Ab initio investigation of the intermetallics in the Nb Sn binary system

Ab initio investigation of the intermetallics in the Nb–Sn binary system

I.Papadimitriou,C.Utton and P.Tsakiropoulos

?

Department of Materials Science and Engineering,The University of She?eld,Sir Robert Had?eld Building,Mappin Street,

She?eld S13JD,UK

Received 3August 2014;revised 8December 2014;accepted 10December 2014

Abstract—The elastic and thermodynamic properties of the stable intermetallics in the Nb–Sn system were studied by the ?rst-principles pseudo-potential plane-wave method based on density functional theory.The elastic constants,Debye temperatures,bulk,shear and Young’s moduli and Poisson’s ratios were calculated for all the phases.Nb 3Sn has the highest bulk,shear and elastic moduli of the Nb–Sn intermetallics.The elastic properties at 0K and the Debye temperatures of the Nb 6Sn 5and NbSn 2phases are reported for the ?rst time.The enthalpies of formation were calculated for all the intermetallics.The ?nite-temperature elastic properties of the Nb and Nb 3Sn were calculated using the quasi-static approxima-tion.The thermal expansion coe?cients of Nb and Nb 3Sn were also obtained.ó2014Acta Materialia Inc.Published by Elsevier Ltd.All rights reserved.

Keywords:Ab initio calculations;Elastic constants;Enthalpy of formation;Intermetallic phases

1.Introduction

High-temperature structural materials with operating temperature capability that exceeds that of modern Ni-based superalloys ($1423K)are currently being developed to meet environmental and performance targets for future gas turbines.Creep and oxidation property goals have been proposed for the next generation of ultrahigh-temperature alloys [1,2].These are forecast to require coatings,like the Ni-based superalloys that they will replace.

Alloys based on refractory metal intermetallics have been studied as candidate materials due to their potential to o?er a balance of mechanical and environmental proper-ties combined with low density [1,2].Among the alloys studied,developmental Nb-silicide-based alloys have exceeded the proposed creep goal and have room-tempera-ture fracture toughness above 20MPa m 1/2[1].Alloying has signi?cantly improved the intrinsically poor oxidation of binary Nb–Si alloys [1–4],eliminating pest oxidation [5],and has closed the gap with the target property [1].Tin is one of the elements that has been shown to bene?t the oxidation of Nb-silicide-based alloys [1,6]when present at low concentrations and in synergy with speci?c alloying additions.Tin suppresses Nb 3Si [7],whereas in synergy with Ti and with Ti,Fe and Cr encourages,respectively,the transformation of b Nb 5Si 3to a Nb 5Si 3[7]and the for-mation of metastable Nb 3Si [8],while improvement in

oxidation is linked with the formation of Sn-rich interme-tallic below the scale [5,6].Whether or not spallation of the scale occurs seems to depend on the type of Nb–Sn intermetallic(s)stabilized at the scale–alloy interface and on their properties.

In order to understand alloy behavior in ternary and higher-order systems,knowledge of thermal and physical properties of the intermetallic compounds that are key to the development of the new alloys is critical.Phase equilib-ria data in Nb–Si-based systems with Sn are limited.Advancing our understanding of how alloying with Sn a?ects the microstructure and properties of Nb-silicide-based alloys and improving alloy design require a better understanding of the properties of the phases in the Nb–Sn binary system.

In the Nb–Sn system there are three stable intermetallics [9].Nb 3Sn has the A15structure,which is a close-packed structure whose stability is largely governed by size [10],has a primitive cell of 8atoms and belongs to the space group Pm 3n ;its Pearson symbol is cP 8and is of the Cr 3Si type;its melting temperature is 2647K.Nb 6Sn 5has a D2H-25orthorhombic structure with a primitive cell of 22atoms and belongs to the Immm space group with oI 45Pearson symbol and is of the a Ti 6Sn 5type;its melting temperature is $1180K.NbSn 2has the D2H-24orthorhombic struc-ture,Pearson symbol oI 48,space group Fddd and is of the CuMg 2type with its primitive cell containing 12atoms;its melting temperature is $1100K.Nb 3Sn has attracted interest due to its superconducting properties [11],with a transition temperature of 18.9K,and its high melting tem-perature.The other two intermetallics are also regarded as

https://www.360docs.net/doc/f818373465.html,/10.1016/j.actamat.2014.12.017

1359-6462/ó2014Acta Materialia Inc.Published by Elsevier Ltd.All rights reserved.

?Corresponding

author.Fax:+44(0)1142225943;e-mail:p.tsakir-opoulos@she?https://www.360docs.net/doc/f818373465.html,

Available online at https://www.360docs.net/doc/f818373465.html,

ScienceDirect

Acta Materialia 86(2015)

23–33

https://www.360docs.net/doc/f818373465.html,/locate/actamat

superconductors,with transition temperatures of 2.68and 2.07K for NbSn 2and Nb 6Sn 5,respectively [12].

The resistivity [13],heat capacity [14],electron–phonon interaction [15]and magnetic susceptibility [16]of the Nb 3Sn compound have been studied but there is limited data [14,17]about its thermodynamic properties.The elas-tic properties of the Nb 3Sn have also been calculated [18],but to the best of the authors’knowledge no data exists for the other two intermetallics in the Nb–Sn system.There is experimental and theoretical data for the vibrational and elastic properties of Nb [19]and Sn [20]and their Debye temperatures [21,22].

The motivation for the present study was to investigate the elastic and thermodynamic properties of the stable inter-metallics in the Nb–Sn binary system.The paper focuses on the calculation of the elastic constants and phonon proper-ties to produce a complete set of data for the Nb 3Sn,Nb 6Sn 5and NbSn 2intermetallics.This data is currently being used to support the design of Nb-silicide-based https://www.360docs.net/doc/f818373465.html,putational details 2.1.Methodology

Calculations were performed using the CASTEP (Cam-bridge Serial Total Energy Package)code [23].The Kohn–Sham approach was used to calculate the fundamental eigenvalues [24].The interaction between valence electrons and core electrons was treated under the pseudo-potential approximation and the plane-wave approach [25].The exchange-correlation energy was evaluated with the help of the Perdew–Wang functional (PW91)approach [26].To reduce the basis set of plane-wave functions used to describe the real electronic functions,norm-conserving pseudo-potentials [27]were implemented and the valences for the atomic con?gurations were Sn-5s 25p 2and Nb-4d 45s 1.After conducting careful convergence tests it was found that an energy cuto?of 500eV was su?cient to reduce the error in the total energy to <0.1meV atom à1.

A Monkhorst–Pack k-point grid separation of 0.03A

?à1was employed for the integration over the Brillouin zone according to the Monkhorst–Pack scheme [28].A well-con-verged k-point set is needed to calculate high-quality ther-modynamic property values,and therefore separate convergence tests were carried out to ensure that the error in the phonon frequencies was <10à3cm à1.A ?nite basis set correction and the Pulay scheme of density mixing were applied for the evaluation of energy and stress,while the electronic energy tolerance for the self-consistent ?eld (SCF)solver was 1?10à10eV.A Gaussian smearing of 0.7eV was introduced to eliminate discontinuous changes in energy when an energy band crosses the Fermi level dur-ing the self-consistent procedure,ensuring that k-points will be more e?ective on the Fermi surface.Geometry optimiza-tions of the structures were performed within the Broyden–Fletcher–Goldfarb–Shanno (BFGS)minimization scheme [29],with the following thresholds for converged structures:

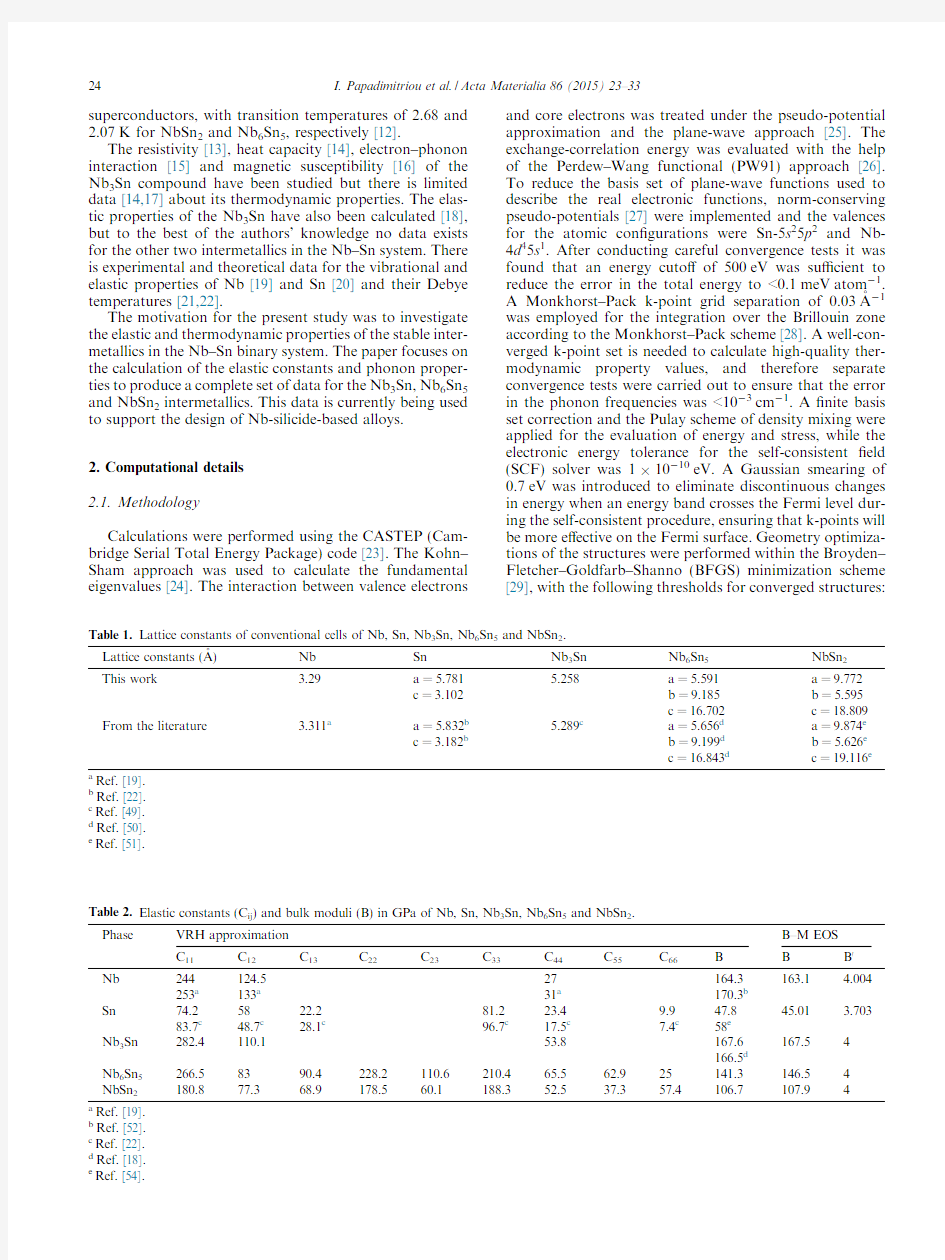

Table 2.Elastic constants (C ij )and bulk moduli (B)in GPa of Nb,Sn,Nb 3Sn,Nb 6Sn 5and NbSn 2.Phase VRH approximation B–M EOS C 11C 12C 13

C 22

C 23

C 33

C 44C 55

C 66

B B B 0Nb 244124.527164.3163.1 4.004253a 133a 31a 170.3b Sn 74.25822.281.223.49.947.845.01 3.70383.7c 48.7c 28.1c 96.7c 17.5c 7.4c

58e Nb 3Sn 282.4110.153.8167.6167.54166.5d Nb 6Sn 5266.58390.4228.2110.6210.465.562.925141.3146.54NbSn 2

180.8

77.3

68.9178.560.1188.352.5

37.357.4

106.7

107.9

4

a

Ref.[19].b

Ref.[52].c

Ref.[22].d

Ref.[18].e

Ref.[54].

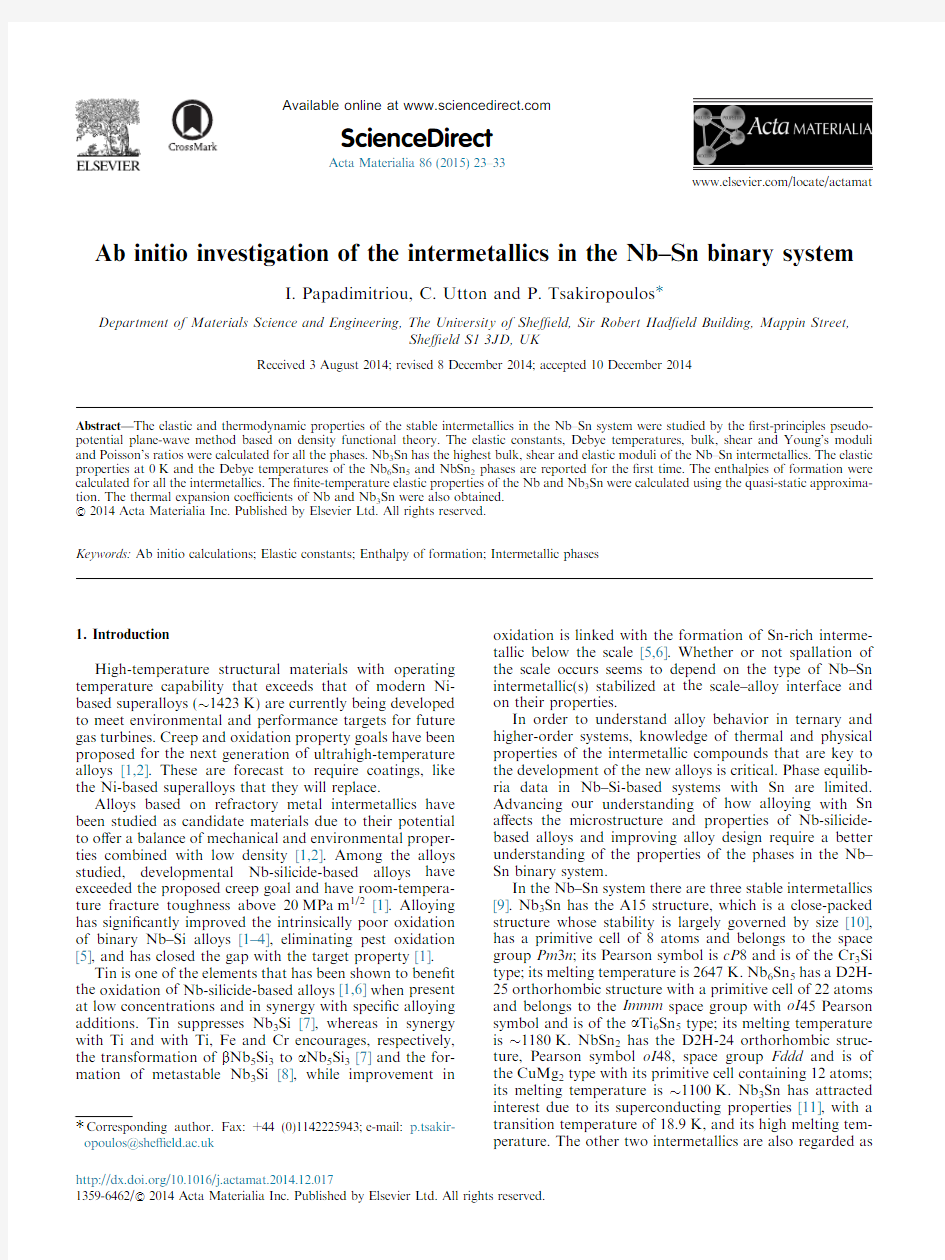

Table https://www.360docs.net/doc/f818373465.html,ttice constants of conventional cells of Nb,Sn,Nb 3Sn,Nb 6Sn 5and NbSn 2.

