Electrospinning of Chitosan

Electrospinning of Chitosan

Kousaku Ohkawa,*1Dongil Cha,1Hakyong Kim,2Ayako Nishida,1Hiroyuki Yamamoto1

1Institute of High Polymer Research,Faculty of Textile Science and Technology,Shinshu University,Tokida3-15-1, Ueda386-8567,Japan

Fax:(t81)268-21-5571;E-mail:kohkawa@giptc.shinshu-u.ac.jp

2Department of Textile Engineering,Chonbuk National University,Chonju644-765,Republic of Korea

Received:June16,2004;Revised:July29,2004;Accepted:July30,2004;DOI:10.1002/marc.200400253 Keywords:chitosan;electron microscopy;electrospinning;?bers;poly(vinyl alcohol)

Introduction

The nano?ber technology of present interest focuses on the electrospinning technique,which conveniently allows the preparation of?brous materials with very?ne diameters ranging from submicron to several nanometers.[1,2]The electrospinning phenomenon itself involves basic and signi?cant issues in polymer science for solution dynamics, in which viscoelastic parameters,surface free energy (surface tension)and electroconductivity are critical factors for the successful spinning of nano?bers.[3,4]

The systematic understanding of the spinnability with an applied electric?eld and the polymer solution parameters has been investigated.[5–8]A pioneering research group in this?eld comprehensively investigated the detailed mech-anism of electrospinning,including jet initiation,growth of bending instability,elongation of the jet and solidi?cation of the jet into the nano?ber.[9–12]The polymer solution to be electrospun is usually placed in a pipette connected to the positive electrode.First,as the electric?eld is applied,a charged jet is emitted from the droplet on a pipette tip. Second,the electri?ed liquid jet of the polymer solution evolves its electrically driven bending instability towards the collector,which neutralizes the charge of the jet.Third, the?uid jet solidi?es into a nano?ber through evaporation of the solvent,resulting in the deposition of the nonwoven ?brous membrane on the collector.Thus,the solvent per-forms two crucial roles in electrospinning.One is to solvate the polymer molecules,ready to form the electri?ed jet. The other is to carry the solvated polymer molecules towards the collector,then to leave the polymer?bers by rapid vaporization of the solvent molecules.The appro-priate selection of a solvent system is a prerequisite for successful electrospinning.

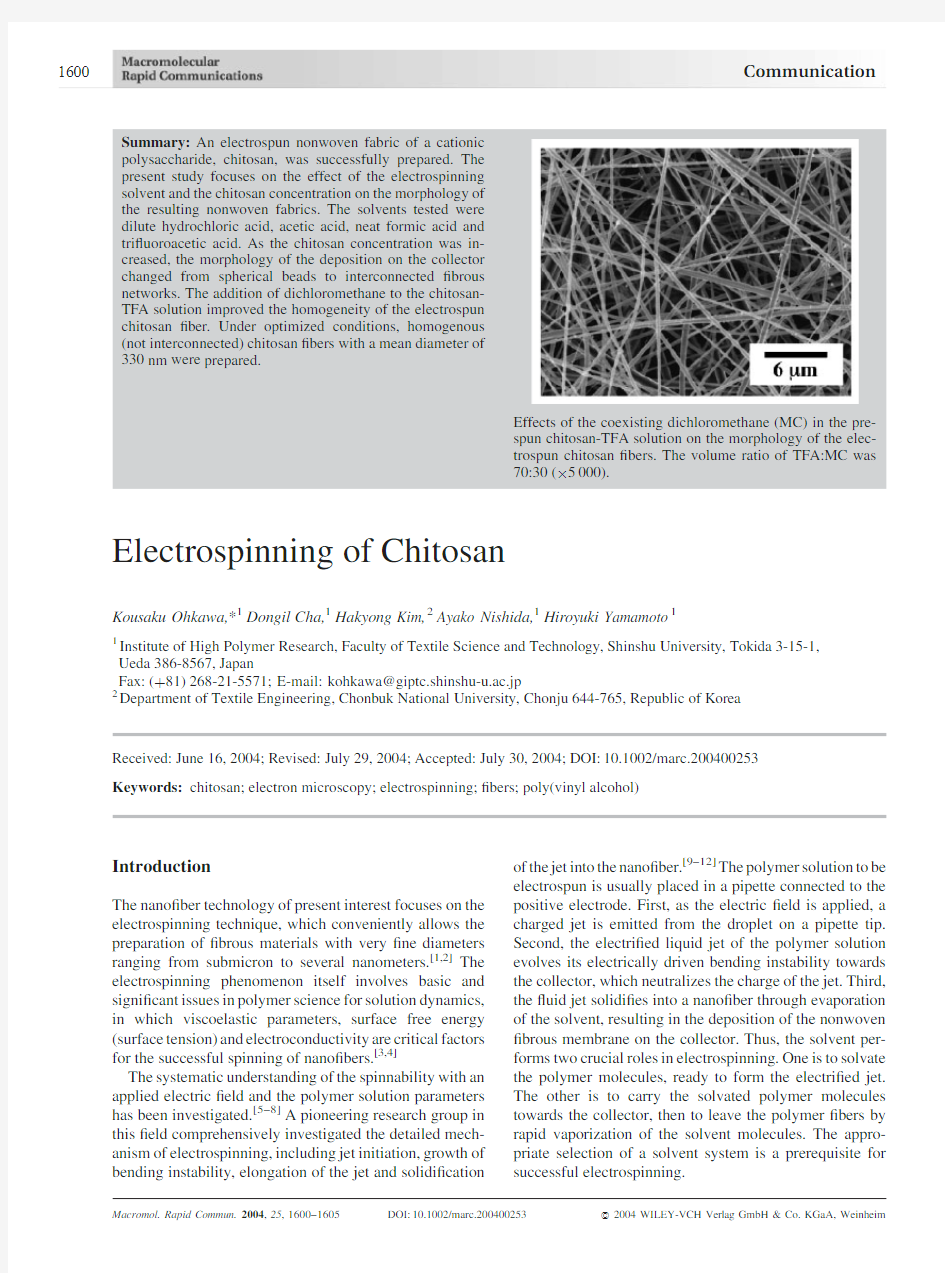

Summary:An electrospun nonwoven fabric of a cationic polysaccharide,chitosan,was successfully prepared.The present study focuses on the effect of the electrospinning solvent and the chitosan concentration on the morphology of the resulting nonwoven fabrics.The solvents tested were dilute hydrochloric acid,acetic acid,neat formic acid and tri?uoroacetic acid.As the chitosan concentration was in-creased,the morphology of the deposition on the collector changed from spherical beads to interconnected?brous networks.The addition of dichloromethane to the chitosan-TFA solution improved the homogeneity of the electrospun chitosan?ber.Under optimized conditions,homogenous (not interconnected)chitosan?bers with a mean diameter of 330nm were

prepared.

