英文压井方法kill well method

Kill Well Method And Procedure

ADMIN SEPTEMBER 18, 2012 DRILLING ENGINEERING 0

inShare

1

The objective of the various kill well method is to circulate out any invading fluid and circulate a satisfactory weight of kill mud into the well without allowing further fluid into the hole. Ideally this should be done with the minimum of damage to the well.

If this can be done, then once the kill mud has been fully circulated around the well, it is possible to open up the well and restart normal operations. Generally, a kill mud which just provides hydrostatic balance for formation pressure is circulated.

This allows approximately constant bottom hole pressure which is slightly greater than formation pressure to be maintained as the kill well circulation proceeds because of the additional small circulating friction pressure loss.

After circulation, the well is opened up again and the mud weight may be further increased to provide a safety or trip margin.

General Kill Well Method

?Balance Of Pressures Kill Well Method

?Constant BHP Kill Well Method

?Driller Kill Well Method

Balance Of Pressures Kill Well Method

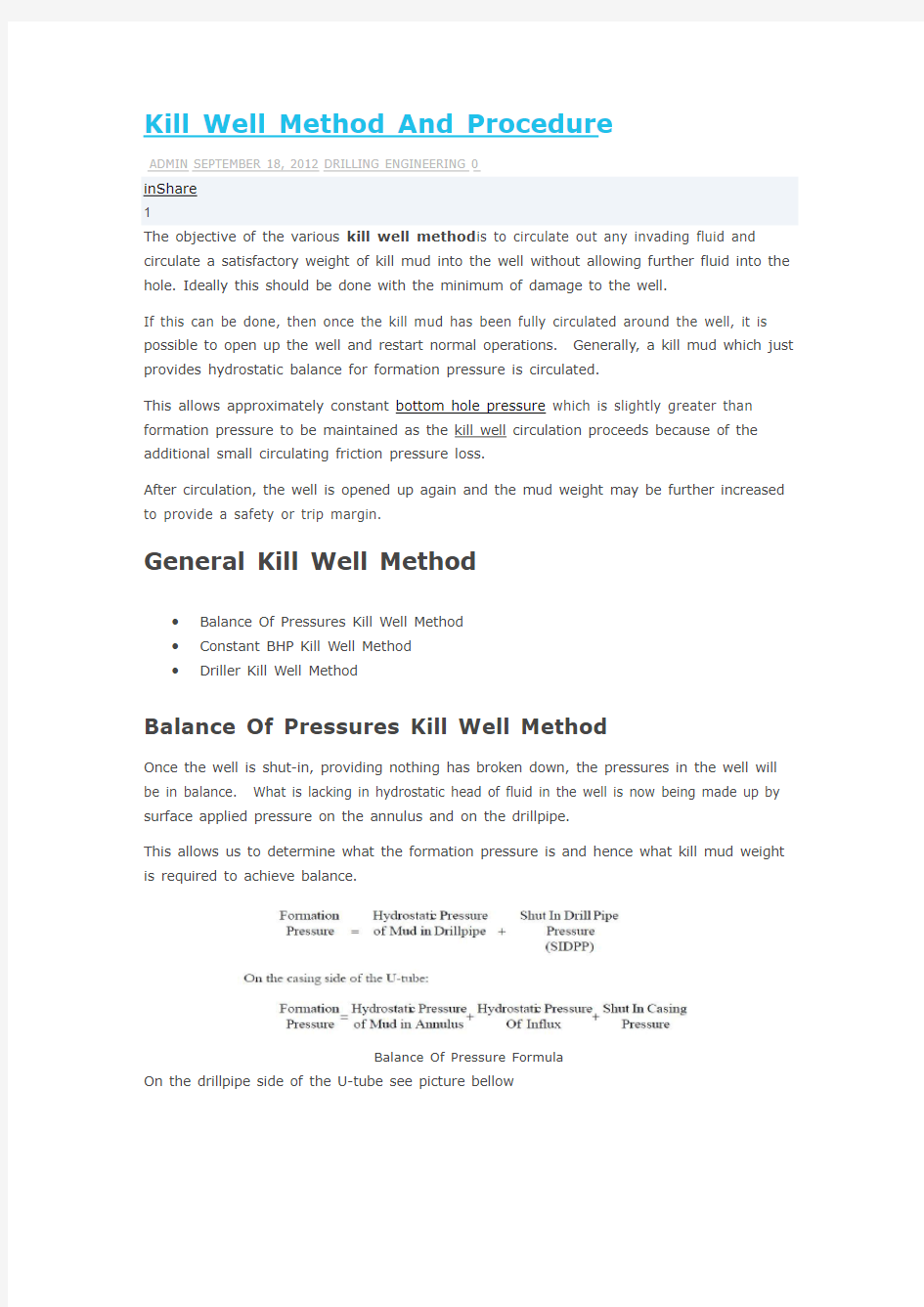

Once the well is shut-in, providing nothing has broken down, the pressures in the well will be in balance. What is lacking in hydrostatic head of fluid in the well is now being made up by surface applied pressure on the annulus and on the drillpipe.

This allows us to determine what the formation pressure is and hence what kill mud weight is required to achieve balance.

Balance Of Pressure Formula

On the drillpipe side of the U-tube see picture bellow

Kill Well

The mixture of mud and formation fluid in the annulus makes it impossible to

determine formation pressure using the casing information. The drillpipe, however, is full of clean mud of known weight and can be used as a ‘barometer’ of what is happening downhole.

P F = Head of Mud in Drillpipe + SIDPP

Once the formation pressure is known, the mud weight required to balance, or ‘kill’, it can be calculated, since

Constant BHP Kill Well Method

There are three ‘constant bottom-hole pressure’ kill well methods in common use today which are:

?Driller’s Method

?Wait & Weight Method (also known as the ‘Engineer’s Method’)

?Concurrent Method.

These three techniques are very similar in principle, and differ only in respect of when kill mud is pumped down. In the Driller’s method, the kill is split into two circulations.During the first, the kick fluid is circulated without changing the mud weight; once the kick is out, the mud is weighted up and pumped around the well on the second circulation. The Wait and Weight method achieves both of these operations simultaneously. Kill mud is prepared before starting the kill, and the kick fluid is circulated out while this mud is circulated into the well. In the Concurrent method, a compromise is adopted between these two methods. The kick fluid is circulated out while the mud being circulated in, is weighted up in stages, towards the kill weight. Of the three methods, the Wait & Weight method is the most popular, and the

one recommended for use in most instances. It produces lower well pressures than either of the other methods, with an evident benefit to safety. Each of the three methods is now described in detail.

