针状晶体生长机理

Journal of Crystal Growth 310(2008)110–115

Crystallization mechanisms of acicular crystals

Franc -ois Puel a ,Elodie Verdurand a ,Pascal Taulelle b ,Christine Bebon a ,Didier Colson a ,

Jean-Paul Klein a ,Ste

phane Veesler b,?a

LAGEP,UMR CNRS 5007,Universite

′Lyon 1,CPE Lyon,Ba ?t.308G,43Bd du 11novembre 1918,F-69622Villeurbanne Cedex,France b

Centre de Recherche en Matie

`re Condense ′e et Nanosciences (CRMCN)1—CNRS,Campus de Luminy,Case 913,F-13288Marseille Cedex 09,France Received 10September 2007;accepted 3October 2007

Communicated by K.Sato Available online 9October 2007

Abstract

In this contribution,we present an experimental investigation of the growth of four different organic molecules produced at industrial scale with a view to understand the crystallization mechanism of acicular or needle-like crystals.For all organic crystals studied in this article,layer-by-layer growth of the lateral faces is very slow and clear,as soon as the supersaturation is high enough,there is competition between growth and surface-activated secondary nucleation.This gives rise to pseudo-twinned crystals composed of several needle individuals aligned along a crystallographic axis;this is explained by regular over-and inter-growths as in the case of twinning.And when supersaturation is even higher,nucleation is fast and random.

In an industrial continuous crystallization,the rapid growth of needle-like crystals is to be avoided as it leads to fragile crystals or needles,which can be partly broken or totally detached from the parent crystals especially along structural anisotropic axis corresponding to weaker chemical bonds,thus leading to slower growing faces.When an activated mechanism is involved such as a secondary surface nucleation,it is no longer possible to obtain a steady state.Therefore,the crystal number,size and habit vary signi?cantly with time,leading to troubles in the downstream processing operations and to modi?cations of the ?nal solid-speci?c properties.

These results provide valuable information on the unique crystallization mechanisms of acicular crystals,and show that it is important to know these threshold and critical values when running a crystallizer in order to obtain easy-to-handle crystals.r 2007Elsevier B.V.All rights reserved.

PACS:81.10.Aj;81.10.Dn;78.30.Jw

Keywords:A1.Crystal morphology;A2.Growth from solutions;https://www.360docs.net/doc/6e12624912.html,anic compounds

1.Introduction

Many organic molecules exhibit anisotropic structural properties in their crystalline form,which gives rise to acicular or needle-like crystals.In the chemical and pharmaceutical industry,crystallization from solution is used as a separation technique,and this crystal habit is usually not desirable,especially when the internal length-to-width ratio is high,as it will lead to problems in

downstream processes (?ltration,drying,storage,handling,etc.).

A better understanding of the mechanisms of nucleation and growth of these needle-like crystals will therefore lead to better control of crystallization processes.In the literature,papers on molecular modeling of these needle-like crystals [1–3]suggest that in the case of needle-like crystals,there is no slow-growing face in the needle direction.Practical aspects have been also studied for a few years now in our different research teams [4–6].

In this contribution,we present an experimental investigation of the growth of four different organic molecules produced at industrial scale with a view to understand the crystallization mechanism of acicular

https://www.360docs.net/doc/6e12624912.html,/locate/jcrysgro

0022-0248/$-see front matter r 2007Elsevier B.V.All rights reserved.doi:10.1016/j.jcrysgro.2007.10.006

?Corresponding author.Tel.:+33662922866;fax:+33491418916.

E-mail address:veesler@crmcn.univ-mrs.fr (S.Veesler).

1

Laboratory associated to the Universities Aix-Marseille II and III.

crystals from the molecular to the macroscopic scales.For all organic crystals studied in this article,layer-by-layer growth of the lateral faces is very slow and clearly,as soon as supersaturation is high enough,there is competition between growth and activated secondary nucleation.These investigations show that crystals are agglomerated with the same crystallographic orientation for the individual con-stituents,as observed by optical microscopy,scanning electron microscope(SEM)and atomic force microscopy (AFM);this is explained by regular over-and inter-growths as in the case of twinning.And when supersaturation is even higher,nucleation is fast and random.These results provide valuable information on the unique crystallization mechanisms of acicular crystals,and show that it is important to know these threshold and critical values when running a crystallizer in order to obtain easy-to-handle crystals.

2.Materials and methods

2.1.Materials

The four organic molecules studied were:

(i)Irbesartan(C25H28N6O),an active pharmaceutical

ingredient crystallized in2-propanol and used by Sano?-Aventis in the treatment of hypertension; (ii)Product2(for the sake of con?dentiality),an organic molecule exhibiting an alkyl cycle with one polar chemical group:this molecule crystallizes in its industrial solvent;

(iii)Hydroquinone(C6H6O2),which crystallizes in water in the presence of an additive used at industrial scale to speci?cally reduce growth along the length axis of the needle;

(iv)Product4(for the sake of con?dentiality)known to exhibit only needle-like habit whatever the solvent used.

Structural data for the?rst three molecules are presented in Table1.2.2.Solid Characterization

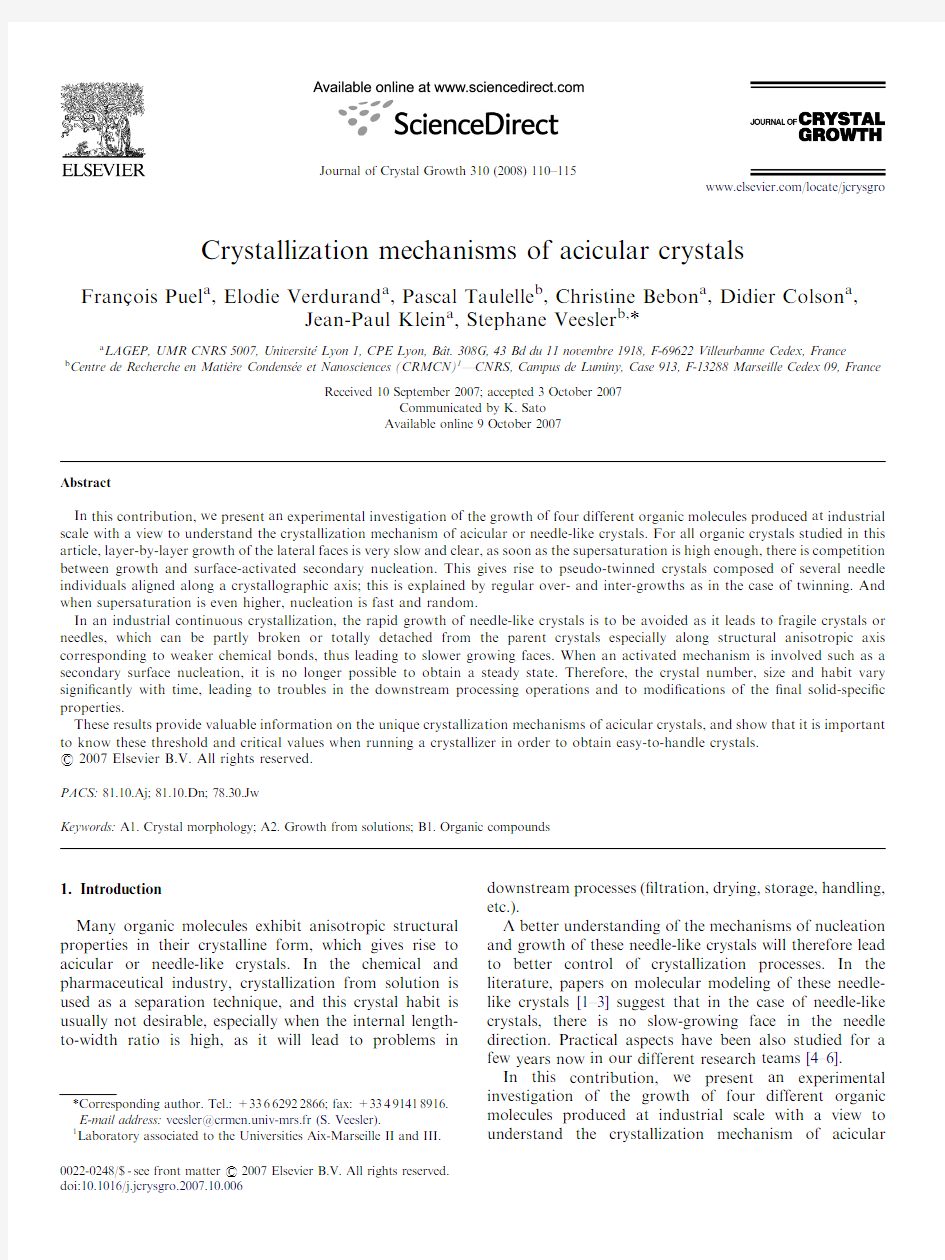

Crystals were observed under a(SEM;JEOL6320F). SEM photographs clearly show the needle-like crystal habit for the four systems studied(Fig.1).Crystals of Irbesartan phase A were also observed by AFM using a Digital Nanoscope III atomic force microscope equipped with a12m m scanner.Images were collected in tapping mode using oxide-sharpened Si3N4cantilever tips(nano-probe TM).

