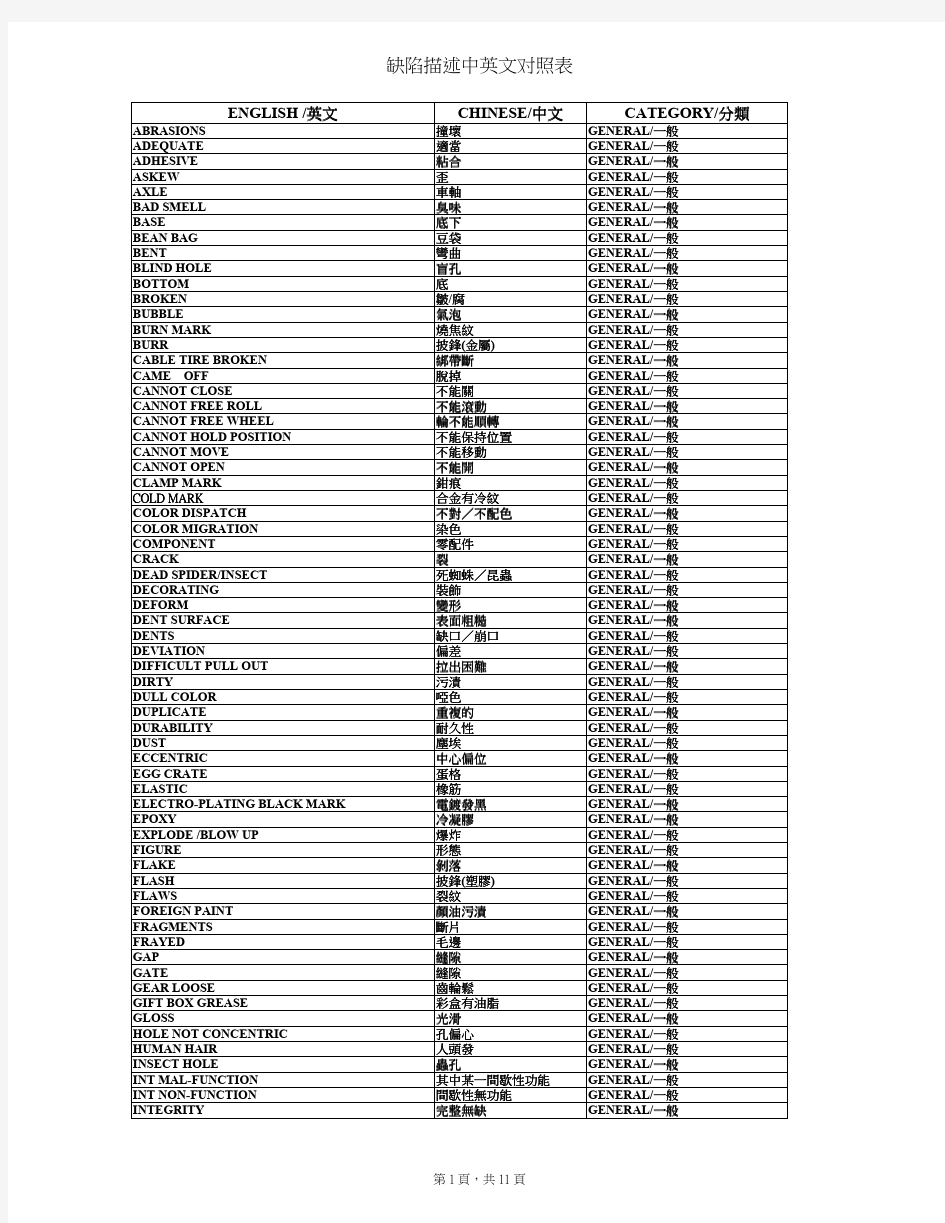

产品不良描述-详细中英文对照

不良品项目定义中英文对照版

521不良項目定義

度較長的線狀痕跡 S02毛刺:產品沖裁后留在零件剪切邊的批鋒 S03模痕:模具在成形零件過程中造成的均勻類似刮痕現象 S04壓傷:由于模具表面有異物,使產品在沖壓成形過程中受壓力作用在表 面留下塊狀的下凹的現象 S05 切邊不齊:產品沖裁后零件剪切邊呈現出不整齊的現象 S06晃動:由于產品平面度超出spec,而呈現出凹凸不平的現象 507尺寸超差:產品的尺寸超出Spec 508材料外觀不良:原材料本身就具有的一些如白斑,黑點, 麻點,發黑,白灰,刮傷, 氧化等方面的不良 S09抽牙不良:抽牙尺寸超出Spec,或是出現抽牙抽歪,抽牙抽裂的現象 S10 攻牙不良:攻牙孔攻歪,通規不通,止規不止,或是出現實配螺絲打不進, 實配螺絲滑牙的現象 S11鉚合不良:鐵件鉚合后,鐵件與鐵件間間隙超Spec或鉚合孔偏位,鉚合不牢固 之現象 512凸包/拱橋沖裂:受模具,沖床壓力,或材料硬度的影響,產品在成形 過程中凸包/拱橋表面產生明顯的裂紋,或完全開裂的現象 513少工程:產品成形的工程數少于作業文件所規定的工程數的現象 514變形:由于受外力作用,產品失去其本身所應具有的形狀的現象 515生鏽:基體材料表面或切邊呈現經色,發生化學氧化的現象 516不潔:產品表面附著除油污,毛刺以外的其它異物 517油污:粘附於零件表面能擦除的呈塊狀或膜狀的油脂或變色異物 518碰刮傷:受尖銳硬物刮踫而在零件表面留下的,長度相對於寬度和深度 較長的表面斑痕 519包裝不良:產品的包裝方式未完全按照相應的作業文件來執行,可能會 造成品質隱患的現象 520混料:兩種或兩種以上的產品同時放置在某單一產品所存放的區域 521點焊不良:產品點焊后鐵件與鐵件間連接不牢固,拉力測試超Spec. 存在點焊點錯位,漏焊,虛焊, 燒穿, 焊渣等缺陷的現象522字模不清/殘缺/錯誤:Mark 字體不完整,模糊不清,字模的位置,式樣 等未完全按作業文件要求作業的現象 5.2.2 涂裝不良項目定義 P01雜質:由于烤漆面粘附有雜質,烤漆后在表面形成一種凸起的可剝落的塊 狀或點狀漆的現象 P02刮傷/掉漆:烤漆表面在外力(碰撞,擦刮)作用下,漆層呈點狀,塊

SMT焊接不良现象中英文对照表

[replyview]不良现象中英文对照表 1.缺件(MISSING PARTS) 28.脚未弯(PIN NOT BENT) 55.印章错误(WRONG STAMPS) 2.错件(WRONG PARTS) 29.缺盖章(MISSING STAMP) 56.尺寸错误 (DIMENSION WRONG) 3.多件(EXCESSIVE PARTS) 30.缺卷标(MISSING LABEL) 57.二极管坏 (DIODE NG) 4.短路(SHORT) 31.缺序号(MISSING S/N) 58.晶体管坏(TRANSISTOR NG) 5.断路(OPEN) 32.序号错(WRONG S/N) 59.振荡器坏(X’TL NG) 6.线短(WIRE SHORT) 33.卷标错(WRONG LABEL) 60.管装错误(TUBES WRONG) 7.线长(WIRE LONG) 34.标示错(WRONG MARK) 61.阻值错误(IMPEDANCE WRONG) 8.拐线(WIRE POOR DDRESS) 35.脚太短(PIN SHORT) 62.版本错误(REV WRONG) 9.