地铁站主体施工方案

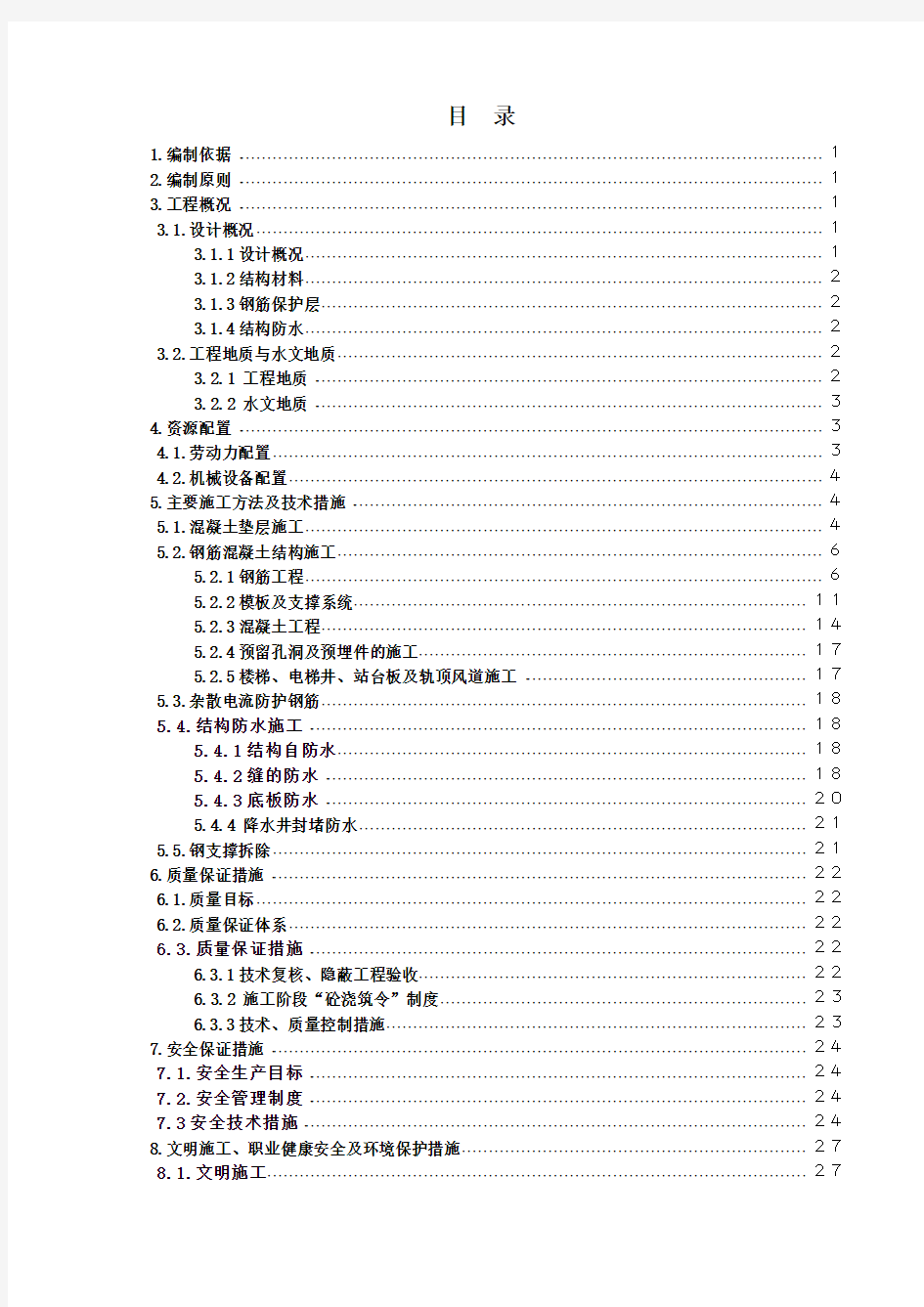

目录

1.编制依据 ·············································································································1

2.编制原则 ·············································································································1

3.工程概况 ·············································································································13.1.设计概况·········································································································1

3.1.1设计概况································································································1

3.1.2结构材料································································································2

3.1.3钢筋保护层·····························································································2

3.1.4结构防水································································································23.2.工程地质与水文地质··························································································2

3.2.1 工程地质 ·······························································································2

3.2.2 水文地质 ·······························································································3

4.资源配置 ·············································································································34.1.劳动力配置······································································································3

4.2.机械设备配置···································································································4

5.主要施工方法及技术措施 ························································································45.1.混凝土垫层施工································································································45.2.钢筋混凝土结构施工··························································································6

5.2.1钢筋工程································································································6

5.2.2模板及支撑系统····················································································11

5.2.3混凝土工程··························································································14

5.2.4预留孔洞及预埋件的施工········································································17

5.2.5楼梯、电梯井、站台板及轨顶风道施工 ·····················································175.3.杂散电流防护钢筋··························································································185.4.结构防水施工 ·····························································································18

5.4.1结构自防水·······················································································18

5.4.2缝的防水 ··························································································18

5.4.3底板防水 ··························································································20

5.4.4 降水井封堵防水···················································································21

5.5.钢支撑拆除···································································································21

6.质量保证措施 ····································································································226.1.质量目标······································································································226.2.质量保证体系································································································226.3.质量保证措施 ·····························································································22

6.3.1技术复核、隐蔽工程验收········································································22

6.3.2 施工阶段“砼浇筑令”制度····································································23

6.3.3技术、质量控制措施··············································································23