2.3.Crystal preparation

Irbesartan and Product4crystals were grown in quiescent solutions(2mL)at known concentrations, under optical microscope(Nikon,Diaphot),at given temperatures,using the experimental setup previously described[7].

Product2and hydroquinone crystals were obtained from isothermal crystallization in2.5L stirred vessels in semi-batch and continuous operations,respectively.Experimental pro-cedures can be found in the following references[5,6,8]. The supersaturation is de?ned as b=C/C e,with C and C e are the concentration and solubility of the organic molecule.

3.Results and discussion

As shown in Fig.1,all the crystals present a needle-like habit,which is due to a strong structural anisotropy along the z-axis for Irbesartan and hydroquinone,and x-axis for Product2(see Table1).This was con?rmed by molecular modeling for Irbesartan[4]and Product2[9].Product4 structure has not yet been determined.

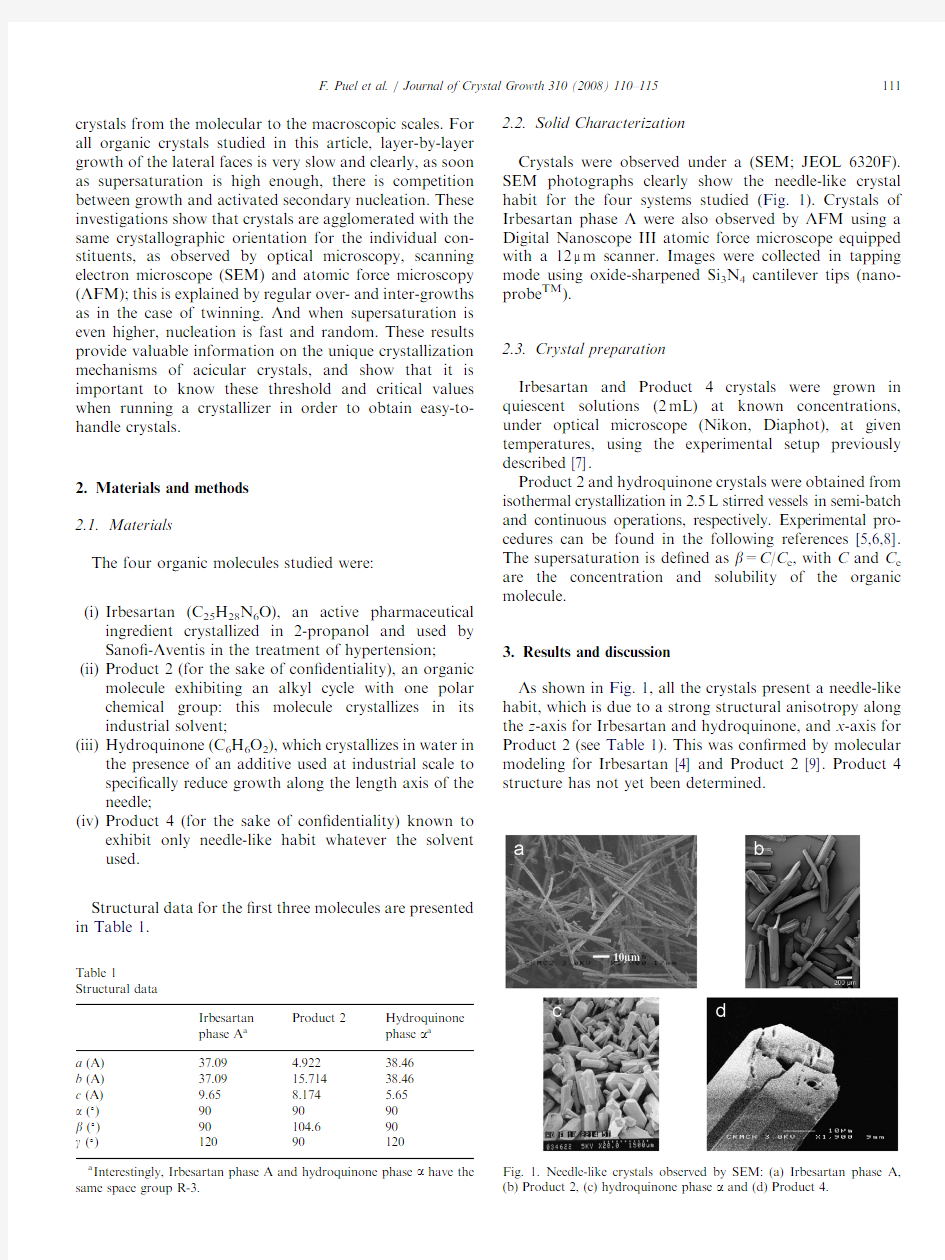

Table1 Structural data

Irbesartan phase A a Product2Hydroquinone

phase a a

a(A)37.09 4.92238.46

b(A)37.0915.71438.46

c(A)9.658.174 5.65

a(1)909090

b(1)90104.690

g(1)12090120

a Interestingly,Irbesartan phase A and hydroquinone phase a have the same space group

R-3.

Fig.1.Needle-like crystals observed by SEM:(a)Irbesartan phase A,

(b)Product2,(c)hydroquinone phase a and(d)Product4.

F.Puel et al./Journal of Crystal Growth310(2008)110–115111

3.1.Crystallization of Irbesartan in stagnant conditions The experiments show that in all the temperature and supersaturation ranges,2–201C and 3–10,respectively,crystals obtained (Fig.2a,c and d )have a needle-like habit,composed by crystalline agglomerates.2Moreover,when supersaturation is too low,top faces do not grow.Supersaturation must exceed a threshold value in order for growth of the crystal in the needle direction (crystal-lographic z -axis)to be observed.The width of this dead zone is a function of the temperature and increases when the temperature decreases.The growth rate of the needle increases with increasing supersaturation up to a critical supersaturation (a second threshold)from which activated secondary nucleation appears,leading to a random nucleation of needles (Fig.2b ).

In the growth zone,below the critical supersaturation (second threshold),AFM observations clearly indicate that the agglomerate is composed of few needle-like crystals of different sizes but with the same crystallographic orienta-tion along the z -crystallographic axis (Fig.2c and d ).

3.2.Crystallization of Product 2and hydroquinone in isothermal stirred tank

Crystallizations in stirred crystallizers were studied for the two other systems,Product 2and hydroquinone.

3.2.1.Product 2

In the case of Product 2,crystallizations were realized in semi-batch operations,supersaturation was increased by feeding the crystallizer with a hot,undersaturated and clear solution.Moreover,the crystallizer was initially seeded with well-de?ned crystals in order to study activated secondary nucleation and crystal growth.Supersaturation was measured during the experiment by HPLC measure-ment and resulted in the pro?le given in Fig.3.When feeding starts (at time 0),supersaturation begins to rise.Until supersaturation reaches 1.98,only growth of seed crystals is observed,mainly for the lateral faces.Impurities from the industrial solvent slow down the growth of the terminal faces (Fig.4a ).It is noteworthy that as in the case of Irbesartan (Fig.2),we do not observe growth of a single crystal but a polycrystalline growth.Then,supersaturation in the crystallizer reaches a maximum of 1.98,a threshold value (see supersaturation pro?le in Fig.3).At this value,activated surface secondary nucleation starts creating ?ne needle crystals (secondary nuclei)with a longer length-to-width ratio than seed crystals (Fig.4b ).Crystals are composed of a few needle-like crystals of different sizes but with the same crystallographic orientation along the x -crystallographic axis (Fig.4c ).

Moreover,in unseeded semi-batch experiments,when greater supersaturations are reached up to 2.8,crystals showing random agglomeration are observed due to fast primary nucleation (Fig.4d )as in the case of Irbesartan phase A (Fig.2b ).

3.2.2.Hydroquinone

Preliminary batch-seeded crystallization was performed.For continuous isothermal crystallization,?rst a hot undersaturated solution was fed in,then crystals were

Fig.2.Crystals of Irbesartan phase A:(a,b)optical-microscopy images,(c)AFM image and (d)SEM image.

