Gold Colloids from Cationic Surfactant Solutions. 1.

Gold Colloids from Cationic Surfactant Solutions.1.

Mechanisms That Control Particle Morphology

Epameinondas Leontidis,*,?Konstantina Kleitou,?Tasoula Kyprianidou-Leodidou,?Vlasoula Bekiari,?and Panagiotis Lianos?

Department of Chemistry,University of Cyprus,P.O.Box20537,1678Nicosia,Cyprus,and Engineering Science Department,University of Patras,GR-26500Patras,Greece

Received August29,2001.In Final Form:January23,2002

The mechanism of formation of gold particles by reduction of Au III in solutions of alcyltrimethylammonium chloride surfactants was studied in the absence and in the presence of NaCl.Au III anions interact strongly with trimethylammonium cations forming insoluble ion pairs(Torigoe et https://www.360docs.net/doc/fe14688218.html,ngmuir1992,8,59).Above the surfactant critical micelle concentration,the ion pairs are solubilized in the micelles returning to the solution.Gold particles were produced by photochemical reduction of the clear micellar solutions.The coupling between surfactant aggregation and inorganic crystallization phenomena in these systems was investigated using transmission electron microscopy(TEM),UV-vis,and time-resolved fluorescence spectroscopy.At concentrations close to the phase boundary of the L1phase with the lyotropic liquid crystalline phases many gold particles have a threadlike morphology,as previously noted by Esumi et al. (Langmuir1995,11,3285).The presence of NaCl modifies the micellar size and affects the gold crystallization process in surprising and unexpected ways,as evidenced by intermediate structures observed by TEM. Our observations support the idea that the formation of threadlike gold particles occurs primarily through a combination of crystal aggregation and specific crystal face stabilization and not through templating mechanisms.

I.Introduction

Gold colloids have fascinated science from the times of the alchemists.Although the modern era of research on gold colloids was initiated by Michael Faraday150years ago,1the scientific interest has always been strong.In recent years,the emergence of nanotechnology and the evolution of modern analytical methods that allow easy observation and manipulation of nanoparticles have created an explosion of interest in the synthesis and study of gold clusters and colloids.2A major current research theme is to tailor the size and shape of the particles at will using colloid chemistry methods.While size-control and stabilization have been demonstrated in numerous cases, and ingenious new methods for the production and stabilization of gold nanoparticles have been reported,3 only a limited number of papers dealing with effective shape control of gold particles exists in the literature. Controlling the shape of nanoparticles is technologically important,since the optical,electronic,magnetic,and catalytic properties of a nanomaterial often depend critically not only on particle size but also on particle shape.4In the case of gold,for example,it was recently demonstrated that the longitudinal plasmon resonance shifts to higher wavelengths with increasing aspect ratio of the particles5and also that nanoparticles with a high aspect ratio exhibit a strong fluorescence enhancement.6 Forcing colloidal particles to acquire a nonspherical, elongated shape is no easy matter as it involves a fight against thermodynamics,which dictates that the mini-mum free energy structure is that with the minimum specific area,hence a sphere,a cube,or some other compact shape.Forcing gold particles to acquire shapes with high aspect ratios using wet chemical routes has been dem-onstrated only in a handful of experimental systems to date.In all these cases it is either certain or possible that a templating mechanism is operating.The rodlike gold particles,prepared in the pores of alumina membranes by electrochemical reduction,are a clear demonstration of the success of a hard template.7Formation of rodlike gold particles by an electrochemical reduction method in a surfactant solution was demonstrated by the group of

*To whom all correspondence should be addressed.?University of Cyprus.

?University of Patras.

(1)Faraday,M.Philos.Trans.R.Soc.London,Ser.A1857,147,145.

(2)(a)Henglein,A.Top.Curr.Chem.1988,143,113.(b)Henglein,

A.Chem.Rev.1989,89,1861.(c)Schmid,G.Chem.Rev.1992,92,1709.

(d)Wang,Z.-L.Adv.Mater.1998,10,13.(e)Templeton,A.C.;Wuelfing, P.W.;Murray,R.W.Acc.Chem.Res.2000,33,27.

(3)(a)Brust,M.;Walker,M.;Bethell,D.;Schiffrin,D.J.;Whyman, https://www.360docs.net/doc/fe14688218.html,mun.1994,801.(b)Yee,C.K.;Jordan,R.;Ulman,A.; White,H.;King,A.;Rafailovich,M.;Sokolov,https://www.360docs.net/doc/fe14688218.html,ngmuir1999,15, 3486.(c)Templeton,A.C.;Chen,S.;Gross,M.;Murray,https://www.360docs.net/doc/fe14688218.html,ngmuir 1999,15,66.(d)Han,M.Y.;Quek,C.H.;Huang,W.;Chew,C.H.;Gan, L.M.Chem.Mater.1999,11,1144.(e)Warner,M.G.;Reed,S.M.; Hutchison,J.E.Chem.Mater.2000,12,3316.(f)Bronstein,L.M.; Chernyshov,D.M.;Valetsky,P.M.;Wilder,E.A.;Spontak,R.J. Langmuir2000,16,8221.(g)Brown,K.R.;Walter,D.G.;Natan,M. J.Chem.Mater.2000,12,306.(h)Zhou,Y.;Itoh,H.;Uemura,T.;Naka, K.;Chujo,https://www.360docs.net/doc/fe14688218.html,mun.2001,613.(i)Yonezawa,T.;Yasui,K.; Kimizuka,https://www.360docs.net/doc/fe14688218.html,ngmuir2001,17,271.(j)Shon,Y.-S.;Wuelfing,P.W.; Murray,https://www.360docs.net/doc/fe14688218.html,ngmuir2001,17,1255.

(4)(a)Creighton,J.A.;Eadon,D.G.J.Chem.Soc.,Faraday Trans. 1991,87,3881.(b)Dirix,Y.;Bastiaansen,C.;Caseri,W.;Smith,P.Adv. Mater.1999,11,223.(c)Dickson,R.M.;Lyon,L.A.J.Phys.Chem.B 2000,104,6095.

(5)(a)Van der Zande,B.M.I.;Bo¨hmer,M.R.;Fokkink,L.G.J.; Scho¨nenberger,C.J.Phys.Chem.1997,101,852.(b)Link,S.;Mohamed, M.B.;El-Sayed,M.A.J.Phys.Chem.B1999,103,3073.(c)Link,S.; El-Sayed,M.A.J.Phys.Chem.B1999,103,8410.

(6)Mohamed,M.B.;Volkov,V.;Link,S.;El-Sayed,M.A.Chem. Phys.Lett.2000,317,517.

(7)(a)Tierney,M.J.;Martin,C.R.J.Phys.Chem.1989,93,2878.

(b)Foss,C.A.;Tierney,M.J.,Martin,C.R.J.Phys.Chem.1992,96, 9001.(c)Foss,C.A.;Hornyak,G.L.;Stockert,J.A.;Martin,C.R.J. Phys.Chem.1994,98,2963.(d)Hornyak,G.L.;Patrissi,C.J.;Martin, C.R.J.Phys.Chem.B1997,101,1548.(e)Al-Rawashdeh,N.A.F.; Sandrock,M.L.;Seugling,C.J.;Foss,C.A.J.Phys.Chem.B1998,102, 361.(f)Van der Zande,B.M.I.;Bo¨hmer,M.R.;Fokkink,L.G.J.; Scho¨nenberger,https://www.360docs.net/doc/fe14688218.html,ngmuir2000,16,451.

3659

Langmuir2002,18,3659-3668

10.1021/la011368s CCC:$22.00?2002American Chemical Society

Published on Web04/02/2002

Wang8and postulated to depend on some unidentified templating mechanism.Gold particles formed with the previous two methods have been used in very interesting experiments,including thermal and laser-shape anneal-ing9and examination of the crystal faces by high-resolution transmission electron microscopy(TEM),10while they have shown interesting light propagation,4c absorption,5fluo-rescence,6and self-assembly11properties.A third method to produce long,threadlike gold particles s although not exclusively s was advanced by Esumi and Torigoe in a series of publications.12In their method,gold particles are produced by photochemical reduction in the presence of cationic surfactant micelles.The authors expressed the opinion that the templating effect of rodlike micelles is essential for the formation of particles with very large aspect ratios in these systems.12b,e

Despite the reported successful attempts to modify gold crystal shapes in surfactant solutions,8,12little is known about the actual mechanism behind shape control.Rela-tively few recent studies are concerned with the formation mechanism of gold colloids,13even though such studies have appeared in much older pioneering work.14While important investigations using theγ-irradiation method have focused on the reduction steps of the reaction AuCl4-f Au0f Au n,15gold particle formation by photoreduction in the presence of surfactants and electrolytes is little understood.