Lattice constants (A ?)Nb Sn Nb 3Sn Nb 6Sn 5NbSn 2This work

3.29

a =5.781

c =3.102 5.258

a =5.591

b =9.185

c =16.702a =9.772b =5.595c =18.809From the literature

3.311a a =5.832b c =3.182b

5.289c

a =5.656d

b =9.199d

c =16.843d

a =9.874e

b =5.626e

c =19.116e

a

Ref.[19].b

Ref.[22].c

Ref.[49].d

Ref.[50].e

Ref.[51].

24I.Papadimitriou et al./Acta Materialia 86(2015)23–33

energy change per atom,maximum residual force,maxi-mum atomic displacement and maximum stress less than

1?10à7eV,1?10à4eV A

?à1,1?10à4A ?and 0.001GPa,respectively.2.2.Elastic properties

The elastic constants of a material describe its response to an applied stress,or the stress required to maintain a dis-tortion.The method to determine elastic constants con-sisted of applying a given strain and calculating the stress.The unit cell was kept ?xed at each deformation and the internal coordinates were optimized.Both stress and strain have three tensile and three shear components,giving six in total.The linear elastic constants form a 6?6matrix such that r i =C ij e j for small stress r and strain e .This matrix can be reduced as the strain patterns (sets of distortions)are based on the crystal structure of each phase by taking advantage of the linear combinations of the second-order elastic constants.Thus,the maximum number of patterns required for an orthorhombic structure is three,two for tetragonal and one for cubic cells.Six strain steps (varying from à0.003to 0.003)were used for each pattern to obtain a reliable linear ?t of the stress–strain relationship.

For the orthorhombic Nb 6Sn 5and NbSn 2phases a ser-ies of 18geometry optimizations were conducted in order to evaluate the nine independent elastic constants C 11,C 12,C 13,C 22,C 23,C 33,C 44,C 55and C 66.After acquiring the elastic constants matrix and con?rming that the mechanical stability criteria [30]are satis?ed,the bulk (B),Young’s (E)and shear (G)moduli and Poisson’s ratio (v)were obtained by using the Voigt–Reuss–Hill approxi-mation (VRH)[31,32].The Debye temperature at low tem-peratures was determined from elastic constants using the equations in Ref.[33],since at low temperatures the vibra-tional excitations arise solely from acoustic modes,i.e.when the Debye temperature is associated with lattice vibrations.In order to con?rm the values of the bulk mod-uli,a ?t of the energies vs.the volumes of the strained struc-tures in the third-order Birch–Murnaghan equation of state (B–M EOS)[34]was carried out.2.3.Linear response method

The entropic contributions play a predominant role in the structural stability of intermetallic phases.In the case of strongly ordered compounds the main contribution comes from the vibrational entropy,as the electronic and con?gurationally entropies are considered to be relatively small [35].Density functional perturbation theory (DFPT),or linear response,which is one of the most popular meth-ods of lattice dynamics [36,37],was used in order to obtain the vibrational density of states.When ionic positions are perturbed,the dynamic matrix and phonon frequencies can be obtained.It was ?rst ensured that every system was in the ground state,i.e.the geometry optimization was fully converged as any underconverged structure could yield imaginary phonon frequency eigenvalues,which is indicative of mechanical instability.After directly comput-ing the phonon frequencies on a Monkhorst–Pack q-vector

grid with 0.05A

?à1separation,the results were interpolated onto a very dense q-point set,and thus the phonon density of states (DOS)was obtained for each phase under investi-gation.By using the phonon DOS and the data in Ref.[36],

T a b l e 3.C a l c u l a t e d s h e a r m o d u l u s (G ),e l a s t i c m o d u l u s (E )i n G P a ,P o i s s o n ’s r a t i o (v ),C a u c h y p r e s s u r e s (C 12–C 44f o r c u b i c ,C 13–C 44a n d C 12–C 66f o r t e t r a g o n a l a n d h e x a g o n a l a n d C 12–C 66,C 13–C 55a n d C 23–C 44f o r o r t h o r h o m b i c )i n G P a ,G /B r a t i o a n d D e b y e t e m p e r a t u r e (H D )f r o m e l a s t i c c o n s t a n t s f o r N b ,S n ,N b 6S n 5,N b S n 2a n d N b 3S n .

P h a s e

G E

v

C 12–C 44C 13–C 44C 12–C 66C 13–C 55C 23–C 44G /B

H D (K )V R H

V R H

P h o n o n D O S

E l a s t i c c o n s t a n t s N b 37.437.5a

104.3101.9a

0.39497.5

0.228277268275b

267c

S n 17.318f

46.250f

0.339à1.248.10.362181170202e

N b 3S n 6574.9d

172.7195.3d

0.32856.30.388291336308b

282d N b 6S n 5

54143.70.3315827.545.10.382201218N b S n 251.4

132.9

0.292

19.9

31.67.6

0.482239256

a

R e f .[52].b R e f .[21].c R e f .[53].d R e f [18].e R e f .[22].f R e f .[54].

I.Papadimitriou et al./Acta Materialia 86(2015)23–33

25

Fig.1.Phonon density of states of Nb,Sn,Nb3Sn,Nb6Sn5and NbSn2.

Phonon contribution to free energies calculated by the linear response method for all intermetallics and single elements.The Nb,Nb3Sn(numbered3,4and5,respectively)are very close to each other.The NbSn2curve is denoted as1and the curve of Sn diagram as(a),for a smaller range of temperatures(1200–1700K),showing the curves of Nb6Sn5,Nb,Nb3Sn.

are extracted from the volume dependencies of the pho-non density of states calculated at 0K.The procedure consists of three main steps.The ?rst is to express the

0K elastic constants as a function of volume,using the stress–strain approach described in Section 2.2.The sec-ond step is to calculate the equilibrium volume V(T,P)at every given temperature using the quasi-harmonic approximation (see Section 2.3)by minimizing the total free energy with respect to volume,thus ?nding the equi-librium volume at each temperature.In the present study the investigated structures were obtained by varying the ratio V/V 0(V 0being the equilibrium volume)from 0.991to 1.006in increments of 0.003.In all the structures the internal freedoms within the unit cell were fully relaxed before proceeding to the phonon calculations.In the third step the computed elastic constants from the ?rst step at the volume V(T,P)were approximated as the correspond-ing values at ?nite temperatures.In order for the evalua-tion of the elastic constants as a function of temperature to be as accurate as possible,high-precision geometry optimization calculations for di?erent volumes and

robust

contributions to the enthalpy of formation and (b)calculated total enthalpy of formation vs.temperature for Table 4.Calculated enthalpies of formation of Nb 6Sn 5,NbSn 2and Nb 3Sn.

Temperature (K)Enthalpy of formation (kJ mol à1)Nb 3Sn Nb 6Sn 5NbSn 20à16.542à25.755à18.434298à15.628à24.829

à17.583

298à16.57c 298à16.19c 298à16.4b 298à16a

à22a à16a

a

Ref.[42].b Ref.[43].c

Ref.[44].

phonon calculations are needed to obtain accurate pho-non DOS at di?erent https://www.360docs.net/doc/f818373465.html,ing the approximation described above,resource-intensive free energy vs.strain calculations are avoided.Furthermore,application of inhomogeneous strain is not required as this method con-siders volume rather than strain,which is much cheaper in calculation cost terms as the symmetry of the crystal is retained.

In the above procedure the assumption was made that any change in the elastic constants was solely due to the thermal expansion,which is in accordance with reports [40]for cubic symmetry.Furthermore,the thermal expan-sion of cubic systems can be regarded as isotropic.Hence,in this study the quasi-static approximation was imple-mented only for the cubic Nb and Nb3Sn phases.

3.Results and discussion

3.1.Elastic properties at0K

The calculated lattice constants of Nb,Sn,Nb3Sn, Nb6Sn5and NbSn2are given in Table1.The values obtained in the present work are in good agreement with those reported in the literature.The highest deviation ($2.5%)is for the c lattice parameter of Sn.Table2

gives Fig.4.Temperature dependence of the volume of(a)Nb and(b)Nb3Sn.

the results for the independent elastic constants (C ij ),bulk moduli (B)calculated from elastic constants according to the VRH approximation,and the bulk moduli and ?rst pressure derivatives of bulk moduli (B 0)from the B–M EOS for all compounds and elements at 0K.The mechan-ical stability criteria [30]were satis?ed for all phases.The elastic constants and bulk moduli were in good agreement with experimental data for the pure elements [19,22]and with a previous theoretical study [18]of Nb 3Sn.Further-more,the bulk moduli obtained by the B–M EOS ?tting were in very good agreement with those calculated

using

Fig.5.The C 11(1),C 12(2)and C 44(3)elastic constants of (a)Nb and (b)Nb 3Sn vs.temperature.

