附录给出的材料性能参数只是典型范围值。用于实际工程分析或工程设计时,请咨询材料制造商或供应商。 除非特别说明,本附录给出的弹性模量、屈服强度均指拉伸时的值。 表 1 材料的弹性模量、泊松比、密度和热膨胀系数 材料名称弹性模量E GPa 泊松比V 密度 kg/m3 热膨胀系数a 1G6/C 铝合金-79 黄铜 青铜 铸铁 混凝土(压 普通增强轻质17-31 2300 2400 1100-1800

7-14 铜及其合金玻璃 镁合金镍合金( 蒙乃尔铜镍 塑料 尼龙聚乙烯 2.1-3.4 0.7-1.4 0.4 0.4 880-1100 960-1400 70-140 140-290 岩石(压 花岗岩、大理石、石英石石灰石、沙石40-100 20-70 0.2-0.3 0.2-0.3 2600-2900 2000-2900 5-9 橡胶130-200 沙、土壤、砂砾钢

高强钢不锈钢结构钢190-210 0.27-0.30 7850 10-18 14 17 12 钛合金钨木材(弯曲 杉木橡木松木11-13 11-12 11-14 480-560 640-720 560-640 1 表 2 材料的力学性能 材料名称/牌号屈服强度s CT MPa 抗拉强度b CT

MPa 伸长率 5 % 备注 铝合金LY12 35-500 274 100-550 412 1-45 19 硬铝 黄铜青铜 铸铁( 拉伸HT150 HT250 120-290 69-480 150 250 0-1 铸铁( 压缩混凝土(压缩铜及其合金 玻璃

材料级《材料力学性能》考试答案AB

贵州大学2007-2008学年第一学期考试试卷 A 缺口效应; 因缺口的存在,改变了缺口根部的应力的分布状态,出现: ① 应力状态变硬(由单向拉应力变为三向拉应力); ② 应力集中的现象称为缺口效应。 解理台阶; 在拉应力作用下,将材料沿某特定的晶体学平面快速分离的穿晶脆性断裂方式称为解理断裂,称该晶体学平面为解理平面;在该解理平面上,常常会出现一些小台阶,叫解理台阶;这些小台阶有汇聚为大的台阶的倾向,表现为河流状花样。 冷脆转变; 当温度T ℃低于某一温度T K 时,金属材料由韧性状态转变为脆性状态,材料的αK 值明显降低的现象。 热疲劳; 因工作温度的周期性变化,在构件内部产生交变热应力循环所导致的疲劳断裂,表现为龟裂。 咬合磨损; 在摩擦面润滑缺乏时,摩擦面间凸起部分因局部受力较大而咬合变形并紧密结合,并产生形变强化作用,其强度、硬度均较高,在随后的相对分离的运动时,因该咬合的部位因结合紧密而不能分开,引起其中某一摩擦面上的被咬合部分与其基体分离,咬合吸附于另一摩擦面上,导致该摩擦面的物质颗粒损失所形成的磨损。 二、计算题(共42分,第1题22分,第2题20分) 1、一直径为10mm ,标距长为50mm 的标准拉伸试样,在拉力P=10kN 时,测 得其标距伸长为50.80mm 。求拉力P=32kN 时,试样受到的条件应力、条件应变及真应力、真应变。(14分) 该试样在拉力达到55.42kN 时,开始发生明显的塑性变形;在拉力达到67.76kN 后试样断裂,测得断后的拉伸试样的标距为57.6mm ,最小处截面直径为8.32mm ;求该材料的屈服极限σs 、断裂极限σb 、延伸率和断面收缩率。(8分) 解: d 0 =10.0mm, L 0 = 50mm, P 1=10kN 时L 1 = 50.80mm ;P 2=32kN 因P 1、P 2均远小于材料的屈服拉力55.42kN ,试样处于弹性变形阶段,据虎克 得 分 评分人

《材料力学》实验报告

材料力学 实验报告 对应课程 学号 学生 专业 班级 指导教师 成绩总评 学年第学期

目录 1.低碳钢及铸铁拉伸破坏实验???????????????(3 ) 2.低碳钢及铸铁压缩破坏实验???????????????(8 ) 3.引伸计法测定材料的弹性模量??????????????( 12 ) 4.低碳钢及铸铁扭转破坏实验???????????????(15) 5.载荷识别实验?????????????????????( 19) 成绩总评定 : 拉伸压缩测E扭转载荷识别

低碳钢及铸铁拉伸破坏实验 实验日期: 同组成员: 一、实验目的及原理 二、实验设备和仪器 1、试验机名称及型号: 吨位: 精度: 2、量具名称: 精度: 三、实验步骤 (一)、低碳钢、铸铁拉伸实验步骤:

四、试样简图 低碳钢试样 实验前实验后试 样 简 图 铸铁试样 实验前实验后试 样 简 图

五、实验数据及计算 低碳钢拉伸试验 (一)试件尺寸 (a)试验前 试件标直径d0( mm )最小横截距 横截面 1横截面 2横截面 3面面积L0平平平A (1)(2)(1)(2)(1) ( 2)02 ( mm )均均均( mm ) (b)试验后 断后标断口直径 d 1 ( mm )距 L1 12平均( mm )断口(颈缩处)最小横截面面 积 A1 ( mm2 ) 屈服极限:强度极限:断后延伸率: F s s (MPa) A0 F b b (MPa) A0 ( L 1 L O ) 100% L0

A0 A1100% 断面收缩率: A0 铸铁拉伸试验 (a)试验前 试件标直径d0( mm )最小横截距 横截面 1横截面 2横截面 3面面积L0平平平A (1)(2)(1)(2)(1) ( 2)02 ( mm )均均均( mm ) (b)试验后 F b 强度极限:b(MPa ) (二)绘出低碳钢的“力—位移、及铸铁的“ 力-位移”曲线低碳钢铸铁

材料力学实验报告答案

篇一:材料力学实验报告答案 材料力学实验报告 评分标准拉伸实验报告 一、实验目的(1分) 1. 测定低碳钢的强度指标(σs、σb)和塑性指标(δ、ψ)。 2. 测定铸铁的强度极限σb。 3. 观察拉伸实验过程中的各种现象,绘制拉伸曲线(p-δl曲线)。 4. 比较低碳钢与铸铁的力学特性。 二、实验设备(1分) 机器型号名称电子万能试验机 测量尺寸的量具名称游标卡尺精度 0.02 mm 三、实验数据(2分) 四、实验结果处理(4分) ?s??b? psa0pba0 =300mpa 左右=420mpa 左右 =20~30%左右=60~75%左右 ?? l1?l0 ?100% l0a0?a1 ?100% a0 ?= 五、回答下列问题(2分,每题0.5分) 1、画出(两种材料)试件破坏后的简图。略 2、画出拉伸曲线图。 3、试比较低碳钢和铸铁拉伸时的力学性质。 低碳钢在拉伸时有明显的弹性阶段、屈服阶段、强化阶段和局部变形阶段,而铸铁没有明显的这四个阶段。 4、材料和直径相同而长短不同的试件,其延伸率是否相同?为什么?相同 延伸率是衡量材料塑性的指标,与构件的尺寸无关。压缩实验报告 一、实验目的(1分) 1. 测定压缩时铸铁的强度极限σb。 2. 观察铸铁在压缩时的变形和破坏现象,并分析原因。 二、实验设备(1分) 机器型号名称电子万能试验机(0.5分) 测量尺寸的量具名称游标卡尺精度 0.02 mm (0.5分) 三、实验数据(1分)四、实验结果处理(2分) ?b? pb =740mpaa0 左右 五、回答下列思考题(3分) 1.画出(两种材料)实验前后的试件形状。略 2. 绘出两种材料的压缩曲线。略 3. 为什么在压缩实验时要加球形承垫?