The Driller’s Kill Well Method

In the Driller’s method, the kick is circulated out of the hole using the existing mud weight. The mud weight is then raised to the required level and circulated around the well. Two complete circulation’s are thus required, as a minimum, for this method.Since it deals separately with the removal of the kick and the addition of kill weight mud, it is generally considered to be the simplest of well control methods, and it requires least arithmetic. However, this results, in the well being circulated under pressure for a relatively long time, possibly the longest of the three methods, with an increased possibility of choke problems. Also, the annular pressures produced during the first circulation are higher than produced with any other method.

CAUTION: Because very high annular pressure may arise when killing a gas kick well with this method, care should be taken. Annular will be at a maximum immedietly before gas arrives at surface, and casing burst pressure limitations may be critical. For this reason, the driller’s method is not generally recommended.

In general, this method is most used on small land rigs where the Driller may have little help and limited equipment. A variant of this method is also used in some workover operations. In addition the simplicity of the Driller’s method makes it useful when only limited information is available about the well conditions.

To summarise:

?FIRST CIRCULATION: Pump the kick out of the well, using existing mud weight ?SECOND CIRCULATION: Pump kill weight mud around the well.

a)Advantages of driller’s method

?Minimum arithmetic

?Minimum waiting around time – can start kill well at once

?Minimum information required.

b) Disadvantages of driller’s method

?Highest annular pressure produced

?Maximum well under pressure time

?Longest one chock time.

c)Procedure for driller’s method

Driller Method Kill Well Schamatic

1) The well is closed in and the information recorded.

First Circulation

2) If a slow circulating rate pressure, P SCR, has been taken, then calculate the pressure required on the drillpipe for the first circulation of the well.

This is:

Initial Circulation = Slow Circulation Rate + Shut In Drillpipe

or :

Pressure Pressure

ICP = P SCR + SIDPP Pressure

3) Open the choke about one quarter, start the pump and break circulation; then bring the pump up to the Kill Well Rate.

4) While the Driller is bringing the pump up to the Kill Well Rate, the choke operator should operate the choke so as to keep the casing pressure at or near the closed in casing pressure reading.

5) Once the pump is up to the Kill Well Rate, the choke operator should transfer his attention to the drillpipe pressure gauge and adjust the choke to maintain the

INITIAL CIRCULATING PRESSURE on the drillpipe pressure gauge.

6) The INITIAL CIRCULATING PRESSURE is held constant on the drillpipe pressure gauge by adjusting the choke throughout the whole of the first circulation, until all of the kick fluid has been circulated out of the well. The pump rate must also be held

constant at the KILL WELL RATE throughout this period.

7) Once the kick is out of the hole, shut the well in and mix up the kill mud

weight required.

Kill Weight Mud (ppg) = Old Mud Weight + [SIDPP (psi)÷ TVD (ft)÷ 0.052]

NOTE 1: This is a kill weight mud to balance formation pressure. It is the

lowest possible mud weight which will ‘kill’ the well.Once the well is dead, it will be necessary to increase the mud weight further to provide a trip margin.

NOTE 2: Some operators prefer to continue circulating the well while kill

weight mud is being mixed. There is no theoretical reason why this should not be done, though it does result in further wear and tear on equipment under pressure –in particular the choke.

Second Sirculation

8) Once the kill mud is ready, open the choke about one quarter, start the pump and break circulation. Then bring the pump up to the kill rate.

9) While the Driller is bringing the pump up to the kill rate, the choke operator

should operate the choke so as to keep the casing pressure steady at the same pressure as when closed in.

10) While the drillpipe is being filled with heavy mud, hold the casing pressure constant. The drillpipe pressure will go down as the drillpipe is being slugged with the heavier mud. In practice, if all the kick was properly removed in the first circulation, the choke should not need to be touched once the pumps are steady at the Kill Well Rate, until kill mud reaches the bit.Once the kill mud reaches the bit, the pressure held on the drillpipe is just that required to circulate the mud around the well. This is the slow circulating rate pressure, increased slightly for the extra mud weight.

We will continue the article on next posting and do not forget for bookmark our site by type CTRL + D , visit to well control spreadsheet and other drilling engineering .

Incoming Popular Post On Our Site:

Control Well Kill Using Wait and Weight Method (Balanced Method)

Register - Login

You must login to access ALL the articles in this site

Remember Me

?Forgot your password?

?Forgot your username?

?Create an account

Thank You...

Please consider supporting our efforts.

Amount:

Well Kill Using Wait and Weight Method (Balanced Method)

The “Wait and Weight” method is th e method recommended, in some circumstances, for controlling an influx taken while drilling or circulating on bottom. When drillpipe (string) volume is greater than open hole volume, the influx will already be inside the casing before heavy mud reaches the open hole.

In this case the “Driller’s Method” can be a better solution as the danger of gas expansion is removed immediately while weighing up mud can take hours.

Advantages of “Wait and Weight” method

the annular pressure will usually be lower and the chance of formation breakdown is therefore

reduced.

the hole and the wellhead equipment are subjected to high pressures for the shortest possible time since the influx is circulated out and the well is killed in one circulation.

Disadvantages of “Wait and Weight” method

considerable waiting time while weighing up mud can cause gas migration

if large increases in mud weight is required, this may be possible in stages only

This method involves one circulation. Kill mud is prepared and is pumped from surface to bit while following a prepared drillpipe pressure drop schedule. Once the kill mud enters the annulus, a constant drillpipe pressure is maintained until the heavy mud returns to surface.

Procedure

The procedure for the Wait and Weight method is as follows:

After the well has been secured and pressures have stabilised, complete kill sheet including kill graph

Bring pumps up to speed keeping casing pressure constant by manipulating the choke

When pump is up to kill speed the choke is manipulated to keep the drill pipe pressure at initial circulating pressure (ICP).

