UPS试摔测试程序

Master Carton Drop Test Process

1.Objective

目的

To reduce damage in transit through a standardized program of pre-shipment testing on the spot.

在装运前通过标准的测试程序来减少货物在运输途中的损失.

2.SCOPE

范围

2.1.This test applies to all hard goods for packaged products under 201 pounds (91.17kg) when prepared

for shipment.

此项测试使用于所有准备装运的, 包装在201磅(91.17GK)以下的坚硬货物.

2.2.This test is derived from ASTM Drop Test, Assurance Level III.

此项测试源自美国材料实验协会摔箱测试, 保险标准III

3.EQUIPMENT NEEDED

所需设备

3.1.tape measure (minimum 45 inches long)

卷尺(至少45英尺)

3.2.Balance to weigh the carton.

称纸箱重量的砰.

3.3.Concrete floor (minimum 2mX2m).

混凝土地面(至少2MX2M)

4.SAMPLING

取样

4.1.Draw one carton at random by style from the shipment.

在同一款的大货中随意抽取一箱.

4.2.If only pattern/color is different on same item, the inspector can perform on representative

pattern/color for drop test and its result can be referred to the others.

在同一款货物中, 如仅是图案/颜色有异, 检验员可抽取典型图案/颜色进行摔箱测试, 其结果可参考其他项目.

5.DROP HEIGHT

摔箱高度

Packaged Product Weight Free Fall Drop Height

完整包装重量自由降落高度

1 (4.54kgs) Thru 20.99 Pounds (9.52kgs) 30 inches (76.20cms)

1(4.54kgs)—20.99磅(9.52kgs) 30英寸(76.20cms)

21 (9.53kgs) Thru 40.99 Pounds (18.59kgs) 24 inches (60.96cms)

21(9.53kgs)—40.99磅(18.59kgs) 24英寸(60.96cms)

41 (18.60kgs) Thru 60.99 Pounds (27.66kgs) 18 inches(45.72cms)

41(18.60kgs)—60.99磅(27.66kgs) 18英寸(45.72cms)

61 (27.67kgs) Thru 100.00 pounds (45.36kgs) 12 inches (30.48cms)

61(27.67kgs)-100.00磅(45.36kgs) 12英寸(30.48cms)

101 (36.74kgs) Thru 150.00 Pounds (45.81kgs) 8 inches (20.3cm)

101(36.74kgs)—150磅(45.81kgs) 8英寸(20.3cms)

6.TEST PROCEDURE

测试程序

6.1.Before performing drop test, the inspector should inspect all pieces in the carton for testing and

make sure the goods in the carton has no damage or breakage. If any piece has damage or breakage before testing, the inspector should mark at defect area on the sample to identify them after drop test, and record it on the report.

进行测试之前, 检验员应先检验每一箱用来测试的货物, 确保其是完好无损的. 若在测试前发现任何一件有损坏, 检验员应在那件样品上标出损坏的地方, 以便摔箱测试以后能分辨出来, 并情况记录在报告上.

6.2.Repack the carton.

重新包装好.

6.3.Perform the drop test, in accordance with height prescribed on point 5., in the following sequence:

为了符合上述第5点要求, 按照以下步骤进行摔箱测试.