We have decided to further investigate the formation of gold particles in trimethylammonium surfactant solu-tions to achieve a better understanding of the crystal-lization process in the presence of surfactant aggregates. The solution of cationic trimethylammonium surfactants is simpler than other systems that have been used so far. In addition,these surfactants appear to play a rather unique role in crystallizing systems,as they are involved in a variety of cases,in which rodlike particles are formed. The most notable example is the synthesis of a large range of mesoporous zeolites,which is thought to involve either cylindrical micelles or the organization of micelles into bundles during the gelation process.16Other cases include the electrochemical method of Wang discussed before,8 the production of silver through reduction by ascorbic acid,17and the formation of nanowires of CdS and Mo3Se3-.18We would like to understand the formation mechanism of the rodlike or threadlike particles.Is this really a templating mechanism,requiring the presence of long micelles or not?There is much discussion about“soft”templating phenomena in surfactant solutions in the literature.Important work by the group of Pileni,which examines the formation of rodlike Cu particles in sur-factant lyotropic phases,is a related example.19Recent evidence from Pileni’s group suggests that templating is not the only and sometimes probably not the dominant force operating in the particle production process.19c,d A second issue that we address for the first time in this work is the effect of additional electrolyte on gold crystallization.Ions present in such solutions may not only affect micellar sizes and shapes and gold particle interactions but also interfere with the photochemical reduction process and affect the activity and solubility of various components.Finally,ions affect the coordination chemistry of Au III,a fact that is overlooked in recent literature.To examine electrolyte effects on gold particle growth,we have conducted parallel experiments in the presence and absence of excess NaCl.

Wishing to keep the crystallizing system as simple as possible,we have opted to avoid stabilizers or chemical reducing agents and have used photochemical reduction almost exclusively in this work.Photochemical reduction has been used as a method for the preparation of gold colloids in several recent publications.12,20Its main disadvantage is that it does not permit efficient nucleation control:nuclei are continuously formed,as long as gold precursor ions exist in solution.

We make extensive use of TEM to investigate gold particle formation.TEM has been used to study gold crystal formation already from the early years of its invention14and is a necessary tool in gold nanoparticle research.21The main disadvantage of TEM is that one must remove the solvent before viewing the particles, which sometimes leads to aggregate formation on the TEM grid.22Finally,time-resolved fluorescence spectroscopy with pyrene as a fluorescent probe is used to examine potential changes in the surfactant aggregates present in our solutions.Fluorescence was preferred over the more

(8)(a)Yu,Y.-Y.;Chang,S.-S.;Lee,C.-L.;Wang,C.R.J.Phys.Chem. B1997,101,6661.(b)Chang,S.-S.;Shih,C.-W.;Chen,C.-D.;Lai,W.-

C.;Wang,https://www.360docs.net/doc/fe14688218.html,ngmuir1999,15,701.

(9)(a)Mohamed,M.B.;Ismail,K.Z.;Link,S.;El-Sayed,M.A.J. Phys.Chem.B1998,102,9370.(b)Link,S.;Burda,C.;Mohamed,M.

B.;Nikoobakht,B.;El-Sayed,M.A.J.Phys.Chem.A1999,103,1165.

(c)Mohamed,M.B.;Wang,Z.L.;El-Sayed,M.A.J.Phys.Chem.B 1999,103,10255.(d)Takami,A.;Kurita,H.;Koda,S.J.Phys.Chem. B1999,103,1226.(e)Maye,M.M.;Zheng,W.;Leibowitz,F.L.;Ly,N.

K.;Zhong,https://www.360docs.net/doc/fe14688218.html,ngmuir2000,16,490.

(10)(a)Wang,Z.L.;Mohamed,M.B.;Link,S.;El-Sayed,M.A.Surf. Sci.1999,440,L809.(b)Wang,Z.L.J.Phys.Chem.B2000,104,1153.

(c)Wang,Z.L.;Gao,R.P.;Nikoobakht,B.;El-Sayed,M.A.J.Phys. Chem.B2000,104,5417.

(11)(a)Nikoobakht,B.;Wang,Z.L.;El-Sayed,M.A.J.Phys.Chem. B2000,104,8635.(b)Dujardin,E.;Hsin,L.-B.;Wang,C.R.C.;Mann, https://www.360docs.net/doc/fe14688218.html,mun.2001,1264.

(12)(a)Torigoe,K.;Esumi,https://www.360docs.net/doc/fe14688218.html,ngmuir1992,8,59.(b)Esumi,K.; Matsuhisa,K.;Torigoe,https://www.360docs.net/doc/fe14688218.html,ngmuir1995,11,3285.(c)Esumi,K.; Megumi,N.;Aihara,N.;Usui,K.New J.Chem.1998,22,719.(d)Esumi, K.;Hara,J.;Aihara,N.;Usui,K.;Torigoe,K.J.Colloid Interface Sci. 1998,208,578.(e)Kameo,A.;Suzuki,A.;Torigoe,K.;Esumi,K.J. Colloid Interface Sci.2001,241,289.

(13)(a)Chen,S.;Templeton,A.C.;Murray,https://www.360docs.net/doc/fe14688218.html,ngmuir2000, 16,3543.(b)Jana,N.R.;Gearheart,L.;Murphy,C.J.Chem.Mater. 2001,13,2313.(c)Okitsu,K.;Yue,A.;Tanabe,S.;Matsumoto,H.; Yobiko,https://www.360docs.net/doc/fe14688218.html,ngmuir2001,17,7717.

(14)Turkevich,J.;Stevenson,P.C.;Hillier,J.Discuss.Faraday Soc. 1951,11,55.

(15)(a)Kurihara,K.;Kizling,J.;Stenius,P.;Fendler,J.H.J.Am. Chem.Soc.1983,105,2574.(b)Mosseri,S.;Henglein,A.;Janata,E. J.Phys.Chem.1989,93,6791.(c)Gachard,E.;Remita,H.;Khatouri, J.;Keita,B.;Nadjo,L.;Belloni,J.New J.Chem.1998,22,1257.(d) Henglein,A.;Meisel,https://www.360docs.net/doc/fe14688218.html,ngmuir1998,14,7392.(e)Henglein,A. Langmuir1999,15,6738.(f)Bronstein,L.;Chernyshov,D.;Valetsky, P.;Tkachenko,N.;Lemmetyinen,H.;Hartmann,J.;Fo¨rster,S. Langmuir1999,15,83.

(16)(a)Beck,J.S.;Vartuli,J.C.Curr.Opin.Solid State Mater.Sci. 1996,1,76.(b)Ying,J.Y.;Mehnert,C.P.;Wong,M.S.Angew.Chem., Int.Ed.1999,38,56.

(17)(a)Jana,N.R.;Gearheart,L.;Murphy,https://www.360docs.net/doc/fe14688218.html,mun. 2001,617.(b)Jana,N.R.;Gearheart,L.;Murphy.C.Adv.Mater.2001, 13,1389.

(18)(a)Chen,C.-C.;Chao,C.-Y.,Lang,Z.-H.Chem.Mater.2000,12, 1516.(b)Messer,B.;Song,J.H.;Huang,M.;Wu,Y.;Kim,F.;Yang,P. Adv.Mater.2000,12,1526.

(19)(a)Pileni,M.-P.;Gulik-Krzywicki,T.;Tanori,J.;Filankembo,

A.;Dedieu,https://www.360docs.net/doc/fe14688218.html,ngmuir1998,14,7359.(b)Pileni,M.-P.;Ninham,

B.W.;Gulik-Krzywicki,T.;Tanori,J.;Lisiecki,I.;Filankembo,A.Adv. Mater.1999,11,1358.(c)Filankembo,A.;Pileni,M.-P.J.Phys.Chem. B2000,104,5865.(d)Pileni,https://www.360docs.net/doc/fe14688218.html,ngmuir2001,17,7476.

(20)(a)Yonezawa,Y.;Sato,T.;Ohno,M.;Hada,H.J.Chem.Soc., Faraday Trans.11987,83,1559.(b)Itakura,T.;Torigoe,K.;Esumi, https://www.360docs.net/doc/fe14688218.html,ngmuir1995,11,4129.(c)Sato,T.;Ito,T.;Iwabuchi,H.;Yonezawa, Y.J.Mater.Chem.1997,7,1837.(d)Moriguchi,I.;Fujiyoshi,N.; Sakamoto,R.;Teraoka,Y.;Kagawa,S.Colloids Surf.,A1997,126,159.

(e)Ravaine,S.;Fanucci,G.E.;Seip,C.T.;Adair,J.H.;Talham,D.R. Langmuir1998,14,708.(f)Zhou,Y.;Wang,C.Y.;Zhu,Y.R.;Chen, Z.Y.Chem.Mater.1999,11,2310.(g)Han,M.Y.;Quek,https://www.360docs.net/doc/fe14688218.html,ngmuir 2000,16,362.

(21)Wang,Z.L.J.Phys.Chem.B2000,104,1153.

