procast教程精品2

Gravity-Sand

This tutorial will guide you step by step in the ProCAST set-up of a sand casting simulation.

The geometry used for this tutorial is composed of a:

·casting

·sand box

·cores

本指南将指导你在ProCAST 中一步一步地建立一个砂型铸件模拟。

本指南中需要的几何模型包括:

·铸件

·砂型

·砂芯

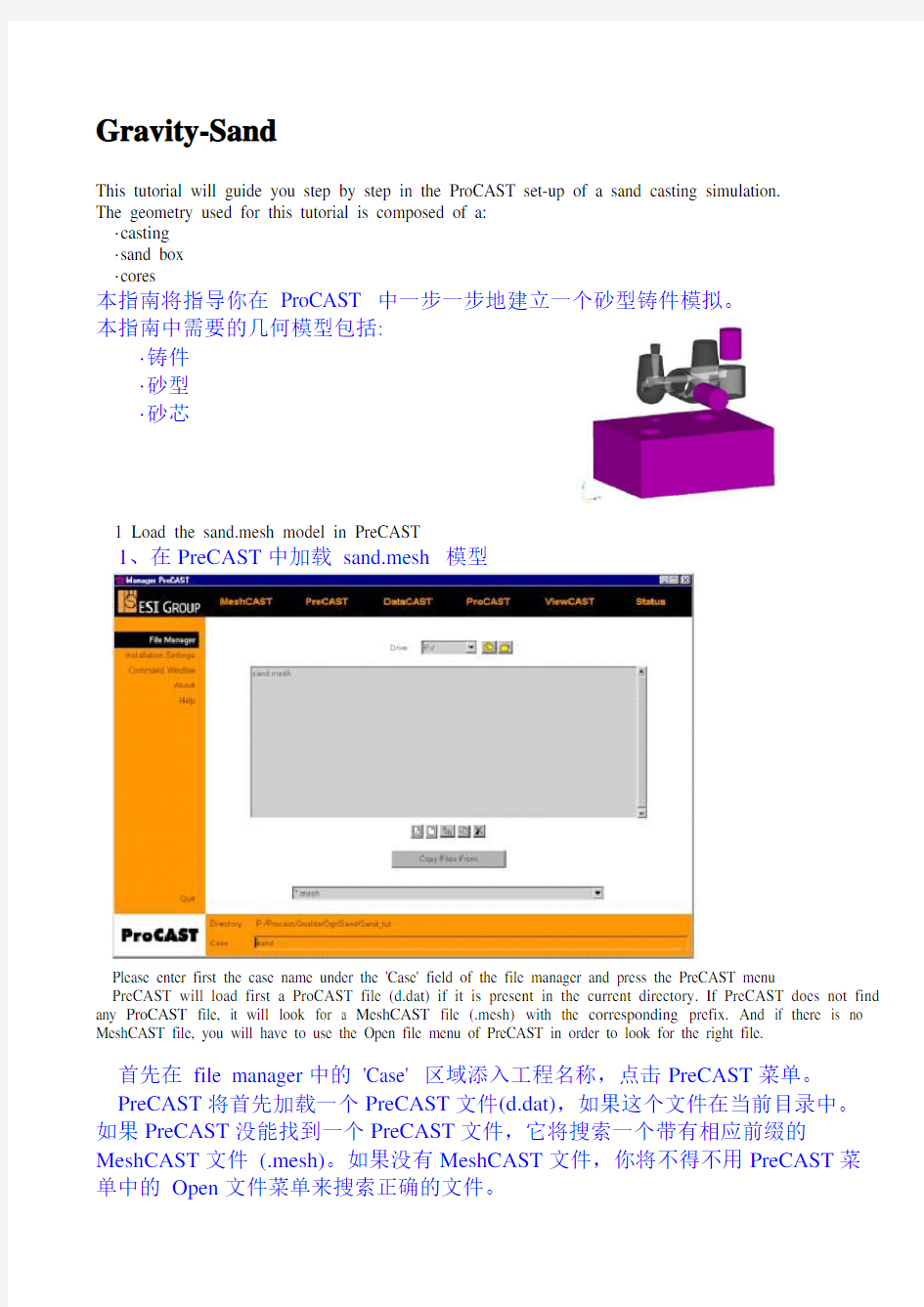

1 Load the sand.mesh model in PreCAST

1、在PreCAST中加载sand.mesh 模型

Please enter first the case name under the 'Case' field of the file manager and press the PreCAST menu

PreCAST will load first a ProCAST file (d.dat) if it is present in the current directory. If PreCAST does not find any ProCAST file, it will look for a MeshCAST file (.mesh) with the corresponding prefix. And if there is no MeshCAST file, you will have to use the Open file menu of PreCAST in order to look for the right file.

