英文翻译第二章

The understanding of heat treatment is embraced by the broader study of metallurgy. Metallurgy is the physics, chemistry, and engineering related to metals from ore extraction to the final product.

Heat treatment is the operation of heating and cooling a metal in its solid state to change its physical properties. According to the procedure used, steel can be hardened to resist cutting action and abrasion, or it can be softened to permit machining.

With the proper heat treatment internal stresses may be removed, grain size reduced, toughness increased, or a hard surface produced on a ductile interior. The analysis of the steel must be known because small percentages of certain elements, notably carbon, greatly affect the physical properties.

Alloy steel owe their properties to the presence of one or more elements other than carbon, namely nickel, chromium, manganese, molybdenum, tungsten, silicon, vanadium, and copper. Because of their improved physical properties they are used commercially in many ways not possible with carbon steels.

The following discussion applies principally to the heat treatment of ordinary commercial steels known as plain carbon steels. With this process the rate of cooling is the controlling factor, rapid cooling from above the critical range results in hard structure, whereas very slow cooling produces the opposite effect.

? A Simplified Iron-carbon Diagram

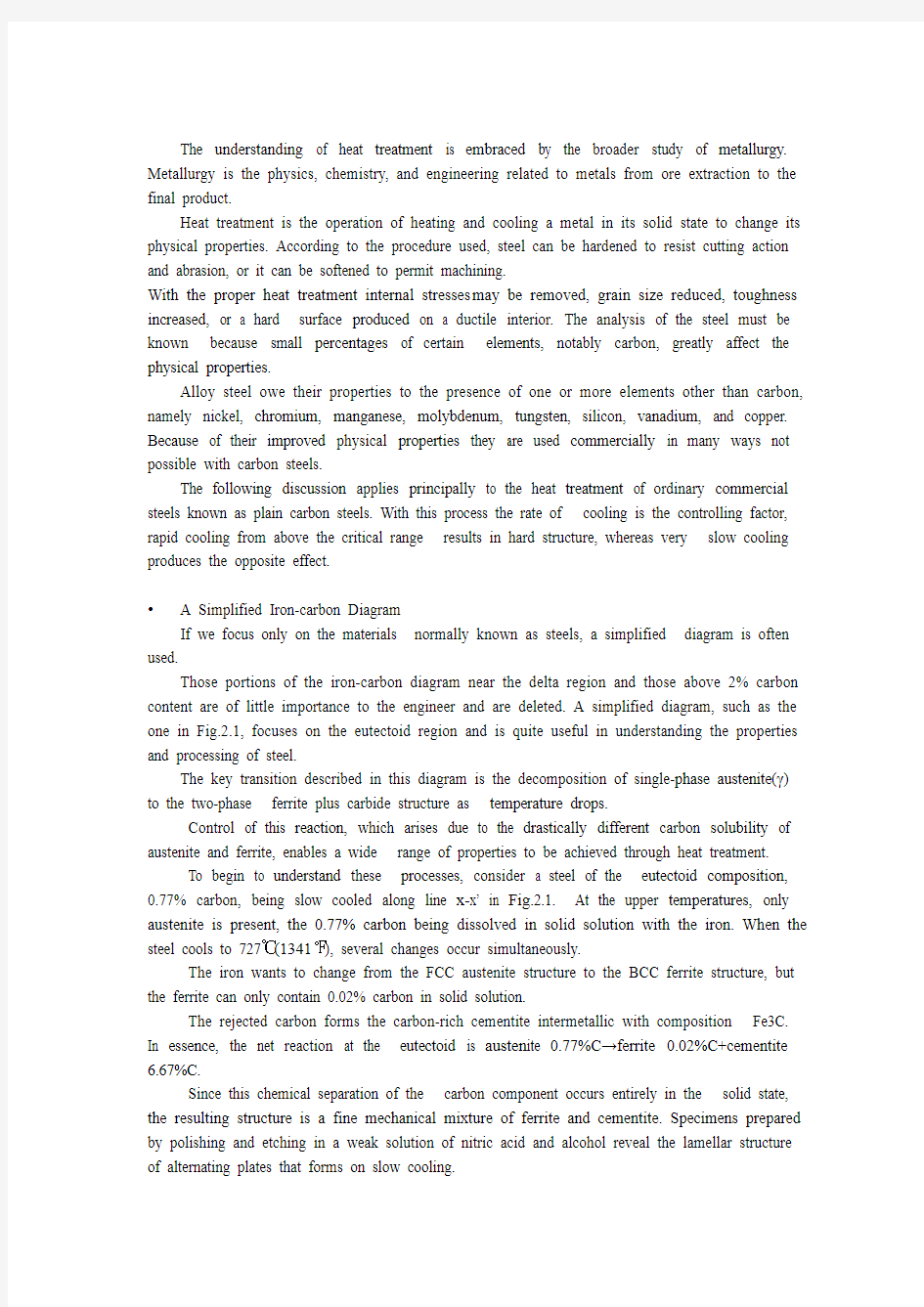

If we focus only on the materials normally known as steels, a simplified diagram is often used.

Those portions of the iron-carbon diagram near the delta region and those above 2% carbon content are of little importance to the engineer and are deleted. A simplified diagram, such as the one in Fig.2.1, focuses on the eutectoid region and is quite useful in understanding the properties and processing of steel.

The key transition described in this diagram is the decomposition of single-phase austenite(γ) to the two-phase ferrite plus carbide structure as temperature drops.

Control of this reaction, which arises due to the drastically different carbon solubility of austenite and ferrite, enables a wide range of properties to be achieved through heat treatment.

To begin to understand these processes, consider a steel of the eutectoid composition, 0.77% carbon, being slow cooled along line x-x’ in Fig.2.1. At the upper temperatures, only austenite is present, the 0.77% carbon being dissolved in solid solution with the iron. When the steel cools to 727℃(1341℉), several changes occur simultaneously.

The iron wants to change from the FCC austenite structure to the BCC ferrite structure, but the ferrite can only contain 0.02% carbon in solid solution.

The rejected carbon forms the carbon-rich cementite intermetallic with composition Fe3C. In essence, the net reaction at the eutectoid is austen ite 0.77%C→ferrite 0.02%C+cementite 6.67%C.

Since this chemical separation of the carbon component occurs entirely in the solid state, the resulting structure is a fine mechanical mixture of ferrite and cementite. Specimens prepared by polishing and etching in a weak solution of nitric acid and alcohol reveal the lamellar structure of alternating plates that forms on slow cooling.

This structure is composed of two distinct phases, but has its own set of characteristic properties and goes by the name pearlite, because of its resemblance to mother- of- pearl at low magnification.

Steels having less than the eutectoid amount of carbon (less than 0.77%) are known as hypo-eutectoid steels. Consider now the transformation of such a material represented by cooling along line y-y’ in Fig.2.1.

At high temperatures, the material is entirely austenite, but upon cooling enters a region where the stable phases are ferrite and austenite. Tie-line and level-law calculations show that low-carbon ferrite nucleates and grows, leaving the remaining austenite richer in carbon.

At 727℃(1341℉), the austenite is of eutectoid composition (0.77% carbon) and further cooling transforms the remaining austenite to pearlite. The resulting structure is a mixture of primary or pro-eutectoid ferrite (ferrite that formed above the eutectoid reaction) and regions of pearlite.

Hypereutectoid steels are steels that contain greater than the eutectoid amount of carbon. When such steel cools, as shown in z-z’ of Fig.2.1 the process is similar to the hypo-eutectoid case, except that the primary or pro-eutectoid phase is now cementite instead of ferrite.