Pump kill mud down drill pipe keeping casing pressure constant and allowing drill pipe pressure to fall from ICP to final circulating pressure (FCP).

When kill mud reaches the bit the drill pipe pressure should be at FCP. Continue pumping kill mud keeping drill pipe pressure constant at FCP until the kick is circulated out and kill mud reaches surface.

Equations

KMW = (SIDPP / (0.052 * TVD)) + OMW

Trip margin may not be included in the calculation for kill mud weight. The major reason for this is to avoid any unnecessary additional wellbore pressure that could result in formation breakdown. Calculate initial circulating pressure:

ICP = SCRP + SIDPP (psi)

Calculate Final circulating pressure:

FCP = KMW x SCRP (psi)

OMW

Calculate surface to bit strokes:

Strokes = Drillstring volume (bbls)

Pump output (bbls/stroke)

Calculate time to pump surface to bit:

Time (mins) = Total strokes from surface to bit)

Strokes per minute Where:

?KMW = Kill mud weight (ppg)

?SIDPP = Shut in Drillpipe pressure (psi)

?TVD = True vertical depth (ft)

?OMW = Original Mud Weight (ppg)

?ICP = Initial circulating pressure (psi)

?SCRP = slow circulating rate pressure (psi)

?FCP = Final circulating pressure (psi)

四种常规压井方法

四种常规压井方法 四种常规压井方法 1、边加重钻井液边循环压井法。这种处置方法可以在最短的时间防喷制住溢流,使井控装置承受的压力最小、承压时间最短,可以减少钻具粘卡等井下事故,因此是最安全的,但这种处置方法计算较复杂,需要进行许多的计算。 2、继续关井,先加重钻井液,再循环压井(等待加重法或工程师法)法。该处置可以在一个循环周完成,所需时间最短,井口压力较小,也较安全,压井多采用这种方法,但是关井时间长,对循环不利,因此该方法效果的好坏关键取决于是

否能迅速加重钻井液。以不变的泵速循环注入加重钻井液;在加重钻井液到达钻头的过程中,调节节流阀使立压由初始循环值下降到终了循环值(加重钻井液低泵冲泵压),使套压值保持不变;当加重钻井液到达钻头后向环空上返过程中,立压值保持不变,套压值逐渐下降,当加重钻井液到达井口时,套压降为零,重建起地层——井眼压力平衡,压井结束。 3、先循环排出受侵污的钻井液,关井、加重钻井液,再循环压井(两步控制法或司钻法)法。这种处置相对来说是安全的,技术上也比较容易掌握,但需要最长的时间和最大程度的应用井口装置。钻井液在第一个循环周内未加重,因此立

压不变(或初始与终了循环压力相等),同时第一循环周结束,关闭节流阀时,套压应该等于立压。 4、先循环排出受侵污的 4、先循环排出受侵污的钻井液,然后边加重钻井液边循环压井法。这种处置方法既复杂又需要时间更长。

附件1-13 井压井施工单年月日 井号井队 填表 人井 深 H0 M 垂深 H1M 原浆密 度γMg/m3 钻进 排量Q L/S 低泵冲泵 压P Ci MPa 漏失压 力 梯度Gf MPa/M 压井 排量Q k L/S 套管鞋 深度h M 钻柱内 容 积系数 V A L/M 钻头位 置 斜深H M 压井附加 密度γ e g/cm3 环空容 积 系数V B L/M 钻头位 置 垂深H2

英语数字的表示方法972861

英语数字的表示方法 英语数字的表示方法 数词 数词主要分为基数词和序数词两类。 一、数词的分类(2002.02.21) 1. 基数词 表示数目的词称为基数词。其形式如下: A.从1——10 one,two,three,four,five,six,seven,eight,nine,ten. B.从11——19 eleven,twelve,thirteen,fourteen,fifteen,sixteen,seventeen,eighteen,nineteen. 这里除eleven,twelve,thirteen,fifteen,eighteen为特殊形式外,fourteen,sixteen,seventeen,nineteen 都是由其个位数形式后添加后缀-teen构成。 C.从21——99 整数几十中除twenty,thirty, forty,fifty,eighty为特殊形式外,sixty,seventy,ninety都是其个位数形式后添加后缀-ty构成。 表示几十几时,在几十和个位基数词形式之间添加连字符“-” 21 twenty-one 76 seventy-six D.百位数 个数基数词形式加“hundred”,表示几百,在几十几与百位间加上and. 101 a hundred and one 320 three hundred and twenty 648 six hundred and forty-eight E.千位数以上 从数字的右端向左端数起,每三位数加一个逗号“,”。从右开始,第一个“,”前的数字后添加thousand,第二个“,” 前面的数字后添加million,第三个“,”前的数字后添加billion。然后一节一节分别表示,两个逗号之间最大的数为百位数形式。 2,648 two thousand six hundred and forty-eight 16,250,064 sixteen million two hundred and fifty thousand sixty-four 5,237,166,234 five billion,two hundred and thirty-seven million,one hundred and sixty-six thousand,two hundred ,and thirty-four F.基数词在表示确切的数字时,不能使用百、千、百万、十亿的复数形式;但是,当基数词表示不确切数字,如成百、成千上万,三三两两时,基数词则以复数形式出现。 There are hundreds of people in the hall. 大厅里有数以百计的人。 Thousands and thousands of people come to visit the Museum of Qin Terra-Cotta Warriors and Horses every day.