7.安全保证措施 ····································································································247.1.安全生产目标 ·····························································································247.2.安全管理制度 ·····························································································24

7.3安全技术措施 ······························································································24

8.文明施工、职业健康安全及环境保护措施································································278.1.文明施工····································································································27

8.2.职业健康安全 ·····························································································278.3.环境保护措施 ·····························································································28

1.编制依据

(1)《大卿桥站车站主体结构施工图》和《大卿桥站车站主体结构防水图》;

(2)《大卿桥站岩土工程勘察报告》;

(3)《实施性施工组织设计》;

(4)《地下铁道工程施工及验收规范》(GB50299-1999)2003版;

(5)《地铁设计规范》(GB50157-2003);

(6)《工程测量规范》(GB50026-93);

(7)《人民防空工程设计规范》(GB50225-95);

(8)《混凝土结构工程施工质量验收规范》(GB50204-2002);

(9)《地下防水工程质量验收规范》(GB50208-2002);

(10)《地下工程防水技术规范》(GB50108-2001);

(11)《建筑施工碗扣式脚手架安全技术规范》(JGJ166-2008)

(12)《建筑扣件式钢管脚手架安全技术规范》(JGJ130-2001);

(13)适用于本工程的合同文件及有关的国家、部及浙江省、宁波市技术规范、规程、标准、法规文件等。

2.编制原则

以满足业主期望、投标承诺为目标,充分理解宁波市轨道交通1号线一期工程大卿桥站施工的特点、难点,科学管理、精心组织,按各节点工期要求,“优质、高效、安全、快速”地完成大卿桥站主体结构施工任务。

3.工程概况

3.1.设计概况

3.1.1设计概况

本站为地下二层岛式车站,采取明挖顺作法施工。车站长172.6m,标准段宽20.7m,深16.31m;端头井宽25.6m,深17.91m;换乘节点段宽22.5m,深24.91m。车站共设4个出入口和2个风井。基坑设五道支撑(换乘节点七道),第一道为混凝土支撑(换乘节点第一、五道),其它为φ609钢管支撑。顶板厚700mm,中板厚400,底板标准段厚900mm、端头井厚1000mm;内衬墙厚700mm;站台层标准段净高6.26m,端头井净高7.76m;站厅层净高4.75m。

3.1.2结构材料

车站顶板采用C35混凝土,抗渗等级P8;车站内部框架柱采用C45混凝土;车站内部结构底板及侧墙采用C35混凝土,抗渗等级P8(节点P10);其余内部结构采用C35混凝土;垫层采用C30早强混凝土。主体结构钢筋采用HPB235、HRB335。

3.1.3钢筋保护层

钢筋混凝土结构受力筋净保护层厚度:底板:外侧50mm、内侧40mm;顶板:外侧50mm、内侧40mm ;中板:30mm;柱:35mm;侧墙:外侧50mm、内侧40mm;站台板:25mm;梁:外侧50mm、内侧40mm。

3.1.4结构防水

结构防水设计原则:车站主体结构防水遵循“以防为主、刚柔结合、多道防线、因地制宜、综合治理”的原则;确立钢筋混凝土结构自防水体系,即以结构自防水为根本,采取措施控制结构混凝土裂缝的开展,提高混凝土的抗渗性能;以诱导缝、施工缝、变形缝、穿墙管、桩头等细部构造的防水为重点,同时在结构迎水面设置柔性全包防水层。

车站主体结构的防水等级为一级,不允许渗水,结构表面无湿渍。

3.2.工程地质与水文地质

3.2.1 工程地质

根据工程地质勘察资料,本场地自地表至2H深度范围内,按其成因类型、土层结构及地层特性见表1。

基坑底部主要位于第③

2、④

1

层中,换乘节点基坑底部位于第⑤

1

、⑤

2

层中。

3.2.2 水文地质

孔隙潜水主要赋存于表部填土和粘土、淤泥质土层中。表部填土富水性和透水性均

较好,水量大;浅层粘土和淤泥质土富水性、透水性差水量贫乏。

承压水有三层:③层粘性土粉砂或粉土层中的浅层微承压水;第I-1层孔隙承压水主要赋存于⑤3层和⑤5层粉土中;第I-2层孔隙承压水赋存于⑥5和⑧层粉砂、细砂、

粗砂、砾砂和圆砾层中。车站端头井受⑤

5

层承压水的影响。

4. 资源配置

4.1.劳动力配置

劳动力配置见表2。

表2 劳动力配置表

4.2.机械设备配置

机械设备配置见表3。

表3 机械设备配备表

5.主要施工方法及技术措施

5.1.混凝土垫层施工

基坑开挖的同时,随时检查地墙内净空尺寸,地墙鼓包混凝土及时凿除,以确保主体结构内衬墙截面尺寸。

基坑开挖到距坑底设计标高300mm时,改用人工配合机械进行清底并整平,以免超挖或扰动基底原状土层。同时进行垫层底各项施工,埋设综合接地装置,挖下翻梁沟槽,修整地模。当出现超深现象时,用碎石加拌砂子垫平。开挖完成并经监理验收合格后及时进行垫层施工,防止基底软化。垫层采用C30早强混凝土,保护层采用C20细石

混凝土。

垫层施工根据基坑开挖段分段施工。垫层施工靠土方开挖端比结构诱导缝超前2~3m,垫层遇降水井处按照降水井封堵措施施工,待主体结构施工完毕并达到设计强度后再封闭降水井。垫层砼浇注采用平板振动器振实,表面用人工压实,抹光,垫层顶适当降低2~3cm,其强度未达到2.5Mpa以前禁止在上面作业。

表4 主体结构每施工段施工流程图