冷焊(COLD SOLDER) 36.J1不洁(J1 DIRTY) 63.电测不良(TEST FAILURE) 10.包焊(EXCESS SOLDER) 37.锡凹陷(SOLDER SCOOPED) 64.版本未标(NON REV LEBEL) 11.空焊(MISSING SOLDER) 38.线序错(W/L OF WIRE) 65.包装损坏 (PACKING DAMAGED) 12.锡尖(SOLDER ICICLE) 39.未测试(NO TEST) 66.印章模糊(STAMPS DEFECTIVE) 13.锡渣(SOLDER SPLASH) 40.VR变形(VR DEFORMED) 67.卷标歪斜(LABEL TILT) 14.锡裂(SODER CRACK) 41.PCB翘皮(PCB PEELING) 68.外箱损坏(CARTON DAMAGED) 15.锡洞(PIN HOLE) 42.PCB弯曲(PCB TWIST) 69.点胶不良(POOR GLUE) 16.锡球(SOLDER BALL) 43.零件沾胶(GLUE ON PARTS) 70.IC座氧化 (SOCKET RUST)

不良现象中英文对照表

良现象中英文对照表 不良现象中英文对照表 1.缺件(MISSING PARTS)…missing parts 2.错件(WRONG PARTS)…wrong parts 3.多件(EXCESSIVE PARTS)…excessive parts 4.短路(SHORT)…short 5.断路(OPEN)…open 6.线短(WIRE SHORT)…wire short 7.线长(WIRE LONG)…wire long 8.拐线(WIRE POOR DDRESS)…wire poor adress 9.冷焊(COLD SOLDER) …cold solder 10.包焊(EXCESS SOLDER)…excess solder 11.空焊(MISSING SOLDER)…missing solder 12.锡尖(SOLDER ICICLE)…icicle 13.锡渣(SOLDER SPLASH)…solder splash 14.锡裂(SODER CRACK)…solder crack 15.锡洞(PIN HOLE)..solder hole 16.锡球(SOLDER BALL)..sloder ball 17.锡桥(SOLDER BRIDGE)…solder bridge 18.滑牙(SCREW LOOSE)…screw loose 19.氧化(RUST) …rust 20.异物(FOREIGNER MATERIAL)…foreigner material 21.溢胶(EXCESSIVE GLUE) 22.锡短路(SOLDER BRIDGE) 23.锡不足(SOLDER INSUFFICIENT) 24.极性反(WRONG POLARITY) 25.脚未入(PIN UNSEATED) 26.脚未出(PIN UNVISIBLE) 27.脚未剪(PIN NO CUT) 28.脚未弯(PIN NOT BENT) 29.缺盖章(MISSING STAMP) 30.缺标签(MISSING LABEL)…missing label 31.缺序号(MISSING S/N) 32.序号错(WRONG S/N) 33.标签错(WRONG LABEL) 34.标示错(WRONG MARK) 35.脚太短(PIN SHORT) 36.J1不洁(J1 DIRTY) 37.锡凹陷(SOLDER SCOOPED) 38.线序错(W/L OF WIRE)