Effects of the coexisting dichloromethane(MC)in the pre-

spun chitosan-TFA solution on the morphology of the elec-

trospun chitosan?bers.The volume ratio of TFA:MC was

70:30(?5000).

1600Communication

Nano?bers from various synthetic polymers have been reported,as well as those from natural polymers,including proteins,[13,14]nucleic acids[15]and polysaccharides.[16,17] Electrospun nonwoven?brous materials of several natural polymers have been characterized with respect to their app-lications as biocompatible or bioresorbable materials.[16] Because of its abundant production in nature and excellent biocompatibility,the cationic polysaccharide chitosan (Scheme1)is a very promising polymer for this purpose.[18,19]Recently,we reported the utilization of chito-san as a new type of?ber[20–23]or capsule material.[24,25] Chitosan is an interesting polymer because of its phy-sicochemical properties,including its solid-state struc-ture[26,27]and the dissolving state conformation.[28,29]In the solid state,relatively rigid crystallites form due to the regu-larly arranged hydroxyl and amino groups at the equatorial positions in the b(1,4)-linked D-glucosamine repeating units,[30]while in solution,hydrogen bonding drives the formation of micro?brils,depending on the chitosan con-centration.[31]Such characteristics of chitosan guide the methodology for the successful electrospinning of this material and will further form an interplay between basic polymer chemistry and advanced materials science.There have been several attempts to prepare a nonwoven fabric of chitosan by the electrospinning technique.However,these attempts were not for a pure chitosan system but used a blended system of chitosan with poly(ethylene glycol)[32] or employed chitosan derivatives.[33]Thus,an electrospun nonwoven fabric has not yet been prepared from a pure chitosan system.Therefore,the present study was under-taken to examine the electrospinning of pure chitosan. The present study involved two parts to prepare the electrospun nonwoven fabric of chitosan.In the?rst part, the blended system was examined.The chitosan was mixed with another polymer,which can interfere with the rigid association of the chitosan molecules.Poly(vinyl alcohol) (PV A)was chosen for two reasons:(i)PV A strongly inter-acts with chitosan through hydrogen bonding on a molec-ular level;[34,35](ii)PV A can be conveniently electrospun from an aqueous medium.[5,36]In the second part,the pure chitosan system was con?rmed.The appropriate solvent for the electrospinning of chitosan was experimentally determined from a range of several acidic media,including dilute hydrochloric acid,acetic acid,neat formic acid,di-chloroacetic acid and tri?uoroacetic acid.These solvents were selected because they are frequently used in solution dynamic studies of chitosan.[28,29,34,37,38] Experimental Part

Materials

The viscosity average molecular weights of the chitosan samples were determined according to Robert.[38]For the elec-trospinning experiments,two grades of commercial chitosan were purchased from Wako Pure Chemical Industries,Ltd., Japan.The?rst was chitosan10(viscosity average molecular weight,M v?2.1?105;[20]degree of deacetylation,0.78)and the second was chitosan100(M v?1.3?106;degree of deacetylation,0.77).Poly(vinyl alcohol)(PV A;degree of polymerization,approximately2000;M n?8.8?104)was purchased from Wako.Acetic acid(AcOH),formic acid (FA)and dichloromethane were also purchased from Wako. Tri?uoroacetic acid(TFA)was obtained from Tokyo Chemical Industry Co.,Ltd.All the solvents were used without further puri?cation.

Electrospinning Apparatus

The apparatus for the electrospinning experiments was assem-bled based on previous studies.[6,7]The electrospinning experiments were performed at room temperature.The poly-mer solution was placed into a3mL syringe with a capillary tip having an inner diameter of0.6mm.A copper wire connected to the positive electrode was inserted into the polymer solution.

A copper plate wrapped with aluminum foil was used as the collector and the collector was connected to the ground.A high voltage power supply(HAR-50P2,Matsusada Precision Inc., Japan)was employed to generate the electric?eld(0–30kV). The applied voltage and the tip-to-collector distance were?xed at15kV and150mm,respectively.

Electrospinning Procedures

First,PV A was dissolved in distilled water(DW)at a concen-tration of9wt.-%,and chitosan10was dissolved in neat FA at 7wt.-%.A PV A-DW solution(9wt.-%)was mixed with a chitiosan10-FA solution(7wt.-%)in the volume ratios90:10, 70:30,50:50and30:70.Separately,a chitosan100-neat FA (2wt.-%,or0.2M AcOH)solution was mixed with a PV A-DW solution(9wt.-%)in a volume ratio of50:50.The mixed solutions were then subjected to the electrospinning experi-ments with the apparatus parameters as described above. Second,the chitosan10was dissolved at concentrations ranging from3to9wt.-%in the following solvents:neat FA, DCA,TFA and aqueous acetic acid(0.2M AcOH)and hydro-chloric acid(0.1M HCl),and their mixtures with methanol, ethanol,1,4-dioxane,dichloromethane,N,N-dimethylform-amide or dimethylsulfoxide were used as the solvents.The electrospinning of pure chitosan?bers was examined with the apparatus parameters described

above.

The morphologies of the electrospun?bers were observed using a Hitachi S-2380N scanning electron microscope(SEM) or a Hitachi S-5000FE-SEM at an accelerating voltage of5or 10kV.All samples were sputtered with platinum for2min prior to their observation.

Results and Discussion

Nonwoven Fabric from Chitosan/PVA Blend System The solvents used for dissolving chitosan10and PV A were formic acid(FA)and distilled water(DW),respectively.At a chitosan10:PV A ratio of100:0(corresponding to a7wt.-% chitosan10-FA solution),no jet was seen upon applying the high voltage even above25kV.Therefore,under these conditions,an electrospun?ber of chitosan could not be obtained.

Figure1shows SEM photographs of the chitosan/PV A blended electrospun fabrics.When a small portion of the PV A was mixed with chitosan,as presented in Figure1a (chitosan:PVA?90:10),beads were deposited on the col-lector.As the ratio of the chitosan solution increased (chitosan:PVA?70:30),the size of the beads became smal-ler and thin?bers coexisted among the beads(Figure1b). When equal volumes of the chitosan and PV A(50:50) solutions were blended,homogenous?bers with an average diameter of120nm could be spun(Figure1c;diameter distribution,83–170nm).At a chitosan:PV A ratio of

30:70, Figure1.SEM photographs of the chitosan and PV A blended electrospun?bers(magni?cation?