(22)(a)Ohara,P.C.;Heath,J.R.;Gelbart,W.M.Angew.Chem.,Int. Ed.Engl.1997,36,1078.(b)Haidara,H.;Mougin,K.;Schultz,J. Langmuir2001,17,659.(c)Maillard,M.;Motte,L.;Pileni,M.-P.Adv. Mater.2001,13,200.

3660Langmuir,Vol.18,No.9,2002Leontidis et al.

conventional scattering methods for reasons that will become apparent below.

II.Experimental Section

Chemicals.Tetrachloroauric acid(HAuCl4),its sodium salt (NaAuCl4),pyrene,and dodecyl-(DTAC)and hexadecyltri-methylammonium chloride(CTAC)were obtained from Fluka. All other chemicals were obtained from Sigma,Aldrich,or Fluka. All were of analytical grade and used without further purification.

Solution Preparation.Dilute solutions were simply made by mixing appropriate volumes of separate aqueous solutions of AuCl4-(5mmol/L),surfactant(usually0.1M),and electrolyte. For concentrated solutions(25-45wt%surfactant),we dissolve the appropriate amount of solid surfactant within an aqueous solution containing the gold salt and the electrolyte.Concentrated DTAC solutions were found to have a density close to that of pure water.For DTAC,which was used much more extensively, a solution of35wt%is roughly1.3M.For the concentrated surfactant solutions,we have kept the molar ratio,r g,of gold to surfactant equal to1/60,which we prove below to be sufficient for complete solubilization of the gold-surfactant ion pair in the micelles.Fresh solutions were used for reduction;they were protected to avoid partial gold reduction by ambient light.

Gold(III)Reduction.The photochemical reduction of the gold solutions was carried out under air,using a high-pressure 400-W Hg lamp.Although some oxidation of newly formed gold nanocrystals is possible and has been reported in some cases,15e,23 gold is much less sensitive than other metals.Previous photo-chemical work with gold was also made mostly under air.12,20 Three to four milliliters of the solutions were placed in small glass vials with a wide opening.The vials were held inside a jacketed beaker that contained water thermostated at25°C. This precaution was found necessary,since the powerful Hg lamp can heat up the samples significantly.Loss of water by evapora-tion during the reduction process can be particularly troublesome, especially for concentrated surfactant solutions that are close to the phase boundaries with lyotropic phases.After the prescribed reduction time,each vial was removed,capped with Parafilm, covered with aluminum foil,and stored in a dark place,prior to further analysis.We have also occasionally reduced Au III with sodium borohydride or hydrazine,but we invariably found that, in the absence of specific stabilizers,chemical reduction proceeds always in a fast,uncontrollable way and produces large ag-gregates.

Spectroscopic Measurements.UV-vis absorption spectra of gold-containing surfactant solutions were obtained on a Shimadzu UV-160A or on a UV-1601spectrometer.FTIR spectra of the ion pairs that precipitate upon mixing equal amounts of surfactant cations and AuCl4-were measured with the KBr pellet method on a Shimadzu FTIR-8900spectrometer.Time-resolved fluorescence measurements were made by registering fluores-cence decay profiles with the photon-counting technique,using a homemade nanosecond hydrogen flash lamp and ORTEC electronics.

Electron Microscopy.TEM was performed at the Institute of Neurology and Genetics,Cyprus,on a JEOL-1010A instrument, with an acceleration voltage of80kV.Drops of the solutions were put on Formvar-coated grids and left there a few minutes for water evaporation.Concentrated solutions(25-45wt% surfactant)were diluted with sufficient amounts of water,before being examined by TEM.

III.Results

III.1.On Ion-Pair Formation between DTAC and AuCl4-and the Coordination of Au III.To understand the gold reduction results presented below,we must first consider two important points.The first is the formation of insoluble1:1ion pairs between AuCl4-and cationic surfactants,12,24a general phenomenon exhibited by other complex ions of heavy metals,25which has been effectively used for the production of mesostructured materials from alkylamines.26

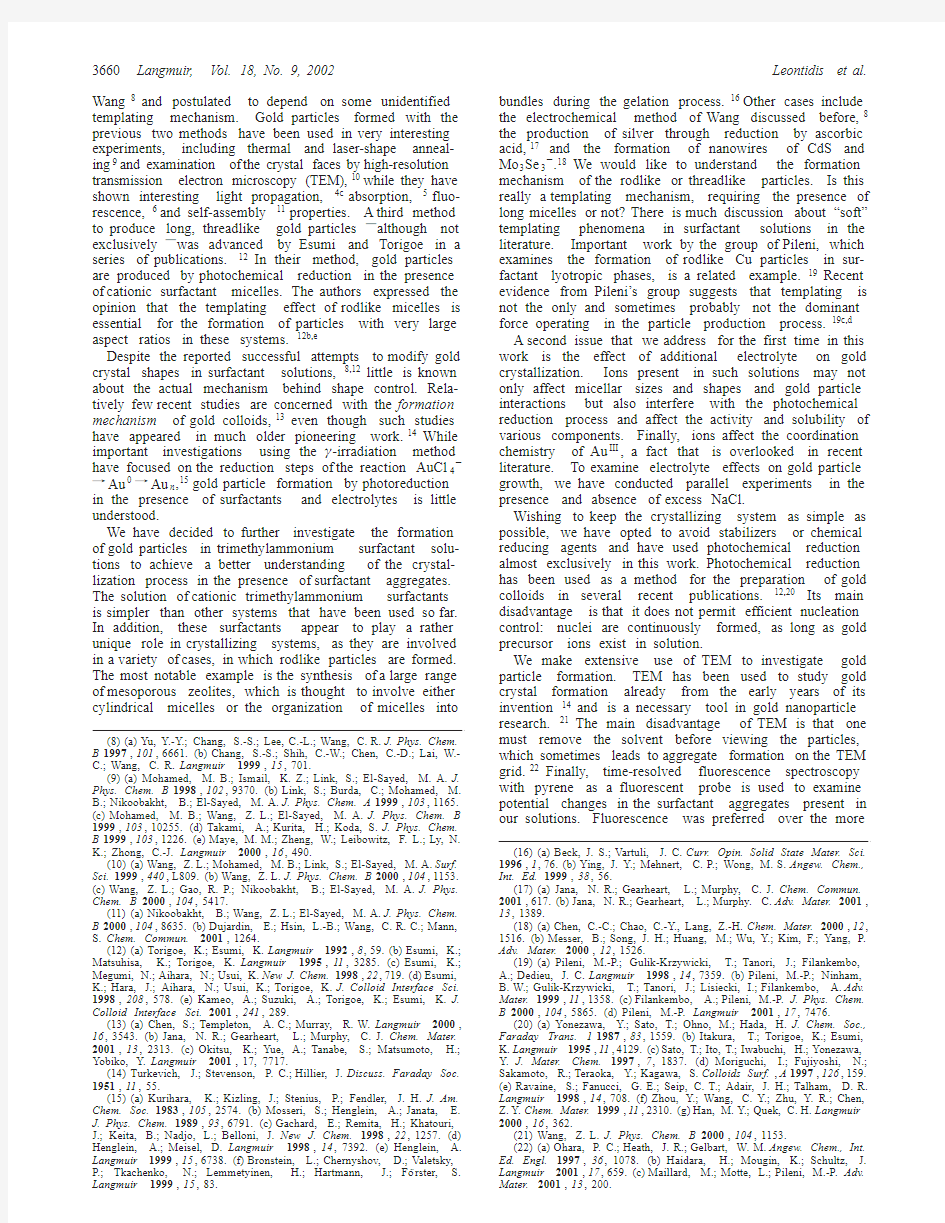

Esumi et al.have observed that the ion pairs formed between C n TAC and AuCl4-can be solubilized in the micelles formed in excess surfactant.Because we would like to work with clear solutions and avoid precipitates that would hinder our mechanistic investigation,we identified the surfactant-to-gold ratio,beyond which complete dissolution of the precipitated ion-pairs occurs, in the absence and in the presence of1M NaCl.We have prepared solutions with a AuCl4-concentration of1 mmol/L and surfactant concentrations smaller than0.1 M.For small surfactant concentrations the final solutions were turbid as expected.Precipitation of the formed ion pairs was enhanced by centrifugation.The FTIR spectrum of the precipitate clearly showed all the expected bands of the dodelyltrimethylammonium ion.Increasing sur-factant concentration above the critical micelle concen-tration(cmc),we observed a gradual dissolution of the precipitate in the supernatant after centrifugation,with a corresponding increase of AuCl4-absorbance.The positions of the two principal gold bands are originally located at221and295nm in the absence of NaCl and at 228and312nm in the presence of NaCl.This is a proof that AuCl4-exists in its hydrolyzed form in the absence of NaCl in dilute DTAC solutions.However,with increas-ing DTAC concentration the gold-surfactant adducts return to the solution and the gold peaks are now found at235and332nm(Figure1a).This implies that the gold-surfactant adduct is solubilized intact in the micelles formed above the cmc,as already discussed by Esumi et al.12b,e In Figure1b we plot the absorbance of the solution at the new band maximum(332nm)and observe that(a) the absorbance starts increasing above the cmc(which is equal to20mmol/L for DTAC at25°C),27and(b)levels off at a surfactant concentration of60-70mmol/L. Observation(a)is a strong indication that we are dealing with a solubilization phenomenon involving the micelles. Observation(b)indicates that the ratio of micellized surfactant to Au III required for complete solubilization of the ion pairs is roughly equal to([DTAC]plateau-cmc)/ [AuCl4-]≈50.Given the aggregation numbers of DTAC micelles(50-100,see below),we anticipate that each micelle contains on average one to two gold-surfactant adducts.In the ensuing experiments we have kept the ratio r g)[Au III]/[DTAC]equal to1/60,with two goals in mind:(a)that all Au III species be associated with the surfactant micelles,and(b)that the solutions be clear and do not contain precipitates that would hinder the mechanistic investigation.