质量手册翻译中英文对照解析

质量手册翻译中英文术语表 3.1.1 质量 quality 3.1.2 要求 requirement 3.1.3 等级 grade 3.1.4 顾客满意 customer satisfaction 3.1.5 能力 capability 3.2.1 体系(系统) system 3.2.2 管理体系 management system 3.2.3 质量管理体系 quality management syste m 3.2.4 质量方针 quality policy 3.2.5 质量目标 quality objective 3.2.6 管理 management 3.2.7 最高管理者 top management 3.2.8 质量管理 quality management 3.2.9 质量策划 quality planning 3.2.10 质量控制 quality control 3.2.11 质量保证 quality assurance 3.2.12 质量改进 quality improvement 3.2.13 持续改进 continual improvement 3.2.14 有效性 effectiveness 3.2.15 效率 efficiency 3.3.1 组织 organization 3.3.2 组织结构 organizational structure 3.3.3 基础设施 infrastructure 3.3.4 工作环境 '77ork environment 3.3.5 顾客 customer 3.3.6 供方 supplier 3.3.7 相关方 interested party 3.4.1 过程 process 3.4.2 产品 product 3.4.3 项目 project 3.4.4 设计和开发 design and development 3.4.5 程序 procedure

电子电器产品不良缺陷对应英文描述

General Defect - 通用电器缺陷 cord untied or irregularly tied电线未绑或绑的不规则exposed wires金属线外露 brass wire in power cord exposed电源线的铜丝外露ground wire discontinuous地线间断 burn down烧坏 jam刮/卡死 excessive noise噪音过多 shock noise振动有噪音 switch operated not smoothly开关不顺 polarity reversed极性接反 open circuited开路 short circuited短路 grounding continuity test failed接地失败 Hi-pot test failed高压失败 leakage current test failed漏电 power supply dead无电源 dielectric strength test failed介质强度测试失败current or wattage out of specification电流/电压不合规格live wire exposed火线外露 General location - 电器通用缺陷 位置 jack插口 AC-IN jack交流输入口 DC-IN jack直流输入口 socket插座 socket cover插座盖 plug插头 plug foot插脚 polarized plug极性插头 coupling plug转化/耦合插头 flat blade plug扁脚插头 channel频道 function key功能键 nut螺母 LCD液晶显示屏 power LED indicator电源电子指示灯power cord电源线 electrode plate电极片 ON-Off switch开关 adapter适配器

不良现象中英文对照表

1.缺件(MISSING PARTS) 2.错件(WRONG PARTS) 3.多件(EXCESSIVE PARTS) 4.短路(SHORT) 5.断路(OPEN) 6.线短(WIRE SHORT) 7.线长(WIRE LONG) 8.拐线(WIRE POOR DDRESS) 9.冷焊(COLD SOLDER) 10.包焊(EXCESS SOLDER) 11.空焊(MISSING SOLDER) 12.锡尖(SOLDER ICICLE) 13.锡渣(SOLDER SPLASH) 14.锡裂(SODER CRACK) 15.锡洞(PIN HOLE) 16.锡球(SOLDER BALL) 17.锡桥(SOLDER BRIDGE) 18.滑牙(SCREW LOOSE) 19.氧化(RUST) 20.异物(FOREIGNER MATERIAL) 21.溢胶(EXCESSIVE GLUE) 22.锡短路(SOLDER BRIDGE) 23.锡不足(SOLDER INSUFFICIENT) 24.极性反(WRONG POLARITY)25.脚未入(PIN UNSEATED) 26.脚未出(PIN UNVISIBLE) 27.脚未剪(PIN NO CUT) 28.脚未弯(PIN NOT BENT) 29.缺盖章(MISSING STAMP) 30.缺标签(MISSING LABEL) 31.缺序号(MISSING S/N) 32.序号错(WRONG S/N) 33.标签错(WRONG LABEL) 34.标示错(WRONG MARK) 35.脚太短(PIN SHORT) 36.J1不洁(J1 DIRTY) 37.锡凹陷(SOLDER SCOOPED) 38.线序错(W/L OF WIRE) 39.未测试(NO TEST) 40.VR变形(VR DEFORMED 41.PCB翘皮(PCB PEELING) 42.PCB弯曲(PCB TWIST) 43.零件沾胶(GLUE ON PARTS) 44.零件脚长(PARTS PIN LONG) 45.浮件(PARTS LIFT) 46.零件歪斜(PARTS TILT) 47.零件相触(PARTS TOUCH) 48.零件变形(PARTS DEFORMED)

