DAISI 光纤端面3D测试仪操作手册

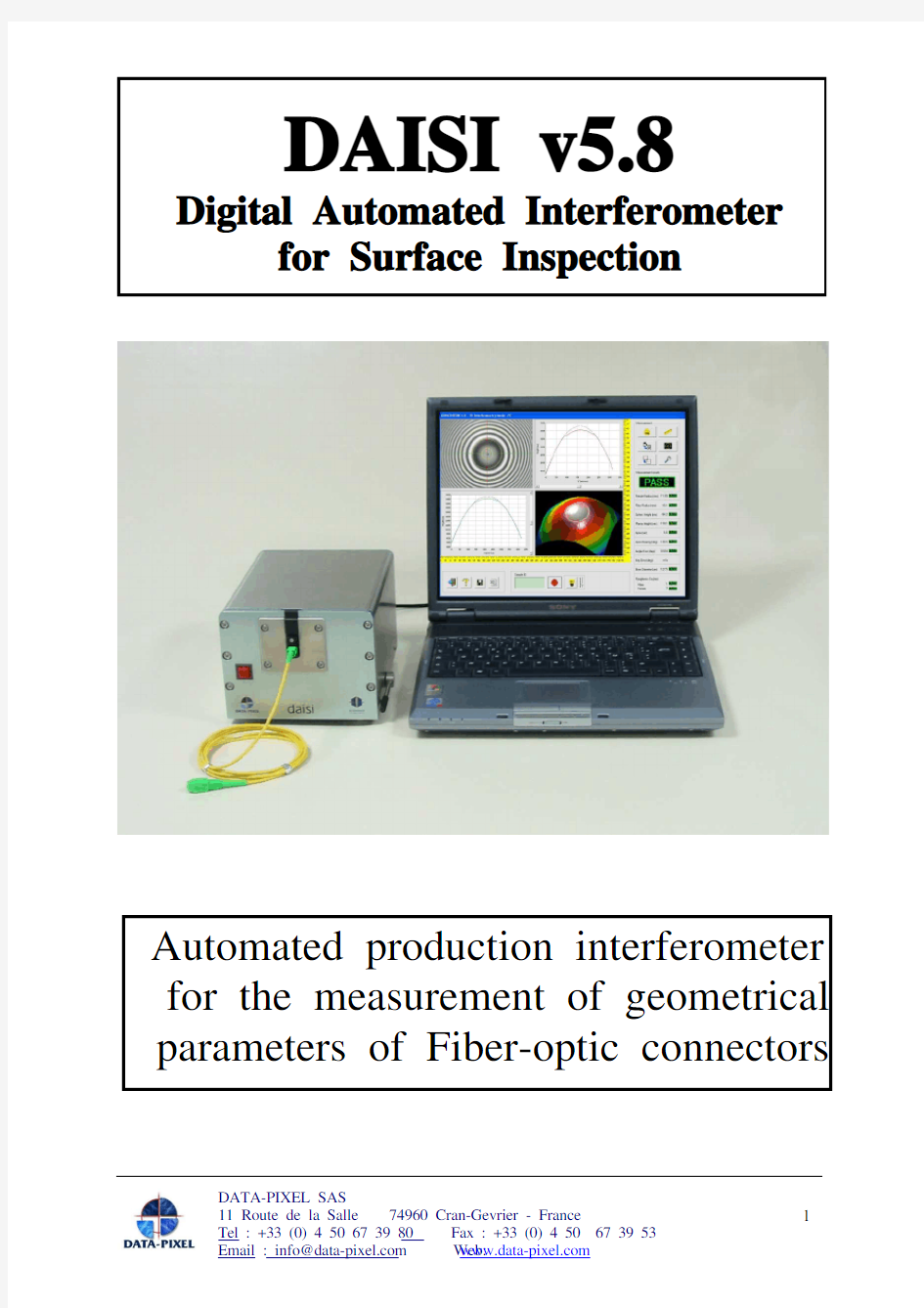

DAISI v5.8

Digital Automated Interferometer for Surface Inspection

Automated production interferometer for the measurement of geometrical parameters of Fiber-optic connectors