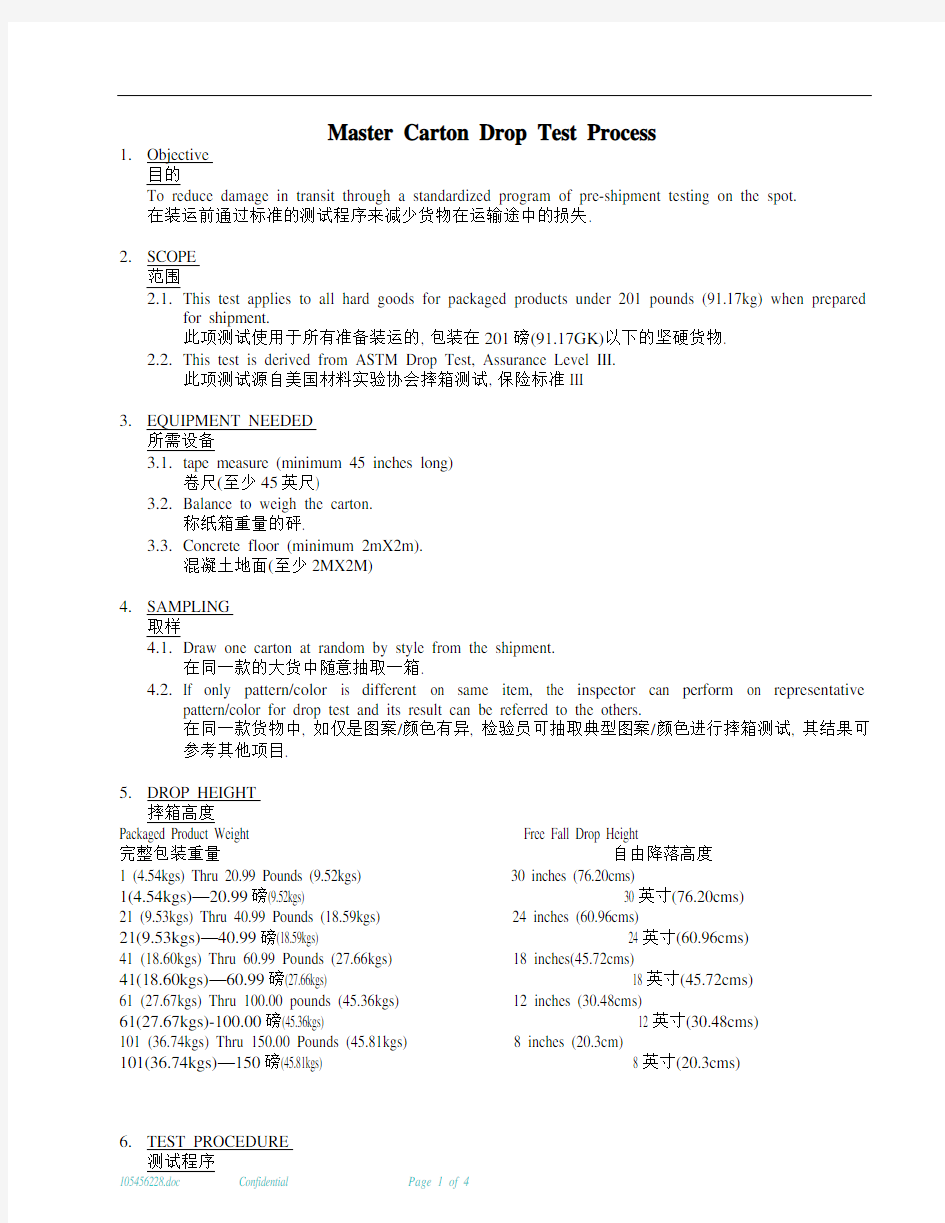

6.3.1.Test the corner of most fragile face which is near to the manufacturer’s joint.

测试最脆弱的一角, 靠近纸箱接合处的一面.