2

Usually the term agglomeration is used for a two-step process:encounter and association between particles suspended in solution,while in this article,the term agglomerate is used to qualify polycrystallinity with no assumption on the mechanism of formation.

F.Puel et al./Journal of Crystal Growth 310(2008)110–115

112

nucleated and developed after which the suspension was withdrawn automatically to maintain the level of the reactor and immediately ?ltered.The solute concentration was measured regularly by a potentiometry analysis.Thus,the supersaturation was calculated from the knowledge of the solubility.After washing the crystals in acetone and vacuum drying,the crystals were weighed and measured [10](image analysis)and observed under SEM.

Fig.5illustrates the supersaturation pro?le during one typical run.For 20residence times,supersaturation did not reach a constant level,as normally expected.It showed two local maxima for the sixth and the seventeenth residence times.By coupling the mass balance and the crystal size distribution measurements,it was possible to evaluate the total number of crystals.This number decreased with an

increase in supersaturation,and suddenly rose after a supersaturation maximum.These signi?cant bursts of nuclei were visible to the naked eye.Before and after each supersaturation maximum,the mean dimensions of the crystals,respectively,showed a signi?cant rise and fall.The evolution of the length-to-width ratio around the ?rst supersaturation maximum was monitored [8].Crystals nucleated and grown before this maximum were quite thick and exhibited a rod-like habit.Conversely,most of the crystals which were nucleated and grown after this maximum had a 40%higher length-to-width ratio leading to a needle-like habit (see Fig.11in Ref.[8]).Moreover,it was very instructive to observe how the appearance of the crystal surface evolved.During the ?rst hours of the continuous operation,crystal surfaces were very smooth (see Fig.6a ).With the increase in supersaturation,crystals appeared to be more and more twinned.After the ?rst maximum,the surfaces were rougher.On SEM

1.0

1.2

1.41.61.8

2.00

50

100150200

250

Time (min)

β

Fig. 3.Supersaturation pro?le of seeded semi-batch crystallization of Product

2.

Fig.4.SEM pictures of Product 2crystals withdrawn (a)before threshold value at the beginning of the experiment,(b,c)after threshold value—respectively ?ne and seed crystals and (d)at higher supersaturation.

1,050

1,100

5

10152025

Residence time (-)

S u p e r s a t u r a t i o n r a t i o β (-)

Fig.5.Supersaturation pro?le in suspension of continuous

crystallization of hydroquinone.

Fig.6.SEM pictures of hydroquinone withdrawn at different residence times during a continuous isothermal crystallization—(a)reduced time ?5:before ?rst burst of nuclei,(b)reduced time ?7:after ?rst burst of nuclei,(c)reduced time ?13:before second burst of nuclei and (d)reduced time ?19:after second burst of nuclei.

F.Puel et al./Journal of Crystal Growth 310(2008)110–115

113

observations,the crystals were composed of numerous needle-like crystals with the same crystallographic orienta-tion along the z -crystallographic axis (see Fig.6b ).Never-theless,progressively with time,the surface appeared smoother (see Fig.6c ).A second increase in supersatura-tion followed by a second burst of nuclei was observed.Contrarily to the usual continuous operation,an unsteady state lasted throughout the run (20h)although a steady state was expected after only https://www.360docs.net/doc/6e12624912.html,stly,whatever the operating conditions tested in terms of stirring rate and solid concentration,an irregular unsteady state was always observed,including one or two local maxima of super-saturation corresponding to thresholds where surface-activated secondary nucleation events started.Modi?ca-tions in crystal surface appearance were systematically observed at different levels of supersaturation.3.3.Discussion

In the case of Irbesartan,growth of the lateral faces was not observed under these conditions,meaning that the threshold supersaturation (from which growth is observa-ble)of these faces is higher than the critical supersaturation for secondary nucleation.Thus,layer-by-layer growth of the lateral faces is more dif?cult than nucleation,meaning that surface-activated secondary nucleation is easier than growth.However,from AFM experiments (Fig.2c ),it can be assumed that the thickness of the acicular crystals is the result of agglomeration of several single needle-crystals.This agglomeration mechanism is not known but we can speak of regular over-and inter-growths,and as in the case of twinned crystals,two mechanisms need to be considered:

Synosis :one individual nucleates,grows and deposits itself by one of its natural face on a face of a second already existing individual,in a proper crystallographic orientation according to the laws of regularity [11].

Faulted two-dimensional (2D)nucleation on the original composition plane :the island is put on a twin orientation on the face of the original composition plane and grows to give the twin.Twins appear,once a threshold supersaturation has been exceeded [12,13].

The observation of reentrant angles in Fig.7con?rms the assumption of twinning;this effect is commonly

observed for contact twins and named as the reentrant corner effect.

The crystallization of Irbesartan and Product 4were observed for individual crystals,which are giving informa-tion on microscopic growth mechanisms.Experiments for Product 2and hydroquinone were performed in stirred vessels,providing macroscopic information for a popula-tion of crystals on the overall growth rate;similar experiments were carried-out on b -cyclodextrin [14].However,whether one looks at the results from the microscopic or macroscopic scale experiments,similar nucleation and growth mechanisms of acicular crystals are observed.The crystallization mechanisms of Product 2crystals are probably the same as for Irbesartan form A crystals described previously.However,the growth dead zone at lower supersaturation is not observed for Product 2,probably because the semi-batch crystallizations per-formed here do not provide enough information.In these experiments,at lower supersaturation,overall growth of crystals is regular and smooth but polycrystalline (see SEM pictures in Fig.4a ).At higher supersaturation,the growth mechanism is different and 2D nuclei can form onto crystal surfaces.Once formed,these nuclei detach and either (i)dissolve or grow inside the solution depending on their size,or (ii)grow on the surface of the parent crystal (synosis mechanism).Moreover,new nuclei can form on these still-growing surface needles giving an irregular appearance to seed crystals (faulted 2D nucleation).

The key parameter of these changes in behavior detected during the continuous crystallization of hydroquinone is the competition between growth and surface-activated secondary nucleation mechanisms.When the crystals came from a seeded batch operation,at low supersaturation levels,they exhibited a very smooth surface.The growth of the lateral surfaces was slow.The kinetics of attrition was poor and the total number of crystals decreased with time;consumption of solute by growth was thus less and less able to compensate for solute feeding.Supersaturation increased until a threshold was reached,leading to a burst of nuclei by a surface-activated secondary nucleation.On this emerging population,the lateral surfaces were striped along the needle direction and the secondary nucleation was more intense.This rough surface appearance was also observed on crystals produced during semi-batch experi-ments performed at higher level of supersaturation than continuous operations [10].The kinetic of the secondary nucleation is then linked to the crystals surface appearance.For all organic crystals studied in this article,layer-by-layer growth of the lateral faces is very slow and clearly,as soon as the supersaturation is high enough,there is competition between growth and surface-activated second-ary nucleation.Moreover,at high supersaturation levels,surface-activated secondary nucleation and 2D nucleation,or the ‘‘Birth and Spread’’growth mechanism,are closely linked.This gives rise to pseudo-twinned crystals composed of several needle individuals aligned along a crystal-lographic axis.

Fig.7.Optical-microscopy image of needle-like crystal of Product 4.

F.Puel et al./Journal of Crystal Growth 310(2008)110–115

114

4.Conclusion

In this contribution,we present results for four different organic molecules,produced at industrial scale,crystal-lizing in needle-like habits.As supersaturation increases, several growth and nucleation mechanisms can be ob-served.

Experiments on Irbesartan show that at?rst,top faces do not grow at lower supersaturations(dead zone).Then, after a threshold value has been reached,growth starts and above a critical value,surface-activated secondary nuclea-tion prevails.

The usual hypothesis,namely the crystallization mechan-isms and consequently their kinetics remain constant during a continuous process can no longer be assumed, especially if the surface appearance of the faces shows modi?cations.In the case of hydroquinone,an increase in the level of supersaturations led to a change in surface appearance:thus,a surface-activated secondary nucleation linked to the surface appearance develops.

For all organic crystals studied in this article,layer-by-layer growth of the lateral faces is very slow and clearly,as soon as the supersaturation is high enough,there is competition between growth and surface-activated second-ary nucleation.

This gives rise to pseudo-twinned crystals composed of several needle individuals aligned along a crystallographic axis as observed by optical microscopy,SEM and AFM; this is explained by regular over-and inter-growths as in the case of twinning.And when supersaturation is even higher,energy supplied to the system is high enough for nucleation to be fast and random.