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

1

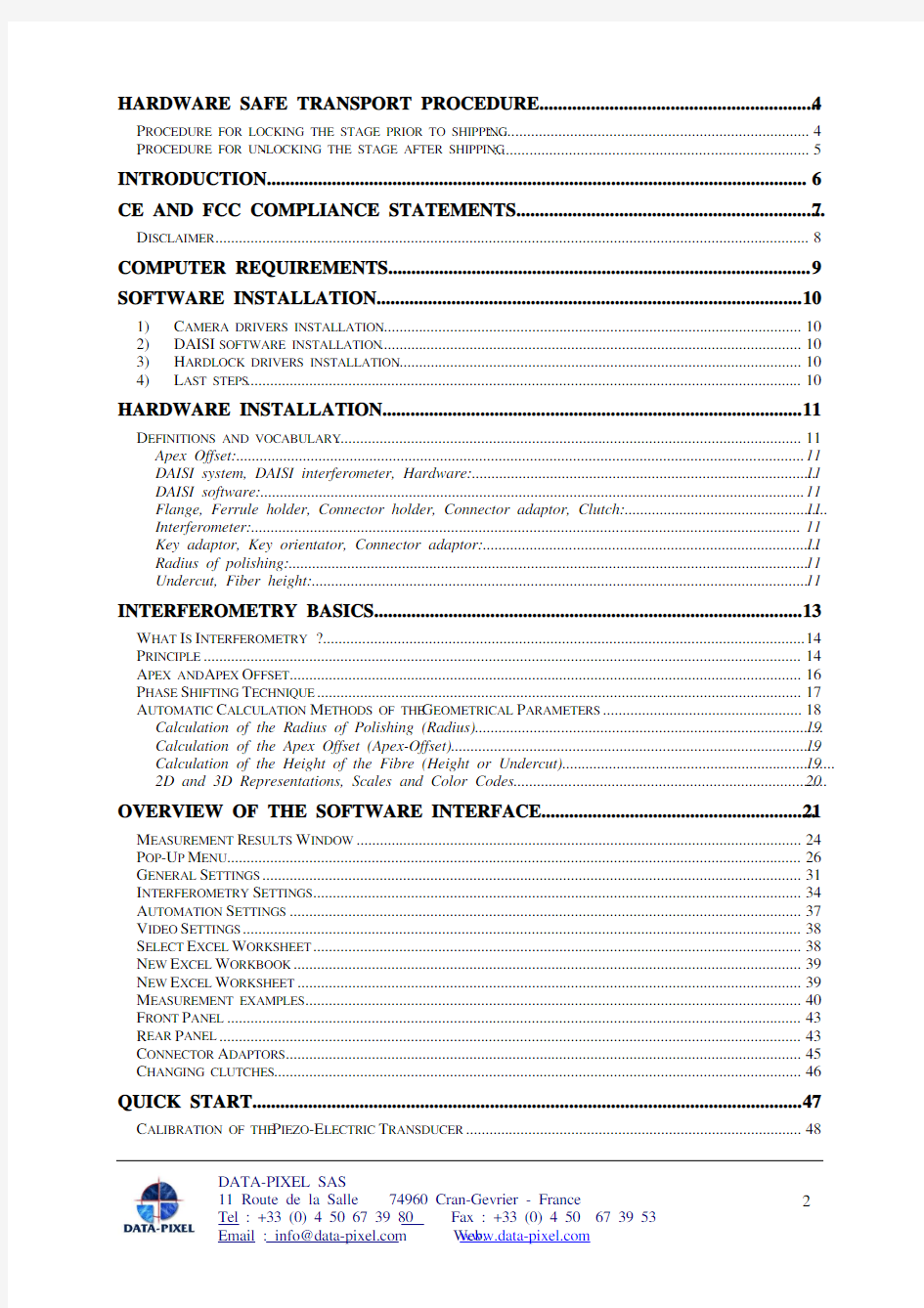

HARDWARE SAFE TRANSPORT PROCEDURE ............................................................ 4

PROCEDURE FOR LOCKING THE STAGE PRIOR TO SHIPPING: ................................................................................. 4 PROCEDURE FOR UN-LOCKING THE STAGE AFTER SHIPPING: ............................................................................... 5

