有机合成英文文献翻译2

Organic Syntheses, Vol. 81, p. 254-261 (2005); Coll. Vol. 11, p. 874-878 (2009).

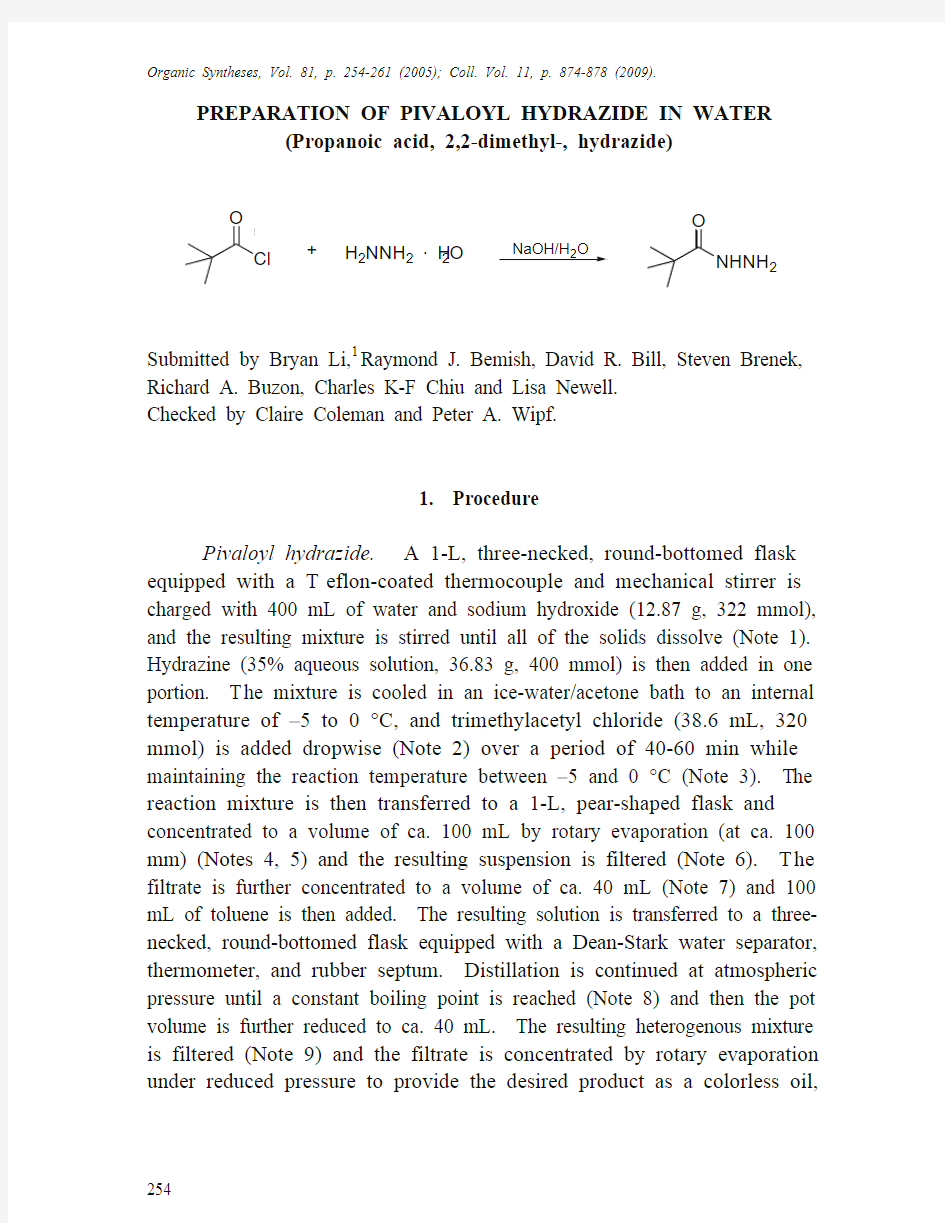

254 PREPARATION OF PIVALOYL HYDRAZIDE IN WATER (Propanoic acid, 2,2-dimethyl-, hydrazide)

2 +NaOH/H2O

H2NNH2 · H2O

Submitted by Bryan Li,1Raymond J. Bemish, David R. Bill, Steven Brenek, Richard A. Buzon, Charles K-F Chiu and Lisa Newell.

Checked by Claire Coleman and Peter A. Wipf.