The second important point to consider is that AuCl4-is partly hydrolyzed through the following reaction:28-30 The equilibrium constant for this reaction at298K was reported to be equal to2.4×10-6M2in dilute aqueous

(23)Weaver,S.;Taylor,D.;Mills,https://www.360docs.net/doc/fe14688218.html,ngmuir1996,12,4618.

(24)(a)Buslaeva,T.M.;Sinitsyn,N.M.;Samarova,L.V.;Koteneva, N.A.Rus.J.Inorg.Chem.1989,34,882.(b)Moriguchi,I.;Fujiyoshi, N.;Sakamoto,R.;Teraoka,Y.;Kagawa,S.Colloids Surf.,A1997,126, 159.

(25)(a)Yonezawa,T.;Tominaga,T.;Richard,D.J.Chem.Soc.,Dalton Trans.1996,783.(b)Yonezawa,T.;Toshima,N.;Wakai,C.;Nakahara, M.;Nishinaka,M.;Tominaga,T.;Nomura,H.Colloids Surf.,A2000, 169,35.

(26)(a)Antonelli,D.M.;Ying,J.Y.Chem.Mater.1996,8,874.(b) Antonelli,D.M.;Ying,J.Y.Angew.Chem.,Int.Ed.Engl.1996,35,426.

(c)Antonelli,D.M.;Nakahira,A.;Ying,J.Y.Inorg.Chem.1996,35, 3126.(d)Liu,P.;Moudrakovski,I.L.;Liu,J.;Sayari,A.Chem.Mater. 1997,9,2513.(e)Do,J.;Jacobson,A.J.Chem.Mater.2001,13,2436.

(27)Malliaris,A.;Lang,J.;Zana,R.J.Colloid Interface Sci.1986, 110,237.

AuCl

4

-+H

2

O h AuCl

3

OH-+H++Cl-

Gold Colloids from Cationic Surfactant Solutions Langmuir,Vol.18,No.9,20023661

solutions,29although a smaller value (7×10-7M 2)has also been reported.30Further chloride substitution by hydroxide ions in the coordination sphere of gold is possible at very dilute solutions,while water may also play the role of ligand.Chemical equilibrium calculations show that in the absence of electrolyte and at small surfactant concentrations,a significant percentage of Au III must be in the form of AuCl 3OH -or of even more strongly hydrolyzed complexes,a fact corroborated by the spectra in Figure 1a.This may have an impact on the photore-duction process,since each complex species is character-ized by a different reduction potential,while a different reduction pathway may be followed in each case.However,at the high DTAC and NaCl concentrations used in the experiments presented in this work,there is always abundant chloride in the system,which should force most of the Au III to be in the AuCl 4-form.We have measured the pH of the 35%DTAC solutions and found it to be 2.37in the absence of NaCl and 2.45in the presence of NaCl.The overall AuCl 4-concentration being 0.022M,these pH values imply that the degree of hydrolysis of AuCl 4-before reduction may be as high as 20%.31

III.2.Time Evolution of Gold Particle Formation in the Absence and Presence of NaCl.According to recent results by Esumi’s group,12e threadlike gold par-ticles are obtained by irradiation in DTAC solutions,provided that the surfactant concentration is in excess of 20wt %.To examine the formation mechanism of threadlike gold particles in concentrated DTAC solutions,we have undertaken experiments,in which identical samples containing 35wt %DTAC and having ratio r g )1/60were irradiated for different periods of time.A second set of samples identical to the first,but also containing 0.65M NaCl,was investigated in a similar way.The sequence of TEM pictures presented in Figure 2was obtained for the salt-free case.Initially,small irregular aggregates of gold nuclei are observed.The individual nuclei are smaller than 5nm in size,their aggregates being of the order of 50nm (Figure 2a).After 10min of irradiation,the aggregates have undergone a sintering process (as manifested by their irregular contours)and continue growing to sizes of about 30nm (Figure 2b).One can observe numerous such compact particles with a relatively narrow size distribution.At 15min (picture available in the supporting material)a distribution of spherical particles with sizes ranging from 15to 75nm is observed.A wider size distribution is indeed expected as new nuclei are continuously formed in this system,because of the continuous irradiation.The TEM picture obtained from a sample after 35min of irradiation is revealing.In a collection of spherical particles,we now find some particles with rodlike shape and with morphol-ogy strongly suggestive of linear particle aggregation (pointed by arrows in Figure 2c).At the same time,we observe new nuclei continuously forming in the system.After 90min the system has evolved a number of particle morphologies ranging from spherical to rodlike,with a few large,thin,triangular or polygonal particles that are often observed in gold reduction work and are known to result from Ostwald ripening (Figure 2d).32For longer irradiation times the percentage of rodlike particles increases.

In the presence of excess NaCl,the TEM pictures are quite remarkable and present a completely different evolution of the crystallizing system (Figure 3).At times smaller than 15min we observe the formation of thin,irregular surfactant-based structures,as evidenced by their low electron contrast (Figure 3a).These structures appear to evolve into delicate dendritic forms after 30min of irradiation,which break up on the microscope grid (Figure 3b).We believe that these dendrites are genuine structures in the solution and not artifacts obtained upon drying of the solution on the TEM grids.Dendritic structures in similar systems are usually associated with diffusion-limited particle aggregation processes.33After 1h of irradiation time we observe numerous,surprising,large,crosslike structures,with segments as long as 1μm (Figure 3c).Nucleation of small spherical gold particles goes on at the same time.Figure 4is a close-up of one of these remarkable structures,the formation of which has not been observed before to our knowledge.The structures contain gold atoms (hence the contrast under the TEM),but they also contain surfactant,as evidenced by the fact

(28)Elding,L.I.;Gro ¨ning,A.-B.Acta Chem.Scand.A 1978,32,867.(29)Carlsson,L.;Lundgren,G.Acta Chem.Scand.1967,21,819.(30)Chateau,H.;Gadet,M.-C.;Pouradier,J.J.Chim.Phys.1966,63,269.

(31)AuCl 4-and AuCl 3OH -in these systems are expected to be bound on DTA +and do not exist free in solution.However,assuming that the equilibrium constant for the reaction in water (2.4×10-6M 2)still holds and neglecting ionic activity coefficients or the fact that the water concentration is not 55.5M,we obtain a hydrolysis degree for AuCl 4-equal to only 1.0%in the presence of 1M DTAC and without excess NaCl.A much higher hydrolysis degree is implied by the pH measure-ments (≈10-2.4/0.022)18%).

(32)(a)Bruche,B.Kolloid-Z .1960,170,97.(b)Milligan,W.O.;Morriss,R.H.J.Am.Chem.Soc.1964,86,3461.

(33)(a)Servan,https://www.360docs.net/doc/fe14688218.html,mun.1998,351.(b)Zhou,Y.;Yu,S.H.;Wang,C.Y.;Li,X.G.;Zhu,Y.R.;Chen,Z.Y.Adv.Mater.1999,11,

850.

Figure 1.UV absorption investigation of ion-pair formation between DTA +and AuCl 4.All solutions contained 1mmol/L AuCl 4-.(a)UV -vis spectra of solutions containing 0.2mmol/L DTAC (dashed line),0.2mmol/L DTAC and 1M NaCl (dashed-and-dotted line),and 80mmol/L (solid line)DTAC.(b)Solution absorbance at 332nm as a function of DTAC concentration for [DTAC]>cmc.A solubilization plateau can be seen above 60mmol/L.

3662Langmuir,Vol.18,No.9,2002Leontidis et al.

that they disintegrate under electron-beam focus (see Supporting Information).These structures are reproduc-ible and always appear in this system,although sometimes at shorter or longer irradiation times,depending on the amount of material in the sample,fluctuations in lamp intensity,etc.For longer irradiation times we observe the formation of very long threadlike gold particles,along with a smaller amount of particles of other morphologies,as was also observed in the absence of NaCl.When NaCl is present,however,the percentage of threadlike particles is much larger,and their length increases dramatically (Figure 3d).The sequence of structures in Figure 3and the dramatic differences in the crystallization evolution with and without NaCl strongly contradict the idea of gold particle templating by rodlike micelles .In fact,we have here the proof that surfactant structures other than micelles are present and may contribute to the reduction mechanism.