INTRODUCTION.................................................................................................................... 6 CE AND FCC COMPLIANCE STATEMENTS .................................................................. 7

DISCLAIMER ........................................................................................................................................................ 8

COMPUTER REQUIREMENTS........................................................................................... 9 SOFTWARE INSTALLATION ........................................................................................... 10

1) 2) 3) 4) CAMERA DRIVERS INSTALLATION ............................................................................................................ 10 DAISI SOFTWARE INSTALLATION............................................................................................................ 10 HARDLOCK DRIVERS INSTALLATION ........................................................................................................ 10 LAST STEPS .............................................................................................................................................. 10

HARDWARE INSTALLATION .......................................................................................... 11

DEFINITIONS AND VOCABULARY ....................................................................................................................... 11 Apex Offset: ................................................................................................................................................. 11 DAISI system, DAISI interferometer, Hardware: ........................................................................................ 11 DAISI software: ........................................................................................................................................... 11 Flange, Ferrule holder, Connector holder, Connector adaptor, Clutch:.................................................... 11 Interferometer: ............................................................................................................................................ 11 Key adaptor, Key orientator, Connector adaptor: ...................................................................................... 11 Radius of polishing:..................................................................................................................................... 11 Undercut, Fiber height:............................................................................................................................... 11

INTERFEROMETRY BASICS............................................................................................ 13

WHAT IS INTERFEROMETRY ? ........................................................................................................................... 14 PRINCIPLE ......................................................................................................................................................... 14 APEX AND APEX OFFSET................................................................................................................................... 16 PHASE SHIFTING TECHNIQUE ............................................................................................................................ 17 AUTOMATIC CALCULATION METHODS OF THE GEOMETRICAL PARAMETERS ................................................... 18 Calculation of the Radius of Polishing (Radius) ......................................................................................... 19 Calculation of the Apex Offset (Apex-Offset) .............................................................................................. 19 Calculation of the Height of the Fibre (Height or Undercut)...................................................................... 19 2D and 3D Representations, Scales and Color Codes ................................................................................ 20

OVERVIEW OF THE SOFTWARE INTERFACE........................................................... 21

MEASUREMENT RESULTS WINDOW .................................................................................................................. 24 POP-UP MENU................................................................................................................................................... 26 GENERAL SETTINGS .......................................................................................................................................... 31 INTERFEROMETRY SETTINGS............................................................................................................................. 34 AUTOMATION SETTINGS ................................................................................................................................... 37 VIDEO SETTINGS ............................................................................................................................................... 38 SELECT EXCEL WORKSHEET ............................................................................................................................. 38 NEW EXCEL WORKBOOK .................................................................................................................................. 39 NEW EXCEL WORKSHEET ................................................................................................................................. 39 MEASUREMENT EXAMPLES ............................................................................................................................... 40 FRONT PANEL ................................................................................................................................................... 43 REAR PANEL ..................................................................................................................................................... 43 CONNECTOR ADAPTORS.................................................................................................................................... 45 CHANGING CLUTCHES ....................................................................................................................................... 46

QUICK START ...................................................................................................................... 47

CALIBRATION OF THE PIEZO-ELECTRIC TRANSDUCER ...................................................................................... 48 DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

2

CALIBRATION OF THE APEX FOR A PC TYPE ADAPTER..................................................................................... 49 Principle ...................................................................................................................................................... 49 In Practice ................................................................................................................................................... 49 FIBER CLEAVES MEASUREMENT ....................................................................................................................... 51 OK, so how does it work and how do I calibrate ?...................................................................................... 53 How do I calibrate ?.................................................................................................................................... 54 To what exactly do the numbers on the measurement report correspond ? ................................................ 55

EXCEL REPORTS ................................................................................................................ 56 APPENDIX ............................................................................................................................. 60

TROUBLE SHOOTING ......................................................................................................................................... 61 MAINTENANCE .................................................................................................................................................. 62 STANDARDS ...................................................................................................................................................... 62 STANDARDS ...................................................................................................................................................... 63

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

3

HARDWARE SAFE TRANSPORT PROCEDURE

Prior to shipping a DAISI interferometer, it is safer to lock the internal mechanical stage in order to avoid hammering effects during transportation with potential damaging effects.