常规压井方法

常规压井方法 常规方法包括关井立管压力为零的压井和关井立管压力不为零的压井。关井立管压力为零的压井,是钻井液的静液压力可以平衡地层压力,发生溢流是因为抽汲、井壁扩散气、钻屑气等进人井内的气体膨胀所致,其处理方法如下:关井立管压力为零 ①当关井套压也为零时,保持钻进时的排量和泵压,敞开井口循环就可恢复井的压力控制。 ②当关井套压不为零时,通过节流阀节流循环,在循环过程中,控制循环立压不变,当观察到套压为零时,停止循环。 上述两种情况经循环排除溢流后,应再用短程起下钻检验,判断是否需要调整钻井液密度,然后恢复正常作业。 关井立管压力和套管压力都不为零时 常规压井方法主要有以下几种: 1 .司钻法压井(二次循环法) 司钻法是发生溢流关井求压后,第一循环周用原密度钻井液循环,排除环空中已被地层流体污染的钻井液,第二循环周再将压井液泵人井内,用两个循环周完成压井,压井过程中保持井底压力不变。 1 )司钻法压井步骤 ①录取关井资料,计算压井所需数据,填写压井施工单,绘出压力控制进度表,作为压井施工的依据。 ②第一步用原钻井液循环排除溢流。 a .缓慢开泵,逐渐打开节流阀,调节节流阀使套压等于关井套压并维持不变,直到排量达到选定的压井排量。 b .保持压井排量不变,调节节流阀使立管压力等于初始循环压力几,,在整个循环周保持不变。调节节流阀时,注意压力传递的迟滞现象。液柱压力传递速度大约为 300 m/s , 3000m 深的井,需 20s 左右才能把节流变化的压力传递到立管压力表上。 c .排除溢流,停泵关井,则关井立压等于关井套压。在排除溢流的过程中,应配制加重钻井液,准备压井。 ③第二步泵人压井液压井,重建井内压力平衡。 a .缓慢开泵,迅速开节流阀平板阀,调节节流阀、保持关井套压不变。

压井方法优选与存在的问题

压井方法优选与存在的问题 压井是利用井控设备和压井方法向井内注入一定比重和性能的压井液,重新建立井下压力平衡的过程。选取合适、有效的压井方法关系到压井是否成功的关键,一旦发生井喷失控,将会造成重大损失,甚至巨大社会影响,因此,发生溢流或井涌后编制压井方案,选择最优的压井方法是压井成功的前提。 一、压井方法及优缺点 压井方法包括常规压井法和非常规压井法,常规压井法含司钻法、工程师法、边循环边加重法;非常规压井法含平推压井法、置换压井法、低节流压井法、体积控制压井法。 1.常规压井法 ⑴司钻法压井。司钻法又称二次循环法,是指当溢流发生时并且完成关井工作后,考虑先利用钻井液循环将溢流排除,然后再结合钻井液压井的方法。这种方法的优点在于比较容易掌握,并且最关键的是操作时间短。缺点是设备承压高,风险相对较大。 ⑵工程师法压井。工程师法又称一次循环法,是指当发生溢流时,要实现迅速的关井行为并记录重要的溢流数据,通过计算填写压井施工单,然后利用加重钻井液,保证全部工作的实现在一个循环内完成。工程师法压井的最大优势是装置所承受的压力小,相对风险小,经济效益高。缺点是:①精确控制井底压力难,影响因素多,一旦控制不好,容易引起油气侵,造成反复压井。比如:井眼轨迹、井身质量、泥浆密度与循环压降的精确计算困难,高密度泥浆差距大,另外,地面装置在压井过程中,地

层砂子反出堵塞通道,需要反复开大、关小节流阀。因此,立管压力的控制难度大。②在压井过程中井底漏失量不好掌握,若漏失严重,压井泥浆不够用,也会造成压井失败。 ⑶边循环边加重法压井。边循环边加重法又称同步法或循环加重法。是指当溢流关井求得地层压力之后,采用边循环边加重的办法压井。它的优点是在重浆储备不足,边远地区能够很快的开展压井作业。但是,这种方法的最大缺点是压力的计算比较复杂,因此在实践中很少采用。 2.非常规法压井 ⑴平推法压井。平推法又称压回地层法、挤压法或顶回法,是指从地面管汇向井内注入钻井液将进入井内的地层流体压回地层的压井方法。其优点是适用于地层流体中含硫化氢等有害物质、钻杆堵塞或断裂、压井液不能到达井底等情况下的溢流处理;缺点是:①高压的小溶洞、裂缝性油气层(定容体)不宜采用平推法压井,由于地层储藏空间有限,平推法压井容易越推压力越高,反而不能建立井内压力平衡。②井口段钻具内外压差大,容易刺坏钻具,造成钻具断裂不能压井。③操作不得当可能进一步损坏井眼,挤入的流体将进入最薄弱的地层段,出现“又喷又漏”复杂情况,特别高含H2S的井,将造成重大井控风险。 ⑵置换法压井。井喷关井后,若天然气已上升至井口或者整个井眼被喷空充满天然气,在不能用平推法压井时就需要用置换法压井。其原理是,在关井情况下和确定的套管上限与下限压力范围内,分次注入一定数量的压井液、分次放出井内气体,直至井内充满压井液,完成压井作业。该方法的关键是,注入和放出气体时应始终保持井底压力略大于地层压力。

最新英语数字表达方式汇总

英语数字表达方式汇总 数词:主要分为基数词和序数词两类。 一、数词的分类 (4类-只有40相关的写法为forty,9类只有第九写作ninth) 1. 基数词表示数目的词称为基数词。其形式如下: A.从1——10 one,two,three,four,five,six,seven,eight,nine,ten. B.从11——19 eleven,twelve,thirteen,fourteen,fifteen,sixteen,seventeen,eighteen,nineteen.这里除eleven,twelve,thirteen,fifteen,eighteen为特殊形式外,fourteen,sixteen,seventeen,nineteen都是由其个位数形式后添加后缀-teen构成。 C.从21——99 整数几十中除twenty,thirty, forty,fifty,eighty为特殊形式外,sixty,seventy,ninety都是其个位数形式后添加后缀-ty构成。表示几十几时,在几十和个位基数词形式之间添加连字符“-” 21 twenty-one 76 seventy-six D.百位数 个数基数词形式加“hundred”,表示几百,在几十几与百位间加上and. 101 a hundred and one 320 three hundred and twenty 648 six hundred and forty-eight E.千位数以上 从数字的右端向左端数起,每三位数加一个逗号“,”。从右开始,第一个“,”前的数字后添加thousand,第二个“,”前面的数字后添加million,第三个“,”前的数字后添加billion。然后一节一节分别表示,两个逗号之间最大的数为百位数形式。【and 读作【n】】 2,648 two thousand six hundred and forty-eight 16,250,064 sixteen million two hundred and fifty thousand sixty-four 5,237,166,234 five billion,two hundred and thirty-seven million,one hundred and sixty-six thousand,two hundred and thirty-four F.基数词在表示确切的数字时,不能使用百、千、百万、十亿的复数形式;但是,当基数词表示不确切数字,如成百、成千上万,三三两两时,基数词则以复数形式出现。 There are hundreds of people in the hall. 大厅里有数以百计的人。 Thousands and thousands of people come to visit the Museum of Qin Terra-Cotta Warriors and Horses every day. 每天有成千上万的人来参观秦兵马涌博物馆。 They went to the theatre in twos and threes. 他们三三两两地来到了剧院。 G.表示人的不确切岁数或年代,用几十的复数形式表示。 He became a professor in his thirties. 他三十多岁时成为了教授。 She died of lung cancer in forties. 她四十来岁时死于肺癌。