10000).The chitosan10was dissolved in formic acid at7wt.-%and PV A was dissolved in distilled

water at9wt.-%.The two solutions were mixed in the speci?ed volume ratios and then electrospun.

The volume ratios were chitosan10:PVA?90:10(panel a),70:30(panel b),50:50(panel c),

30:70(panel d)and0:100(panel e).Chitosan100was dissolved in formic acid(or0.2M acetic acid)at

2wt.-%and the solution was mixed with9wt.-%PV A in a volume ratio of50:50,then the mixed

solution was electrospun(panel f).

1602K.Ohkawa,D.Cha,H.Kim,A.Nishida,H.Yamamoto

the?bers were thicker(Figure1d,average diameter,170nm; diameter distribution,110–220nm)than those prepared at50:50.This could be due to the electrospun pure PV A ?ber having a relatively thick mean diameter of470nm (Figure1e;diameter distribution,370–620nm).Electro-spun?bers were also prepared from a blended solution of chitosan100(2wt.-%)-FA(or0.2M AcOH)and PV A (9wt.-%)-DW in the volume ratio50:50(Figure1f;average diameter,170nm;diameter distribution,120–220nm). Electrospinnig of Chitosan Fibers

Among the solvents tested for the electrospinning of chito-san(0.2M AcOH,0.1M HCl,neat FA,DCA and their mixtu-res with the volatile organic solvents such as methanol,ethanol and1,4-dioxane,dichloromethane,and also with aprotic solvents including N,N-dimethylformamide and dimethylsulfoxide),none of them produced a visible jet as the electric?eld was applied(data not shown).

Only when TFA was used as the solvent,chitosan?bers were deposited onto the collector.The SEM photographs of the deposited chitosan are represented in Figure2.The morphology of the deposited chitosan depended on its con-centration in the TFA solution.When the chitosan concen-tration was6wt.-%or less,the beads and?bers coexisted in the SEM images(Figure2a and2b).At a chitosan concen-tration of7wt.-%,?bers were predominantly deposited while the bead fraction remarkably decreased(Figure2c and2d;average diameter,490nm;diameter distribution, 330–610nm).An almost homogenous network of

the Figure2.Morphological changes in the electrospun?bers of chitosan10.Chitosan10was dissolved

in tri?uoroacetic acid(TFA)at the speci?ed concentration,then the chitosan-TFA solutions were

electrospun.Chitosan10concentrations were5wt.-%(panel a;magni?cation,?1000),6wt.-%(panel

b,?1000),7wt.-%(panel c,?1000;panel d,?10000)and8wt.-%(panel e,?1000;panel f,

?10000).

Electrospinning of Chitosan1603

electrospun chitosan?bers was observed at8wt.-% (Figure2e;average diameter,490nm;diameter distribu-tion,390–610nm).There are two possible reasons why the electrospinning of chitosan is successful when using TFA: (i)TFA forms salts with the amino groups of chitosan[28] and this salt formation destroys the rigid interaction between the chitosan molecules,making them ready to be electrospun;(ii)the high volatility of TFA is advantageous for the rapid solidi?cation of the electri?ed jet of the chitosan-TFA solution.

In the case of8wt.-%chitosan-TFA solution,small beads (Figure2e)and interconnected?bers(Figure2f)were still found,suggesting that optimization of the electrospinning conditions would be necessary for the preparation of a homogenous(not interconnected)?ber network of chit-osan.One possible approach to this optimization was to mix a volatile organic solvent with TFA.Hence,a TFA and dichloromethane(MC)mixed solvent was examined (Figure3).When the network morphology prepared from the TFA:MC?80:20solvent(Figure3b;average diameter, 380nm;diameter distribution,200–660nm)was compared with that from90:10(Figure3a;average diameter,390nm; diameter distribution,230–650nm),the network of chito-san?bers became more homogenous.At a TFA:MC ratio of 70:30(Figure3c),small beads and interconnected?bers mostly cannot be seen,indicating that a homogenous?ber network could be prepared under these conditions.The mean diameter of the chitosan?ber thus obtained was 330nm and the?ber diameters were distributed from210to 650nm.By increasing the MC ratio above70:30,the chitosan partly separated from the solution. Conclusion

In this study,we succeeded for the?rst time in preparing pure chitosan?bers by an electrospinning technique.Both the chitosan/PVA blended system and the pure chitosan system produced homogenous?brous materials,having average diameters in the submicron range.Our ongoing studies will focus on the effectiveness of the solvent,TFA, in the electrospinning of chitosan in order to prepare?ner electrospun?bers in the nanometer range.In parallel,elec-trospinning experiments using other polysaccharides, especially cellulose,crosslinkable chitosan derivatives[22] and synthetic polypeptides are in progress and these results will be published

elsewhere.

Figure3.Effects of the coexisting dichloromethane(MC)in the prespun chitosan-TFA solution on

the morphology of the electrospun chitosan?bers.Concentration of chitosan10was?xed at8wt.-%.

Chiotsan10was dissolved in a series of the TFA:MC mixed solvents and then the chitosan-TFA-MC

solutions were electrospun.The volume ratios of TFA:MC were90:10(panel a;magni?cation,

?5000),80:20(panel b,?5000),and70:30(panel c,?5000;panel d,?10000).

1604K.Ohkawa,D.Cha,H.Kim,A.Nishida,H.Yamamoto

Acknowledgements:This work was supported by the Grants-in-aid for21st Century COE Program for Scienti?c Research(No. 13555178,No.14750709,No.16651064)from the Ministry of Education,Culture,Sports,Science,and Technology of Japan.

[1]J.Doshi,D.H.Reneker,J.Electrostat.1995,35,151.

[2]H.Fong,D.H.Reneker,‘‘Electrospinning and the Formation

of Nano?bers’’,in:Structure Formation in Polymeric Fibers,

D.R.Salem,Ed.,Hanser Gardner Publishers,Mu¨nchen

2001,p.225.

[3] D.H.Reneker,I.Chun,Nanotechnology1996,7,216.

[4]Z.-M.Huang,Y.Z.Zhang,M.Kotaki,S.Ramakrishna,

Compos.Sci.Technol.2003,63,2223.