材料力学性能考试答案

《工程材料力学性能》课后答案 机械工业出版社 2008第2版 第一章 单向静拉伸力学性能 1、 试述退火低碳钢、中碳钢和高碳钢的屈服现象在拉伸力-伸长曲线图上的区别?为什么? 2、 决定金属屈服强度的因素有哪些?【P12】 答:内在因素:金属本性及晶格类型、晶粒大小和亚结构、溶质元素、第二相。 外在因素:温度、应变速率和应力状态。 3、 试述韧性断裂与脆性断裂的区别。为什么脆性断裂最危险?【P21】 答:韧性断裂是金属材料断裂前产生明显的宏观塑性变形的断裂,这种断裂有一个缓慢的撕裂过程,在裂纹扩展过程中不断地消耗能量;而脆性断裂是突然发生的断裂,断裂前基本上不发生塑性变形,没有明显征兆,因而危害性很大。 4、 剪切断裂与解理断裂都是穿晶断裂,为什么断裂性质完全不同?【P23】 答:剪切断裂是在切应力作用下沿滑移面分离而造成的滑移面分离,一般是韧性断裂,而解理断裂是在正应力作用以极快的速率沿一定晶体学平面产生的穿晶断裂,解理断裂通常是脆性断裂。 5、 何谓拉伸断口三要素?影响宏观拉伸断口性态的因素有哪些? 答:宏观断口呈杯锥形,由纤维区、放射区和剪切唇三个区域组成,即所谓的断口特征三要素。上述断口三区域的形态、大小和相对位置,因试样形状、尺寸和金属材料的性能以及试验温度、加载速率和受力状态不同而变化。 6、 论述格雷菲斯裂纹理论分析问题的思路,推导格雷菲斯方程,并指出该理论的局限性。 【P32】 答: 212?? ? ??=a E s c πγσ,只适用于脆性固体,也就是只适用于那些裂纹尖端塑性变形可以忽略的情况。 第二章 金属在其他静载荷下的力学性能 一、解释下列名词: (1)应力状态软性系数—— 材料或工件所承受的最大切应力τmax 和最大正应力σmax 比值,即: () 32131max max 5.02σσσσσστα+--== 【新书P39 旧书P46】 (2)缺口效应—— 绝大多数机件的横截面都不是均匀而无变化的光滑体,往往存在截面的急剧变化,如键槽、油孔、轴肩、螺纹、退刀槽及焊缝等,这种截面变化的部分可视为“缺口”,由于缺口的存在,在载荷作用下缺口截面上的应力状态将发生变化,产生所谓的缺口效应。【P44 P53】 (3)缺口敏感度——缺口试样的抗拉强度σbn 的与等截面尺寸光滑试样的抗拉强度σb 的比值,称为缺口敏感度,即: 【P47 P55 】 (4)布氏硬度——用钢球或硬质合金球作为压头,采用单位面积所承受的试验力计算而得的硬度。【P49 P58】 (5)洛氏硬度——采用金刚石圆锥体或小淬火钢球作压头,以测量压痕深度所表示的硬度【P51 P60】。 (6)维氏硬度——以两相对面夹角为136。的金刚石四棱锥作压头,采用单位面积所承

金属材料力学性能检测样品制样作业指导书

力学性能检测样品制样作业指导书使用目的: 规范金属原材及焊接件力学性能试样的制样方法及尺寸。 试样依据: 《钢及钢产品力学性能试验取样位置及试样制备》GB/T2975-1998 《金属材料拉伸试验第1部分:室温拉伸试验方法》GB/ 《金属材料弯曲试验方法》GB/T232-2010 《金属材料夏比摆锤冲击试验方法》GB/T229-2007 《厚度方向性能钢板》GB/T5313-2010 《承压设备产品焊接试件的力学性能检验》NB/T47016-2011 《钢筋焊接接头试验方法标准》JGJ/T27-2001 一、拉伸试样取样方法:GB/T 1、厚度<3mm的薄板和薄带试样加工类型 1)试样形状: 试样的夹持头部一般比其平行长度部分宽(见图1)。试样头部与平行长度之 间应有过渡半径至少为20mm的过渡弧相连接。头部宽度应≥,b 为原始宽度。 通过协议,也可使用不带头试样。 2)试样尺寸: 比例试样尺寸见表1。 较广泛使用的三种非比例试样尺寸见表2。 平行长度不应小于L 0+b /2。

有争议时,平行长度应为L 0+2b 0,除非材料尺寸不足够。 对宽度等于或小于20mm 的不带头试样,除非产品标准中另有规定,原始标距L 0应等于50mm 。对于这类试样,两夹头间的自由长度应等于L 0+3b 0。 加工尺寸应满足表3给出的形状公差。 3)试样制备: 制备试样应不影响其力学性能,应通过机加工方法去除由于剪切或冲切而产生的加工硬化部分材料。 这些试样优先从板材或带材上制备。如果可能,应保留原轧制面。 图1 机加工的矩形横截面试样 表1 矩形横截面比例试样 表2 矩形横截面非比例试样 表3 试样宽度公差(单位:mm ) 2、直径或厚度小于4mm 线材、棒材和型材试样加工类型 1)试样形状: 试样通常为产品的一部分,不经机加工(见图2)。 2)试样尺寸: 原始标距L 0应取200mm ±2mm 或100mm ±1mm 。试验机两夹头之间的试样长度至少 等于L 0+3b 0,或L 0+3d 0,最小值为L 0+20mm 。见表4。 如果不测定断后伸长率,两夹头间的最小自由长度可以为50mm 。 3)如以盘卷交货的产品,可进行校直。 图2 产品一部分的不经机加工试样 表4 非比例试样