In an industrial continuous crystallization,the rapid growth of needle-like crystals is to be avoided as it leads to fragile crystals or needles,which can be partly broken or totally detached from the parent crystals especially along structural anisotropic axis corresponding to weaker che-mical bonds,thus leading to slower growing faces.When an activated mechanism is involved such as a secondary surface nucleation,it is no longer possible to obtain a steady state.Therefore,the crystal number,size and habit vary signi?cantly with time,leading to troubles in the downstream processing operations and to modi?cations of the?nal solid-speci?c properties.

These results provide valuable information on the unique crystallization mechanisms of acicular crystals, and show that it is important to know these threshold and critical values when running a crystallizer in order to obtain easy-to-handle crystals.

Acknowledgments

The authors are indebted to Sano?-Aventis,Arkema and Rhodia chemical companies for their?nancial supports for funding projects and for providing the industrial chemical compounds for the studies.We thank Mrs.M.Sweetko for English revision.

References

[1]H.M.Cuppen,A.R.T.Van Eerd,H.Meekes,Crystal Growth Des.4

(2004)989.

[2]H.M.Cuppen,G.Beurskens,S.Kozuka,K.Tsukamoto,J.M.M.

Smits,R.De Gelder,R.F.P.Grimbergen,H.Meekes,Crystal Growth Des.,2005.

[3]D.Winn,M.F.Doherty,AIChE J.44(1998)2501.

[4]P.Taulelle,J.P.Astier,C.Hoff,G.Pe pe,S.Veesler,Chem.Eng.

Technol.29(2006)239.

[5]F.Puel,G.Fevotte,J.P.Klein,Chem.Eng.Sci.58(2003)3729.

[6]E.Verdurand,C.Bebon,D.Colson,J.-P.Klein,A.-F.Blandin,J.-M.

Bossoutrot,J.Crystal Growth275(2005)e1363.

[7]S.Veesler,https://www.360docs.net/doc/6e12624912.html,fferrere,E.Garcia,C.Hoff,Org.Proc.Res.Dev.7

(2003)983.

[8]F.Puel,P.Marchal,J.P.Klein,Trans.IChemE Part A75(1997)193.

[9]E.Verdurand,Etude expe rimentale et mode lization de la nucle ation

secondaire lors de la crystallization d’un produit organique, Universite Claude Bernard Lyon1,2004.

[10]F.Puel,Bilan de population pour deux tailles caracte ristiques de

particules:application a la crystallization de l’hydroquinone,UCB Lyon1,1994.

[11]G.Friedel,Lec-ons de cristallographie,Nancy,Paris,1926.

[12]D.Aquilano,G.Sgualdino,in:N.Garti,K.Sato(Eds.),Crystal-

lization Processes in Fats and Lipid Systems,Marcel Dekker,Inc., New York,2001,pp.1–51.

[13]R.Kern,Bull.Soc.Fr.Miner.Crist.LXXXIV(1961)292.

[14]M.Kohl,F.Puel,J.P.Klein,C.Hoff,O.Monnier,J.Crystal Growth

270(2004)633.

F.Puel et al./Journal of Crystal Growth310(2008)110–115115

晶体生长方法

晶体生长方法 一、提拉法 晶体提拉法的创始人是J. Czochralski,他的论文发表于1918年。提拉法是熔体生长中最常用的一种方法,许多重要的实用晶体就是用这种方法制备的。近年来,这种方法又得到了几项重大改进,如采用液封的方式(液封提拉法,LEC),能够顺利地生长某些易挥发的化合物(GaP等);采用导模的方式(导模提拉法)生长特定形状的晶体(如管状宝石和带状硅单晶等)。所谓提拉法,是指在合理的温场下,将装在籽晶杆上的籽晶下端,下到熔体的原料中,籽晶杆在旋转马达及提升机构的作用下,一边旋转一边缓慢地向上提拉,经过缩颈、扩肩、转肩、等径、收尾、拉脱等几个工艺阶段,生长出几何形状及内在质量都合格单晶的过程。这种方法的主要优点是:(a)在生长过程中,可以方便地观察晶体的生长情况;(b)晶体在熔体的自由表面处生长,而不与坩埚相接触,这样能显著减小晶体的应力并防止坩埚壁上的寄生成核;(c)可以方便地使用定向籽晶与“缩颈”工艺,得到完整的籽晶和所需取向的晶体。提拉法的最大优点在于能够以较快的速率生长较高质量的晶体。提拉法中通常采用高温难熔氧化物,如氧化锆、氧化铝等作保温材料,使炉体内呈弱氧化气氛,对坩埚有氧化作用,并容易对熔体造成污杂,在晶体中形成包裹物等缺陷;对于那些反应性较强或熔点极高的材料,难以找到合适的坩埚来盛装它们,就不得不改用其它生长方法。 二、热交换法

热交换法是由D. Viechnicki和F. Schmid于1974年发明的一种长晶方法。其原理是:定向凝固结晶法,晶体生长驱动力来自固液界面上的温度梯度。特点:(1) 热交换法晶体生长中,采用钼坩埚,石墨加热体,氩气为保护气体,熔体中的温度梯度和晶体中的温度梯度分别由发热体和热交换器(靠He作为热交换介质)来控制,因此可独立地控制固体和熔体中的温度梯度;(2) 固液界面浸没于熔体表面,整个晶体生长过程中,坩埚、晶体、热交换器都处于静止状态,处于稳定温度场中,而且熔体中的温度梯度与重力场方向相反,熔体既不产生自然对流也没有强迫对流;(3) HEM法最大优点是在晶体生长结束后,通过调节氦气流量与炉子加热功率,实现原位退火,避免了因冷却速度而产生的热应力;(4) HEM可用于生长具有特定形状要求的晶体。由于这种方法在生长晶体过程中需要不停的通以流动氦气进行热交换,所以氦气的消耗量相当大,如Φ30 mm的圆柱状坩埚就需要每分钟38升的氦气流量,而且晶体生长周期长,He气体价格昂贵,所以长晶成本很高。 三、坩埚下降法 坩埚下降法又称为布里奇曼-斯托克巴格法,是从熔体中生长晶体的一种方法。通常坩埚在结晶炉中下降,通过温度梯度较大的区域时,熔体在坩埚中,自下而上结晶为整块晶体。这个过程也可用结晶炉沿着坩埚上升方式完成。与提拉法比较该方法可采用全封闭或半封闭的坩埚,成分容易控制;由于该法生长的晶体留在坩埚中,因而适于生长大块晶体,也可以一炉同时生长几块晶体。另外由于工艺条件

晶体生长的机理

第五章 一、什么是成核相变、基本条件 成核相变:在亚稳相中形成小体积新相的相变过程。 条件:1、热力学条件:ΔG=G S-G L<0;ΔT>0。2、结构条件:能量起伏、结构起伏、浓度起伏、扩散→短程规则排列(大小不等,存在时间短,时聚时散,与固相有相似结构,之间有共享原子)→晶坯→晶胞。 相变驱动力:f=-Δg/ΩS;Δg每个原子由流体相转变成晶体相所引起的自由能降低;ΩS单个原子的体积。 气相生长体系:(T0 P0)→(T0 P1),Δg=-kT0σ,σ=α-1= P1/ P0;溶液生长体系:(C0 T0 P0)→(C1 T0 P0),Δg=-kT0σ,σ=α-1= C1/ C0;熔体生长体系:Δg=-l mΔT/T m,l m单个原子的相变潜热。 二、均匀成核、非均匀成核 不含结晶物质时的成核为一次成核,包括均匀成核(自发产生,不是靠外来的质点或基底诱发)和非均匀成核。 三、均匀成核的临界晶核半径与临界晶核型成功 临界晶核:成核过程中,能稳定存在并继续长大的最小尺寸晶核。 ΔG=ΔG V+ΔG S,球形核ΔG=-4πr3Δg/ΩS+4πr2γSL→r C=2γSLΩS/Δg,r