[5] B.Ding,E.Kimura,T.Sato,S.Fujita,S.Shiratori,Polymer

2004,45,1895.

[6]K.H.Lee,H.Y.Kim,https://www.360docs.net/doc/f115869970.html,,D.R.Lee,N.H.Sung,

J.Polym.Sci.,Part B:Polym.Phys.2002,40,2259.

[7]K.H.Lee,H.Y.Kim,Y.J.Ryu,K.W.Kim,S.W.Choi,

J.Polym.Sci.,Part B:Polym.Phys.2003,41,1256.

[8]Z.Jun,H.Hou,A.Schaper,J.H.Wendorff,A.Greiner,

e-Polymers2003,9.

[9] D.H.Reneker,A.L.Yarin,H.Fong,S.Koombhongse,

J.Appl.Phys.2000,87,4531.

[10]S.Koombhongse,W.Liu,D.H.Reneker,J.Polym.Sci.,

Part B:Polym.Phys.2001,39,2598.

[11] A.L.Yarin,S.Koombhongse,D.H.Reneker,J.Appl.Phys.

2001,90,4836.

[12] A.L.Yarin,S.Koombhongse,D.H.Reneker,J.Appl.Phys.

2001,89,3018.

[13]K.Ohgo,C.Zhao,M.Kobayashi,T.Asakura,Polymer2002,

44,841.

[14]G.E.Wnek,M.E.Carr,D.G.Simpson,G.L.Bowlin,

NanoLett.2003,3,213.

[15]X.Fang,D.H.Reneker,J.Macromol.Sci.Phys.1997,B36,

169.

[16]H.Jiang, D.Fang, B.S.Hsiao, B.Chu,W.Chen,

Biomacromolecules2004,5,326.[17]W.K.Son,J.H.Youk,W.H.Park,Biomacromolecules2004,

5,197.

[18]R.A.A.Muzzarelli,‘‘Chitin’’,Pergamon,Oxford1977.

[19]‘‘Applications of Chitin and Chitosan(Kitin,Kitosan no

Ouyou)’’,M.Yabuki,Ed.,Gihoudo Press,Tokyo1990. [20]H.Yamamoto,Y.Senoo,Macromol.Chem.Phys.2000,

201,84.

[21]K.Ohkawa,M.Ando,Y.Shirakabe,Y.Takahashi,

M.Yamada,H.Yamamoto,Text.Res.J.2002,42,120. [22]Y.Kuboe,H.Tonegawa,K.Ohkawa,H.Yamamoto,

Biomacromolecules2004,5,348.

[23]K.Ohkawa,Y.Takahashi,M.Yamada,H.Yamamoto,

Macromol.Mater.Eng.2001,286,168.

[24]K.Ohkawa,T.Kitagawa,H.Yamamoto,Macromol.Mater.

Eng.2004,289,33.

[25]K.Ohkawa,H.Yamamoto,‘‘Modi?cation of Proteins and

Poly(amino acids)by Enzymatic and Chemical Methods’’, in:Biopolymers,V olume7,A.Steinbu¨hel,S.R.Fahnestock, Eds.,Wiley-VCH,Weinheim2003,Chapter15,p.465. [26]S.Grant,H.S.Blair,G.McKay,Makromol.Chem.1989,

190,2279.

[27]R.J.Samuels,J.Polym.Sci.Polym.Phys.Ed.1981,19,1081.

[28]M.Hasegawa,A.Isogai,F.Onabe,https://www.360docs.net/doc/f115869970.html,uda,J.Appl.Polym.

Sci.1992,45,1857.

[29]J.-H.Pa,T.L.Yu,Macromol.Chem.Phys.2001,202,985.

[30]K.Sakurai,T.Shibano,K.Kimura,T.Takahashi,Sen’i

Gakkaishi1985,41,361.

[31] E.Titoba, E.Belavtseva, A.Gamzazade, A.Sklyar,

S.Pavlova,S.Rogozhin,Acta Polym.1986,37,121. [32] B.Duan,C.Dong,X.Yuan,K.Yao,J.Biomater.Sci.Polym.

Ed.2004,15,797.

[33]H.Jiang,D.Fang,B.Hsiao,B.Chu,W.Chen,J.Biomater.

Sci.,Polym.Ed.2004,15,279.

[34]M.Miya,R.Iwamoto,S.Mima,J.Polym.Sci.Polym.Phys.

Ed.1984,22,1149.

[35]H.Zheng,Y.Du,J.Yu,R.Huang,L.Zhang,J.Appl.Polym.

Sci.2001,80,2558.

[36]H.Q.Dai,J.Gong,H.Y.Kim,D.R.Lee,Nanotechnology

2002,13,674.

[37]T.Matsumoto,H.Zenkoh,Nihon Reoroji Gakkaishi1989,

17,43.

[38]G.A.F.Roberts,J.G.Domsy,Int.J.Biol.Macromol.1982,

4,374.

Electrospinning of Chitosan1605

如何写先进个人事迹

如何写先进个人事迹 篇一:如何写先进事迹材料 如何写先进事迹材料 一般有两种情况:一是先进个人,如先进工作者、优秀党员、劳动模范等;一是先进集体或先进单位,如先进党支部、先进车间或科室,抗洪抢险先进集体等。无论是先进个人还是先进集体,他们的先进事迹,内容各不相同,因此要整理材料,不可能固定一个模式。一般来说,可大体从以下方面进行整理。 (1)要拟定恰当的标题。先进事迹材料的标题,有两部分内容必不可少,一是要写明先进个人姓名和先进集体的名称,使人一眼便看出是哪个人或哪个集体、哪个单位的先进事迹。二是要概括标明先进事迹的主要内容或材料的用途。例如《王鬃同志端正党风的先进事迹》、《关于评选张鬃同志为全国新长征突击手的材料》、《关于评选鬃处党支部为省直机关先进党支部的材料》等。 (2)正文。正文的开头,要写明先进个人的简要情况,包括:姓名、性别、年龄、工作单位、职务、是否党团员等。此外,还要写明有关单位准备授予他(她)什么荣誉称号,或给予哪种形式的奖励。对先进集体、先进单位,要根据其先进事迹的主要内容,寥寥数语即应写明,不须用更多的文字。 然后,要写先进人物或先进集体的主要事迹。这部分内容是全篇材料