英语数字表达方式大全

英语数字表达方式大全 0 nought;zero; 1 one 2 two 3 three 4 four 5 five 6 six 7 seven 8 eight 9 nine 10 ten 11 eleven 12 twelve 13 thirteen 14 fourteen 15 fifteen 16 sixteen 17 seventeen 18 eighteen 19 nineteen 20 twenty 21 twenty-one 22 twenty-two 23 twenty-three 30 thirty 32 thirty-two 40 forty 50 fifty 60 sixty 70 seventy 80 eighty 90 ninety 100 one hundred 101 one hundred and one 156 one hundred and fifty-six 192 one hundred and ninty-two 200 two hundred 300 three hundred 400 four hundred 500 five hundred 600 six hundred 700 seven hundred 800 eight hundred 900 nine hundred 1,000 one thousand 1,001 one thousand and one 1,300 thirteen hundred;one thousand and three hundred 2,000 two thousand 2,034 two thousand and thirty-four 6,502 six thousand five hundred and two 38,000 thirty-eight thousand 45,672 forty-five thousand six hundred and seventy-two 500,000 five hundred thousand 1,000,000 one million 3,123,400 three million,one hundred and twenty-three thousand and four hundred 8,000,000 eight million 47,000,000 forty-seven million

英文数字表示方法大全

数词主要分为基数词和序数词两类。 一、数词的分类 1. 基数词 表示数目的词称为基数词。其形式如下: A.从1——10 one,two,three,four,five,six,seven,eight,nine,ten. B.从 11——19 eleven,twelve, thirteen, fourteen, fifteen,sixteen, seventeen,eighteen, nineteen. 这里除 eleven, twelve, thirteen, fifteen, eighteen 为特殊形式外,fourteen,sixteen,seventeen,nineteen 都是由其个位数形式后添加后缀-teen构成。 C.从 21——99 整数几十中除twenty,thirty, forty,fifty,eighty为特殊形式外,sixty,seventy,ninety都是其个位数形式后添加后缀-ty构成。 表示几十几时,在几十和个位基数词形式之间添加连字符“-” 21 twenty-one 76 seventy-six D.百位数 个数基数词形式加“hundred”,表示几百,在几十几与百

位间加上and. 101 a hundred and one 320 three hundred and twenty 648 six hundred and forty-eight E.千位数以上 从数字的右端向左端数起,每三位数加一个逗号“,”。从右开始,第一个“,”前的数字后添加 thousand,第二个“,” 前面的数字后添加 million,第三个“,”前的数字后添加 billion。然后一节一节分别表示,两个逗号之间最大的数为百位数形式。 2,648 two thousand six hundred and forty-eight 16,250,064 sixteen million two hundred and fifty thousand sixty-four 5,237,166,234 five billion,two hundred and thirty-seven million,one hundred and sixty-six thousand,two hundred ,and thirty-four F.基数词在表示确切的数字时,不能使用百、千、百万、十亿的复数形式;但是,当基数词表示不确切数字,如成百、成千上万,三三两两时,基数词则以复数形式出现。 There are hundreds of people in the hall. 大厅里有数以百计的人。 Thousands and thousands of people come to visit the Museum of Qin Terra-Cotta Warriors and Horses every day.每天有成千上万的人来参观秦兵马涌博物馆。

非常规压井方法

非常规压井方法 非常规压井方法是溢流、井喷井不具备常规压井方法的条件而采用的压井方法,如空井井喷、钻井液喷空的压井等。 1 .平衡点法 平衡点法适用于井内钻井液喷空后的天然气井压井,要求井口条件为防喷器完好并且关闭,钻柱在井底,天然气经过放喷管线放喷。这种压井方法是一次循环法在特殊情况下压井的具体应用。 此方法的基本原理是:设钻井液喷空后的天然气井在压井过程中,环空存在一“平衡点”。所谓平衡点,即压井钻井液返至该点时,井口控制的套压与平衡点以下压井钻井液静液柱压力之和能够平衡地层压力。压井时,当压井钻井液未返至平衡点前,为了尽快在环空建立起液柱压力,压井排量应以在用缸套下的最大泵压求算,保持套压等于最大允许套压;当压井钻井液返至平衡点后,为了减小设备负荷,可采用压井排量循环,控制立管总压力等于终了循环压力,直至压井钻井液返出井口,套压降至零。平衡点按下式求出: H B=P aB /0 . 0098ρk 式中H B―平衡点深度,m ; P aB―最大允许控制套压,MPa ; 根据上式,压井过程中控制的最大套压等于“平衡点”以上至井口压井钻井液静液柱压力。当压井钻井液返至“平衡点”以后,随着液柱压力的增加,控制套压减小直至零,压井钻井液返至井口,井底压力始终维持一常数,且略大于地层压力。因此,压井钻井液密度的确定尤其要慎重。 2 .置换法 当井内钻井液已大部分喷空,同时井内无钻具或仅有少量钻具,不能进行循环压井,但井口装置可以将井关闭,压井钻井液可以通过压井管汇注人井内,这种条件下可以采用置换法压井。通常情况下,由于起钻抽极,钻井液不够或灌钻井液不及时,电测时井内静止时间过长导致气侵严重引起的溢流,经常采用此方法压井。 操作方法: ①通过压井管线注人一定量的钻井液,允许套压上升某一值(以最大允许值为限)。 ②关井一段时间,使泵人的钻井液下落,通过节流阀缓慢释放气体,套压