首先在file manager中的'Case' 区域添入工程名称,点击PreCAST菜单。PreCAST将首先加载一个PreCAST文件(d.dat),如果这个文件在当前目录中。如果PreCAST没能找到一个PreCAST文件,它将搜索一个带有相应前缀的MeshCAST文件(.mesh)。如果没有MeshCAST文件,你将不得不用PreCAST菜单中的Open文件菜单来搜索正确的文件。

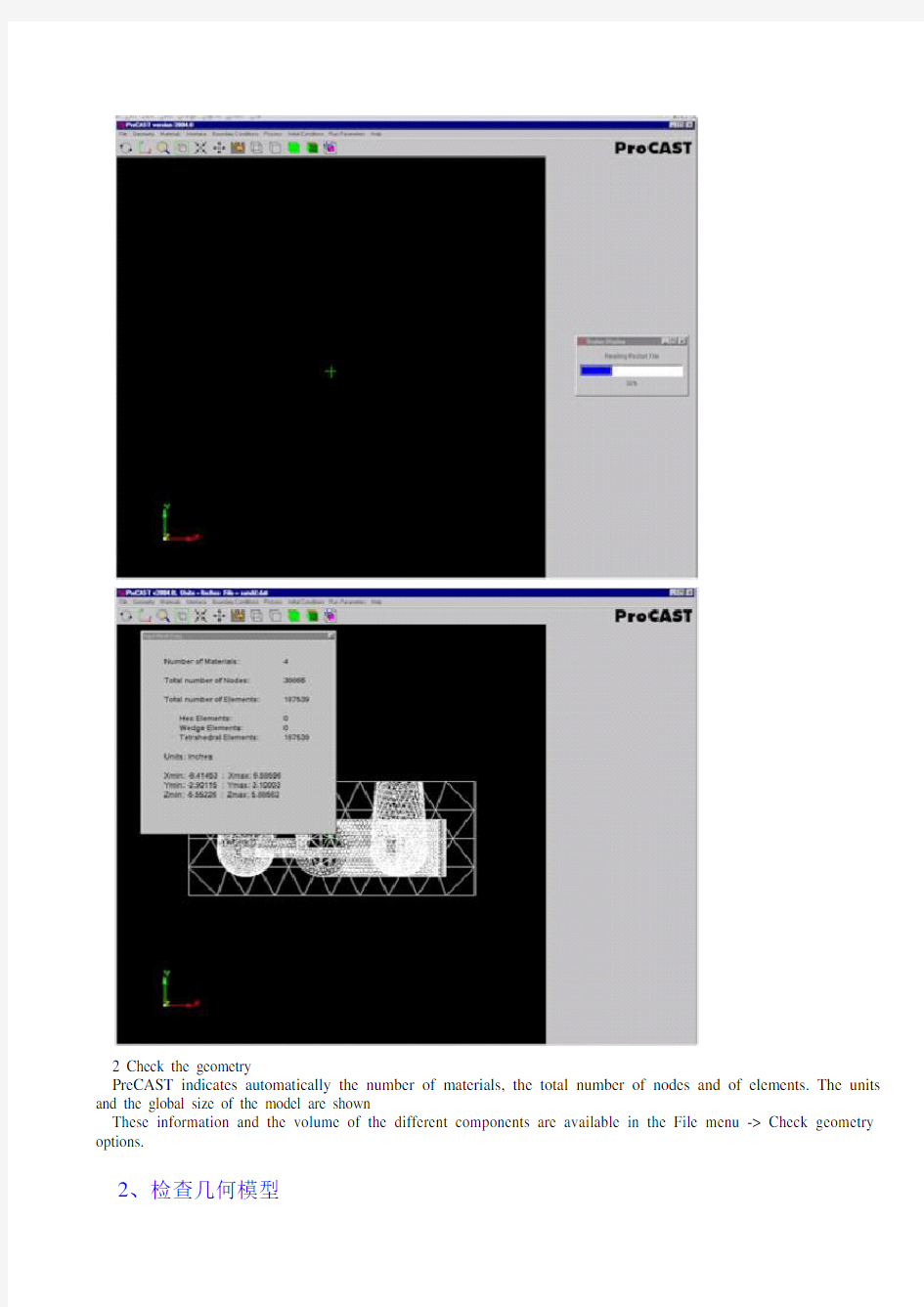

2 Check the geometry

PreCAST indicates automatically the number of materials, the total number of nodes and of elements. The units and the global size of the model are shown

These information and the volume of the different components are available in the File menu -> Check geometry options.

PreCAST自动显示材料的数量,节点和零件的总数。模型的单位和轮廓尺寸也将显示。

这些信息和不同零件的体积在菜单File menu -> Check geometry 选项中。

3 Assign material properties to the casting, mold and cores. In this case, Ductile Iron is assigned to the casting material, Sand silica to the mold and Steel_H13 to the core domains.

3、对铸件、砂型、砂芯设置材料参数。在本例中,铸件材料为球铁,砂型材料为硅砂,砂芯材料为Steel_H13 。

4 Create and Assign the Interfaces between the components

In this case all interfaces have to be converted from EQUIV to COINC. In order to validate this choice, press the Apply button.

4、创建和设置不同零件的界面

在本例中,所有的界面将EQUIV 转化成COINC。为了使该项选择有效,点击Apply按钮。

Once the interfaces are created, assign a heat transfer value to each interface. Typical values are 500 W/m2K between casting and sand and 1000 W/m2K between casting and steel cores.

一旦界面被创建,对每个界面设置一个热传导数值。典型值铸件与砂型界面为500 W/m2K ,铸件与钢制砂芯之间为1000 W/m2K。

5 Assign the Boundary conditions

5、设置边界条件

A natural air cooling heat Boundary condition will be applied all around the sand box, a velocity Boundary condition will be applied and a temperature Boundary condition will be imposed to some nodes of the top surface of the down sprue.