材料力学扭转实验实验报告

扭 转 实 验 一.实验目的: 1.学习了解微机控制扭转试验机的构造原理,并进行操作练习。 2.确定低碳钢试样的剪切屈服极限、剪切强度极限。 3.确定铸铁试样的剪切强度极限。 4.观察不同材料的试样在扭转过程中的变形和破坏现象。 二.实验设备及工具 扭转试验机,游标卡尺、扳手。 三.试验原理: 塑性材料和脆性材料扭转时的力学性能。(在实验过程及数据处理时所支撑的理论依据。参考材料力学、工程力学课本的介绍,以及相关的书籍介绍,自己编写。) 四.实验步骤 1.a 低碳钢实验(华龙试验机) (1)量直径: 用游标卡尺量取试样的直径。在试样上选取3各位置,每个位置互相垂直地测量2次直径,取其平均值;然后从3个位置的平均值中取最小值作为试样的直径。。 (2)安装试样: 启动扭转试验机,手动控制器上的“左转”或“右转”键,调整活动夹头的位置,使前、后两夹头钳口的位置能满足试样平口的要求,把试样水平地放在两夹头之间,沿箭头方向旋转手柄,夹紧试样。 (3)调整试验机并对试样施加载荷: 在电脑显示屏上调整扭矩、峰值、切应变1、切应变2、夹头间转角、时间的零点;根据你所安装试样的材料,在“实验方案读取”中选择“教学低碳钢试验”,并点击“加载”而确定;用键盘输入实验编号,回车确定(按Enter 键);鼠标点“开始测试”键,给试样施加扭矩;在加载过程中,注意观察屈服扭矩的变化,记录屈服扭矩的下限值,当扭矩达到最大值时,试样突然断裂,后按下“终止测试”键,使试验机停止转动。 (4)试样断裂后,从峰值中读取最大扭矩 。从夹头上取下试样。 (5)观察试样断裂后的形状。 1.b 低碳钢实验(青山试验机) (1)量直径: 用游标卡尺量取试样的直径。在试样上选取3各位置,每个位置互相垂直地测量2次直径,取其平均值;然后从3个位置的平均值中取最小值作为试样的直径。 (2)安装试样: 启动扭转试验机,手动“试验机测控仪”上的“左转”或“右转”键,调整活动夹头的位置,使前、后两夹头钳口的位置能满足试样平口的要求,把试样水平地放在两夹头之间,s τb τb τ 0d S M b M 0d

材料的力学性能

材料的力学性能 mechanical properties of materials 主要是指材料的宏观性能,如弹性性能、塑性性能、硬度、抗冲击性能等。它们是设计各种工程结构时选用材料的主要依据。各种工程材料的力学性能是按照有关标准规定的方法和程序,用相应的试验设备和仪器测出的。表征材料力学性能的各种参量同材料的化学组成、晶体点阵、晶粒大小、外力特性(静力、动力、冲击力等)、温度、加工方式等一系列内、外因素有关。材料的各种力学性能分述如下: 弹性性能材料在外力作用下发生变形,如果外力不超过某个限度,在外力卸除后恢复原状。材料的这种性能称为弹性。外力卸除后即可消失的变形,称为弹性变形。表示材料在静载荷、常温下弹性性能的一些主要参量可以通过拉伸试验进行测定。 拉伸试样常制成圆截面(图1之a)或矩形截面(图1之b)棒体,l为标距,d为圆形试样的直径,h和t分别为矩形截面试样的宽度和厚度,图中截面形状用阴影表示,面积记为A。长度和横向尺寸的比例关系也有如下规定:对于圆形截面试样,规定l=10d或l=5d;对于矩形截 面试样,按照面积换算规定或者。试样两端的粗大部分用以和材料试验 机的夹头相连接。试验结果通常绘制成拉伸图或应力-应变图。图2为低碳钢的拉伸图,横坐标表示试样的伸长量Δl(或应变ε=Δl/l),纵坐标表示载荷P(或应力σ=P/A)。图中的曲线从原点到点p为直线,pe段为曲线,载荷不大于点e所对应的值时,卸载后试样可恢复原状。反映材料弹性性质的参量有比例极限、弹性极限、弹性模量、剪切弹性模量和泊松比等。 比例极限应力和应变成正比例关系的最大应力称为比例极限,即图中点p所对应的应力,以σp表示。在应力低于σp的情况下,应力和应变保持正比例关系的规律叫胡克定律。载荷超过点p对应的值后,拉伸曲线开始偏离直线。 弹性极限试样卸载后能恢复原状的最大应力称为弹性极限,即图中点e所对应的应力,以σe表示。若在应力超出σe后卸载,试样中将出现残余变形。比例极限和弹性极限的测试值敏感地受测试精度的影响,并不易测准,所以在有关标准中规定,对于拉伸曲线的直线部分产生规定偏离量(用切线斜率的偏差表示)的应力作为"规定比例极限"。对于弹性