常规压井方法

常规压井方法常规方法包括关井立管压力为零的压井和关井立管压力不为零的压井。关井立管压力为零的压井,是钻井液的静液压力可以平衡地层压力,发生溢 流是因为抽汲、井壁扩散气、钻屑气等进人井内的气体膨胀所致,其处理方法如下:关井立管压力为零 ①当关井套压也为零时,保持钻进时的排量和泵压,敞开井口循环就可恢复井 的压力控制。 ②当关井套压不为零时,通过节流阀节流循环,在循环过程中,控制循环立压 不变,当观察到套压为零时,停止循环。 上述两种情况经循环排除溢流后,应再用短程起下钻检验,判断是否需要调整钻井液密度,然后恢复正常作业。 关井立管压力和套管压力都不为零时常规压井方法主要有以下几种: 1 .司钻法压井(二次循环法) 司钻法是发生溢流关井求压后,第一循环周用原密度钻井液循环,排除环空中已被地层流体污染的钻井液,第二循环周再将压井液泵人井内,用两个循环周完成压井,压井过程中保持井底压力不变。 1 )司钻法压井步骤 ①录取关井资料,计算压井所需数据,填写压井施工单,绘出压力控制进度表,作为压井施工的依据。 ②第一步用原钻井液循环排除溢流。 a .缓慢开泵,逐渐打开节流阀,调节节流阀使套压等于关井套压并维持不 变,直到排量达到选定的压井排量。 b .保持压井排量不变,调节节流阀使立管压力等于初始循环压力几,,在整 个循环周保持不变。调节节流阀时,注意压力传递的迟滞现象。液柱压力传递速 度大约为300 m/s , 3000m 深的井,需20s 左右才能把节流变化的压力传递到立管 压力表上。 c .排除溢流,停泵关井,则关井立压等于关井套压。在排除溢流的过程中, 应配制加重钻井液,准备压井。 ③第二步泵人压井液压井,重建井内压力平衡。 a .缓慢开泵,迅速开节流阀平板阀,调节节流阀、保持关井套压不变。 b .排量逐渐达到压井排量并保持不变。在压井液从井口到钻头这段时间内,

压井计算公式

井控公式 1.静液压力:P=0.00981ρ H MPa ρ-密度g/cm3;H-井深 m。 例:井深3000米,钻井液密度1.3 g/cm3,求:井底静液压力。 解:P=0.00981*1.3*3000=38.26 MPa 2,压力梯度: G=P/H=9.81ρ kPa/m =0.0098ρMPa; 例:井深3600米处,密度1.5 g/cm3,计算井内静液压力梯度。 解:G=0.0098*1.5=0.0147MPa=14.7kPa/m 3.最大允许关井套压 Pamax =(ρ破密度-ρm)0.0098H MPa H—地层破裂压力试验层(套管鞋)垂深,m。 Ρm—井内密度 g/cm3 例;已知密度1.27 g/cm3,套管鞋深度1067米,压力当量密度1.71 g/cm3,求:最大允许关井套压 解; Pamax =(1.71-1.27)0.0098*1067=4.6 MPa 4.压井时(极限)关井套压 Pamax =(ρ破密度-ρ压)0.0098H MPa Ρ压—压井密度 g/cm3 (例题略) 5.溢流在环空中占据的高度 hw=ΔV/Va m ΔV—钻井液增量(溢流),m3; Va—溢流所在位置井眼环空容积,m3/m。 6.计算溢流物种类的密度ρw=ρm- (Pa-Pd)/0.0098 hw g/cm3; ρm—当前井内泥浆密度,g/cm3; Pa —关井套压,MPa; Pd —关井立压,MPa。

如果ρw在0.12~0.36g/cm3之间,则为天然气溢流。 如果ρw在0.36~1.07g/cm3之间,则为油溢流或混合流体溢流。 如果ρw在1.07~1.20g/cm3之间,则为盐水溢流。 7.地层压力 Pp =Pd+ρm gH Pd —关井立压,MPa。 ρm—钻具内钻井液密度,g/cm3 8.压井密度ρ压=ρm+Pd/gH 9、(1)初始循环压力 =低泵速泵压+关井立压 注:在知道关井套压,不清楚低泵速泵压和关井立压情况下,求初始循环压力方法:(1)缓慢开节流阀开泵,控制套压=关井套压(2)排量达到压井排量时,保持套压=关井套压,此时立管压力=初始循环压力。 (2)求低泵速泵压:(Q/Q L)2=P/P L 例:已知正常排量=60冲/分,正常泵压=16.548MPa,求:30冲/分时小泵压为多少? 解:低泵速泵压P L=16.548/(60/30)2=4.137 MPa 10.终了循环压力= (压井密度/原密度)X低泵速泵压 (一)注:不知低泵速泵压,求终了循环压力方法:(1)用压井排量计算出重浆到达钻头的时间,此时立管压力=终了循环压力。边循环边加重压井法

英文数字表示方法大全

英文数字表示方法大全(2009-07-24 15:26:59) 转载 标签:教育分类:少儿英语学习方法 数字的表示方法数词 数词主要分为基数词和序数词两类。 一、数词的分类 1. 基数词 表示数目的词称为基数词。其形式如下: A.从1——10 one,two,three,four,five,six,seven,eight,nine,ten. B.从 11——19 eleven,twelve, thirteen, fourteen,fifteen, sixteen, seventeen,eighteen, nineteen.这里除 eleven, twelve, thirteen, fifteen,eighteen为特殊形式外,fourteen,sixteen,seventeen,nineteen 都是由其个位数形式后添加后缀-teen构成。

C.从 21——99 整数几十中除twenty,thirty, forty,fifty,eighty为特殊形式外,sixty,seventy,ninety都是其个位数形式后添加后缀-ty构成。 表示几十几时,在几十和个位基数词形式之间添加连字符“-” 21 twenty-one 76 seventy-six D.百位数 个数基数词形式加“hundred”,表示几百,在几十几与百位间加上and. 101 a hundred and one 320 three hundred and twenty 648 six hundred and forty-eight E.千位数以上 从数字的右端向左端数起,每三位数加一个逗号“,”。从右开始,第一个“,”前的数字后添加 thousand,第二个“,” 前面的数字后添加 million,第三个“,”前的数字后添加billion。然后一节一节分别表示,两个逗号之间最大的数为百位数形式。