As the carbon-rich phase forms, the remaining austenite decreases in carbon content, reaching the eutectoid composition at 727℃(1341℉). As before, any remaining austenite transforms to pearlite upon slow cooling through this temperature.

t should be remembered that the transitions that have been described by the phase diagrams are for equilibrium conditions, which can be approximated by slow cooling. With slow heating, these transitions occur in the reverse manner.

However, when alloys are cooled rapidly, entirely different results may be obtained, because sufficient time is not provided for the normal phase reactions to occur, in such cases, the phase diagram is no longer a useful tool for engineering analysis.

?Hardening

Hardening is the process of heating a piece of steel to a temperature within or above its critical range and then cooling it rapidly.

If the carbon content of the steel is known, the proper temperature to which the steel should be heated may be obtained by reference to the iron-iron carbide phase diagram. However, if the composition of the steel is unknown, a little preliminary experimentation may be necessary to determine the range.

A good procedure to follow is to heat-quench a number of small specimens of the steel at various temperatures and observe the result, either by hardness testing or by microscopic examination. When the correct temperature is obtained, there will be a marked change in hardness and other properties.

In any heat-treating operation the rate of heating is important. Heat flows from the exterior to the interior of steel at a definite rate. If the steel is heated too fast, the outside becomes hotter than the interior and uniform structure cannot be obtained.

If a piece is irregular in shape, a slow rate is all the more essential to eliminate warping and cracking. The heavier the section, the longer must be the heating time to achieve uniform results. Even after the correct temperature has been reached, the piece should be held at that temperature for a sufficient period of time to permit its thickest section to attain a uniform temperature.

he hardness obtained from a given treatment depends on the quenching rate, the carbon content, and the work size. In alloy steels the kind and amount of alloying element influences only the hardenability (the ability of the workpiece to be hardened to depths) of the steel and does not affect the hardness except in unhardened or partially hardened steels.

Steel with low carbon content will not respond appreciably to hardening treatment. As the carbon content in steel increases up to around 0.60%, the possible hardness obtainable also increases.

Above this point the hardness can be increased only slightly, because steels above the eutectoid point are made up entirely of pearlite and cementite in the annealed state. Pearlite responds best to heat-treating operations; and steel composed mostly of pearlite can be transformed into a hard steel.

As the size of parts to be hardened increases, the surface hardness decreases somewhat even though all other conditions have remained the same. There is a limit to the rate of heat flow through steel.

No matter how cool the quenching medium may be, if the heat inside a large piece cannot escape faster than a certain critical rate, there is a definite limit to the inside hardness. However, brine or water quenching is capable of rapidly bringing the surface of the quenched part to its own temperature and maintaining it at or close to this temperature.

Under these circumstances there would always be some finite depth of surface hardening regardless of size. This is not true in oil quenching, when the surface temperature may be high during the critical stages of quenching.

?Tempering

Steel that has been hardened by rapid quenching is brittle and not suitable for most uses. By tempering or drawing, the hardness and brittleness may be reduced to the desired point for service conditions.

As these properties are reduced there is also a decrease in tensile strength and an increase in the ductility and toughness of the steel. The operation consists of reheating quench-hardened steel to some temperature below the critical range followed by any rate of cooling.

Although this process softens steel, it differs considerably from annealing in that the process lends itself to close control of the physical properties and in most cases does not soften the steel to the extent that annealing would. The final structure obtained from tempering a fully hardened steel is called tempered martensite.

Tempering is possible because of the instability of the martensite, the principal constituent of hardened steel. Low-temperature draws, from 300℉ to 400℉ (150℃~205℃), do not cause much decrease in hardness and are used principally to relieve internal strains.

As the tempering temperatures are increased, the breakdown of the martensite takes place at a faster rate, and at about 600℉(315℃) the change to a structure called tempered martensite is very rapid. The tempering operation may be described as one of precipitation and agglomeration or coalescence of cementite.

A substantial precipitation of cementite begins at 600℉(315℃), which produces a decrease in hardness. Increasing the temperature causes coalescence of the carbides with continued decrease in hardness.

In the process of tempering, some consideration should be given to time as well as to

temperature. Although most of the softening action occurs in the first few minutes after the temperature is reached, there is some additional reduction in hardness if the temperature is maintained for a prolonged time.

Usual practice is to heat the steel to the desired temperature and hold it there only long enough to have it uniformly heated.

Two special processes using interrupted quenching are a form of tempering. In both, the hardened steel is quenched in a salt bath held at a selected lower temperature before being allowed to cool. These processes, known as austempering and martempering, result in products having certain desirable physical properties.

?Annealing

The primary purpose of annealing is to soften hard steel so that it may be machined or cold worked.

This is usually accomplished by heating the steel too slightly above the critical temperature, holding it there until the temperature of the piece is uniform throughout, and then cooling at a slowly controlled rate so that the temperature of the surface and that of the center of the piece are approximately the same.

This process is known as full annealing because it wipes out all trace of previous structure, refines the crystalline structure, and softens the metal. Annealing also relieves internal stresses previously set up in the metal.

The temperature to which a given steel should be heated in annealing depends on its composition; for carbon steels it can be obtained readily from the partial iron-iron carbide equilibrium diagram. When the annealing temperature has been reached, the steel should be held there until it is uniform throughout.

This usually takes about 45min for each inch(25mm) of thickness of the largest section. For maximum softness and ductility the cooling rate should be very slow, such as allowing the parts to cool down with the furnace. The higher the carbon content, the slower this rate must be.

The heating rate should be consistent with the size and uniformity of sections, so that the entire part is brought up to temperature as uniformly as possible.

?Normalizing and Spheroidizing

The process of normalizing consists of heating the steel about 50℉to 100℉(10℃~40℃) above the upper critical range and cooling in still air to room temperature.

This process is principally used with low- and medium-carbon steels as well as alloy steels to make the grain structure more uniform, to relieve internal stresses, or to achieve desired results in physical properties. Most commercial steels are normalized after being rolled or cast.

Spheroidizing is the process of producing a structure in which the cementite is in a spheroidal distribution. If steel is heated slowly to a temperature just below the critical range and held there for a prolonged period of time, this structure will be obtained.

The globular structure obtained gives improved machinability to the steel. This treatment is particularly useful for hypereutectoid steels that must be machined.

?Surface Hardening

Carburizing

The oldest known method of producing a hard surface on steel is case hardening or carburizing. Iron at temperatures close to and above its critical temperature has an affinity for carbon.

The carbon is absorbed into the metal to form a solid solution with iron and converts the outer surface into high-carbon steel. The carbon is gradually diffused to the interior of the part. The depth of the case depends on the time and temperature of the treatment.

Pack carburizing consists of placing the parts to be treated in a closed container with some carbonaceous material such as charcoal or coke. It is a long process and used to produce fairly thick cases of from 0.03 to 0.16 in.(0.76~4.06mm) in depth.

Steel for carburizing is usually a low-carbon steel of about 0.15% carbon that would not in itself responds appreciably to heat treatment. In the course of the process the outer layer is converted into high-carbon steel with a content ranging from 0.9% to 1.2% carbon.

A steel with varying carbon content and, consequently, different critical temperatures requires a special heat treatment.

Because there is some grain growth in the steel during the prolonged carburizing treatment, the work should be heated to the critical temperature of the core and then cooled, thus refining the core structure. The steel should then be reheated to a point above the transformation range of the case and quenched to produce a hard, fine structure.

The lower heat-treating temperature of the case results from the fact that hypereutectoid steels are normally austenitized for hardening just above the lower critical point. A third tempering treatment may be used to reduce strains.

Carbonitriding

Carbonitriding, sometimes known as dry cyaniding or nicarbing, is a case-hardening process in which the steel is held at a temperature above the critical range in a gaseous atmosphere from which it absorbs carbon and nitrogen.