Table 5.Calculated elastic constants and bulk and shear moduli in GPa of Nb and Nb 3Sn at 300K compared with available experimental results.Phase C 11C 12C 44B G Nb 233.7119.325.2157.435.2235a 121a 28.2a 159a 37.5a Nb 3Sn

265.4104.851.3158.361.4253.8b

112.4b

39.6b

159.5b

50.1b

a Ref.[47].

b

Ref.[48](single crystal).

the VRH approximation,with the biggest deviation ($3.5%)for Nb6Sn5.Nb3Sn had the highest bulk modulus (166.5GPa).The bulk modulus decreased to141.3GPa for Nb6Sn5and to106.7GPa for NbSn2.Thus,among the three intermetallics the Nb3Sn phase is the most resistant to uniform compression.

The calculated values of the shear(G)and Young’s(E) moduli are given in Table3.Nb3Sn has the highest shear modulus,and this decreases in the same sequence as the bulk modulus,which means that Nb3Sn is the most resis-tant compound of the three to plastic deformation.The same is true for the ranking of the intermetallics in terms of their sti?ness with the elastic modulus(E)values being 172.7GPa for Nb3Sn,143.7GPa for Nb6Sn5and 132.9GPa for NbSn2.

The values of the Cauchy pressures(C12–C44for cubic, C13–C44and C12–C66for tetragonal and hexagonal,and C12–C66,C13–C55and C23–C44for orthorhombic)are also listed in Table3.According to Ref.[41],for metallic bond-ing a positive value of Cauchy pressure means a more duc-tile material.Pugh’s index of ductility[55](the shear modulus over bulk modulus ratio(G/B))and the

Poisson’s Fig.6.Bulk(1),shear(2)and Young’s(3)moduli of(a)Nb and(b)Nb3Sn vs.temperature.

ratio(v)are the parameters that also indicate ductility.A compound is considered brittle if the G/B ratio is>0.57 or v is<0.26.Thus,the data in Table3indicates that the least ductile stable intermetallic in the Nb–Sn binary system is NbSn2.

3.2.Enthalpies of formation

The vibrational DOS for the compounds and elemental phases is shown in Fig.1.All the eigenfrequencies were found to be real,hence it is con?rmed that the compounds under investigation are mechanically stable.After obtain-ing the computed phonon DOS,the vibrational contribu-tion to the free energy per atom(F phon(T))was calculated and is presented for the compounds and elemen-tal phases in Fig.2.The F phonon(T)of the intermetallics decreases in the following order:Nb3Sn–Nb6Sn5–NbSn2 with the?rst two almost coinciding and the latter decreas-ing much faster.After taking F phonon(T)into account,the phonon contribution to the enthalpy of formation(D H f phon (T))was evaluated(Fig.3a).The D H f phon(T)rises faster in the following order:NbSn2–Nb6Sn5–Nb3Sn.In Fig.3b the enthalpy of formation vs.temperature of all the stable intermetallic compounds of the Nb–Sn system is

shown. Fig.7.The Poisson’s ratios of(a)Nb and(b)Nb3Sn vs.temperature.

In Table4the enthalpies of formation of the intermetallics of the present study are compared with the available litera-ture[42–44]and it can be seen that there is good agreement.

3.3.Temperature dependence of elastic properties

In order to investigate the temperature dependence of the elastic properties of the cubic phases in the present study(Nb and Nb3Sn),the quasi-static approximation was implemented.First the temperature dependence of the volume was calculated,as discussed in Section 2.4. The volume vs.temperature curves of Nb and Nb3Sn are shown in Fig.4.The linear thermal expansion coe?cients at293K of Nb and Nb3Sn were calculated using this data and were respectively$7.9?10à6and$6.4?10à6Kà1,in good agreement with the literature[45,46].In Fig.5the elastic constants vs.temperature of the cubic phases are https://www.360docs.net/doc/f818373465.html,paring the results for Nb with the literature [47]it can be seen that overall the agreement is very good (Table5).The C44constant of Nb becomes negative at 2750K,which coincides with its melting point.Moreover C44decreased slower than the other independent constants, and C11decreased the fastest.The results for Nb3Sn were also in good agreement with the experimental data[48]. The curves of the C12and C44constants had similar slopes, with the latter decreasing slightly slower than the former, while the curve of C11showed the steepest descent of all three independent elastic constants.The largest discrepancy at300K was noticed for the C44coe?cient with the results of the current study and the literature being$51and $40GPa,respectively.

After obtaining the elastic constants of both phases,the bulk,shear and elastic moduli were computed with the VRH approximation(Fig.6).All the moduli decreased with increasing temperature.The bulk and elastic moduli of the Nb and Nb3Sn exhibited similar gradients and the shear modulus decreased more slowly.The bulk modulus curve of the Nb3Sn crosses the Young’s modulus curve at 2600K where the former becomes higher.Furthermore, owing to the above behavior of the bulk and shear moduli of both phases,the Poisson’s ratio showed an increasing slope(Fig.7).In the case of Nb,v increased to$0.47close to the melting point,starting from$0.39(see Table3)at 0K.For Nb3Sn,onthe other hand,the total increase was smaller,from$0.328at0K(Table3)to$0.335at the compound’s melting point.In addition,it must be noted that the curve increases more slowly until$2200K,above which it rises signi?cantly.

3.4.Debye temperatures

The phonon DOS was used to calculate the Debye tem-peratures.It should be noted that it is considered more dif-?cult to obtain accurate values using phonon DOS rather than the elastic constants(see Section3.3),because as a low-temperature property the Debye temperature is deter-mined by low-energy phonons,i.e.the acoustic phonons. The lower the temperature,the smaller the part that the Brillouin zone contributes to thermodynamics.The values calculated using the phonon DOS(Table3)were in very good agreement with Refs.[18,21]and those calculated from the elastic constant values.For the elemental and intermetallic phases,both the results for the Debye temper-atures calculated from the phonon DOS and the elastic constants were in excellent agreement with the available data in the literature(Table3).

4.Conclusions

First-principles calculations were carried out for the intermetallic compounds Nb3Sn,Nb6Sn5and NbSn2and for the elements Nb and Sn.The elastic constants,bulk, shear and Young’s moduli,Poisson’s ratio and Debye tem-peratures were calculated for all the phases and were in good agreement with the available data in the literature. It is concluded that of all the Nb–Sn intermetallic com-pounds,Nb6Sn5is the least brittle.The elastic properties and Debye temperature of the Nb6Sn5and NbSn2interme-tallics were reported for the?rst time.Furthermore,the enthalpies of formation vs.temperature were calculated for all the intermetallic https://www.360docs.net/doc/f818373465.html,bining the quasi-harmonic with the quasi-static approximation,the temper-ature dependence of the bulk,shear and elastic moduli and Poisson’s ratios of Nb and Nb3Sn were calculated and were in good agreement with the available data in the literature. The thermal expansion coe?cients of Nb and Nb3Sn were also obtained.

Acknowledgements

The support of this work by the FP-7Accelerated Metallurgy project and the EPSRC–Rolls Royce research partnership,and useful discussion with Dr A.Scott,are gratefully acknowledged. References

[1]B.P.Bewlay,M.R.Jackson,M.F.X.Gigliotti,in:R.L.

Fleischer,J.H.Westbrook(Eds.),Intermetallic Compounds: Principles and Practice,vol.3,John Wiley,New York,2001, p.541.

[2]P.Tsakiropoulos,Beyond nickel based superalloys,in:R.

Blockley,W.Shyy(Eds.),Encyclopedia of Aerospace Engi-neering,John Wiley,New York,2010,p.2345.