1. Procedure

Pivaloyl hydrazide. A 1-L, three-necked, round-bottomed flask equipped with a T eflon-coated thermocouple and mechanical stirrer is charged with 400 mL of water and sodium hydroxide (12.87 g, 322 mmol), and the resulting mixture is stirred until all of the solids dissolve (Note 1). Hydrazine (35% aqueous solution, 36.83 g, 400 mmol) is then added in one portion. T he mixture is cooled in an ice-water/acetone bath to an internal temperature of –5 to 0 °C, and trimethylacetyl chloride (38.6 mL, 320 mmol) is added dropwise (Note 2) over a period of 40-60 min while maintaining the reaction temperature between –5 and 0 °C (Note 3). T he reaction mixture is then transferred to a 1-L, pear-shaped flask and concentrated to a volume of ca. 100 mL by rotary evaporation (at ca. 100 mm) (Notes 4, 5) and the resulting suspension is filtered (Note 6). T he filtrate is further concentrated to a volume of ca. 40 mL (Note 7) and 100 mL of toluene is then added. The resulting solution is transferred to a three-necked, round-bottomed flask equipped with a Dean-Stark water separator, thermometer, and rubber septum. Distillation is continued at atmospheric pressure until a constant boiling point is reached (Note 8) and then the pot volume is further reduced to ca. 40 mL. The resulting heterogenous mixture is filtered (Note 9) and the filtrate is concentrated by rotary evaporation under reduced pressure to provide the desired product as a colorless oil,

255

which on sta nding solidifies to a white semi-solid. This ma teria l is recrysta llized from 100 mL of isopropyl ether to a fford 18.6-20.4 g (50-55%) of pivaloyl hydrazide (Notes 10, 11).

2. Notes

1. All rea gents were purcha sed from Aldrich Chemica l Compa ny (except for trimethyla cetyl chloride, which the checkers obta ined from Acros) and were used without further purification. The checkers used a low temperature alcohol thermometer in place of a Teflon-coated themocouple. The third neck of the flask was left open to the atmosphere.

2. A syringe pump was used for the addition of acid chloride in order to achieve a steady flow rate. The tip of the syringe needle (gauge 20) was submerged in the rea ction mixture. Dropwise a ddition of trimethyla cetyl chloride at 0-5 °C resulted in the immediate formation of a precipitate.

3. The rea ction wa s complete a t the end of the piva loyl chloride addition. On 5-L or larger scale, the reaction was conducted at temperatures of 10-15 °C without loss of selectivity.

4. A small a mount of hydrazine hydrate was present in the reaction mixture a t this point, but a sa fety eva lua tion indica ted the fina l rea ction mixture ha d a very low therma l potentia l (DH=1

5.3 J/g). This poses a minimum thermal hazard for vacuum distillation.

5. The submitters concentra ted the rea ction mixture by va cuum distilla tion (100 mm, ba th tempera ture 70 °C, va por tempera ture 51 °C). The weight a fter concentra tion wa s ca. 120 g. The checkers used rota ry evaporation with a bath temperature of 65 to 70 °C without any problems, and employed an explosion shield as a safety precaution.

6. The bis-a cyl a tion byproduct (Me 3CCONHNHCOCMe 3) w a s removed by filtration; 20 mL of water was used for washing the filter cake.

7. The submitters removed solvent by vacuum distillation (100 mm, bath temperature 70 °C, vapor temperature 51 °C).

8. Azeotropic remova l of wa ter wa s complete when the va por temperature reached 111 °C.

9. Sodium chloride was removed by filtration.

10.T he submitters obtained the product in 72% yield without recrystallization and determined the product to be >97% pure by HPLC (by area; conditions: 250 mm Kromasil C4 column using acetonitrile (A)/water

(B) and 0.1% TFA in water (C), 0:90:10 A:B:C ramp to 90:0:10 A:B:C over

15 min and hold for 5 min.

Waste Disposal Information

All toxic materials were disposed of in accordance with “Prudent Practice in the Laboratory”; National Academy Press; Washington, DC, 1995.

3. Discussion

Hydrazides (RCON HN H2) are highly useful starting materials and intermediates in the synthesis of heterocyclic molecules.2 They can be synthesized by hydrazinolysis of amides, esters and thioesters.3 The reaction of hydrazine with acyl chlorides or anhydrides is also well known,4 but it is complicated by the formation of 1,2-diacylhydrazines, and often requires the use of anhydrous hydrazine which presents a high thermal hazard. Diacylation products predominate when hydrazine reacts with low molecular weight aliphatic acyl chlorides, which makes the reaction impractical for preparatory purposes.5

Recently we needed to prepare large amounts of pivaloyl hydrazide (1). A literature survey indicated several approaches: (1) heating pivalic acid with hydrazine hydrate with a Lewis acid catalyst such as activated alumina6 or titanium oxide;7 (2) heating hydrazine hydrate at high temperature (140 °C) with ethyl pivalate;8 (3) condensing phthaloyl hydrazine with pivaloyl chloride, followed by deprotection of the phthaloyl group;9 and (4) reaction of ethyl thiopivalate with hydrazine hydrate. Reaction safety evaluations revealed that hydrazine monohydrate has an onset temperature of ca. 125 °C in a Differential Scanning Calorimetry (DSC) experiment, and possesses a very high thermal potential ( H = 2500 J/g),10,11 which prompted us to develop a method for the synthesis of 1 that did not require heating. After some experimentation we determined that the reaction of pivaloyl chloride with hydrazine proceeds most efficiently in water to give a 4:1 ratio12 of 1 to Me3CCONHNHCOCMe3(2). The use of organic solvents (MeOH, THF, 2-propanol) with water13 invariably led to formation of biphasic mixtures and predominant formation of 2.14 Reaction workup is also simplified using