III.3.Photochemical Gold Reduction Experiments in CTAC Solutions.Esumi et al.12b,e have

performed

Figure 2.TEM pictures showing the time evolution of gold-particle formation in salt-free solutions containing 35%DTAC and AuCl 4-with r g )1/60:(a)5min;(b)10min;(c)35min;(d)90min.

Gold Colloids from Cationic Surfactant Solutions Langmuir,Vol.18,No.9,20023663

extensive gold photoreduction experiments in CTAC solutions;therefore we will not present our own results here.Esumi et al.attributed the formation of threadlike particles to a templating effect of the large micelles formed in this system above a surfactant concentration of roughly 1.2M,12,34while a sphere-to-rod transition for CTAC is already documented at 7.5wt %.34c In the presence of

high NaCl concentrations,CTAC has been reported to form flexible,wormlike micelles.34b,c However,DTAC does not form large rodlike micelles,even at high external NaCl concentration,34a since it has a much shorter alkyl chain.34

(34)(a)Ozeki,S.;Ikeda,S.Bull.Chem.Soc.Jpn.1981,54,552.(b)Imae,T.;Ikeda,S.Colloid Polym.Sci.1987,265,1090.(c)Lee,Y.S.;Surjadi,D.;Rathman,https://www.360docs.net/doc/fe14688218.html,ngmuir 1996,12,

6202.

Figure 3.TEM pictures showing the time evolution of gold-particle formation in solutions containing 0.65M NaCl,35%DTAC,and AuCl 4-with r g )1/60:(a)15min;(b)30min;(c)1h;(d)8h.

3664Langmuir,Vol.18,No.9,2002Leontidis et al.

In our experiments with CTAC we have found that rodlike gold particles are formed only after considerably longer irradiation times than is the case with DTAC,even in the presence of excess NaCl.This relative difficulty of forming rodlike gold particles in CTAC systems contradicts the micellar templating model .To further assess the micellar templating idea,we have performed dynamic fluorescence measurements to measure how the DTAC and CTAC micelles develop in the presence of NaCl and AuCl 4-and also upon gold particle formation.To our knowledge such extensive measurements have not been performed before in the presence of Au III anions and gold particles.We have preferred the dynamic fluorescence method to more conventional light scattering,because the complexity of the structures observed in the presence of gold particles (Figures 2and 3)would render the light scattering results impossible to interpret.

III.4.Time-Resolved Pyrene Fluorescence Prob-ing.The number of micelles in a given aqueous micellar solution can be counted by time-resolved fluorescence probing.A micelle-bound fluorophore is introduced in the micellar solution,together with a micelle-bound quencher.By analyzing the intramicellar quenching kinetics using standard models,one can deduce the number of micelles,given the number of quencher molecules and provided that a certain statistics of quencher distribution is adopted.A standard probe of the aqueous micellar environment,used for a long time by numerous researchers,is pyrene,a hydrophobic molecule that binds to the dispersed phase in aqueous micellar solutions.36-38In the case of aqueous micelles,pyrene is both the fluorophore and the quencher,

since it can quench monomer fluorescence by excimer https://www.360docs.net/doc/fe14688218.html,ually,pyrene is solubilized at concentrations comparable with the concentration of micelles,and it is accepted that its distribution among micelles follows Poisson statistics.36We have used pyrene decay kinetics to count micelles in solution by analyzing monomer fluorescence decay profiles with the following model:39

A 2)1/τ0,where τ0is the decay time in the absence of quenching;A 3)[P]/[M],where [P]is the pyrene concen-tration and [M]is the micellar concentration;A 4)k q ,which is the pseudo-first-order intramicellar quenching rate constant.The above parameters are valid if we accept that there is no quencher migration among micelles.39Given the pyrene concentration [P],the micellar concen-tration [M]can be directly obtained by fitting the model of eq 1to the decay profile.The micellar aggregation number N ,a measure of the micellar size,can also be calculated by the following formula for a specific surfactant concentration c s

where cmc is the critical micelle concentration and [M]is the micellar concentration.Another important parameter to be deduced from eq 1is the intramicellar quenching rate,k q .Increase or decrease of k q is an index of structural variations in the https://www.360docs.net/doc/fe14688218.html,bination of k q and N can offer another useful parameter that characterizes micellar structure,the so-called microviscosity of the micellar environment,given by

V being the effective micellar volume,V )(n +1)N ,where n is the number of carbon atoms in the surfactant alkyl chain.40This correlation holds true for spherical or spheroidal micelles.40

The advantage of pyrene fluorescence in the systems studied here is that it focuses on the surfactant aggregates,while scattering methods would be strongly affected by the presence of the gold particles and would not yield useful information about micellar shape and size.We have verified that pyrene fluorescence is not affected by the presence of gold salts and particles and that quenching occurs only through excimer formation.We have calculated [M],k q ,N ,and ηi by pyrene time-resolved fluorescence analysis,and the results are tabulated in Tables 1and 2,for DTAC and CTAC,respectively.Inspection of Table 1reveals that the variation of DTAC concentration in the range 0.05-1.0M has a small effect on micellar size,which increases with surfactant concentration.Indeed,N was found to vary from 55to 68.These values are close to those found previously by others.41Addition of NaCl,in the range 0.1-1.0M caused a further increase of N ,which in the case of 1.0M DTAC and 1.0M NaCl was 96.The increase of the micellar size is accompanied by an analogous decrease of the intramicellar quenching rate,which is expected,since reaction efficiency decreases when

(35)(a)Israelachvili,J.N.;Mitchell,D.J.;Ninham,B.W.J.Chem.Soc.,Faraday Trans.21976,72,1525.(b)Gelbart,W.M.,Ben-Shaul,A.,Roux,D.,Eds.Micelles,Membranes,Microemulsions,and Mono-layers ;Springer-Verlag:New York,1994.

(36)Infelta,P.P.;Gratzel,M.J.Chem.Phys.1979,70,179.(37)Lianos,P.;Zana,R.J.Colloid Interface Sci.1981,84,100.

(38)Alargova,R.G.,Kochijashky,I.I.;Sierra,M.L.;Zana,https://www.360docs.net/doc/fe14688218.html,ngmuir 1988,14,5412.

(39)Zana,R.Surfactant Solutions :New Methods for Investigation ;Marcel Dekker:New York,1987.

(40)Anthony,O.;Zana,https://www.360docs.net/doc/fe14688218.html,ngmuir 1996,12,3590.

(41)Wikander,G.;Eriksson,P.-O.;Burnell,E.E.;Lindblom,G.J.Phys.Chem.1990,94,

5964.

Figure 4.Close-up of one of the crosslike particles of Figure 3c.

I (t ))I 0exp {-A 2t -A 3[1-exp(-A 4t )]}

(1)

N )

c s -cmc [M]

(2)

ηi ≈1/Vk q

(3)

Gold Colloids from Cationic Surfactant Solutions Langmuir,Vol.18,No.9,20023665

the effective reaction volume increases.On the contrary, the effective microviscosity of the micellar phase increased only slightly in going from the pure micellar phase to the one containing salt but remained,otherwise,unaffected by the change in the micellar size.These results indicate that the present micellar system does not suffer any important structural variations,either by changing sur-factant concentration or by introducing additional ionic strength.The micelles do increase in size and decrease in number,but they remain in the same structural domain, that of the small spheroidal micelles.In addition,the small micellar-charge neutralization effected by the DTA+AuCl4-pairs and the additional ionic strength induces a further small increase in the micellar size,without changing the micellar structural domain,i.e.,the micelles remain small and spheroidal.Finally,after UV irradiation of the solutions and the formation of gold colloidal particles,we have detected a further decrease in the number of micelles, which gives even higher N values.However,the un-changedηi values suggest that the micellar structural domain did not change even after formation of colloidal gold.Part of the surfactant may participate in the stabilization of the metal particles,but most of it is still expended in the formation of small spheroidal micelles. The case of CTAC micelles is very similar,as seen in Table2.CTAC micelles keep their size practically un-changed in the presence of AuCl4-or reduced gold,even when NaCl is present.Micellar size increases gradually with NaCl concentration,in agreement with the litera-ture.41,42The large wormlike CTAC micelles reported in other works34were obtained at conditions of very high external salt concentrations(2-4M NaCl),used appar-ently because they are relevant to the production of mesoporous zeolites.We have observed by TEM that high NaCl concentrations lead to significant salting-out of the surfactant,while NaCl itself is hard to dissolve in concentrated surfactant solutions(see TEM picture in Supporting Information),and we have opted to avoid such high salt concentrations.