低节流法压井施工工艺压力窗口低的井

低节流法压井施工工艺压力窗口低的井 Company number【1089WT-1898YT-1W8CB-9UUT-92108】

低节流法压井施工工艺 低节流法压井是一种非常规的压井方法,使用于泥浆密度窗口比较窄,也就是一些压力较敏感的地层,如塔里木油田的轮古地区。在发生溢流后用常规的压井方法会压漏地层,用而反推法)压井,对于有的地层--特别是裂缝不发育、储层连通性不好及稠油地层等,反复压井会造成井底压力越蹩越高。 低节流法压井是第一循环周用和井浆密度相同的泥浆把进入井筒的地层流体循环出来,在这期间,可以允许少量的地层流体进入井筒,在第二循环周再调整泥浆密度到一定的值,目的是不压漏地层,实现井底的压力近平衡,压井过程中控制好节流阀是关键,以控制立压为主,尽量避免压漏地层。在起钻时,一般打一个重泥浆帽。 低节流法压井使用于对地层压力已经完全掌握的井,对山前的高压气井不实用。 一.轮古情况简介 轮南低凸起位于塔里木盆地塔北隆起中段,是一个在古生界残余古隆起上发育起来的呈北东-南西走向的大背斜。钻探的主要目的层为奥陶系潜山面以下碳酸盐岩岩溶裂缝储层,具有裂缝和溶洞随机发育并控制油气藏分布;地层压力系数低(左右),钻井液平衡窗口小甚至没有,易井漏、易污染等特征。 奥陶系潜山随位置不同其表层缝洞多少、规模大小有很大差异。 1.轮南奥陶系碳酸盐岩地层压力系数低,地层对钻井液液柱压力相 当敏感,钻井液安全密度窗口非常小,甚至一些井找不到这个窗口。当钻遇

到裂缝、溶洞时,即使钻井液密度与裂缝、溶洞内充填的地层流体当量压力系数相当甚至还低,由于裂缝、溶洞通道大,在循环压耗、下钻激动压力等的作用下,也会发生钻井液与地层流体的置换,在实钻过程中就会表现出既喷又漏的现象,严重时有进无出,而这种井一般是裂缝尤其是溶洞非常发育的井。 2.特别是地层流体为气体时,表现得尤为突出。这时,往往关井后 井内气体越积越多,同时造成套压升高和井漏加剧。通过常规计算求得的地层压力常常不准确。同样,常规压井方法也不适用。如果只因为 g/cm3的密度压井后,仍然有套压,就认为是钻井液密度不够,从而再提密度,就会走入恶性循环,即越压越漏,越漏越压。 3.正是由于碳酸盐岩地层一般裂缝和溶洞非常发育,一旦有油气发 现,钻井液与油气间的置换是快速的,往往是不可避免的,这就是碳酸盐岩地层容易井漏的主要原因。 二.轮古地区压井实例 实例1 轮古405溢流 1、基础资料 5742—5749米,取心7米,当时泥浆密度,粘度48s, 层位:O,岩性:灰岩。 2、事故发生经过: 钻进至井深,7:50地质循环,发现液面上涨,8:00关井观察(立压,套压),8:00–10:50关井观察,立压–,套压–。

英语数字表达方式大全

1/2 : one-half;a half 1/3 : one-third 3/4 : three-fourths 1/5 : one-fifth 2/5 : two-fifths 7/8 : seven-eighths 1/10 : one-tenth;a tenth 1/100 : one-hundredth;one per cent 1/1000 : one-thousandth 1/10000 : one ten-thousandth 2… 1/2:two and one half;two a nd a half 4? 2/3:four and two-thirds 100% : one hundred per cent 0.5% : point five per cent 0.46% : point four six per cent 2.05 : two point nought five;two point O five 6.003 : six point nought nought three;six point O O three 78.12 : seventy-eight point one two 119 : one one nine 120 : one two oh 688 : six double-eight 5337 : five double-three seven 6512 : six five one two 97868 : nine seven eight six eight 893493 : eight nine three four nine three 737964 : seven three seven nine six four 62374881 : six two three seven four double-eight one 1840 eighteen forty 1900 nineteen hundred

英语数字表达方式大全

英语数字表达方式大全 基数词 0 nought;zero;O 1 one 2 two 3 three 4 four 5 five 6 six 7 seven 8 eight 9 nine 10 ten 11 eleven 12 twelve 13 thirteen 14 fourteen 15 fifteen 16 sixteen 17 seventeen 18 eighteen 19 nineteen 20 twenty21 twenty-one 22 twenty-two 23 twenty-three 30 thirty 32 thirty-two 40 forty 50 fifty 60 sixty 70 seventy 80 eighty 90 ninety 100 one hundred 101 one hundred and one 156 one hundred and fifty-six 192 one hundred and ninty-two 200 two hundred 300 three hundred 400 four hundred 500 five hundred 600 six hundred

700 seven hundred 800 eight hundred 900 nine hundred 1,000 one thousand 1,001 one thousand and one 1,300 thirteen hundred;one thousand and three hundred 2,000 two thousand 2,034 two thousand and thirty-four 6,502 six thousand five hundred and two 38,000 thirty-eight thousand 45,672 forty-five thousand six hundred and seventy-two 500,000 five hundred thousand 1,000,000 one million 3,123,400 three million,one hundred and twenty-three thousand and four hundred 8,000,000 eight million 47,000,000 forty-seven million 900,000,000 nine hundred million 1,000,000,000 a milliard,one milliard(美作:a billion,one billion) 1,050,000,000 one billion and fifty million 10,000,000,000 ten billion 200,000,000,000 two hundred billion 1,000,000,000,000 a billion,one billion(美作:a trillion,one trillion) 6,000,000,000,000 six million million 序数词 first第一 second第二 third第三 fourth第四 fifth第五 sixth第六 seventh第七 eighth第八 ninth第九 tenth第十 eleventh第十一 twelfth第十二 thirteenth第十三 fourteenth第十四 fifteenth第十五