256

water as solvent. Upon partial concentration the bis-acylhydrazide by

product 2precipitated out of the reaction mixture and is conveniently

removed by filtration. Removal of the remainder of the water by

displacement with toluene leads to precipitation of NaCl, which is also

easily removed by filtration. The filtrate is then further concentrated to

provide 1 in >97% purity, typically in 55–75% yield. This procedure has

been employed to prepare 10 Kg batches of 1 with no difficulty.

译文:

在水相中制备特戊酰氯 (丙酸,2,2-二甲基酰肼)

论文由Bryan Li, Raymond J 、Bemish, David R 、Bill, Steven Brenek,Richard A 、Buzon, Charles K-F Chiu 和 Lisa Newell 等发表,经Claire Coleman 与Peter A. Wipf 审核。

1.1.步骤步骤步骤

特戊酰氯合成:将一升的三颈圆底烧瓶配备一个有特氟龙涂层的热电偶和机械搅拌器,装上400mL 水和氢氧化钠(12.87g,322mmol ),将产生的混合物搅拌,直至所有固体全部溶解(注解1)。随后加入部分酰肼(35%水溶液,36.83克,400毫摩尔)。用冰水/丙酮浴将该混合物冷却到内部温度为–5~0℃,连续滴加(注解2)三甲基乙酰氯(38.6mL,320mmol)40~60分钟,同时保持反应温度在–5~0℃(注解3)。反应混合物随后用旋转蒸发仪(在约100mL )转移到一个一升的梨形烧瓶中,收集到体积约100mL ,并将产生的悬浮物过滤(注解6),滤液进一步浓缩体积到40毫升(注解7),然后加入100毫升甲苯。将产生的溶液转移到一个配备有迪安-斯达克水分分离器,温度计和橡胶隔膜的三颈圆底烧瓶中。连续常压蒸馏直到达到一个恒定沸点(注解8)然后体积进一步减少到约40毫升。将产生的异构混合物过滤(注9),滤液用旋转蒸仪减压蒸馏浓缩以得到无色油状产品,凝固成半固体状白色物质。将该产品用100mL 异丙醚溶解并重结晶得到18.6-20.4克(50 - 55 %)特戊酰氯(注解10)。

2.2.注解注解注解

1. 所有试剂购自Aldrich 化学公司(除三甲基乙酰氯是论文审核者购自 Acros 公司),使用时没有进一步提纯,论文审核者用低温酒精温度计代替有特氟隆涂层的热电偶,烧瓶的第三个瓶颈与大气相通。

2.注射泵用于酰氯的添加以达到稳定流速,注射器针头尖端插入反应混合物液面下,在0~5℃滴加三甲基乙酰氯会导致立即形成沉淀。

3.在特戊酰氯添加结束时反应完成。对于5 L 或更大规模,反应在10 - 15°进行没有选择性的损失。

4. 这时候少量水合肼出现在在反应混合物中,但安全性评价表明最终反应混合物有非常低的热势。(DH=1

5.3 J/g),这就造成真空蒸馏的最低热危险。

5.提交者用真空蒸馏收集反应混合物,(100 mm, bath temperature 70 °C, vapor temperature 51 °C)蒸馏收集后重约120g.审核者成功在65~70℃水浴下使用旋转蒸发进行实验,并采用一个防爆盾作为预防措施。

6.双酰化副产品(Me 3CCONHNHCOCMe 3)被过滤除去,用20mL 水洗涤滤饼。

7.提交者通过真空蒸馏除去溶剂(100 mm,bath temperature 70 °C, vapor

temperature 51 °C)

8.当蒸汽温度达到111 °C 时共沸除水完成

9. 氯化钠经过滤除去。

10. 提交者在没有重结晶的情况下获得72%的产率,用高效液相色谱(按面积;条件:250毫米Kromasil C4色谱柱采用乙腈(A )/水(B )和0.1%三氟乙酸水溶液(C ),0:90:10的A:B:C 到90:0:10的A:B:C 过柱15分钟,并保持5分钟)确定产品为>97%纯。

废物处置信息

危险材料处理和处置应按照“实验室谨慎操作”;国家科学院出版社出版,华盛顿特区,1995年。

3.3.讨论讨论讨论

在杂环分子的合成中酰肼(RCONHNH 2)是非常有用的起始原料和中间体,酰肼可以用肼解酰胺,酯和硫酯合成,肼与酰氯或酸酐的反应也是众所周知的,但它因同时生成1,2-二乙酰基肼而显得复杂,往往要求使用无水肼从而出现很高的热危险。二酰基产品占主导地位时,肼与低分子量的脂肪酰氯反应,这使得反应没有实际生产意义。