材料力学性能-第2版课后习题答案

第一章单向静拉伸力学性能 1、 解释下列名词。 2. 滞弹性:金属材料在弹性范围内快速加载或卸载后,随时间延长产生附加弹性应变的现象称为滞弹性,也就是应变落 后于应力的现象。 3?循环韧性:金属材料在交变载荷下吸收不可逆变形功的能力称为循环韧性。 4?包申格效应: 金属材料经过预先加载产生少量塑性变形,卸载后再同向加载,规定残余伸长应力增加;反向加载,规 定残余伸长应力降低的 现象。 11. 韧脆转变:具有一定韧性的金属材料当低于某一温度点时,冲击吸收功明显下降,断裂方式由原来的韧性断裂变为脆 性断裂,这种现象称 为韧脆转变 2、 说明下列力学性能指标的意义。 答:E 弹性模量G 切变模量 r 规定残余伸长应力 0.2屈服强度 gt 金属材料拉伸时最大应力下的总伸长率 n 应 变硬化指数 【P15】 3、 金属的弹性模量主要取决于什么因素?为什么说它是一个对组织不敏感的力学性能指标? 答:主要决定于原子本性和晶格类型。合金化、热处理、冷塑性变形等能够改变金属材料的组织形态和晶粒大小,但 是不改变金属原子的本性和晶格类型。组织虽然改变了,原子的本性和晶格类型未发生改变,故弹性模量对组织不敏 感。【P4】 4、 现有4 5、40Cr 、35 CrMo 钢和灰铸铁几种材料,你选择哪种材料作为机床起身,为什么? 选灰铸铁,因为其含碳量搞,有良好的吸震减震作用,并且机床床身一般结构简单,对精度要求不高,使用灰铸铁可 降低成本,提高生产效率。 5、 试述韧性断裂与脆性断裂的区别。为什么脆性断裂最危险? 【P21】 答:韧性断裂是金属材料断裂前产生明显的宏观塑性变形的断裂,这种断裂有一个缓慢的撕裂过程,在裂纹扩展过程 中不断地消耗能量;而脆性断裂是突然发生的断裂, 断裂前基本上不发生塑性变形, 没有明显征兆,因而危害性很大。 6、 何谓拉伸断口三要素?影响宏观拉伸断口性态的因素有哪些? 答:宏观断口呈杯锥形,由纤维区、放射区和剪切唇三个区域组成,即所谓的断口特征三要素。上述断口三区域的形 态、大小和相对位置,因试样形状、尺寸和金属材料的性能以及试验温度、加载速率和受力状态不同而变化。 7、 板材宏观脆性断口的主要特征是什么?如何寻找断裂源? 断口平齐而光亮,常呈放射状或结晶状,板状矩形拉伸试样断口中的人字纹花样的放射方向也 与裂纹扩展方向平行,其尖端指向裂纹源。 第二章 金属在其他静载荷下的力学性能 一、解释下列名词: (1 )应力状态软性系数—— 材料或工件所承受的最大切应力T max 和最大正应力(T max 比值,即: (3)缺口敏感度一一缺口试样的抗拉强度 T bn 的与等截面尺寸光滑试样的抗拉强度 T b 的比值,称为缺口敏感度,即:【P47 P55】 max 1 3 max 2 1 0.5 2 3 【新书P39旧书P46】

材料力学性能课后习题答案

材料力学性能课后答案(整理版) 1、解释下列名词。 1弹性比功:金属材料吸收弹性变形功的能力,一般用金属开始塑性变形前单位体积吸收的最大弹性变形功表示。 2.滞弹性:金属材料在弹性范围内快速加载或卸载后,随时间延长产生附加弹性应变的现象称为滞弹性,也就是应变落后于应力的现象。 3.循环韧性:金属材料在交变载荷下吸收不可逆变形功的能力称为循环韧性。4.包申格效应:金属材料经过预先加载产生少量塑性变形,卸载后再同向加载,规定残余伸长应力增加;反向加载,规定残余伸长应力降低的现象。 5.解理刻面:这种大致以晶粒大小为单位的解理面称为解理刻面。 6.塑性:金属材料断裂前发生不可逆永久(塑性)变形的能力。 韧性:指金属材料断裂前吸收塑性变形功和断裂功的能力。 7.解理台阶:当解理裂纹与螺型位错相遇时,便形成一个高度为b的台阶。 8.河流花样:解理台阶沿裂纹前端滑动而相互汇合,同号台阶相互汇合长大,当汇合台阶高度足够大时,便成为河流花样。是解理台阶的一种标志。 9.解理面:是金属材料在一定条件下,当外加正应力达到一定数值后,以极快速率沿一定晶体学平面产生的穿晶断裂,因与大理石断裂类似,故称此种晶体学平面为解理面。 10.穿晶断裂:穿晶断裂的裂纹穿过晶内,可以是韧性断裂,也可以是脆性断裂。 沿晶断裂:裂纹沿晶界扩展,多数是脆性断裂。 11.韧脆转变:具有一定韧性的金属材料当低于某一温度点时,冲击吸收功明显下降,断裂方式由原来的韧性断裂变为脆性断裂,这种现象称为韧脆转变 12.弹性不完整性:理想的弹性体是不存在的,多数工程材料弹性变形时,可能出现加载线与卸载线不重合、应变滞后于应力变化等现象,称之为弹性不完整性。弹性不完整性现象包括包申格效应、弹性后效、弹性滞后和循环韧性等决定金属屈服强度的因素有哪些? 答:内在因素:金属本性及晶格类型、晶粒大小和亚结构、溶质元素、第二相。外在因素:温度、应变速率和应力状态。 2、试述韧性断裂与脆性断裂的区别。为什么脆性断裂最危险? 答:韧性断裂是金属材料断裂前产生明显的宏观塑性变形的断裂,这种断裂有一个缓慢的撕裂过程,在裂纹扩展过程中不断地消耗能量;而脆性断裂是突然发生的断裂,断裂前基本上不发生塑性变形,没有明显征兆,因而危害性很大。 3、剪切断裂与解理断裂都是穿晶断裂,为什么断裂性质完全不同? 答:剪切断裂是在切应力作用下沿滑移面分离而造成的滑移面分离,一般是韧性断裂,而解理断裂是在正应力作用以极快的速率沿一定晶体学平面产生的穿晶断裂,解理断裂通常是脆性断裂。 4、何谓拉伸断口三要素?影响宏观拉伸断口性态的因素有哪些? 答:宏观断口呈杯锥形,由纤维区、放射区和剪切唇三个区域组成,即所谓的断口特征三要素。上述断口三区域的形态、大小和相对位置,因试样形状、尺寸和金属材料的性能以及试验温度、加载速率和受力状态不同而变化。5、论述格雷菲斯裂纹理论分析问题的思路,推导格雷菲斯方程,并指出该理论 的局限性。