[3]J.Geng,P.Tsakiropoulos,G.Shao,Mater.Sci.Eng.A441

(2006)26.

[4]K.Zelenitsas,P.Tsakiropoulos,Mater.Sci.Eng.A416

(2006)269.

[5]J.Geng,P.Tsakiropoulos,G.Shao,Intermetallics15(2007)

69.

[6]J.Geng,P.Tsakiropoulos,G.Shao,Intermetallics15(2007)

270.

[7]N.Vellios,P.Tsakiropoulos,Intermetallics15(2007)1518.

[8]N.Vellios,P.Tsakiropoulos,Intermetallics18(2010)1729.

[9]C.To?olon,C.Servant,J.C.Gachon,B.Sundman,J.Phase

Equil.23(2002)134.

[10]A.K.Sinha,Prog.Mater.Sci.15(1972)79.

[11]D.Dew-Hughes,Cryogenics15(1975)435.

[12]J.P.Charlesworth,Phys.Lett.21(1966)501.

[13]Z.Fisk,G.W.Webb,Phys.Rev.Lett.36(1976)1084.

[14]G.W.Webb,Z.Fisk,J.J.Engelhardt,S.D.Bader,Phys.Rev.

B15(1977)2624.

[15]B.M.Klein,L.L.Boyer,D.A.Papaconstantopoulos,Phys.

Rev.Lett.42(1979)530.

[16]W.Rehwald,M.Rayl,R.W.Cohen,G.D.Cody,Phys.Rev.

B6(1972)363.

[17]G.S.Knapp,S.D.Bader,Z.Fisk,Phys.Rev.B13(1976)

3783.

[18]M.Sundareswari,S.Ramasubramanian,M.Rajagopalan,

Solid State Commun.150(2010)2057.

32I.Papadimitriou et al./Acta Materialia86(2015)23–33

[19]P.Soderlind,O.Eriksson,J.M.Wills,A.M.Boring,Phys.

Rev.B48(1993)5844.

[20]J.Moon,K.Cho,M.Cho,Int.J.Precis.Eng.Manuf.13

(2012)1191.

[21]C.Kittel,Introduction to Solid State Physics,eigth ed.,John

Wiley,New York,2005,p.116.

[22]J.A.Rayne,B.S.Chandrasekhar,Phys.Rev.120(1960)1658.

[23]S.J.Clark,M.D.Segall, C.J.Pickard,P.J.Hasnip,M.J.

Probert,K.Refson,M.C.Payne,Z.Kristall.220(2005)567.

[24]W.Kohn,L.J.Sham,Phys.Rev.140(1965)A1133.

[25]M.C.Payne,M.P.Teter, D.C.Allan,T.A.Arias,J.D.

Joannopoulos,Rev.Mod.Phys.64(1992)1045.

[26]J.P.Perdew,J.A.Chevary,S.H.Vosko,K.A.Jackson,M.R.

Pederson,D.J.Singh,C.Fiolhais,Phys.Rev.B46(1992) 6671.

[27]J.S.Lin,A.Qteish,M.C.Payne,V.Heine,Phys.Rev.B47

(1993)4174.

[28]H.J.Monkhorst,J.D.Pack,Phys.Rev.B13(1976)5188.

[29]B.G.Pfrommer,M.Cote,S.G.Louie,M.L.Cohen,J.

Comput.Phys.131(1997)233.

[30]M.Born,J.Phys.Chem.Solids7(1939)591.

[31]R.Hill,Proc.Phys.Soc.Lond.Sect.A65(1952)349.

[32]A.Z.Reuss,Angew.Math.Mech.9(1929)49.

[33]O.L.Anderson,J.Phys.Chem.Solids24(1963)909.

[34]F.Birch,Phys.Rev.71(1947)809.

[35]Y.Wang,C.Woodward,S.H.Zhou,Z.K.Liu,L.Q.Chen,

Scr.Mater.52(2005)17.

[36]S.Baroni,S.de Gironcoli,A.Dal Corso,P.Giannozzi,Rev.

Mod.Phys.73(2001)515.

[37]S.De Gironcoli,Phys.Rev.B51(1995)6773.[38]S.L.Shang,H.Zhang,Y.Wang,Z.K.Liu,J.Phys.Condens.

Matter.22(2010)375403.

[39]Y.Wang,J.J.Wang,H.Zhang,V.R.Manga,S.L.Shang,

L.Q.Chen,Z.K.Liu,J.Phys.Condens.Matter.22(2010) 225404.

[40]O.Gulseren,R.E.Cohen,Phys.Rev.B65(2002)064103.

[41]D.G.Pettifor,Mater.Sci.Technol.8(1992)345.

[42]F.deBoer,R.Boom,W.C.Mattens, A.R.Miedema,

A.K.Niessen,Cohesion in Metals,Transition Metal Alloys.

Amsterdam:North Holland,1988.

[43]A.R.Miedema,P.F.Dechatel,F.R.Deboer,Phys.B&C100

(1980)1.

[44]R.A.Schi?man,D.M.Bailey,High Temp.Sci.15(1982)165.

[45]R.Grill,A.Gnadenberger,Int.J.Refract.Metal Hard Mater.

24(2006)275.

[46]D.P.Boso,M.Le?k,B.A.Schre?er,Cryogenics46(2006)

569.

[47]R.J.Wasilewski,J.Phys.Chem.Solids26(1965)1643.

[48]K.R.Keller,J.J.Hanak,Phys.Lett.21(1966)263.

[49]C.Paduani,Braz.J.Phys.37(2007)1073.

[50]J.R.Ogren,T.G.Ellis,J.F.Smith,Acta Crystallogr.A18

(1965)968.

[51]T.Wo¨lpl,W.Jeitschko,J.Alloy Compd.210(1994)185.

[52]C.J.Smithells,Metal References Book,?fth ed.,Butterworth,

London,1976,p.975.

[53]F.Chu,M.Lei,S.A.Maloy,J.J.Petrovic,T.E.Mitchell,Acta

Mater.44(1996)3035.

[54]A.M.James,M.P.Lord,Macmillan’s Chemical and Physical

Data,Macmillan,London,1992.

[55]S.F.Pugh,Phil.Mag.45(1954)823.

I.Papadimitriou et al./Acta Materialia86(2015)23–3333

数学快速计算法

数学快速计算法 二位数乘法速算总汇 1、两位数的十位相同的,而个位的两数则是相补的(相加等于10)女口:78 X 72= 37 X 33= 56 X 54= 43 X 47 = 28 X 22 46 X 44 (1) 分别取两个数的第一位,而后一个的要加上一以后,相乘。 (2) 两个数的尾数相乘,(不满十,十位添作0) 78X 72=5616 37 X 33=1221 56 X 54= 3024 43 X 47= 2021 (7+1) X 7=56 (3+1) X 3=12 (5+1) X 5=30 (4+1) X 4=20 8X 2=16 7 X 3=21 6 X 4=24 3 X 7=21 口决:头加1,头乘头,尾乘尾 2、两个数的个位相同,十位的两数则是相补的 如:36 X 76= 43 X 63= 53 X 53= 28 X 88= 79 X 39 (1) 将两个数的首位相乘再加上未位数 (2) 两个数的尾数相乘(不满十,十位添作0) 36X 76=2736 43 X 63=2709 3X 7+6=27 4 X 6+3=27 6X 6=36 3 X 3=9 口决:头乘头加尾,尾乘尾 3、两位数的十位差1,个位的两数则是相补的。 如:48 X 52 12 X 28 39 X 11 48 X 32 96 X 84 75 X 65