最近,我们需要准备大量的特戊酰肼(1)查阅文献得以下几种方法(1)加热路易斯酸催化剂如活性氧化铝或二氧化钛及水合肼和特戊酸混合物(2)在高温(140°)加热水合肼与特戊酸乙酯(3)冷凝邻苯二甲酰肼与特戊酰氯然后邻苯二甲酰基团脱保护。(4)含硫三甲基乙酸乙酯与水合肼的反应。反应安全性评价表明,在差示扫描量热(DSC)实验中肼水合物起始温度约125°,并具有很高的热势(?H = 2500 J/g)这促使我们开发一种不需要加热的用于合成1的方法。经过一些实验我们确定特戊酰氯与肼的反应在水中有效的得到高产率,1和Me3CCONHNHCOCMe3是4:1的比例(2)。使用有机溶剂(甲醇,四氢呋喃,异丙醇)水必然导致形成两相混合物并主要形成2,反应以水为溶剂得到简化,在部分浓度二酰基酰肼副产2从反应混合物沉淀出来并可方便地通过过滤除去。用甲苯置换去除剩余的水并产生氯化钠沉淀,这沉淀也很容易通过过滤去除,然后滤液进一步浓缩得到1且有>97%的纯度,通常有55-75%的产率。这个合成步骤已轻松用于10kg批量的1的合成。

《化学工程与工艺专业英语》课文翻译 完整版

Unit 1 Chemical Industry 化学工业 1.Origins of the Chemical Industry Although the use of chemicals dates back to the ancient civilizations, the evolution of what we know as the modern chemical industry started much more recently. It may be considered to have begun during the Industrial Revolution, about 1800, and developed to provide chemicals roe use by other industries. Examples are alkali for soapmaking, bleaching powder for cotton, and silica and sodium carbonate for glassmaking. It will be noted that these are all inorganic chemicals. The organic chemicals industry started in the 1860s with the exploitation of William Henry Perkin‘s discovery if the first synthetic dyestuff—mauve. At the start of the twentieth century the emphasis on research on the applied aspects of chemistry in Germany had paid off handsomely, and by 1914 had resulted in the German chemical industry having 75% of the world market in chemicals. This was based on the discovery of new dyestuffs plus the development of both the contact process for sulphuric acid and the Haber process for ammonia. The later required a major technological breakthrough that of being able to carry out chemical reactions under conditions of very high pressure for the first time. The experience gained with this was to stand Germany in good stead, particularly with the rapidly increased demand for nitrogen-based compounds (ammonium salts for fertilizers and nitric acid for explosives manufacture) with the outbreak of world warⅠin 1914. This initiated profound changes which continued during the inter-war years (1918-1939). 1.化学工业的起源 尽管化学品的使用可以追溯到古代文明时代,我们所谓的现代化学工业的发展却是非常近代(才开始的)。可以认为它起源于工业革命其间,大约在1800年,并发展成为为其它工业部门提供化学原料的产业。比如制肥皂所用的碱,棉布生产所用的漂白粉,玻璃制造业所用的硅及Na2CO3. 我们会注意到所有这些都是无机物。有机化学工业的开始是在十九世纪六十年代以William Henry Perkin 发现第一种合成染料—苯胺紫并加以开发利用为标志的。20世纪初,德国花费大量资金用于实用化学方面的重点研究,到1914年,德国的化学工业在世界化学产品市场上占有75%的份额。这要归因于新染料的发现以及硫酸的接触法生产和氨的哈伯生产工艺的发展。而后者需要较大的技术突破使得化学反应第一次可以在非常高的压力条件下进行。这方面所取得的成绩对德国很有帮助。特别是由于1914年第一次世界大仗的爆发,对以氮为基础的化合物的需求飞速增长。这种深刻的改变一直持续到战后(1918-1939)。 date bake to/from: 回溯到 dated: 过时的,陈旧的 stand sb. in good stead: 对。。。很有帮助

机械专业外文翻译(中英文翻译)

外文翻译 英文原文 Belt Conveying Systems Development of driving system Among the methods of material conveying employed,belt conveyors play a very important part in the reliable carrying of material over long distances at competitive cost.Conveyor systems have become larger and more complex and drive systems have also been going through a process of evolution and will continue to do so.Nowadays,bigger belts require more power and have brought the need for larger individual drives as well as multiple drives such as 3 drives of 750 kW for one belt(this is the case for the conveyor drives in Chengzhuang Mine).The ability to control drive acceleration torque is critical to belt conveyors’performance.An efficient drive system should be able to provide smooth,soft starts while maintaining belt tensions within the specified safe limits.For load sharing on multiple drives.torque and speed control are also important considerations in the drive system’s design. Due to the advances in conveyor drive control technology,at present many more reliable.Cost-effective and performance-driven conveyor drive systems covering a wide range of power are available for customers’ choices[1]. 1 Analysis on conveyor drive technologies 1.1 Direct drives Full-voltage starters.With a full-voltage starter design,the conveyor head shaft is direct-coupled to the motor through the gear drive.Direct full-voltage starters are adequate for relatively low-power, simple-profile conveyors.With direct fu11-voltage starters.no control is provided for various conveyor loads and.depending on the ratio between fu11-and no-1oad power requirements,empty starting times can be three or four times faster than full load.The maintenance-free starting system is simple,low-cost and very reliable.However, they cannot control starting torque and maximum stall torque;therefore.they are