The general conclusion of the fluorescence experiments is that in the range of system compositions that we have worked there exists no well-defined transition to rodlike micelles.The micellar aggregation number shows a slow, gradual increase with surfactant and gold concentration, but the most elongated micelles observed in these systems cannot have aspect ratios larger than2-2.5.43

IV.Final Discussion and Conclusions

The formation of gold particles in solutions containing trialkylammonium surfactants is a very complex process. We have focused on the formation of threadlike gold particles,initially reported in the interesting series of papers by Torigoe and Esumi.12Most of the evidence,which we have obtained from TEM and fluorescence spectros-copy,suggests that the rodlike or threadlike particle morphologies that dominate the distribution at long irradiation times do not originate from a templating mechanism.Time-resolved fluorescence results show that the surfactant micelles remain spheroidal even at35%

(42)(a)Hayter,J.B.;Penfold,J.Colloid Polym.Sci.1983,261,1022.

(b)Magid,L.J.;Han,Z.;Warr,G.G.;Cassidy,M.A.;Butler,P.D.; Hamilton,W.A.J.Phys.Chem.B1997,101,7919.

(43)Assuming spherocylinders with area per surfactant head equal to40?2,one deduces a micellar radius of13?.The aggregation number increases from55(for spheres)to125(for spheroids).From these data one obtains a cylinder length of34?,which yields an overall aspect ratio of2.3.

Table1.Data Obtained by Analysis of Pyrene Decay Profiles in Aqueous DTAC Micelles in the Absence and

Presence of Additives

surfactant concn

(M)NaCl

concn

(M)

AuCl4-

concn

(mM)

micelle

concn

(mM)

micellar

aggregation

no.(N)a

intramicellar

quenching

rate

constant

(107s-1)

micellar

micro-

viscosity

n i

No Additives

0.05000.5455 1.80.08

0.07000.9155 1.70.08

0.4000 6.8056 1.60.09

0.60009.4062 1.50.08

1.000014.468 1.40.08

Addition of NaCl

0.070.100.8658 1.50.09

0.07 1.000.6676 1.10.10

1.00.1014.866 1.20.10

1.00.3014.269 1.10.10

1.00.6011.1880.970.09

1.0 1.0010.2960.840.10

Addition of AuCl4-

0.07 1.00.070.6478 1.10.09

0.07 1.00.200.6083 1.00.10

0.07 1.00.600.5985 1.00.10

1.00.6 6.09.11080.750.09

1.0 1.00.0710.2960.840.09

1.0 1.00.109.71010.840.10

1.0 1.00.209.41040.760.09

1.0 1.00.409.11080.750.10

1.0 1.00.608.81110.750.09

1.0 1.0 6.08.41170.740.10

UV Treatment

0.07 1.00.070.7467 1.200.10

0.07 1.00.200.6676 1.100.09

0.07 1.00.600.63790.970.10

1.00.6 6.07.81250.620.10

1.0 1.00.078.11210.710.09

1.0 1.00.107.91240.650.10

1.0 1.00.207.91240.620.10

1.0 1.00.407.71270.610.10

1.0 1.00.607.41320.580.10

1.0 1.0 6.00.71380.560.10

a Micellar aggregation numbers,N,have been calculated by adopting that the cmc is20×10-3M.

Table2.Data Obtained by Analysis of Pyrene Decay Profiles in Aqueous CTAC Micelles in the Absence and

Presence of Additives

surfactant

concn

(M)

NaCl

concn

(M)

AuCl4-

concn

(mM)

micelle

concn

(mM)

micellar

aggregation

no.(N)a

intramicellar

quenching

rate

constant

(107s-1)

micellar

micro-

viscosity

n i

No Additives

0.07000.82840.610.16

0.4000 4.3930.590.14

0.75007.9950.540.15

Addition of NaCl

0.750.107.8960.570.14

0.750.307.6980.570.14

0.75 1.007.41010.510.15

Addition of AuCl4-

0.75 1.00.077.41010.510.14

0.75 1.00.107.41020.540.14

0.75 1.00.407.41020.500.15

0.75 1.00.607.41020.500.15

UV Treatment

0.75 1.00.077.41020.510.15

0.75 1.00.107.41020.540.15

0.75 1.00.407.41020.500.15

0.75 1.00.607.41020.500.15

a Micellar aggregation numbers,N,have been calculated by adopting that the cmc is1.6×10-3M.

3666Langmuir,Vol.18,No.9,2002Leontidis et al.

surfactant and in the presence of0.6-1M NaCl,in systems that produce a large percentage of threadlike gold particles.Some of the TEM evidence(see,e.g.,Figure2c) strongly suggests that threadlike particles evolve through a one-dimensional aggregation process.In fact,Figure2 suggests that a hierarchy of aggregation phenomena occurs:First,nuclei are aggregated and sintered into compact primary particles,then these particles themselves aggregate to form rodlike structures.Such two-level colloid aggregation processes have recently been observed and studied in the case of gold spheroids,44although aggrega-tion appears to be strongly directional in the present system.The remarkable sequence of structures observed in the presence of NaCl further weakens the micellar templating argument.The experimental fact that gold and surfactant concentration must be above certain thresholds for the threadlike particles to form12is a further argument in favor of the aggregation hypothesis.Why would such an aggregation pattern be favored in these systems?The phenomenon of crystal shape(or“habit”) modification by tailor-made substances is well-known and has been studied for many years by the crystal-growth community.45Recent work by the group of Alivisatos46 suggests that rodlike particle shapes can be obtained when a surfactant present in the system adsorbs specifically on a particular face of a growing crystal and stabilizes it, allowing the crystal to grow in different directions only. Surfactants are thus postulated to act as tailor-made additives.Production of silver nanowires in the presence of additives was also recently reported and assumed to occur because of preferential stabilization of specific crystal faces.47To generalize the previous ideas,one might propose that growth by aggregation occurs also under a similar limitation.Faces on which the surfactant adsorbs strongly would be better stabilized than other faces.The aggrega-tion would proceed by joining particles along faces,which are not properly stabilized.48,49d The resulting aggregates would then show defects,which however can be efficiently

healed,as was demonstrated in fundamental work by the group of El-Sayed.10c The rodlike particles produced by the Wang et al.method8were shown to be dominated by the theoretically unstable{110}faces,their axial growth direction being?112?.10a It may well be that we are looking at a similar growth phenomenon,but detailed high-resolution TEM work would be needed to clarify this issue. There has been much discussion in recent literature about the growth of crystals by primary crystal aggregation.49 It has been shown in several systems that the unique particle morphologies observed by electron microscopy are a result of particle aggregation.48,49In our system, surfactant molecules are used to stabilize an ever-increasing number of gold particles.The total percentage of surfactant expended to stabilize the particles is, however,rather small.We have made a rough estimate of the amount of surfactant adsorbed on gold particles for the35%DTAC and0.022M AuCl4-solution mostly used in this work.Assuming that all gold atoms can be found in particles with25nm radius and that the surfactant (with molecular length15?)forms bilayers on the particles50,51with average cross-sectional area40?2/ molecule,we find that only0.1%of the surfactant molecules adsorbs on the particles.The surfactant micelles do not change their size or shape in a significant way as the surfactant and gold concentrations in the system increase,even at1M NaCl,as indicated by the fluorescence decay results.

The most remarkable results of the present investigation were obtained in the presence of a high NaCl concentration in the surfactant solution.The obvious effect of NaCl is to increase the ionic strength and decrease electrostatic repulsion between micelles and particles,thus enhancing aggregation phenomena.However,this cannot be so important,since the ionic strength due to DTAC is already high.The unexpected evolution of the system through the crosslike structures of Figures3c and4implies that the surfactant may be salted out to a certain extent,because of the high salt concentration,forming a sequence of structures.The development of the gold crystals,through

(44)(a)Adachi,https://www.360docs.net/doc/fe14688218.html,ngmuir2000,16,6460.(b)Adachi,https://www.360docs.net/doc/fe14688218.html,ngmuir 2001,17,3863.

(45)(a)Addadi,L.;Berkovitch-Yellin,Z.;Weissbuch,I.;van Mil,J.; Shimon,L.J.W.;Lahav,M.;Leiserowitz,L.Angew.Chem.,Int.Ed. Engl.1985,24,466.(b)Sugimoto,T.;Itoh,H.;Mochida,T.J.Colloid Interface Sci.1998,205,42.

(46)Puntes,V.F.;Krishnan,K.M.;Alivisatos,A.P.Science2001, 291,215.

(47)Liu,S.,Yue,J.;Gedanken,A.Adv.Mater.2001,13,656.

(48)(a)Penn.R.L.;Banfield,J.F.Geochim.Cosmochim.Acta1999, 63,1549.(b)Banfield,J.F.;Welch,S.A.;Zhang,H.;Ebert,T.T.;Penn, R.L.Science2000,289,751.(c)Penn,R.L.;Oskam,G.;Strathmann, T.J.;Searson,P.C.;Stone,A.T.;Veblen,D.R.J.Phys.Chem.B2001, 105,2177.