Procedure for locking the stage prior to shipping:

Step 1: remove the nylon M4 screw (if any) located on the rear panel of the DAISI unit.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

4

Step 2: insert a 2.5mm Allen key inside the aperture and rotate clockwise (when facing the rear panel) until you feel the stage came to a mechanical stop. This can take a few turns. NEVER FORCE !!! Step 3: rotate the Allen key anti-clockwise over 5-10 degrees.

Procedure for un-locking the stage after shipping:

No particular procedure is necessary, the unit is ready to be used. You will have however to bring the focus towards the front panel of the unit using the PAGE-DOWN keyboard key as it is fully up in locked mode.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

5

INTRODUCTION

DAISI is a fully automated system dedicated to the measurement of geometrical parameters of optical fiber connectors end-face such as “Radius of polishing”, “Fiber Height” and “Apex Offset”, using an optical interferometry technique. DAISI uses the quality and the non-contact property of optical measurements associated with the power of numerical data processing to provide measurements of great accuracy. It is made of a software linked to an opto-mechanical hardware system, which it drives automatically through a USB2.0 link. The optical part of the hardware forms an image of the end face of the ferrule on a high resolution CMOS video camera (resolution is 1280 x 1024 pixels); the actual magnification factor of the ferrule end face when displayed on the computer monitor is approx. ×400 with a field of view of approx. 400 x 300 square-microns. The use of the hardware and of the software is simple and only requires a one-day training on the system. Why is DAISI better than other interferometers ? DAISI combines a number of unique features which enables its use in the production environment in a better and easier way than any other interferometer. Some of these features are: Non-contact measurement. Fast autofocus. One button easy operation. Servo-controlled reference mirror for automatic Apex calibration. Strongest ferrule holder in the industry with automated open/close feature. Can perform measurements while handling the cable. No exterior moving parts or adjustment screw -> No apex decalibration. Vibration insensitive. Measurements can be made when holding the system by hand. Easy and fast switching from PC to APC, no change of ferrule holder required. Connector key adaptors for most connector types. Special design provides easy loading feature. Fast and automated measurement of radius, apex offset, fiber height + more. Accurate and repeatable measurements. Interfaceable to laptop computers, only one USB2.0 link required. Compliance with Industry Standards for interferometer measurements. Measure angle of cleaving of bare fibers with great precision. High resolution 2D & 3D surface profiles. Measurement Reports and History Reports in Excel. Measure Fiber and Ferrule Roughness (Sq parameter).

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

6

CE AND FCC COMPLIANCE STATEMENTS

DECLARATION OF CONFORMITY

In accordance with the Directive 89/336/EEC for Electro-Magnetic Compatibility, we declare that the following electronic product: DAISI identified with the ‘‘CE’’ mark, when installed and used in accordance with the instructions given in the product user manual, is in conformity with the following standards: Generic Standard: Emission EN50081-1 Immunity EN50082-2 DATA-PIXEL SAS 11 Route de la Salle F-74960 Cran-Gevrier France 15th June 2004

Company Address:

Date of issue :

Authorised by:

Title of Authority:

President

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

7

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense."

Disclaimer

Changes or modifications onto the DAISI system not expressly approved by Data-Pixel could void the user’s authority to operate the equipment. DAISI system shall be exclusively used with the provided power supply. Data-Pixel does not guaranty the proper functioning of the system otherwise.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

8

COMPUTER REQUIREMENTS

Computer Requirements :

DAISI works on WINDOWS-2000 Professional (Service Pack 3) as well as XP (Service Pack 1) and VISTA operating systems. The processor should be an INTEL 1.4 GHz or more and at least 256 Mb of RAM are required (512 Mb recommended). A strong multimedia-oriented video display card should be used with at least 64Mb of onboard video memory. The monitor should be set to a resolution of at least 1024x768 pixels and the taskbar (bottom of desktop) should be set to “AUTOHIDE” if vertical resolution is 768 (not necessary if it is higher). If resolution is set to 1024x768 pixels, make sure there are no “tool-bar” locked onto the desktop such as the office-bar. The font size should be set to the default font, i.e. 96 dpi. One USB2.0 ports should be available. Finally, a printer should be installed by default on the PC and Microsoft EXCEL (2000 or higher) should be installed too.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

9

SOFTWARE INSTALLATION

Before proceeding to installation, make sure you are logged into the computer with administrator privileges. Insert the DAISI CD-ROM into the computer but do not plug the DAISI USB 2.0 cable in the port for the moment.