电气外文文献-翻译

Circuit breaker 断路器 Compressed air circuit breaker is a mechanical switch equipm ent, can be i 空气压缩断路器是一种机械开关设备,能够在n normal and special conditions breaking current (such as sho rt circuit cur 正常和特殊情况下开断电流(比如说短路电流)。 rent). For example, air circuit breaker, oil circuit breaker, interf erence circ 例如空气断路器、油断路器,干扰电路的导体uit conductor for the application of the safety and reliability o f the circuit 干扰电路的导体因该安全可靠的应用于其中, breaker, current in arc from is usually divided into the followin g grades: a 电流断路器按灭弧远离通常被分为如下等级:ir switch circuit breaker, oil circuit breaker, less oil circuit break er, compr 空气开关断路器、油断路器、少油断路器、压缩空essed air circuit breaker, a degaussing of isolating switch, six s ulfur hexaf

污水处理 英文文献3 翻译

丹宁改性絮凝剂处理城市污水 J.Beltrán-heredia,J.ánche z-Martin 埃斯特雷马杜拉大学化学工程系和物理化学系,德埃娃儿,S / N 06071,巴达霍斯,西班牙 摘要 一种新的以丹宁为主要成分的混凝剂和絮凝剂已经过测试用以处理城市污水。TANFLOC 证实了其在浊度的去除上的高效性(接近100%,取决于剂量),并且近50%的BOD5和COD 被去除,表明TANFLOC是合适的凝集剂,效力可与明矾相媲美。混凝絮凝剂过程不依赖于温度,发现最佳搅拌速度和时间为40转/每分钟和30分钟。多酚含量不显著增加,30%的阴离子表面活性剂被去除。沉淀过程似乎是一种絮凝分离,所以污泥体积指数和它随絮凝剂剂量的改变可以确定。证明TANFLOC是相当有效的可用于污水处理的混凝絮凝剂。 关键词: 基于丹宁的絮凝剂城市污水絮凝天然混凝剂 1.简介 人类活动是废物的来源。特别是在城市定居点,来自家庭和工业的废水可能是危险有害的产品[ 1 ],需要适当的处理,以避免对环境[ 2 ]和健康的影响[ 3,4 ]。2006年12月4日联合国大会通过决议宣布2008为国际卫生年。无效的卫生基础设施促使每年220万人死于腹泻,主要在3岁以下儿童,600万人因沙眼失明,两亿人感染血吸虫病,只是为了给出一些数据[ 5 ]。显然,他们中的大多数都是在发展中国家,所以谈及城市污水,必须研究适当的技术来拓宽可能的处理技术种类。 在这个意义上,许多类型的水处理被使用。他们之间的分歧在于经济和技术特点上。了摆脱危险的污染[ 6 ],一些令人关注的论文已经发表的关于城市污水处理的几种天然的替代方法,包括绿色过滤器、化学初步分离、紫外消毒[ 7 ]和多级程序[ 8 ]。 几个以前的文件指出了城市污水管理[9,10]的重要性。这种类型的废物已成为社会研究的目标,因为它涉及到几个方面,都与社会结构和社会组织[11 ]相关。根据这一维度,必须认识到废水管理作为发展中国家的一种社会变化的因素,事关污水处理和生产之间的平衡,是非常重要的,一方面,人类要发展,另一方面,显而易见。 对水处理其它程序的研究一直是这和其他文件的范围。几年来,研究者关注的是发展中国家间的合作,他们正在致力于水处理的替代过程,主要考虑可持续发展,社会承受能力和可行性等理念。在这个意义上,自然混凝絮凝剂这一广为传播,易于操作的资源即使是非专业人员也不难操作。有一些例子,如辣木[ 14 ]和仙人掌榕[ 15 ]。丹宁可能是一个新的混凝剂和絮凝剂。 一些开拓者已经研究了丹宁水处理能力。 ?zacar和sengil [ 16 ]:从瓦罗NIA获得的丹宁,从土耳其的autoctonous树的果壳中获得丹宁,并用于他们的–污水混凝絮凝过程。他们表明,丹宁有很好的效果,结合Al2(SO4)3可进一步提高污泥去除率。 詹和赵[ 17 ]试着用丹宁为主要成分的凝胶作为吸收剂除去水中的铝,丹宁凝胶改进了金属去除过程,一定意义上也可参照Nakano等人的[ 18 ],Kim 和Nakano[ 19 ]。 ?zacar和sengil [ 20 ]加强以前的文章给出了关于三卤甲烷的形成和其他不良化合物特殊的数据,以及处理后的水质安全。他们始终使用丹宁与Al2(SO4)3的组合。 帕尔马等人将丹宁从辐射松的树皮为原位提取,用于重金属去除中聚合固体。树皮本

