S-3528WF0W00S-4x01A00+REV2.0

SPECIFICATIONS FOR HANGKE LED

TOP Model : HK S-3528WF0W00S

S-3528WF0W00S-4701A00 S-3528WF0W00S-4801A00

S-3528WF0W00S-4901A00

◆ ◆ .*. ◆ ◆ :°◆ ◆ :/IR reflow process compatible 3528mm SMD LEDS Low Power Consumption Wide View Angle 120Excellent Product Quality and Reliability

Package 2000pcs reel ◆ ◆ ◆ ◆ ◆ Optical Indicator

and Telecommunication Household Appliances

Decorative and Entertainment Lighting Backlighting

Automotive Features :

Applications :

典型应用? ? ? ? ? 光源指示

装饰和娱乐照明背光源

汽车和通讯室内应用

? ? 产品特点

可以通过红外热风回流焊接低功耗视角? ? 3528mm SMD LEDS ? 120? 2000.*. °

优良的品质和可靠性包装:只/盘

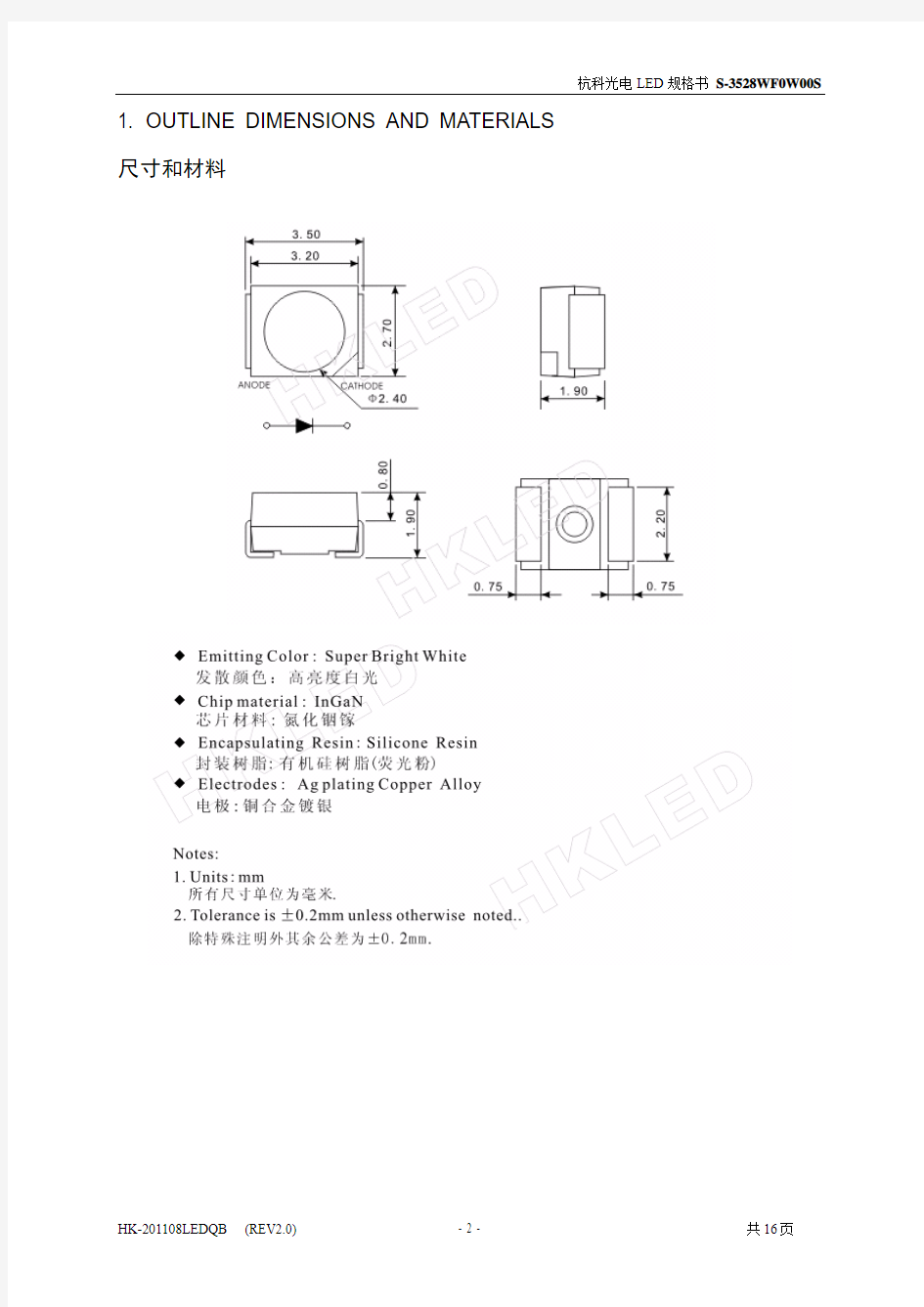

1. OUTLINE DIMENSIONS AND MATERIALS 尺寸和材料

2. SPECIFICATIONS

Absolute Maximum Ratings

绝对最大额定值

[1] IFP conditions: pluse width 10msec. and duty 0.1

IFP 条件: 脉冲宽度10msec. , 占空比0.1.