Manufactory's Joint/接口处

第一次摔箱

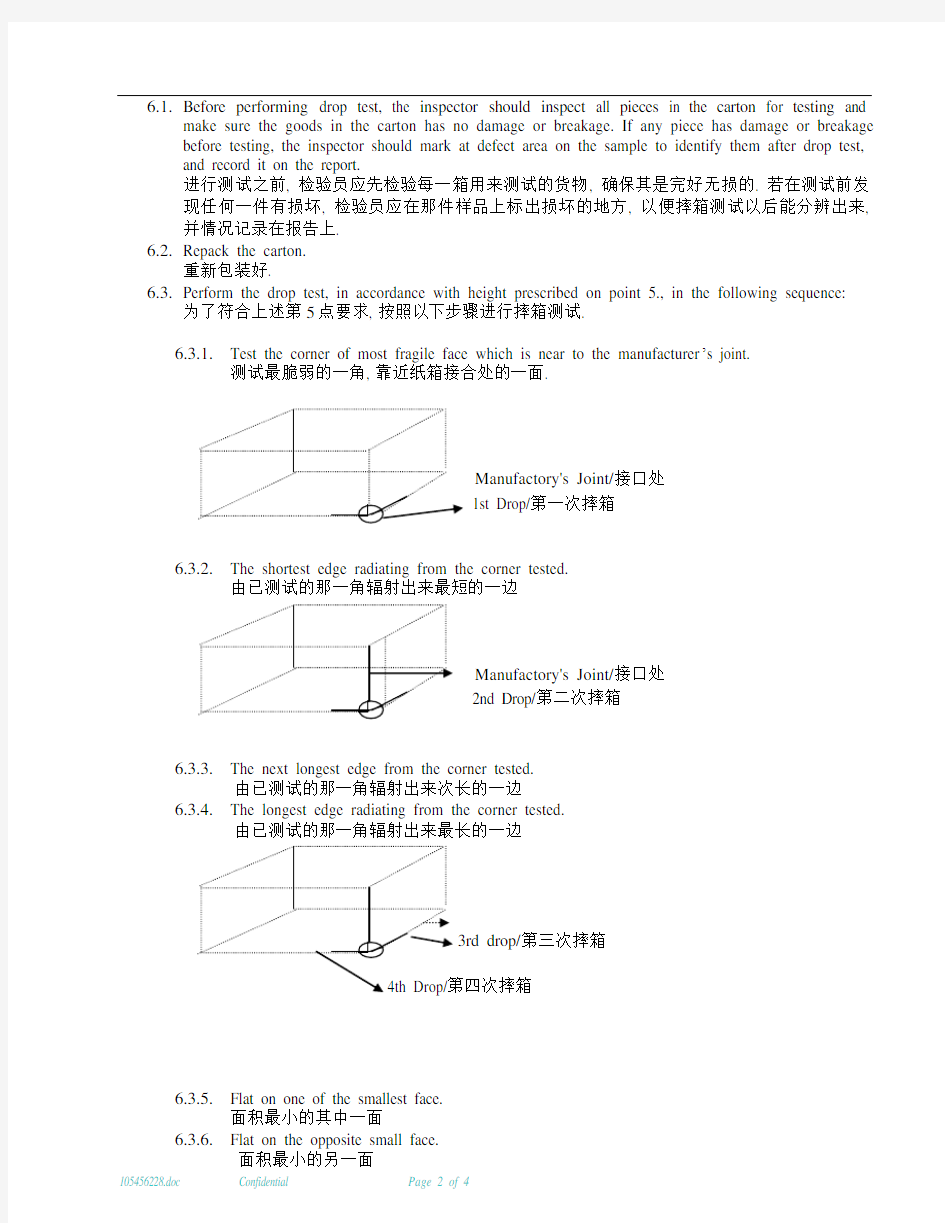

6.3.2.The shortest edge radiating from the corner tested.

由已测试的那一角辐射出来最短的一边

Manufactory's Joint/接口处

2nd Drop/第二次摔箱

6.3.3.The next longest edge from the corner tested.

由已测试的那一角辐射出来次长的一边

6.3.4.The longest edge radiating from the corner tested.

由已测试的那一角辐射出来最长的一边

3rd drop/第三次摔箱

6.3.5.Flat on one of the smallest face.

面积最小的其中一面

6.3.6.Flat on the opposite small face.

面积最小的另一面

6.3.

7.Flat on one of the medium faces.

面积居中的其中一面

6.3.8.Flat on the opposite medium face.

面积居中的另一面.

第八次摔箱

7th Drop/

6.3.9.Flat on one of the largest faces.

面积最大的一面.

6.3.10.Flat on the opposite large face.

面积最大的另一面.

第九次摔箱

10th Drop/

6.4.Inspect both the package and the product in the carton tested. After examination, the inspector will

rate the package and the product using the following rating categories:

检验包装及纸箱里的货物. 检查完以后, 检验员可参照下列标准进行测评:

6.4.1.Pass-everything remains the same as original.

通过-一切保持完好.

6.4.2.Minor-does not affect salability (slight damage to master carton or the product’s package,

creates loose parts, etc.)

一般-不影响销售((外箱或产品包装, 有些许损伤, 引致零件松散, 等等.)

6.4.3.Major-may adversely affect product salability (slight damage to a small % of products or

product components, i.e., surface scratches, detached components, chips or cracks, etc,)

偏差-很可能影响销售(占%的产品或其零件有轻微损伤, 例如:划伤表面, 零件松开或碎

裂, 等等.)

6.4.4.Critical-product is not suitable for sale (i.e., broken product)

很差-产品不适于销售(例如: 产品破碎)

6.5.Disposition of the shipment is dependent of the rating category:

运输的部署取决于测评级别.

6.5.1.Pass-shipment is released immediately.

通过-立即放行货物.

6.5.2.Minor-suitable for shipment.

一般-调整出货日期

6.5.3.Major-buyer and QA review and assess the risk of damages found. Shipment released with

buyer’s approval.

偏差-购买商和QA 评估讨论损失的风险, 并由购买商决定出货日期.

6.5.4.Critical-cannot ship. The failed packaging must be re-engineered or replaced to improve the

protection of the product.

很差-不能装运, 恶劣的包装必须重置或更换保护装置以改善包装.