Any carbon-rich gas with ammonia can be used. The wear-resistant case produced ranges from 0.003 to 0.030 inch(0.08~ 0.76mm) in thickness. An advantage of carbonitriding is that the hardenability of the case is significantly increased when nitrogen is added, permitting the use of low-cost steels.

Cyaniding

Cyaniding, or liquid carbonitriding as it is sometimes called, is also a process that combines the absorption of carbon and nitrogen to obtain surface hardness in low-carbon steels that do not respond to ordinary heat treatment.

The part to be case hardened is immersed in a bath of fused sodium cyanide salts at a temperature slightly above the Ac1 range, the duration of soaking depending on the depth of the case. The part is then quenched in water or oil to obtain a hard surface.

Case depths of 0.005 to 0.015in. (0.13~0.38mm) may be readily obtained by this process. Cyaniding is used principally for the treatment of small parts.

Nitriding

Nitriding is somewhat similar to ordinary case hardening, but it uses a different material and treatment to create the hard surface constituents.

In this process the metal is heated to a temperature of around 950℉(510℃) and held there for a period of time in contact with ammonia gas. Nitrogen from the gas is introduced into the steel, forming very hard nitrides that are finely dispersed through the surface metal.

Nitrogen has greater hardening ability with certain elements than with others, hence, special nitriding alloy steels have been developed.

Aluminum in the range of 1% to 1.5% has proved to be especially suitable in steel, in that it combines with the gas to form a very stable and hard constituent. The temperature of heating ranges from 925℉ to 1,050℉(495℃~565℃).

Liquid nitriding utilizes molten cyanide salts and, as in gas nitriding, the temperature is held below the transformation range. Liquid nitriding adds more nitrogen and less carbon than either cyaniding or carburizing in cyanide baths.

Case thickness of 0.001 to 0.012in.(0.03~0.30mm) is obtained, whereas for gas nitriding the case may be as thick as 0.025 in.(0.64mm). In general the uses of the two-nitriding processes are similar.

Nitriding develops extreme hardness in the surface of steel. This hardness ranges from 900 to 1,100 Brinell, which is considerably higher than that obtained by ordinary case hardening.

Nitriding steels, by virtue of their alloying content, are stronger than ordinary steels and respond readily to heat treatment. It is recommended that these steels be machined and heat-treated before nitriding, because there is no scale or further work necessary after this process.

Fortunately, the interior structure and properties are not affected appreciably by the nitriding treatment and, because no quenching is necessary, there is little tendency to warp, develop cracks, or change condition in any way. The surface effectively resists corrosive action of water, saltwater spray, alkalies, crude oil, and natural gas.

对热处理的理解包含于对冶金学较广泛的研究。冶金学是物理学、化学和涉及金属从矿石提炼到最后产物的工程学。

热处理是将金属在固态加热和冷却以改变其物理性能的操作。按所采用的步骤,钢可以通过硬化来抵抗切削和磨损,也可以通过软化来允许机加工。

使用合适的热处理可以去除内应力、细化晶粒、增加韧性或在柔软材料上覆盖坚硬的表面。因为某些元素(尤其是碳)的微小百分比极大地影响物理性能,所以必须知道对钢的分析。

合金钢的性质取决于其所含有的除碳以外的一种或多种元素,如镍、铬、锰、钼、钨、硅、钒和铜。由于合金钢改善的物理性能,它们被大量使用在许多碳钢不适用的地方。

下列讨论主要针对被称为普通碳钢的工业用钢而言。热处理时冷却速率是控制要素,从高于临界温度快速冷却导致坚硬的组织结构,而缓慢冷却则产生相反效果。

简化铁碳状态图

如果只把注意力集中于一般所说的钢上,经常要用到简化铁碳状态图。

铁碳状态图中靠近三角区和含碳量高于2%的那些部分对工程师而言不重要,因此将它们删除。如图2.1所示的简化铁碳状态图将焦点集中在共析区,这对理解钢的性能和处理是十分有用的。

在此图中描述的关键转变是单相奥氏体(γ) 随着温度下降分解成两相铁素体加渗碳体组织结构。控制这一由于奥氏体和铁素体的碳溶解性完全不同而产生的反应,使得通过热处理能获得很大范围的特性。

为了理解这些过程,考虑含碳量为0.77%的共析钢,沿着图2.1的x-x’线慢慢冷却。在较高温度时,只存在奥氏体,0.77%的碳溶解在铁里形成固溶体。当钢冷却到727℃ (1341℉) 时,将同时发生若干变化。

铁需要从面心立方体奥氏体结构转变为体心立方体铁素体结构,但是铁素体只能容纳固溶体状态的0.02%的碳。

被析出的碳与金属化合物Fe3C形成富碳的渗碳体。本质上,共析体的基本反应是奥氏体0.77%的碳→铁素体0.02%的碳+渗碳体6.67%的碳。

由于这种碳成分的化学分离完全发生在固态中,产生的组织结构是一种细致的铁素体与渗碳体的机械混合物。通过打磨并在弱硝酸酒精溶液中蚀刻制备的样本显示出由缓慢冷却形成的交互层状的薄片结构。

这种结构由两种截然不同的状态组成,但它本身具有一系列特性,且因与低倍数放大时的珠母层有类同之处而被称为珠光体。

含碳量少于共析体(低于0.77%)的钢称为亚共析钢。现在来看这种材料沿着图 2.1中y-y’线冷却的转变情况。

在较高温度时,这种材料全部是奥氏体,但随着冷却就进入到铁素体和奥氏体稳定状态的区域。由截线及杠杆定律分析可知,低碳铁素体成核并长大,剩下含碳量高的奥氏体。

在727℃(1341℉)时,奥氏体为共析组成(含碳量0.77%),再冷却剩余的奥氏体就转化为珠光体。作为结果的组织结构是初步的共析铁素体(在共析反应前的铁素体)和部分珠光体的混合物。

过共析钢是含碳量大于共析量的钢。当这种钢冷却时,就像图2.1的z-z’线所示,除了初步的共析状态用渗碳体取代铁素体外,其余类似亚共析钢的情况。

随着富碳部分的形成,剩余奥氏体含碳量减少,在727℃(1341℉)时达到共析组织。就像以前说的一样,当缓慢冷却到这温度时所有剩余奥氏体转化为珠光体。

应该记住由状态图描述的这种转化只适合于通过缓慢冷却的近似平衡条件。如果缓慢加热,则以相反的方式发生这种转化。

然而,当快速冷却合金时,可能得到完全不同的结果。因为没有足够的时间让正常的状态反

应发生,在这种情况下对工程分析而言状态图不再是有用的工具。

淬火

淬火就是把钢件加热到或超过它的临界温度范围,然后使其快速冷却的过程。

如果钢的含碳量已知,钢件合适的加热温度可参考铁碳合金状态图得到。然而当钢的成分不知道时,则需做一些预备试验来确定其温度范围。

要遵循的合适步骤是将这种钢的一些小试件加热到不同的温度后淬火,再通过硬度试验或显微镜检查观测结果。一旦获得正确的温度,硬度和其它性能都将有明显的变化。

在任何热处理作业中,加热的速率都是重要的。热量以一定的速率从钢的外部传导到内部。如果钢被加热得太快,其外部比内部热就不能得到均匀的组织结构。

如果工件形状不规则,为了消除翘曲和开裂最根本的是加热速率要缓慢。截面越厚,加热的时间就要越长才能达到均匀的结果。

即使加热到正确的温度后,工件也应在此温度下保持足够时间以让其最厚截面达到相同温度。

通过给定的热处理所得到的硬度取决于淬火速率、含碳量和工件尺寸。除了非淬硬钢或部分淬硬钢外,合金钢中合金元素的种类及含量仅影响钢的淬透性(工件被硬化到深层的能力)而不影响硬度。