晶体的生长机理及条件对晶型的影响

1.晶体生长机理 理根据经典的晶体生长理论,液相反应体系中晶体生长包括以下步骤:①营养料在水溶液介质里溶解,以离子、分子团的形式进入溶液(溶 解阶段):②由于体系中存在十分有效的热对流以及溶解区和生长区 之间的浓度差,这些离子、分子或离子团被输运到生长区(输运阶段); ③离子、分子或离子团在生长界面上的吸附、分解与脱附;④吸附物质在界面上的运动;⑤结晶(③、④、⑤统称为结晶阶段)。液相条件下生长的晶体晶面发育完整,晶体的结晶形貌与生长条件密切相关,同种晶体在不同的生长条件下可能有不同的结晶形貌。简单套用经典晶体生长理论不能很好解释许多实验现象,因此在大量实验的基础 上产生了“生长基元”理论模型。。“生长基元"理论模型认为在上述输运阶段②,溶解进入溶液的离子、分子或离子团之间发生反应,形成具有一定几何构型的聚合体一生长基元,生长基元的大小和结构与溶液中的反应条件有关。在一个水溶液反应体系里,同时存在多种形式的生长基元,它们之间建立起动态平衡。某种生长基元越稳定(可从能量和几何构型两方面加以考察),其在体系里出现的几率就越大。在界面上叠合的生长基元必须满足晶面结晶取向的要求,而生长基元在界面上叠合的难易程度决定了该面族的生长速率。从结晶学观点看:生长基元中的正离子与满足一定配位要求的负离子相联结,因此又进一步被称为“负离子配位多面体生长基元"。生长基元模型将晶体的结晶形貌、晶体的结构和生长条件有机地统一起来,很好地解释了许多实验现象。

2晶体生长的影响条件 对于水热合成,晶粒的形成经历了“溶解一结晶"两个阶段。水热法制备常采用固体粉末或新配制的凝胶作为前驱物,所谓“溶解”是指在水热反应初期,前驱物微粒之间的团聚和联结遭到破坏,以使微粒自身在水热介质中溶解,以离子或离子团的形式进入溶液,进而成核、结晶而形成晶粒。在水热条件下,晶体自由生长,晶体各个面族的生长习性可以得到充分显露,由于水热条件下晶体生长是在非受迫的情况下进行,所以生长温度压力、溶液、溶液流向和温度梯度对晶体各个面族的生长速率影响很明显,表现在晶体的结晶形态变化。总的来说,在水热合成中影响材料形貌、大小、结构的因素主要有温度、原材料的种类、浓度、比例、pH值、反应时间、有机物添加剂等 (1)反应温度 反应温度提供合成材料的原动力,因此反应制备过程需要高于一定的温度,不同的材料,不同的体系差别很大。一般温度越高,产物的直径越大,而结晶性会更好,并且容易形成其稳定相。 (2)原料 原料的种类对产物的形貌、大小有很大的影响。在液相反应体系中,不同的原料直接决定了溶液中生成先驱体的浓度,先驱体发生化学反应生成产物达到一定的过饱和度时,结晶析出生长晶体。因此原料的不同得到先驱体的反应特性也不同,如水解速率、浓度等,从而影响产物的形态。 (3)其它条件

晶体生长机理与晶体形貌的控制

晶体生长机理与晶体形貌的控制 张凯1003011020 摘要:本文综述了晶体生长与晶体形貌的基本理论和研究进展,介绍了层生长理论,分析了研究晶体宏观形貌与内部结构关系的3种主要理论,即布拉维法则、周期键链理论和负离子配位多面体生长基元理论。 关键词:晶体生长机理晶体结构晶体形貌晶体 1.引言 固态物质分为晶体和非晶体。从宏观上看,晶体都有自己独特的、呈对称性的形状。晶体在不同的方向上有不同的物理性质,如机械强度、导热性、热膨胀、导电性等,称为各向异性。晶体形态的变化,受内部结构和外部生长环境的控制。晶体形态是其成份和内部结构的外在反映,一定成份和内部结构的晶体具有一定的形态特征,因而晶体外形在一定程度上反映了其内部结构特征。今天,晶体学与晶体生长学都发展到了非常高的理论水平,虽然也不断地有一些晶体形貌方面的研究成果,但都停留在观察、测量、描述、推测生长机理的水平上。然而,在高新技术与前沿理论突飞猛进的今天,晶体形貌学必然也会受到冲击与挑战,积极地迎接挑战,与前沿科学理论技术接轨,晶体形貌学就会有新的突破,并且与历史上 一样也会对其它科学的发展做出贡献。 2.层生长理论 科塞尔(Kossel,1927)首先提出,后经斯特兰斯基(Stranski)加以发展的晶体的层生长理论亦称为科塞尔—斯特兰斯基理论。 它是论述在晶核的光滑表面上生长一层原子面时,质点在界面上进入晶格"座位"的最佳位置是具有三面凹入角的位置。质点在此位置上与晶核结合成键放出的能量最大。因为每一个来自环境相的新质点在环境相与新相界面的晶格上就位时,最可能结合的位置是能量上最有利的位置,即结合成键时应该是成键数目最多,释放出能量最大的位置。质点在生长中的晶体表面上所可能有的各种生长位置:k为曲折面,具有三面凹人角,是最有利的生长位置;其次是S阶梯面,具有二面凹入角的位置;最不利的生长位置是A。由此可以得出如下的结论即晶体在理想情况下生长时,先长一条行列,然后长相邻的行列。在长满一层面网后,再开始长第二层面网。晶面(最外的面网)是平行向外推移而生长的。这就是晶体的层生长理论,用它可以解释如下的一些生长现象。 1)晶体常生长成为面平、棱直的多面体形态。 2)在晶体生长的过程中,环境可能有所变化,不同时刻生成的晶体在物性(如颜色)和成分等方面可能有细微的变化,因而在晶体的断面上常常可以看到带状

晶体生长机理研究综述

晶体生长机理研究综述 摘要 晶体生长机理是研究金属材料的基础,它本质上就是理解晶体内部结构、缺陷、生长条件和晶体形态之间的关系。通过改变生长条件来控制晶体内部缺陷的形成从而改善和提高晶体的质量和性能使材料的强度大大增强开发材料的使用潜能。本文主要介绍了晶体生长的基本过程和生长机理,晶体生长理论研究的技术和手段,控制晶体生长的途径以及控制晶体生长的途径。 关键词:晶体结构晶界晶须扩散成核 一、晶体生长基本过程 从宏观角度看,晶体生长过程是晶体-环境相、蒸气、溶液、熔体、界面向环境相中不断推移的过程,也就是由包含组成晶体单元的母相从低秩序相向高度有序晶相的转变从微观角度来看,晶体生长过程可以看作一个基元过程,所谓基元是指结晶过程中最基本的结构单元,从广义上说,基元可以是原子、分子,也可以是具有一定几何构型的原子分子聚集体所谓的基元过程包括以下主要步骤:(1)基元的形成:在一定的生长条件下,环境相中物质相互作用,动态地形成不同结构形式的基元,这些基元不停地运动并相互转化,随时产生或消失(2)基元在生长界面的吸附:由于对流~热力学无规则的运动或原子间的吸引力,基元运动到界面上并被吸附 (3)基元在界面的运动:基元由于热力学的驱动,在界面上迁移运动 (4)基元在界面上结晶或脱附:在界面上依附的基元,经过一定的运动,可能在界面某一适当的位置结晶并长入固相,或者脱附而重新回到环境相中。 晶体内部结构、环境相状态及生长条件都将直接影响晶体生长的基元过程。环境相及生长条件的影响集中体现于基元的形成过程之中;而不同结构的生长基元在不同晶面族上的吸附、运动、结晶或脱附过程主要与晶体内部结构相关联。不同结构的晶体具有不同的生长形态。对于同一晶体,不同的生长条件可能产生不同结构的生长基元,最终形成不同形态的晶体。同种晶体可能有多种结构的物相,即同质异相体,这也是由于生长条件不同基元过程不同而导致的结果,生长机理如下: 1.1扩散控制机理从溶液相中生长出晶体,首要的问题是溶质必须从过饱和溶液中运送到晶体表面,并按照晶体结构重排。若这种运送受速率控制,则扩散和对流将会起重要作用。当晶体粒度不大于1Oum时,在正常重力场或搅拌速率很低的情况下,晶体的生长机理为扩散控制机理。 1.2 成核控制机理在晶体生长过程中,成核控制远不如扩散控制那么常见但对于很小的晶体,可能不存在位错或其它缺陷。生长是由分子或离子一层一层

晶体生长方法(新)