(49)(a)OcaZa,M.;Rodriguez-Clemente,R.;Serna,C.J.Adv.Mater. 1995,7,212.(b)Goia,D.V.;Matijevic′,E.New J.Chem.1998,22,1203.

(c)Privman,V.;Goia,D.V.;Park,J.;Matijevic′,E.J.Colloid Interface Sci.1999,213,36.(d)Adair,J.H.;Suvaci,E.Curr.Opin.Colloid Interface Sci.2000,5,160.(e)van Hyning,D.L.;Klemperer,W.G.;Zukoski,C.

https://www.360docs.net/doc/fe14688218.html,ngmuir2001,17,3128.

(50)(a)Patil,V.;Mayya,K.S.;Pradhan,S.D.;Sastry,M.J.Am. Chem.Soc.1997,119,9281.(b)Shen,L.;Laibinis,P.E.;Hatton,T.A. Langmuir1999,15,447.

(51)Nikoobakht,B.;El-Sayed,https://www.360docs.net/doc/fe14688218.html,ngmuir2001,17,

6368. Figure5.Schematic of the processes leading to the production of threadlike gold particles:(a)ion-pair precipitation and subsequent solubilization in micelles;(b)formation of gold particles by UV irradiation,their stabilization by surfactant bilayers,and one-dimensional particle growth by aggregation of gold particles.

Gold Colloids from Cationic Surfactant Solutions Langmuir,Vol.18,No.9,20023667

continuous nucleation,disrupts and eventually terminates the crystal growth of the surfactant.Some of the significant NaCl effect must then be due to the drop in surfactant solubility.NaCl also slows down the photochemical formation of zerovalent gold,since it provides additional excess of Cl-ions,which affects some of the photochemical reactions.23A question mark still remains regarding the potential effect of Cl-concentration on Au III coordination. For the present system this effect should not be very significant,since the dissociation of DTAC already pro-vides a high Cl-concentration.

Our current understanding of the sequence of events during gold-particle production in this system is pre-sented schematically in Figure5.There we depict the initial precipitation of the gold-surfactant ion pair,its solubilization in the micelles,the gradual micellar growth observed by fluorescence,the initial formation of secondary gold particles,and their directional aggregation under the influence of preferential surfactant binding,to form long linear aggregates.The present work demonstrates once more that extensive mechanistic investigations are required to clarify inorganic crystallization phenomena in the complex surfactant systems increasingly used today in materials science applications.

Acknowledgment.We are grateful to Professor Paul Smith and Dr.Walter Caseri(Institut fu¨r Polymere,ETH, Zu¨rich)for their strong interest in this project,for their support in the early stages(initial experiments were performed in their laboratory),and for some preliminary TEM measurements.We are grateful to Ms.Konstantina Kapnisi,who performed exploratory experiments for her Undergraduate Diploma Thesis.We are finally grateful to Dr.Kyriacos Kyriacou and Mr.Andreas Zenios of the Department of Microscopy of the Institute of Neurology and Genetics(Nicosia,Cyprus)for support with the TEM measurements.This work was partly supported by research grants from the University of Cyprus to E.L. and by the Greek-French Cooperative Research Program (Platon),where Cyprus participated as a Mediterranean Partner.

Supporting Information Available:Images of gold particles produced after irradiation in surfactant and both salt and salt-free solutions and melting of crosslike structures by electron beams.This material is available free of charge via the Internet at https://www.360docs.net/doc/fe14688218.html,.

LA011368S

3668Langmuir,Vol.18,No.9,2002Leontidis et al.

实时频谱仪—工作原理

实时频谱分析仪(RTSA),这是基于快速傅利叶(FFT)的仪表,可以实时捕获各种瞬态信号,同时在时域、频域及调制域对信号进行全面分析,满足现代测试的需求。 一、实时频谱分析仪的工作原理 在存在被测信号的有限时间内提取信号的全部频谱信息进行分析并显示其结果的仪器主要用于分析持续时间很短的非重复性平稳随机过程和暂态过程,也能分析40兆赫以下的低频和极低频连续信号,能显示幅度和相位。 傅里叶分析仪是实时式频谱分析仪,其基本工作原理是把被分析的模拟信号经模数变换电路变换成数字信号后,加到数字滤波器进行傅里叶分析;由中央处理器控制的正交型数字本地振荡器产生按正弦律变化和按余弦律变化的数字本振信号,也加到数字滤波器与被测信号作傅里叶分析。正交型数字式本振是扫频振荡器,当其频率与被测信号中的频率相同时就有输出,经积分处理后得出分析结果供示波管显示频谱图形。正交型本振用正弦和余弦信号得到的分析结果是复数,可以换算成幅度和相位。分析结果也可送到打印绘图仪或通过标准接口与计算机相连。 二、实时频谱分析仪中的数字信号处理技术 1. IF 数字转换器 一般会数字化以中间频率(IF)为中心的一个频段。这个频段或跨度是可以进行实时分析的最宽的频率范围。在高IF 上进行数字转换、而不是在DC 或基带上进行数字转换,具有多种信号处理优势(杂散性能、DC抑制、动态范围等),但如果直接处理,可能要求额外的计算进行滤波和分析。 2. 采样 内奎斯特定理指出,对基带信号,只需以等于感兴趣的最高频率两倍的速率取样 3. 具有数字采集的系统中触发 能够以数字方式表示和处理信号,并配以大的内存容量,可以捕获触发前及触发后发生的事件。数字采集系统采用模数转换器(ADC),在深内存中填充接收的信号时戳。从概念上说,新样点连续输送到内存中,最老的样点将离开内存。

幻想战姬竞技场剑系4大战姬推荐

幻想战姬竞技场剑系4大战姬推荐 幻想战姬竞技场剑系4大战姬推荐,推荐幻想战姬竞技场剑系4大战姬。希望这篇幻想战姬竞技场剑系4大战姬推荐,能帮助到各位正在玩幻想战姬的玩家朋友们! 剑系第一名:花嫁妲己 排第一的毫无疑问是花嫁妲己,从属性上来看,姬65的花嫁接近4W血,1600的攻击。从技能上来说,后排主动高倍率全体AOE,被动贯通回能量。从卡面来看,呆萌的新娘子,你还要啥自行车? 这么完美的卡你有什么不练她的理由? 我想很多人都有打死对面三个后被花嫁一个AOE清场的经历,所以,这卡的评价,中低端局有个作为核心卡的能力,高端局则绝对是目前最强辅助。 剑系第二名:孙悟空 首先,大圣的血量足以支撑其撑在前排。并且前排主动技能贯通伤害的倍率也不错,大圣在前排,对对面除妲己以外的盾系职业来说都是毁灭性的打击。唯一的不足就是,大圣的后排技能略逗,放后排没什么意义。

剑系第三名:哪吒 首先我说要,哪吒后排的技能相当不错。在PVE中对很多难啃的BOSS有奇效,许多人都是靠天女和大腿的哪吒过的老牛,而且哪吒的攻击力成长也非常不错。但哪吒这卡有几个不协调的 缺点,首先,作为前排,血过少,不是很能抗,而且作为前排,贯通技能的倍率略感人,作为后排,虽然技能的眩晕3回合对PVP来说十分不错,发动实在太慢,很可能在发动前就会被打飞。

剑系第四名:钟馗姬 说实话,馗姬更适合推图,血量一般,前排AOE技能的倍率也一般。攻击虽然不错,但站不住的话就意义不大了,JJC中用的人也不算多。 最后说几张福袋剑卡

狂欢卡莉: 就是弱化版的后排钟馗姬,PVP价值不大。 心愿土特产: 技能相当优秀,奈何本身属性实在不行,本来是唯一可以痛打盾妲己的存在,奈何从属性上来看却不能对盾妲己造成什么实质的威胁。 华阳: 只能说技能看上很美,但是有两点致命缺点一、横扫回能量只回后排二、和贯通回能量不叠加。所以,实际来说,华阳很鸡肋。 另外,推荐非洲战神之一的赵萌萌,首充即送,初始相阶,成长却意外的还不错,前排技能倍率也很不错,是各位非洲大草原人民最忠实的好朋友,萌萌大法,千秋万代,一统江湖。 责任编辑【威尔】