含碳量低的钢对淬火处理没有明显的反应。随着钢的含碳量增加到大约0.60%,可能得到的硬度也增加。

高于此点,由于超过共析点钢完全由珠光体和退火状态的渗碳体组成,硬度增加并不多。珠光体对热处理作业响应最好;基本由珠光体组成的钢能转化成硬质钢。

即使所有其它条件保持不变,随着要淬火的零件尺寸的增加其表面硬度也会有所下降。热量在钢中的传导速率是有限的。

无论淬火介质怎么冷,如果在大工件中的热量不能比特定的临界速率更快散发,那它内部硬度就会受到明确限制。然而盐水或水淬火能够将被淬零件的表面迅速冷却至本身温度并将其保持或接近此温度。

在这种情况下不管零件尺寸如何,其表面总归有一定深度被硬化。但油淬情况就不是如此,因为油淬时在淬火临界阶段零件表面的温度可能仍然很高。

回火

快速淬火硬化的钢是硬而易碎的,不适合大多数场合使用。通过回火,硬度和脆性可以降低到使用条件所需要的程度。

随着这些性能的降低,拉伸强度也降低而钢的延展性和韧性则会提高。回火作业包括将淬硬钢重新加热到低于临界范围的某一温度然后以任意速率冷却。

虽然这过程使钢软化,但它与退火是大不相同的,因为回火适合于严格控制物理性能并在大多数情况下不会把钢软化到退火那种程度。回火完全淬硬钢得到的最终组织结构被称为回火马氏体。

由于马氏体这一淬硬钢主要成分的不稳定性,使得回火成为可能。低温回火, 300℉到400℉(150℃~205℃),不会引起硬度下降很多,主要用于减少内部应变。

随着回火温度的提高,马氏体以较快的速率分解,并在大约600℉(315℃)迅速转变为被称为回火马氏体的结构。回火作业可以描述为渗碳体析出和凝聚或聚结的过程。

渗碳体的大量析出开始于600℉(315℃),这使硬度下降。温度的上升会使碳化物聚结而硬度继续降低。

在回火过程中,不但要考虑温度而且要考虑时间。虽然大多数软化作用发生在达到所需温度后的最初几分钟,但如果此温度维持一段延长时间,仍会有些额外的硬度下降。

通常的做法是将钢加热到所需温度并且仅保温到正好使其均匀受热。

两种采用中断淬火的特殊工艺也是回火的形式。这两种工艺中,淬硬钢在其被允许冷却前先在一选定的较低温度盐浴淬火。这两种分别被称为奥氏体回火和马氏体回火的工艺,能使产品具有特定所需的物理性能。

退火

退火的主要目的是使坚硬的钢软化以便机加工或冷作。

通常是非常缓慢地将钢加热到临界温度以上,并将其在此温度下保持到工件全部均匀受热,然后以受控的速率慢慢地冷却,这样使得工件表面和内部的温度近似相同。

这过程被称为完全退火,因为它去除了以前组织结构的所有痕迹、细化晶粒并软化金属。退火也释放了先前在金属中的内应力。

给定的钢其退火温度取决于它的成分;对碳钢而言可容易地从局部的铁碳合金平衡图得到。达到退火温度后,钢应当保持在此温度等到全部均匀受热。

加热时间一般以工件的最大截面厚度计每英寸(25mm )大约需45min。为了得到最大柔软性和延展性冷却速率应该很慢,比如让零件与炉子一起冷下来。含碳量越高,冷却的速率必须越慢。加热的速率也应与截面的尺寸及均匀程度相协调,这样才能使整个零件尽可能均匀地加热。

正火和球化

正火处理包括先将钢加热到高于上临界区50℉到100℉(10℃~40℃)然后在静止的空气中冷却到室温。

退火主要用于低碳钢、中碳钢及合金钢,使晶粒结构更均匀、释放内应力或获得所需的物理特性。大多数商业钢材在轧制或铸造后都要退火。

球化是使渗碳体产生成类似球状分布结构的工艺。如果把钢缓慢加热到恰好低于临界温度并且保持较长一段时间,就能得到这种组织结构。

所获得的球状结构改善了钢的可切削性。此处理方法对必须机加工的过共析钢特别有用。表面硬化

渗碳

最早的硬化钢表面的方法是表面淬火或渗碳。铁在靠近并高于其临界温度时对碳具有亲合力。碳被吸收进金属与铁形成固溶体使外表面转变成高碳钢。碳逐渐扩散到零件内部。渗碳层的深度取决于热处理的时间和温度。

固体渗碳的方法是将要处理的零件与木炭或焦炭这些含碳的材料一起放入密闭容器。这是一个较长的过程,用于产生深度为0.03到0.16 英寸(0.76~4.06mm)这么厚的硬化层。

用于渗碳的一般是含碳量约为0.15%、本身不太适合热处理的低碳钢。在处理过程中外层转化为含碳量从0.9%到1.2%的高碳钢。

含碳量变化的钢具有不同的临界温度,因此需要特殊的热处理。

由于在较长的渗碳过程中钢内部会有些晶粒生长,所以工件应该加热到核心部分的临界温度再冷却以细化核心部分的组织结构。然后重新加热到高于外层转变温度再淬火以生成坚硬、细致的组织结构。

由于恰好高于低临界温度通常使过共析钢奥氏体化而硬化,所以对外层采用较低的热处理温度。第三次回火处理可用于减少应变。

碳氮共渗

碳氮共渗,有时也称为干法氰化或渗碳氮化,是一种表面硬化工艺。通过把钢放在高于临界温度的气体中,让它吸收碳和氮。

可以使用任何富碳气体加氨气,能生成厚度从0.003到0.030英寸(0.08~ 0.76mm)的耐磨外层。碳氮共渗的优点之一是加入氮后外层的淬透性极大增加,为使用低价钢提供条件。

氰化

氰化,有时称为液体碳氮共渗,也是一种结合了吸收碳和氮来获得表面硬度的工艺,它主要用于不适合通常热处理的低碳钢。

需表面硬化的零件浸没在略高于Ac1温度熔化的氰化钠盐溶液中,浸泡的持续时间取决于硬化层的深度。然后将零件在水或油中淬火。

通过这样处理可以容易地获得0.005到0.015英寸(0.13~0.38mm)的硬化深度。氰化主要用于处理小零件。

渗氮

渗氮有些类似普通表面硬化,但它采用不同的材料和处理方法来产生坚硬表面成分。这种工艺中金属加热到约950℉(510℃),然后与氨气接触一段时间。氨气中的氮进入钢内,形成细微分布于金属表面又十分坚固的氮化物。

氮与某些元素的硬化能力比其它元素大,因此开发了专用的渗氮合金钢。

在钢中含铝1%到1.5%被证明特别合适,它能与氨气结合形成很稳定坚固的成分。其加热温度范围为925℉到1,050℉ (495℃~565℃)。

液体渗氮利用熔化的氰化物盐,就像气体渗氮,温度保持在低于转化范围内。液体渗氮时在氰化物溶液中加入比氰化及渗碳都较多的氮和较少的碳。

液体渗氮可以获得厚度为0.001到0.012英寸 (0.03~0.30mm)的硬化层,然而气体渗氮则能获得厚0.025英寸(0.64mm)的硬化层。一般而言两种渗氮方法的用途是类似的。

渗氮在钢表面获得远远超出正常标准的硬度。其硬度范围为900到1,100布氏硬度,这远高于普通表面硬化所获得的硬度。

由于渗氮钢的合金比例,它们比普通钢更强,也容易热处理。建议对这种钢在渗氮前先机加工和热处理,因为渗氮后没有剥落并不需要更多的加工。

值得庆幸的是由于渗氮处理一点都不影响内部结构和性能,也无需淬火,所以几乎没有任何产生翘曲、裂缝及变化条件的趋势。这种表面能有效地抵御水、盐雾、碱、原油和天然气的腐蚀反应。