1) Camera drivers installation

Start the “LuCamSDKv4.6.exe” application located in the Lumenera folder on this CD and follow the installation steps. Plug the DAISI USB plug into a free USB2.0 port of the computer. The computer should now automatically detect the newly plugged instrument and install its necessary drivers. Follow the installation steps, letting the computer automatically search for the drivers. You will need to repeat this procedure for each USB port you wish to plug DAISI into.

2) DAISI software installation

Start the “Setup.exe” application located in the DAISI and follow the installation steps. Once done, copy the “DAISI.exe” file located in the “DAISI UPDATE” folder (if any) on the CD-ROM into the newly created “C:\Program Files\DAISI” folder.

3) Hardlock drivers installation

Install the HARDLOCK drivers by starting the file “hldrv32.exe” located in the HARDLOCK folder on this CD and follow the installation steps.

4) Last steps

Make sure the TASKBAR at the bottom of the screen is setup to “auto hide” (right-click on it and select “Properties”, then check the 'auto-hide' checkbox) and that the screen resolution is set to at least 1024x768. If your screen resolution is set to 1024x768, make sure you do not have other “toolbars” on the desktop such as the “Office Bar”. If your vertical screen resolution is higher than 768, it may not be necessary to set the Taskbar to “auto hide”. Select the “Properties” on the desktop and choose “none” for the screen saver. Then, select the “Monitor Power Control” and check “never” for all options. Restart your computer before starting the DAISI software. Please refer to the DAISI user manual for instructions on how to use the DASI software and hardware.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

10

HARDWARE INSTALLATION Definitions and vocabulary

Apex Offset: See section Interferometry Basics DAISI system, DAISI interferometer, Hardware: the main opto-mechanical system DAISI software: specific Windows-based software installed on a computer (laptop or desktop) and interfaced to the DAISI system via a USB2.0 link. Flange, Ferrule holder, Connector holder, Connector adaptor, Clutch: Mechanical part located on the front panel of the DAISI system. This part enables a precise prehension of the ferrule of the connector during a measurement. Each specific ferrule diameter requires a specific Clutch. Interferometer: Optical system that uses the wave properties of light in order to compare the local phase deviations of one wavefront from another. In the present case, a reference wavefront (the wavefront reflected from the reference mirror) is compared to the wavefront reflected from the sample under measurement (the ferrule endface). Key adaptor, Key orientator, Connector adaptor: Mechanical part that adapts onto a Clutch in order to pecisely orientate vertically the orientation key (APC key) of a connector housing. Specific connector types require specific key adaptors. Radius of polishing: See section Interferometry Basics. Undercut, Fiber height: See section Interferometry Basics.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

11

The mains power for the computer should be 240 Volts, 50Hz for Europe or 110 Volts, 60 Hz for certain countries (for instance: US, Japan…). Please check the standards which apply in your country before plugging your computer to the mains power supply. ? The PC and the hardware are simply connected via a high-speed USB2.0 connection. Make sure the PC USB port supports the USB2.0 standard, as a USB1.0 port would not work.

Image 1: View of part of the rear panel of the DAISI hardware.

A USB2.0 B-type plug is used to connect the hardware to the PC. A POWER connector is used to plug a 12V DC - 1.7 Amps power supply to the hardware. Use exclusively the power supply provided with the system.

Images 2 and 3: Front and rear view of the DAISI hardware.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

12

INTERFEROMETRY BASICS

Image 4: 3D Profile of the front face of a ferrule at x450 magnification measured by interferometry. The undercut of the fiber (circular shape) can be noticed on the ferrule surface.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

13

What Is Interferometry ?

Interferometry is a measurement technique that uses the light wave-properties to calculate the topography of a surface, for example a fibre optic’s surface.