即用较大的因数的十位数的平方,减去它的个位数的平方。

48 X 52=2496 12 X 28 = 336 39 X 11= 819 48 X 32=1536 2500-4=2496 400-64=336 900-81=819 1600-64=1536 口决:大数头平方 —尾平方 4、一个乘数十位加个位是 9,另一个乘数十位和个位是顺数 X 78 = 81 X 23 = 27 X 89 = 5 23 2 如:12 X 13= 13 X 15= 14 X 15= 16 X 18= 17 X 19= 19 X 18= (1) 尾数相乘 ,写在个位上 (满十进位 ) (2) 被乘数加上乘数的尾数 12X 13=156 13 X 15= 195 14 X 15=210 16 X 18= 288 2X 3=6 3 X 5=154X 5=20 6 X 8=48 12+3=15 13+5=18 14+5=19 16+8=24 口决:尾数相乘 ,被乘数加上乘数的尾数 (满十进位 ) 6、任何二位数数乘于 11 如 :36 X 45 = 72 X 67 = 45 1 、解 : 3+1=4 4 X 4 = 1的6补5 数是 4X 5=20所以 36 X 45= 1620 2、解: 7+1=8 8 X 6 = 4的8补7 数是 8X 3=24所以 72 X 67 = 4824 3、解: 4+1=5 5 X 7=3的5补8 数是 5X 2=10所以 45 X 78 = 3510 5、10-20 的两位数乘法

数学快速计算方法_乘法速算

一.两个20以内数的乘法 两个20以内数相乘,将一数的个位数与另一个数相加乘以10,然后再加两个尾数的积,就是应求的得数。如12×13=156,计算程序是将12的尾数2,加至13里,13加2等于15,15×10=150,然后加各个尾数的积得156,就是应求的积数。 二.首同尾互补的乘法 两个十位数相乘,首尾数相同,而尾十互补,其计算方法是:头加1,然后头乘为前积,尾乘尾为后积,两积连接起来,就是应求的得数。如26×24=624。计算程序是:被乘数26的头加1等于3,然后头乘头,就是3×2=6,尾乘尾6×4=24,相连为624。 三.乘数加倍,加半或减半的乘法 在首同尾互补的计算上,可以引深一步就是乘数可加倍,加半倍,也可减半计算,但是:加倍、加半或减半都不能有进位数或出现小数,如48×42是规定的算法,然而,可以将乘数42加倍位84,也可以减半位21,也可加半倍位63,都可以按规定方法计算。48×21=1008,48×63=3024,48×84=4032。有进位数的不能算。如87×83=7221,将83加倍166,或减半41.5,这都不能按规定的方法计算。 四.首尾互补与首尾相同的乘法 一个数首尾互补,而另一个数首尾相同,其计算方法是:头加1,然后头乘头为前积,尾乘尾为后积,两积相连为乘积。如37×33=1221,计算程序是(3+1)×3×100+7×3=1221。 五.两个头互补尾相同的乘法

两个十位数互补,两个尾数相同,其计算方法是:头乘头后加尾数为前积,尾自乘为后积。如48×68=3264。计算程序是4×6=24 24+8=32 32为前积,8×8=64为后积,两积相连就得3264。 六.首同尾非互补的乘法 两个十位数相乘,首位数相同,而两个尾数非互补,计算方法:头加1,头乘头,尾乘尾,把两个积连接起来。再看尾和尾的和比10大几还是小几,大几就加几个首位数,小几就减掉几个首位数。加减的位置是:一位在十位加减,两位在百位加减。如36×35=1260,计算时(3+1)×3=12 6×5=30 相连为1230 6+5=11,比10大1,就加一个首位3,一位在十位加,1230+30=1260 36×35就得1260。再如36×32=1152,程序是(3+1)×3=12,6×2=12,12与12相连为1212,6+2=8,比10小2减两个3,3×2=6,一位在十位减,1212-60就得1152。 七.一数相同一数非互补的乘法 两位数相乘,一数的和非互补,另一数相同,方法是:头加1,头乘头,尾乘尾,将两积连接起来后,再看被乘数横加之和比10大几就加几个乘数首。比10小几就减几个乘数首,加减位置:一位数十位加减,两位数百位加减,如65×77=5005,计算程序是(6+1)×7=49,5×7=35,相连为4935,6+5=11,比10大1,加一个7,一位数十位加。4935+70=5005 八.两头非互补两尾相同的乘法 两个头非互补,两个尾相同,其计算方法是:头乘头加尾数,尾自乘。两积连接起来后,再看两个头的和比10大几或小几,比10大几就加几个尾数,小几就减几个尾数,加减位置:一位数十位加减,两位数百位加减。如67×87=5829,计算程序是:6×8+7=55,7×7=49,相连为5549,6+8=14,比10大4,就加四个7,4×7=28,两位数百位加,5549+280=5829

工程量快速计算的基本方法经验

工程量快速计算的基本方法经验 本章所述工程量快速计算的基本方法包括:练好“三个基本功”;合理安排工程量计算顺序;灵活运用“统筹法”计算原理;充分利用“工程量计算手册”等四项内容。在实际工作中,只要能够熟练掌握,充分利用以上“基本方法”,就可以快速提高工程量计算业务水平。 第一节练好“三个基本功” 练好“三个基本功”包括:提高看图技能;熟悉常用标准图做法;熟悉工程量计算规则,等三个方面。 一、提高看图技能 工程量计算前的看图,要先从头到尾浏览整套图纸,待对其设计意图大概了解后,再选择重点详细看图。在看图过程中要着重弄清以下几个问题: (一)建筑图部分 1、了解建筑物的层数和高度(包括层高和总高)、室内外高差、结构形式、纵向总长及跨度等。 2、了解工程的用料及作法,包括楼地面、屋面、门窗、墙柱面装饰的用料及法。 3、了解建筑物的墙厚、楼地面面层、门窗、天棚、内墙饰面等在不同的楼层上有无变化(包括材料做法、尺寸、数量等变化),以便采用不同的计算方法。 (二)结构图部分 1、了解基础形式、深度、土壤类别、开挖方式(按施工方案确定)以及基础、墙体的材料及做法。 2、了解结构设计说明中涉及工程量计算的相关内容,包括砌筑砂浆类别、强度等级,现浇和预制构件的混凝土强度等级、钢筋的锚固和搭接规定等,以便全面领会图纸的设计意图,避免重算或漏算。 3、了解构件的平面布置及节点图的索引位置,以免在计算时乱翻图纸查找,浪费时

间。 4、砖混结构要弄清圈梁有几种截面高度,具体分布在墙体的那些部位,圈梁在阳台及门窗洞口处截面有何变化,内外墙圈梁宽度是否一致,以便在计算圈梁体积时,按不同宽度进行分段计算。 5、带有挑檐、阳台、雨篷的建筑物,要弄清悬挑构件与相交的连梁或圈梁的连结关系,以便在计算时做到心中有数。 目前施工图预算和工程量清单的编制主要是围绕工程招投标进行的,工程发标后按照惯例,建设单位一般在三天以内要组织有关方面对图纸进行答凝,因此,预算(或清单)编制人员在此阶段应抓紧时间看图,对图纸中存在的问题作好记录整理。在看图过程中不要急于计算,避免盲目计算后又有所变化造成来回调整。但是对“门窗表”、“构件索引表”、“钢筋明细表”中的构件以及钢筋的规格型号、数量、尺寸,要进行复核,待图纸答凝后,根据“图纸答凝纪要”对图纸进行全面修正,然后再进行计算。 计算工程量时,图中有些部位的尺寸和标高不清楚的地方,应该用建筑图和结构图对照着看,比如装饰工程在计算天棚抹灰时,要计算梁侧的抹灰面积,由于建筑图中不标注梁的截面尺寸,因此,要对照结构图中梁的节点大样计算。再如计算框架间砌体时,要扣除墙体上部的梁高度,其方法是按结构图中的梁编号,查出大样图的梁截面尺寸,标注在梁所在轴线的墙体部位上,然后进行计算。 从事概预算工作时间不长,而又渴望提高看图技能的初学人员,在必要时应根据工程的施工进度,分阶段深入现场了解情况,用图纸与各分项工程实体相对照,以便加深对图纸的理解,扩展空间思维,从而快速提高看图技能。 二、熟悉常用标准图做法 在工程量计算过程中,时常需要查阅各种标准图集,实在繁琐,如果能把常用标准图中的一些常用节点及做法,留在记忆里,在工程量计算时,不需要查阅图集就知道其工程内容和做法,这将节省不少时间,从而可以大大提高工作效率。 工程中常用标准图集基本上为各省编制的民用建筑及结构标准图集,而国标图集以采用