道德经全文及译文,老子道德经全文及翻译

道德经全文及译文,老子道德经全文及翻译【老子·第一章】 道可道,非常道。名可名,非常名[1]。 无名天地之始;有名万物之母。 故常无,欲以观其妙;常有,欲以观其徼。 此两者,同出而异名,同谓之玄。玄之又玄,众妙之门。 【注释】: [1]通常译为"可以说出来的道,就不是永恒不变的道",强调道是不可言说的。但这样的翻译,等于一开始就剥夺了老子言说真道的可能性和可靠性。其实"常"字在《老子》中多为"通常"之意。另一方面,"道"字,到老子之时,已经用得很泛:有"道路"之意,如《易经》"履道坦坦,幽人贞吉";有"王道"之意,如《尚书》"无有作好,遵王之道" ;有"方法"之意,如《尚书》"我道惟宁王德延";又有"言说"之意,如《诗经》"中之言,不可道也"。《尚书序》(相传为孔子所作)说:"伏牺、神农、黄帝之书,谓之三坟,言大道也。少昊、颛乙、高辛、唐、虞之书,谓之五典,言常道也"。这里用了"常道"一词,指一般的道理。又有冯友兰先生考证说,古时所谓道,均为人道,到了老子才赋与道形而上学的意义。可见,老子要宣示上天大道,必须一开始就澄清概念,强调他下面要讲的道,

绝非人们一般常指的道,不是一般的道理,即非"常道",而是……是什么呢?就要听老子娓娓道来了。 【翻译】: 道可以说,但不是通常所说的道。名可以起,但不是通常所起的名。 可以说他是无,因为他在天地创始之前;也可以说他是有,因为他是万物的母亲。 所以,从虚无的角度,可以揣摩他的奥妙。从实有的角度,可以看到他的踪迹。 实有与虚无只是说法不同,两者实际上同出一源。这种同一,就叫做玄秘。玄秘而又玄秘啊!宇宙间万般奥妙的源头。 【老子·第二章】 天下皆知美之为美,斯恶已。皆知善之为善,斯不善已。 有无相生,难易相成,长短相形,高下相盈,音声相和,前后相随。恒也。 是以圣人处无为之事,行不言之教;万物作而弗始,生而弗有,为而弗恃,功成而不居。夫唯弗居,是以不去。

当今最潮的英语翻译

伪球迷biased fans 紧身服straitjacket 团购group buying 奉子成婚shortgun marriage 婚前性行为premartial sex 开博to open a blog 家庭暴力family volience 问题家具problem furniture 炫富flaunt wealth 决堤breaching of the dike 上市list share 赌球soccer gambling 桑拿天sauna weather 自杀Dutch act 假发票fake invoice 落后产能outdated capacity 二房东middleman landlord 入园难kindergarten crunch 生态补偿ecological compensation 金砖四国BRIC countries 笑料laughing stock 泰国香米Thai fragrant rice 学历造假fabricate academic credentials 泄洪release flood waters 狂热的gaga eg: I was gaga over his deep blue eyes when I first set eyes on him 防暑降温补贴high temperature subsidy 暗淡前景bleak prospects 文艺爱情片chick flick 惊悚电影slasher flick 房奴车奴mortgage slave 上课开小差zone out 万事通know-it-all 毕业典礼commencement 散伙饭farewell dinner 毕业旅行after-graduation trip 节能高效的fuel-efficient 具有时效性的time-efficient 死记硬背cramming 很想赢be hungry for success 面子工程face job 捉迷藏play tag 射手榜top-scorer list 学历门槛academic threshold 女学究blue stocking

科技英语翻译的原则_方法及技巧.

翻译是把一种语言里已经表达出来的事物用另一种语言准确流畅地进行重新表达的过程。与其他题材的文章相比,科技专业文章在内容、表达形式和风格上有很大的差别,具有科技性强、专业性强、逻辑严密、表达要求简练的特点,在翻译上力求准确全面、严谨明确和通顺简练。 1科技英语翻译遵循的基本原则 从科技文章的特点来看,大多具有以下几个特征:述说事理、逻辑性强、结构严密、术语繁多,语言严谨、数据精确。这就要求译文必须概念清楚、条理分明、逻辑正确、数据无误,尤其对定义、定律、公式、图表、结论等更应特别注意。科技英语作为特殊英语的一个分支,在词汇构成、遣词造句等方面都有其自身的特点,其语法结构不十分严密、语言习惯和汉语也有不少差别、词汇量大、词语繁多,因此科技英语翻译起来比较困难。另外,科技文章比较重视叙事逻辑上的连贯及表达上的明晰与畅达; 避免行文晦涩,避免表露个人感情,避免论证上的主观随意性。因此,科技英语翻译力求少用或不用描述性形容词以及具有抒情作用的副词、感叹词及疑问词,而是大量使用科技词汇、专业技术用语,译者应尊重客观事实,不能随意改动数据、回避不易翻译的文字,更不能加进自己的主观想象,进行自由翻译。 我国著名翻译家严复提出的“信、达、雅”三准则一直为不少翻译工作者所接受。 “信”指的是译文要忠实于原文,“达”是指译文的通顺达意,“雅”指的是译文的用词修辞。三准则体现了译文和原文信息等值这一基本要领。 “信、达、雅”的翻译准则对各种英语文体的翻译实践都具有指导意义,是衡量一篇译文好坏的标准,也同样适用于科技文献的翻译。由于科技文章特有的文体特征,与其他类文章相比,其“达”和“雅”的内涵不同,它要求在准确传达信息的基础上,使译文更加简洁明快,流畅通顺。2科技英语翻译的基本方法

50个很潮的英文单词

发表日期:2015-09-29 07:48 来源:80后励志网编辑:80后点击:3321次 文章标签: 英语名言教育好文读书励志英语教育 文章导读:英语是国际性的语言,英语在我们的生活中使用率也越来越高,下面这50个很潮的英文单词,年轻人一定要学会哦! 50个很潮的英文单词,年轻人一定要学会! 1.预约券 reservation ticket 2.下午茶 high tea 3.微博 Microblog/ Tweets 4.裸婚 naked wedding 5.亚健康 sub-health 6.平角裤 boxers 7.愤青 young cynic 8.灵魂伴侣 soul mate 9.小白脸 toy boy 10.精神出轨 soul infidelity 11.人肉搜索 flesh search 12.浪女 dillydally girl 13.公司政治 company politics 14.剩女 3S lady(single,seventies,stuck)/left girls 15.山寨 copycat 16.异地恋 long-distance relationship 17.性感妈妈 yummy mummy ; milf(回复中指出的~) 18.钻石王老五 diamond bachelor;most eligible bachelor 20.时尚达人 fashion icon 21.御宅 otaku 22.上相的,上镜头的 photogenic 23.脑残体 leetspeak 24.学术界 academic circle 25.哈证族 certificate maniac 26.偶像派 idol type 27.住房公积金 housing funds 28.个税起征点 inpidual income tax threshold 29.熟女 cougar(源自电影Cougar Club) 30.挑食者 picky-eater 31.伪球迷 fake fans 32.紧身服 straitjacket 33.团购 group buying 34.奉子成婚 shotgun marriage 35.婚前性行为 premarital sex 36.开博 to open a blog 37.家庭暴力 family/domestic violence (由回复更正) 38.问题家具 problem furniture