注塑件缺陷中英文对照表

注塑件缺陷中英文对照表 中文英文 -------- -------------------- 起泡 Blister 起霜 Blooming 破孔 Blow hole 泛白 Blushing 侧壁皱纹 Body wrinkle 冒口带肉 Breaking-in 膜泡、气泡 Bubble 糊斑 Burn mark 毛边(金属) Burr (for metal)翘曲 Camber 气泡 Cell 表面中部波皱 Center buckle 细裂痕 Check 龟裂 Checking 修整表面缺陷 Chipping 铸件凹痕 Clamp-off 塌陷 Collapse 色斑 Color mottle 腐蚀 Corrosion 外观不良 Cosmetic defect 裂痕 Crack 碎裂、龟裂 Crazing 变形 Deformation 切边碎片 Edge 裂边 Edge crack 退色 Fading 填充料斑 Filler speak 裂纹 Fissure 凸缘起皱 Flange wrinkle 毛边 Flash 刮伤 Flaw 流痕 Flow mark, flow line 字体模糊 Foggy 毛边 Galling 光滑 Glazing 光泽 Gloss 污斑 Grease pits 油污、脏污 Grease, oil stains 磨痕 Grinding defect 发裂 Haircrack 雾度 Haze

水锈 Incrustation 杂质 Inclusion 压痕 Indentation 内部气孔 Internal porosity 发霉 Mildewed, moldy, mouldy 偏模 Mismatch 杂色 Mixed color 斑点 Mottle 缩颈 Necking 割痕 Nick 橘皮状表面缺陷 Orange peel 溢流 Overflow 剥离 Peeling, peel-off 坑 Pit 点状腐蚀 Pitting corrosion 模板印痕 Plate mark 麻点 Pock 痘斑 Pock mark 树脂流纹 Resin streak 树脂脱落 Resin wear 凹陷 Riding 松垂 Sagging 皂化 Saponification 疤痕 Scar 废料 Scrap 废料阻塞 Scrap jam 刮伤、划痕、划伤 Scratch 深冲表面划伤 Scuffing 裂痕 Seam 模口挤痕 Shock line 充填不足 Short shot 凹孔 Shrinkage pool 缩水 Shrinking, shrinkage 凹痕、凹陷 Sink mark, shrink Line , sink mark 表皮折迭 Skin inclusion 螺丝滑头、滑手 Slipped screw head, slippery screw thread 斑点 Speckle 矫直 Straightening 条状痕、条纹 Streak 表面裂痕 Surface check 橘皮状表皮皱折 Surface roughening 波动 Surging 冒汗 Sweat out 扭曲 Torsion

不良描述中英文对照

不良描述中英文对照 Goods Supplement补货 1.Plastic parts 塑胶部件 Abrasion/划痕、 Bubbles/气泡、 Burrs/毛刺、 Bad Plating/电镀不良、 Contamination/杂质、 Crack/爆裂、 Combine Lines/结合线、 Deformation/变形、 Flow Marks/流痕、 GreasyDirt/油污、 Haze/雾状、 Jelly/泠胶、 Mold Marks/模痕、 Melange Color/混色、 Oppilation Hole/盲孔、 Pull White/拉白、 Pour Hole uneven/浇口不平、 Wrong Stamping/字麦不符、 Short Shots/缺料、 Shrinkage/缩水、 Stripped Screw/螺丝滑牙、 Top White/顶白、 Weld Lines/夹水纹、 Wrong Dimension/尺寸不符、 Wrong Texture/纹理错误、 Light/发亮, Gaps裂缝、 Steps 披峰、 表面有手指印Surface finger prints、 丝印错误Wrong printing、 丝印偏移Printing slanted、 丝印重影Printing double image、 丝印有污点,拖尾Printing smearing、 丝印不平坦(多油或少油)Printing uneven ( thin / thick )、丝印对于中心偏位Printing off centre、 压痕或凹痕Press mark 或dented mark、 反光或毛刺Flashing 或 burr、 镜片有针孔Pin hole on lens. 光泽luster/白点white dot、 黑点black dot、

品质相关英文缩写和不良现象表述

CEM Contract Manufacture service 合约委托代工 IBSC Internet Business Solution Center 国际互联网应用中心 PCEG Personal Computer Enclosure group 个人计算机外设事业群(FOXTEQ) SABG system assembly business group 系统组装事业群 Engineer standard 工标 Document center (database center)资料中心 Design Center 设计中心 Painting 烤漆(厂) Assembly组装(厂) Stamping 冲压(厂) Education and Training教育训练 proposal improvement/creative suggestion提案改善 Technological exchange and study 技术交流研习会 Technology and Development Committee 技术发展委员会