Manufacturing Engineering and Technology(机械类英文文献+翻译)

Manufacturing Engineering and Technology—Machining Serope kalpakjian;Steven R.Schmid 机械工业出版社2004年3月第1版 20.9 MACHINABILITY The machinability of a material usually defined in terms of four factors: 1、Surface finish and integrity of the machined part; 2、Tool life obtained; 3、Force and power requirements; 4、Chip control. Thus, good machinability good surface finish and integrity, long tool life, and low force And power requirements. As for chip control, long and thin (stringy) cured chips, if not broken up, can severely interfere with the cutting operation by becoming entangled in the cutting zone. Because of the complex nature of cutting operations, it is difficult to establish relationships that quantitatively define the machinability of a material. In manufacturing plants, tool life and surface roughness are generally considered to be the most important factors in machinability. Although not used much any more, approximate machinability ratings are available in the example below. 20.9.1 Machinability Of Steels Because steels are among the most important engineering materials (as noted in Chapter 5), their machinability has been studied extensively. The machinability of steels has been mainly improved by adding lead and sulfur to obtain so-called free-machining steels. Resulfurized and Rephosphorized steels. Sulfur in steels forms manganese sulfide inclusions (second-phase particles), which act as stress raisers in the primary shear zone. As a result, the chips produced break up easily and are small; this improves machinability. The size, shape, distribution, and concentration of these inclusions significantly influence machinability. Elements such as tellurium and selenium, which are both chemically similar to sulfur, act as inclusion modifiers in

电气供配电系统大学毕业论文英文文献翻译及原文

毕业设计(论文) 外文文献翻译 文献、资料中文题目:供配电系统 文献、资料英文题目:POWER SUPPLY AND DISTRIBUTION SYSTEM 文献、资料来源: 文献、资料发表(出版)日期: 院(部): 专业: 班级: 姓名: 学号: 指导教师: 翻译日期: 2017.02.14

POWER SUPPLY AND DISTRIBUTION SYSTEM ABSTRACT The basic function of the electric power system is to transport the electric power towards customers. The l0kV electric distribution net is a key point that connects the power supply with the electricity using on the industry, business and daily-life. For the electric power, allcostumers expect to pay the lowest price for the highest reliability, but don't consider that it's self-contradictory in the co-existence of economy and reliable.To improve the reliability of the power supply network, we must increase the investment cost of the network construction But, if the cost that improve the reliability of the network construction, but the investment on this kind of construction would be worthless if the reducing loss is on the power-off is less than the increasing investment on improving the reliability .Thus we find out a balance point to make the most economic,between the investment and the loss by calculating the investment on power net and the loss brought from power-off. KEYWARDS:power supply and distribution,power distribution reliability,reactive compensation,load distribution

各专业的英文翻译剖析

哲学Philosophy 马克思主义哲学Philosophy of Marxism 中国哲学Chinese Philosophy 外国哲学Foreign Philosophies 逻辑学Logic 伦理学Ethics 美学Aesthetics 宗教学Science of Religion 科学技术哲学Philosophy of Science and Technology 经济学Economics 理论经济学Theoretical Economics 政治经济学Political Economy 经济思想史History of Economic Thought 经济史History of Economic 西方经济学Western Economics 世界经济World Economics 人口、资源与环境经济学Population, Resources and Environmental Economics 应用经济学Applied Economics 国民经济学National Economics 区域经济学Regional Economics 财政学(含税收学)Public Finance (including Taxation) 金融学(含保险学)Finance (including Insurance) 产业经济学Industrial Economics 国际贸易学International Trade 劳动经济学Labor Economics 统计学Statistics 数量经济学Quantitative Economics 中文学科、专业名称英文学科、专业名称 国防经济学National Defense Economics 法学Law 法学Science of Law 法学理论Jurisprudence 法律史Legal History 宪法学与行政法学Constitutional Law and Administrative Law 刑法学Criminal Jurisprudence 民商法学(含劳动法学、社会保障法学) Civil Law and Commercial Law (including Science of Labour Law and Science of Social Security Law ) 诉讼法学Science of Procedure Laws

机械专业中英文对照翻译大全.