的主体,要下功夫写好,关键是要写得既具体,又不繁琐;既概括,又不抽象;既生动形象,又很实在。总之,就是要写得很有说服力,让人一看便可得出够得上先进的结论。比如,写一位端正党风先进人物的事迹材料,就应当着重写这位同志在发扬党的优良传统和作风方面都有哪些突出的先进事迹,在同不正之风作斗争中有哪些突出的表现。又如,写一位搞改革的先进人物的事迹材料,就应当着力写这位同志是从哪些方面进行改革的,已经取得了哪些突出的成果,特别是改革前后的.经济效益或社会效益都有了哪些明显的变化。在写这些先进事迹时,无论是先进个人还是先进集体的,都应选取那些具有代表性的具体事实来说明。必要时还可运用一些数字,以增强先进事迹材料的说服力。 为了使先进事迹的内容眉目清晰、更加条理化,在文字表述上还可分成若干自然段来写,特别是对那些涉及较多方面的先进事迹材料,采取这种写法尤为必要。如果将各方面内容材料都混在一起,是不易写明的。在分段写时,最好在每段之前根据内容标出小标题,或以明确的观点加以概括,使标题或观点与内容浑然一体。 最后,是先进事迹材料的署名。一般说,整理先进个人和先进集体的材料,都是以本级组织或上级组织的名义;是代表组织意见的。因此,材料整理完后,应经有关领导同志审定,以相应一级组织正式署名上报。这类材料不宜以个人名义署名。 写作典型经验材料-般包括以下几部分: (1)标题。有多种写法,通常是把典型经验高度集中地概括出来,一

关于时间管理的英语作文 manage time

How to manage time Time treats everyone fairly that we all have 24 hours per day. Some of us are capable to make good use of time while some find it hard to do so. Knowing how to manage them is essential in our life. Take myself as an example. When I was still a senior high student, I was fully occupied with my studies. Therefore, I hardly had spare time to have fun or develop my hobbies. But things were changed after I entered university. I got more free time than ever before. But ironically, I found it difficult to adjust this kind of brand-new school life and there was no such thing called time management on my mind. It was not until the second year that I realized I had wasted my whole year doing nothing. I could have taken up a Spanish course. I could have read ten books about the stories of successful people. I could have applied for a part-time job to earn some working experiences. B ut I didn’t spend my time on any of them. I felt guilty whenever I looked back to the moments that I just sat around doing nothing. It’s said that better late than never. At least I had the consciousness that I should stop wasting my time. Making up my mind is the first step for me to learn to manage my time. Next, I wrote a timetable, setting some targets that I had to finish each day. For instance, on Monday, I must read two pieces of news and review all the lessons that I have learnt on that day. By the way, the daily plan that I made was flexible. If there’s something unexpected that I had to finish first, I would reduce the time for resting or delay my target to the next day. Also, I would try to achieve those targets ahead of time that I planed so that I could reserve some more time to relax or do something out of my plan. At the beginning, it’s kind of difficult to s tick to the plan. But as time went by, having a plan for time in advance became a part of my life. At the same time, I gradually became a well-organized person. Now I’ve grasped the time management skill and I’m able to use my time efficiently.

英语演讲稿:未来的工作

英语演讲稿:未来的工作 这篇《英语演讲稿范文:未来的工作》,是特地,希望对大家有所帮助! 热门演讲推荐:竞聘演讲稿 | 国旗下演讲稿 | 英语演讲稿 | 师德师风演讲稿 | 年会主持词 | 领导致辞 everybody good afternoon:. first of all thank the teacher gave me a story in my own future ideal job. everyone has a dream job. my dream is to bee a boss, own a pany. in order to achieve my dreams, i need to find a good job, to accumulate some experience and wealth, it is the necessary things of course, in the school good achievement and rich knowledge is also very important. good achievement and rich experience can let me work to make the right choice, have more opportunities and achievements. at the same time, munication is very important, because it determines whether my pany has a good future development. so i need to exercise their municative ability. i need to use all of the free time to learn

最新小学生个人读书事迹简介怎么写800字

小学生个人读书事迹简介怎么写800字 书,是人类进步的阶梯,苏联作家高尔基的一句话道出了书的重要。书可谓是众多名人的“宠儿”。历来,名人说出关于书的名言数不胜数。今天小编在这给大家整理了小学生个人读书事迹,接下来随着小编一起来看看吧! 小学生个人读书事迹1 “万般皆下品,惟有读书高”、“书中自有颜如玉,书中自有黄金屋”,古往今来,读书的好处为人们所重视,有人“学而优则仕”,有人“满腹经纶”走上“传道授业解惑也”的道路……但是,从长远的角度看,笔者认为读书的好处在于增加了我们做事的成功率,改善了生活的质量。 三国时期的大将吕蒙,行伍出身,不重视文化的学习,行文时,常常要他人捉刀。经过主君孙权的劝导,吕蒙懂得了读书的重要性,从此手不释卷,成为了一代儒将,连东吴的智囊鲁肃都对他“刮目相待”。后来的事实证明,荆州之战的胜利,擒获“武圣”关羽,离不开吕蒙的“运筹帷幄,决胜千里”,而他的韬略离不开平时的读书。由此可见,一个人行事的成功率高低,与他的对读书,对知识的重视程度是密切相关的。 的物理学家牛顿曾近说过,“如果我比别人看得更远,那是因为我站在巨人的肩上”,鲜花和掌声面前,一代伟人没有迷失方向,自始至终对读书保持着热枕。牛顿的话语告诉我们,渊博的知识能让我们站在更高、更理性的角度来看问题,从而少犯错误,少走弯路。

读书的好处是显而易见的,但是,在社会发展日新月异的今天,依然不乏对读书,对知识缺乏认知的人,《今日说法》中我们反复看到农民工没有和用人单位签订劳动合同,最终讨薪无果;屠户不知道往牛肉里掺“巴西疯牛肉”是犯法的;某父母坚持“棍棒底下出孝子”,结果伤害了孩子的身心,也将自己送进了班房……对书本,对知识的零解读让他们付出了惨痛的代价,当他们奔波在讨薪的路上,当他们面对高墙电网时,幸福,从何谈起?高质量的生活,从何谈起? 读书,让我们体会到“锄禾日当午,汗滴禾下土”的艰辛;读书,让我们感知到“四海无闲田,农夫犹饿死”的无奈;读书,让我们感悟到“为报倾城随太守,西北望射天狼”的豪情壮志。 读书的好处在于提高了生活的质量,它填补了我们人生中的空白,让我们不至于在大好的年华里无所事事,从书本中,我们学会提炼出有用的信息,汲取成长所需的营养。所以,我们要认真读书,充分认识到读书对改善生活的重要意义,只有这样,才是一种负责任的生活态度。 小学生个人读书事迹2 所谓读一本好书就是交一个良师益友,但我认为读一本好书就是一次大冒险,大探究。一次体会书的过程,真的很有意思,咯咯的笑声,总是从书香里散发;沉思的目光也总是从书本里透露。是书给了我启示,是书填补了我无聊的夜空,也是书带我遨游整个古今中外。所以人活着就不能没有书,只要爱书你就是一个爱生活的人,只要爱书你就是一个大写的人,只要爱书你就是一个懂得珍惜与否的人。可真所谓