Principle

The above sketch shows how a Michelson interferometer works. The camera of the interferometer is simultaneously focused on the end-face of the ferrule and on the reference mirror, resulting in the superimposition of two images on the CCD sensor, thanks to the beamsplitter : ? ? The image of the reference mirror (assimilated to a perfect plane), The image of the face of the ferrule, which is very close to the reference mirror.

From the perfect superimposition of these two images results the phenomenon of ? Interference ?, based on the light wave-property. Interference fringes then appear on the final image. These fringes are similar to contour lines, as the ones we can find on a

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

14

geographic map. The front face of the ferrule being generally spherically polished, we can understand now why these curves are circular.

The observation of these fringes by an experienced eye gives some indications on the geometrical parameters of the ferrule : ? ? The more numerous the fringes are, the smaller the polishing radius of the face is. The position of the centre of these fringes indicates the point of the front face of the ferrule that is the closest to the reference surface. If the axis of the ferrule is perpendicular to the plane of the reference surface, this point is called the “Apex”, i.e. the top of the polishing dome. The distance between this point and the optical axis of the ferrule is the “Apex offset”. A shift of the fringes at the interface ferrule/fibre shows that the surface of the fibre is not at the same height than the surface of the ferrule. If the height of the fibre is lower than the height of the ferrule, it is called an “Undercut”. In the opposite case, it is called a ? Protrusion ?.

?

Image 5 : Interference Fringes on the front face of a ferrule and qualitative analysis of the geometrical parameters.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

15

Apex and Apex Offset

In this part, we are going to show that the Apex Offset (given in μm) is directly linked to the polishing angle. In fact, it is easier to talk about the Apex Offset than about the polishing angle because the Apex Offset is independent of the angular reference frame that has been chosen. Trying to analyze the meaning of an Apex measurement must be done very cautiously and more particularly for an Apex Offset. Actually, when we observe the interference fringes on the front face of a ferrule (cf. image 5), the centre of these fringes is not always corresponding to the actual Apex position (i.e. the top of the polishing dome). If the axis of the ferrule is perfectly perpendicular to the reference surface plane, then, and in this case only, the centre of the fringes corresponds to the Apex position. Sketch 6 explains the reason why. We understand now why the Apex Offset is related to the polishing angle (or angle of positioning of the ferrule). The relationship between both is: (Apex Offset) = (Polishing Radius) x tan (Polishing Angle) This formula shows that for a polished ferrule with a radius of 10mm, a change in the polishing angle (or in the positioning of the ferrule in the interferometer) of ±0,3° leads to an Apex Offset value of approximately 50μm.

Fringes

8°

APC Ferrule 8°orientated Apparent Apex Offset = 0μ m Real Apex Offset = 0μm Sketch6

OA

PC Ferrule 0,3° orientated Apparent Apex Offset OA = 50μm Real Apex Offset = 0μm

PC Ferrule 0° orientated Apparent Apex Offset= 0μm Real Apex Offset = 0μm

: Relationships between Apparent Apex Offset, Ferrule orientation and Polishing Angle

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

16

Phase Shifting Technique

A simple observation of the fringes at a given moment (fixed) is not sufficient to reconstruct without any ambiguities the topography of the surface of a ferrule. For example, it is impossible, a priori, to know if a local distortion of the interference fringes characterizes a dig or a bump on the surface of the ferrule. In order to clear these ambiguities, the ? Phase Shifting ? technique is used. The principle is the following: the reference plane is slightly moved along the optical axis (over a fraction of a micron) in a known direction, and the result on the fringes is analysed. From this, the calculation of the ? Phase image ? can be done (cf. image 8), and then, based on this one, a demodulated image (cf. image 9) can be deduced, whose intensity profile corresponds to the topography of the surface (cf. image 10). Once the topography of the surface has been evaluated, the computer automatically calculates the geometrical parameters of the face of the ferrule : ? ? ? The polishing radius (? Radius ?), The Apex offset (“Apex-Offset”), The height of the fibre (? Fiber Height ?)