BS Brain Storming 脑力激荡 QCC Quality Control Circle 品质圈PDCA Plan Do Check Actio n 计划执行检查总结DCC delivery control center 交货管制中心Computer 计算机类产品 Consumer electronics 消费性电子产品Communication 通讯类产品 Core value(核心价值) Love 爱心 Confidence 信心 Decision 决心 Corporate culture(公司文化) Integration 融合 Responsibility 责任 Progress 进步

不良中英文对照表

不良现象中英文对照表 1.缺件(missing parts) 2.错件(wrong parts) 3.多件(excessive parts) 4.短路(short) 5.断路(open) 6.线短(wire short) 7.线长(wire long) 8.拐线(wire poor ddress) 9.冷焊(cold solder) 10.包焊(excess solder) 11.空焊(missing solder) 12.锡尖(solder icicle) 13.锡渣(solder splash) 14.锡裂(soder crack) 15.锡洞(pin hole) 16.锡球(solder ball) 17.锡桥(solder bridge) 18.滑牙(screw loose) 19.氧化(rust) 20.异物(foreigner material) 21.溢胶(excessive glue) 22.锡短路(solder bridge) 23.锡不足(solder insufficient) 24.极性反(wrong polarity) 25.脚未入(pin unseated) 26.脚未出(pin unvisible) 27.脚未剪(pin no cut) 28.脚未弯(pin not bent) 29.缺盖章(missing stamp) 30.缺标签(missing label) 31.缺序号(missing s/n) 32.序号错(wrong s/n) 33.标签错(wrong label) 34.标示错(wrong mark) 35.脚太短(pin short) 36.j1不洁(j1 dirty) 37.锡凹陷(solder scooped) 38.线序错(w/l of wire) 39.未测试(no test) 40.vr变形(vr deformed) 43.零件沾胶(glue on parts) 41.pcb翘皮(pcb peeling) 42.pcb弯曲(pcb twist) 44.零件脚长(parts pin long) 45.浮件(parts lift) 46.零件歪斜(parts tilt) 47.零件相触(parts touch) 48.零件变形(parts deformed) 49.零件损坏(parts damaged) 50.零件脚脏(pin dirty) 51.零件多装(parts excess) 52.零件沾锡(solder on parts) 53.零件偏移(parts shift) 54.包装错误(wrong packing) 55.印章错误(wrong stamps) 56.尺寸错误(dimension wrong) 57.二极管坏(diode ng) 58.晶体管坏(transistor ng) 59.振荡器坏(x’tl ng) 60.管装错误(tubes wrong) 61.阻值错误(impedance wrong) 62.版本错误(rev wrong) 63.电测不良(test failure) 64.版本未标(non rev lebel) 65.包装损坏(packing damaged) 66.印章模糊(stamps defective) 67.标签歪斜(label tilt) 68.外箱损坏(carton damaged) 69.点胶不良(poor glue) 70.ic座氧化(socket rust) 71.缺ul标签(missing ul label) 72.线材不良(wire failure) 73.零件脚损坏(pin damaged) 74.金手指沾锡(solder on golden fingers) 75.包装文件错(racking doc wrong) 76.包装数量错(packing q’ty wrong) 77.零件未定位(parts unseated) 78.金手指沾胶(glue on golden fingers) 79.垫片安装不良(washer unseated) 80.线材安装不良(wire unseated) 81.立碑(tombstone)

不良描述中英文对照

不良描述中英文对照(五金,塑料,PCB) 1.Plastic parts 塑膠部件- Inspection Points /檢查要點: Abrasion/划痕,Bubbles/气泡, Burrs/毛刺, Bad Plating/電鍍不良, Contamination/雜質, Crack/爆裂, Combine Lines/結合線, Deformation/變形, Flow Marks/流痕, Greasy Dirt/油污, Haze/霧狀, Jelly/泠膠, Mold Marks/模痕, Melange Color/混色, Oppilation Hole/盲孔, Pull White/拉白, Pour Hole uneven/澆口不平, Wrong Stamping/字麥不符, Short Shots/缺料, Shrinkage/縮水, Stripped Screw/螺絲滑牙, Top White/頂白, Weld Lines/夾水紋, Wrong Dimension/尺寸不符, Wrong Texture/紋理錯誤, Light/發亮;-质量- 2. Metal Parts 五金部件 Inspection Points /檢查要點: Abrasion/划痕, Bad Weld/焊接不良, Burrs/毛刺, Bad Plating/電鍍不良, Bend angle/折彎角度, Contamination/雜質, Crack/爆裂, Deformation/變形, Dents/凹痕, Greasy Dirt/油污, Mold Marks/模痕, Missing Stamp/漏沖壓, Oppilation Hole/盲孔, Pressing Marks/壓痕, Rust/生鏽, Wrong Stamping/字麥錯誤, Short Shots/缺料, Stripped Screw/螺絲滑牙, Pits/疤痕, Specks/斑點 Wrong Texture/紋理錯誤, Wrong Dimension/尺寸不符;bb 3. Painting parts / SilkScreen parts 噴油/絲印部件 Inspection Points /檢查要點: Bleeding/滲色, Bad Painting/噴油不良, Contamination/雜質, deviate position/偏位, Flow Marks/流痕, Missing paint/漏噴, Over Paint/肥油, Pits/疤痕, Poor Adhesion/附著力差, Print Words Leans/印刷字體傾斜, Pooring Paint/薄油, Silkscreen Haze/絲印模糊, Silkscreen Stamping Inconsistency/絲印字樣不一致, Scratch/划傷, Speck/斑點, Uneven Surface Oil/表面油層不均勻, Words Break Off/字体斷開, Wrong Color/錯誤顏色, Wrong Texture/紋理錯誤;-