关于坚持的英语演讲稿

关于坚持的英语演讲稿 Results are not important, but they can persist for many years as a commemoration of. Many years ago, as a result of habits and overeating formed one of obesity, as well as indicators of overall physical disorders, so that affects my work and life. In friends to encourage and supervise, the participated in the team Now considered to have been more than three years, neither the fine rain, regardless of winter heat, a day out with 5:00 time. The beginning, have been discouraged, suffering, and disappointment, but in the end of the urging of friends, to re-get up, stand on the playground. 成绩并不重要,但可以作为坚持多年晨跑的一个纪念。多年前,由于庸懒习惯和暴饮暴食,形成了一身的肥胖,以及体检指标的全盘失常,以致于影响到了我的工作和生活。在好友的鼓励和督促下,参加了晨跑队伍。现在算来,已经三年多了,无论天晴下雨,不管寒冬酷暑,每天五点准时起来出门晨跑。开始时,也曾气馁过、痛苦过、失望过,但最后都在好友们的催促下,重新爬起来,站到了操场上。 In fact, I did not build big, nor strong muscles, not a sport-born people. Over the past few years to adhere to it, because I have a team behind, the strength of a strongteam here, very grateful to our team, for a long time, we encourage each other, and with sweat, enjoying common health happy. For example, Friends of the several run in order to maintain order and unable to attend the 10,000 meters race, and they are always concerned about the brothers and promptly inform the place and time, gives us confidence and courage. At the same time, also came on their own inner desire and pursuit for a good health, who wrote many of their own log in order to refuel for their own, and inspiring. 其实我没有高大身材,也没健壮肌肉,天生不属于运动型的人。几年来能够坚持下来,因为我的背后有一个团队,有着强大团队的力量,在这里,非常感谢我们的晨跑队,长期以来,我们相互鼓励着,一起流汗,共同享受着健康带来的快

关于管理的英语演讲

1.How to build a business that lasts100years 0:11Imagine that you are a product designer.And you've designed a product,a new type of product,called the human immune system.You're pitching this product to a skeptical,strictly no-nonsense manager.Let's call him Bob.I think we all know at least one Bob,right?How would that go? 0:34Bob,I've got this incredible idea for a completely new type of personal health product.It's called the human immune system.I can see from your face that you're having some problems with this.Don't worry.I know it's very complicated.I don't want to take you through the gory details,I just want to tell you about some of the amazing features of this product.First of all,it cleverly uses redundancy by having millions of copies of each component--leukocytes,white blood cells--before they're actually needed,to create a massive buffer against the unexpected.And it cleverly leverages diversity by having not just leukocytes but B cells,T cells,natural killer cells,antibodies.The components don't really matter.The point is that together,this diversity of different approaches can cope with more or less anything that evolution has been able to throw up.And the design is completely modular.You have the surface barrier of the human skin,you have the very rapidly reacting innate immune system and then you have the highly targeted adaptive immune system.The point is,that if one system fails,another can take over,creating a virtually foolproof system. 1:54I can see I'm losing you,Bob,but stay with me,because here is the really killer feature.The product is completely adaptive.It's able to actually develop targeted antibodies to threats that it's never even met before.It actually also does this with incredible prudence,detecting and reacting to every tiny threat,and furthermore, remembering every previous threat,in case they are ever encountered again.What I'm pitching you today is actually not a stand-alone product.The product is embedded in the larger system of the human body,and it works in complete harmony with that system,to create this unprecedented level of biological protection.So Bob,just tell me honestly,what do you think of my product? 2:47And Bob may say something like,I sincerely appreciate the effort and passion that have gone into your presentation,blah blah blah-- 2:56(Laughter) 2:58But honestly,it's total nonsense.You seem to be saying that the key selling points of your product are that it is inefficient and complex.Didn't they teach you 80-20?And furthermore,you're saying that this product is siloed.It overreacts, makes things up as it goes along and is actually designed for somebody else's benefit. I'm sorry to break it to you,but I don't think this one is a winner.

关于工作的优秀英语演讲稿

关于工作的优秀英语演讲稿 Different people have various ambitions. Some want to be engineers or doctors in the future. Some want to be scientists or businessmen. Still some wish to be teachers or lawers when they grow up in the days to come. Unlike other people, I prefer to be a farmer. However, it is not easy to be a farmer for Iwill be looked upon by others. Anyway,what I am trying to do is to make great contributions to agriculture. It is well known that farming is the basic of the country. Above all, farming is not only a challenge but also a good opportunity for the young. We can also make a big profit by growing vegetables and food in a scientific way. Besides we can apply what we have learned in school to farming. Thus our countryside will become more and more properous. I believe that any man with knowledge can do whatever they can so long as this job can meet his or her interest. All the working position can provide him with a good chance to become a talent. 1 ————来源网络整理,仅供供参考

个人先进事迹简介

个人先进事迹简介 01 在思想政治方面,xxxx同学积极向上,热爱祖国、热爱中国共产党,拥护中国共产党的领导.利用课余时间和党课机会认真学习政治理论,积极向党组织靠拢. 在学习上,xxxx同学认为只有把学习成绩确实提高才能为将来的实践打下扎实的基础,成为社会有用人才.学习努力、成绩优良. 在生活中,善于与人沟通,乐观向上,乐于助人.有健全的人格意识和良好的心理素质和从容、坦诚、乐观、快乐的生活态度,乐于帮助身边的同学,受到师生的好评. 02 xxx同学认真学习政治理论,积极上进,在校期间获得原院级三好生,和校级三好生,优秀团员称号,并获得三等奖学金. 在学习上遇到不理解的地方也常常向老师请教,还勇于向老师提出质疑.在完成自己学业的同时,能主动帮助其他同学解决学习上的难题,和其他同学共同探讨,共同进步. 在社会实践方面,xxxx同学参与了中国儿童文学精品“悦”读书系,插画绘制工作,xxxx同学在班中担任宣传委员,工作积极主动,认真负责,有较强的组织能力.能够在老师、班主任的指导下独立完成学院、班级布置的各项工作. 03 xxx同学在政治思想方面积极进取,严格要求自己.在学习方面刻苦努力,不断钻研,学习成绩优异,连续两年荣获国家励志奖学金;作