快速计算方法

快速计算方法? 1.十几乘十几口诀:头乘头,尾加尾,尾乘尾。例:12×14=?解: 1×1=1 2+4=6 2×4=8 12×14=168 注:个位相乘,不够两位数要用0占位。 2.头相同,尾互补(尾相加等于1 0):口诀:一个头加1后,头乘头,尾乘尾。例:23×27=?解:2+1=3 2×3=6 3×7=21 23×27=621 注:个位相乘,不够两位数要用0占位。 3.第一个乘数互补,另一个乘数数字相同:口诀:一个头加1后,头乘头,尾乘尾。例:37×44=?解:3+1=4 4×4=16 7×4=28 37×44=1628 注:个位相乘,不够两位数要用0占位。 4.几十一乘几十一:口诀:头乘头,头加头,尾乘尾。例:21×41=?解:2×4=8 2+4=6 1×1=1 21×41=861 5.11乘任意数:口诀:首尾不动下落,中间之和下拉。例:11×23125=?解:2+3=5 3+1=4 1+2 =3 2+5=7 2和5分别在首尾11×23125=254375 注:和满十要进一。 6.十几乘任意数: 口诀:第二乘数首位不动向下落,第一因数的个位乘以第二因数后面每一个数字,加下一位数,再向下落。例:13×326=?解:13个位是3 3×3+2=11 3×2+6=12 3×6=18 13×326=42 38 注:和满十要进一。 快速计算方法? 数学快速计算方法 第一讲加法速算 一.凑整加法 凑整加法就是凑整加差法,先凑成整数后加差数,就能算的快。8+7=15 计算时先将8凑成10 8加2等于 10 7减2等于5 10+5=15

如17+9=26 计算程序是17+3=20 9-3=6 20+6=26 二 .补数加法 补数加法速度快,主要是没有逐位进位的麻烦。补数就是两个数的和为10 100 1000 等等。8+2=10 78+22=100 8是2的补数,2也是8的补数,78是22的补数,22也是78的补数。利用补数进行加法计算的方法是十位加1,个位减补。例如6+8=14 计算时在6的十位加上1,变成16,再从16中减去8的 补数2就得14 如6+7=13 先6+10=16 后16-3=13 如27+8=35 27+10=37 37-2=35 如25+85=110 25+100=125 125-15=110 如867+898=1765 867+1000=1867 1867-102=1765 三.调换位置的加法 两个十位数互换位置,有速算方法是:十位加个位,和是一位和是双,和是两位相加排中央。例如61+16

工程量快速计算方法

工程量快速计算方法 工程量是施工企业编制工程形象进度统计报表,向工程建设投资方结算工程价款的重要依据。今天我们总结了几方面工程量估算的便捷方法,一起来看吧。 平整场地 计算规则: 1、清单规则:按设计图示尺寸以建筑物首层面积计算。 2、定额规则:按设计图示尺寸以建筑物首层面积计算。 计算方法: 1、清单规则的平整场地面积:清单规则的平整场地面积=首层建筑面积。 2、定额规则的平整场地面积:定额规则的平整场地面积=首层建筑面积。 注意事项:

1、有的地区定额规则的平整场地面积:按外墙外皮线外放2m计算。计算时按外墙外边线外放2m的图形分块计算,然后与底层建筑面积合并计算;或者按“外放2m 的中心线×2=外放2m面积”与底层建筑面积合并计算。?为什么夫妻“雲雨”,女性很难达到“癫峰”?与这几点有关这样的话计算时会出现如下难点: 1)划分块比较麻烦,弧线部分不好处理,容易出现误差; 2)2m的中心线计算起来较麻烦,不好计算; 3)外放2m后可能出现重叠部分,到底应该扣除多少不好计算。 2、清单环境下投标人报价时候可能需要根据现场的实际情况计算平整场地的工程量,每边外放的长度不一样。 开挖土方 计算规则: 1、清单规则:挖基础土方按设计图示尺寸以基础垫层底面积乘挖土深度计算。

2、定额规则:人工或机械挖土方的体积应按槽底面积乘以挖土深度计算。槽底面积应以槽底的长乘以槽底的宽,槽底长和宽是指混凝土垫层外边线加工作面,如有排水沟应算至排水沟外边线。排水沟的体积应纳入总土方量内。当需要放坡时,应将放坡的土方量合并于总土方量中。 计算方法: 1、清单规则: 1)计算挖土方底面积: 方法一:利用底层的建筑面积+外墙外皮到垫层外皮的面积。外墙外边线到垫层外边线的面积计算(按外墙外边线外放图形分块计算或者按“外放图形的中心线×外放长度”计算)。 方法二:分块计算垫层外边线的面积(同分块计算建筑面积)。 2)计算挖土方的体积: 土方体积=挖土方的底面积×挖土深度。 2、定额规则: 利用棱台体积公式计算挖土方的上下底面积。 V=1/6×H×(S上+ 4×S中+ S下)计算土方体积(其中,S上为上底面积,S中为中截面面积,S下为下底面面积)。

快速算法大全

内部函授教材(全套二十六讲) 第一讲:1、十几乘十几速算法——将前边的数加后边尾数,然后两个尾数再相乘。(注:满10进1)。 例:12×14=(12+4)连接(2×4)=168。2、十几乘几十几一将被乘数的个位乘以 乘数的十位,再加到乘数、最后加上它们的个位乘积。例:14×72=[(4×7)+72]连 接(4×2)=1008。3、一百零几乘一百零几一将一个数加上另一个数的个位数,最后加上它们个位数乘积。例:104×108=(104+8)连接(4×8)=11232。4、如果十位相同,个位之和为10的两个两位数相乘,其速算法一将十位加上1后再乘以十位,最后加上它们个位乘积。例:63×67=(6+1) ×6连接(3×7)=4221。5、十位数相同,个位不同且之和不等10的两个两位数相乘,只要将其中一个数加上另一个数的个位数,并乘以十位,最后加上它们个位乘积。例:63×69=(63+9) ×6连接(3×9)=4347。6、 一百零几乘几十几,方法是一将一百零几分成两段计算,将1乘以乘数,然后又用零 几乘以乘数(注:满10进1)。例:102×24=2448。说明:1×24=24。02×24=48。这时,只需将两段之乘积加以排列即是2448。 第二讲:求九十几与九十几的积。 方法:用一个数减去另一个数的补数,在差的后接着写两个数的补数积,如果补数积不满10,就在它前面添一个“0”此数就是得数。例:97×96=(97-4)连接(3× 4)=9312 第三讲:求两个九百九十几的数的积。 方法:在一个数减去另一个数的补数的差的后面,添一个“0”,再添上两个数的补 数的积。如果补数积不满10,就在它前面再添一个“0”,此数就是得数。例:994×992=(994-8) ×1000+8×6=986048 (994的补数6,992补数8) 第四讲:求两个连续数的积。方法:用较小数的平方加上较小数,或用较大数的平方减去较大数,皆可。 例1:35×36=1225+35=1260(1225即352) 例2:49×50=2500-50=2450(2500即502) 第五讲:求首差一,尾合十的两个两位数之积。方法:用较大数的十位数的平方减去 1,在差的后面添上较大的个位数的平方对于100的补数,所得的数就是积。 例1:42×38(42-1) ×100(100-22)=1596 例2:57×63=(62-1) ×100(100-32)=3591