小议科技英语翻译技巧

小议科技英语翻译技巧 科技文体崇尚严谨周密,概念准确,逻辑性强,行文简练,重点突出,句式严整,少有变化,常用前置性陈述,即在句中将主要信息尽量前置,通过主语传递主要信息。科技文章文体的特点是:清晰、准确、精练、严密。那末,科技文章的语言结构特色在翻译过程中如何处理,这是进行英汉科技翻译时需要探讨的问题。现分述如下: 一、大量使用名词化结构 大量使用名词化结构(Nominalization)是科技英语的特点之一。因为科技文体要求行文简洁、表达客观、内容确切、信息量大、强调存在的事实。而非某一行为。 Archimedes first discovered the principle of displacement of water by solid bodies. 阿基米德最先发展固体排水的原理。 句中of displacement of water by solid bodies 系名词化结构,一方面简化了同位语从句,另一方强调displacement 这一事实。 The rotation of the earth on its own axis causes the change from day to night. 地球绕轴自转,引起昼夜的变化。 名词化结构the rotation of the earth on its own axis 使复合句简化成简单句,而且使表达的概念更加确切严密。 If you use firebricks round the walls of the boiler, the heat loss, can be considerably reduced. 炉壁采用耐火砖可大大降低热耗。 科技英语所表述的是客观规律,因之要尽量避免使用第一、二人称;此外,要使主要的信息置于句首。 Television is the transmission and reception of images of moving objects by radio waves. 电视通过无线电波发射和接受活动物体的图象。 名词化结构the transmission and reception of images of moving objects by radio waves 强调客观事实,而"谓语动词则着重其发射和接受的能力。 二、广泛使用被动语句 根据英国利兹大学John Swales 的统计,科技英语中的谓语至少三分之一是被动态。这是因为科技文章侧重叙事推理,强调客观准确。第一、二人称使用过多,会造成主观臆断的印象。因此尽量使用第三人称叙述,采用被动语态,例如:Attention must be paid to the working temperature of the machine.应当注意机器的工作温度。而很少说:You must pay attention to the working temperature of the machine .你们必须注意机器的工作温度。此外,如前所述,科技文章将主要信息前置,放在主语部份。这也是广泛使用被动态的主要原因。试观察并比较下列两段短文的主语。 We can store electrical energy in two metal plates separated by an insulating medium. We call such a device a capacitor, or a condenser, and its ability to store electrical energy capacitance .It is measured in farads. 电能可储存在由一绝缘介质隔开的两块金属极板内。这样的装置称之为电容器,

《英汉翻译课程教学大纲》

英汉翻译课程教学大纲 一、课程的目的和任务 《英汉翻译教程》和《汉英翻译教程》的教学目的和任务是,从英译汉和汉译英的一般规律和原则出发,围绕翻译的基本理论、英汉异同的对比以及翻译实践中成功或失败的实例,介绍汉英两种语言的对比与分析、各类文体的语言特点以及不同翻译方法,向学生传授基本的翻译理论和常用方法、技巧,通过反复实践培养学生汉英翻译基本技能。通过学习,学生能够熟练地运用已掌握的英语基本语法和词汇等知识,忠实、准确、通顺、完整地将汉语句子、段落和短文译成英语,并对文化差异有着较强的敏感性,能够较好地处理英汉互译中具有民族特色的形象、比喻等,胜任一般性的政治、经济、文化、科技、应用文等的翻译工作。同时,还要注重培养学生严谨的学风,避免不求甚解、逐词死译和望文生义。 适当补充口译实践,训练学生在政治、经济、文化等方面的能力,并提高学生的政策水平和涉外工作能力。 二、课程的基本要求 《英汉翻译教程》和《汉英翻译教程》课程的教学分为翻译方法和技巧训练阶段和短文翻译两个阶段,其分别要求是: 1、翻译方法和技巧训练阶段的基本要求: (1)、词汇: 掌握10000-12000 个词汇以及这些单词构成的常用词组;正确而熟练地使用其中5000-6000 个词 汇及最常用的搭配,能够运用到汉英互译中。 (2)语法: 熟练地使用各种衔接手段,连贯地表达思想,侧重语法结构在翻译过程中的理解和应用。 (3)阅读能力: 能读懂一般英美报刊杂志上的社论和书评,理解文章大意,分辨事实与细节;能读懂有一定难度的 历史传记及文学作品,理解其真实含义;能分析上述题材文章的思想观点,语篇结构,语言特点和修辞手法。 (4)翻译能力: 能借词典将文字资料译成理解正确、表达准确、译文连贯通顺具一定修辞手段的规范语句,写译的速度达到每小时250-300 词。 2. 短文翻译阶段的基本要求: (1)词汇 1

英汉互译一第1课教案

广西师范学院《英汉互译(一)》课程教案 编号: 15-1 开课单位:外语系授课教研室:翻译写作 课程名称:《英汉互译(一)》授课教师:唐旭光 教材:《新编英汉互译教程》,授课对象:06级英语专业2、3、5班

《英汉互译(一)》第一讲翻译简论与主要翻译方法 (A Brief Discussion of Translation and Major Translation Approaches) 1. Introduction Translation studies started along with translation practice. Translation theories developed flourishingly in the 20th century, especially in the second half of the last century. In fact, translation, which is a very complex phenomenon, is related to different disciplines, such as linguistics, psychology, sociology, cultural anthropology, communication theory, literary criticism, aesthetics, and semiotics. As translation study is a cross-discipline and cross-culture subject involving many aspects of human knowledge, the lack of a fully acceptable theory of translation should not come as a surprise. Meanwhile, quite a number of translation approaches and strategies have become universally acceptable and widely applicable. They are, of course, the fruits of many translation theorists and translation practitioners at home and abroad. 2.The Origin of Translation Language makes it possible for people to communicate with one another freely so as to complete important tasks in human life. Translation makes it possible for people from different languages to communicate with one another so as to complete important tasks in their life. Theodore Savory points out, “Translation is almost as old as original authorship and has a history as honorable and as complex as that of any other branch of literature”(申雨平, 2002:4). In Zhou Dynasty there were different forms of address for translators in different places. “Translators are called Ji in the east, Xiang in the south, Didi in the west, and

《道德经》老子翻译

《老子》正译 《老子》一章 (原文) 道可道,非常道;名可名,非常名。无,名天地之始;有,名万物之母。故常无欲以观其妙,常有欲以观其徼。此两者同出,异名同谓,玄之又玄,众妙之门。 [正译] 道可以用语言说得出,但是却不是用一般的语言;也可以给它取名称,但是却不是用一般的名称。我们称道是“无”,用以表述它是天地的开始;我们称道是“有”,用以表述它是万物的母亲。所以我们经常要用“无”的观点来观看它的微妙,经常要用“有”的观点来观看它的边界。“无”和“有”这两者同时从道中出现,虽然名称不同,但它们都是对道的表述,它玄妙而又玄妙,它是世界上一切奥妙的总门。 《老子》二章 (原文) 天下皆知美之为美,斯恶矣;皆知善之为善,斯不善矣。故有无之相生,难易之相成,长短之相形,高下之相倾,音声之相和,前后之相随。是以圣人处无为之事,行不言之教,万物作焉而不辞,生而不有,为而不恃,功成而不居。夫唯不居,是以不去。 [正译] 天下人都知道美之成为美,这就出现丑陋了;都知道善之成为善,这就出现不善了。所以有和无是相互转化的,难和易是相互产生的,长和短是相互比较的,高和下是相互倾应的,音与声是相互附和的,前和后是相互跟随的。所以圣人用无为的方式处理世事,用不言的方式施行教化,兴作万物而不加以辞谢,产生万物而不占为自有,从事万物而不自恃为大,大功告成而不自居有功。正由于不居有功,所以就没有失去。 《老子》三章 (原文) 不尚贤,使民不争;不贵难得之货,使民不为盗;不见可欲,使民心不乱。是以圣人之治,虚其心,实其腹,弱其志,强其骨,常使民无知无欲,使夫智者不敢为也。为无为,则无不治。 [正译] 不推崇圣贤,使百姓不争名位;不贵重难得的财物,使百姓不去偷盗;不见可以引起欲望的事物,使百姓的心不被迷乱。因此圣人治理国家的办法是:空虚百姓的心灵,用气充实百姓的下腹,减弱百姓的意志,增强百姓的体魄,这就经常使百姓没有知识没有欲望,致使那些有才智的人也不敢有所作为。圣人按照无为的原则去治理天下,就没有什么治理不好的。 《老子》四章 (原文) 道冲,而用之又不盈。渊兮似万物之宗,湛兮似若存。吾不知其谁之子,象帝之先。 [正译] 大道虽然空虚,但是它发挥起作用来却没有穷尽。它是那样渊深啊,好象是万物的宗主;它是