Initial Electrical/Optical Characteristics 初始光电特性

3. BIN CODE

Bin code form: X1X2X3X4

(1) X1 : Luminous Flux (If=20ma)

(2)X2 X3 : Correlated Color Temperature (If=20ma)

(3)X 4

: CRI Rank (If=20ma)

可靠性测试

5. REFLOW SOLDERING INSTRUCTIONS 回流焊说明

Profile Feature

Sn42Bi58Sn64Bi35Ag1

Preheat ramp-up rate 1 3 °C/second 1 3 °C/second T

100°C

110 °C 130 °C 160 °C 953(Tsmin to Tsmax)econd 2econd 138 °C

178 °C

5080second 6090 second

Tp (tp)

4 - -- -emperature min (Tsmin) Temperature max (Tsmax) Time (Tsmin to Tsmax) (t )

0-10 seconds 60-10 seconds Average ramp-up rate 2 °C/s max.

°C/s max.

Liquidous temperature (T )

Time at liquidous (t ) Peak temperature (Tp)

165 °C 215°C Time within 5 °C of the 20s 20s Average ramp-down rate (Tp to Tsmax)

4 °C/second max.

°C/second max.

s L L

Caution

1. Reflow soldering should not be done more than one time.

2. Precautions should be taken to avoid the strong pressure on the encapsulated part

3. After soldering, do not warp the circuit board.

4Recommend to use low temperature and medium soldering material If use high temperature soldering material will cause damage to the reliability of the LED 5. Recommend to use a convection type reflow machine with more than 8 zones.

6The preset temperature and actual temperature will have some difference in the reflow soldering machine Reflow soldering equipment temperature suggested to be set as below .

. . ,.

. .

.:

回流焊次数不得超过次.

封装部分须避免受到外部的强力挤压.

焊接完成后,不得弯曲线路板.

推荐使用低温或中温焊料.一旦使用高温焊料,可能会影响的可靠性.

推荐使用温区以上的回流焊焊接设备.

回流焊设备内实际温度和设置温度会存在一定程度的偏差.

回流焊设备温度设置可参考以下:

1LED LED 87

701952115313041455155616571458Sn42Bi58Sn64Bi35Ag1

100

130

140

160

190

210

215

190

Solder

6. TYPICAL INITIAL OPTICAL/ELECTRICAL CHARACTERISTICS 典型光电特性

Spectrum 光谱(Ta=25℃IF=20mA )

Directivity 配光曲线 (Ta=25℃ IF=20mA )

100%75%50%25%0%25%50%75%100%

Iv(%)

Forward Current & Forward Voltage

伏安特性曲线 (Ta=25℃ )

F o r w a r d C u r r e n t m A ()

Forward Voltage V ()

正向电流()

m A 正向电压()

V 50

40

302010020

.24.28.32.36.40

.

Relative Luminous Flux & Forward Current

相对光通量与正向电流关系特性

R e l a t i v e L u m i n o u s F l u x

Forward Current mA (

)

相对光通量

正向电流()

mA 05.10.15.20

.25

.050

40

30

20

10

Allowable Forward Current & Ambient Temperature

最大允许正向电流和环境温度关系特性

A l l o w a b l e F o r w a r d C u r r e n t m A ()

Am bient Tem perature Ta °C ()

最大允许正向电流()

m A 环境温度 Ta °C ()

504030201000

20

40

60

80

100

Relative Luminous Flux & Ambient Temperature

相对光通量和环境温度关系特性

20

40

60

80

100

-40-20

R e l a t i v e L u m i n o u s F l u x

Ambient Temperature Ta °C ()

相对光通量

环境温度 Ta °C ()

Luminous Flux Attenuation 光衰特性 (IF=20mA Ta=25°C)

L u m i n o u s F l u x o u t p u t

相对输出光通量

(%)

7. PACKING SPECIFICATIONS 包装说明

Units:mm

单位:mm

Quantitu:2000pcs/Reel

数量:2000只/卷