机械专业英语词汇中英文对照翻译一览表 陶瓷ceramics 合成纤维synthetic fibre 电化学腐蚀electrochemical corrosion 车架automotive chassis 悬架suspension 转向器redirector 变速器speed changer 板料冲压sheet metal parts 孔加工spot facing machining 车间workshop 工程技术人员engineer 气动夹紧pneuma lock 数学模型mathematical model 画法几何descriptive geometry 机械制图Mechanical drawing 投影projection 视图view 剖视图profile chart 标准件standard component 零件图part drawing 装配图assembly drawing

尺寸标注size marking 技术要求technical requirements 刚度rigidity 内力internal force 位移displacement 截面section 疲劳极限fatigue limit 断裂fracture 塑性变形plastic distortion 脆性材料brittleness material 刚度准则rigidity criterion 垫圈washer 垫片spacer 直齿圆柱齿轮straight toothed spur gear 斜齿圆柱齿轮helical-spur gear 直齿锥齿轮straight bevel gear 运动简图kinematic sketch 齿轮齿条pinion and rack 蜗杆蜗轮worm and worm gear 虚约束passive constraint 曲柄crank 摇杆racker

机械类英文文献+翻译)

机械工业出版社2004年3月第1版 20.9 MACHINABILITY The machinability of a material usually defined in terms of four factors: 1、Surface finish and integrity of the machined part; 2、Tool life obtained; 3、Force and power requirements; 4、Chip control. Thus, good machinability good surface finish and integrity, long tool life, and low force And power requirements. As for chip control, long and thin (stringy) cured chips, if not broken up, can severely interfere with the cutting operation by becoming entangled in the cutting zone. Because of the complex nature of cutting operations, it is difficult to establish relationships that quantitatively define the machinability of a material. In manufacturing plants, tool life and surface roughness are generally considered to be the most important factors in machinability. Although not used much any more, approximate machinability ratings are available in the example below. 20.9.1 Machinability Of Steels Because steels are among the most important engineering materials (as noted in Chapter 5), their machinability has been studied extensively. The machinability of steels has been mainly improved by adding lead and sulfur to obtain so-called free-machining steels. Resulfurized and Rephosphorized steels. Sulfur in steels forms manganese sulfide inclusions (second-phase particles), which act as stress raisers in the primary shear zone. As a result, the chips produced break up easily and are small; this improves machinability. The size, shape, distribution, and concentration of these inclusions significantly influence machinability. Elements such as tellurium and selenium, which are both chemically similar to sulfur, act as inclusion modifiers in resulfurized steels. Phosphorus in steels has two major effects. It strengthens the ferrite, causing

电气工程及其自动化专业_外文文献_英文文献_外文翻译_plc方面

1、 外文原文 A: Fundamentals of Single-chip Microcomputer Th e si ng le -c hi p m ic ro co mp ut er i s t he c ul mi na ti on of both t h e de ve lo pm en t o f t he d ig it al co m pu te r an d th e i n te gr at ed c i rc ui t a rg ua bl y t h e to w m os t s ig ni f ic an t i nv en ti on s o f t he 20th c e nt ur y [1]. Th es e t ow ty pe s of ar ch it ec tu re a re fo un d i n s in g le -ch i p m i cr oc om pu te r. So m e em pl oy t he spl i t pr og ra m/da ta m e mo ry o f th e H a rv ar d ar ch it ect u re , sh ow n in Fi g.3-5A -1, o th ers fo ll ow t he p h il os op hy , wi del y a da pt ed f or ge n er al -p ur po se co m pu te rs a nd m i cr op ro ce ss o r s, o f ma ki ng n o log i ca l di st in ct ion be tw ee n p r og ra m an d d at a m e mo ry a s i n t he P r in ce to n ar ch ite c tu re , sh ow n i n F ig.3-5A-2. In g en er al te r ms a s in gl e -chi p m ic ro co mp ut er i s c h ar ac te ri ze d b y t h e i nc or po ra ti on o f a ll t he un it s of a co mp uter i n to a s in gl e d ev i ce , as s ho wn in Fi g3-5A -3. Fig.3-5A-1 A Harvard type Program memory Data memory CPU Input& Output unit memory CPU Input& Output unit