材料力学性能测试实验报告

材料力学性能测试实验 报告 标准化管理部编码-[99968T-6889628-J68568-1689N]

材料基本力学性能试验—拉伸和弯曲一、实验原理 拉伸实验原理 拉伸试验是夹持均匀横截面样品两端,用拉伸力将试样沿轴向拉伸,一般拉 至断裂为止,通过记录的力——位移曲线测定材料的基本拉伸力学性能。 对于均匀横截面样品的拉伸过程,如图 1 所示, 图 1 金属试样拉伸示意图 则样品中的应力为 其中A 为样品横截面的面积。应变定义为 其中△l 是试样拉伸变形的长度。 典型的金属拉伸实验曲线见图 2 所示。 图3 金属拉伸的四个阶段 典型的金属拉伸曲线分为四个阶段,分别如图 3(a)-(d)所示。直线部分的斜率E 就是杨氏模量、σs 点是屈服点。金属拉伸达到屈服点后,开始出现颈缩 现象,接着产生强化后最终断裂。 弯曲实验原理 可采用三点弯曲或四点弯曲方式对试样施加弯曲力,一般直至断裂,通过实 验结果测定材料弯曲力学性能。为方便分析,样品的横截面一般为圆形或矩形。 三点弯曲的示意图如图 4 所示。 图4 三点弯曲试验示意图 据材料力学,弹性范围内三点弯曲情况下C 点的总挠度和力F 之间的关系是 其中I 为试样截面的惯性矩,E 为杨氏模量。 弯曲弹性模量的测定 将一定形状和尺寸的试样放置于弯曲装置上,施加横向力对样品进行弯曲, 对于矩形截面的试样,具体符号及弯曲示意如图 5 所示。 对试样施加相当于σpb0.01。 (或σrb0.01)的10%以下的预弯应力F。并记录此力和跨中点处的挠度,然后对试样连续施加弯曲力,直至相应于σpb0.01(或σrb0.01)的50%。记录弯曲力的增量DF 和相应挠度的增量Df ,则弯曲弹性模量为 对于矩形横截面试样,横截面的惯性矩I 为 其中b、h 分别是试样横截面的宽度和高度。 也可用自动方法连续记录弯曲力——挠度曲线至超过相应的σpb0.01(或σrb0.01)的弯曲力。宜使曲线弹性直线段与力轴的夹角不小于40o,弹性直线段的高度应超过力轴量程的3/5。在曲线图上确定最佳弹性直线段,读取该直线段的弯曲力增量和相应的挠度增量,见图 6 所示。然后利用式(4)计算弯曲弹性模量。 二、试样要求

材料力学实验报告

青岛黄海学院实验指导书 课程名称:材料力学 课程编码: 04115003 主撰人:吕婧 青岛黄海学院

目录 实验一拉、压实验 (1) 实验二扭转实验 (6) 实验三材料弹性模量E和泊松比μ的测定 (8) 实验四纯弯曲梁的正应力实验 (12)