为一名学生干部,她总是充满激情的迎接并完成各项工作,荣获优秀团干部称号.在社会实践和志愿者活动中起到模范带头作用. 04 xxxx同学在思想方面,积极要求进步,为人诚实,尊敬师长.严格 要求自己.在大一期间就积极参加了党课初、高级班的学习,拥护中国共产党的领导,并积极向党组织靠拢. 在工作上,作为班中的学习委员,对待工作兢兢业业、尽职尽责 的完成班集体的各项工作任务.并在班级和系里能够起骨干带头作用.热心为同学服务,工作责任心强. 在学习上,学习目的明确、态度端正、刻苦努力,连续两学年在 班级的综合测评排名中获得第1.并荣获院级二等奖学金、三好生、优秀班干部、优秀团员等奖项. 在社会实践方面,积极参加学校和班级组织的各项政治活动,并 在志愿者活动中起到模范带头作用.积极锻炼身体.能够处理好学习与工作的关系,乐于助人,团结班中每一位同学,谦虚好学,受到师生的好评. 05 在思想方面,xxxx同学积极向上,热爱祖国、热爱中国共产党,拥护中国共产党的领导.作为一名共产党员时刻起到积极的带头作用,利用课余时间和党课机会认真学习政治理论. 在工作上,作为班中的团支部书记,xxxx同学积极策划组织各类 团活动,具有良好的组织能力. 在学习上,xxxx同学学习努力、成绩优良、并热心帮助在学习上有困难的同学,连续两年获得二等奖学金. 在生活中,善于与人沟通,乐观向上,乐于助人.有健全的人格意 识和良好的心理素质.

自我管理演讲稿英语翻译

尊敬的领导,老师,亲爱的同学们, 大家好!我是5班的梁浩东。今天早上我坐车来学校的路上,我仔细观察了路上形形色色的人,有开着小车衣着精致的叔叔阿姨,有市场带着倦容的卖各种早点的阿姨,还有偶尔穿梭于人群中衣衫褴褛的乞丐。于是我问自己,十几年后我会成为怎样的自己,想成为社会成功人士还是碌碌无为的人呢,答案肯定是前者。那么十几年后我怎样才能如愿以偿呢,成为一个受人尊重,有价值的人呢?正如我今天演讲的题目是:自主管理。 大家都知道爱玩是我们孩子的天性,学习也是我们的责任和义务。要怎样处理好这些矛盾,提高自主管理呢? 首先,我们要有小主人翁思想,自己做自己的主人,要认识到我们学习,生活这一切都是我们自己走自己的人生路,并不是为了报答父母,更不是为了敷衍老师。 我认为自主管理又可以理解为自我管理,在学习和生活中无处不在,比如通过老师,小组长来管理约束行为和同学们对自身行为的管理都属于自我管理。比如我们到一个旅游景点,看到一块大石头,有的同学特别兴奋,会想在上面刻上:某某某到此一游话。这时你就需要自我管理,你需要提醒自己,这样做会破坏景点,而且是一种素质低下的表现。你设想一下,如果别人家小孩去你家墙上乱涂乱画,你是何种感受。同样我们把自主管理放到学习上,在我们想偷懒,想逃避,想放弃的时候,我们可以通过自主管理来避免这些,通过他人或者自己的力量来完成。例如我会制定作息时间计划表,里面包括学习,运动,玩耍等内容的完成时间。那些学校学习尖子,他们学习好是智商高于我们吗,其实不然,在我所了解的哪些优秀的学霸传授经验里,就提到要能够自我管理,规范好学习时间的分分秒秒,只有辛勤的付出,才能取得优异成绩。 在现实生活中,无数成功人士告诉我们自主管理的重要性。十几年后我想成为一位优秀的,为国家多做贡献的人。亲爱的同学们,你们们?让我们从现在开始重视和执行自主管理,十几年后成为那个你想成为的人。 谢谢大家!

关于工作的英语演讲稿

关于工作的英语演讲稿 【篇一:关于工作的英语演讲稿】 关于工作的英语演讲稿 different people have various ambitions. some want to be engineers or doctors in the future. some want to be scientists or businessmen. still some wish to be teachers or lawers when they grow up in the days to come. unlike other people, i prefer to be a farmer. however, it is not easy to be a farmer for iwill be looked upon by others. anyway,what i am trying to do is to make great contributions to agriculture. it is well known that farming is the basic of the country. above all, farming is not only a challenge but also a good opportunity for the young. we can also make a big profit by growing vegetables and food in a scientific way. besides we can apply what we have learned in school to farming. thus our countryside will become more and more properous. i believe that any man with knowledge can do whatever they can so long as this job can meet his or her interest. all the working position can provide him with a good chance to become a talent. 【篇二:关于责任感的英语演讲稿】 im grateful that ive been given this opportunity to stand here as a spokesman. facing all of you on the stage, i have the exciting feeling of participating in this speech competition. the topic today is what we cannot afford to lose. if you ask me this question, i must tell you that i think the answer is a word---- responsibility. in my elementary years, there was a little girl in the class who worked very hard, however she could never do satisfactorily in her lessons. the teacher asked me to help her, and it was obvious that she expected a lot from me. but as a young boy, i was so restless and thoughtless, i always tried to get more time to play and enjoy myself. so she was always slighted over by me. one day before the final exam, she came up to me and said, could you please explain this to me? i can not understand it. i

关于时间管理的英语演讲

Dear teacher and colleagues: my topic is on “spare time”. It is a huge blessing that we can work 996. Jack Ma said at an Ali's internal communication activity, That means we should work at 9am to 9pm, 6 days a week .I question the entire premise of this piece. but I'm always interested in hearing what successful and especially rich people come up with time .So I finally found out Jack Ma also had said :”i f you don’t put out more time and energy than others ,how can you achieve the success you want? If you do not do 996 when you are young ,when will you ?”I quite agree with the idea that young people should fight for success .But there are a lot of survival activities to do in a day ,I want to focus on how much time they take from us and what can we do with the rest of the time. As all we known ,There are 168 hours in a week .We sleep roughly seven-and-a-half and eight hours a day .so around 56 hours a week . maybe it is slightly different for someone . We do our personal things like eating and bathing and maybe looking after kids -about three hours a day .so around 21 hours a week .And if you are working a full time job ,so 40 hours a week , Oh! Maybe it is impossible for us at