晶体生长方法 1) 提拉法(Czochralski,Cz ) 晶体提拉法的创始人是J. Czochralski ,他的 论文发表于1918年。提拉法是熔体生长中最常 用的一种方法,许多重要的实用晶体就是用这 种方法制备的。近年来,这种方法又得到了几 项重大改进,如采用液封的方式(液封提拉法, LEC ),如图1,能够顺利地生长某些易挥发的化 合物(GaP 等);采用导模的方式(导模提拉法) 生长特定形状的晶体(如管状宝石和带状硅单 晶等)。 所谓提拉法,是指在合理的温场下,将装 在籽晶杆上的籽晶下端,下到熔体的原料中, 籽晶杆在旋转马达及提升机构的作用下,一边 旋转一边缓慢地向上提拉,经过缩颈、扩肩、 转肩、等径、收尾、拉脱等几个工艺阶段,生长出几何形状及内在质量都合格单晶的过程。这种方法的主要优点是:(a) 在生长过程中,可以方便地观察晶体的生长情况;(b) 晶体在熔体的自由表面处生长,而不与坩埚相接触,这样能显著减小晶体的应力并防止坩埚壁上的寄生成核;(c) 可以方便地使用定向籽晶与“缩颈”工艺,得到完整的籽晶和所需取向的晶体。提拉法的最大优点在于能够以较快的速率生长较高质量的晶体。 提拉法中通常采用高温难熔氧化物,如氧化锆、氧化铝等作保温材料,使炉体内呈弱氧化气氛,对坩埚有氧化作用,并容易对熔体造成污杂,在晶体中形成包裹物等缺陷;对于那些反应性较强或熔点极高的材料,难以找到合适的坩埚来盛装它们,就不得不改用其它生长方法。 图1 提拉法晶体生长装置结构示意图

2)热交换法(Heat Exchange Method, HEM) 热交换法是由D. Viechnicki和 F. Schmid于1974年发明的一种长晶方法。 其原理是:定向凝固结晶法,晶体生长 驱动力来自固液界面上的温度梯度。特 点:(1) 热交换法晶体生长中,采用钼 坩埚,石墨加热体,氩气为保护气体, 熔体中的温度梯度和晶体中的温度梯 度分别由发热体和热交换器(靠He作 为热交换介质)来控制,因此可独立地 控制固体和熔体中的温度梯度;(2) 固 液界面浸没于熔体表面,整个晶体生长 过程中,坩埚、晶体、热交换器都处于 静止状态,处于稳定温度场中,而且熔 体中的温度梯度与重力场方向相反,熔 体既不产生自然对流也没有强迫对流; (3) HEM法最大优点是在晶体生长结束 后,通过调节氦气流量与炉子加热功率, 实现原位退火,避免了因冷却速度而产 生的热应力;(4) HEM可用于生长具有 图2HEM晶体生长装置结构示意图 特定形状要求的晶体。 由于这种方法在生长晶体过程中需要不停的通以流动氦气进行热交换,所以氦气的消耗量相当大,如Φ30mm的圆柱状坩埚就需要每分钟38升的氦气流量,而且晶体生长周期长,He气体价格昂贵,所以长晶成本很高。

晶体生长复习资料

第二章几种典型的晶体生长方法 1.什么是晶体生长的技术要求及选择晶体生长的基本原则? 物质在一定温度、压力、浓度、介质、pH等条件下由气相、液相、固相转化,形成特定线度尺寸、满足一定技术要求的晶体的过程称为晶体生长。 晶体生长的技术要求: 合理的驱动力场分布; 驱动力场的稳定、可控; 各生长技术参数的良好匹配; 精确配料和必要、合理的热处理; 力求避免各种形式的污染; 选择何种生长技术,取决于晶体的物理、化学性质和应用要求。一般原则为: ?满足相图的基本要求; ?有利于快速生长出具有较高实用价值、符合一定技术要求的晶体; ?有利于提高晶体的完整性,严格控制晶体中的杂质和缺陷; ?有利于提高晶体的利用率、降低成本。生长大尺寸的晶体始终是晶体生长工作者追求的重要目标; ?有利于晶体的后加工和器件化; ?有利于晶体生长的重复性和产业化。 2.熟悉各种晶体生长方法的工艺、特点、局限性。 熔体法生长:提拉法坩埚下降法焰熔法区熔法冷坩埚熔壳法 溶液法生长:低温(水)溶液法高温溶液法水热与溶剂热法 气相法生长:物理气相沉积(PVD)化学气相沉积(CVD) 溶液法的基本原理是将原料(溶质)溶解在溶剂中,采取适当的措施造成溶液的过饱和状态,使晶体在其中生长。包括有水溶液法、水热法与助熔剂法等。水溶液法一般是在常压和较低温度(100℃以下)下进行。 降温法基本原理:利用物质大的溶解度和较大的正溶解度温度系数,在晶体生长过程中逐渐降低温度,使析出的溶质不断在晶体上生长。 关键:晶体生长过程中掌握适合的降温速度,使溶液始终处在亚稳态区内并维持适宜的过饱和度。 要求:物质溶解度温度系数不低于1.5g/kg℃;生长温度一般在50~60℃,降温区间15~25℃为宜。蒸发法基本原理:将溶剂不断蒸发,通过控制蒸发量来控制溶液过饱和度,使溶液始终保持在一定过饱和状态,从而使晶体不断生长。 特点:比较适合于溶解度较大而溶解度温度系数很小或者是具有负温度系数的物质。与流动法一样也是在恒温条件下进行的,适用于高温(>60℃)晶体生长。 高温溶液法 将晶体的原成分在常压高温下溶解于低熔点助熔剂溶液内,形成均匀的饱和溶液;然后通过缓慢降温或其他方法,形成过饱和溶液而使晶体析出。 助熔剂法的特点及不足: 设备简单,适应性强,特别适用于新材料的探索和研究; 生长温度低,特别适宜生长难熔化合物、在熔点处极易挥发、变价或相变的材料,以及非同成分熔融化合物; 只要采取适当的措施,可生长比熔体法生长的晶体热应力更小、更均匀和完整; 生长速度慢,生长周期较长,晶体尺寸较小; 助熔剂往往带有腐蚀性或毒性; 由于采用的助熔剂往往是多种组分的,各组分间的相互干扰和污染是很难避免的。遇到的主要问题是: 如何有效地控制成核数目和成核位置; 如何提高溶质的扩散速度和晶体的生长速度; 如何提高溶质的溶解度和加大晶体的生长尺寸; 如何控制晶体的成分和掺质的均匀性。 水热法 基本原理:使用特殊设计的装置,人为地创造一个高温高压环境,由于高温高压下水的解离常数增大、黏度大大降低、水分子和离子的活动性增加,可使那些在通常条件下不溶或难溶于水的物质溶解度、水解程度极大提高,从而快速反应合成新的产物。 可分为温差法、等温法和降温法等。 特点: 适于生长熔点很高,具有包晶反应或非同成分熔化而在常温常压下又不溶于各种溶剂或溶解后即分解,且不能再结晶的晶体材料。 反应温度相对较低,可以制备其他方法难以制备的物质低温同质异构体。 可以制备其他方法难以制备的具有多型性的相变材料。 生长区基本处于恒温和等浓度状态,温度梯度小,晶体热应力小。

晶体生长理论

晶体生长理论 晶体生长理论是用以阐明晶体生长这一物理-化学过程。形成晶体的母相可以是气相、液相或固相;母相可以是单一组元的纯材料,也可以是包含其他组元的溶液或化合物。生长过程可以在自然界中实现,如冰雪的结晶和矿石的形成;也可以在人工控制的条件下实现,如各种技术单晶体的培育和化学工业中的结晶。 基础 晶体生长的热力学理论[1]J.W.吉布斯于1878年发表的著名论文《论复相物质的平衡》奠定了热力学理论的基础。他分析了在流体中形成新相的条件,指出自然体自由能的减少有利新相的形成,但表面能却阻碍了它。只有通过热涨落来克服形成临界尺寸晶核所需的势垒,才能实现晶体的成核。到20世纪20年代M.福耳默等人发展了经典的成核理论,并指出了器壁或杂质颗粒对核的促进作用(非均匀成核)。一旦晶核已经形成(或预先制备了一块籽晶),接下去的就是晶体继续长大这一问题。吉布斯考虑到晶体的表面能系数是各向异性的,在平衡态自由能极小的条件就归结为表面能的极小,于是从表面能的极图即可导出晶体的平衡形态。晶体平衡形态理论曾被P.居里等人用来解释生长着的晶体所呈现的多面体外形。但是晶体生长是在偏离平衡条件下进行的,表面能对于晶体外形的控制作用限于微米尺寸以下的晶体。一旦晶体尺寸较大时,表面能直接控制外形的能力就丧失了,起决定性作用的是各晶面生长速率的各向异性。这样,晶面生长动力学的问题就被突出了。 动力学理论 晶体生长的动力学理论晶面生长的动力学指的是偏离平衡的驱动力(过冷或过饱和)与晶面生长的速率的关系,它是和晶体表面的微观形貌息息相关的。从20世纪20年代就开始了这方面的研究。晶面的光滑(原子尺度而言)与否对生长动力学起了关键性的作用。在粗糙的晶面上,几乎处处可以填充原子成为生长场所,从而导出了快速的线性生长律。至于偏离低指数面的邻位面,W.科塞耳与 F.斯特兰斯基提出了晶面台阶-扭折模型,晶面上台阶的扭折处为生长的场所。由此可以导出相应的生长律。至于光滑的密集平面(这些是生长速率最低,因而在晶体生长中最常见的),当一层原子填满后,表面就没有台阶提供继续填充原子的场所,则要通过热激活来克服形成二维晶核的势垒后,方能继续生长。这样,二维成核率就控制晶面生长速率,导出了指数式的生长律。只有在甚高的驱动力(例如过饱和度达50%)作用下方可观测到生长。但实测的结果与此推论有显著矛盾。为了解释低驱动力作用下光滑晶面的生长,F.C.夫兰克于1949年提出螺型位错在晶面露头处会形成永填不满的台阶,促进晶面的生长。在晶体生长表面上观测到的螺旋台阶证实了夫兰克的设想。在W.伯顿、N.卡夫雷拉与夫兰克1951年题为《晶体生长与表面平衡结构》这一重要论文中,对于理想晶体和实际晶体的晶面生长动力学进行了全面的阐述,成为晶体生长理论发展的重要里程碑。