实验一低碳钢拉伸实验 一、实验目的要求: (一)目的 σ、延伸率δ,截面收缩率ψ。 1.测定低碳钢的屈服极限σS,强度极限 b σ,观察上述两种材料的拉伸和破坏现象,绘制拉伸时2.测定铸铁的强度极限 b 的P-l?曲线。 (二)要求 1.复习讲课中有关材料拉伸时力学性能的内容;阅读本次实验内容和实设备中介绍万能试验机的构造原理、操作方法、注意事项,以及有关千分表和卡尺的使用方法。 2.预习时思考下列问题:本次实验的内容和目的是什么?低碳钢在拉伸过程中可分哪几个阶段,各阶段有何特征?试验前、试验中、试验后需要测量和记录哪些数据?使用液压式万能试验机有哪些注意事项? 二、实验设备和工具 1.万能实验 2.千分尺和游标卡尺。 3.低碳钢和铸铁圆形截面试件。 三、实验性质: 验证性实验 四、实验步骤和内容: (一)步骤 1.取表距L =100mm.画线 2.取上,中,下三点,沿垂直方向测量直径.取平均值

3.实验机指针调零. 4.缓慢加载,读出 s P .b P .观察屈服及颈缩现象,观察是否出现滑移线. 5.测量低碳钢断裂后标距长度1l ,颈缩处最小直径1d (二)实验内容: 1.低碳钢试件 (1)试件 (2)计算结果 屈服荷载 s P =22.1KN 极限荷载 b P =33.2KN 屈服极限 s σ=s P /0A =273.8MPa 强度极限 b σ=b P /0A =411.3MPa 延伸率 δ=(1l -0l )/0l *100%=33.24% 截面收缩率ψ=(0A -1A )/0A *100%=68.40% (3)绘制低碳钢P~ l ? 曲线

材料力学实验报告答案

材料力学实验报告答案 Prepared on 22 November 2020

材料力学实验报告 评分标准 拉伸实验报告 一、实验目的(1分) 1. 测定低碳钢的强度指标(σs、σb)和塑性指标(δ、ψ)。 2. 测定铸铁的强度极限σb。 3. 观察拉伸实验过程中的各种现象,绘制拉伸曲线(P-ΔL曲线)。 4. 比较低碳钢与铸铁的力学特性。 二、实验设备(1分) 机器型号名称电子万能试验机 测量尺寸的量具名称游标卡尺精度0.02 mm 三、实验数据(2分)

四、实验结果处理 (4分) 0A P s s = σ =300MPa 左右 0 A P b b = σ =420MPa 左右 %10000 1?-= L L L δ =20~30%左右 %= 1000 1 0?-A A A ψ =60~75%左右 五、回答下列问题(2分,每题分) 1、画出(两种材料)试件破坏后的简图。 略 2、画出拉伸曲线图。 3、试比较低碳钢和铸铁拉伸时的力学性质。 低碳钢在拉伸时有明显的弹性阶段、屈服阶段、强化阶段和局部变形阶段,而铸铁没有明显的这四个阶段。 4、材料和直径相同而长短不同的试件,其延伸率是否相同为什么 相同 延伸率是衡量材料塑性的指标,与构件的尺寸无关。 压缩实验报告 一、实验目的(1分)

1. 测定压缩时铸铁的强度极限σb 。 2. 观察铸铁在压缩时的变形和破坏现象,并分析原因。 二、实验设备 (1分) 机器型号名称电子万能试验机 (分) 测量尺寸的量具名称 游标卡尺 精度 0.02 mm (分) 三、实验数据(1分) 四、实验结果处理 (2分) A P b b = σ =740MPa 左右 五、回答下列思考题(3分) 1.画出(两种材料)实验前后的试件形状。 略 2. 绘出两种材料的压缩曲线。 略 3. 为什么在压缩实验时要加球形承垫

材料力学实验报告标准答案

力学实验报告 标准答案 长安大学力学实验教学中心 目录 一、拉伸实验 (2) 二、压缩实验 (4)

三、拉压弹性模量E测定实验 (6) 四、低碳钢剪切弹性模量G测定实验 (8) 五、扭转破坏实验 (10) 六、纯弯曲梁正应力实验 (12) 七、弯扭组合变形时的主应力测定实验 (15) 八、压杆稳定实验 (18) 一、拉伸实验报告标准答案 问题讨论: 1、为何在拉伸试验中必须采用标准试件或比例试件,材料相同而长短不同的试 件延伸率是否相同? 答:拉伸实验中延伸率的大小与材料有关,同时与试件的标距长度有关.试件局部变形较大的断口部分,在不同长度的标距中所占比例也不同.因此拉伸试验中必须采用标准试件或比例试件,这样其有关性质才具可比性. 材料相同而长短不同的试件通常情况下延伸率是不同的(横截面面积与长度存在某种特殊比例关系除外). 2、分析比较两种材料在拉伸时的力学性能及断口特征. 答:试件在拉伸时铸铁延伸率小表现为脆性,低碳钢延伸率大表现为塑性;低碳钢具有屈服现象,铸铁无.低碳钢断口为直径缩小的杯锥状,且有450的剪切唇,