塑胶产品常见不良现象分析

塑胶产品常见不良现象分析 1.填充不足(SHOT SHORT):是熔融塑料未完全流遍成型空间(模穴)的各个角落之现象. 2.毛边:熔融塑料流入分模面或侧向蕊型的对合面间隙会发生BURR;模具锁模力足够,但在浇道与横流道会合处产生薄膜状多余树脂为FLUSH. 3.收缩下陷:成型品表面产生凹陷的现象.这是体积收缩所致,通常见于肉厚部分、肋或凸出的背面、直接浇口肉厚不均的部份. 4:气泡:熔融塑料中有水份、挥发性气体于成型过程进入成型品内部而残留的空洞现象谓气泡 5:破裂(CRACKING)与龟裂(CRAXING):成型品表面裂痕严重而明显者为破裂(CRACKING).成型品表面呈毛发状裂纹,制品尖锐突角处常呈现此现象谓之龟裂现象. 6:白化定义:成型品脱模之际,因顶出销的顶力或成型品倒钩(UNDERCUT)位之阻力,该部呈现白色痕迹称为白化(BLUSHING).白化并非裂纹,但却是裂纹(龟裂)之前兆,当见于ABS.HIPS等塑件.白化是成型品内部显著的残留应力所致,应注意龟裂现象之发生. 7:变形(STRAIN)-翘曲、扭曲:变形可分成翘曲与扭曲两种现象.平行边变形者称为翘曲(WRAPING); 对角线方向的变形称为扭曲(TORSION). 8:熔合线(weld line)是熔融材料二道或二道以上合流的部分所形成的细线. 9:流痕(flow mark)是熔融材料流动的痕迹,以浇口为中心而呈现的条纹模样. 10:喷流痕是熔融塑料由浇口往成型空间(模穴)内射出时呈纽带状固化,而在成型品表面成蛇行状态. 11:银条(sliver streak)是在成型品表面或表面附近,沿材料流动方向,呈现的银白色条纹. 12:一般所谓的烧焦(burn marks),包括成形品表面因材料过热所致的变色及成型品的锐角部份或毂部.肋的前端等材料焦黑的现象.烧焦是滞留成型空间内的空气,在熔融材料进人时未能迅速排出,被压缩而显著升温,再将材料烧焦所致.烧焦之有效防止对策是在易聚集空气部位设置排气孔或利用顶出销.芯型销等的

化工产品常见危险性符号描述-中英文对照

Risk Phrases 英文解释中文解释 R1 Explosive when dry. 干燥时有爆炸性; R2 Risk of explosion by shock, friction, fire or other sources of ignition. 受冲击、摩擦、着火或其他引燃源有爆炸危险; R3 Extreme risk of explosion by shock, friction, fire or other sources of ignition. 受冲击、摩擦、着火或其他引燃源有极高爆炸危险; R4 Forms very sensitive explosive metallic compounds. 生成极敏感的爆炸性金属化合物;R5 Heating may cause an explosion. 受热可能引起爆炸; R6 Explosive with or without contact with air. 与空气或未与空气接触发生爆炸; R7 May cause fire. 可能引起火灾; R8 Contact with combustible material may cause fire. 与可燃物料接触可能引起火灾; R9 Explosive when mixed with combustible material. 与可燃物料混合时发生爆炸; R10 Flammable. 易燃的; R11 Highly flammable. 高度易燃的; R12 Extremely flammable. 极易燃的; R14 Reacts violently with water. 与水猛烈反应; R14/15 Reacts violently with water, liberating highly flammable gases. 与水猛烈反应,释放出极易燃气体; R15 Contact with water liberates extremely flammable gases. 与水接触释放出极易燃气体;R15/29 Contact with water liberates toxic, highly flammable gas. 与水接触释放出有毒的,极易燃气体; R16 Explosive when mixed with oxidizing substances. 与氧化性物质混合时发生爆炸; R17 Spontaneously flammable in air. 在空气中易自燃; R18 In use, may form flammable/explosive vapour-air mixture. 使用中可能形成易燃/爆炸性蒸气空气混合物; R19 May form explosive peroxides. 可能生成爆炸性过氧化物; R20 Harmful by inhalation. 吸入有害; R20/21 Harmful by inhalation and in contact with skin. 吸入和与皮肤接触是有害的; R20/21/22 Harmful by inhalation, in contact with skin and if swallowed. 吸入、与皮肤接触和吞食是有害的; R20/22 Harmful by inhalation and if swallowed. 吸入和吞食是有害的; R21 Harmful in contact with skin. 与皮肤接触是有害的; R21/22 Harmful in contact with skin and if swallowed. 与皮肤接触和吞食是有毒的; R22 Harmful if swallowed. 吞食是有害的; R23 Toxic by inhalation. 吸入有害; R23/24 Toxic by inhalation and in contact with skin. 吸入和与皮肤接触是有毒的; R23/24/25 Toxic by inhalation, in contact with skin and if swallowed. 吸入、与皮肤接触和吞食是有毒的; R23/25 Toxic by inhalation and if swallowed. 吸入和吞食是有毒的; R24 Toxic in contact with skin. 与皮肤接触有毒; R24/25 Toxic in contact with skin and if swallowed. 与皮肤接触和吞食是有毒的; R25 Toxic if swallowed. 吞食有毒; R26 Very toxic by inhalation. 吸入有极高毒性;

