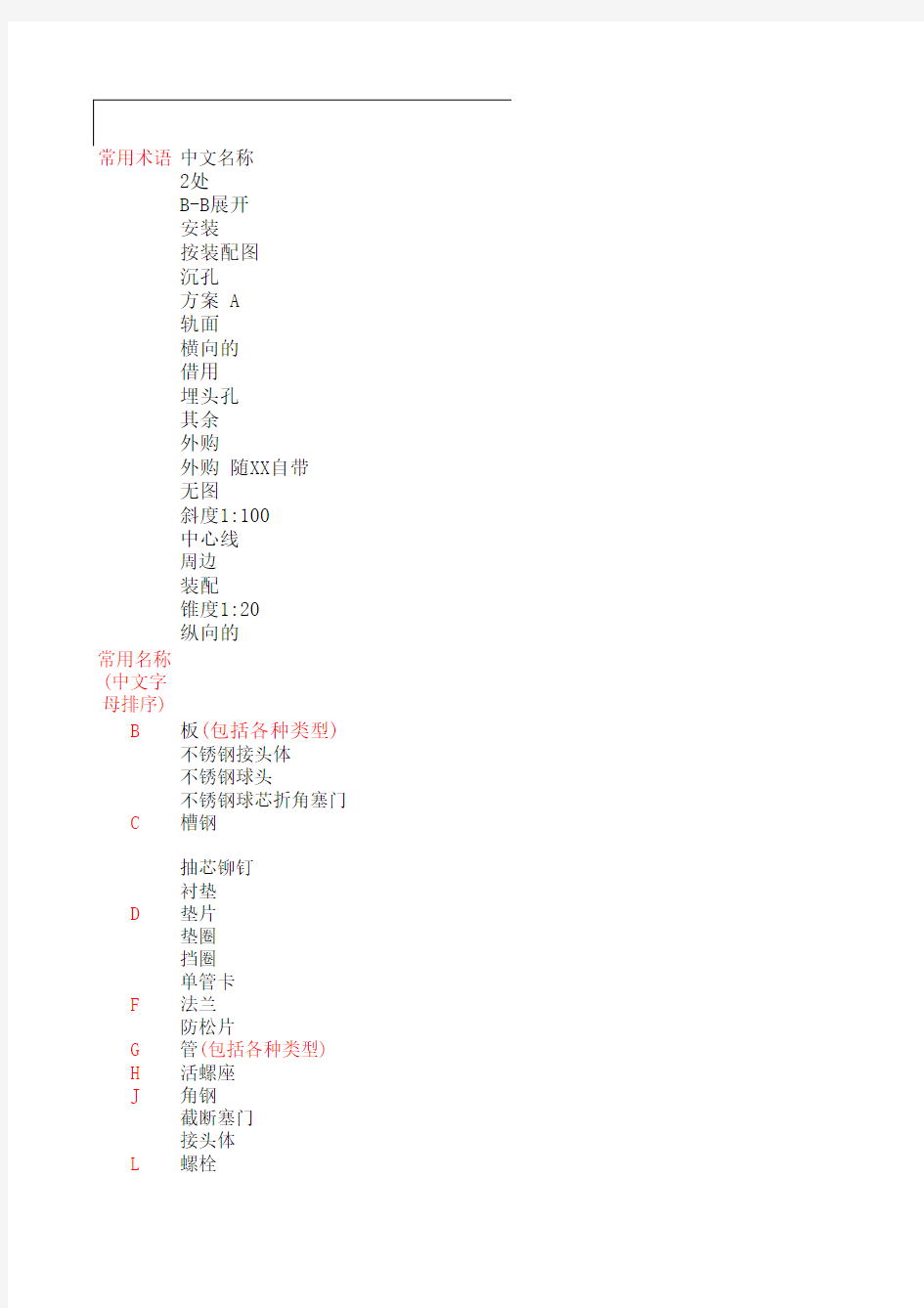

常用技术术语

2处

B-B展开

安装

按装配图

沉孔

方案 A

轨面

横向的

借用

埋头孔

其余

外购

外购 随XX自带

无图

斜度1:100

中心线

周边

装配

锥度1:20

纵向的

常用名称

(中文字

母排序)

B板(包括各种类型)

不锈钢接头体

不锈钢球头

不锈钢球芯折角塞门C槽钢

抽芯铆钉

衬垫

D垫片

垫圈

挡圈

单管卡

F法兰

防松片

G管(包括各种类型)