断口组织为暗灰色纤维状组织。铸铁断口为横断面,为闪光的结晶状组织。. 二、压缩实验报告标准答案 问题讨论: 1、分析铸铁试件压缩破坏的原因. 答:铸铁试件压缩破坏,其断口与轴线成45°~50°夹角,在断口位置剪应力已达到其抵抗的最大极限值,抗剪先于抗压达到极限,因而发生斜面剪切破坏。 2、低碳钢与铸铁在压缩时力学性质有何不同? 结构工程中怎样合理使用这 两类不同性质的材料? 答:低碳钢为塑性材料,抗压屈服极限与抗拉屈服极限相近,此时试件不会发生断裂,随荷载增加发生塑性形变;铸铁为脆性材料,抗压强度远大于抗拉强度,无屈服现象。压缩试验时,铸铁因达到剪切极限而被剪切破坏。 通过试验可以发现低碳钢材料塑性好,其抗剪能力弱于抗拉;抗拉与抗压相近。铸铁材料塑性差,其抗拉远小于抗压强度,抗剪优于抗拉低于抗压。 故在工程结构中塑性材料应用范围广,脆性材料最好处于受压状态,比如车床机座。 三、拉压弹性模量E测定试验报告 问题讨论: 1、试件的尺寸和形状对测定弹性模量有无影响?为什么? 答: 弹性模量是材料的固有性质,与试件的尺寸和形状无关。 2、逐级加载方法所求出的弹性模量与一次加载到最终值所求出的弹性模量是 否相同?为什么必须用逐级加载的方法测弹性模量? 答: 逐级加载方法所求出的弹性模量与一次加载到最终值所求出的弹性模量不相同,采用逐级加载方法所求出的弹性模量可降低误差,同时可以验证材料此时是否处于弹性状态,以保证实验结果的可靠性。 四、低碳钢剪切弹性模量G测定实验报告标准答案 问题讨论: 1、试验过程中,有时候在加砝码时,百分表指针不动,这是为什么?应采取什么 措施? 答:检查百分表是否接触测臂或超出百分表测量上限,应调整百分表位置。

材料力学性能

第一章 一.静载拉伸实验 拉伸试样一般为光滑圆柱试样或板状试样。 若采用光滑圆柱试样,试样工作长度(标长)l0 =5d0 或l0 =10d0,d0 为原始直径。 二.工程应力:载荷除以试件的原始截面积。σ=F/A0 工程应变:伸长量除以原始标距长度。ε=ΔL/L0 低碳钢的变形过程:弹性变形、不均匀屈服塑性变形(屈服)、均匀塑性变形(明显塑性变形)、不均匀集中塑性变形、断裂。 三.低碳钢拉伸力学性能 1.弹性阶段(Ob) (1)直线段(Oa): 线弹性阶段,E=σ/ε(弹性模量,比例常数) σp—比例极限 (2)非直线段(ab): 非线弹性阶段 σe—弹性极限 2. 屈服阶段(bc) 屈服现象:当应力超过b点后,应力不再增加,但应变继续增加,此现象称为屈服。 σs—屈服强度(下屈服点),屈服强度为重要的强度指标。 3.强化阶段(ce) 材料抵抗变形的能力又继续增加,即随试件继续变形,外力也必须增大,此现象称为材料强化。 σb—抗拉强度,材料断裂前能承受的最大应力 4.局部变形阶段(颈缩)(ef) 试件局部范围横向尺寸急剧缩小,称为颈缩。 四.主要力学性能指标 弹性极限(σe):弹性极限即指金属材料抵抗这一限度的外力的能力 屈服强度(σs):抵抗微量塑性变形的应力 五.铸铁拉伸力学性能 特点: (1)较低应力下被拉断 (2)无屈服,无颈缩 (3)延伸率低 (4)σb—强度极限 (5)抗压不抗拉 讨论1:σs 、σr0.2、σb都是机械设计和选材的重要论据。实际使用时怎么办? 塑性材料:σs 、σr0.2 脆性材料:σb 屈强比:σs /σb 讨论2:屈强比σs /σb有何意义? 屈强比s / b值越大,材料强度的有效利用率越高,但零件的安全可靠性降低。 六.弹性变形及其实质 定义:当外力去除后,能恢复到原来形状和尺寸的变形。 特点:单调、可逆、变形量很小(<0.5~1.0%)