工程师法压井施工单

工程师法压井施工单 身份证号: 姓名: 岗位: 成绩: 基础数据: 泵参数: 缸套直径 冲程 活塞杆直径 泵效 升/冲 选用 低泵速数据 套管参数: _ ______in(OD) ______in(ID) 套管鞋测深_______ m 套管鞋垂深_______ m 最大井口压力: BOP 工作压力 _________MPa 井口装置工作压力 _________MPa 套管抗内压(80%) _________MPa 最大允许关井压力_________MPa 套管鞋处破裂压力(A )MPa ____ 允许关井套压(破裂)=A -0.0098ρH=_________MPa 钻柱数据: 钻头尺寸 in 钻杆长度: 米,钻铤长度 米 钻杆1___in(OD) ____in(ID) 内容积______升/米 环空容积(对套管)______升/米 钻杆2 ___in(OD) ____in(ID) 内容积______升/米 环空容积(对裸眼)______升/米 钻铤1 ___in(OD) ___in(ID) 内容积______升/米 环空容积(对裸眼)______升/米 钻具内容积: 升 总环空容积: 升 溢流后记录的数据: A. 溢流时间: __:_:___ B. 原浆密度: _________g/cm 3 C. 关井立压: _________MPa D. 关井套压: _________MPa E. 泥浆池增量: _________ m 3 F. 垂直井深: _________ m 测量井深(计算容积用) _________ m

地层压力P P=0.0098 原泥浆密度×垂深+关井立压 __________MPa 泥浆加重参数: G. 压井泥浆比重ρ1=ρ0 +102P立/H _________ g/cm3 初始循环压力: P初=低泵速压力+关井立压_________MPa 终了循环压力 P终=低泵速压力×(压井泥浆密度/原浆密度) _________ MPa 立压下降曲线 容积冲数时间钻柱内容积: __________ m3__________ _________ 环空容积: __________ m3 __________ _________系统体积__________ m3_____ _ ___ _________ 压力下降值(△P)= (初始循环压力K-终了循环压力L)×冲数增加量/钻杆内的冲数 =_________MPa/冲数增加量 中原井控培训中心

英语中阿拉伯数字表达法

英语中阿拉伯数字的表达方法 一.1——10 : one two three four five six seven eight nine ten 二.11——19: eleven twelve thirteen fourteen fifteen sixteen seventeen eighteen nineteen eleven ,twelve,thirteen,fifteen,eighteen特殊情况,fourteen,sixteen,seventeen,eighteen,nineteen由其个 位数后加teen后缀构成。 三.21——99: 除twenty,thirty,forty,fifty,eighty外sixty,seventy,ninety为 个位数后加ty后缀构成。 四.百位数: 由个位基数词加hundred表示几百,在其后在加and和几

十几或几。 101 one hundred and one 262 two hundred and sixty-two 425 four hundred and twenty-five 五.千位数以上: 从数字的右端向左端数起,每三位数加一个逗号“,”。从右开始,第一个“,”前的数字后添加thousand,第二个“,” 前面的数字后添加million,第三个“,”前的数字后添加billion。然后一节一节分别表示,两个逗号之间最大的数为百位数形式。 2,648 two thousand six hundred and forty-eight 16,250,064 sixteen million two hundred and fifty thousand sixty-four 5,237,166,234 five billion,two hundred and thirty-seven million,one hundred and sixty-six thousand,two hundred ,and thirty-four

英语数字表达法

英语数字表达法 一、熟读牢记关键数字 迅速无误识别数字的前提是必须能够流利地读出数字。要从读两位数起,然后练习读三位和四位数乃至五位或六位以上的数字。其中两位和三位数的读法是读所有数字的基础。 英文数字中的每一个逗点的读法也要牢记: 有一个逗点读“thousand” 两个逗点读“million” 三个逗点读“billion” 还要清楚,每个逗点间由三位数组成。英文数字中的第四位数、第七位数、第十位数是很关键的数位。 Examples: 1,234 读作:one thousand, two hundred and thirty-four 4,567,809 读作:four million, five hundred and sixty-seven thousand, eight hundred and nine 5,678,120,000 读作:five billion, six hundred and seventy-eight million, one hundred and twenty thousand 二、“-teen和“-ty”的区别 “-teen”和“-ty”是比较容易混淆的一对读音。我们可以通过音和音素的差异来区别两者。含有“- teen ”的词有两个重音,即“-teen”要重读,且“-teen”中的元音为长元音[ti:n],发音长而清晰;而含有“-ty”的词只有一个重音,即“-ty”不重读,且“-ty ”中的元音为短元音[ti],发音短而急促。 Examples: fifteen['fif'ti:n] fifty['fifti] nineteen['nai'ti:n] ninety['naiti] 三、英美数字读法的差异 有时,同样一个数字,英国人和美国人的读法也不尽相同,这无疑会使本来就棘手的数字雪上加霜。如:部分有一个逗点的数字(四位数),英国人用“thousand”表示,而美国人则多用“hundred”。再如,有三个逗点的数字(十位数),美式读法为“billion”,而英式读法为“thousand million”。因此,熟悉英美两种不同的读法对消除数字理解上的歧义是十分必要的。 例词 英式1,900 one thousand, nine hundred 美式1,900 nineteen hundred 英式4,000,000,000 four thousand million 美式4,000,000,000 four billion 再者,英国英语在百位和十位之间加读“and”,而美国英语往往不用“and”。比如754这个数字。英国英语读成seven hundred and fifty-four,而美国英语则读为

英语数字表达方式大全98813

英语数字表达方式大全 0 zero;1 one2 two3 three4 four5 five6 six7 seven8 eight9 nine10 ten11 eleven12 twelve13 thirteen14 fourteen15 fifteen16 sixteen17 seventeen18 eighteen19 nineteen20 twenty21 twenty-one22 twenty-two23 twenty-three30 thirty32 thirty-two40 forty50 fifty60 sixty70 seventy80 eighty90 ninety100 one hundred101 one hundred and one156 one hundred and fifty-six192 one hundred and ninty-two200 two hundred300 three hundred400 four hundred500 five hundred600 six hundred700 seven hundred800 eight hundred900 nine hundred1,000 one thousand1,001 one thousand and one1,300 thirteen hundred;one thousand and three hundred2,000 two thousand2,034 two thousand and thirty-four6,502 six thousand five hundred and two38,000 thirty-eight thousand45,672 forty-five thousand six hundred and seventy-two500,000 five hundred thousand1,000,000 one million3,123,400 three million,one hundred and twenty-three thousand and four hundred8,000,000 eight million47,000,000 forty-seven