不良项目中英文对照

1>Abrasion: A surface imperfection that removes or displaces material characterized by its large width and length relative to its depth. 中译: 擦破/磨损一个表面的瑕疵。 移动材料时造成较大的宽度、长度、深度之 特徵。 2>Bleeding: This defect is the discoloration created by the diffusion of coloring material through an applied coating from the substrate to the surface of the coating. 中译: 渗出染料扩散,自底层到表层,造成表面上的瑕 疵。 3>Blemish: The change in the surface appearance due to a flaw or cosmetic defect. 中译: 污损/污点因为一个瑕疵或外观不良而改变表面外部 4>Blister: The raised bumps in the surface, caused by air or solvent vapors forming within or under the coating. 中译: 水泡由於来自烤漆内部或表面的空气或溶剂气体 造成表面隆起突出。 5>Blush: Discoloration or change in gloss, generally appearing at the gates, abrupt thickness changes or other structures along flow pat. 中译: 异色通常发生在射出进料口、肉厚突然缩减、 或流道交错之处 6>Bubble: A gas pocket in a plastic molded part. For a coating, it is the same as blister. 中译: 气泡一个气体包覆(中空)在塑胶件上,对烤漆 来说,与blister意义相同 7>Burn Mark: A condition where supper-heated trapped air in the cavity heats or burns the surface of the plastic part. 中译: 焦痕 8>Burr:This defect appears as a rough or sharp edge on metal after it has been cast, cut, drilled, stamped, and so forth. Burrs will

不良现象英文翻译

中文名称英文名称中文名称英文名称 管脚长lead long 屏蔽罩击穿shield breakdown 脱脚lead pull off PCB不清洁PCB dirty 弯脚角度大lead bend angle big PCB变形PCB deformation 弯脚角度小lead bend angle small PCB来料不良Incoming PCB NG 元件插反component insert inverse PCB线路不良Circuit NG on PCB 元件插错component insert wrong PCB有裂/缺PCB crack/flaw 元件漏插missing component 批峰burr 元件损伤component damaged 破损dilapidation 元件压铜皮component press pad 偏移shift 按键不良keystroke no click 气泡air bulb 按键装反keystroke assemble inverse 其它others 表盖刮伤surface cover scratch 日期印漏missing date code stamp 包焊excess solder 日期印错wrong date code stamp 标签不良label NG 日期印模糊date code stamp vague 标签刮伤label scratch 绕线交叉wrap wire cross 标签漏missing label 绕组不均匀wrap no even 标签来料不良incoming label NG 绕组错coil wrong 标签模糊label vague 输出插头松output plug loose 标签填错fill wronly in label 手插管脚长M/I lead long 标签贴错label stick wrongly 手插管脚短M/I lead short 标签贴反label stick inverse 输出.输入线破损output&input wire dameged 标签贴偏label stick with offset 少插跳线missing jumper wire 标签贴斜label stick lean 输出线断output wire open 标签有气泡label with air bulb 输出线内部错位output wire wrong inside 标签脏污label dirty 输出线头断output wire head breakdown 有灰尘dust 手插元件插错M/I component wrong 板响board with noise 手插元件插反M/I component inverse 保险管夹松fuse clip loose 手插元件多插M/I component excessive 变压器断线wire of transformer breakdown 手插元件高M/I component high 插错insert wrongly 手插元件漏插miss M/I component 初,次级绕反inverse 手插元件损伤M/I component damage 贴反mounting inverse 少垫片lack of gasket 次级对磁蕊短路secondary short to magnet 上盖变形upper case deformation 初级短路primary circuit short 少件lack of component 次级短路secondary circuit short 高件component raise up 初级断线open circuit in primary 红胶溢出red adhesive overflow 次级断线open circuit in secondary 竖件component stand up 初级胶带破tape damage in primary 少锡insufficient solder 次级胶带破tape damage in secondary 元件氧化component oxidize 初级圈数多excessive primary wrap 元件虚焊empty solder 初级圈数少insufficient primary wrap 元件短路component short circuit 次级圈数少insufficient secondary wrap 元件贴反component mount inverse 次级圈数多excessive secondary wrap 元件翘起component lift up 次级绕错匝数is wrong 元件损伤component damage 插破侧盖side cover break 元件偏移component excursion 插破骨架bobbin break 元件翻面component turnover 超声波压伤ultrasonic press injury 元件多贴excessive component 磁头装反magnetic core inverse 元件漏贴missing component 错位wrong position 元件脱落component break off 磁芯不干净magnetic core dirty 输入插头松input plug loose