50个很潮的英文单词

50个很潮的英文单词,年轻人一定要学会! 发表日期:2015-09-29 07:48 来源:80后励志网编辑:80后点击:3321次 文章标签: 英语名言教育好文读书励志英语教育 文章导读:英语是国际性的语言,英语在我们的生活中使用率也越来越高,下面这50个很潮的英文单词,年轻人一定要学会哦! 50个很潮的英文单词,年轻人一定要学会! 1.预约券 reservation ticket 2.下午茶 high tea 3.微博 Microblog/ Tweets 4.裸婚 naked wedding 5.亚健康 sub-health 6.平角裤 boxers 7.愤青 young cynic 8.灵魂伴侣 soul mate 9.小白脸 toy boy 10.精神出轨 soul infidelity 11.人肉搜索 flesh search 12.浪女 dillydally girl 13.公司政治 company politics 14.剩女 3S lady(single,seventies,stuck)/left girls 15.山寨 copycat 16.异地恋 long-distance relationship 17.性感妈妈 yummy mummy ; milf(回复中指出的~) 18.钻石王老五 diamond bachelor;most eligible bachelor

20.时尚达人 fashion icon 21.御宅 otaku 22.上相的,上镜头的 photogenic 23.脑残体 leetspeak 24.学术界 academic circle 25.哈证族 certificate maniac 26.偶像派 idol type 27.住房公积金 housing funds 28.个税起征点 inpidual income tax threshold 29.熟女 cougar(源自电影Cougar Club) 30.挑食者 picky-eater 31.伪球迷 fake fans 32.紧身服 straitjacket 33.团购 group buying 34.奉子成婚 shotgun marriage 35.婚前性行为 premarital sex 36.开博 to open a blog 37.家庭暴力 family/domestic violence (由回复更正) 38.问题家具 problem furniture 39.炫富 flaunt wealth 40.决堤 breaching of the dike 41.上市 list share 42.赌球 soccer gambling 43.桑拿天 sauna weather 44.自杀 Dutch act 45.假发票 fake invoice 46.落后产能 outdated capacity 47.二房东 middleman landlord 48.入园难 kindergarten crunch 49.生态补偿 ecological compensation 50.金砖四国 BRIC countrie

道德经全文及译文老子道德经全文及翻译

道德经全文及译文,老子道德经全文及翻译 【老子·第一章】道可道,专门道。名可名,专门名[1]。 无名天地之始;有名万物之母。 故常无,欲以观其妙;常有,欲以观其徼。 此两者,同出而异名,同谓之玄。玄之又玄,众妙之门。 【注释】: [1]通常译为"能够讲出来的道,就不是永恒不变的道",强调道是不可言讲的。但如此的翻译,等于一开始就剥夺了老子言讲真道的可能性和可靠性。事实上"常"字在《老子》中多为"通常"之意。另一方面,"道"字,到老子之时,差不多用得非常泛:有"道路"之意,如《易经》"履道坦坦,幽人贞吉";有"王道"之意,如《尚书》"无有作好,遵王之道" ;有"方法"之意,如《尚书》"我道惟宁王德延";又有"言讲"之意,如《诗经》"中之言,不可道也"。《尚书序》(相传为孔子所作)讲:"伏牺、神农、黄帝之书,谓之三坟,言大道也。少昊、颛乙、高辛、唐、虞之书,谓之五典,言常道也"。那个地点用了"常道"一词,指一般的道理。又有冯友兰先生考证讲,古时所谓道,均为人道,到了老子才赋与道形而上学的意义。可见,老子要宣示上天大道,必须一开始就澄清概念,强调他下面要讲的道,绝非人们一般常指的道,不是一般的道理,即非"常道",而是……是什么呢?就要听老子娓娓道来了。 【翻译】: 道能够讲,但不是通常所讲的道。名能够起,但不是通常所起的名。 能够讲他是无,因为他在天地创始之前;也能够讲他是有,因为他是万物的母亲。 因此,从虚无的角度,能够揣摩他的奥妙。从实有的角度,能够看到他的踪迹。 实有与虚无只是讲法不同,两者实际上同出一源。这种同一,就叫做玄秘。玄秘而又玄秘啊!宇宙间万般奥妙的源头。 【老子·第二章】天下皆知美之为美,斯恶已。皆知善之为善,斯不善已。 有无相生,难易相成,长短相形,高下相盈,音声相和,前后相随。恒也。 是以圣人处无为之事,行不言之教;万物作而弗始,生而弗有,为而弗恃,功成而不居。夫唯弗居,是以不去。 【翻译】: 1天下的人都明白以美为美,这就是丑了。都明白以善为善,这就是恶了。 2有和无是相互依存的,难和易是相互促成的,长和短互为比较,高和下互为方向,声响和

潮语俚语英语翻译词典

1)特困生super-sleepy students 2)讨债人debt collector 3)老赖deadbeat 4)另类offbeat 5)蕾丝边lesbian 6)油条flirtatious boy 7)晒黑族injustice exposer 8)新新人类new-new generation 9)麦霸microphone monopolist 10)楼主thread starter 11)姐弟恋cradle snatcher 12)达人pro/doyen 13)潮人trendsetter 14)性情中人unsophisticated person 15)钻石王老五diamond bachelor 16)毒枭drug lord 17)菜鸟rookie/novice 18)三夹板sandwich husband 19)熟女sophisticated lady 20)型男metro-sexual men 21)作女high-maintenance woman 22)潜规则hidden rule 23)傍大款live off a moneybags 24)爆料tip off/blow the whistle 25)拆烂污mess up knowingly 26)强档prime time 27)哑巴亏take it on the chin 28)找不着北lose one’s bearings 29)不折腾Don’t stir up turmoil. 30)双规double designation 31)高考状元college entrance exam ace 32)走光wardrobe malfunction 33)开光consecrate/bless/deify 34)骨感型boney clan 35)素人layman, bungler 36)敲门砖door opener, stepping stone 37)淘客online shopper 38)内鬼inner culprit 39)死党sworn friend 40)名嘴popular TV presenter 41)老娘舅avuncular arbitrator 42)奔奔族car-less drivers 43)考托exam scalper 44)医托hospital scalper, hospital stoolie