频谱仪原理及使用方法

频谱仪原理及使用方法 频谱仪是一种将信号电压幅度随频率变化的规律予以显示的仪器。频谱仪在电磁兼容分析方面有着广泛的应用,它能够在扫描范围内精确地测量和显示各个频率上的信号特征,使我们能够“看到”电信号,从而为分析电信号带来方便。 1.频谱仪的原理 频谱仪是一台在一定频率范围内扫描接收的接收机,它的原理图如图1所示。 频谱分析仪采用频率扫描超外差的工作方式。混频器将天线上接收到的信号与本振产生的信号混频,当混频的频率等于中频时,这个信号可以通过中频放大器,被放大后,进行峰值检波。检波后的信号被视频放大器进行放大,然后显示出来。由于本振电路的振荡频率随着时间变化,因此频谱分析仪在不同的时间接收的频率是不同的。当本振振荡器的频率随着时间进行扫描时,屏幕上就显示出了被测信号在不同频率上的幅度,将不同频率上信号的幅度记录下来,就得到了被测信号的频谱。进行干扰分析时,根据这个频谱,就能够知道被测设备或空中电波是否有超过标准规定的干扰信号以及干扰信号的发射特征。 2.频谱分析仪的使用方法 要进行深入的干扰分析,必须熟练地操作频谱分析仪,关键是掌握各个参数的物理意义和设置要求。 (1)频率扫描范围 通过调整扫描频率范围,可以对所要研究的频率成分进行细致的观察。扫描频率范围越宽,则扫描一遍所需要时间越长,频谱上各点的测量精度越低,因此,在可能的情况下,尽量使用较小的频率范围。在设置这个参数时,可以通过设置扫描开始频率目”无“’。04朋和终止频率来确定,例如:startfrequeney=150MHz,stopfrequency=160MHz;也可以通过设置扫描中心频率和频率范围来确定,例如:eenterfrequeney=155MHz,span=10MHz。这两种设置的结果是一样的。Span越小,光标读出信号频率的精度就越高。一般扫描范围是根据被观测的信号频谱宽度或信道间隔来选择。如分析一个正弦波,则扫描范围应大于2f(f为调 制信号的频率),若要观测有无二次谐波的调制边带,则应大于4f。 (2)中频分辨率带宽 频谱分析仪的中频带宽决定了仪器的选择性和扫描时间。调整分辨带宽可以达到两个目的,一个是提高仪器的选择性,以便对频率相距很近的两个信号进行区别,若有两个频率成分同时落在中放通频带内,则频谱仪不能区分两个频率成分,所以,中放通频带越窄,则频谱仪的选择性越好。另一个目的是提高仪器的灵敏度。因为任何电路都有热噪声,这些噪声会将微弱信号淹没,而使仪器无法观察微弱信号。噪声的幅度与仪器的通频带宽成正比,带宽越宽,则噪声越大。因此减小仪器的分辨带宽可以减小仪器本身的噪声,从而增强对微弱信号的检测能力。根据实际经验,在测量信号功率时,一般来说,分辨率带宽RBW宜为

频谱分析仪使用注意

正确使用频谱分析仪需注意的几点 首先,电源对于频谱分析仪来说是非常重要的,在给频谱分析仪加电之前,一定要确保电源接法正确,保证地线可靠接地。频谱仪配置的是三芯电源线,开机之前,必须将电源线插头插入标准的三相插座中,不要使用没有保护地的电源线,以防止可能造成的人身伤害。 其次,对信号进行精确测量前,开机后应预热三十分钟,当测试环境温度改变3—5度时,频谱仪应重新进行校准。 三,任何频谱仪在输入端口都有一个允许输入的最大安全功率,称为最大输入电平。如国产多功能频谱分析仪AV4032要求连续波输入信号的最大功率不能超过+30dBmW(1W),且不允许直流输入。若输入信号值超出了频谱仪所允许的最大输入电平值,则会造成仪器损坏;对于不允许直流输入的频谱仪,若输入信号中含有直流成份,则也会对频谱仪造成损伤。 一般频谱仪的最大输入电平值通常在前面板靠近输入连接口的地方标出。如果频谱仪不允许信号中含有直流电压,当测量带有直流分量的信号时,应外接一个恰当数值的电容器用于隔直流。 当对所测信号的性质不太了解时,可采用以下的办法来保证频谱分析仪的安全使用:如果有RF功率计,可以用它来先测一下信号电平,如果没有功率计,则在信号电缆与频谱仪的输入端之间应接上一个一定量值的外部衰减器,频谱仪应选择最大的射频衰减和可能的最大基准电平,并且使用最宽的频率扫宽(SPAN),保证可能偏出屏幕的信号可以清晰看见。我们也可以使用示波器、电压表等仪器来检查DC及AC信号电平。 频谱分析仪的工作原理 频谱分析仪架构犹如时域用途的示波器,外观如图1.2所示,面板上布建许多功能控制按键,作为系统功能之调整与控制,系统主要的功能是在频域里显示输入信号的频谱特性.频谱分析仪

频谱仪的简单原理

频谱仪的简单原理 通常我们要对即将传输或者已经接收的信号进行分析,以获取我们所需要的信息。为了获取不同的信息我们通常将信号放在不同的域进行分析,如下图所示: 对于时域(时间和幅值)的分析我们通常采用示波器,获取信号的幅度、周期、频率等信息;对于频域(频率和幅值)的分析我们通常采用频谱分析仪,获取信号的频率、功率、谐波、噪声等信息;剩下的则是时间和频率的域,我们称之为矢量域,我们可以通过适量分析仪获取信号的幅度误差、矢量误差、相位误差等信息。现在的许多频谱分析仪也兼有矢量分析仪的功能。 按照工作原理分,频谱有两种基本的类型:实时频谱仪和扫频调谐式频谱仪。实时频谱仪包括多通道滤波器(并联型)频谱仪和FFT频谱仪。扫频调谐式频谱仪包括扫描射频调谐型频谱仪和超外差式频谱仪。其中超外差频谱仪应用最为广泛。 1.超外差频谱仪

如下图所示是典型的超外差频谱分析仪的实现框图: 原始输入信号首先经过一个低通滤波器,随后经过衰减器到达混频器以后,与来自本振的信号相混频。因为混频器本身就是非线性器件,所以输出信号除了包含两个原始的信号之外,还包含谐波,以及原始信号与谐波的差信号与和信号。如果混频信号落在中频滤波器的通带范围内,则信号会被进一步处理,中频信号再经过放大、滤波后送到检波器检波.检波输出信号经视频滤波器滤波,成为与输入信号功率幅度相对应的视频信号,体现在显示屏的Y轴上;扫频控制器将扫描电压与本振频率对应起来,改变频谱仪本振频率的同时将改变显示屏X轴的扫描电压。这样,频谱仪就可以将输入信号在不同频率处的功率幅度大小体现在显示屏上了。 假设频率轴上有一个特定的窗口,那么只有进入到该窗口内的信号才能被检测到,这就是它的基本原理。如果窗口从频率点f1 扫描到频率点f2,就可以得到不同频率上的信号功率,也就得到了被测信号

频谱仪原理与使用介绍

---------------------------------------------------------------最新资料推荐------------------------------------------------------ 频谱仪原理与使用介绍 2008年4月频谱仪原理与使用介绍主讲: 李家杰2008年4月频谱测量的意义频谱仪的工作原理 频谱仪各主要组件的功能频谱仪的正确使用频谱仪的各项参数设置介绍频谱仪的校准利用频谱仪进行测量的一些技巧2008年4月频谱测量的意义频谱分析仪对于信号分析来说是不可少的。 它是利用频率域对信号进行分析、研究,同时也应用于诸多领域,如通讯发射机以及干扰信号的测量,频谱的监测,器件的特性分析等等,各行各业、各个部门对频谱分析仪应用的侧重点也不尽相同。 2008年4月频谱测量的意义科学发展到今天,我们可以用许多方法测量一个信号,不管它是什么信号。 通常所用的最基本的仪器是示波器---观察信号的波形、频率、幅度等,但信号的变化非常复杂,许多信息是用示波器检测不出来的,如果我们要恢复一个非正弦波信号F,从理论上来说,它是由频率F1、电压V1与频率为F2、电压为V2信号的矢量迭加。 2008年4月频谱测量的意义从分析手段来说,示波器横轴表示时间,纵轴为电压幅度,曲线是表示随时间变化的电压幅度,这是时域的测量方法。 如果要观察其频率的组成,要用频域法,其横坐标为频率,纵 1 / 24

轴为功率幅度。 这样,我们就可以看到在不同频率点上功率幅度的分布,就可以了解这两个(或是多个)信号的频谱分布。 Atf时域频域2008年4月频谱测量的意义所以说有了这些单个信号的频谱,我们就能把复杂信号再现、复制出来。 这一点在我们要对复杂信号进行频率测量和分析时,是非常重要的,是时域分析所无法实现的。 2008年4月频谱仪的工作原理从技术实现来说,目前有两种方法对信号频率进行分析。 其一是对信号进行时域的采集,然后对其进行傅里叶变换,将其转换成频域信号。 我们把这种方法叫作动态信号的分析方法。 特点是比较快,有较高的采样速率,较高的分辨率。 即使是两个信号间隔非常近,用傅立叶变换也可将它们分辨出来。 2008年4月频谱仪的工作原理但由于其分析是用数字采样,所能分析信号的最高频率受其采样速率的影响,限制了对高频的分析。 目前来说,最高的分析频率只是在10MHz或是几十MHz,也就是说其测量范围是从直流到几十MHz。 是矢量分析。 这种分析方法一般用于低频信号的分析,如声音,振动等。 2008年4月频谱仪的工作原理另一方法原理则不同。