工程量快速计算的基本方法75434

工程量快速计算的基本方法 工程量快速计算的基本方法包练好“三个基本功”;合理安排工程量计算顺序;灵活运用“统筹法”计算原理;充分利用“工程量计算手册”等四项内容。在实际工作中,只要能够熟练掌握,充分利用以上“基本方法”,就可以快速提高工程量计算业务水平。 第一节:练好“三个基本功” 练好“三个基本功”包括:提高看图技能;熟悉常用标准图做法;熟悉工程量计算规则,等三个方面。 一、提高看图技能工程量计算前的看图,要先从头到尾浏览整套图纸,待对其设计意图大概了解后,再选择重点详细看图。在看图过程中要着重弄清以下几个问题: (一)建筑图部分 1、了解建筑物的层数和高度(包括层高和总高)、室内外高差、结构形式、纵向总长及跨度等。 2、了解工程的用料及作法,包括楼地面、屋面、门窗、墙柱面装饰的用料及法。 3、了解建筑物的墙厚、楼地面面层、门窗、天棚、内墙饰面等在不同的楼层上有无变化(包括材料做法、尺寸、数量等变化),以便采用不同的计算方法。 (二)结构图部分 1、了解基础形式、深度、土壤类别、开挖方式(按施工方案确定)以及基础、墙体的材料及做法。 2、了解结构设计说明中涉及工程量计算的相关内容,包括砌筑砂浆类别、强度等级,现浇和预制构件的混凝土强度等级、钢筋的锚固和搭接规定等,以便全面领会图纸的设计意图,避免重算或漏算。 3、了解构件的平面布置及节点图的索引位置,以免在计算时乱翻图纸查找,浪费时间。 4、砖混结构要弄清圈梁有几种截面高度,具体分布在墙体的那些部位,圈梁在阳台及门窗洞口处截面有何变化,内外墙圈梁宽度是否一致,以便在计算圈梁体积时,按不同宽度进行分段计算。 5、带有挑檐、阳台、雨篷的建筑物,要弄清悬挑构件与相交的连梁或圈梁的连结关系,以便在计算时做到心中有数。 目前施工图预算和工程量清单的编制主要是围绕工程招投标进行的,工程发标后按照惯例,建设单位一般在三天以内要组织有关方面对图纸进行答凝,因此,预算(或清单)编制人员在此

【精编】工程量快速计算的基本方法技巧

工程量快速计算的基本方法 本章所述工程量快速计算的基本方法包括:练好“三个基本功”;合理安排工程量计算顺序;灵活运用“统筹法”计算原理;充分利用“工程量计算手册”等四项内容。在实际工作中,只要能够熟练掌握,充分利用以上“基本方法” ,就可以快速提高工程量计算业务水平。 第一节练好“三个基本功” 练好“三个基本功” 包括:提高看图技能;熟悉常用标准图做法;熟悉工程量计算规则,等三个方面。 一、提高看图技能工程量计算前的看图,要先从头到尾浏览整套图纸,待对其设计意图 大概了解后,再选择重点详细看图。在看图过程中要着重弄清以下几个问题: (一)建筑图部分 1、了解建筑物的层数和高度(包括层高和总高)、室内外高差、结构形式、纵向总长及跨度等。 2、了解工程的用料及作法,包括楼地面、屋面、门窗、墙柱面装饰的用料及法。 3、了解建筑物的墙厚、楼地面面层、门窗、天棚、内墙饰面等在不同的楼层上有无变化(包括材料做法、尺寸、数量等变化),以便采用不同的计算方法。 (二)结构图部分 1、了解基础形式、深度、土壤类别、开挖方式(按施工方案确定)以及基

础、墙体的材料及做法。 2、了解结构设计说明中涉及工程量计算的相关内容,包括砌筑砂浆类别、强度等级,现浇和预制构件的混凝土强度等级、钢筋的锚固和搭接规定等,以便全面领会图纸的设计意图,避免重算或漏算。 3、了解构件的平面布置及节点图的索引位置,以免在计算时乱翻图纸查找,浪费时间。 4、砖混结构要弄清圈梁有几种截面高度,具体分布在墙体的那些部位,圈梁在阳台及门窗洞口处截面有何变化,内外墙圈梁宽度是否一致,以便在计算圈梁体积时,按不同宽度进行分段计算。 5、带有挑檐、阳台、雨篷的建筑物,要弄清悬挑构件与相交的连梁或圈梁的连结关系,以便在计算时做到心中有数。 目前施工图预算和工程量清单的编制主要是围绕工程招投标进行的,工程发标后按照惯例,建设单位一般在三天以内要组织有关方面对图纸进行答凝,因此,预算(或清单)编制人员在此阶段应抓紧时间看图,对图纸中存在的问题作好记录整理。在看图过程中不要急于计算,避免盲目计算后又有所变化造成来回调整。但是对“门窗表” 、“构件索引表”、“钢筋明细表” 中的构件以及钢筋的规格型号、数量、尺寸,要进行复核,待图纸答凝后,根据“图纸答凝纪要”对图纸进行全面修正,然后再进行计算。 计算工程量时,图中有些部位的尺寸和标高不清楚的地方,应该用建筑图和结构图对照着看,比如装饰工程在计算天棚抹灰时,要计算梁侧的抹灰面积,由于建筑图中不标注梁的截面尺寸,因此,要对照结构图中梁的节点大样计算。再如计算框架间砌体时,要扣除墙体上部的梁高度,其方法

快速心算法(五

快速心算法(五、六年級適用) A.乘以11的心算法 某數乘以11、111、……,只要將該某數錯位相加,其和即為所求乘樍。 例1 36×11=? 心算過程: 將36錯位相加,即: 36……36×10。其和396即為所求乘積。 36……36×1 396……積 例2 438×11=? 心算過程: 將438錯位相加,即: 438……438×10。其和4818即為所求乘積。 438……438×1 4818……積 例3 48×111=? 心算過程: 將48錯位相加,即: 48……48×100。其和5328即為所求乘積。 48……48×10 48……48×1 5328……積 當遇到乘以11、111、……的倍數時,可先把它化為a×11、a×111…… 的形式,然後將a與某數的乘積錯位相加,其和即為所求乘積。 p.1

心算過程: 因為33是11的3倍,所以48×3=144,所得乘積 錯位相加,即: 144……48×3。其和1584即為所求乘積。 144……48×3 1584……積 例5 316×66=? 心算過程: 因為66是11的6倍,所以316×6=1896,所得乘積 錯位相加,即: 1896……316×60。其和20856即為所求乘積。 1896……316×6 20856……積 例6 34×777=? 心算過程: 因為777是111的7倍,所以34×7=238,所得乘積 錯位相加,即: 238……34×700。其和26418即為所求乘積。 238……34×70 238……34×7 26418……積 當遇到一個因數的各位之間只差1的數相乘時,如45、445、23、223等。可以先用其數乘以11、111、……倍數的方法求出乘積,最後加上或減去 一個數即求得其乘積。 p.2

很详细的快速幂算法

快速幂取模算法 在网站上一直没有找到有关于快速幂算法的一个详细的描述和解释,这里,我给出快速幂算法的完整解释,用的是C 语言,不同语言的读者只好换个位啦,毕竟读C 的人较多~ 所谓的快速幂,实际上是快速幂取模的缩写,简单的说,就是快速的求一个幂式的模(余)。在程序设计过程中,经常要去求一些大数对于某个数的余数,为了得到更快、计算范围更大的算法,产生了快速幂取模算法。[有读者反映在讲快速幂部分时有点含糊,所以在这里对本文进行了修改,作了更详细的补充,争取让更多的读者一目了然] 我们先从简单的例子入手:求c a b mod = 几。 算法1.首先直接地来设计这个算法: int ans = 1; for (int i = 1;i<=b;i++) { ans = ans * a; } ans = ans % c; 这个算法的时间复杂度体现在for 循环中,为O (b ).这个算法存在着明显的问题,如果a 和b 过大,很容易就会溢出。 那么,我们先来看看第一个改进方案:在讲这个方案之前,要先有这样一个公式: c c a c a b b mod )mod (mod =.这个公式大家在离散数学或者数论当中应该学过,不过这里为了方便大家的阅读,还是给出证明: 引理1: c c b c a c de c de c dk te tkc c e kc d tc c ab e kc b e c b d tc a d c a c c b c a c ab mo d )]mod ()mod [(mod mod ))((mod ))((mod mod mod mod )]mod ()mod [(mod )(:2?==+++=++=+=?=+=?=?=证明: 公式 上面公式为下面公式的引理,即积的取余等于取余的积的取余。 c a c c a c c c a c c a c c a c a b b b b b b mo d mod ])mod [() (mod ])mod )mod [((mod ])mod [(mod )mod (mod ===由上面公式的迭代证明:公式: 证明了以上的公式以后,我们可以先让a 关于c 取余,这样可以大大减少a 的大小, 于是不用思考的进行了改进: 算法2: int ans = 1; a = a % c; //加上这一句