不良现象中英文对照表

不良現象中英文對照表【字体:大中小】大家就看看吧,可以做在文件上. .缺件(MISSING PARTS) 28.腳未彎(PIN NOT BENT) 55.印章錯誤(WRONG STAMPS) 2.錯件(WRONG PARTS) 29.缺蓋章(MISSING STAMP) 56.尺寸錯誤(DIMENSION WRONG) 3.多件(EXCESSIVE PARTS) 30.缺標籤(MISSING LABEL) 57.二極體壞(DIODE NG) 4.短路(SHORT) 31.缺序號(MISSING S/N) 58.電晶體壞(TRANSISTOR NG) 5.斷路(OPEN) 32.序號錯(WRONG S/N) 59.振盪器壞(X’TL NG) 6.線短(WIRE SHORT) 33.標籤錯(WRONG LABEL) 60.管裝錯誤(TUBES WRONG) 7.線長(WIRE LONG) 34.標示錯(WRONG MARK) 61.阻值錯誤(IMPEDANCE WRONG) 8.拐線(WIRE POOR DDRESS) 35.腳太短(PIN SHORT) 62.版本錯誤(REV WRONG) 9.冷焊(COLD SOLDER) 36.J1不潔(J1 DIRTY) 63.電測不良(TEST FAILURE) 10.包焊(EXCESS SOLDER) 37.錫凹陷(SOLDER SCOOPED) 64.版本未標(NON REV LEBEL) 11.空焊(MISSING SOLDER) 38.線序錯(W/L OF WIRE) 65.包裝損壞(PACKING DAMAGED) 12.錫尖(SOLDER ICICLE) 39.未測試(NO TEST) 66.印章模糊(STAMPS DEFECTIVE) 13.錫渣(SOLDER SPLASH) 40.VR變形(VR DEFORMED) 67.標籤歪斜(LABEL TILT) 14.錫裂(SODER CRACK) 41.PCB翹皮(PCB PEELING) 68.外箱損壞(CARTON DAMAGED) 15.錫洞(PIN HOLE) 42.PCB彎曲(PCB TWIST) 69.點膠不良(POOR GLUE) 16.錫球(SOLDER BALL) 43.零件沾膠(GLUE ON PARTS) 70.IC座氧化(SOCKET RUST) 17.錫橋(SOLDER BRIDGE) 44.零件腳長(PARTS PIN LONG) 71.缺UL標籤(MISSING UL LABEL) 18.滑牙(SCREW LOOSE) 45.浮件(PARTS LIFT) 72.線材不良(WIRE FAILURE) 19.氧化(RUST) 46.零件歪斜(PARTS TILT) 73.零件腳損壞(PIN DAMAGED) 20.異物(FOREIGNER MATERIAL) 47.零件相ON GOLDEN FINGERS) 21.溢觸(PARTS TOUCH) 74.金手指沾錫(SOLDER膠(EXCESSIVE GLUE) 48.零件變形(PARTS DEFORMED) 75.包裝文件錯(RACKING DOC WRONG) 22.錫短路(SOLDER BRIDGE) 49.零件損壞(PARTS DAMAGED) 76.包裝數量錯(PACKING Q’TY WRONG) 23.錫不足(SOLDER INSUFFICIENT) 50.零件腳髒(PIN DIRTY) 77.零件未定位(PARTS UNSEATED) 24.極性反(WRONG POLARITY) 51.零件多裝(PARTS EXCESS) 78.金手指沾膠(GLUE ON GOLDEN FINGERS) 25.腳未入(PIN UNSEATED) 52.零件沾錫(SOLDER ON PARTS) 79.墊片安裝不良(WASHER UNSEATED) 26.腳未出(PIN UNVISIBLE) 53.零件偏移(PARTS SHIFT) 80.線材安裝不良(WIRE UNSEATED) 27.腳未剪(PIN NO CUT) 54.包裝錯誤(WRONG PACKING) 81. 立碑(TOMBSTONE)