关于人英语演讲稿(精选多篇)

关于人英语演讲稿(精选多篇) 关于人的优美句子 1、“黑皮小子”是我对在公交车上偶遇两次的一个男孩的称呼代号。一听这个外号,你也定会知道他极黑了。他的脸总是黑黑的;裸露在短袖外的胳膊也是黑黑的;就连两只有厚厚耳垂的耳朵也那么黑黑的,时不时像黑色的猎犬竖起来倾听着什么;黑黑的扁鼻子时不时地深呼吸着,像是在警觉地嗅着什么异样的味道。 2、我不知道,如何诠释我的母亲,因为母亲淡淡的生活中却常常跳动着不一样的间最无私、最伟大、最崇高的爱,莫过于母爱。无私,因为她的爱只有付出,无需回报;伟大,因为她的爱寓于

普通、平凡和简单之中;崇高,是因为她的爱是用生命化作乳汁,哺育着我,使我的生命得以延续,得以蓬勃,得以灿烂。 3、我的左撇子伙伴是用左手写字的,就像我们的右手一样挥洒自如。在日常生活中,曾见过用左手拿筷子的,也有像超级林丹用左手打羽毛球的,但很少碰见用左手写字的。中国汉字笔画笔顺是左起右收,适合用右手写字。但我的左撇子伙伴写字是右起左收的,像鸡爪一样迈出田字格,左看右看,上看下看,每一个字都很难看。平时考试时间终了,他总是做不完试卷。于是老师就跟家长商量,决定让他左改右写。经过老师引导,家长配合,他自己刻苦练字,考试能够提前完成了。现在他的字像他本人一样阳光、帅气。 4、老师,他们是辛勤的园丁,帮助着那些幼苗茁壮成长。他们不怕辛苦地给我们改厚厚一叠的作业,给我们上课。一步一步一点一点地给我们知识。虽然

他们有时也会批评一些人,但是他们的批评是对我们有帮助的,我们也要理解他们。那些学习差的同学,老师会逐一地耐心教导,使他们的学习突飞猛进。使他们的耐心教导培养出了一批批优秀的人才。他们不怕辛苦、不怕劳累地教育着我们这些幼苗,难道不是美吗? 5、我有一个表妹,还不到十岁,她那圆圆的小脸蛋儿,粉白中透着粉红,她的头发很浓密,而且好像马鬓毛一样的粗硬,但还是保留着孩子一样的蓬乱的美,卷曲的环绕着她那小小的耳朵。说起她,她可是一个古灵精怪的小女孩。 6、黑皮小子是一个善良的人,他要跟所有见过的人成为最好的朋友!这样人人都是他的好朋友,那么人人都是好友一样坦诚、关爱相交,这样人与人自然会和谐起来,少了许多争执了。 7、有人说,老师是土壤,把知识化作养分,传授给祖国的花朵,让他们茁壮成长。亦有人说,老师是一座知识的桥梁,把我们带进奇妙的科学世界,让

优秀党务工作者事迹简介范文

优秀党务工作者事迹简介范文 优秀党务工作者事迹简介范文 ***,男,198*年**月出生,200*年加入党组织,现为***支部书记。从事党务工作以来,兢兢业业、恪尽职守、辛勤工作,出色地完成了各项任务,在思想上、政治上同党中央保持高度一致,在业务上不断进取,团结同事,在工作岗位上取得了一定成绩。 一、严于律己,勤于学习 作为一名党务工作者,平时十分注重知识的更新,不断加强党的理论知识的学习,坚持把学习摆在重要位置,学习领会和及时掌握党和国家的路线、方针、政策,特别是党的十九大精神,注重政治理论水平的提高,具有坚定的理论信念;坚持党的基本路线,坚决执行党的各项方针政策,自觉履行党员义务,正确行使党员权利。平时注重加强业务和管理知识的学习,并运用到工作中去,不断提升自身工作能力,具有开拓创新精神,在思想上、政治上和行动上时刻同党中央保持高度一致。 二、求真务实,开拓进取 在工作中任劳任怨,踏实肯干,坚持原则,认真做好学院的党务工作,按照党章的要求,严格发展党员的每一个步骤,认真细致的对待每一份材料。配合党总支书记做好学院的党建工作,完善党总支建设方面的文件、材料和工作制度、管理制度等。

三、生活朴素,乐于助人 平时重视与同事间的关系,主动与同事打成一片,善于发现他人的难处,及时妥善地给予帮助。在其它同志遇到困难时,积极主动伸出援助之手,尽自己最大努力帮助有需要的人。养成了批评与自我批评的优良作风,时常反省自己的工作,学习和生活。不但能够真诚的指出同事的缺点,也能够正确的对待他人的批评和意见。面对误解,总是一笑而过,不会因为误解和批评而耿耿于怀,而是诚恳的接受,从而不断的提高自己。在生活上勤俭节朴,不铺张浪费。 身为一名老党员,我感到责任重大,应该做出表率,挤出更多的时间来投入到**党总支的工作中,不找借口,不讲条件,不畏困难,将总支建设摆在更重要的位置,解开工作中的思想疙瘩,为攻坚克难铺平道路,以支部为纽带,像战友一样团结,像家庭一样维系,像亲人一样关怀,践行入党誓言。把握机遇,迎接挑战,不负初心。

关于时间的英语演讲稿范文_演讲稿.doc

关于时间的英语演讲稿范文_演讲稿 and organizing people to learn from advanced areas to broaden their horizons in order to understand the team of cadres working conditions in schools, the ministry of education has traveled a number of primary and secondary schools to conduct research, listen to the views of the school party and government leaders to make school leadership cadres receive attention and guidance of the ministry of education to carry out a variety of practical activities to actively lead the majority of young teachers work hard to become qualified personnel and for them to put up the cast talent stage, a single sail swaying, after numerous twists and turns arrived in port, if there is wind, a hand, and naturally smooth arrival and guide students to strive to e xcel, need to nazhen “wind” - teacher. teachers should be ideological and moral education, culture education and the needs of students organically combining various activities for the students or students to carry out their own. for example: school quiz competitions, essay contests, ke benju performances and other activities to enable students to give full play to their talents. teachers rush toil, in order to that will enable students to continue to draw nutrients, to help them grow up healthily and become pillars of the country before. for all students in general education, the government departments have also not forget those who cared about the