《英汉翻译》教学大纲

《英汉翻译》教学大纲 课程编号: 课程名称:英汉翻译 课程模块:三年制英语教育专业的专业方向必选课 课程属性:必修课 学时:总学时为36学时,一学期内上完,每周2课时。 先修课程:综合英语;英语泛读;英语口语;英语听力 适用专业:三年制英语教育专业 成绩考核:考试课 开课教研室:英语教研室 一、课程性质与任务 课程性质:《英汉翻译教程》是英语专业的必修课,教学分配在英语专业二年级进行。 课程任务:《英汉翻译教程》任务是,从英译汉和汉译英的一般规律和原则出发,围绕翻译的基本理论、英汉异同的对比以及翻译实践中成功或失败的实例,介绍汉英两种语言的对比与分析、各类文体的语言特点以及不同翻译方法,向学生传授基本的翻译理论和常用方法、技巧,通过反复实践培养学生汉英翻译基本技能。通过学习,学生能够熟练地运用已掌握的英语基本语法和词汇等知识,忠实、准确、通顺、完整地将汉语句子、段落和短文译成英语,并对文化差异有着较强的敏感性,能够较好地处理英汉互译中具有民族特色的形象、比喻等,胜任一般性的政治、经济、文化、科技、应用文等的翻译工作。同时,还要注重培养学生严谨的学风,避免不求甚解、逐词死译和望文生义。适当补充口译实践,训练学生在政治、经济、文化等方面的能力,并提高学生的政策水平和涉外工作能力。 二、课程教学内容、学时安排与要求 第一章翻译概论 【教学目的要求】 通过介绍世界和中国翻译史中理论与实践的发展情况,使学生对翻译标准、翻译基本方法、翻译中的可译性与不可译性等理论与实践问题有初步的了解,认识到翻译工作的重要性。 【教学重点难点】 注意在翻译练习中体现并强调翻译理论的运用。 【教学内容】 翻译的作用与使命,翻译的标准,翻译的方式,笔译与口译,可译性与不可译的补偿,中国翻译史,翻译练习

英文版道德经

英文版道德经 1. The Way The Way that can be experienced is not true; The world that can be constructed is not true. The Way manifests all that happens and may happen; The world represents all that exists and may exist. To experience without intention is to sense the world; To experience with intention is to anticipate the world. These two experiences are indistinguishable; Their construction differs but their effect is the same. Beyond the gate of experience flows the Way, Which is ever greater and more subtle than the world. 2. Abstraction When beauty is abstracted Then ugliness has been implied; When good is abstracted Then evil has been implied. So alive and dead are abstracted from nature, Difficult and easy abstracted from progress, Long and short abstracted from contrast, High and low abstracted from depth, Song and speech abstracted from melody, After and before abstracted from sequence. The sage experiences without abstraction, And accomplishes without action; He accepts the ebb and flow of things, Nurtures them, but does not own them, And lives, but does not dwell. 3. Without Action Not praising the worthy prevents contention, Not esteeming the valuable prevents theft, Not displaying the beautiful prevents desire. In this manner the sage governs people: Emptying their minds, Filling their bellies, Weakening their ambitions, And strengthening their bones. If people lack knowledge and desire Then they can not act; If no action is taken Harmony remains. 4. Limitless The Way is a limitless vessel; Used by the self, it is not filled by the world;

汉英翻译教案

汉英翻译教案 【篇一:翻译教案】 使用教材:张培基等编《英汉翻译教程》,上海外语教育出版社,2003年 第一讲翻译原则简介 教学目标:了解基本的翻译原则和翻译研究的问题 教学方法:理论讲授、课堂讨论、翻译练习讲评相结合 重点:1.翻译的定义和内涵(translation is an n art/science/craft?) 2.中国几位翻译家的理论:严复、傅雷、钱钟书、刘重德 3.中国翻译史上的论争:鲁迅—宁信而不顺;梁秋实、赵景深:宁 顺而不信 难点:1.直译与意译 2.归化与异化:归化派代表人物尤金.奈达,异化派代表人物韦努蒂 课时分配:课堂讲授60分钟;课堂小节10分钟;课堂作业20分 钟 教学内容: 1.翻译的定义和内涵:(definition and connotation) translation is an art/ science/craft? 2.中国几位翻译家的理论(influential translation principles):严复:信达雅--- faithfulness/expressiveness/elegance. the “three character guide” is regarded as a plumb-line of long standing to measure the professional level of translating. 傅雷:神似---spiritual conformity. emphasizing the reproduction of the spirit of the flavor of the original.强调原作神韵再现。 钱钟书:化境---sublimed adaptation. focus on the translator’s smooth and idiomatic chinese version for the sake of the chinese reader. 刘重德:信、达、切---faithfulness/expressiveness/closeness. 阅读本讲全文 课后练习:p.6 第三大题 第二讲翻译的过程 教学目标:怎样去理解和表达;学会表达的基本策略 教学方法:理论讲授、课堂讨论、翻译练习讲评相结合

道德经(中英对照)

《道德经》中英文对照版 第一章:道可道,非常道;名可名,非常名。无名,天地之始;有名,万物之母。故常无欲,以观其妙;常有欲,以观其徼。此两者,同出而异名,同谓之玄。玄之又玄,众妙之门。 The Way that can be told of is not an Unvarying Way;The names that can be named are not unvarying names. It was from the Nameless that Heaven and Earth sprang;The named is but the mother that rears the ten thousand creatures,each after its kind. Truly,‘Only he that rids himself forever of desire can see the Secret Essences’;He that has never rid himself of desire can see only the Outcomes. These two things issued from the same mould,but nevertheless are different in name. This‘same mould’we can but call the Mystery,Or rather the‘Darker than any Mystery’,The Doorway whence issued all Secret Essences. 第二章:天下皆知美之为美,斯恶已;皆知善之为善,斯不善已。故有无相生,难易相成,长短相形,高下相倾,音声相和,前后相随。是以圣人处无为之事,行不言之教,万物作焉而不辞,生而不有,为而不恃,功成而弗居。夫唯弗居,是以不去。 It is because every one under Heaven recognizes beauty as beauty,that the idea of ugliness exists. And equally if every one recognized virtue as virtue,this would merely create fresh conceptions of wickedness. For truly‘Being and Not-being grow out of one another;Difficult and easy complete one another. Long and short test one another;High and low determine one another. Pitch and mode give harmony to one another. Front and back give sequence to one another’。Therefore[1] the Sage relies on actionless activity,Carries on wordless teaching,But the myriad creatures are worked upon by him;he does not disown them. He rears them,but does not lay claim to them,Controls them,but does not lean upon them,Achieves his aim,but does not call attention[2] to what he does;And for the very reason that he does not call attention to what he does He is not ejected from fruition of what he has done. [1]Because‘action’can only make one thing high at the expense of making something else low,etc. [2]Literally,‘does not place(i.e.classify)himself as a victor’。cf. MenciusⅡ,Ⅰ; 第三章:不尚贤,使民不争;不贵难得之货,使民不为盗;不见可欲,使民心不乱。是以圣人之治,虚其心,实其腹;弱其志,强其骨。常使民无知无欲,使夫智不敢为也。为无为,则无不治。 If we stop looking for‘persons of superior morality’(hsien)to put in power,there will be no more jealousies among the people. If we cease to set store by products that are hard to get,there will be no more thieves. If the people never see such things as excite desire,their hearts will remain placid and undisturbed. Therefore the Sage rules By emptying their hearts And filling their bellies,Weakening their intelligence[1] And toughening their sinews Ever striving to make the people knowledgeless and desireless. Indeed he sees to it that if there be any who have knowledge,they dare not interfere. Yet through his actionless activity all things are duly regulated. [1]Particularly in the sense of‘having ideas of one’s own‘。 第四章:道冲而用之,或不盈。渊兮,似万物之宗。(挫其锐,解其纷,和其光,同其尘。)湛兮,似或存。吾不知谁之子,象帝之先。 The Way is like an empty vessel That yet may be drawn from Without ever needing to be filled. It is bottomless;the very progenitor of all things in the world. In it all sharpness is blunted,All tangles untied,All glare tempered,All dust[1] smoothed. It is like a deep pool that never dries. Was it too the child of something else?We cannot tell. But as a substanceless image[2] it existed before the Ancestor.[3]