针状晶体生长机理

Journal of Crystal Growth 310(2008)110–115 Crystallization mechanisms of acicular crystals Franc -ois Puel a ,Elodie Verdurand a ,Pascal Taulelle b ,Christine Bebon a ,Didier Colson a , Jean-Paul Klein a ,Ste phane Veesler b,?a LAGEP,UMR CNRS 5007,Universite ′Lyon 1,CPE Lyon,Ba ?t.308G,43Bd du 11novembre 1918,F-69622Villeurbanne Cedex,France b Centre de Recherche en Matie `re Condense ′e et Nanosciences (CRMCN)1—CNRS,Campus de Luminy,Case 913,F-13288Marseille Cedex 09,France Received 10September 2007;accepted 3October 2007 Communicated by K.Sato Available online 9October 2007 Abstract In this contribution,we present an experimental investigation of the growth of four different organic molecules produced at industrial scale with a view to understand the crystallization mechanism of acicular or needle-like crystals.For all organic crystals studied in this article,layer-by-layer growth of the lateral faces is very slow and clear,as soon as the supersaturation is high enough,there is competition between growth and surface-activated secondary nucleation.This gives rise to pseudo-twinned crystals composed of several needle individuals aligned along a crystallographic axis;this is explained by regular over-and inter-growths as in the case of twinning.And when supersaturation is even higher,nucleation is fast and random. In an industrial continuous crystallization,the rapid growth of needle-like crystals is to be avoided as it leads to fragile crystals or needles,which can be partly broken or totally detached from the parent crystals especially along structural anisotropic axis corresponding to weaker chemical bonds,thus leading to slower growing faces.When an activated mechanism is involved such as a secondary surface nucleation,it is no longer possible to obtain a steady state.Therefore,the crystal number,size and habit vary signi?cantly with time,leading to troubles in the downstream processing operations and to modi?cations of the ?nal solid-speci?c properties. These results provide valuable information on the unique crystallization mechanisms of acicular crystals,and show that it is important to know these threshold and critical values when running a crystallizer in order to obtain easy-to-handle crystals.r 2007Elsevier B.V.All rights reserved. PACS:81.10.Aj;81.10.Dn;78.30.Jw Keywords:A1.Crystal morphology;A2.Growth from solutions;https://www.360docs.net/doc/6e12624912.html,anic compounds 1.Introduction Many organic molecules exhibit anisotropic structural properties in their crystalline form,which gives rise to acicular or needle-like crystals.In the chemical and pharmaceutical industry,crystallization from solution is used as a separation technique,and this crystal habit is usually not desirable,especially when the internal length-to-width ratio is high,as it will lead to problems in downstream processes (?ltration,drying,storage,handling,etc.). A better understanding of the mechanisms of nucleation and growth of these needle-like crystals will therefore lead to better control of crystallization processes.In the literature,papers on molecular modeling of these needle-like crystals [1–3]suggest that in the case of needle-like crystals,there is no slow-growing face in the needle direction.Practical aspects have been also studied for a few years now in our different research teams [4–6]. In this contribution,we present an experimental investigation of the growth of four different organic molecules produced at industrial scale with a view to understand the crystallization mechanism of acicular https://www.360docs.net/doc/6e12624912.html,/locate/jcrysgro 0022-0248/$-see front matter r 2007Elsevier B.V.All rights reserved.doi:10.1016/j.jcrysgro.2007.10.006 ?Corresponding author.Tel.:+33662922866;fax:+33491418916. E-mail address:veesler@crmcn.univ-mrs.fr (S.Veesler). 1 Laboratory associated to the Universities Aix-Marseille II and III.

NaCo2O4晶体的生长形貌和生长机理英文

第41卷第3期 人工晶体学报Vol.41No.32012年6月JOURNAL OF SYNTHETIC CRYSTALS June ,2012 Growth ,Morphology and Growth Mechanism of NaCo 2O 4Crystals HAN Shu-juan 1,WANG Ji-yang 1,LI Jing 1,GUO Yong-jie 1,WANG Yong-zheng 1, ZHAO Lan-ling 1,YAO Shu-hua 2,CHEN Yan-bin 2,Boughton R.I.3 (1.State Key Laboratory of Crystal Materials ,Shandong University ,Jinan 250100,China ; 2.College of Materials Science and Engineering ,Nanjing University ,Nanjing 210093,China ; 3.Department of Physics and Astronomy ,Bowling Green State University ,Bowling Green ,Ohio 43403,USA ) (Received 28September 2011, accepted 5March 2012)Abstract :Millimetre-sized NaCo 2O 4crystals were grown from a molten flux based on NaCl-Na 2CO 3by spontaneous nucleation method.Details of the preparation and growth procedures are provided.The as- grown crystals were characterized by X-ray powder diffraction (XRPD ).The morphology and growth mechanism were investigated by scanning electron microscopy (SEM )and atomic force microscopy (AFM ).The results show that the obtained crystal are well crystallized and indexed in a hexagonal crystal system with lattice parameters a =b =0.2842nm ,c =1.0894nm ,and V =0.0761997nm 3.The growth of NaCo 2O 4single crystals was controlled by a two-dimensional (2D )layer-by-layer mechanism acting along the c -axis.Furthermore ,the morphology of the crystals was also interpreted in the viewpoint of anionic coordination polyhedron growth units. Key words :layered compounds ;crystal growth ;microstructure Received date :2011-09-28;accepted date :2012-03-05 Foundation item :National Natural Science Foundation of China (50872066);National Fundamental Research Project (2010CB833103);Graduate Independent Innovation Foundation of Shandong University (GIIFSDU ) Biography :HAN Shu-juan (1983-),female ,from Shandong province ,Doctor.E-mail :shujuanhan84@163.com Corresponding author :WANG Ji-yang ,professor.E-mail address :jywang@sdu.edu.cn CLC number :O78Document code :A Article ID :1000-985X (2012)03-0573-05 NaCo 2O 4晶体的生长,形貌和生长机理研究 韩树娟1,王继扬1,李静1,郭永解1,王永政1,赵兰玲1, 姚淑华2,陈延彬2, Boughton R.I.3(1.山东大学晶体材料国家重点实验室,济南250100;2.南京大学材料科学与工程学院,南京210093; 3.博林格林州立大学天文和物理学系,俄亥俄博林格林43403) 摘要:采用自发成核方法,以NaCl-Na 2CO 3为助熔剂,生长了毫米级的NaCo 2O 4晶体。通过X 射线衍射对晶体作了 表征。利用扫描电子显微镜和原子力显微镜研究了晶体的形貌和生长机理。结果表明:所得晶体是NaCo 2O 4,属于 六方晶系,晶胞参数:a =b =0.2842nm ,c =1.0894nm ,V =0.0761997nm 3。NaCo 2O 4晶体是沿c 轴层状生长的,同 时从阴离子配位多面体的角度分析了晶体的形貌。 关键词:层状化合物;晶体生长;微观结构