砂型周围是一个自然空气冷却的热边界条件。一个速度边界条件和一个温度边界条件将被设置到直浇口的上平面的一些节点上。

6 Set the gravity

In order to set the gravity vector, go in the Process menu.

6、设置重力

为了设置重力矢量,转到Process菜单。

7Set the constant Initial conditions

7、设置初始条件常量。

8Set the run parameters

In the Preferences menu, select the Gravity filling option. The right and dedicated run parameters will be automatically set.

8、设置浇注参数

在Preferences菜单中,选择Gravity filling选项。合适的专用浇注参数将自动设置。

In the General run parameters panel, DTMAX is set to 5 seconds in this case.

在General run parameters 面板中,DTMAX在本例中被设置为5秒。

In the Thermal run parameters panel, TFREQ is set to 5 here.

在Thermal run parameters 面板中,TFREQ被设置为5。

In the Flow run parameters panel, VFREQ is set to 5 (equal to TFREQ).

在Flow参数面板中,VFREQ被设置为5(等于TFREQ)。

Do not forget to press Apply in order to validate the Run Parameters selection. 为了使参数选择有效,不要忘了点击Apply。

9Save and Exit PreCAST

9、保存并退出PreCAST

10Run DataCAST and ProCAST

10、运行DataCAST 和ProCAST 11Visualize the results in ViewCAST 11、在ViewCAST中显示结果

Position the model using the picture manipulation tools (zoom, drag, rotate, ...). 用图像处理工具(zoom, drag, rotate, ...)定位模型

Select the casting material.

选择铸件材料。

Visualization of the flow behavior using the 'tape player' buttons. 用'tape player' 按纽显示流动效果。

Analysis of the velocity vectors. Possible mold erosion can be studied. 分析速度矢量。可以分析可能的模具腐蚀。

Temperature map in a cross section through the total model:

整个模型的一个截面的温度场

Isolated pockets of liquid are displayed using the Fraction of Solid cut-off option. 用Fraction of Solid cut-off option显示孤立的液体区。