Image 7 : Contour fringes of ferrule end-face

Image 8 : Phase image

Image 9 : Demodulated image

Image 10 : 3D profile of ferrule end-face

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

17

Automatic Calculation Methods of the Geometrical Parameters

The front face of the ferrule is divided into two separate zones, determined by three circles centred on the optical axis (cf. sketch 11) : ? ? ? The ? Fitting ? zone : It is bounded by the two circles D and E. The “Extraction” zone : It is located within the E circle. This zone permits to avoid taking into account the height of the fibre for the calculation of the polishing radius. The ?Averaging ? zone : It is located within the F circle.

Fiber

D

E

F

Sketch 11 : Zones used for the calculation of the geometrical parameters of the front face of the ferrule.

The diameters of the three circles can be defined by the user. By default, the diameters of these circles are : ? ? ? D = 250μm E = 140μm F = 50μm

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

18

Calculation of the Radius of Polishing (Radius) The points of the ferrule surface located in the Fitting zone are used to calculate a perfect theoretical sphere that corresponds to the Radius of polishing of the ferrule’s face. The radius of this sphere is assigned to the value of ? Radius ?. Calculation of the Apex Offset (Apex-Offset) The distance between the centre of the theoretical sphere (centre of the fringes) and the centre of the circles defining the zones D, E, F is assigned to the value of the Apex Offset. For an accurate calculation, it is essential that the optical axis is aligned with the centre of the circles D, E, F.

As a result, the fibre must be centred in the E circle before each measurement. Calculation of the Height of the Fibre (Height or Undercut) The height of the fibre is used to characterize an Undercut or a Protrusion of the fibre’s surface from the ferrules’ surface. The polishing method and the epoxy glue used to assemble together the fibre and the ferrule are two factors that typically can have an influence upon the value of the height of the fibre. Conventionally, DAISI considers that a negative height is an undercut, and a positive height is a protrusion. Here are the steps to follow to calculate the value of the height of a fibre: ? ? ? Subtraction of the theoretical sphere to the topography of the surface in order to obtain a plane surface, Calculation of the average heights of the fiber’ surface in the Fitting and Averaging zones, The height difference between these two zones is assigned to the value of the height of the fiber.

The four images of the next page display the 2D and 3D profiles before and after subtracting the theoretical sphere to the surface topography. Image 12 shows a 2D horizontal profile of the topography (green line). The dotted blue line describes a 2D horizontal profile of the theoretical sphere. We can notice that this last one perfectly fits to the measured profile (in green) except at the center. This is normal because the central part is located within the Extraction zone, which is not taken into account for the calculation of the theoretical sphere. Another remark is that as the measured profile (in green) is underneath the theoretical profile (in blue), the fiber shows an undercut. On image 13, we can observe that the fiber’s surface after subtraction of the theoretical sphere to the topography is shaped like a basin. This means that the polishing radius of the fiber is smaller than the polishing radius of the ferrule. If its shape had been like an inversed basin, it would have meant that the polishing radius of the fiber would have been greater than the one of the ferrule.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

19

Image 12 : 2D Horizontal profile of the topography

Image 13 : Subtraction of the theoretical sphere to the topography

Image 14 : 3D Representation of the topography

Image 15 : 3D Representation of the topography after subtraction of the theoretical sphere

2D and 3D Representations, Scales and Color Codes Image14 represents the topography of a ferrule’ surface. The colors used for the 3D representation are depending on the height of the surface. They are spread out from violet (the lowest point of the surface) to white (the highest point of the surface). The Z scale is extremely expanded in comparison with the X and Y scales, in order to clearly visualize the details of the topography. Note that the 2D and 3D representations take automatically the appropriate Z scale to cover the whole color dynamic range. As a result, the Z scale can vary from one measurement to another, even for the same ferrule. Two successive measurements of a same ferrule can display a curvature more or less sharp on the 2D and 3D representations although the measured value will remain the same. It is therefore important to check the quantitative result of the measurement of ? Radius ? to evaluate the polishing radius of the ferrule, and not interpret what you see on the 3D display.

DATA-PIXEL SAS 11 Route de la Salle 74960 Cran-Gevrier - France Tel : +33 (0) 4 50 67 39 80 Fax : +33 (0) 4 50 67 39 53 Email : info@https://www.360docs.net/doc/6516319998.html, Web: https://www.360docs.net/doc/6516319998.html,

20