晶体生长理论综述教学文案

综述晶体生长理论的发展现状 1前言 晶体生长理论是用以阐明晶体生长这一物理化学过程。形成晶体的母相可以是气相、液相或固相;母相可以是单一组元的纯材料,也可以是包含其他组元的溶液或化合物。生长过程可以在自然界中实现,如冰雪的结晶和矿石的形成;也可以在人工控制的条件下实现,如各种技术单晶体的培育和化学工业中的结晶等。 近几十年来,随着基础学科(如物理学、化学)和制备技术的不断进步,晶体生长理论研究无论是研究手段、研究对象,还是研究层次都得到了很快的发展,已经成为一门独立的分支学科。它从最初的晶体结构和生长形态研究、经典的热力学分析发展到在原子分子层次上研究生长界面和附加区域熔体结构,质、热输运和界面反应问题,形成了许多理论或理论模型。当然,由于晶体生长技术和方法的多样性和生长过程的复杂性,目前晶体生长理论研究与晶体生长实践仍有相当的距离,人们对晶体生长过程的理解有待于进一步的深化。可以预言,未来晶体生长理论研究必将有更大的发展[1]。 2晶体生长理论的综述 自从1669年丹麦学者斯蒂诺(N.Steno)开始晶体生长理论的启蒙工作以来[2],晶体生长理论研究获得了很大的发展,形成了包括晶体成核理论、输运理论、界面稳定性理论、晶体平衡形态理论、界面结构理论、界面动力学理论和负离子配位多面体模型的体系。这些理论在某些晶体生长实践中得到了应用,起了一定的指导作用。本文主要对晶体平衡形态理论、界面生长理论、PBC理论、晶体逆向生长等理论作简要的介绍。 2.1晶体平衡形态理论 晶体具有特定的生长习性,即晶体生长外形表现为一定几何形状的凸多面体,为了解释这些现象,晶体生长理论研究者从晶体内部结构和热力学分析出发,先后提出了Bravais法则、Gibbs-Wulff晶体生长定律、Frank运动学理论。

晶体生长原理与技术

晶体生长原理与技术课程教学大纲 一、课程说明 (一)课程名称、所属专业、课程性质、学分; 课程名称:晶体生长原理及电化学基础 所属专业:金属材料物理学 课程性质:专业方向选修课,学位课,必修环节 学分: 4 学时: 72 (二)课程简介、目标与任务; 课程简介:本课程将在绪论中,对人工晶体生长的基本概念,研究范畴,研究历史和晶体生长 方法分类等基本概念进行简要介绍。然后分4篇进行论述。第一篇为晶体生长的基本原理,将分5 章,对晶体生长过程的热力学和动力学原理,结晶界面形貌与结构,形核与生长的动力学过程进行 描述。第二篇为晶体生长的技术基础,将分3章,对晶体生长过程的涉及的传热、传质及流体流动 原理,晶体生长过程的化学原理和晶体生长过程控制涉及的物理原理进行论述。第三篇为晶体生长 技术,将分4章对熔体生长、溶液生长、气相生长的主要方法及其控制原理进行论述。第四篇,晶 体的性能表征与缺陷,将分2章,分别对晶体的结构、性能的主要表征方法,晶体的结构缺陷形成 与控制原理进行论述。 目标与任务:掌握晶体生长的基本物理原理,学会将基本物理知识运用与晶体生长过程分析讨论。 (三)先修课程要求,与先修课与后续相关课程之间的逻辑关系和内容衔接; 修完普通物理学及四大力学课程、固体物理课程后才可学习该课程,该课程向前联系基本物理知识的运用,向后衔接研究生科学研究中遇到的实际结晶学问题。 (四)教材与主要参考书。 教材两本: 《晶体生长原理与技术》,介万奇,北京:科学出版社,2010 参考书: 《晶体生长科学与技术》[上、下册],张克从,凝聚态物理学丛书,北京:科学出版社,1997 《人工晶体:生长技术、性能与应用》,张玉龙,唐磊,化学工业出版社,2005 《晶体生长基础》,姚连增,中国科学技术大学出版社,1995

蓝宝石各种生长方法

一、蓝宝石生长 1.1 蓝宝石生长方法 1.1.1 焰熔法Verneuil (flame fusion) 最早是1885年由弗雷米(E. Fremy)、弗尔(E. Feil) 和乌泽(Wyse)一起,利用氢氧火焰熔化天然的红宝石粉末 与重铬酸钾而制成了当时轰动一时的“ 日内瓦红宝石”。后 来于1902年弗雷米的助手法国的化学家维尔纳叶(Verneuil) 改进并发展这一技术使之能进行商业化生产。因此,这种方 法又被称为维尔纳叶法。 1)基本原理 焰熔法是从熔体中生长单晶体的方法。其原料的粉末在 通过高温的氢氧火焰后熔化,熔滴在下落过程中冷却并在种 晶上固结逐渐生长形成晶体。 2)合成装置与条件、过程 焰熔法的粗略的说是利用氢及氧气在燃烧过程中产生 高温,使一种疏松的原料粉末通过氢氧焰撒下焰融,并落在 一个冷却的结晶杆上结成单晶。下图是焰熔生长原料及设备 简图。这个方法可以简述如下。图中锤打机构的小锤7按一 定频率敲打料筒,产生振动,使料筒中疏松的粉料不断通过 筛网6,同时,由进气口送进的氧气,也帮助往下送粉料。 氢经入口流进,在喷口和氧气一起混合燃烧。粉料在经过高温火焰被熔融而落在一个温度较低的结晶杆2上结成晶体了。炉体4设有观察窗。可由望远镜8观看结晶状况。为保持晶体的结晶层在炉内先后维持同一水平,在生长较长晶体的结晶过程中,同时设置下降机构1,把结晶杆2缓缓下移。 焰熔法合成装置由供料系统、燃烧系统和生长系统组成,合成过程是在维尔纳叶炉中进行的。 A.供料系统 原料:成分因合成品的不同而变化。原料的粉末经过充分拌匀,放入料筒。如果合成红宝石,则需要Al2O 粉末和少量的 Cr2O3参杂,Cr2O3用作致色剂,添加量为 1-3%。三氧化 3 二铝可由铝铵矾加热获得。料筒:圆筒,用来装原料,底部有筛孔。料筒中部贯通有

晶体生长方法

1.1.5 热交换法Heat exchange method (HEM) 该方法的实质是熔体在坩埚内直径凝固。它 与坩埚移动法的区别是在这种方法中,坩埚不做 任何方向的移动。这是近年来生长大尺寸晶体的 又一发展。Schmid最初的生长是在一个梯度单 晶炉内进行,用以生长大尺寸白宝石单晶。右图 所示的是这种方法的示意图。该梯度炉就是在真 空墨电阻炉的底部装上一个钨铝制成的热交换 器,内有冷却氦气流过。把装有原料的坩埚放在 热交换器的顶端,两者中心互相重合,而籽晶置 于坩埚底部的中心处(注意,热交换器与坩埚底 面积之比应有一定的比例),当坩埚内的原料被 加热熔化以后,此时,由于氦气流经热交换器冷却,使籽晶并未熔化,当氦气流量逐渐加大后,则从熔体带走的热量亦相应增加,使籽晶逐渐长大。最后使整个坩埚内的熔体全部凝固。整个晶体生长过程分两个阶段进行,即成核阶段和生长阶段。在这个过程中晶体生长的去的驱动力来自固—液界面上的温度梯度。通过调节石墨加热器的功率,可达到调节熔体温度的目的。而晶体的热量可通过氦气的流量带走。因此,在生长过程中,晶体的生长界面上可以建立起所需要的温度梯度。 这种方法的主要优点如下: 1)晶体生长时,坩埚、晶体和加热区都不移动,这就消除了由于机械运动而产生的熔体涡流,控制热交换器的温度,是晶体生长在温度梯度场中进行,抑制了熔体的涡流和对流,可以消除固—液界面上温度和浓度的波动,以避免晶体造成过多的缺陷。 2)刚生长出来的晶体被熔体所包围,这样就可以控制它的冷却速率,以减少晶体的热应力及由此产生的开裂和位错等缺陷。同时,也可以长出与坩埚形状和尺寸相仿的单晶。 当然热交换法生长晶体的周期较长,例如,Schmid生长32cm直径的白宝石单晶约需一周左右的时间。 1.1.6水平结晶法Horizontal directional crystallization method(HDC) 其生长原理如右图所示,将原料放入船形坩埚之中,船形坩埚之船头部位主要是放置晶种,接着使坩埚经过一加热器,邻近加热器之部份原料最先熔化形成熔汤,形成熔汤之原料便与船头之晶种接触,即开始生长晶体,当坩埚完全经过加热器后,便可得一单晶体。为了晶体品质及晶体生张结束后,方便取出晶体,坩埚应采用不沾其熔汤之材料所製,如石英、