H活螺座

J角钢

截断塞门

接头体

L螺栓

螺钉

螺母

螺柱

螺堵

M铆钉

木螺钉

铆钉

Q球接头

S三通管接头

三通塞门

绳栓

双管卡

T弹簧

弹簧垫圈

W弯头

X销

销轴

Y压型槽钢

Z自攻铆钉

自攻螺钉

座

常用

技术要求

B不允许有 型砂、毛刺、缩孔及冷硬边角C淬火及回火

除另有规定外,加工余量按3mm

渗碳层加工后厚度1-7.5,调质硬度

45HRC-50HRC

D钝化处理

锻造斜度(拔模率)均为7度

锻造斜度(拔模率)均为2度,但须保证

最小尺寸

锻件按虚线所示尺寸

F方框内口尺寸应按照规定在组装时加工发兰

G滚花直纹0.6JB2-59

滚花网纹

H壁厚公差3.0

L冷处理

螺纹部分应涂以厌氧胶或硝化纤维粘结

剂

两端磨平后的支承圈数不得少于3/4圈

两端面对弹簧轴线的不垂直度在全长上

不大于0.5

Q清除毛刺及锐缘

全压缩试验三次后不允有残余变形

清铲毛刺飞边并除去氧化皮

R锐边倒钝

S时效处理

T探伤后退磁

退火及正火

调质,即硬化后回火处理

弹簧钢丝末端厚度不允许小于0.8

弹簧的上下端面对于弹簧中心线的垂直

高度偏差不大于3度

涂漆前喷丸处理

调质硬度为HB***

W未注明圆角半径为R5

未注公差的铸造尺寸应按DL75-013二级

精度

X消除应力

洗净或吹风清理

旋向:左右或任意

Y圆弹簧

有效圈数,工作圈数

有效圈距允差0.3

Z总圈数

展开长度约为2010

自由高度不作验收根据

中英文对照表(通用部分)

英文翻译

2 Plcs.

B-B Developed

Installation

As Assy. Drawing

Counterbored Hole

Variant A

Rail Surface

Horizontal

Borrowed

Countersunk Hole

Unspecified

Purchased

Purchased with XX

No Drawing

Incline 1:100

Center Line

Peripheral

Assembly

Taper 1:20 on Diameter

Longitudinal

Plate

Stainless Steel Joint Body

Stainless Steel Ball Joint

Stainless Steel Ball Core Angle Cock Channel

Self-plugging Rivet

Pad

Shim

Washer

Ring-retainer

Single Pipe Clamp

Flange

Locking Plate

Pipe

Bolt Base

Angle

Cutout Cock

Joint Body

Bolt

Screw

Nut

Stud

Plug

Rivet

Wood Screw

Rivet

Ball Joint

T-joint

T-cock

Rope

Double Pipe Clamp

Spring

Spring Washer

Elbow

Pin

Pin Shaft

Pressed Channel

Rivet Drive

Self Tapping Screw

Seat

Must be free from sand,burrs,shrink and chilled edges

Quenching and tempering

Finish allowance 3mm unless otherwise specified

Carburize 1-7.5 finish case depth,harden and temper to 45HRC-50HRC Passivating treatment

All draft angle 7°

All draft angle 2°additional to dimension specified

Forge to phantom line

Dimensions shown in shall be machined to at assembly in accordance with the Specification

Bluing

0.6pitch straight knurl per specification JB2-59

Diamond knurl

Variation of wall thicknesses within 3.0

Sub-zero treatment

Apply anaerobic adhesive or nitrocellulose binder to at assembly in accordance with the Specification

Actual ground bearing surfaces at both ends shall not be shorter than three fourths of the mean coil circumference

Squareness of the two ends to the spring axis shall be within 0.5 total

Burrs and sharp edges to be removed(or remove burrs and sharp

edges,deburr and round sharp edges)

No permanent set is permitted after free-to-solid compression test for 3times

Snag and remove scale

Break all sharp edges

Aging treatment

Demagnetizing after flaw detecting

Annealing and normalizing

Hardening and tempering

Thickness of the tapered wire ends is no less than 0.8

Ends of the spring shall not deviate more than 3°from the perpendicular to the spring axis

Shot-peening before painting

Harden and temper to HB***

Fillet and round radius to be 5mm unless otherwise noted(all radius to be 5mm unless otherwise stated)

Casting dimensions without limits shall be in accordance with the accuracy grade 2 specified in DL75-013

Stress relieving

Cleanse or blow-wash

wind:right,left or optional

Helical spring

Effective coils

Effective pitch variation within 0.3

Total coils

Developed length 2010mm approx

Free height is not restricted by any tolerance

Inst. Assy.