常见的有机化学基团名称翻译

有机化学基团名称翻译 A 伸乙烷合萘基;伸二氢苊基acenaphtheneylene 亚乙烷合萘基;亚二氢苊基acenaphthenylidene 醋酰胺基;乙酰胺基acetamido; acetamino 乙炔基acetenyl;ethynyl 乙酰乙酰基acetoacetyl 丙酮基acetonyl 亚丙酮基acetonylidene 乙酰氧基acetoxy 乙酰基acetyl 乙酰亚胺基acetylimino 酸硝基aci-nitro 吖啶基acridinyl 丙烯酰基acrylyl; acryloyl 己二酰基adipoyl; adipyl 脲[基]羰基;脲甲酰基allophanyl; allophanoyl 烯丙基allyl 甲脒基amidino; guanyl 酰胺基amido 酰胺草酰基;草酰胺酰基amidoxalyl; oxamoyl 胺基amino 戊基amyl; pentyl 伸戊基amylene 亚戊基amylidene 亚戊基amylidene; pentylidene 苯胺基anilino 大茴香亚甲基;对甲氧苯亚甲基;对甲氧亚苄 基anisal; anisylidene 甲氧苯胺基anisidino 大茴香酰基;对甲氧苯甲酰基;对甲氧苄酰基anisoyl 大茴香亚甲基;对甲氧亚苄基;对甲氧苯亚甲 基anisylidene; p-methoxybenzylidene; anisal 邻胺苯甲酰基;邻胺苄酰基anthraniloyl; anthranoyl 蒽基anthranyl; anthryl 蒽醌基anthraquinonyl 伸蒽基;次蒽基anthrylene 精胺酰基arginyl 亚胂酸基arsinico 胂基arsino 胂酸基arsono 亚胂基arsylene 细辛基;2,4,5-三甲氧苯基asaryl; 2,4,5-trimethoxyphenyl 天[门]冬酰胺酰基asparaginyl; asparagyl 天[门]冬胺酰基aspartyl 阿托酰基;颠茄酰基;2-苯丙烯酰基atropoyl 壬二酰基azelaxyl 迭氮基;三氮基azido; triazo 偶氮亚胺基azimino; azimido 次偶氮基azino 偶氮基azo 氧偶氮基azoxy B 苯亚甲基;亚苄基benzal 苯甲酰胺基;苄酰胺基benzamido 苯亚磺酰基benzene sulfinyl; phenylsulfinyl 苯磺酰胺基benzenesulfonamido 苯磺酰基benzenesulfonyl 次苄基benzenyl; benzylidyne 二苯甲基benzhydryl; diphenylmethyl 二苯亚甲基benzhydrylidene; diphenylmethylene 联苯胺基benzidino 亚苄基;苯亚甲基benzilidene 二苯羟乙酰基benziloyl 苯并咪唑基benzimidazolyl 苯甲酰亚胺基benzimido; benzoylimino 亚胺苄基benzimidoyl; benzimidoyle 苯并呋喃基;熏草基benzofuryl 苯并哌喃基benzopyranyl 苯并【口+咢】【口+井】基benzoxazinyl 苯并【口+咢】唑基benzoxazolyl 苯甲酰氧基;苄酰氧基benzoxy; benzoyloxy 苯甲酰基;苄酰基benzoyl 伸苯甲酰基benzoylene 苯甲酰亚胺基benzoylimino; benzimido 苯甲酰氧基benzoyloxy; benzoxy 苄基;苯甲基benzyl 亚苄基;苯亚甲基benzylidene; benzylene; benzal 次苄基;苯次甲基benzylidyne; benzenyl 联苯基biphenylyl 【草(之上)+伯】基;龙脑基;冰片基;莰基bornyl; camphenyl 丁二烯基butadienyl 次丁烯基butenylidyne 丁氧基butoxy 丁基butyl 伸丁基butylene 亚丁基butylidene

机械专业外文文献翻译

翻译部分 英文原文 High-speed machining and demand for the development of High-speed machining is contemporary advanced manufacturing technology an important component of the high-efficiency, High-precision and high surface quality, and other features. This article presents the technical definition of the current state of development of China's application fields and the demand situation. High-speed machining is oriented to the 21st century a new high-tech, high-efficiency, High-precision and high surface quality as a basic feature, in the automobile industry, aerospace, Die Manufacturing and instrumentation industries gained increasingly widespread application, and has made significant technical and economic benefits. contemporary advanced manufacturing technology an important component part. HSC is to achieve high efficiency of the core technology manufacturers, intensive processes and equipment packaged so that it has a high production efficiency. It can be said that the high-speed machining is an increase in the quantity of equipment significantly improve processing efficiency essential to the technology. High-speed machining is the major advantages : improve production efficiency, improve accuracy and reduce the processing of cutting resistance. The high-speed machining of meaning, at present there is no uniform understanding, there are generally several points as follows : high cutting speed. usually faster than that of their normal cutting 5 -10 times; machine tool spindle speed high, generally spindle speed in -20000r/min above 10,000 for high-speed cutting; Feed at high velocity, usually 15 -50m/min up to 90m/min; For different cutting materials and the wiring used the tool material, high-speed cutting the meaning is not necessarily the same; Cutting process, bladed through frequency (Tooth Passing Frequency) closer to the "machine-tool - Workpiece "system the dominant natural frequency (Dominant Natural Frequency), can be considered to be high-speed cutting. Visibility high-speed machining is a comprehensive concept. 1992. Germany, the Darmstadt University of Technology, Professor H. Schulz in the 52th on the increase of high-speed cutting for the concept and the scope, as shown in Figure 1. Think different cutting targets, shown in the figure of the transition area (Transition), to be what is commonly called the high-speed cutting, This is also the time of metal cutting process related to the technical staff are looking forward to, or is expected to achieve the cutting speed. High-speed machining of machine tools, knives and cutting process, and other aspects specific requirements. Several were from the following aspects : high-speed machining technology development status and trends.